Page 1

Richland, MI 49083 Tel: (269) 629-5000

!

WARNING

!

To avoid unpredictable system behavior that can cause personal injury

and property damage:

• Disconnect electrical supply (when necessary) before installation,

servicing, or conversion.

• Disconnect air supply and depressurize all air lines connected to this

product before installation, servicing, or conversion.

• Operate within the manufacturer’s specifi ed pressure, temperature,

and other conditions listed in these instructions.

• Medium must be moisture-free if ambient temperature is below

freezing.

• Service according to procedures listed in these instructions.

• Installation, service, and conversion of these products must be

performed by knowledgeable personnel who understand how

pneumatic products are to be applied.

• After installation, servicing, or conversion, air and electrical supplies

(when necessary) should be connected and the product tested for

proper function and leakage. If audible leakage is present, or the

product does not operate properly, do not put into use.

• Warnings and specifi cations on the product should not be covered by

paint, etc. If masking is not possible, contact your local representative

for replacement labels.

INSTALLATION

1. Refer to the WARNING above.

2. Do not install until you have read the entire product information

sheet.

3. Maximum pressure rating is 150 psig (10.3 bar). Temperature

range is 40°F to 150°F (4.4°C to 65.5°C).

4. Prior to installation, insure that the pressure in the air line

where this product is to be installed is depressurized (0 psig).

5. It is recommended to install an appropriate Wilkerson fi lter

upstream of the unit for maximum trouble free operation.

6. Install with the air fl ow in the same direction as the arrow on the

unit.

7. AVOID restricting the air fl ow with undersize piping or fi ttings,

unless maximum fl ow is not required.

8. Install the valve to the top of the unit. Follow the supplied

instructions with actuating valve for proper installation and

wiring if using an electric solenoid actuating valve.

9.

There are two exhaust ports, one in the rear of the unit and one

on the down stream side of the unit cap. INSTALL THE PIPE

PLUG IN THE EXHAUST PORT THAT WILL NOT BE USED.

CAUTION: If plug is not installed securely, plug may

!

dislodge when valve exhausts and could possibly cause

injury.

10. Install the optional muffl er, if used, in the active exhaust port.

11. Turn the adjusting screw one turn open from fully closed for

initial setting; this will set the slow start portion of the valve at

approximately TEN seconds.

NOTE: Do not over tighten adjusting screw one this could

result in damage to the adjusting screw.

CAUTION: If adjusting screw is backed out until the

!

threads are disengaged, the adjusting screw could

dislodge when pressure is induced.

12. Apply pressure to the inlet port of the valve.

Installation & Service Instructions

83-273-000

E18/E28 Slow-Start / Quick Dump

Valve and Accessories

ISSUED: April, 2006

Supersedes: November, 2005

Doc. #83273000, ECN# 060325, Rev. 5

13. To actuate apply the appropriate voltage signal to actuating

valve. Turn the adjusting screw in 1/8 increments, clockwise

to increase opening time. Turn the needle counterclockwise to

decrease opening time.

NOTE: There will be a slight time delay between the

actuating of the valve and the pressure response due to

resetting of the internal components.

14. Removing the signal voltage from the activating valve will shut

off the supply pressure and depressurize the downstream side

(P2) of the valve.

MAINTENANCE

1. Depressurize the air line prior to attempting any service to the

unit.

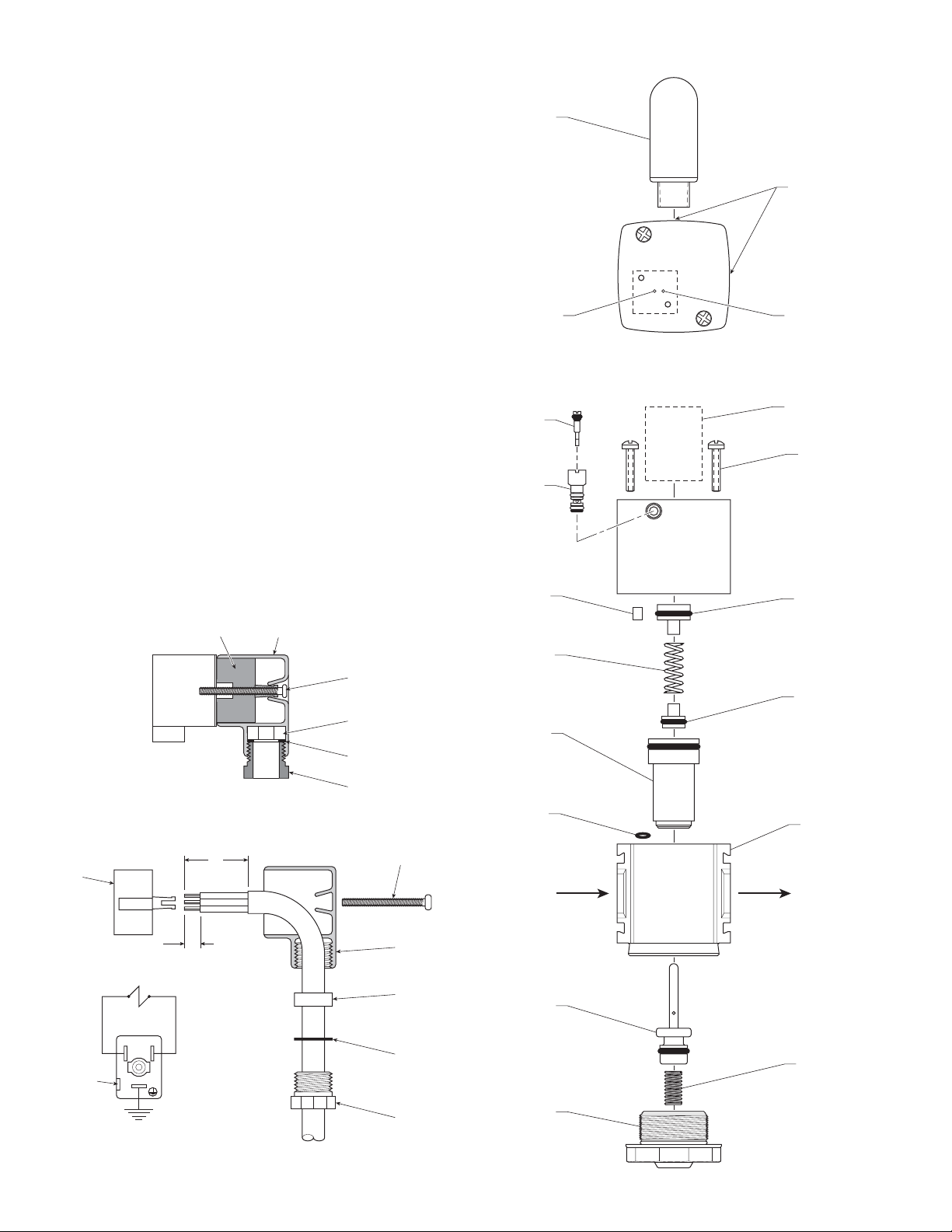

2. Remove bottom plug, valve assembly and valve spring. Inspect

all the seals and components for damage and replace as

required. Clean all seals and components using a clean soft

cloth. Lightly lubricate the valve o-ring and bottom plug o-ring

with Magnalube-G lubricant and reassemble in reverse order.

3. Loosen the two screws that retain the top cap and remove it

from the unit. Remove the slide valve from the top cap and the

two pistons and spring from inside the slide valve. Clean all

seals and components of the slide valve pistons. Using a soft

cloth, wipe dry the slide valve, piston and internal bore (in cap).

Lightly lubricate the slide valve o-ring and piston o-rings with

Magnalube-G lubricant.

4. Inspect the top cap for damage and contaminant. Check the

internal fi lter for dogging. If internal fi lter is clogged, replace as

required.

5. Reassemble in reverse order.

6.

Remove the needle from the cap and wipe clean. Inspect for

damage and replace as required. Prior to reassembly lubricate

the threads with grease Lubriplate 630-AA or equivalent and

o-ring with Magnalube-G. If needle is damaged, replace cap

assembly.

7. The electric actuating valve solenoid can not be serviced

internally. If the solenoid fails to operate, remove the solenoid

and replace.

WARNING

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE

PRODUCTS AND/OR SYSTEMS DESCRIBED HEREIN OR RELATED ITEMS

CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY DAMAGE.

This document and other information from The Company, its subsidiaries

and authorized distributors provide product and/or system options for further

investigation by users having technical exper tise. It is important that you

analyze all aspects of your application, including consequences of any failure

and review the information concerning the product or systems in the current

product catalog. Due to the variety of operating conditions and applications for

these products or systems, the user, through its own analysis and testing, is

solely responsible for making the fi nal selection of the products and systems

and assuring that all performance, safety and warning requirements of the

application are met.

The products described herein, including without limitation, product features,

specifi cations, designs, availability and pricing, are subject to change by The

Company and its subsidiaries at any time without notice.

EXTRA COPIES OF THESE INSTRUCTIONS ARE AVAILABLE FOR INCLUSION

IN EQUIPMENT / MAINTENANCE MANUALS THAT UTILIZE THESE PRODUCTS.

CONTACT YOUR LOCAL REPRESENTATIVE.

Page 2

E18/E28 Slow-Start / Quick Dump Valve and Accessories 83-273-000

REPAIR KITS AND REPLACEMENT PARTS

Actuating Valve with KR mount 24 VDC ................... VRP-95-776

Actuating Valve with KR mount 120 VAC .................. VRP-95-777

Actuating Valve with C.N.O.M.A mount 24 VDC ....... VRP-95-778

Actuating Valve with C.N.O.M.A mount 230 VAC ...... VRP-95-779

Muffl er ....................................................................... VRP-95-780

Adjusting Needle Kit ................................................. VRP-95-786

Repair Kit .................................................................. VRP-95-782

Valve / Spring Kit ...................................................... VRP-95-781

Replacement O-ring Kit ............................................ VRP-95-783

E18 Body Cap Kit ..................................................... VRP-95-784

E28 Body Cap Kit ..................................................... VRP-95-785

WIRING INSTRUCTIONS FOR CABLE PLUG

1. Remove the holding screw (A) from the cable plug, and pry the

contact holder (B) from the plug case (C) (see Figure 1).

2. Remove the gland nut (D), thrust washer (E) and gland (F) from

the plug case and slide each part over the multiconductor cable

in the order removed. Insert cable through the plug case (see

Figure 2).

3. Strip the cable as shown in Figure 2.

4. Insert conductors into contacts in contact holder, as shown in

the wiring schematic, and securely tighten the contact screws

to retain the conductors.

5.

Work contact holder back into the plug case and snap it into place.

6. Slide the gland, thrust washer and gland nut into the plug case.

Tighten the gland nut to provide strain relief for conductors.

7. Reinsert the holding screw.

8. To connect the cable plug to the solenoid operator, push the

plug onto the male terminals and tighten the holding screw.

BC

A

F

E

D

FIGURE 1

1'

B

A

Muffler

Actuating

Valve

Inlet Port (1)

Adjusting

Needle

Adjusting

Needle

Seat

Filter

Spring

Slide

Valve

and

O-Ring

Cap

O-Ring

Seal

Exhaust

Location

Actuating

Valve

Outlet Port (2)

Actuating

Valve

Cap

Screws

Upper

Piston

and

O-Ring

Lower

Piston

and

O-Ring

Unit

Body

PRY

SLOT

SOLENOID

21

PLUG

(EQUIPMENT

GROUND)

1/4"

FIGURE 2

Inlet Port Outlet Port

C

F

E

D

Bottom

Valve

Assembly

Valve

Spring

Bottom

Plug

Loading...

Loading...