Page 1

Filter w/

Manual

Drain

Adsorber w/

Manual

Drain

Coalescing

Filter w/

Manual

Drain

A

Pneumatic Division

!

!

Richland, Michigan 49083

269-629-5000

Installation & Service Instructions:

2F300E

1" Particulate, Adsorber &

Coalescing Filter

ISSUED: October, 2006

Supersedes: March, 2005

Doc.# 2F300, ECN# 061068, Rev. 9

WARNING

To avoid unpredictable system behavior that can cause personal

injury and property damage:

• Disconnect electrical supply (when necessary) before installation,

servicing, or conversion.

• Disconnect air supply and depressurize all air lines connected

to this product before installation, servicing, or conversion.

• Op erate with in th e ma nufac turer ’s spec ifi ed pr essur e,

temperature, and other conditions listed in these instructions.

• Medium must be moisture-free if ambient temperature is below

freezing.

• Service according to procedures listed in these instructions.

• Installation, service, and conversion of these products must be

performed by knowledgeable personnel who understand how

pneumatic products are to be applied.

• After installation, servicing, or conversion, air and electrical

supplies (when necessary) should be connected and the product

tested for proper function and leakage. If audible leakage is

present, or the product does not operate properly, do not put into

use.

• Warnings and specifications on the product should not be

covered by paint, etc. If masking is not possible, contact your

local representative for replacement labels.

Installation

1. The filter should be installed with reasonable accessibility for

service whenever possible – repair service kits are available.

Keep pipe or tubing lengths to a minimum with inside clean

and free of dirt and chips. Pipe joint compound should be used

sparingly and applied only to the male pipe – never into the

female port. Do not use PTFE tape to seal pipe joints – pieces

have a tendency to break off and lodge inside the unit, possibly

causing malfunction. Also, new pipe or hose should be installed

between the filter and equipment being protected.

2. The upstream pipe work must be clear of accumulated dirt and

liquids.

3. Select a filter location as close as possible to the equipment

being protected and upstream of any pressure regulator.

4. Install filter so that air flows in the direction of arrow on body.

5. Install filter vertically with bowl drain mechanism at the bottom.

Free moisture will thus drain into the sump “quiet zone” at the

bottom of the bowl.

Operation and Service

1. Manual drain filters must be drained regularly before the

separated moisture and oil reaches the bottom of the lower

baffle.

Safety Guide

For more complete information on recommended application

guidelines, see the Safety Guide section of Pneumatic Division

catalogs or you can download the Pneumatic Division Safety

Guide at: www.parker.com/safety

2. The particulate filter element should be removed and replaced

when pressure differential across the filter is 10 PSIG.

3. Ad sorbe r el ement s ar e designe d to adso rb vaporou s

contaminates. The relative efficiency of an adsorber varies

depending on the vapor to be adsorbed and the environmental

temperature. At higher temperatures, adsorbers become less

efficient.

Introduction

Follow these instructions when installing, operating, or servicing the

product.

Application Limits

These products are intended for use in general purpose compressed

air systems only.

Adsorber Filters are not effective on: Carbon monoxide, carbon dioxide,

methane, ethane, ethylene or hydrogen. For a complete list of vapors

Adsorber elements are not particle filters. All particles and

aerosols should be removed prior to adsorbing vaporous

contaminants. The initial pressure drop across an adsorber

element (1.5 PSIG maximum) should never increase. The

presence of any liquids, aerosols or particulate matter in an

adsorber indicates that the effective life of the element has been

exceeded and the element should be replaced and the system

cleaned.

that can and cannot be adsorbed effectively by activated charcoal

adsorbers consult the factory.

Maximum Recommended Pressure Drop:

kPa PSIG bar

Particulate Filter 70 10 0.7

Operating Pressure Maximum 1700 250 17.0

Operating Temperature Maximum 80°C (175°F)

Operating Temperature Minimum 0°C (32°F)

ANSI Symbols

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF

THE PRODUCTS AND/OR SYSTEMS DESCRIBED HEREIN OR

RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND

PROPERTY DAMAGE.

This document and other information from The Company, its subsidiaries

and authorized distributors provide product and/or system options for

further investigation by users having technical expertise. It is important

that you analyze all aspects of your application, including consequences of

any failure and review the information concerning the product or systems

in the current product catalog. Due to the variety of operating conditions

and applications for these products or systems, the user, through its own

analysis and testing, is solely responsible for making the final selection of

the products and systems and assuring that all performance, safety and

warning requirements of the application are met.

The products described herein, including without limitation, product

features, specifications, designs, availability and pricing, are subject to

change by The Company and its subsidiaries at any time without notice.

EXTRA COPIES OF THESE INSTRUCTIONS ARE AVAILABLE FOR

INCLUSION IN EQUIPMENT / MAINTENANCE MANUALS THAT UTILIZE

THESE PRODUCTS. CONTACT YOUR LOCAL REPRESENTATIVE.

WARNING

Page 2

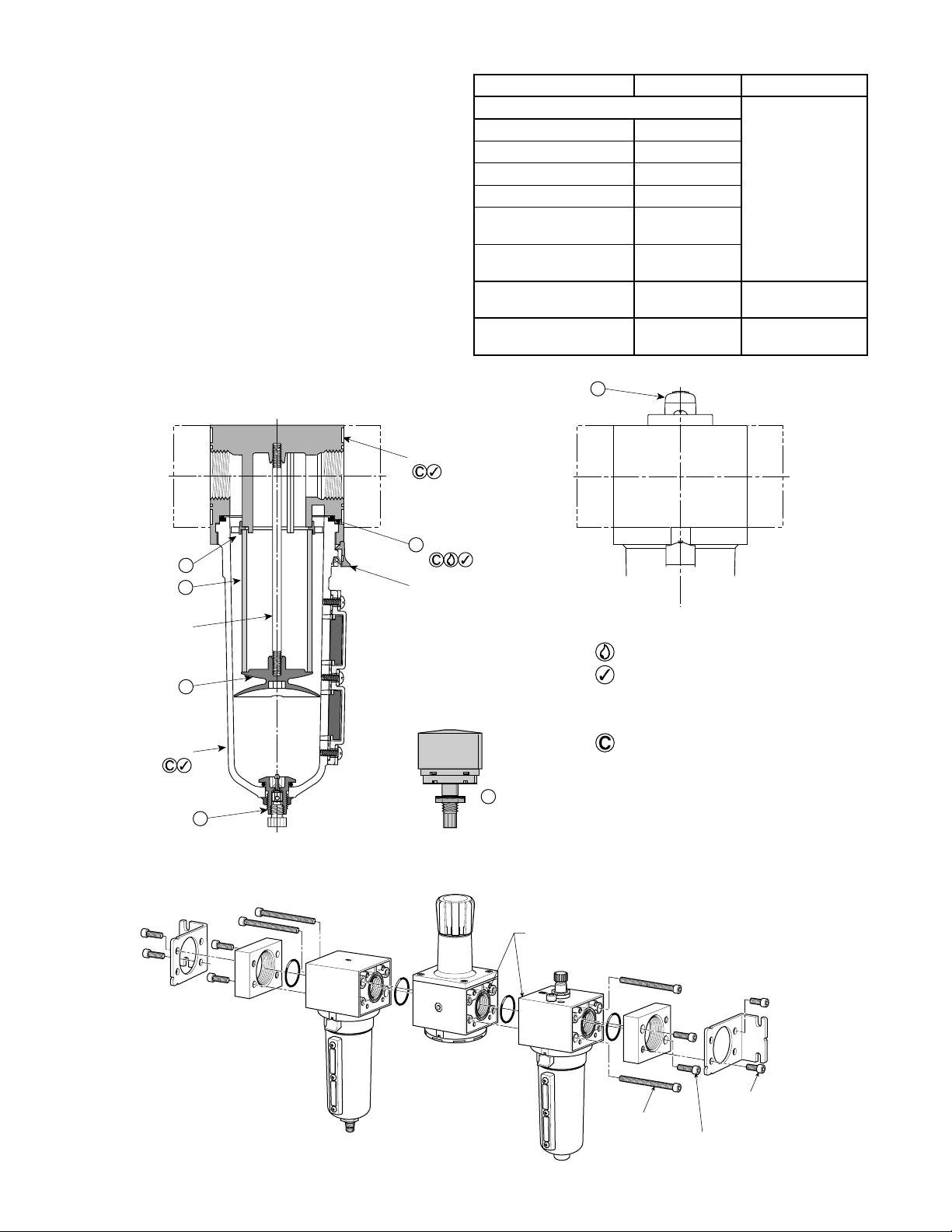

Bowl Seal

Snap Fit Tab

Detent must snap

in groove for proper

assembly.

(To remove bowl

depress tab, turn

& pull bowl down. )

Bowl rotated 90

for illustration purposes

Filter Body

Element

Baffle

Torque:

.4 to .6Nm

(3 to 5 in. lb.)

Twist Drain

Torque: 1.1 - 1.7Nm

(

10 - 15 in. lb.

)

Deflector

Stem

Bowl

Differential

Pressure

Indicator (DPI)

Optional

Coalescing Unit Shown

1

2

3

4

5

Auto Drain

7

6

Particulate, Adsorber & Coalescing Filter 2F300E

O

IL

Torque value for assembling

units together, port blocks,

and mounting brackets:

5 to 6 Nm (48 to 52 in.lb.)

M8 x 90 Bolt

(4 Places)

Note: If both mating faces have

an o-ring groove, units may need

to be assembled with two seals.

( One square and one round seal.)

M8 x 15 Bolt

(4 Places)

M8 x 20 Bolt

(4 Places)

The most effective method of testing whether an element needs

to be replaced is to smell the air coming from the adsorber.

Offensive odors will be present well before oil levels become

detectable.

4. For Coalescing filter, a 5 micrometer pre-filter is recommended

to protect the high efficiency filter and to prolong the elements

life.

5. The differential pressure indicator, located on top of the filter

body, gives a visual indication of the pressure differential

across the filter element. Change the filter element when half

or more of the orange piston is above the retaining ring when

air is flowing. For units without a differential pressure indicator,

pressure differential gauges should be used to determine when

the maximum recommended pressure differential has been

reached.

6. Shut off air supply and depressurize the unit, before servicing.

7. After servicing, apply system pressure and check for air leaks. If

leakage occurs, Do Not Operate — conduct servicing again.

Service Kits Available

Description Kit Number Contains Items

Element Kits -

5 Micron

40 Micron P3NKA00ESG

Adsorber P3NKA00ESA

25 Micron Porous Bronze P3NKA00ESJ

Coalescing / Element

Grade 6

Coalescing / Element

Grade 10

DPI Repair Kit

Auto Drain Kit PS506

P3NKA00ESE

P3NKA00ESC

P3NKA00ES9

PS781

(5) Bowl Seal and

(2) Element

(6) DPI components

(not all shown)

(7) Auto Drain

Assembly

Lightly grease with provided lubricant.

Inspect for nicks, scratches, and surface

imperfections. If present, reduced service life

is probable and future replacement should

be planned.

Clean with lint-free cloth.

Loading...

Loading...