Page 1

Richland, MI 49083 Tel: (269) 629-5000

Installation & Service Instructions

83-964-000

E08 and E12 Slow-Start /

Quick Dump Valve

ISSUED: October, 2005

Supersedes: October, 2004

Doc# 83964000, ECN# 051075, Rev. 3

WARNING

!

To avoid unpredictable system behavior that can cause personal injury

and property damage:

• Disconnect electrical supply (when necessary) before installation,

servicing, or conversion.

• Disconnect air supply and depressurize all air lines connected to

this product before installation, servicing, or conversion.

• Operate within the manufacturer’s specified pressure, temperature,

and other conditions listed in these instructions.

• Medium must be moisture-free if ambient temperature is below

freezing.

• Service according to procedures listed in these instructions.

• Installation, service, and conversion of these products must be

performed by knowledgeable personnel who understand how

pneumatic products are to be applied.

• After installation, servicing, or conversion, air and electrical supplies

(when necessary) should be connected and the product tested for

proper function and leakage. If audible leakage is present, or the

product does not operate properly, do not put into use.

• Warnings and specifications on the product should not be covered

by paint, etc. If masking is not possible, contact your local

representative for replacement labels.

Introduction

Follow these instructions when installing, operating, or servicing

the product.

Application Limits

These products are intended for use in general purpose compressed

air systems only.

Operating Pressure Range

Operator Type kPa PSIG bar

Solenoid, Air Pilot

Minimum 413 60 4.1

Maximum 1034 150 10.3

Installation

E08 and E12 valves should be installed with reasonable accessibility

for service whenever possible. Keep pipe or tubing lengths to a

minimum with inside clean and free of dirt and chips. Pipe joint

compound should be used sparingly and applied only to the male

pipe — never into the female port. Do not use PTFE tape to seal

pipe joints — pieces have a tendency to break off and lodge inside

the unit, possibly causing malfunction. Care should be taken to

avoid undue strain on the valve.

Air applied to the valve must be filtered to realize maximum

component life.

Life Expectancy - Normal multi-million cycle life expectancy of

these valves is based on the use of properly filtered and lubricated

air at room temperature. These valves are also designed to operate

under non-lubricated conditions and will yield millions of

maintenance free cycles.

Factory Pre-Lubrication - Valves are pre-lubricated at

assembly with a petroleum based grease which has a lithium

content.

In-Service Lubrication - In-service lubrication is not required;

however, if lubrication is to be used, use an air line lubricant

(compatible with Nitrile & Polyurethane seals) which will readily

atomize and be of the medium aniline type. Aniline point range

must be between 180° and 220°F. Viscosity at 100°F:

140 - 170 SUS.

CAUTION: Do not use synthetic, reconstituted, or oils with

!

an alcohol content or detergent additive.

CAUTION: Do not restrict the inlet of valves having an

!

internal pilot supply. Pressure supply piping must be the

same size as the inlet port or larger to insure that the pilot

valve receives sufficient pressure supply during high flow

conditions.

Ambient Temperature Range

Operator Type °C °F

Solenoid

Air Pilot

Minimum 0°C 32°F

Maximum 60°C 140°F

Minimum 0°C 32°F

Maximum 60°C 140°F

Voltage Range: Rated Voltage +10%, -15%

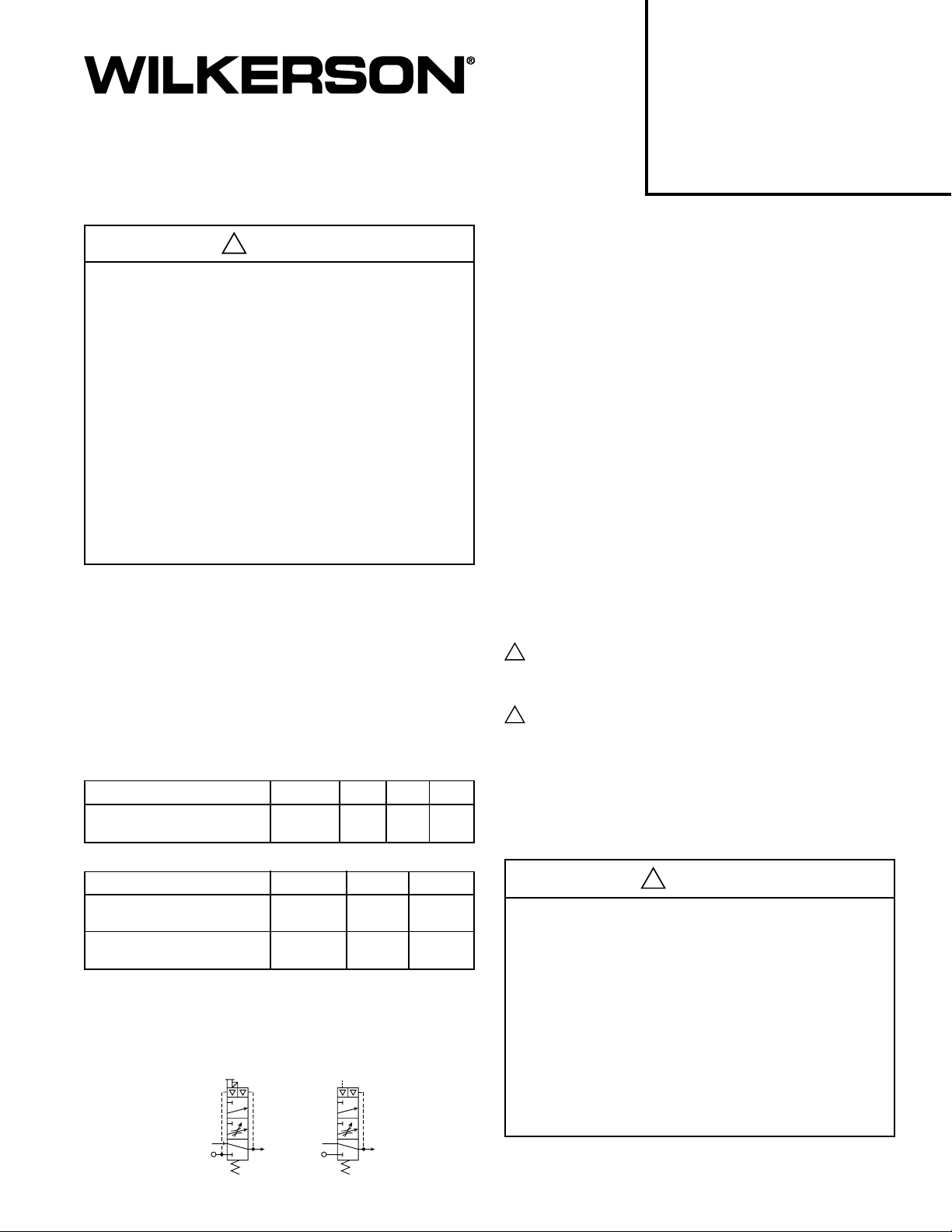

ANSI Symbols

12

For Solenoid

Operated Valves

3

1

2

For Externally

Piloted Valves

3

1

WARNING

!

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF

THE PRODUCTS AND/OR SYSTEMS DESCRIBED HEREIN OR

RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND

PROPERTY DAMAGE.

This document and other information from The Company, its subsidiaries

and authorized distributors provide product and/or system options for

further investigation by users having technical expertise. It is important

that you analyze all aspects of your application, including consequences

of any failure and review the information concerning the product or systems

in the current product catalog. Due to the variety of operating conditions

and applications for these products or systems, the user, through its own

analysis and testing, is solely responsible for making the final selection of

the products and systems and assuring that all performance, safety and

warning requirements of the application are met.

The products described herein, including without limitation, product

features, specifications, designs, availability and pricing, are subject to

change by The Company and its subsidiaries at any time without notice.

2

EXTRA COPIES OF THESE INSTRUCTIONS ARE AVAILABLE FOR

INCLUSION IN EQUIPMENT / MAINTENANCE MANUALS THAT UTILIZE

THESE PRODUCTS. CONTACT YOUR LOCAL REPRESENTATIVE.

Page 2

E08 and E12 Slow-Start / Quick Dump Valve 83-964-000

Function

The Slow-Start / Quick Dump valve is a 3-Port valve which supplies

air in a controlled reliable manner to pneumatic systems and has

the quick exhaust features of a dump valve. This valve replaces

conventional main valves.

The Slow-Start / Quick Dump valve operates much like a standard

3-Way valve. When the valve is installed Port 2 is connected to

Port 3 (downstream system is exhausted to atmosphere). When a

signal (pneumatic or electric depending upon pilot operator) is

received in Port 12, the connection between Port 2 and 3 is closed.

At the same time, supply air from Port 1 is connected to Port 2

through the adjustable throttle (Flow Control Screw). When the

downstream pressure reaches a specific point, the main poppet

opens and permits full air flow through the valve. The table shows

the solenoid pilot. To operate the override, place a small screwdriver

in the slot of the override and turn approximately 45° in either

direction until the solenoid pilot actuates. The solenoid pilot will

remain actuated until the override is released. When released,

the solenoid pilot de-actuates.

Solenoid Replacement

To replace the solenoid, remove the two mounting screws and replace

with the correct voltage solenoid. Tighten new screws 5 to 6 in.lbs.

Voltage Coil No. Voltage Coil No.

12/60 P025422B40 24VDC P025422B49

24/60 P025422B42 120/60 P025422B53

12VDC P025422B45 240/60 P025422B57

the relationship between the inlet pressure and the downstream

pressure at which the main valve opens.

When the pilot signal is removed, the valve returns to its

initial position and the downstream air is dumped rapidly through

Por t 3.

Accessories

Kit No. Description

GPA-96-310 05 Series Modular Body Connectors

GPA-96-738 08 Joiner Set

Installation

Inlet Downstream

Pressure Pressure for

Full Flow

75 psig 50 psig

100 psig 55 psig

125 psig 60 psig

150 psig 65 psig

The Slow-Start / Quick Dump valve

replaces an ordinary main valve;

therefore, it is usually mounted

between the air preparation unit

and the system. The Slow-Start /

Quick Dump valve is specifically

designed to mount directly in line

with the Series using modular

body connectors.

Port Connections

1. Connect inlet air supply to Port 1.

2. Connect mufflers (or plumb exhaust) from Port 3.

3. Connect cylinder Port 2 to cylinder or other system devices to be

supplied air.

4. Signal Connection – Slow-Start / Quick Dump valves may be

remotely controlled electrically or pneumatically.

a. For solenoid pilot operated valves, see the instructions under

“WIRING INSTRUCTIONS.”

b. For air pilot operated valves, connect the air line to the pilot

VRP-96-780 3/8" Exhaust Muffler

VRP-96-306 Snap on Connector Kit with 0.5 meter wires

VRP-96-301 3-Pin Connector Kit - Unlighted

VRP-96-302 3-Pin Connector Kit - Lighted, 24VAC & DC

VRP-96-303 3-Pin Connector Kit - Lighted, 120VAC

VRP-96-300 3-Pin Connector Kit - Unlighted w/2 meter cord

VRP-96-304 3-Pin Connector Kit - Lighted, 24VAC & DC

w/2 meter cord

VRP-96-305 3-Pin Connector Kit - Lighted, 120VAC

w/2 meter cord

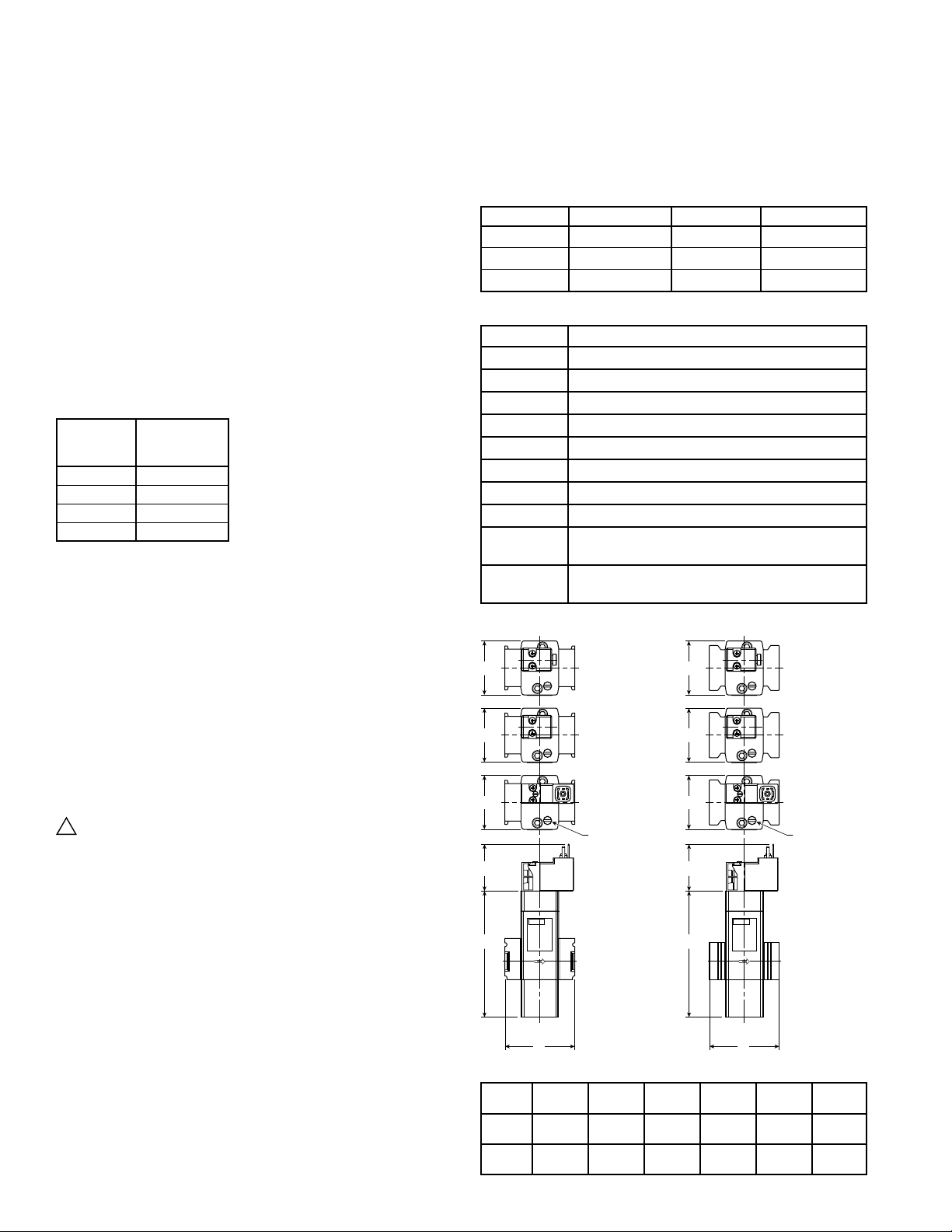

E08

Prestolok

D

D

Fitting for

4mm Dia. Tube

(Air Pilot)

M5 Port

Thread

(Air Pilot)

D

D

E12

Prestolok

Fitting for

4mm Dia. Tube

(Air Pilot)

M5 Port

Thread

(Air Pilot)

port 12, (M5 or 4mm tube).

Wiring Instructions

CAUTION: An interruption of 10 milliseconds or greater to

!

the power supplied to the solenoid of a solenoid operated

valve may cause the valve to shift. Provision must be

made to prevent power interruption of this duration to

avoid unintended, potentially hazardous, consequences.

NOTE: In addition to the following instructions, follow all requirements

for local and national electrical codes.

Attach an electrical cable with connector (that conforms to the DIN

43650, Form C pattern) to the terminals of the solenoid. For

locations in a cabinet or other protected environment, the SnapOn connector with loose wires may be attached. In both cases,

do not attach or remove the connectors until power is off.

Electrical Connection

Valves with 3-Pin male terminals should have power connected to

the parallel terminals. Ground should be connected to the

perpendicular terminal. Use only connectors that comply with DIN

43650, Form C (8mm blade spacing).

Override Operation

The flush non-locking manual override is located on the body of

D

C

B

12

EXH

OUTIN

3

A

Dimensions:

Model

E08 1/4" 3/8"

E12 3/8" 3/8"

Port Exhaust

Size Port

Adjustment

Needle

Screwdriver

Slot

D

Adjustment

Needle

C

B

12

3

EXH

A

ABCD

2.09" 3.53" 1.42" 1.65"

53mm 90mm 36mm 42mm

2.13" 3.53" 1.42" 1.65"

54mm 90mm 36mm 42mm

Screwdriver

Slot

OUTIN

Loading...

Loading...