Wilding Wallbeds Sierra 33 Instruction Booklet

For Wallbed models:

SIERRA

Revision 7/14 BK33

WARNING! ALL MURPHY/WALLBED SYSTEMS CONTAIN STORED ENERGY. FAILURE

TO USE AND FOLLOW THESE INSTRUCTIONS DURING THE INSTALLATION PROCESS

COULD RESULT IN SEVERE PERSONAL INJURY TO USER OR DAMAGE TO PRODUCT.

PLEASE CONTACT CUSTOMER SERVICE AT 866-725-6401 FOR ANY QUESTIONS.

STORAGE HEAD BOARD

INSTRUCTION BOOKLET #33

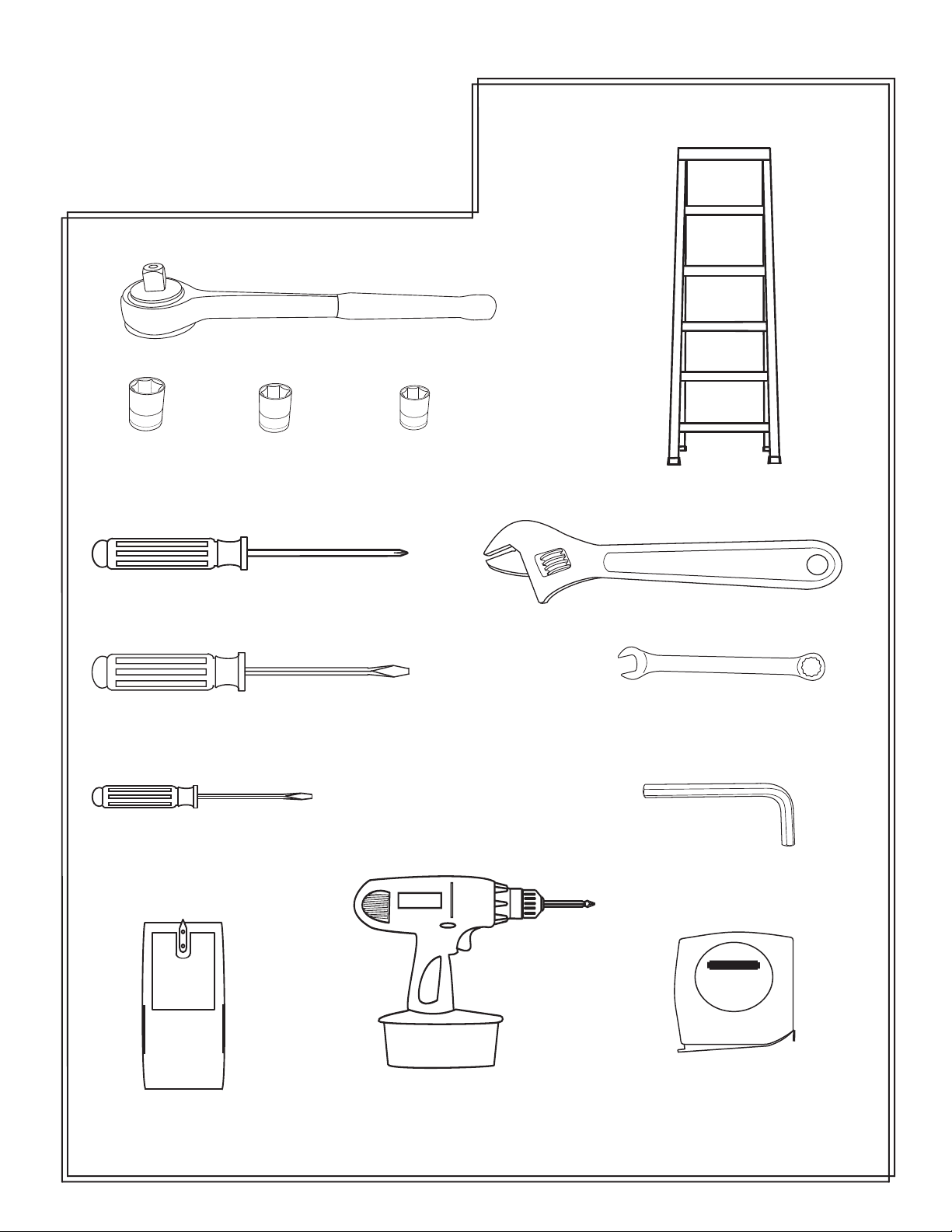

Tools Needed

Ratchet

1/2” Socket

Phillips screwdriver

Large regular screwdriver

Small regular screwdriver

7/16” Socket3/8” Socket

6 foot ladder

Cresent wrench

1/2” open end wrench

1/4” Allen wrench

studsensor

Stud finder

Cordless screw driver

with Phillips bit

STAN LEY

Tape measure

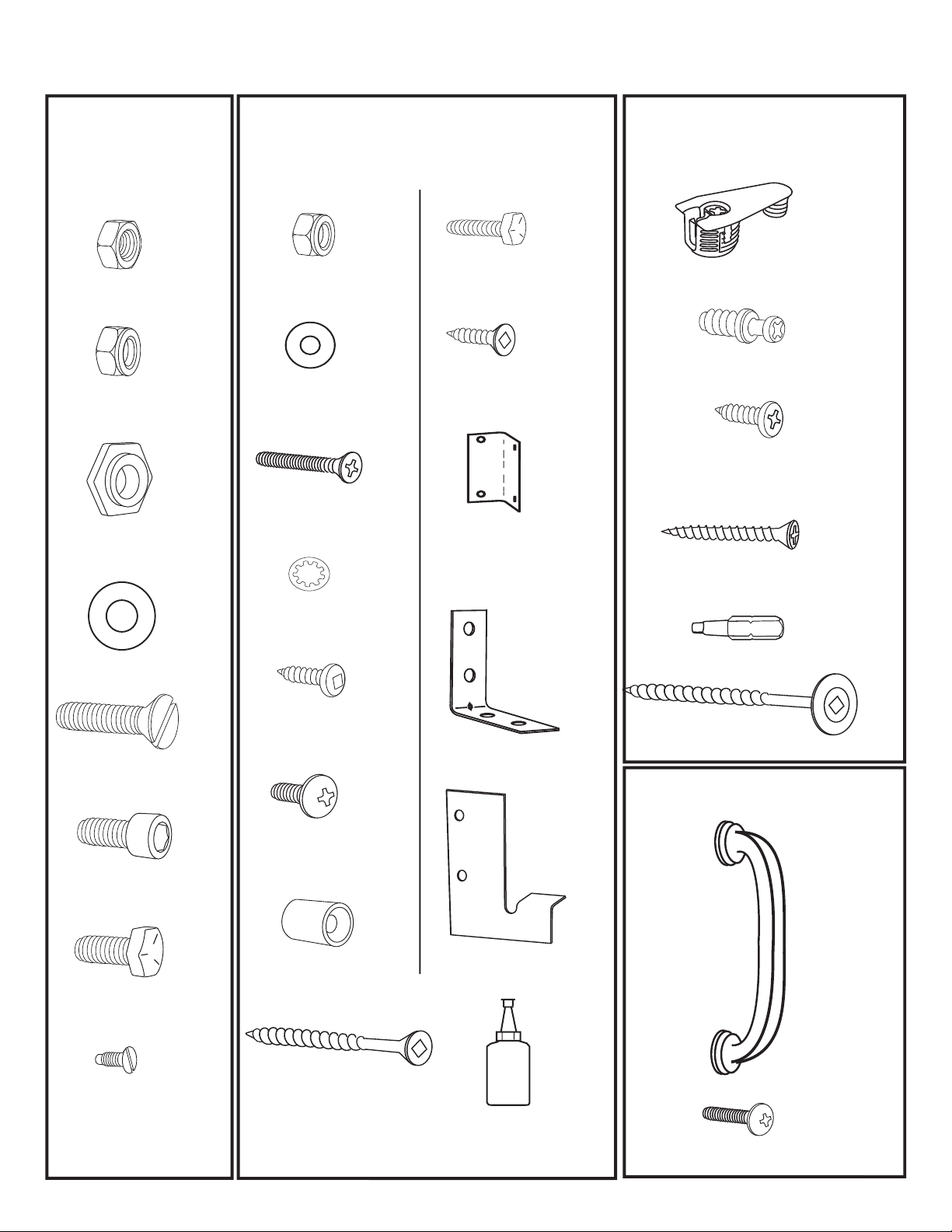

Hardware Page

Bag 7

Item

5/16’’ Plain

Hexagon Nut

5/16’’ Nylock

Hexagon Nut

3/4’’ Cam

Washer

Qty

10

6

2

Item

3/16’’ Nylock

Hexagon Nut

3/16” Washer

3/16’’x 1 Black

Flathead Screw

1/4’’

Bag 8

Qty

16

2

2

2

Item Qty

1/4’’x 3/4’’

Hex Head Bolt

3/4’’ Flat head

Screw

4 hole corner

bracket

Other Hardware

Item

2

Cam Fitting

6

Connecting Bolts

4

5/8’’ Pan

head Screw

1/4’’

1 Wood Screw

Qty

4

32

80

10

7/8” Washer

5/16’’ x 1 1/4’’

Flat Head Bolt

5/16’’ Allen

Head Bolt

5/16’’ x 3/4’’

Hex Head Bolt

4 mm x 1/4’’

Flat Head Screw

2

10

2

4

4

1/4” Star Washer

5/8’’ Pan

head Screw

3/16’’ x 1/2’’

Black Truss

head screw

Leg Stop

2’’ Flathead

Wood Screw

135

14

2

“L” Bracket

1 left

(

1 right

Spacer Plate

6

LOCTITE

Small bottle of Loc-tite

1

3

Square Tip Bit

3

1/2’’

3 Wood Screw

(for optional under mount)

Bed Handles

2

)

1

4

1”

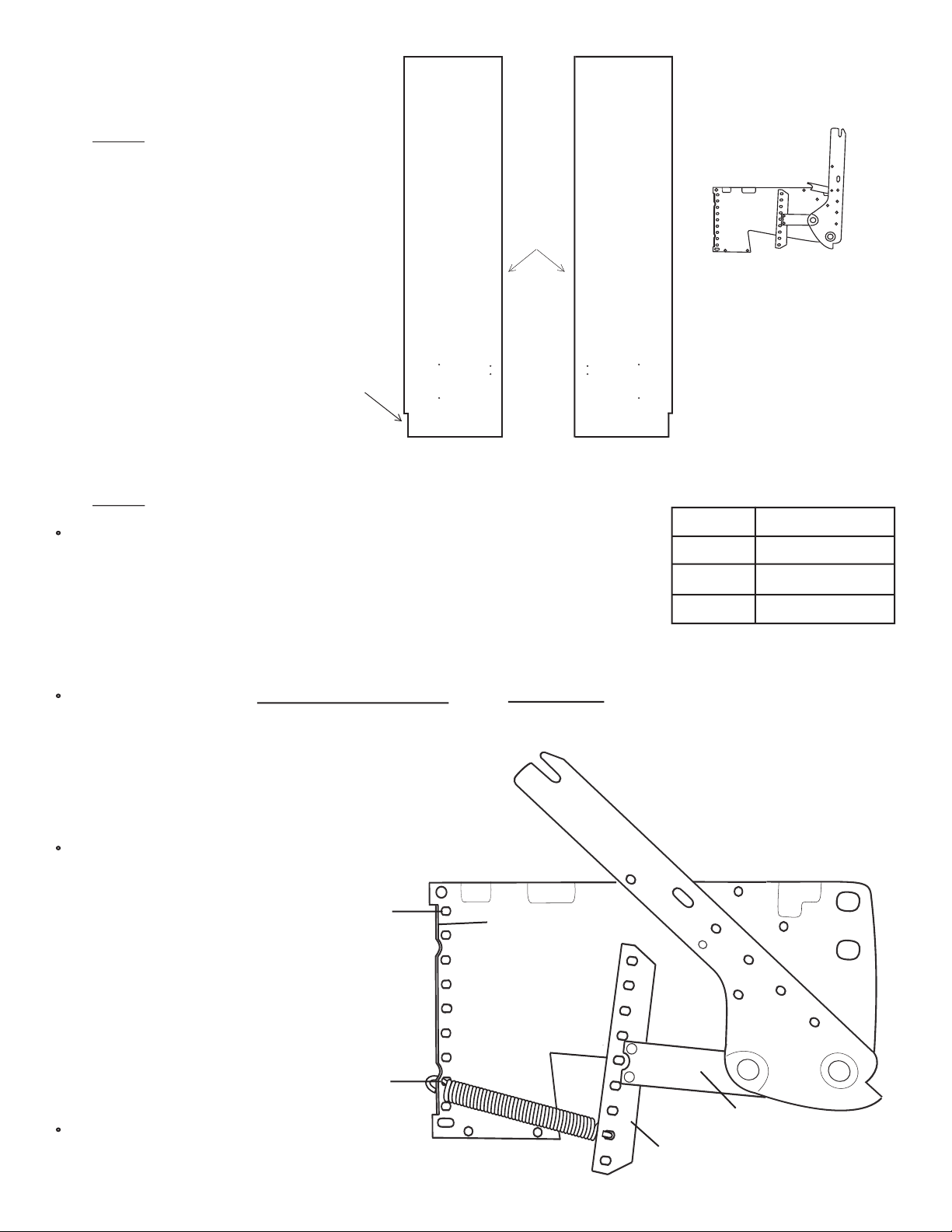

Step 1: Locate the two Side Boards. If you

purchased a Queen size bed the Side Boards

measure 85” long. Full and Twin size Side

boards will measure 80” long. From the

square white box locate the two Lift Mechanisms, hardware bag 7 and springs.

Cut out for room

base molding

Finished edge

X 2

Lift Mechanism

Left Side Board Right Side Board

Step 2:

The number of springs in the Lift Mechanism required varies with the different weights of

mattresses. If you purchased your mattress with your bed from Wilding Wallbeds refer to the

chart to the right. This will also be a good reference point for mattresses not purchased with

your Wall bed.

NOTE: After you have completed installing and checking operation of your Wallbed, you

may find it necessary to add or remove springs to achieve the correct lift effort of between

5 and 10 pounds.

Install the first spring in hole #2 for Queen and Full size beds and hole #3 for twin size on both the Mounting Plate and the

Tension Arm. Hook one end of the spring under the upturned edge of the Mounting Plate. Lay the spring down and slide it

under the matching hole in the Tension Arm. See illustration 1.

HELPFUL HINT: You may find it easier to fit the hook

under the Tension Arm if you pry up the Arm Bracket with

a wooden wedge or similar device.

Continue by working up from, hole

2 (Queen and Full size beds) or hole

3, (for twin size), until you have

installed the required number of

springs.

Install Springs in the Lift Mechanisms

Hole #9

Upturned edge of

Bed Size

Queen

Full/Double

Twin/Single

Number of Springs

8

6

4

Illustration 1

(right lift mechanism)

mounting plate

IMPORTANT! Be sure that holes

of the Mounting Plate correspond

to the holes in the Tension Arm

and use the same number of

springs and the same configura

tion on both Lift Mechanisms

-

Hole #2

Repeat Step 2 for Left Lift Mechanism.

Arm Bracket

Tension Arm

Page 1

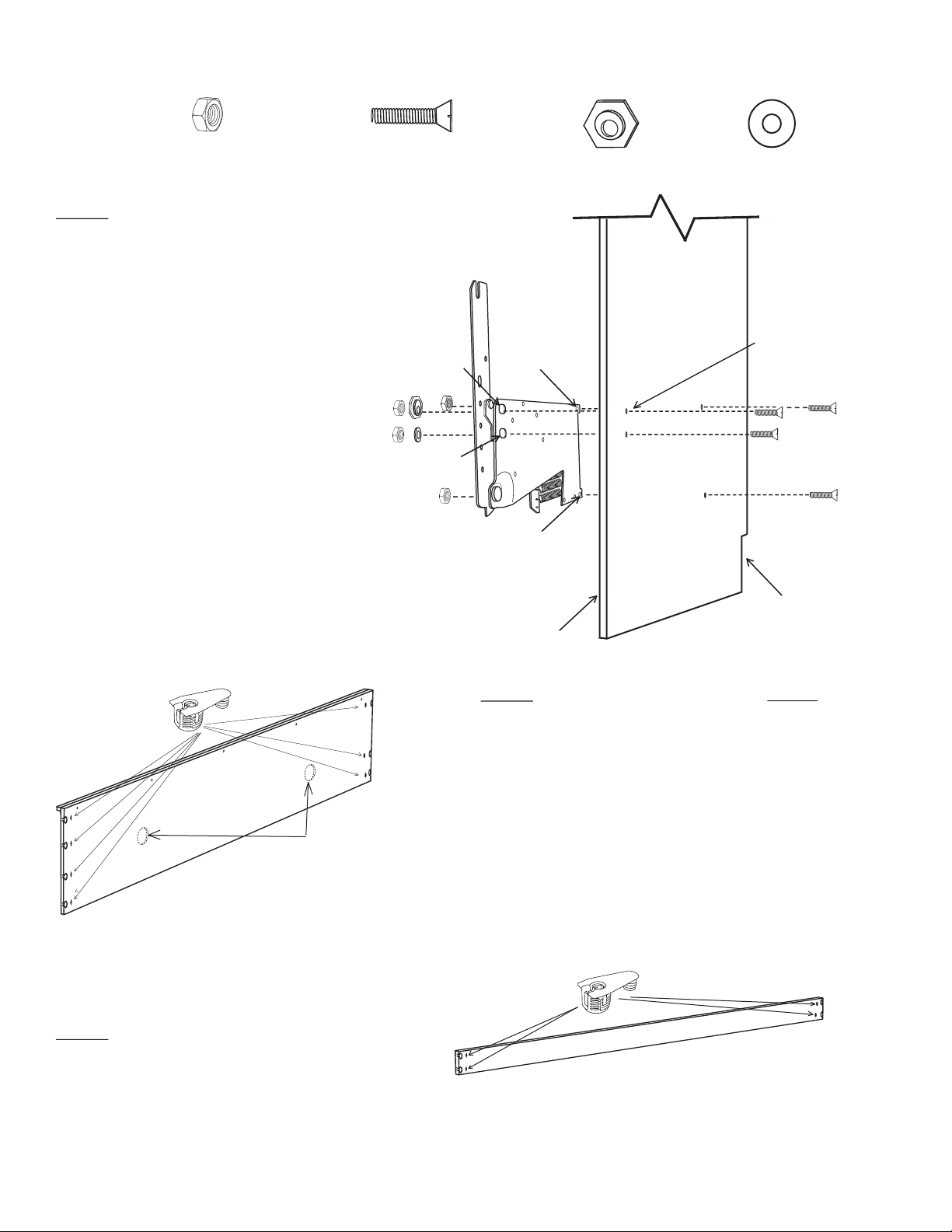

Hardware needed for next 2 steps from Bag #7

x 8

5/16” Plain Hex Nut

Step 3:

a 5/16” x 1 1/4” Flathead Machine Screw through

holes “C” and “D” from the outside (countersunk

holes) of the Right Side Board. Position the cor

responding Right Lift Mechanism holes. Loosely

thread on a 5/16” Plain Hex Nut on each. Insert the

same type screw through holes “A” and “B”. At

hole “A” use one of the Hexagon Cam Washers in

the slot of the mounting plate so that the LARGER

PART OF THE CAM IS UP. At hole “B” use a 5/

16” x 7/8” washer. Thread a nut on each. Tighten

the four nuts evenly, making sure the hexagon cam

washer does not rotate while tightening.

See illustration 2.

IMPORTANT! Over tightening the nuts will pull

the head of the screw too deeply into the Side

Board. Tighten only until the head of the screw is

flush with the Side Board.

Install the Lift Mechanism by inserting

5/16” x 1 1/4” Flathead

Slot Machine Screw

-

Hole A

Hole B

x 8

Hole C

Hole D

x 2

Hexagon Cam Washer

Right

Side Board

x 2

7/8” Washer

Illustration 2

All holes are countersunk

in this side of sideboard

Repeat step 3 with the Left Side Board and Lifting

Mechanism.

Optional holes for lights

Bridge Board has 7 fittings

Step 5:

Boards and insert four Cam Fittings into the

back of each Stretcher. Press the Cam Fit

tings in so they are tight against the part.

Locate the TWO (2) Stretcher

-

Base Board

Notch

Finished Edge

Step 4:

Cam Fittings into the sockets provided. Press the Cam

Fittings in so they are tight against the bed part. You may

need a rubber mallet to get them properly set.

Locate the Bridge Board and Insert

Helpful hint: The Bridge Board and the Head

Board are the same Length and could be eas

ily confused. Note the Bridge Board has 7 cam

fitting sockets and the Head Board has a pre

insatlled black barrel catch on the back.

SEVEN

-

X 2

Page 2

Loading...

Loading...