WILDWOOD OVENS &BBQ’S TOSCANO Installation Instructions

TOSCANO OVEN INSTALLATION INSTRUCTIONS 4.0

WILDWOOD OVENS &BBQ’S

5020 EAGLE ROCK BLVD.

LOS ANGELES, CA 90041

TEL. 323-255-6578

FAX. 323-306-5689

www.wildwoodovens.com

info@wildwoodovens.com

SAVE THESE INSTRUCTIONS!

READ ALL INSTUCTIONS BEFORE INSTALLING AND USING THE APPLIANCE. WHEN THIS OVEN IS

NOT PROPERLY INSTALLED, A FIRE MAY RESULT. TO REDUCE THE RISK OF FIRE, FOLLOW THE

INSTRUCTIONS. A MAJOR CAUSE OF OVEN RELATED FIRES IS FAILURE TO MAINTAIN REQUIRED

CLEARANCES (AIR SPACES) TO COMBUSTIBLE MATERIALS. IT IS OF UTMOST IMPORTANCE THAT

THIS OVEN BE INSTALLED ONLY IN ACCORDANCE WITH THESE INSTRUCTIONS.

WE RECOMMEND THAT YOU CONTACT A LOCAL BUILDING OR FIRE OFFICIAL CONCERNING

ANY INSTALLATION RESTRICTIONS OR NEED FOR INSPECTION OF THE OVEN INSTALLATION

PRIOR TO CONSTRUCTION. THIS OVEN IS TO BE INSTALLED BY A QUALIFIED PERSONNELL ONLY.

OBTAIN THE NECESSARY PERMIT TO CONSTRUCT. IN MOST AREAS THIS WILL INCLUDE A PERMIT

TO CONSTRUCT THE OVEN AND A PERMIT FOR THE EXHAUST SYSTEM. ALL CONSTRUCITON

MUST COMPLY WITH LOCAL BUILDING CODES. WHICHEVER IS MOST RESTRICTIVE MUST BE

FOLLOWED.

TO MAINTAIN THE U.L. LISTING OF THE OVEN THE VENTING APPLICATION MUST BE INSTALLED

PER UL-103 STANDARD AND NEEDS TO BE INSTALLED IN ACCORDANCE WITH THE GUIDELINES

SPECIFIED IN THIS INSTALLATION INSTRUCTION GUIDE.

TABLE OF CONTENTS

MILANO Oven Kit Parts List 1

Oven Base and Enclosure Material List 2

Minimum Clearances 3

Safety Plaque Information 4

Minimum Footprint Requirements 4

Wood-Fired Oven Operating Tips 5

Wood-Fired Oven Maintenance Tips 7

Pre-Construction Checklist 8

Building Foundation and Base 9

Oven Assembly Instructions 11

Roofing and Finishing the Exterior 15

Chimney Assembly 15

Curing the Oven 18

Cooking Pizza in the Oven 19

Using Your Oven 20

Toscano

Wood Fired Oven

Installation Instructions

Version 4.0

INSTALLATION INSTRUCTIONS: Failure to follow instructions may result in significant oven

damage and may void your warranty.

Before you Begin

Please read this entire manual before installing the oven. Failure to follow instructions may result

in property damage, bodily injury, or even death. Be sure to place orders early for any items

that are necessary to complete your project. It is best to have everything you need prior to

beginning construction.

TOSCANO OVEN KIT PARTS LIST

A 2-Pre-cast hearth sections

B 4-Pre-cast dome sections

C 1-Steel oven door (available in stainless steel)

D 5-Tubes Fireplace Mortar *

E 1-Fiber insulation blanket (12 ft roll, 24 in wide)

F 1-SAFETY INFORMATION PLAQUE **

ADDITIONAL RECOMMENDED MATERIALS:

G 1-1” Thick Heat stopper board (48”x48”)

H 1 Roll of Diamond Lath Mesh (8 ft roll, 27 in wide) ***

Chimney System customized to fit the oven application (see pg 15 for contact information)

1-Tube of high temperature sealant for anchor plate

12-24 Alcohol Can Heat (used for buffet tray warmers) Available at Wildwood!

**Oven has to reach 350 degrees on first initial curing. Never cure an insulated oven.

*Fireplace Mortar provided by Wildwood is tested and approved to meet safety standards and therefore must be

the only sealant/adhesive used in oven assembly. Do not use an alternate sealant/adhesive

** SAFETY INFORMATION PLAQUE must be adhered to the facade of the oven, at a location that is visible to the

user at all times. Do not remove this plaque. Please refer to Safety Plaque Location Diagram

recommended locations.

*** DIAMOND LATH MESH can be purchased from any local home improvement/hardware store.

©Wildwood Ovens and BBQs LLC 2009 WWW.WILDWOODOVENS.COM 323.255.6587 All specifications subject to change without notice

on page 4 for

1

Toscano

Wood Fired Oven

Installation Instructions

Version 4.0

OVEN BASE AND ENCLOSURE MATERIAL LIST

The following list is provided for your convenience only; the materials are not part of the oven kit.

List may vary depending on construction method.

MASONARY CONSTRUCTION METHOD

FOUNDATION AND SLAB

Stakes and forms (for smooth finish melamine can be used to build forms)

1500 Lb or higher strength concrete mix

#4 Rebar

WALLS & SHELF

Forms

6” x 8” x 16” masonry blocks

Masonry mortar

#4 Rebar

1500 Lb or higher strength concrete mix

Optional alternative metal stand (contact a wildwood representative for prices)

ROOF

Non-flammable roofing material

CHIMNEY SYSTEM *

1 Anchor plate for 6” pipe

1 Double or triple wall chimney pipe (exact length will depend on individual installation

needs)

1 Chimney cap with spark arrestor

1 Tube high temperature sealant for anchor plate (withstanding up to 2000 degrees F)

IMPORTANT:

Oven shall only be installed with exhaust hoods constructed in accordance with NFPA 96 or

LISTED building heating appliance chimneys also LISTED as grease ducts.

* Material list for chimney system may vary depending on oven application. Interior installations may require

additional parts.

©Wildwood Ovens and BBQs LLC 2009 WWW.WILDWOODOVENS.COM 323.255.6587 All specifications subject to change without notice

2

Toscano

Wood Fired Oven

Installation Instructions

Version 4.0

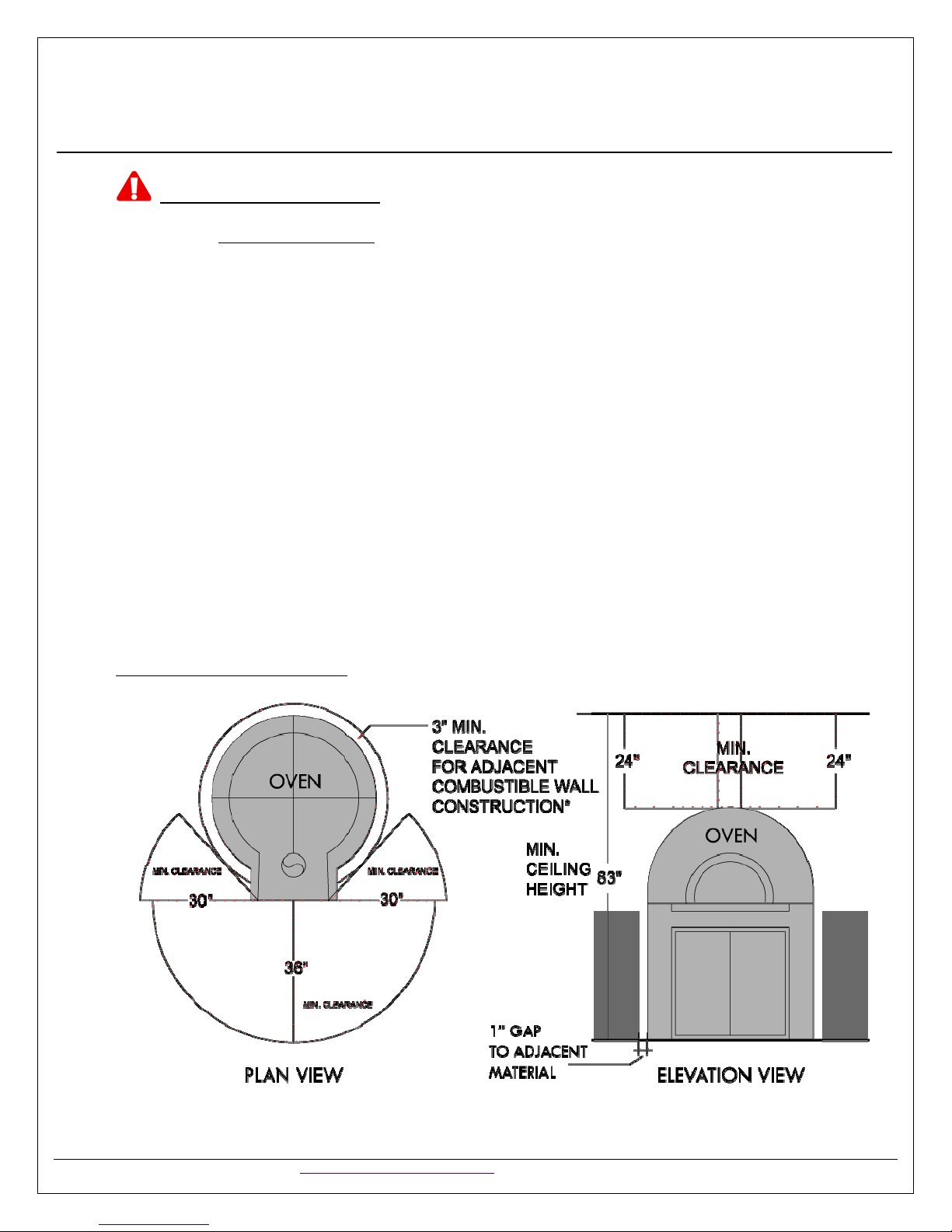

MINIMUM CLEARANCES

Please refer to the Minimum Clearance Diagram below.

1. Build your oven in such an area where smoke will not infiltrate your home or homes close to

you. The minimum clearance from combustibles is 30 inches (762 mm) to each side of the door

opening, and 36 inches (914 mm) in front of the door opening. The minimum clearance from

combustible materials to the oven is 3” from the side walls, 24” from the top of the oven and 1”

from side of the oven base. WARNING: DO NOT PACK REQUIRED CLEARANCES (AIR SPACES)

WITH INSULATION OR OTHER MATERIALS.

2. Check that there is adequate clearance at the ceiling. A height of 83 inches is needed for a

basic installation with direct venting.

3. Check that there is a minimum clearance of 3 inches around assembled oven (measured off of

the fiber insulation blanket and wire mesh) to any adjacent sidewall construction composed of

combustibles. Any adjacent combustible sidewalls which projects beyond the front of the oven

opening must be a minimum of 48 inches, measured from the side of the oven opening closest to

the wall to the surface of the wall. If the distance is less than 48 inches a wall shield must be

mounted on the wall. Any adjacent combustible floor which projects in front of the oven opening

must be a minimum of 30 inches away from each side of the door opening and 36 inch from the

front of the door opening.

Minimum Clearance Diagram:

* NOTE: 3” minimum clearance is measured from the outer edge of the diamond lath mesh, not the oven refractory.

©Wildwood Ovens and BBQs LLC 2009 WWW.WILDWOODOVENS.COM 323.255.6587 All specifications subject to change without notice

3

Toscano

Wood Fired Oven

Installation Instructions

Version 4.0

SAFETY PLAQUE INFORMATION

* NOTE: Diagram above shows recommendations for the location of SAFETY INFORMATION PLAQUE on finished oven. Oven

designs and finishes vary; therefore one or more of the options may not apply. Locate plaque where visible and do not remove.

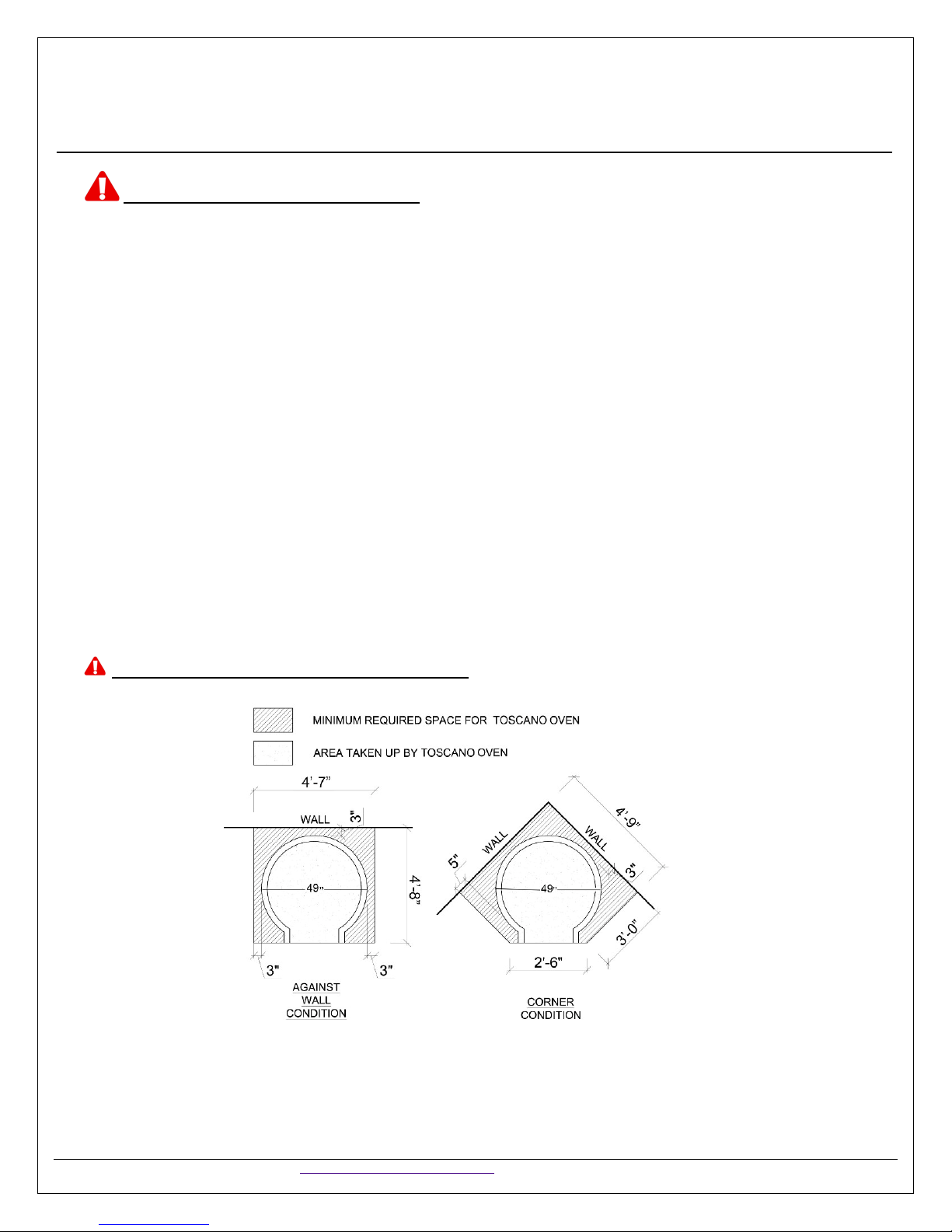

MINIMUM FOOTPRINT REQUIREMENTS

* NOTE: Minimum footprint illustrated above does not include thickness of the enclosure and finish material. Enclosure and finish

material varies based on design.

©Wildwood Ovens and BBQs LLC 2009 WWW.WILDWOODOVENS.COM 323.255.6587 All specifications subject to change without notice

4

Toscano

Wood Fired Oven

Installation Instructions

Version 4.0

WOOD-FIRED OVEN OPERATING TIPS

WARNING-KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE

WOOD-FIRED OVEN IS INTENDED FOR OPERATION BY TRAINED AND QUALIFIED

PERSONNEL ONLY. INQUIRE ABOUT OUR OVEN OPERATION/COOKING CLASSES AT

WILDWOOD!

THIS OVEN IS A HIGH HEAT PRODUCING APPLIANCE AND MAY CAUSE SEVERE BURNS IF

TOUCHED DURING OPERATION.

DO NOT OVERFIRE THE OVEN. IF FLAME SPILLS OUT FROM THE OPENING OR

TEMPERATURE EXCEEDS 700 DEGREES FAHRENHEIT, YOU ARE OVERFIRING.**

IMPORTANT! A WOOD-FIRE RATED FIRE EXTINGUISHER MUST BE KEPT IN CLOSE

PROXIMITY TO THE OVEN AT ALL TIMES. NOTIFY ALL OVEN OPERATORS ABOUT THE

LOCATION AND USE DURING EMERGENCIES.

IN CASE OF OVERFIRING THE OVEN, CLOSE DOOR TIGHTLY.

CAUTION: NEVER USE GASOLINE, GASOLINE-TYPE LANTERN FUEL, KEROSENE,

CHARCOAL LIGHTER FLUID, OR SIMILAR LIQUIDS TO START OR ‘FRESHEN UP’ A FIRE IN

THIS OVEN. KEEP ALL SUCH LIQUIDS WELL AWAY FROM THE OVEN WHEN IN USE.

WHEN USED INDOORS, PROVISIONS MUST BE MADE TO SUPPLY SUFFICIENT

COMBUSTION MAKE-UP AIR INTO STRUCTURE, WHEN USING THIS OVEN.

COMBUSTION AIR MUST BE SUPPLIED IN ACCORDANCE WITH LOCAL BUILDING

CODES.

DO NOT ELEVATE THE FIRE. BUILD THE FIRE DIRECTLY ON THE HEARTH.

DO NOT LEAVE A FIRE UNATTENDED. YOU MUST CLOSE THE OVEN DOOR TIGHTLY TO

EXTINGUISH THE FIRE BEFORE LEAVING OVEN UNATTENED.

STARTING THE FIRE: PLACE TWO SHORT PIECES OF FIREWOOD (3-4 IN DIAMETER)

ABOUT SIX INCHES APART IN THE CENTER OF HEARTH. NEXT, PLACE A SAFE LITE LOG

(AVAILABLE AT WILDWOOD!) BETWEEN THE PIECES OF WOOD. LAY SMALL PIECES OF

KINDLING ACROSS THE FIRST LAYER OF WOOD IN A CROSS HATCH PATTERN,

CREATING SEVERAL LAYERS SO THAT THEY ARE DIRECTLY ABOVE THE NEWSPAPER.

LIGHT THE NEWSPAPER USING A MATCH OR BBQ LIGHTER. AS THE KINDLING BURNS,

ADD ADDITIONAL PIECES, GRADUALLY INCREASING THE SIZE OF THE FIRE. ONCE A

GOOD SIZED FIRE IS BURNING (ONE THAT WON’T GO OUT IF MOVED), GENTLY PUSH

THE FIRE TO THE BACK, LEFT, OR RIGHT OF THE OVEN USING THE OVEN BRUSH.

CONTINUE TO FEED WOOD PERIODICALLY. LEAVE DOOR SLIGHTLY AJAR.

©Wildwood Ovens and BBQs LLC 2009 WWW.WILDWOODOVENS.COM 323.255.6587 All specifications subject to change without notice

5

Loading...

Loading...