Wilden Saniflo DUS Engineering, Operation & Maintenance

DRUM UNLOADER SYSTEM

Sanifl o™ Series

Refine your process

EOM

Engineering

Operation &

Maintenance

Drum

Unloader

System

REPLACES WIL-12070-E-02

WIL-12070-E-03

TABLE OF CONTENTS

SECTION 1 CAUTIONS—READ FIRST! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SECTION 2 DESIGNATION SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

SECTION 3 DIMENSIONAL DRAWINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

SECTION 4 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

SECTION 5 ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SECTION 6 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

SECTION 7 CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

SECTION 8 SCHEMATICS

A. Control Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

B. Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

SECTION 9 EXPLODED VIEW & PARTS LISTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Section 1

CAUTIONS—READ FIRST!

Drum Unloader System

CAUTION : Always wear safety glasses and appropriate safety

gear when operating the Sanifl o™ DUS unit.

CAUTION : Always perform an inspection of the entire system

before each use. Ensure that all parts are in good working

condition and do not show signs of wear.

WARNING: Prior to installing a Sanifl o™ DUS in to an

application, you must fi rst ensure that the DUS components

are compatible with the process media and any cleaning or

sanitation products.

WARNING: Never attempt to modify the Sanifl o™ DUS unit.

Modifi cation will change the dynamics of the DUS and could

damage the unit, result in failure of the unit, or cause harm to

anyone in the area.

CAUTION : Always disconnect the main air supply to the

Sanifl o™ DUS before service or repairs are attempted. Failure

to do so could result in harm to anyone in the area.

CAUTION : The Sanifl o™ DUS unit must be properly secured

while in use. Failure to properly secure the system while in use

could result in harm to anyone in the area.

CAUTION : When using the Sanifl o™ DUS unit, it is extremely

important to note that the retracting downward movement can

cause a pinch point at two areas of the unit.

1. A pinch point is located at the bottom of the structure when

the ram plate is lowered to the base assembly. To avoid injury

to anybody operating this equipment or to anyone in the area

of the equipment, keep hands, arms and head clear of plate

and drum edge.

2. Another pinch point is located at the area where the ram

support bar comes in the vicinity of the header plate. To avoid

injury t o anyb ody operating this e quipment or to anyone in th e

area of the equipment when it is in operation, a safe distance

must be kept from the ram support bar/header plate area.

CAUTION : Do not exceed 8.6 bar (125 psig) air pressure to the

Sanifl o™ DUS unit .

Do not exceed 1.7 bar (25 psig) air pressure to the RAM DOWN.

For normal operation, 1.0 bar (15 psig) is suggested.

Do not exceed 5.5 bar (80 psig) air pressure to the RAM UP. For

normal operation, 4.1 bar (60 psig) is suggested.

CAUTION : Before attaching an air source to the DUS unit,

inspect all hose connections to ensure they are secure.

CAUTION : Before operating Sanifl o™ DU S unit, a t t ach d rum

retention hooks to secure drum during operation. Failure to

do so will result in drum being moved and/or lifted when ram

assembly is moved upward.

WARNING: It is important to follow the assembly instructions

provided when building the Sanifl o™ DUS unit. Altering the

steps or changing the process may result in operation

issues including improper rise and fall of the follower plate

assembly.

Pump

NOTE: Pump not included with Sanifl o™ DUS. Pump sold

separately.

CAUTION : Do not apply compressed air to the exhaust port

– pump will not operate.

CAUTION : Do not exceed 8.6 bar (125 psig) air supply

pressure.

CAUTION : Do not over-lubricate air supply. Excessive

lubrication will reduce pump performance.

TEMPERATURE LIMITS:

Neoprene –17.7°C to 93.3°C 0°F to 200°F

Buna-N –12.2°C to 82.2°C 10°F to 180°F

EPDM –51.1°C to 137.8°C –60°F to 280°F

Viton

Sanifl ex™ –28.9°C to 104.4°C –20°F to 220°F

Polytetrafl uoroethylene (PTFE)

4.4°C to 104.4°C 40°F to 220°F

Polyurethane –12.2°C to 65.6°C 10°F to 150°F

®

–40.0°C to 176.7°C –40°F to 350°F

CAUTION: Maximum temperature limits are based upon

mechanical stress only. Certain chemicals will signifi cantly

reduce maximum safe operating temperatures. Consult

Chemical Resistance Guide (E4) for chemical compatibility and

temperature limits.

WARNING: Prevention of static sparking – if static sparking

occurs, fi re or explosion could result. Pump, valves, and

containers must be grounded to a proper grounding point

when handling fl ammable fl uids and whenever discharge of

static electricity is a hazard.

CAUTION : The process fl uid and cleaning fl uids must be

chemically compatible with all wetted pump components.

Consult Chemical Resistance Guide (E4).

CAUTION : Do not exceed 82.2°C (180.0°F) air inlet temperature

for Pro-Flo V™ models.

CAUTION : Pumps should be thoroughly fl ushed before

installing into process lines. FDA and USDA approved pumps

should be cleaned and /or sanitized before use.

CAUTION : If diaphragm rupture occurs, material being pumped

may be forced out air exhaust.

CAUTION : Before any maintenance or repair is attempted, the

compressed air line to the pump should be disconnected and

all air pressure allowed to bleed from pump. Disconnect all

intake, discharge and air lines. Drain pump by turning it upside

down and allowing any fl uid to fl ow into a suitable container.

WIL-12070-E-03 1 WILDEN PUMP & ENGINEERING, LLC

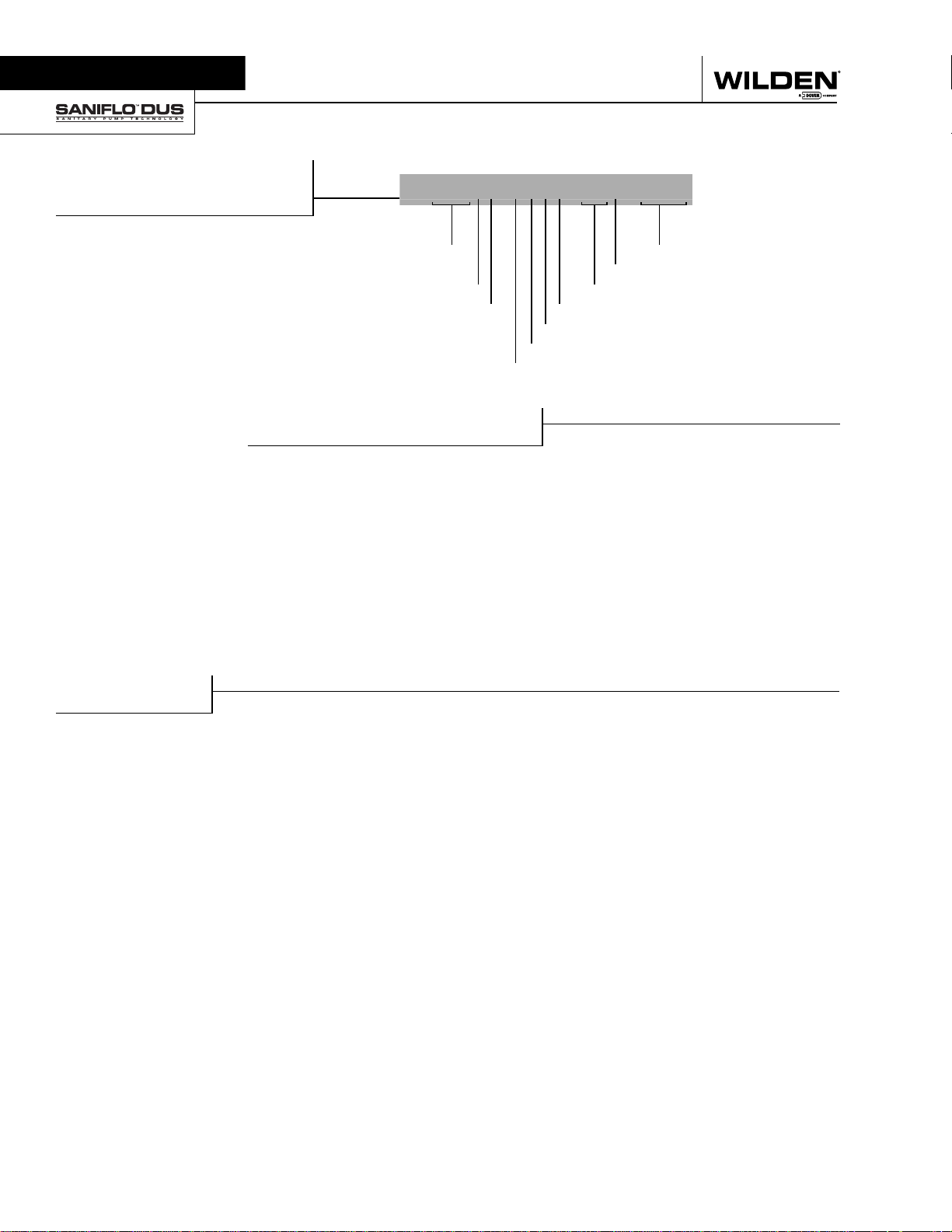

Section 2

WILDEN DESIGNATION SYSTEM

DRUM UNLOADER

SYSTEM

LEGEND

SANIFLO

MODEL

DUS = DRUM UNLOADER

SYSTEM

PUMP SIZE

4 = 38 mm (1-1/2”) ORIGINAL

SERIES

PUMP TYPE

S = SIMPLEX SINGLE ACTING

D = DUPLEX DOUBLE ACTING

TM

DUS MATERIAL CODES

DUSXX/ XXXX / XXX/ XXXX

MODEL

DRUM SIZE

PUMP SIZE GASKET MATERIAL

PUMP TYPE FRAME MATERIAL

FOLLOW PLATE MATERIAL

CYLINDER MATERIAL

BASE TYPE

BASE TYPE

F = FLOOR MOUNTED

B = BASE PLATE MOUNTED

CYLINDER MATERIAL

S = STAINLESS STEEL

FOLLOW PLATE MATERIAL

S = STAINLESS STEEL

SPECIALTY CODE

FRAME MATERIAL

S = STAINLESS STEEL

GASKET MATERIAL

FB = SANITARY BUNA-N

DRUM SIZE (DIA.)

K = 533 - 557 mm (21.0”-21.9”)

L = 558 - 582 mm (22.0”-22.9”)

SPECIALTY CODES

0070 Saniflo™

WILDEN PUMP & ENGINEERING, LLC 2 WIL-12070-E-03

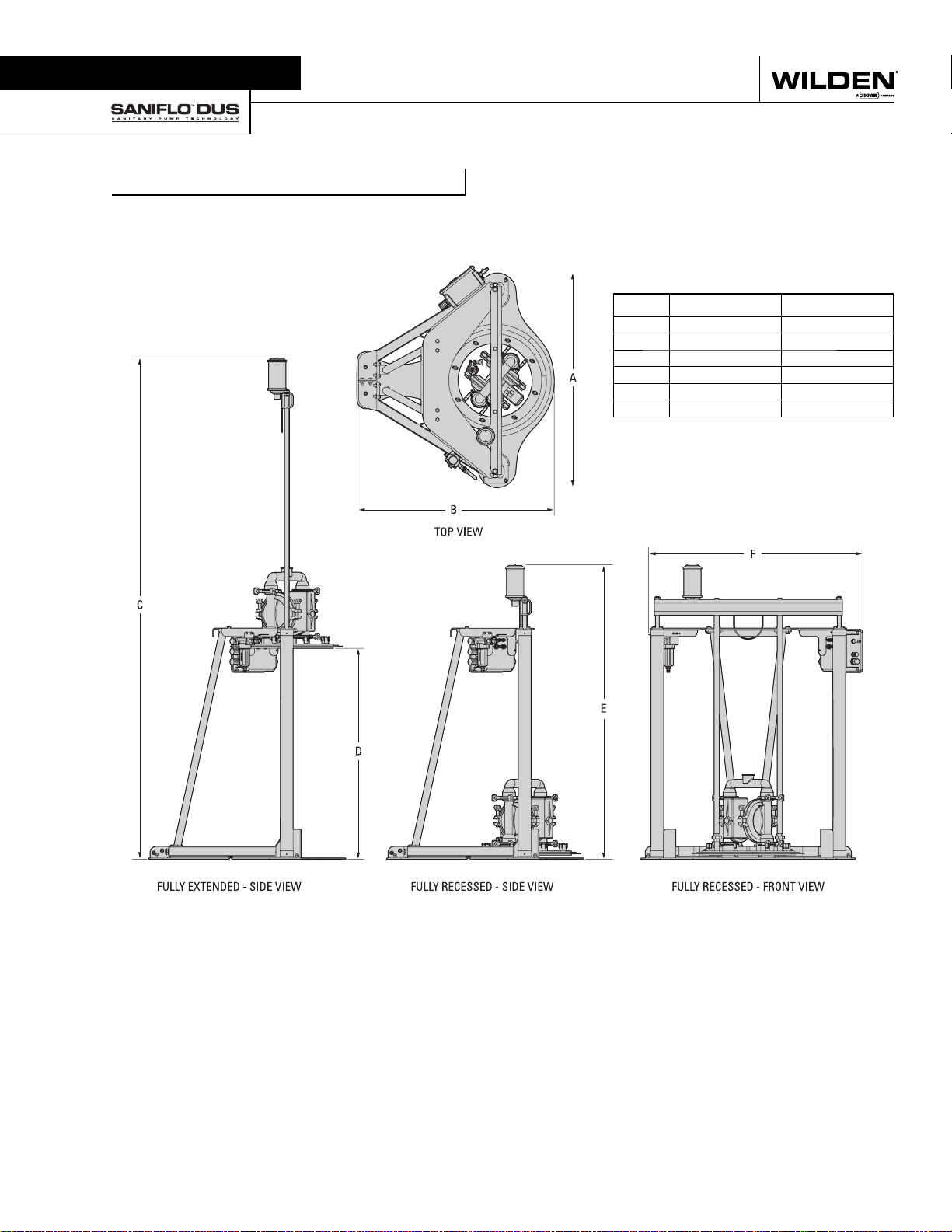

Section 3

DIMENSIONAL DRAWING

DRUM UNLOADER SYSTEM

DIMENSIONS

ITEM METRIC (mm) STANDARD (inch)

A 1143 45.0

B 1049 41.3

C 2667 105.0

D 1123 44.2

E 1567 61.7

F 1140 44.9

WIL-12070-E-03 3 WILDEN PUMP & ENGINEERING, LLC

Section 4

TROUBLESHOOTING

Uneven ram cylinder movement.

1. Ensure that the ram cylinder down pressure is not

excessive. Generally, no more than 1.0 bar (15 psig) is

required to move the ram cylinders in the downward

direction.

2. Check to determine whether or not the ram

cylinder air hoses are connected properly. The

ram down cylinder air hoses consist of two longer

air hoses that are equal in length and one shorter

air hose. The ram up cylinder air hoses consist of

two shorter hoses that are equal in length and one

longer air hose. If the ram cylinder air hoses are

not connected properly, the ram cylinders will fi ll

unevenly, causing the ram cylinder movement to

be inconsistent.

3. It is important to follow the assembly process

(section 5). Altering the steps or changing the

process may result in operation issues including

improper rise and fall of the ram cylinders. Steps 1

through 10 of the assembly process are extremely

critical. Following these steps will ensure that the

ram cylinder movement is unrestricted.

Pump runs but little or no product fl ows.

1. Check for pump cavitation; slow pump speed to

allow thick material to fl ow into liquid chambers.

2. Chec k for sticking b all check valves . If material being

pumped is not compatible with pump elastomers,

swelling may occur. Replace ball check valves and

seats with proper elastomers. Also, as the check

valve balls wear out, they become smaller and can

become stuck in the seats. In this case, replace

balls and seats.

3. Check to ensure that there is suffi cient air pressure

supplied by the ram down regulator on the control

panel.

After evacuating drum contents, ram cylinders are

struggling with upward movement.

1. Check to determine whether or not drum vent

button is activated. This will inject air under the

ram plate and break the vacuum caused when

removing the ram plate from the drum.

Pump air valve freezes.

1. Check for excessive moisture in compressed

air. Either install a dryer or hot air generator

for compressed air. Alternatively, a coalescing

fi lter may be used to remove the water from the

compressed air in some applications.

Air bubbles in pump discharge.

1. Check for ruptured diaphragm.

2. Check tightness of outer pistons.

3. Check tightness of fasteners and integrity of

o-rings and seats, especially at intake manifold.

4. Ensure pipe connections are airtight.

Product comes out air exhaust.

1. Check for diaphragm rupture.

2. Check tightness of outer pistons to shaft.

Excessive drum contents leaking past gaskets.

1. Ensure that the correct gasket size is being used in

accordance with the drum size.

NOTE: The gaskets are NOT designed to completely

seal against sides of drum. Under normal operating

conditions, there will be some slight weeping of

drum contents.

WILDEN PUMP & ENGINEERING, LLC 4 WIL-12070-E-03

Section 7 Assembly / disassembly

Section 5

ASSEMBLY

Tools Required :

• 10 mm Hex Head

Wrench

• 12 mm Wrench

• 18 mm Wrench

• Adjustable Wrench

CAUTION: During assembly it is important not to tighten any bolts completely

until specifi cally instructed. This will ensure system alignment and allow for

proper operation. It is also recommended that an appropriate anti-s eize is us ed on

all stainless steel fasteners during assembly.

Although some air fi ttings may come with a pipe sealant already applied, it is

recommended that a pipe sealant be used with all additional air fi ttings during

assembly.

NOTE: It is important to follow the assembly instructions provided when building

the Sanifl o™ DUS unit. Altering the steps or changing the process may result in

operation issues including improper rise and fall of the follower plate assembly.

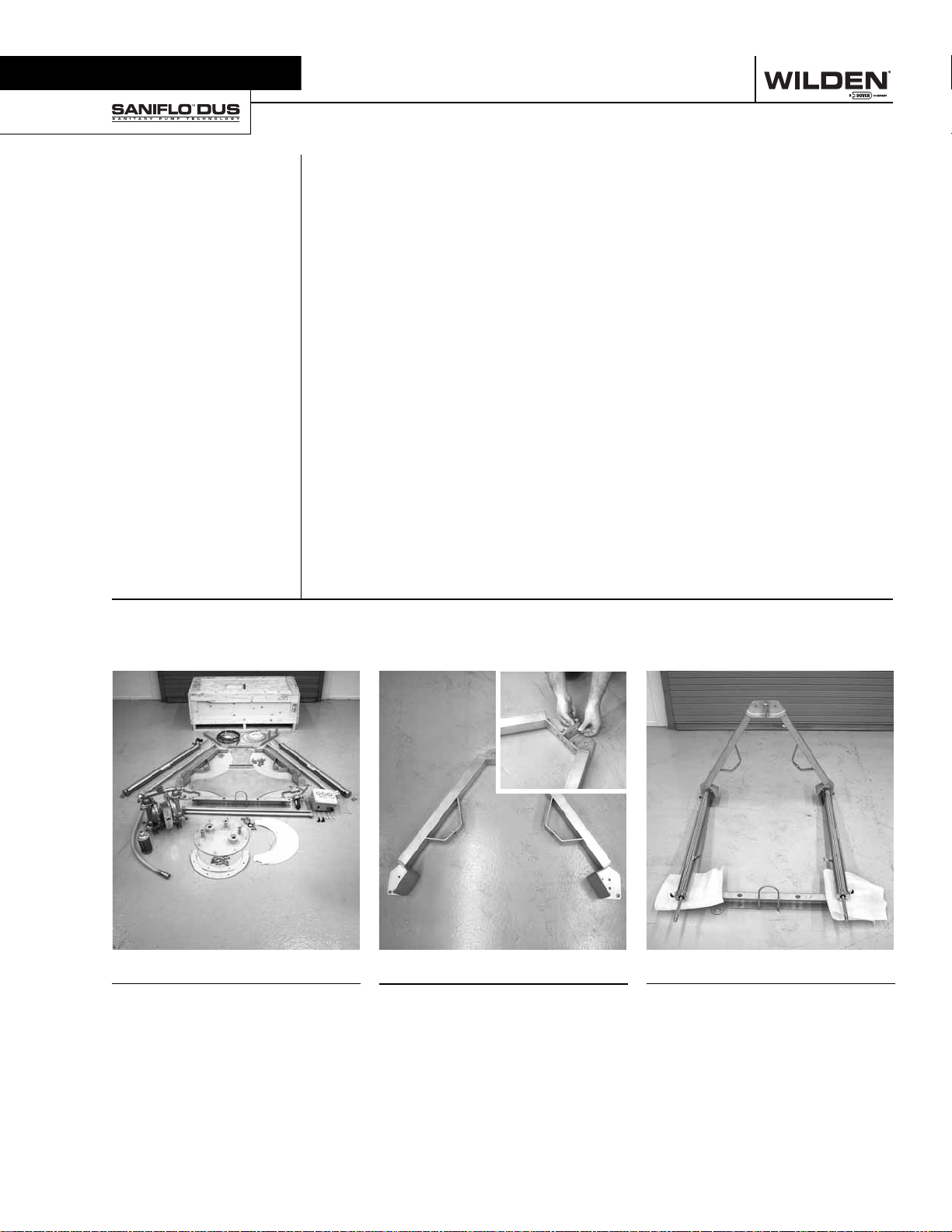

Step 1

Remove all parts from shipping

container and compare with Bill of

Materials listing in Section 9 before

beginning assembly of unit.

WIL-12070-E-03 5 WILDEN PUMP & ENGINEERING, LLC

Step 2

Assemble the left and right base

sections as shown, using two (2) 12

mm bolts, nuts and lock washers.

Leave fasteners hand tight.

Step 3

Raise two connected base pieces

on their side as shown and align

the two pneumatic cylinders. Use

the top support beam to raise the

opposite end of the cylinders for

proper alignment.

ASSEMBLY

Step 4

Install four (4) 10 mm countersunk

screws in the bottom of the base

frame and end of the cylinders.

NOTE: Once screws are snug, back

off one full turn.

Step 5

When cylinders are installed on

the base frame, ensure that the air

connections are facing away from

the center of the frame assembly.

Step 6

Install the fl at header plate on

the top end of the pneumatic

cylinders. Ensure that the header

plate is positioned as shown when

compared to the base frame.

Step 7

Slide ram support bar over threaded

ends of pneumatic cylinders and

install one (1) 18 mm nut on end of

threaded end until it stops at the rod

shoulder then tighten. NOTE: Nut

should be between upper and lower

support bar holes.

WILDEN PUMP & ENGINEERING, LLC 6 WIL-12070-E-03

Step 8

Slide ram support bar farther down

on the cylinder rod until it bottoms

out on the previously installed nut.

Then add a second 18 mm nut and

lock washer on the end of the rod

and hand tighten.

Step 9

Install braces between base frame

header plate. Triangle end goes up

and rectangular end goes down.

Use 12 mm bolts, nuts and lock

washers and leave hand tight.

Loading...

Loading...