Page 1

Englewood, CO 80110

WARNING

!

To avoid unpredictable system behavior that can cause personal

injury and property damage:

• Disconnect electrical supply (when necessary) before installation,

servicing, or conversion.

• Disconnect air supply and depressurize all air lines connected to

this product before installation, servicing, or conversion.

• Operate within the manufacturer’s specified pressure, temperature,

and other conditions listed in these instructions.

• Medium must be moisture-free if ambient temperature is below

freezing.

• Service according to procedures listed in these instructions.

• Installation, service, and conversion of these products must be

performed by knowledgeable personnel who understand how

pneumatic products are to be applied.

• After installation, servicing, or conversion, air and electrical

supplies (when necessary) should be connected and the product

tested for proper function and leakage. If audible leakage is present,

or the product does not operate properly, do not put into use.

• Warnings and specifications on the product should not be covered

by paint, etc. If masking is not possible, contact your local

representative for replacement labels.

Installation & Service Instructions:

83-962-000

12 Series Right Angle Bracket

ISSUED: November, 2001

Supersedes: None

EN# 01085520, Rev.1

6.70

170mm

9.00

229mm

Introduction:

Follow these instructions when installing, operating, or servicing

the product.

Application Limits

These products are intended for use in general purpose

compressed air systems only.

Operating Pressure: kPa PSIG bar

Maximum Inlet Pressure:

Metal Bowl 1734 250 17.3

Poly Bowl 1024 150 10.2

Operating Temperature:

Maximum Temperature (Metal Bowl) 80°C (175°F)

Maximum Temperature (Poly Bowl) 52°C (125°F)

Minimum Temperature 0°C (32°F)

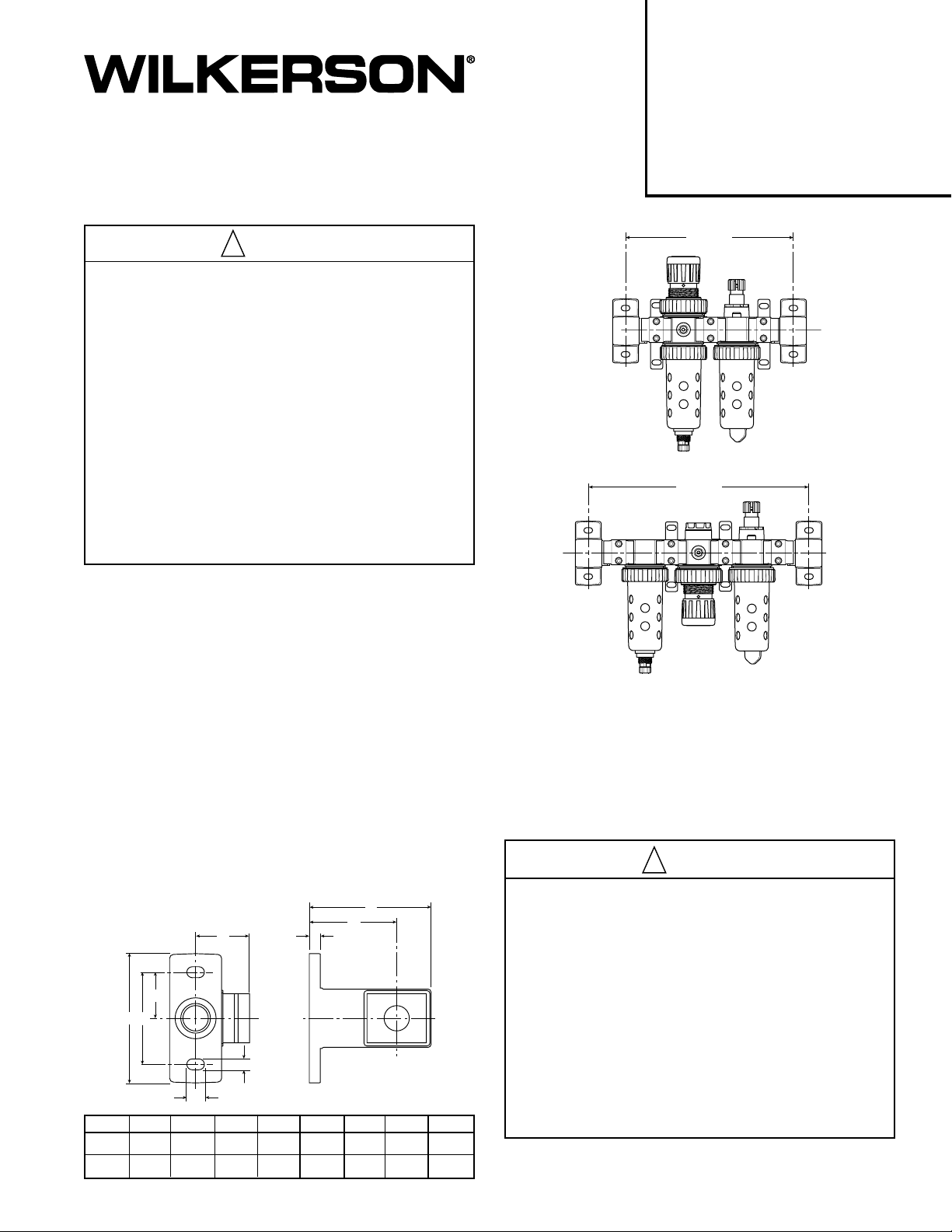

Right Angle Bracket Dimensions

J

D

C

A

B

E

F

ABC DE FGH J

2.83 2.28 1.14 1.16 .28 .43 .28 1.49 2.31

72.0 mm 58.0 mm 29.0 mm 29.5 mm 7.0 mm 11.0 mm 7.0 mm 37.8 mm 58.8 mm

G

H

Installation

The right angle bracket can be installed using the two methods

outlined on reverse side. Keep pipe or tubing lengths to a

minimum with inside clean and free of dirt and chips. Pipe

joint compound should be used sparingly and applied only to

the male pipe - never the female port. Do not use PTFE tape

to seal pipe joints - pieces have a tendency to break off and

lodge inside the unit, possibly causing malfunction.

WARNING

!

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF

THE PRODUCTS AND/OR SYSTEMS DESCRIBED HEREIN OR

RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND

PROPERTY DAMAGE.

This document and other information from The Company, its

subsidiaries and authorized distributors provide product and/or system

options for further investigation by users having technical expertise. It

is important that you analyze all aspects of your application, including

consequences of any failure and review the information concerning

the product or systems in the current product catalog. Due to the

variety of operating conditions and applications for these products or

systems, the user, through its own analysis and testing, is solely

responsible for making the final selection of the products and systems

and assuring that all performance, safety and warning requirements

of the application are met.

The products described herein, including without limitation, product

features, specifications, designs, availability and pricing, are subject

to change by The Company and its subsidiaries at any time without

notice.

EXTRA COPIES OF THESE INSTRUCTIONS ARE AVAILABLE FOR

INCLUSION IN EQUIPMENT / MAINTENANCE MANUALS THAT UTILIZE

THESE PRODUCTS. CONTACT YOUR LOCAL REPRESENTATIVE.

Page 2

Right Angle Bracket 83-962-000

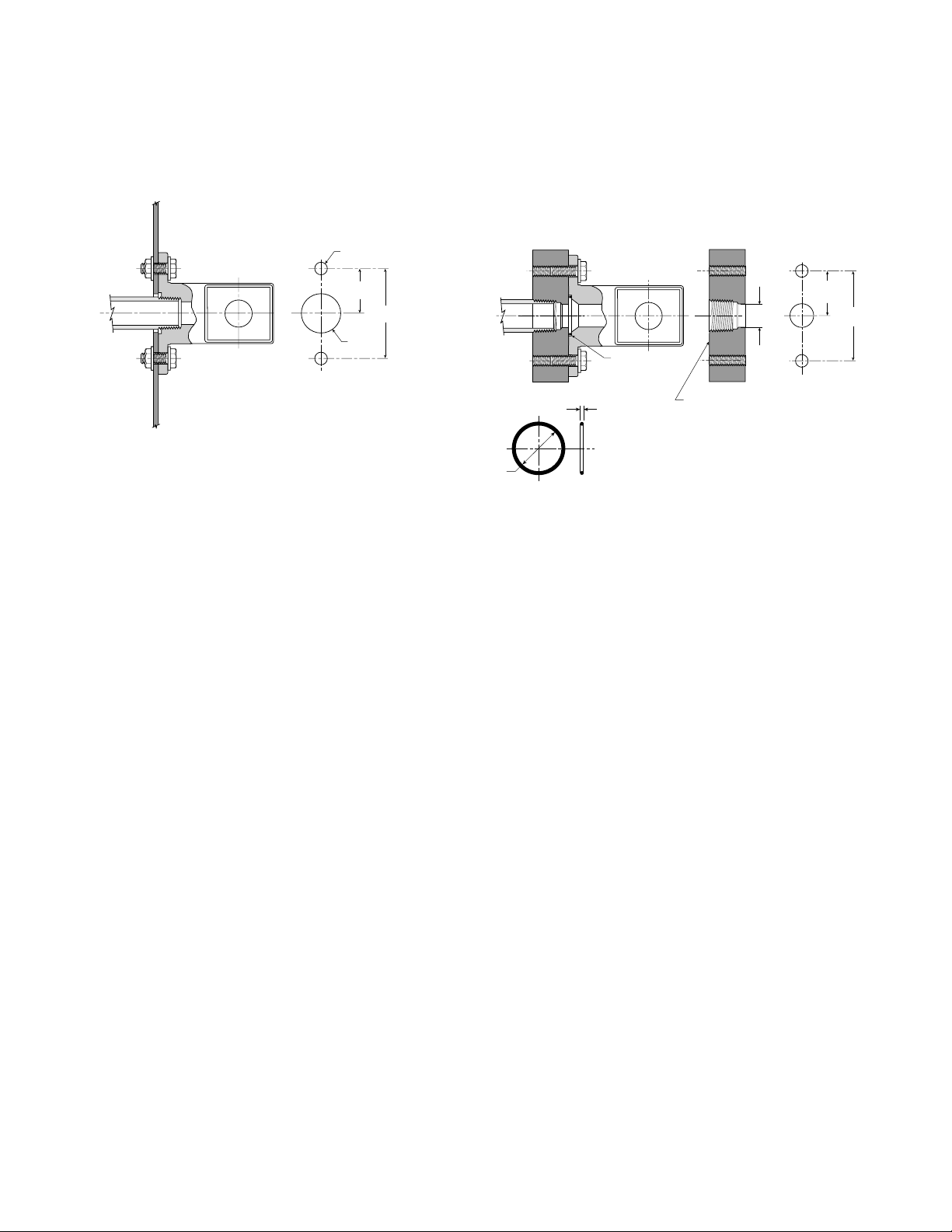

Direct Piped Method

The direct piped method is used when the right angle bracket is

bolted to the user’s machine and the inlet and outlet pipe is

screwed directly into the back of the ninety degree bracket.

A through hole must be provided in the user’s machine to allow

access for the inlet and outlet pipe.

.28 Dia.

(7.1mm)

1.142

29,0mm

2.383

58,0mm

.88Dia.

22,4mm

Mounting Holes

Direct Pipe Ported Method Manifold Mounting Method

Manifold Method

This method is used when the right angle bracket is mounted to

the user’s manifold. The inlet and outlet pipe is screwed into the

manifold. An o-ring is used to seal between the bracket and

manifold.

1.142

29,0mm

Mounting Holes

2.383

58,0mm

.737 ID

.103

O-Ring

.50 Dia.

12,7mm

Manifold

Not Included With

Right Angle Bracket

Loading...

Loading...