Page 1

1

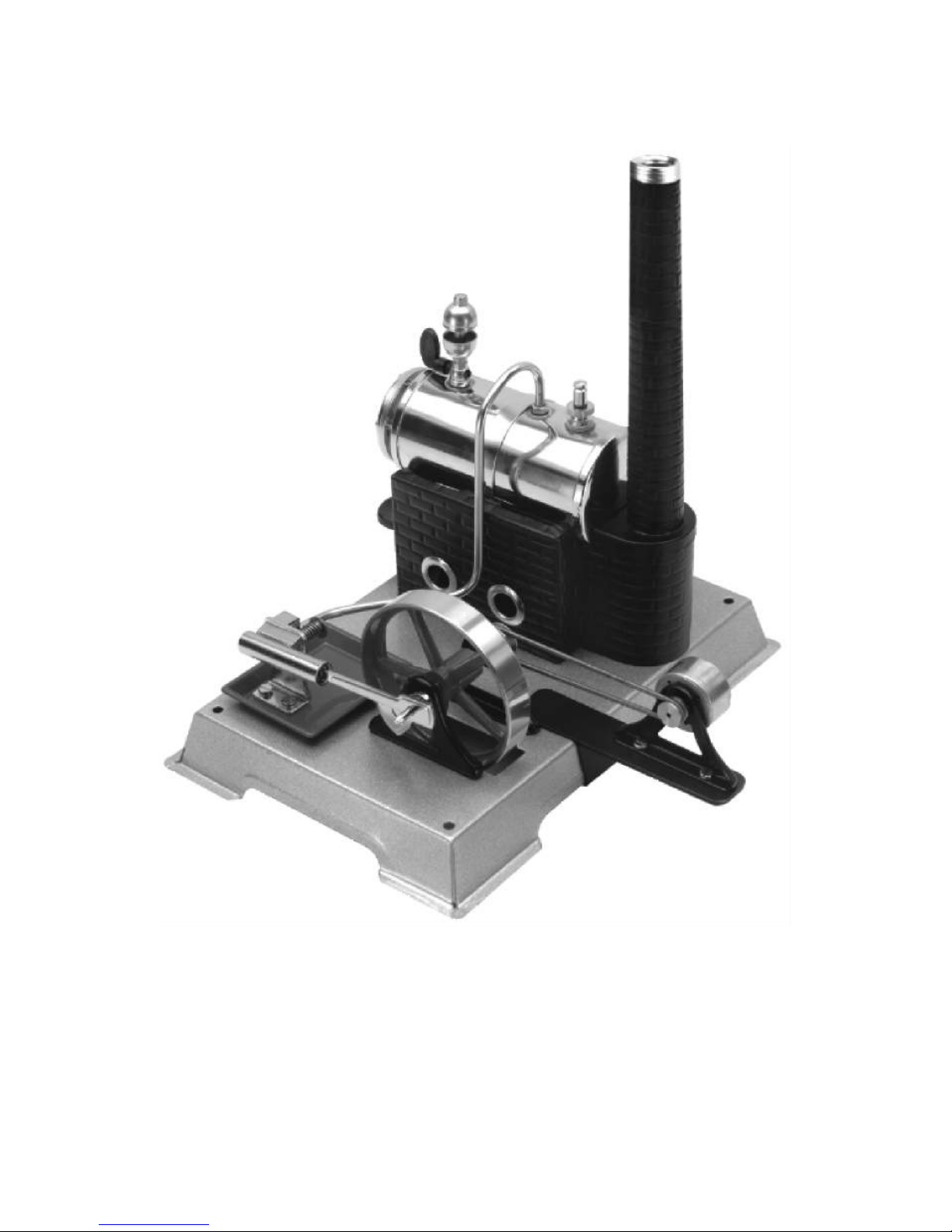

Steambox D 100 E

E-Box E 50

Page 2

2

Page 3

3

Steambox D 100E and E-Box E50

Wilhelm Schröder GmbH & Co. KG

D-58511 LÜDENSCHEID Schützenstraße 12

phone : +49 - 2351 - 9847-0 e-mail : info@wilesco.de

Page 4

4

Important information:

Please read the instructions carefully before using the product. There you

find important information for a successful use.

Any damages caused by not following the instructions or the safety advices

will not be treated as guarantee cases!

We do not take any responsibility in case of following up damages!

All the information has been worked out with great care. On the other hand

one cannot exclude that mistakes may happen. We kindly advise you that

neither Wilesco nor the author will take any guarantee cases, juristically

responsibilities or assume any kind of liability as consequences of wrong

instructions or experiments.

Wilesco invites to send comments about possible mistakes via mail.

A symbol in a triangle is indicating a possible dangerous

situation, which needs more caution and attention.

Imprint:

This is a publication from Wilesco©, Wilhelm Schröder GmbH & Co KG, D-58511

LÜDENSCHEID. All rights including translation are reserved. Any reproduction, f. ex. photo

copies, microfilming, electronic data processing need a written permission of the author. Prints,

also only parts, are forbidden.

This publication has the technical update at moment of print. Changes of technical nature and

equipment are reserved.

© Copyright 2012 by Wilesco, Wilhelm Schröder GmbH & Co. KG

Dampfbox D 100E: EAN 4009807051013

E-Box 50: EAN 4009807012502

Set: Dipl. Ing. Thomas Schröder, Ulrich Stempel

Author: Ulrich Stempel

Translation: Ulrike Krampen

Wilhelm Schröder GmbH & Co. KG

D-58511 LÜDENSCHEID Schützenstraße 12

Telefone : 0049 - 2351 - 9847-0 Fax : 0049-2351-9847-47

e-mail : info@wilesco.de

Page 5

5

Preface:

With this Steam Box or the E–Box 50 in combination with a steam engine

model and the booklet one can experience practically how the steam engine

and the transformation into electricity functions. Wilesco has joined for you

all the needed components in the Steam Box D 100E and the E-Box 50.

You are the owner of the Steam Box D 100E and now you build step by

step your own steam engine as a model. Through joining the different parts

one gets aware of the developed concept and the principle of the steam

engine, which has been invented by Denis Papin, James Watt and others.

This model does not only help to understand how a steam engine works, it

also creates a lot of joy to develop it even further.

With the Steam Box and the E-Box 50 and its components you can

practically experience and understand the transforming processes,

beginning with the thermo energy, through the mechanical energy and

finally turned into electrical energy. The experiments are structured and

build up one on the other. They are easy and in short time to realize.

In the booklet you also find information about the modern standard of the

steam engine and examples and possibilities of developments in the present

time.

I also would like to bring you this beautiful hobby of steam engine model

construction a little closer and wish you a lot of fun building this and other

steam engine models and the experiences you gain with it.

Yours

Ulrich Stempel

Page 6

6

Page 7

7

Inhaltsverzeichnis

1. BASICS ABOUT THE STEAM ENGINE........................................... 9

1.1 THE STEAM ENGINE AND ITS DEVELOPMENT....................... 9

1.2 KNOWLEDGE ABOUT THE STEAM ENGINE........................... 10

1.2.1 How to change water into steam .............................................. 10

1.2.2 The boiler.................................................................................. 11

1.2.3 The flywheel.............................................................................. 11

1.2.4 The oscillating steam engine .................................................... 11

1.2.5 The valve-controlled steam engine........................................... 13

1.3 POWER AN EFFICIENCY ............................................................. 14

1.3.1 Comparison: oscillating and valve-controlled steam engine... 14

1.4 WHAT FUNCTION HAS THE STEAM ENGINE NOWADAYS. 15

1.4.1 Hybrid systems consisting photovoltaic constructions and the

steam engine ...................................................................................... 15

2. ASSEMBLING THE MODEL............................................................. 17

2.1 TRICKS AND TIPS FOR A SUCCESFUL ASSEMBLING ........ 17

2.2 ASSEMBLY INSTRUCTIONS STEP BY STEP............................ 18

Step 1: Assembly of the boiler ........................................................... 18

Step 2: Mounting the burner slide and boiler house......................... 18

Step 3: Assembling and mounting the flywheel ................................. 19

Step 4: Assembling the cylinder unit ................................................. 20

Step 5: Mounting the steam pipe, chimney and final assembly......... 21

2.3 PRECAUTION INSTRUCTIONS................................................... 23

2.4 PREPARATION FOR THE FIRST TEST RUN ............................. 25

3. EXPERIMENTS WITH THE STEAM ENGINE AND

ADDITIONAL COMPONENTS............................................................. 29

3.1 THE COMPONENTS AND THEIR DESCRIPTION..................... 29

3.1.1 The Generator........................................................................... 29

3.1.2 Transmission belt...................................................................... 30

3.1.3 The bread board ....................................................................... 31

3.1.5 LEDs......................................................................................... 33

3.1.6 Electrolytic (Electrolytic capacitors) ....................................... 34

3.1.7 Diode ........................................................................................ 36

3.1.8 Resistors.................................................................................... 37

3.1.9 Crocodile clips (red/black)....................................................... 38

3.1.10 Hook-up wire (red/black) ....................................................... 38

3.1.11 Switch...................................................................................... 39

Page 8

8

3.2 FROM THE MECHANIC ENERGY TO THE ELECTRIC

ENERGY................................................................................................ 41

3.2.1 Connection and function of the current machine ..................... 41

3.3 FIRST EXPERIMENTS WITH THE GENERATOR ..................... 42

3.4 ROTATION DIRECTION INDICATOR ........................................ 43

3.4.1 The transfer of the circuit......................................................... 43

3.4.2 The technical and the real current direction............................ 46

3.5 MOUNTING THE GENERATOR .................................................. 47

3.5.1 Generator, to connect mechanically with the flywheel of the

steam engine ..................................................................................... 48

3.5.2 Measuring the voltage of the generator ................................... 49

3.5.3 The direction of the rotation of the steam engine and the

generator ........................................................................................... 51

3.6 USING STEAM ENERGY TO GENERATE ELECTRICITY....... 52

3.6.1 Evaluating the power of the steam engine and of the

generator ........................................................................................... 52

3.7 STEP BY STEP GENERATING BRIGHT LIGHT OUT OF

STEAM .................................................................................................. 55

3.7.1 More light with 2 white LEDs................................................... 58

3.7.2 Light from four LEDs generated throught the steam engine.... 59

3.8 STORAGE OF THE ELECTRIC ENERGY.................................... 61

3.8.1 Charging the capacitor storage through the steam engine...... 61

3.8.2 Diode blocking discharge, Schottkydiode ................................ 64

3.8.3 Charge indicator for the electrolytic........................................ 66

3.8.4 Using stored energy.................................................................. 69

3.8.5 The steam engine as a charging station for the torch .............. 70

4. ANNEX................................................................................................... 73

4.1 COLLECTION OF THE FORMULARIES..................................... 73

4.1.1 Voltage, current and resistance................................................ 73

4.1.2 Parallel circuit of resistors....................................................... 74

4.1.3 Series connection of resistors................................................... 75

4.1.4 Calculation of the power .......................................................... 75

4.2 TROUBLESHOOTING................................................................... 75

4.2.1 The steam engine ...................................................................... 76

4.2.2 The electronic ........................................................................... 76

4.3 SUPPLIER SOURCES FOR SPARE PARTS AND ELECTRONIC

PARTS.................................................................................................... 77

4.3.1 Consumable supplies for steam engines................................... 77

4.4 WARRANTY................................................................................... 78

Page 9

9

1. Basics about the steam engine

Steam engines are heat engines and they work in contrary to the combustion

motors without inner combustion. Mechanical energy is provided through

the pressure of the steam. One can use different sources of heat to make the

engine work; so all liquid, solid and gaseous fuels. Steam engines are also

capable to transform solar energy and growing fuels for our needs. They do

this in a low emission and climate neutral way.

1.1 The steam engine and its development

Constructions and their precursors, which work with steam pressure, have

been already used in the Greece antique. It is described that the doors of the

temple after lightening the holy fire would open in a magic way due to a

construction which worked with steam.

Leading steps in the development of the steam engine principles happened

during the time of the industrial revolution, f. ex. through Denis Papin. 1690

he invented the pressure cooker, where he developed a first prototype of a

steam engine with cylinder and piston. In 1698 the British engineer Thomas

Savery constructed an engine, working on steam, which was supposed to

pump the groundwater. In 1712 the engineer Thomas Newcomen developed

the principle even further into an atmospheric steam engine.

Information:

The atmospheric steam engine is a precursor model with the following

function: water steam is pressed into the space of the cylinder below the

piston, which cools down through added cold water and finally condenses.

This causes a negative pressure and because of the higher external

atmospheric pressure now the piston is pressed into the cylinder. Through

the flywheel mass and the opened steam valve the piston is again pressed

into the cylinder. The energetic efficiency of this construction is about

1%.

In 1769 James Watt managed to patent a double functioning steam engine.

In this construction the piston is alternately shifted from one side to the

other through steam. This increased the efficiency enormously. James Watt

described the out put of his engine in horsepower, which had been used as a

measurement for power engines for a long period of time, f. ex. with

automobiles.

Page 10

10

At that time the steam engine brought a lot of possibilities in the areas of

transport and construction. From the first rotation on the engine brings a

high torque to the axis and is able to work forwards and backwards. Steam

automobiles can start moving under load and do not need clutch and

gearing.

1.2 Knowledge about the steam engine

Right behind the wind power the steam power is one of the ancient methods

of humankind to produce mechanical energy. The name steam engine is

already indicating the energy source; steam. The energy source steam was

and is transformed into other energy forms through different constructions,

f. ex. piston steam engine or steam - turbines.

Basically we need two components regarding to the principle of the steam

energy: the steam boiler and the piston steam engine or the steam – turbine.

This principle has not changed till nowadays. Still changes have happened

within the modern steam engine regarding to the technical designs, modern

materials and a profound knowledge how to increase the efficiency.

In earlier times the efficiency of the piston steam engine was very low.

Especially to generate electricity they were mainly substituted through

steam turbines, which worked more efficiently. Nowadays functioning

nuclear power bases are so to speak modern steam engines, working with

the same principle. Here one uses the problematic nuclear energy to heat up

the water.

1.2.1. How to change water into steam

To transform the liquid state of H2O into water steam, we need to heat it up

till it boils. Once the water is boiling, which normally happens at 100

degrees C and 1013 hPa (the boiling temperature depends on the altitude of

the place, more exact - on the external air pressure) it changes into steam.

The boiling temperature of water (in general with liquids) changes when the

external air pressure raise. Assuming we have 2 bar pressure in the steam

boiler the boiling temperature raises up to 120 degrees C (theoretical value).

The heating up needs a certain quantity of energy which is called heat of

evaporation. There are needed 4,2 joule to heat up 1 gram of water for 1

degree C. On the other hand it needs 2257 joule to evaporate 1 gram of

water. This high energy consumption can be explained through the

enormous expansion of the volume of the water steam in relation to its

liquid state.1 litre of boiling water will transform into 1673 litres of steam

(these values are related to normal air pressure).

Page 11

11

Keeping the arising steam in a closed vessel will produce a very high

pressure, which can even lead to an explosion of the boiler.

Therefore the steam engines have safety valves which open with high

pressure so the steam can escape.

One uses the pressure of the steam by moving a piston in a cylinder, which

produces mechanical energy.

Information:

In physics we use the parameter “p” for pressure, which acts with a power

“F” on a surface “A”.

When the steam cools down a contrary process is taking place, the steam

condenses. Now the energy which has been used to evaporate is set free.

Water steam condenses f. ex. on colder metals and is then visible in little

water drops.

1.2.2 The boiler

There are different designs of the steam boiler depending on the use and

form of the steam engine. The main intension is to provide constantly

enough steam so that the pistons of the steam engine are moving.

1.2.3 The flywheel

The steam engine transforms the back- and forward movement into a

rotating movement.

The classical steam engine has a heavy flywheel to provide an even

rotation. This helps to overcome the upper and lower dead centres. The

flywheel is an energy storage, which stores the energy of the “power

strokes” and therefore bridges the passive time.

1.2.4 The oscillating steam engine

With the help of the oscillating principle one easily can realize a

functioning steam engine model. The oscillating steam engine regulates the

in and outlet of the steam through the moving cylinders. Constructions of

centred rotatable bearings provide the needed flexibility of the cylinder.

Through a coil spring the cylinder is compressed against the holder. The

sliding surfaces need to be even.

Page 12

12

Fig. 1.01: The oscillating cylinder:

steam engine model of the steam box

On the back of the cylinder we find a hole which is called steam hole. On

the connected surface of the fixing bracket we find a steam supplying hole

and a steam exhausting hole. Steam enters into the cylinder when the steam

hole of the cylinder is exactly positioned on top of the steam supplying

hole. The piston moves out of the cylinder and the lifting movement is

transformed into a rotating movement through the rod bearing and the crank

(eccentric bearing). The flywheel mass leads the piston back so that the

cylinder is tipping backwards with its steam hole on top of the steam

exhausting hole and the used steam escapes. When the piston has overcome

the rear dead centre the steam hole moves again on top of the steam

supplying hole, steam enters the cylinder again and the explained process

repeats itself.

The principle of the oscillating steam engine

The water steam provided by the boiler enters through the steam supplying hole into the cylinder and presses the piston out of the cylinder. Through the crank movement the cylinder moves on and the

steam inlet is closed.

Through the uplifting movement of the piston the cylinder moves on

and reaches the steam exhausting hole. The cooled water steam is

pressed out and escapes to the sides. The process starts again.

The advantage of this type of engine is a much easier construction. It is a

complete and powerful engine and was used in steam navigation.

Page 13

13

1.2.5 The valve–controlled steam engine

Contrary to these simple constructions there are also valve-controlled

models available, such as the steam engine model D9/D10, D20 and other

models from Wilesco.

The valve-controlled steam engine works like this:

Water steam provided by the boiler enters the slide box and a slider presses

on one side of the piston within the cylinder. The high pressure steam

pushes the piston into the cylinder. As the piston is connected with the

crankshaft through a connecting rod the flywheel now turns on half a

rotation. Now the slider is moved. The steam feed happens now on the other

side of the piston, which is then pressed backward through the steam.

The cooled steam leaves through the steam outlet, f. ex. through the

chimney of the steam engine model. The process starts again.

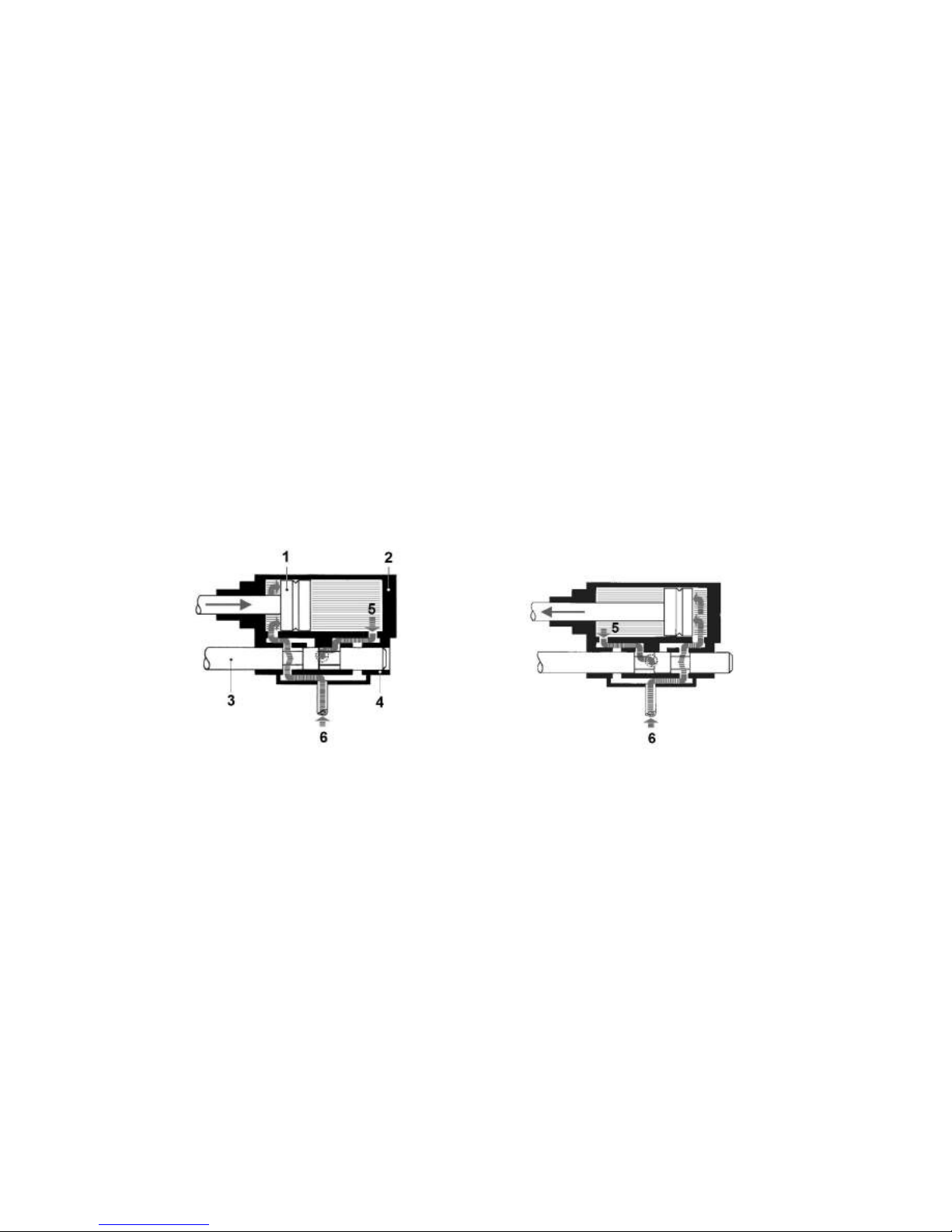

Fig.1.02

The principle of the valve-controlled steam engine (a cut through cylinder

and slider) a) steam presses the piston (1) to the right, b) to the left. 1=

piston, 2= cylinder, 3= slider rod, 4= slider box, 5= steam outlet, 6= steam

inlet

The steam engine can consist out of one or several cylinders. The advantage

of several cylinders is a continuous power transfer.

Page 14

14

1.3 Power and efficiency

One of the real advantages of the steam engine is that through the external

combustion he does not depend on high quality fuel. He works with any

kind of fuel, f. ex. coal, wood, oil, peat, any kind of waste etc. This is not

true for the steam engine model, they are fed with dry spirit tablets. Another

advantage of the steam engine is that they produce relatively little operating

noise. What one can hear is the noise of the mechanics and the exhaustion

of the steam, the engine itself runs almost silent.On the other hand we have

a very essential disadvantage. The steam engine has a very low efficiency;

only 10 to 12%, which means only 12% of the involved energy of the fuel is

transformed into kinetic energy.

1.3.1 Comparison: oscillating and valve-controlled steam

engine

With the model Steam Box and the model D20 one can explore easily the

difference between the oscillating and the valve-controlled steam engine.

Also with the experiments of the Steam Box one can point out the

differences very clearly.

Fig.1.03 on the left side the steam engine model of the Steam Box with the

oscillating cylinder, to the right the model D20 (valve-controlled).

Page 15

15

Beside the different technical structures both models also differ in power

transfer and efficiency. For the same amount of power the Steam Box

model needs more fuel then the D 20 model. The generator is excellent to

explore the power transfer.

1.4 What function has the steam engine nowadays?

In the area of the power engines the steam engine was substituted through

the combustion engine. Because of the high energy content of the fuel (1012 kWh per litre) one gains a higher efficiency together with less weight

and more comfortable operation. Today there are still areas of use for the

steam engine. These constructions are used in the coal mining and conveyor

belts. Here the steam engine works as well as a winding machine for coal

and at the same time as a brake to let down filling material. The kinetic

energy which is produced through the letting down movement is used to

heat up the steam.

Now and again there are engineers who pick up the principle of the steam

engine and bring it into the world with modern materials. One advantage to

the combustion engine is the external combustion process and the use of a

variety of fuels. Another one is the overload capacity of the steam engine.

Overload capacity means that the nominal value and the continuous power

transfer can be shortly and without problems exceeded. One can prove this

in the described experiments, f. ex. by short-circuiting the generator.

Modern steam engines with low emission combustion produce steam

efficiently and then similar like a diesel engine they inject the steam

through nozzles. Those engines work in the 2-stroke process and do not

need common lubricants, because the mechanical parts are made out of

carbonic components.

1.4.1 Hybrid systems consisting photovoltaic constructions and

the steam engine

There exist different explorations and examinations regarding to hybrid

systems consisting modern photovoltaic in combination with modern

concepts of the steam engine.

These combined systems make sense in climate regions where solar energy

mainly is used in the summer season and a complement is needed for the

Page 16

16

winter season. A combined heat and power production serves well, mainly

for the heating season. Systems like this provide f. ex. for private

households or internal consumers, an all year round and energy selfsufficient concept.

Instead of the steam engine one also can use a Stirling engine. Both

constructions can work with all kinds of solid and liquid fuels, f. ex. wood,

coal, biogas etc.

Information: If you work with the E-Box 50 or a different model you can

skip this chapter (2) and move on to the next (3) and continue to

experiment with the steam engine model you have.

Page 17

17

2. Assembling the model

Depending whether you work with the Steam Box D100 E or you already

have a fixed model this chapter continues with putting together the steam

engine model. The following chapter shows experiments with an already

existent steam engine model.

2.1 Tricks and tips for a successful assembling

Sometimes it seems a little difficult to screw in some screws in an

inaccessible positions, like in the area of the flywheel. It is very useful to fix

a little magnet on the screwdriver so that it becomes magnetised. Now the

screw can easily be lead to the prepared drilled hole.

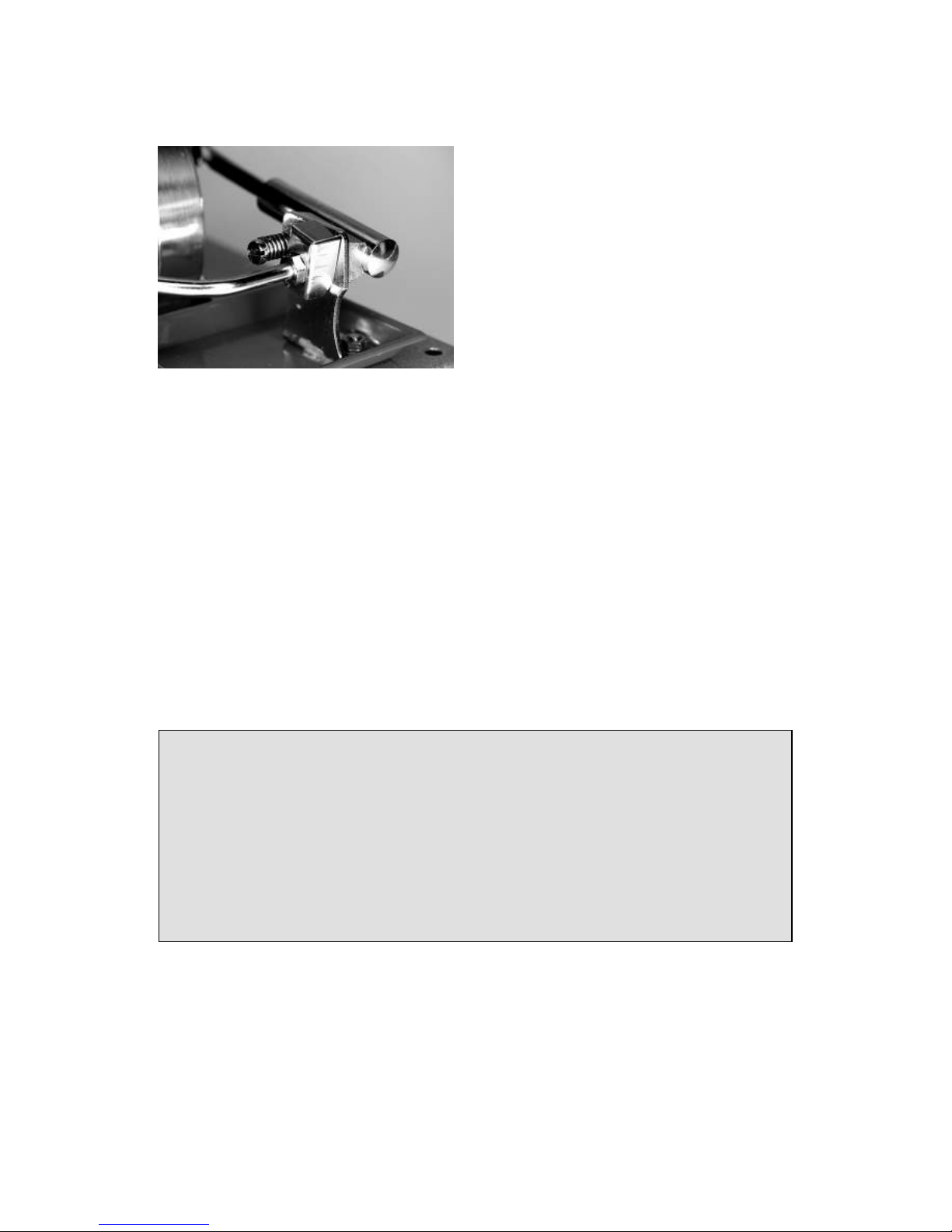

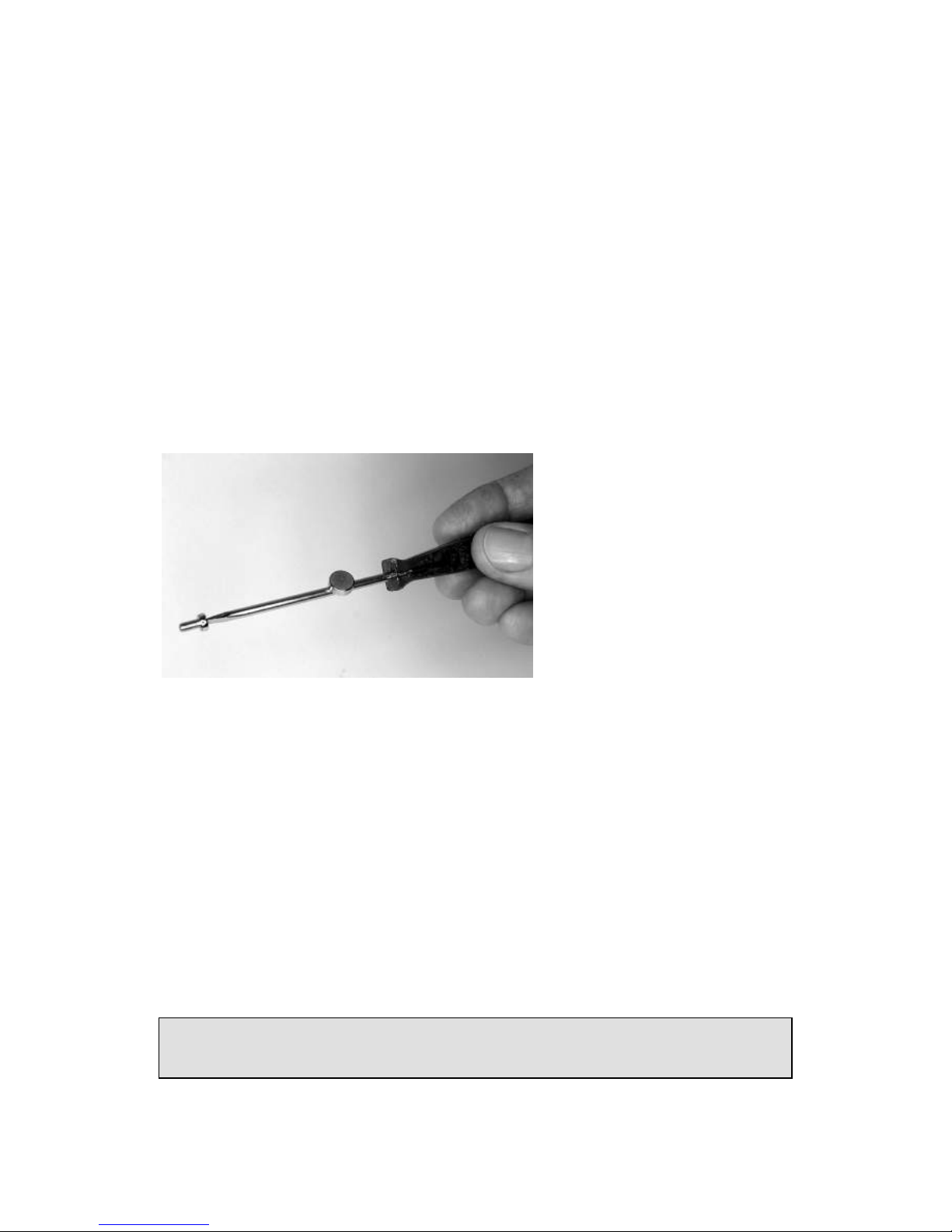

Fig.2.01:

Screwdriver becomes

magnetised and holds the

screw.

To tighten the screw properly it makes sense to use the screwdriver on the

one side and on the other side hold the screw-nut with a spanner.

It is helpful to put all the small pieces like screws, nuts and seals into a flat

container so they do not get lost.

How to lubricate the moving parts:

A good service brings a small disposable syringe, with a blunt needle (the

peak of the needle can be cut of or grinded down). This allows injecting the

steam engine oil well measured onto the oil needing parts.

Do not use any liquid oil for lubricating the piston and cylinder. Please

only use Wilesco steam engine oil.

Page 18

18

Fig. 2.02: Lubricating with a disposable syringe

Before lightening the dry spirit tablets check whether the burner slide

moves easily in and out of the burner slide box (in the boiler house of the

steam engine model). If not you can slightly widen the sides of the burner

slide box.

2.2 Assembly instructions step by step

All the parts that you require to build this steam engine, including the tools,

are contained in the Steam Box D 100E. The instruction leaflet is divided

into assembling steps, and each step is illustrated.

Please follow the instructions exactly and step by step, so that the operation

of the steam engine is successful.

Step 1: Assembly of the boiler

Insert the fixing bracket of the boiler through the boiler house (2) from

beneath until the angled sides fit against the upper flanges of the boiler

house (2). Locate in the centre notches to restrict sideways movement, now

the bracket will stay in place due to its own tension. Push the boiler (3)

according to the Fig. 2.2.1 (The water level glass has to stay on the side of

the fire place) between the fixing bracket (4) and the boiler house. Now

push the boiler up against the bracket, and at the same time slide it forwards

until it locks on the rear boiler support.

Fig. 2.2.1: mounting the boiler

Page 19

19

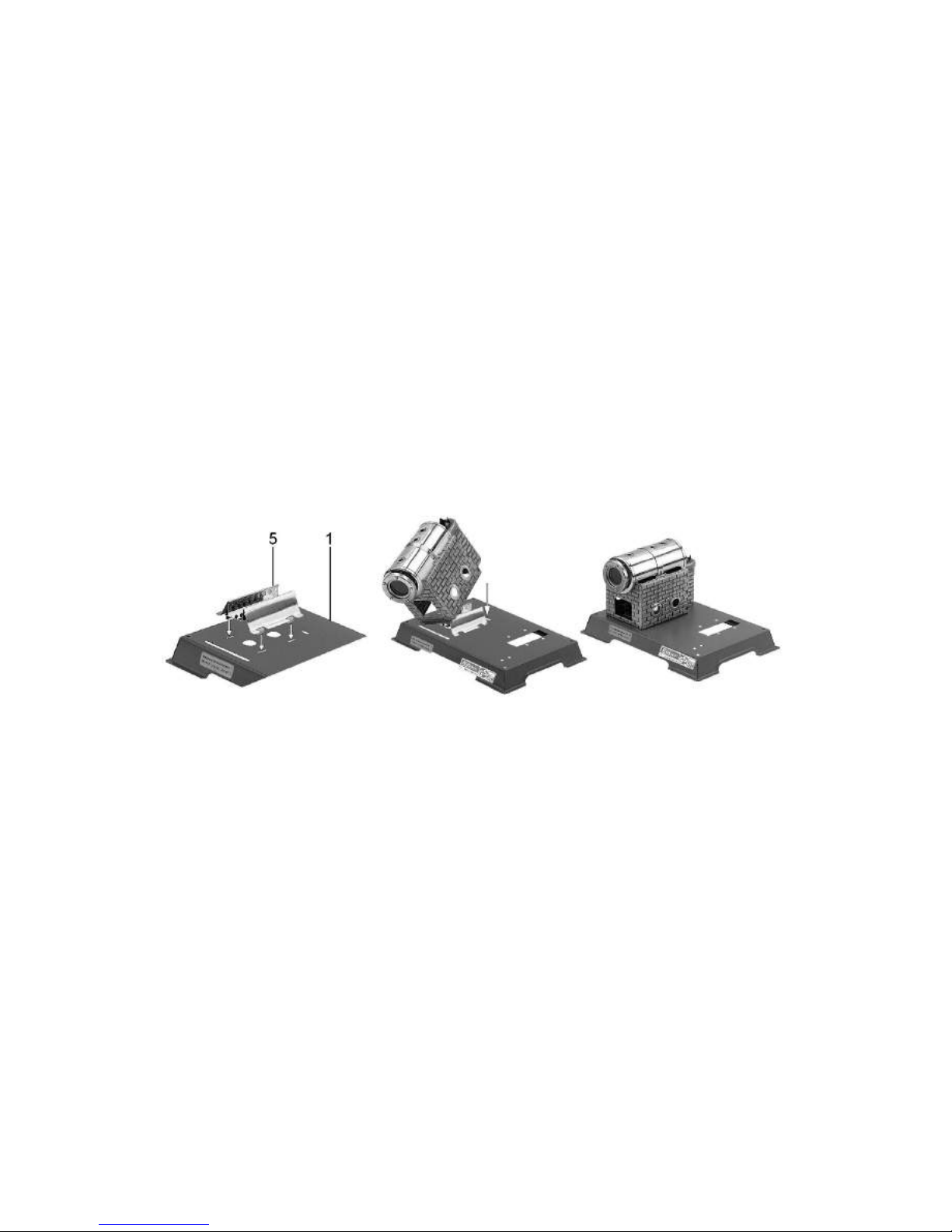

Step 2: Mounting the burner slide and boiler house

CAUTION work carefully because of sharp edges! Insert the tabs on the

burner slide (5) with the point facing towards the front into the

corresponding slots on the base plate (1). Turn the base plate (1) over, and

tap the burner slide tabs outwards, using the screwdriver handle. This is best

done by resting the burner slide on the edge of a table.

Now insert the long tab on the boiler house into the long slot in the base

plate (1), locate the remaining two tabs into the corresponding slots and tap

these over as well. This is best achieved by resting the chimney vent on the

edge of the table. Attach the stickers “watch water level” on the base plate

(1) under the water level glass and the sticker of the model number next to

it.

Fig.2.2.2: mounting the burner slide and the boiler house

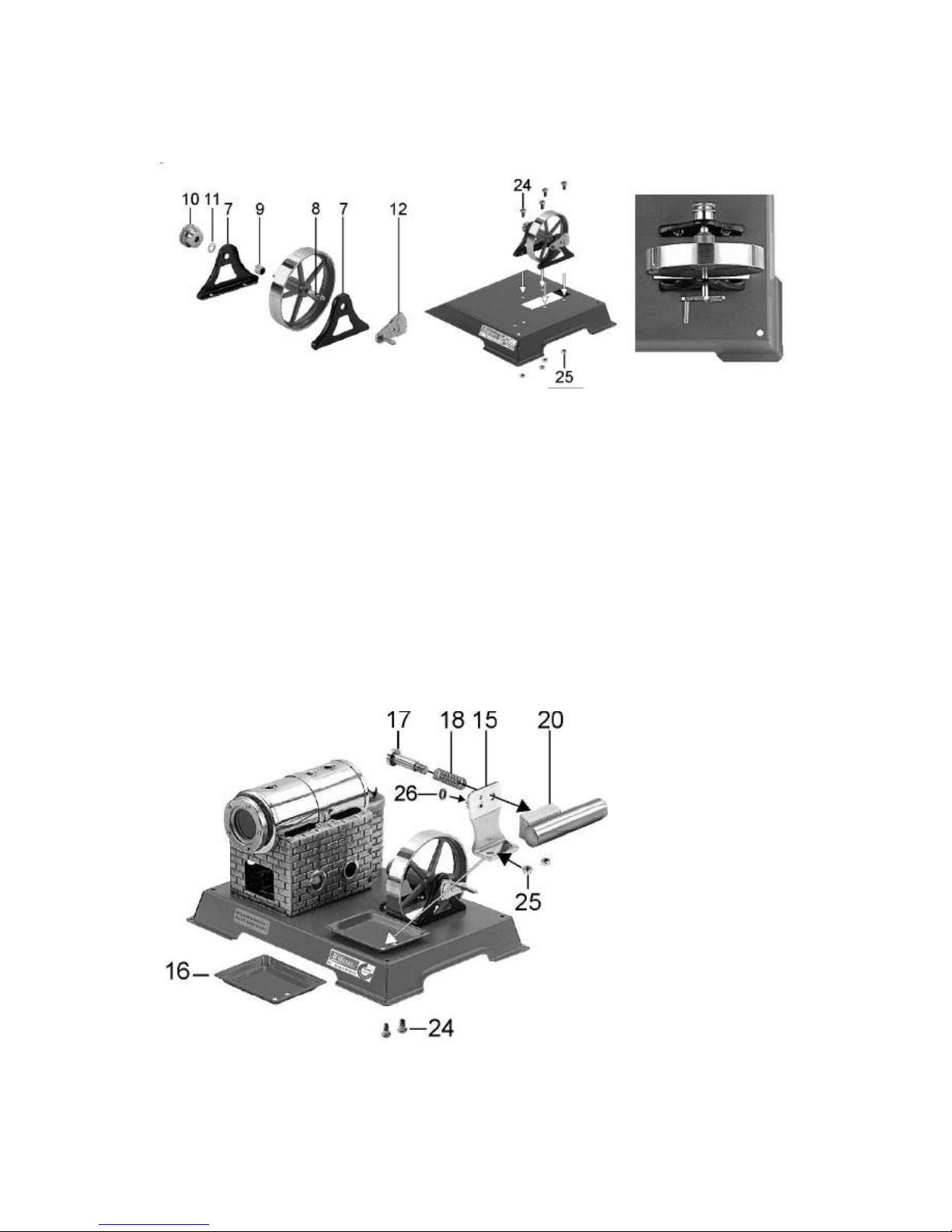

Step 3: Assembling and mounting the flywheel.

On the short side of the flywheel axle (8) fit one bearing frame (7) and then

screw on the crank plate (12). On the other side of the axle slide onto in the

following order the distance bush (9), the second bearing frame (7) and 1

washer (11), then screw on the pulley wheel (10) again. Now tighten the

crank plate (12) and the pulley wheel (10) against each other. This flywheel

unit is now fixed onto the base plate (1) using the screws M3x6 (24) and the

nuts (25) so that the crank plate faces towards the outside.

To mount this part is a little difficult, so please look under tricks and tips

using the idea with the magnet on the screwdriver.

Page 20

20

Fig.2.2.3: mounting the flywheel

Step 4: Assembling the cylinder unit.

Mount the cylinder unit first by fitting the spring (18) and the baffle plate

(15) onto the screw M3x16 (17). Now tighten her into the threaded hole on

the cylinder (20) by turning the screw only 1-2 times. Do not turn further

otherwise this will damage the cylinder. Now fit the baffle plate and the

condensed water tray to the base plate using two screws (24) and nuts (25).

Insert the screws from underneath the base plate.

Fig.2.2.4 mounting

the cylinder unit

Page 21

21

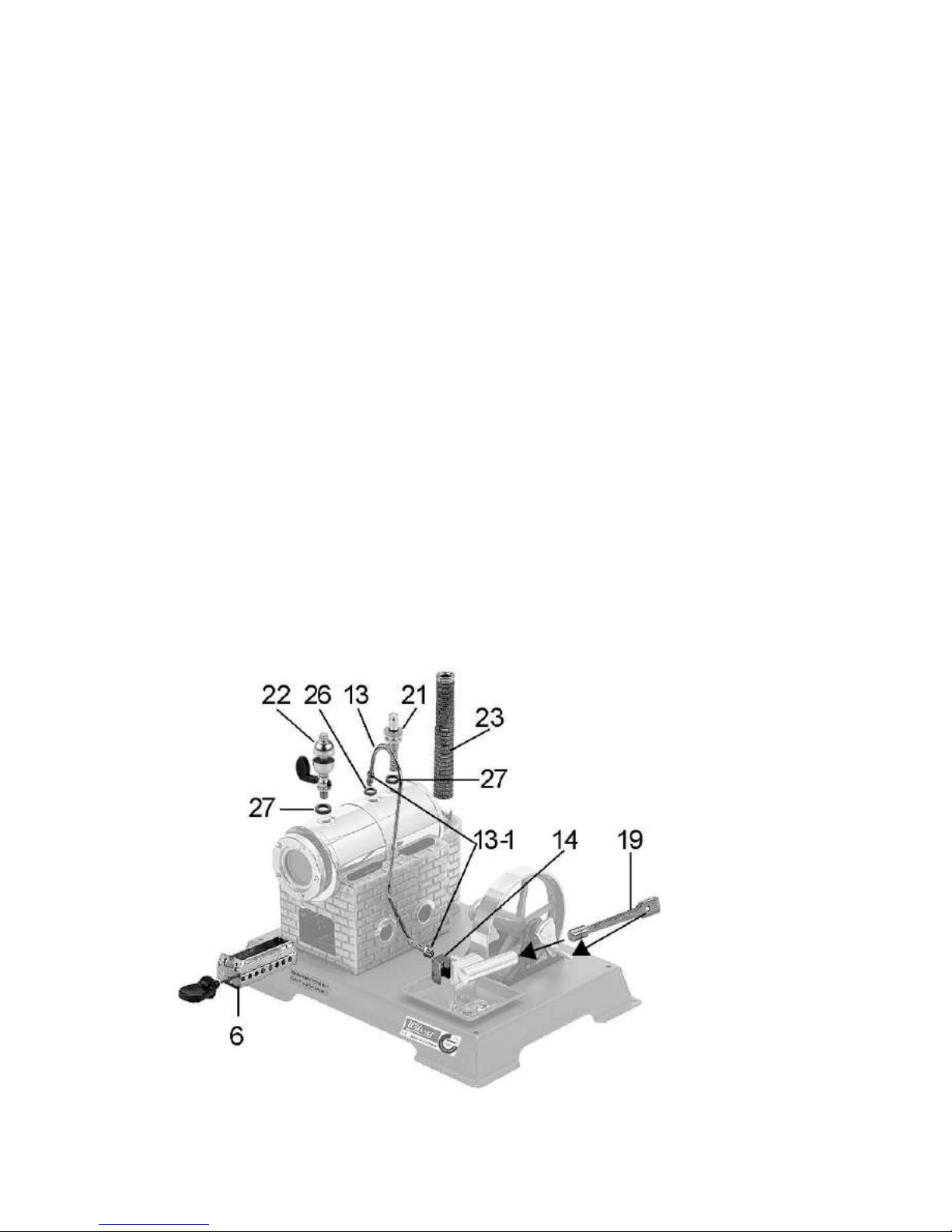

Step 5: Mounting the steam pipe, chimney and final assembly

On the boiler are three threaded holes. Put a gasket (26) into the middle one

and in the threaded bush on the baffle plate (15). Slide the cover (14) over

the packing screw (13-1) on the baffle plate end of the steam pipe (13) and

lightly ( first by hand) screw both ends of the steam pipe into the gasketed

holes. Now insert the piston rod (19) into the cylinder and over the crank

plate (12) pin. Check that the cylinder is at right angles to the flywheel axle,

are any adjustments necessary loosen the nuts holding the baffle plate,

adjust and retighten. Now with the use of the supplied spanner tighten the

steam pipe connections. Put a large gasket onto the whistle (22) and the

spring loaded safety valve (21) and fix it by hand (not using a tool) on the

boiler. Using a combination of gaskets you can position the whistle

correctly and tighten both by hand. Insert the burner tray (6) under the

boiler and fit the chimney (23) over the vent and fix it with 2 metal screws.

Now the assembling of the steam engine is finished. Stick on the sticker:

Baumusterprüfung vom TÜV/Nord

Fig.2.2.5:

Final

assembling

Page 22

22

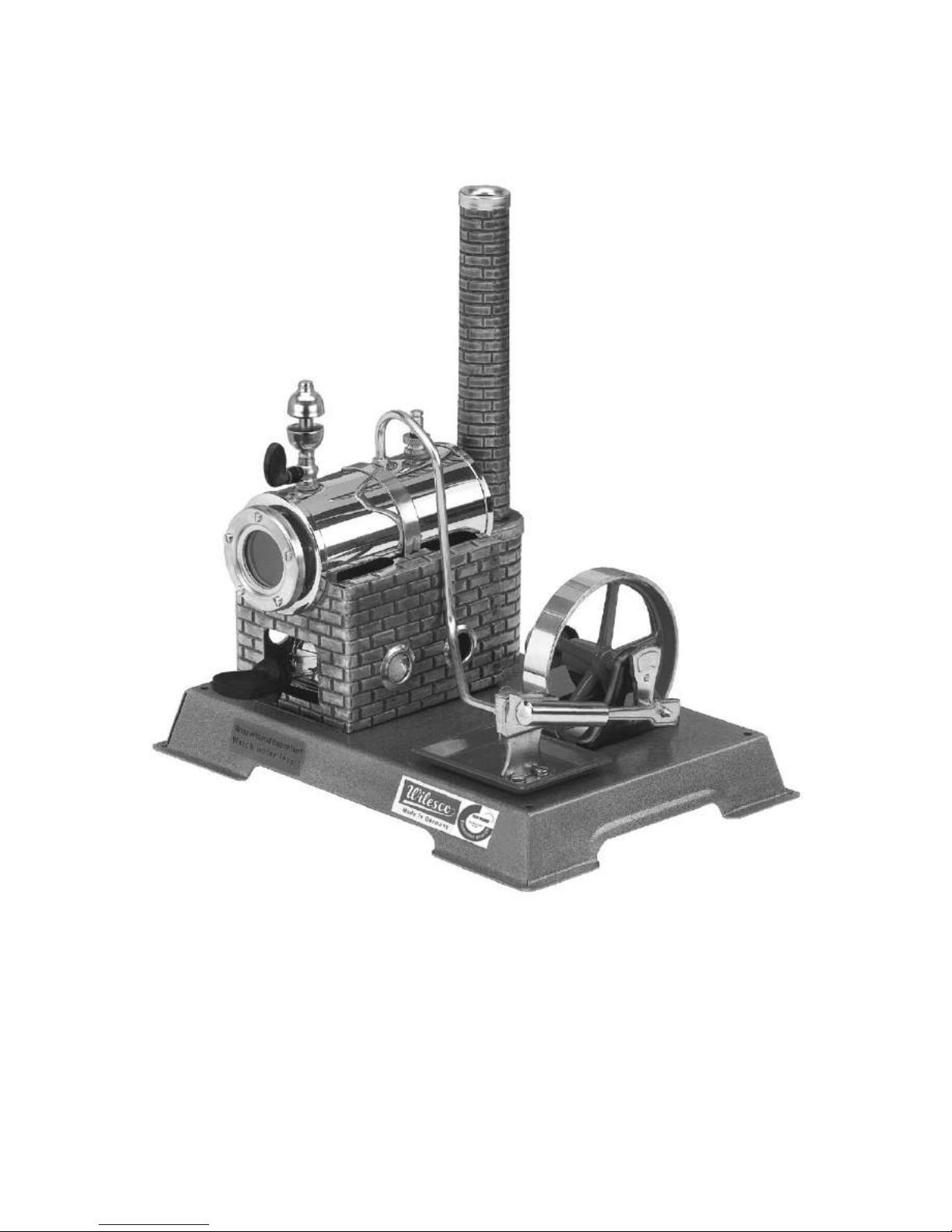

Fig 2.3.1: A complete steam engine model without generator

Before operating read the instructions carefully. We wish you lots of fun in

building and operating this steam engine.

Page 23

23

2.3 Precaution instructions

Attention! Important information and safety

precautions for your own safety:

1. For safety reasons, children should run the steam engine only under

supervision of adults (recommended age: from 8 years on, not

recommended for children under 36 months). During the operation of

the steam model until its complete cooling the engine must be under

constant observation.

Important!

Never operate the engine without safety valve. Only use WILESCO

steam engine oil and dry fuel tablets!

1. Each irregularity during operation has to be repaired by a competent

and authorized person or by WILESCO themselves. Otherwise any

warranty expires.

2. Any unauthorized change, repair or manipulation to the standard

specification will also invalidate the warranty.

3. All parts which are under steam pressure so as boiler, spring loaded

safety valve etc. leave our works only after a 100% examination. The

spring loaded safety valve must not be manipulated. The operation of

the steam engine without any spring loaded safety valve is not

allowed The function of the spring loaded valve has to be checked

before each operation by pressing the spring or by a small pull on the

upper valve rod. If lime residues caused by hard water are visible on

the spring loaded safety valve, it has to be replaced immediately.

4. High temperatures: The principles on which the engine works mean

that the burner slide, boiler, boiler house, the spring loaded safety

valve, the steam pipes etc. become very hot. Do not touch in order to

avoid the risk of burns.

5. Safety precautions: in the course of the running, take care that children

do not touch any of the moving parts.

Page 24

24

6. Danger if the boiler is heated without enough

water! Always ensure that there is enough water in

the boiler of the steam engine. Caution: When

refilling WiTabs dry fuel tablets also refill up to the

max. level.. The water must always be visible at

least at the lower end of the sight glass, otherwise

the joints become leaking and the boiler will be destroyed. Any

resulting claim, damage or consequential damage cannot be accepted.

7. If the boiler or any steam leading part leak, stop the steam model

immediately by removing the burner slide. Any necessary repair

should be carried out by authorized staff or at the WILESCO

company.

8. The steam engine meets all safety standards and actual regulations.

Every boiler has been submitted to a bursting pressure and water test

of 5 bar. The operating pressure is maximally 1,5 bar.

9. Imperatively keep the operating instructions together with your steam

box.

10. We advise you to place the stationary steameEngine on a non sliding

surface or fix it onto a coated chipboard (approx. 16 mm thick) with 4

wooden screws (3,4 x 45 mm). The size of the board depends on how

many models will be running with the steam engine.

Caution: Don't operate the steam model near flammable objects or on a

temperaturesensitive surface. Operation only under windless condition.

Page 25

25

2.4 Preparation for the first test run

Components: distilled water, steam engine oil, dry spirit tablets

Please operate the steam engine model only according to the instructions

and the safety instructions.

Operating instructions

1. Filling with water at the first operation and after cooling of the boiler:

Unscrew the spring loaded safety valve and fill the boiler with the

funnel up to the water level maximum (upper end of the sight glass), if

possible with warm water. Lift the funnel slightly during filling so that

the air inside the boiler can escape. Use only deficient in lime water or,

even better, water without any lime (e.g. distilled water). Then refit

the spring-loaded safety valve.

2. Screw the steam whistle onto the boiler. When screwing in the steam

whistle, the lever should point outwards (use washers if necessary) so

that the operation of the whistle is possible without having contact with

the boiler. Do not pull or pull out the lever, only move it carefully from

side to side.

Note: The steam whistle makes it possible to regulate easily any overpressure in the boiler or check before oiling whether the boiler is still under

pressure.

3. Only oil the piston when there is no pressure in the boiler. To check

this, operate the steam whistle several times. When the piston needs to

be oiled remove the piston rod from the pin of the crank disk and apply

abt. 2-3 drops of Wilesco steam engine oil onto the piston and abt. 2-3

drops into the cylinder itself. 2-3 drops oil are sufficient for approx. 10

minutes operating time. Oil lightly all of the bearings and linkages.

Before refilling the boiler with water, check that no pressure is in the

boiler through operating the steam whistle.

4. Place 1 1/2 WiTabs dry fuel tablets upright in the burner

slide (not more than 1 1/2 pcs.) and light them. Use only

the original WILESCO burner slide. Caution:

Page 26

26

because of the risk of danger from an open flame, always take the

necessary safety precautions. The burner slide is adjustable. The

oxygen supply and the flame height can be adjusted by moving the

burner slide in relation to the air holes of the burner slide guide in the

boiler housing. Before adding new fuel tablets, always check the water

level and refill the boiler with water to ensure that the boiler does not

run dry. The portion of fuel tablets to the quantity of water in the boiler

is designed so that the boiler cannot run dry without any added fuel

tablets. The burner slide must be completely pushed in. Important:

After the heating process, remove the burner slide from the guide

whilst it is still hot, otherwise not burnt fuel may cause the slide to

stick. If the slide is stuck, it can be removed by tilting it slightly to the

left or right.

Caution: dry fuel tablets require a lot of oxygen to

burn properly. That is the reason why, for an indoors

use, the room should be well ventilated.

To prevent unpleasant smells, the fuel tablets should be burnt out they should not be blown out. If there is not enough water in the boiler,

place the burner slide on a fireproofed surface until the tablets have

burned out completely.

5. When steam can be seen turn the flywheel by hand to let the

condensation in the pipes and the cylinder escape. Then the steam

engine will start to operate.

6. After the use of the steam engine and its cooling, the engine should be

serviced. Pour out any water left in the boiler. For this, unscrew the

spring loaded safety valve and take off all of the loose parts before

tipping over the engine. Be very careful if the water is still hot! Water

left in the boiler cannot do any damage but might leave sediment on

the sight glass. Any lime formation on the sight glass or in the boiler

should not be removed by using vinegar or corrosive agent (advise: use

a lime dissolving agent which does not attack the brass and the solder).

The building of soot on the lower side of the boiler does not influence

the function and can be removed with a brush. Finally, dry the model

using a clean piece of cloth.

Page 27

27

Fig.2.3.2: Steam engine of the Steam Box with generator

Page 28

28

Page 29

29

3. Experiments with the steam engine and additional

components

Together with the added components and the steam model one now can start

to build electrical and electronic circuits.

3.1 The components and their description

Here are described the qualities and the use of the added components in the

Steam Box D 100E and the E-Box 50

3.1.1 The generator

You find a permanently excited current machine in the Steam Box D 100E

and the E-Box 50, which is used in the experiments mainly as a generator.

To be more precisely there does not exist any difference between an engine

and a generator. Depending on the use and the electrical wiring a machine

works as an engine or a generator.

The generator with its permanent excitement has the advantage to create the

field for induction/generating electricity through a permanent magnet

instead of using a coil. This construction saves energy which is normally

used to establish the electric field. In cases of low rotating speed of a steam

engine it avoids that there is more energy consumed then being produced.

The direct current generator has a rotor (a coil out of enamelled copper

wire), which turns within a constant magnet field (stator). This rotor coil is

connected through a brush-like commutator to the generator connections

(red and black connection cable). With each half rotation of the rotor the

commutator changes the polarity of the coil.

Fig.3.0.1: circuit symbol, generator

Page 30

30

Fig.3.0.2: direct current

machine with mounting

support

The connecting cables (red/black) are made out of flexible strand and can

be connected f. ex. with crocodile clips with the bread board.

3.1.2 Transmission belt

Through twisting the enclosed transmission belt it is joined together or

pulled apart. Therefore hold - likewise in Fig.3.0.3 – the left end and take

the right end and give it 1-2 turns to the left (a). Now the transmission belt

itself stays without tension. Take the conical end – in the Fig.3.0.3 the right

end - and stick it into the cylindrical end and screw it in with 1-2 turns. The

dismounting you do in the reversed order.

Fig.3.0.3: connecting

the transmission belt,

a) first step, b) second

step

The Steam Box contains transmission belts. One can cut with a strong

scissor the transmission belt into the right length. For the transmission of

the mechanical power of the steam engine to the generator a length of 175

to 185 mm is optimal. It is important to make the cut on the cylindrical end

and leave the conical end for putting together both ends of the belt.

Page 31

31

3.1.3 The bread board

The bread board, also called patch panel, consists in his inside contact

springs, which are connected to one another in a system of rows.

The bread board is excellent for realizing electronic circuits in combination

with the steam engine. The electronic parts, such as the LEDs, resistances

and connecting wires can be repeatedly used and inserted into the contacts.

It allows that the experiments can be configured without soldering or

screwing. One can design circuits and experiment with them by changing or

exchanging different components.

Dates: This bread board has 170 contacts in a 2,54mm grid. The 170

contacts in the middle range are each connected by vertical strips in rows of

five.

measurements: 45mm x 33mm x 9mm

distance of contacts: 2.54 mm (100 mil)

cable connection - size: 0.3 - 0.8 mm (AWG 20 - 28)

shape of the hole: rectangular

fixation: adhesive foil at the back side

Fig.3.04: bread board

Fig.3.05: internal circuit system of

the bread board (connection of the

contacts by vertical strips in rows

of five)

Page 32

32

When the bread board is new, initially it can be difficult to stick in the

pieces and wire jumpers. It helps to prepare the contacts with a thin needle,

which should not be thicker then 0,3 – 0,6 mm, otherwise the contact spring

wears out to an extend that the contacts to the wire connection might suffer.

Fig.3.06: carefully widen the

contact with a needle

All parts can be stuck in directly without soldering. It needs some practice,

so that the connection wires do not bend over. Hold the wire right at its end

and stick it vertically with a little bit of pressure into the contact. The use of

flat pliers can be helpful.

Cutting the end of the wire diagonally with a side cutter is also supportive.

Short wires – like you find at the LEDs – you stick in with flat piers or a

pincer, so they do not bend over. One can cut some jumpers with a diameter

of 0,6 mm out of the jumper wire.

Measure the approximately length of the jumper and add the length of the

ends, which will stick in the contacts. Remove the cable insulation at the

ends. Either you use a wire stripper or cut around the wire with a knife and

remove the insulation.

The bread board can be fixed on a surface, f. ex. a well proportioned

prepared piece of wood. The back side of the bread board has an adhesive

foil. Take of the protection paper and glue it now onto a plain and dust-free

surface.

Attention: Once you glued the bread board onto a surface it is difficult to

remove without damaging it.

Page 33

33

Fig.3.07: bread board glued

to a mounting board

(mounting board not

included)

3.1.5 LEDs

Compared to a normal diode the LED (light emitting diode) has one further

characteristic! It shines when voltage is applied. You find a red, an orange,

2 white shining LEDS and a red flashing LED. You can identify the

flashing LED through its black spot within its red enclosure. The dark spot

is the integrated circuit which causes the LED to flash as soon as the correct

voltage is applied.

LEDs should always be operated with a series resistor for current limiting,

otherwise they can break.

Fig.3.08: circuit symbol, LED, the arrow

shows the technical direction of the

electric current, A symbolises anode (+)

and K cathode (-)

Page 34

34

In some experiments together with the generator are series resistors with

100 Ohm to 1K-Ohm recommended.

Compared to the normal light bulb the LED does not have a filament. They

have a long durability and do not consume a lot of energy.

Fig.3.09: The connections of the LED: the longer

end of the wire is the cathode, the “negative

connection”, also marked through a flattened

enclosure

Fig.3.10: flashing LED with integrated flash-IC

3.1.6 Electrolytic (Electrolytic capacitors)

Electrolytic capacitors have a high capacity compared to normal capacitors.

One can imagine the capacitor with 2 metal plates (as it is usually shown in

the circuit symbol). The first “plate” insulated by an oxide-layer (dielectric).

The “second” plate consists out of an electrolyte, which gives the name to

the capacitor. Due to the electrolyte, an electrolytic capacitor is polaritydependent and the connections are designated with a positive pole and a

Page 35

35

negative pole. When it is connected “the wrong way around” over a longer

period, the electrolyte of the capacitor will be destroyed.

Do not exceed the imprinted maximum voltage indication, because

otherwise the insulation layer can be destroyed.

Enclosed you find radial electrolytic capacitors with the following

capacities: 1000µF and 4700µF

Fig.3.11: circuit symbol, electrolytic

capacitors, left the positive pole

Information: μF means “microfarad”; the unit μ is one millionth of the basic unit.

Fig.3.12: Electrolytic capacitor

with connecting wires. The

positive pole is the longer

connection wire. In addition the

negative pole is designated with

a bright line on the enclosure.

For simplicity, the term “electrolytic capacitor” is sometimes shortened to

“electrolytic”. This abbreviation is mainly used in the US.

Page 36

36

3.1.7 Diode

Diodes let the current pass in only one direction. For that reason, they are

used to rectify AC voltages and to block undesirable polarity with DC

voltage, among other things. You can picture the functioning of a diode in

normal operation most easily as a non-return valve (water installations).

When pressure (current) is directed onto the valve (diode) in blocking

direction then the current will be blocked.

Fig.3.13: circuit symbol, Scottkydiode,

the left side signed with A is the anode

(+), the right side signed with K is the

cathode (-)

The pressure has to built up in contrary direction (direction of the arrow) to

overcome the spring pressure of the valve. The valve opens and the current

flows. The pressure, which is mentioned in this mechanical model to

overcome the spring pressure, corresponds to the forward voltage of the

diode. A certain voltage in the flowing direction of the diode is needed to

move into a conductive state.

Fig.3.14: Schottykdiode, type

BAT48. The cathode of the

diode can be recognized by

the imprinted black ring, the

other connection wire is the

anode. The technical current

direction goes from the anode

to the cathode.

Information: With the enclosed Schottky diodes the current begins to flow

at 0,25V in forward direction (circuit symbol: arrow). This allows an almost loss-free transmission.

Page 37

37

3.1.8 Resistors

A resistor is a passive component in electric and electronic circuits. Its main

task is the reduction of the flowing current to “reasonable” values. The most

famous resistors are the cylindrical ceramic type with axial connection

wires. The resistance values are imprinted in the form of coded coloured

rings. Enclosed are carbon-film resistors with the different values, shown in

the following table.

amount

Resistor value

1. ring

1. number

2. ring

2. number

3. ring

Multiplicator

4. ring

Tolerance

1

1 Ohm

brown

black

gold

gold110 Ohm

brown

black

black

gold1100 Ohm

brown

black

brown

gold21 K-Ohm

brown

black

red

gold

Fig.3.15: to the left a photo of a resistor, to the right the circuit symbol of

the resistor. It does not matter on which side it is connected.

R = resistor

Page 38

38

3.1.9 Crocodile clips (red/black)

With the red and black experimental wires, which have the crocodile clips

on their ends, you can easy and fast connect and combine different electric

parts (without soldering). It makes sense to use the red wire for the positive

pole, the black one for the negative pole.

Fig.3.16: experimental wire

with crocodile clips

3.1.10 Hook-up wire (red/black)

Enclosed you also find hook-up wire. You can make jumpers by estimating

or measuring the approximate length of the jumper (plus the length for the

wire ends that will be inserted into the plug contacts). The ends are stripped

of insulation for ca. 8 mm. Connection wires pinched off diagonally with

the wire cutter make insertion in the bread board contacts easier. With these

wires you can establish the electric connections between the single contacts

of the bread board. Once the jumpers are made, they can be used again and

again.

Fig.3.17: Possible applications

of the hook-up wire. One can

see the pins for the connection

to the crocodile clips in the

upper contacts. The upper 5

rows are connected to the lower

5 rows.

Page 39

39

3.1.11 Switch

According to the figure you find one switch. This type with 2 connections is

suitable for the use on the bread board. The electric flow is as long

established as the switch is pressed. Letting go of the switch is stopping the

flow again. Please mount the 4 legs of the switch as shown in the figure.

The switch will not work with wrongly twisted mounting, because the

connections are internally connected.

Fig.3.18: a) switch on the bread board and b) connecting assignment

Fig.3.19: circuit symbol: switch

Page 40

40

Components in an overview:

amount

type

detail

1

generator, permanent excited, current

machine

1

generator bracket

1

bread board

170 contacts

1

switch

1

LED, red

5 mm

1

LED, orange

5 mm

2

LED, white, extra bright

5 mm

mind. 2500 mcd

1

flash-LED, red

5 mm

1

electrolytic

1000µ, 10 V (or

higher)

2

electrolytic

4700µ, 10 V (or

higher)

1

Diodes, Schottky

BAT 48

2

Crocodile clips

red, black

2

pins

5

resistor, carbon ¼ Watt

1, 10, 100 Ohm, 2x

1K

0,5m

wire, rot

0,6 mm

0,5m

wire, black

0,6 mm

Note:

It is recommended to follow the instructions and the order given in the

booklet. This facilitates the understanding and eases the mounting and

changes. Later on you can repeat the experiments in your own order of

choice.

Recommendation of the following order:

read the instructions

mount the experiments

check the mounting

prepare the components for the experiments

start and run the steam engine

Only use the generator for the here designed purposes!

Page 41

41

3.2 From the mechanic energy to the electric energy

To gain electricity out of steam we need a couple of steps. First happens the

transformation from steam energy into mechanical energy and then from

mechanical energy into electricity. In our day to day life electricity has the

advantage that we can already use the existing installation and its use is

universal.

3.2.1 Connection and function of the current machine

The Steam Box D 100E and the E-Box 50 contain a permanent excited

current machine, which is used in the experiments as a generator. From the

perspective of the electro technique there does not exist any difference

between an engine and a generator; only depending on the use they are

named engine or generator.

You will experience the qualities and functions of the generator in the

following chapters through the practical experiments. In the text the current

machine is named generator when transforming mechanical energy into

electricity.

Connecting the generator:

Components: generator, crocodile clips

The generator has two connections, one with a red and another one with a

black cable. He generates pulsating direct current. You have a positive and

a negative pole same like with a battery. At the exit of a direct- current

generator one receives two half cyclic wave forms. Connect the cables of

the generator with the crocodile clips for the following experiments.

Connect the black cable to the black crocodile clip, the red cable to the red

clip, like shown in Fig.3.20. The connections of the generator can maintain

like this in most of the following experiments.

Note:For a stable contact between connection cable of the generator and

the crocodile clips it is helpful to bend the stripped ends of the

Page 42

42

connection cable towards the insulation and then stick all into the clip.

This connection can maintain like this in most of the following

experiments.

Fig.3.20:a) connection of generator cable and crocodile clips, b) detail,

how to put in the cable to provide a stable contact.

Do not connect the generator to the steam engine for the first experiments!

3.3 First experiments with the generator

Components like before, 1 orange LED added

For the first experiment with generator (not connected to the steam engine)

you mount a circuit with an orange LED. The longer wire of the LED is the

positive pole and shows into the direction where the red connection of the

generator is connected. When all parts are assembled one turns the axis of

the generator (together with the belt wheel) forward and backward, holding

it between thumb and index finger. In one direction the LED will flash, in

the other direction she does not shine.

Page 43

43

Fig.3.21: a) assembly of the experiment and b) circuit diagram

Note:

The orders of the experiments build up on each other. You do not have to

dismount everything after each experiment, but parts can be joined, taken

away or changed.

3.4 Rotation direction indicator

With this circuit you can construct a rotation direction indicator. Depending

in which direction you move the generator one or the other LED flashes.

Also one can exercise whether the LEDs are properly connected or not.

3.4.1 The transfer of the circuit

The transfer of a circuit diagram into a circuit on the bread board will be

described in the following example with the rotation direction indicator and

two LEDs. In the Fig.3.22a) is the circuit diagram shown. It contains

symbols of the electronic components.

Page 44

44

Fig.3.22a) The first circuit diagram, G for generator, R1 for series resistor,

D1 for the orange LED and D3 for the red LED

The electronic components such as resistor R1 or the D1 orange LED or the

D3 red LED can be plugged into the bread board without soldering.

Through the internal connections of the contacts of the bread board and the

added jumpers` one gains the electronic circuit and the electrical circuit.

It does not matter which direction you stick in the resistor (f. ex. R1 series

resistor). It is oposite with the diodes and the LEDs. The LEDs have a

longer and a shorter connection wire. The longer wire is the positive pole,

the anode, the shorter one is the negative connection, the cathode. Even

when they are connected the wrong way around they will not break.

The cables coming from the generator, connected with the red and black

crocodile clips are plugged into the bread board through the pins. The black

cable (negative pole) to the left and the red one (positive pole) to the right,

as shown in the picture.

Fig.3.22b) Composition of the components on the bread board, on the right

a photo of the LED.

red

Page 45

45

In Fig.3.22b) one can see the connections and also the structure of the LEDs

within its enclosure.

The cathode has a shorter connection wire and the metal end within the

transparent enclosure has the shape of a triangle. In the figure you can see

how the LEDs are plugged into the bread board. For an easier overview the

red LED is pictured apart on the right side. One also can recognize the

contacts of the bread board (in rows of five) and their vertical connections

(in grey).

Mounting of the experiment:

Components as before, additional: one red LED, one series resistor 100

Ohm. It makes sense to use the LEDs only in combination with a series

resistor to avoid their destruction when there is a high rotation and therefore

a high voltage of the generator.

In the first experiments the generator is used separately from the steam

engine. You can make the LEDs flash by using your thumb and index finger

and turn the axis of the generator strongly. With the correct mounting of

this simple circuit, in each direction only one LED flashes. F. ex.: right

turns the red LED, left turns the orange one (or opposite around). If both

LEDs are flashing when turning in one direction, then one LED is wrongly

plugged in.

Fig.3.23: Composition of the

bread board, 2 LEDs, antiparallel, series resistors,

cables with crocodile clips,

generator

Page 46

46

3.4.2 The technical and the real current direction

In which direction do the electrons flow within an electric circuit?

Information about technical and real current direction:

Observing the flow of the electrons (f. ex. with the electrolysis), one can

see that the electrons really flow from the negative pole to the positive

pole. This is named the “physical current direction” in contrary to the

“technical current direction”, where is defined, that the electric current

flows from the positive pole to the negative one. The technical current direction is always used in circuit diagrams (f. ex.: with LEDs, diodes and

the generator).

Fig.3.25: Diagram of the principle of the technical current direction (in a

closed electric circuit) from the positive pole to the negative pole

The diode works like a valve, which allows the current to flow in one

direction and stops it in the other direction.

Page 47

47

Fig.3.24: Principle of the direction of the rotation and current direction

3.5 Mounting the generator

Components: generator with mounting support, pulley belt, generator

holders, screws

To mount the generator on the basic plate of the steam machine one uses a

two-piece compression fitting in combination with the generator mounting

support.

You can install the generator to almost all basic plates of the Wilesco steam

engine models.

Depending on the type of the steam engine model they produce rotations

from 1000-2000R/min at the axis of the flywheel.

Fig.3.26: Parts for mounting the generator, a) two-piece holder of the

generator, b) mounting support of the generator and adjusting screw

Page 48

48

Position the lower part underneath the basic plate and the upper part above

and connect together with the generator mounting support/ generator with

two screws and nuts. Before tightening the screws, adjust the holder of the

generator that both pulley wheels – that of the generator and that of the

flywheel of the steam engine – are in one line. Now tighten the screws and

finally also the compression fitting underneath, so that the generator is well

fixed.

Fig.3.27: Assembling of the generator: a) both pulley wheels in one line, b)

compression fitting, underneath the basic plate

3.5.1 Generator, to connect mechanically with the flywheel of

the steam engine

Assemble the transmission belt and arrange it on the pulley wheel of the

generator and the pulley wheel of the shaft of fly wheel. Arrange the tension

of the transmission belt so that the transmission is easy and smoothly.

Page 49

49

Fig.3.28: The right tension

of the belt is important for a

successful work!

The right tension of the belt helps that the transmission of the mechanical

energy to the generator flows optimally and without gaps and at the same

time as less loss as possible through friction occurs. Is the belt too tight, it is

hard for the steam engine to move the generator and he can not establish the

appropriate rotational speed.

Important information:

Please use only the small pulley wheel even if you have access to more

potent steam engine models. With the big pulley wheel (on the shaft of fly

wheel) the rotational speed and the voltage of the generator will become

so high, that the generator and the electric circuits might get damaged.

3.5.2 Measuring the voltage of the generator

Components: generator, multimeter

Now you can measure the voltage of the generator using a multimeter. Put

the multimeter on the indicator for direct current, f. ex. the area till 20V.

With the steam engine model of the Steam Box D 100E you can measure

2.9 to 3V running it full power, bigger steam engine models generate more

then 7V.

Page 50

50

Fig.3.29:

measuring the voltage of the generator with a multimeter

Fig.3.30: Symbols of the circuit diagram, left the symbol for the generator,

right the symbol for the measuring instrument

Page 51

51

Note: Please do not put the bread board with the electronic circuits too

close to the steam outlet (cylinder). Use the cables with the crocodile clips

and put the board with the electrical circuits in an appropriate distant to

the steam engine and continue doing your experiments.

The voltage is depending on the maximal possible rotational speed of the

steam engine model and the transmission to the generator. Especially the

bigger steam engine models allow you to experiment with the rotational

speed by closing or opening the steam inlet more, or less.

3.5.3 The direction of the rotation of the steam engine and the

generator

Depending on the steam engine model you use, one can make experiments

with the direction of the rotation of the steam engine in connection with the

generator.

Oscillating steam engine models like the Steam Box D 100 E model only

have one possible rotation direction, other models like the D10 or D20

model are able to rotate in both directions. The following experiments use

the direction of the rotation of the fly wheel in clockwise direction (looking

directly onto the fly wheel with the boiler in the background).

Fig.3.31 appropriate place for

the bread board

Page 52

52

3.6 Using steam energy to generate electricity

We need a generator to generate electricity out of steam. The word

“generator” has its origins in the Latin language and means freely translated

“to bring out” or “to produce”. Though looking more exactly, energy can

not be produced, only changed from one state into a different one. So in this

sense a generator is an energy transformer.

The generator, which is used here, is a direct current generator and has a

permanent magnet.

Electricity is induced into the rotor (runner), the permanent magnet is on the

outside. The generated electricity will be rectified with a commutator and

can then be taken from the red and black connection cable.

The actual voltage depends on the rotational speed, the actual electricity

depends on the construction of the generator and the torque of the steam

engine.

3.6.1 Evaluating the power of the steam engine and of the

generator

Components: generator, orange LED, series resistor 1K-Ohm, resistors

according to the description

Fig.3.32: Stress test with several resistors, a) mounting the experiment, b)

mounting of the bread board

Page 53

53

Here you find once more the colours and values of the resistors listed and

the sequence of their use within the experiment.

Value of the

resistor

1. ring

2. ring

3. ring

4. ring

1000 Ohm

Brown

black

red

Gold

100 Ohm

Brown

black

brown

Gold

10 Ohm

Brown

black

black

Gold

1 Ohm

Brown

black

gold

Gold

ca. 0 Ohm =

Wire

Prepare the resistors before starting the engine and then you can stick them

into the bread board while the engine is running. You have a little more than

5 minutes to run the experiment if you take 2 dry spirit tablets and the

according amount of water. The orange LED will show you optically

whether the voltage of the generator is dropping or continuous. Wait till the

rotational speed of the steam engine has established and the LED is

continuously shining and only then start with the experiment.

Fig 3.33 circuit diagram to the stress test

Page 54

54

Observations while testing, in connection with the steam engine model of

the Steam Box D 100E:

One can not observe almost any change when the 1K resistor is installed.

The additional need of electricity is only about a couple mA. When you

plug in the following resistor of 100 Ohm you recognize that the orange

LED starts to flicker and the rotation of the steam engine model slows

down. The additionally needed electricity is now by 20mA. With the 10

Ohm resistor the LED does not flash at all and the steam engine slows

down even more. The additional needed electricity is about 40mA. With

the 1 Ohm resistor the additional needed electricity lays around 45 to 50

mA and the rotation of the engine reduces a lot. The jumper brings a short

cut at the generator and now the short-cut electricity of the generator

flows. It might happen that the drive belt slides of or the steam engine

model decelerates drastically. This process does not harm the generator

nor the steam engine model.

Fig.3.34: principle of the circuit: Stress test with a multimeter in the circuit,

to show the power indicator

If there is a multimeter available you can start the steam engine model again

and plug one resistor after the other into the bread board. Depending on the

steam engine model you use, you can observe a direct reaction of the engine

related to the different needs of electricity, which are simulated through the

resistors.

To explore this systematically one can write down the values of the resistors

and the measured electricity into a table. Now you can work out the power

of the generator or the steam engine. You can define the power in milli-watt

according to the formula you find in the annex.

Page 55

55

Fig.3.35: Two different steam engine models and their different power

capacities. Steam Box D 100E and D20 in comparison

The steam engine model of the Steam Box D 100E and of the D20 are two

extremely different models, also in their powers. The experiments with the

resistors show that a bigger steam engine model has no problems with an

additional need of electricity.

If you have a multimeter you also can measure the current.

3.7 Step by step generating bright light out of steam

Components: generator, prepare electrolytic capacitor 1000µF and

electrolytic 4700µF, series resistor 1 K-Ohm, white LEDs, crocodile clips

Through plugging the different components into the bread board according

to the figure you can now mount the circuit.

Page 56

56

Fig.3.36: Light through

steam, the circuit. You see

the series resistor (above on

the right side), the jumpers`

and the white LED (below

on the right side), the longer

connection wire (+) of the

LED on the right side

Prepare the steam engine model as described in chapter 2.4. The pulley

wheel of the generator and the steam engine model are connected with the

transmission belt. For each steam engine model you choose the transmission

in a way that the small pulley wheel on the shaft of fly wheel of the steam

engine model is connected through the transmission belt with the pulley

wheel of the axis of the generator.

Note: Using a higher transmission towards the generator – working with

more powerful steam engine models – does harm the generator and the

electronic, because the rotational speed is too high and the voltage at the

generator can become more then 10V.

Connect the cables of the generator with the crocodile clips. Do not connect

them straight away to the circuit on the bread board. Start the steam engine

model and wait till its touring properly. Now connect the generator to the

circuit of the bread board.

Fig.3.37: The diagram of the

circuit: light through steam

D4

LED white

Page 57

57

Especially with the smaller steam engine models one can observe that the

rotational speed of the steam engine slows down and the white LED starts

to shine. The LED shines bright when the rotational speed has stabilized,

probably still with a little pulsating or flashing. Measuring the initial

voltage with an oscilloscope (a professional instrument to show the voltage

in a graphical diagram) would show us a wave, caused by the continuous

interruptions of the commutator of the generator.

One can use the mounting of the experiment and the running engine and

continue with more experiments to gain an improvement:

In the next experiment one can integrate an electrolytic capacitor, if you

wish to smooth the “wavy” voltage. Make sure that you connect the positive

(+) pole of the electrolytic with the red cable and the negative (-) pole with

the black cable onto the bread board.

Fig.3.38: first

plug in the

electrolytic with

1000µF onto the

bread board

respecting the

right polarity,

then alternatively

the electrolytic

with 4700µF

Page 58

58

Fig.3.39: circuit diagram, both electrolytic are marked in with an arrow to

show that they are used alternatively

The light of the LED goes out shortly and then starts to flash a little less

bright after plugging in the electrolytic 1000µF. Now you replace the

electrolytic 1000µF with the 4700µF in the next step and a calm light will

shine. If you would measure with an oscilloscope the smoothed voltage you

would almost see no wave at all on the diagram.

Picturing the electronically smoothing process:

To create a picture for the expression “smoothing electricity through an

electrolytic” we imagine that electricity behaves like water. We can

compare an electrolytic with “a water bucket with a hole in the bottom”

If you fill intermittently the bucket with a ladle with water, it would

continuously flow out of the hole in an uninterrupted stream.

3.7.1 More light with 2 white LEDs

Assembly of the experiment: components like before, add one white LED

and plug it parallel next to the first one. Both LEDs are connected with the

series resistor 1 K-Ohm (brown, black, red, gold).

D4

LED white

Page 59

59

Fig.3.40: Assembly of

the bread board with a

second white Led

parallel to the first

white LED. Both

LEDs have the

connection wire (+)

on the right side

Fig.3.41: circuit diagram with two LEDs, here the electrolytic can also be

used alternatively

3.7.2 Light from four LEDs generated through the steam engine

All LEDs (except the flashing one) are in use and one can observe how

powerful the small steam engine of the Steam Box D 100E is.

Plug in the series resistors and the red LED in the upper part of the bread

board, like shown in the left picture. The current is lead through the switch

and the jumpers to the LEDs and to the electrolytic in the lower part of the

bread board. The right figure shows the diagram of the circuit on the bread

board, taken from the other side. Once the circuit is connected to the

running generator the red and orange LED are shining. Also both white

LEDs are shining when you press on the switch.

white

white

Page 60

60

Here you have an overview of the series resistors for the LEDs:

Value of the

resistor

1. ring

2. ring

3. ring

4. ring

1 K-Ohm

brown

black

red

gold

100 Ohm

brown

black

brown

gold

Fig.3.42: Assembly of the bread board and b) detail of the assembly (a

picture taken from the other side)

Fig.3.43: circuit diagram with more LEDs

Note: When the steam engine is decelerating one can try to slow down the

fly wheel, even hold it for a short while and then start it again. The LEDs

then will shine brighter again.

white

white

red

Page 61

61

3.8 Storage of the electric energy

We explore in this experiment whether the energy generated by the steam

engine can be stored.

Picturing the process of storage as followed:

Again we take the example of the water bucket. Now the hole on the bottom

of the bucket is replaced through a crane. The level of the water raise when

the crane is closed and one continues filling in water with a ladle. The water

bucket (capacitor) represents the storage; now at any time when opening the

crane we can take out water (voltage).

3.8.1 Charging the capacitor storage through the steam engine

There are different types of energy storages. One possibility of storage we

find in the electrolytic. The advantage is that they last a long time. There

capacity of storage is little compared to a battery. Though for the

experiments it works well and one can explore the principle of storage

within a short time term.

Note: To explore the effect of charge realistically, please discharge the

electrolytic before each experiment. Attention: the discharge might create

a harmless sparkle.

Fig.3.44: Before the experiments discharge the electrolytic with a

screwdriver

Page 62

62

Assembly of the experiment: generator, bread board, one red and one black

cable with crocodile clips, orange LED, series resistor 1 K-Ohm (red, black,

brown, gold), 2x electrolytic 4700µF

Fig.3.45: a) circuit of charge and b) with one electrolytic and LEDs as

charge- respectively consumption indicator

Steps of the experiment:

Mount the circuit according to the figure, circuit diagram. Plug one

electrolytic into the bread board (the positive pole is especially marked) and

charge it through the generator for a couple of seconds while the steam

engine is running.

Additional experiment: slow down and stop the fly wheel of the steam

engine shortly, and then let it run again. The orange LED flashes while the

generator works, it goes of when stopping the fly wheel.

Additional experiment: take away one crocodile clip from the bread board;

the current to the generator is now disconnected. Still the LED continues to

shine.

Fig.3.46: circuit diagram of

the electronics of charge

Page 63

63

Fig.3.47: circuit of charge

with two electrolytic and

one LED as charge- and

consumption indicator

One can repeat those experiments, this time with an additional electrolytic

plugged in parallel. The steam engine charges simultaneously both

electrolytic through the generator.

Fig.3.48: circuit

diagram with 2

electrolytic and one

LED as a chargeand consumption

indicator

In both experiments you can observe that the energy storage does not keep