Page 1

EOM

Engineering

Operation &

Maintenance

PX8

Sani o™ Hygienic Series

Metal Pumps

Where Innovation Flows

www.wildenpump.com

WIL-12310-E- 04

TO REPL ACE W IL-12310-E -0 3

Page 2

TABLE OF CONTENTS

SECTION 1 CAUTIONS—READ FIRST! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SECTION 2 WILDEN PUMP DESIGNATION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

SECTION 3 HOW IT WORKS—PUMP & AIR DISTRIBUTION SYSTEM . . . . . . . . . . . . . . . . 3

SECTION 4 DIMENSIONAL DRAWINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

SECTION 5 PERFORMANCE

A. PX8 Performance Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Operating Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

How to Use this Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Rubber-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

TPE-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Full Stroke PTFE-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Full Stroke SIPD-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Reduced Stroke PTFE-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Reduced Stroke SIPD-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Reduced Stroke Ultra-Flex™-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

B. Suction Lift Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

SECTION 6 SUGGESTED INSTALLATION, OPERATION & TROUBLESHOOTING . . . . . . . 21

SECTION 7 ASSEMBLY / DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

SECTION 8 CLEANING - CIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

SECTION 9 EXPLODED VIEW & PARTS LISTING

PX8 Saniflo™ HS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

SECTION 10 ELASTOMER OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Page 3

Section 1

CAUTIONS—READ FIRST!

CAUTION: Do not apply compressed air to the

exhaust port — pump will not function.

CAUTION: Do not over-lubricate air supply —

excess lubrication will reduce pump performance.

Pump is pre-lubed.

TEMPERATURE LIMITS:

Neoprene –17.7°C to 93.3°C 0°F to 200°F

Buna-N –12.2°C to 82.2°C 10°F to 180°F

Nordel

Viton® –40°C to 176.7°C –40°F to 350°F

Sanifl ex™ –28.9°C to 104.4°C –20°F to 220°F

Polytetrafl uoroethylene (PTFE)

4.4°C to 104.4°C 40°F to 220°F

Polyurethane –12.2°C to 65.6°C 10°F to 150°F

Tetra-Flex™ PTFE w/Neoprene Backed

4.4°C to 107.2°C 40°F to 225°F

Tetra-Flex™ PTFE w/Nordel® Backed

-10°C to 137°C 14°F to 280°F

Wil-Flex™ (Santoprene®)

-40°C to 107.2°C -40°F to 225°F

NOTE: Not all materials are available for all

models. Refer to Section 2 for material options

for your pump.

®

–51.1°C to 137.8°C –60°F to 280°F

CAUTION: Do not exceed 82°C (180°F) air inlet

temperature for Pro-Flo X™ models.

CAUTION: Pumps should be thoroughly fl ushed

before installing into process lines. FDA and

USDA approved pumps should be cleaned and/

or sanitized before being used.

CAUTION: Always wear safety glasses when

operating pump. If diaphragm rupture occurs,

material being pumped may be forced out air

exhaust.

CAUTION: Before any maintenance or repair is

attempted, the compressed air line to the pump

should be disconnected and all air pressure

allowed to bleed from pump. Disconnect all

intake, discharge and air lines. Drain the pump

by turning it upside down and allowing any fl uid

to fl ow into a suitable container.

CAUTION: Blow out air line for 10 to 20 seconds

before attaching to pump to make sure all pipeline

debris is clear. Use an in-line air fi lter. A 5µ (micron)

air fi lter is recommended.

CAUTION: When choosing pump materials, be

sure to check the temperature limits for all wetted

components. Example: Viton® has a maximum

limit of 176.7°C (350°F) but polypropylene has a

maximum limit of only 79°C (175°F).

CAUTION: Maximum temperature limits are

based upon mechanical stress only. Certain

chemicals will signifi cantly reduce maximum

safe operating temperatures. Consult Chemical

Resistance Guide (E4) for chemical compatibility

and temperature limits.

WARNING: Prevention of static sparking — If

static sparking occurs, fi re or explosion could

result. Pump, valves, and containers must be

grounded to a proper grounding point when

handling fl ammable fl uids and whenever

discharge of static electricity is a hazard.

CAUTION: Do not exceed 8.6 bar (125 psig) air

supply pressure.

CAUTION: The process fl uid and cleaning fl uids

must be chemically compatible with all wetted

pump components. Consult Chemical Resistance

Guide (E4).

NOTE: When installing PTFE diaphragms, it is

important to tighten outer pistons simultaneously

(t urning in opposite directions ) to ensure tight fi t.

(See torque specifi cations in Section 7.)

NOTE: Cast Iron PTFE-fi tted pumps come

standard from the factory with expanded PTFE

gaskets installed in the diaphragm bead of the

liquid chamber. PTFE gaskets cannot be re-used.

Consult PS-TG for installation instructions during

reassembly.

NOTE: Before starting disassembly, mark a line

from each liquid chamber to its corresponding air

chamber. This line will assist in proper alignment

during reassembly.

CAUTION: Pumps are available in both

submersible and non-submersible options. Do

not use non-submersible Pro-Flo X™ models in

submersible applications.

CAUTION: Tighten all hardware prior to installation.

WIL-12310-E-04 1 WILDEN PUMP & ENGINEERING, LLC

Page 4

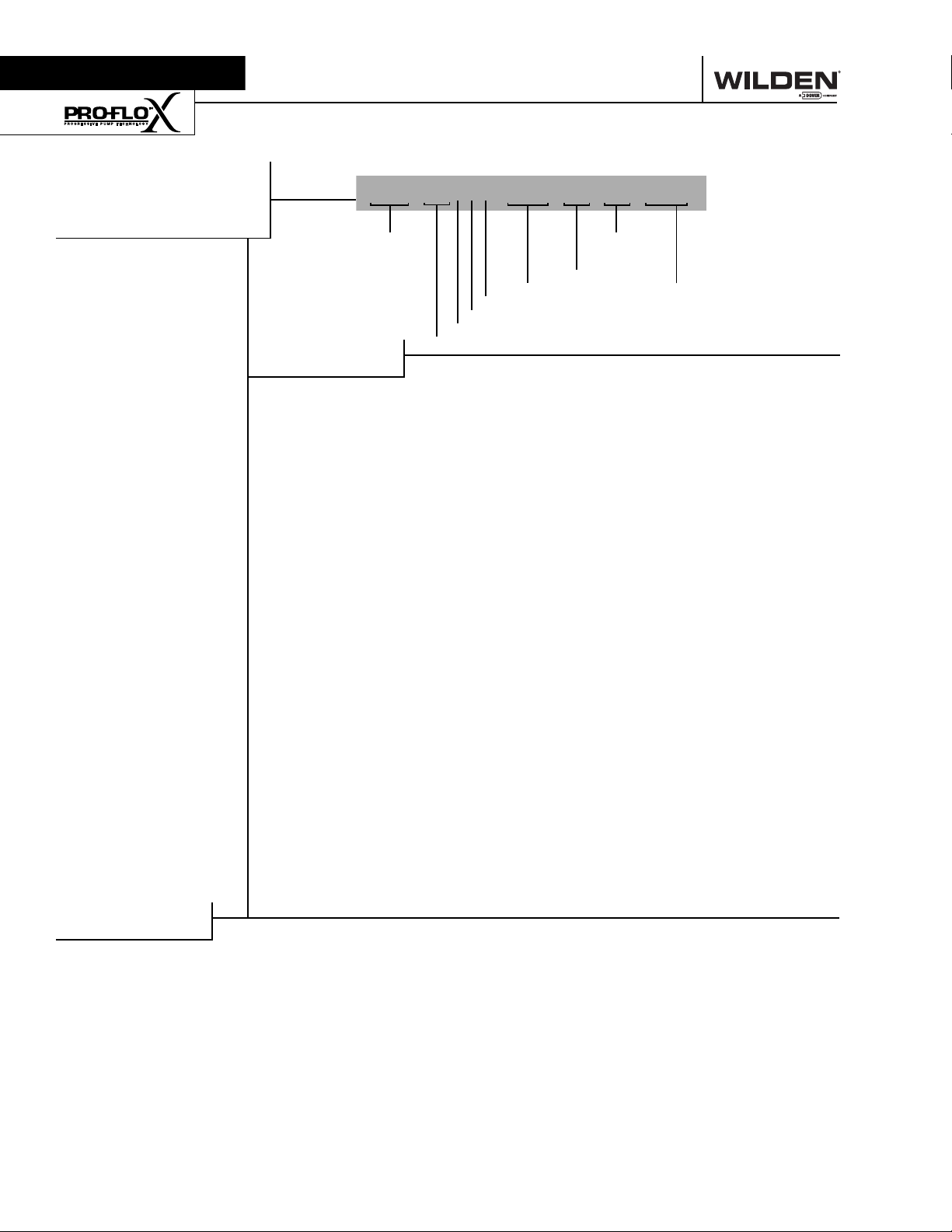

Section 2

WILDEN PUMP DESIGNATION SYSTEM

PX8 SANIFLO

™

HYGIENIC SERIES

51 mm (2") Pump

Maximum Flow Rate:

587 lpm (155 gpm)

LEGEND

PX8 / XXXXX / XXX / XX/ XX/ XXXX

MODEL

MATERIAL CODES

MODEL

PX8 = 51 mm (2")

XPX8 = 51 mm (2") ATEX

WETTED PARTS/

OUTER PISTON

SS = 316L STAINLESS STEEL

SZ = 316L STAINLESS STEEL/

NO PISTON

CENTER BLOCK

N = NICKEL PLATED ALUMINUM

S = 316 STAINLESS STEEL

AIR CHAMBERS

N = NICKEL PLATED ALUMINUM

S = 316 STAINLESS STEEL

AIR VALVE

N = NICKEL PLATED ALUMINUM

S = 316 STAINLESS STEEL

DIAPHRAGMS

VALVE OPTION

AIR VALVE

AIR CHAMBER

CENTER SECTION

WETTED PARTS & OUTER PIS TON

DIAPHRAGMS

BNU = ULTRA-FLEX™ BUNA

EPU = ULTRA-FLEX™ EPDM

FBS = SANITARY BUNA

(two yellow dots)

FES = SANITARY EPDM

(two blue dots)

FSS = SANIFLEX™

FWL = FULL STROKE SANITARY

WIL-FLEX™ IPD

1

1,3,4

FWS = SANITARY WIL-FLEX™

LEL = PTFE-EPDM BACKED

LAMINATE IPD

1,2,3,4,5

TEU = PTFE w/EPDM BACKUP

TSS = FULL STROKE PTFE

w/SANIFLEX™ BACK-UP

TSU = PTFE w/SANIFLEX™

BACK-UP

1,2,5

TWS = FULL STROKE PTFE

w/WIL-FLEX™ BACK-UP

GASKETS

SPECIALTY

CODE

(if applicable)

VALVE BALLS, FLAP VALVES,

1,5

MUSHROOM CHECK

1,5

1

1

FB = SANITARY BUNA

(red dot)

FE = SANITARY EPDM

(green dot)

FS = SANIFLEX™

FW = SANITARY WIL-FLEX™

SF = STAINLESS STEEL FLAP

TF = PTFE

1

TM = PTFE MUSHROOM

CHECK

1,2,5

MANIFOLD GASKET

FB = SANITARY BUNA-N

1,2

(red dot)

1,2,3,4

1,2

FE = SANITARY EPDM

(green dot)

FV = SANITARY VITON®

1,2

(one white/one

yellow dots)

TF = PTFE

1,2,3,4,5

1,3,4

1,3,4

1,3,4

1,3,4

1,5

1,3,4

1,3,4

1, 3, 4

NOTE:

1. Meets Requirements of FDA CFR21.177

2. Meets Requirements of USPClass VI

3. Required for EHEDG Certification

4. Required for 3-A Certification

5. Stainless flap valve not available with reduced stroke PTFE, reduced

stroke Ultra-Flex

TM

or reduced stroke Laminate IP diaphragms

SPECIALTY CODES

0770 SaniFlo HS

0771 SaniFlo HS, w /Swivel Stand

0772 SaniFlo HS, Wil-Gard 110V

0773 SaniFlo HS, Wil-Gard 22 0V

0774 HS, Wil-Gard 110V, w/Swivel Stand

0775 SaniFlo HS, Wil-Gard 220V, w/Swivel Stand

0778 SaniFlo HS, DIN Connection

0779 HS, w/Swivel Stand DIN Connection

0780 SaniFlo HS, Wil-Gard 110V DIN Connection

NOTE: MOST EL ASTOMERIC MATERIA LS USE COLORED DOTS FOR IDENTIFICATION.

®

Viton

is a registered trademark of DuPont Dow Elas tomers.

WILDEN PUMP & ENGINEERING, LLC 2 WIL-12310-E-04

0781 SaniFlo HS, Wil-Gard 22 0V DIN Connection

0782 SaniFlo HS, Wil-Gard 110V, w/Swivel St and DIN Connection

0783 SaniFlo HS, Wil-Gard 22 0V, w/Swivel S tand DIN Connection

0784 SaniFlo HS, SMS Connection

0785 SaniFlo HS, w/Swivel Stand SMS Connection

0786 SaniFlo HS, Wil-Gard 110V SMS Connection

0787 SaniFlo HS, Wil-Gard 22 0V SMS Connection

0788 SaniFlo HS, Wil-Gard 110V, w/Swivel St and SMS Connection

0789 SaniFlo HS, Wil-Gard 22 0V, w/Swivel S tand SMS Connection

Page 5

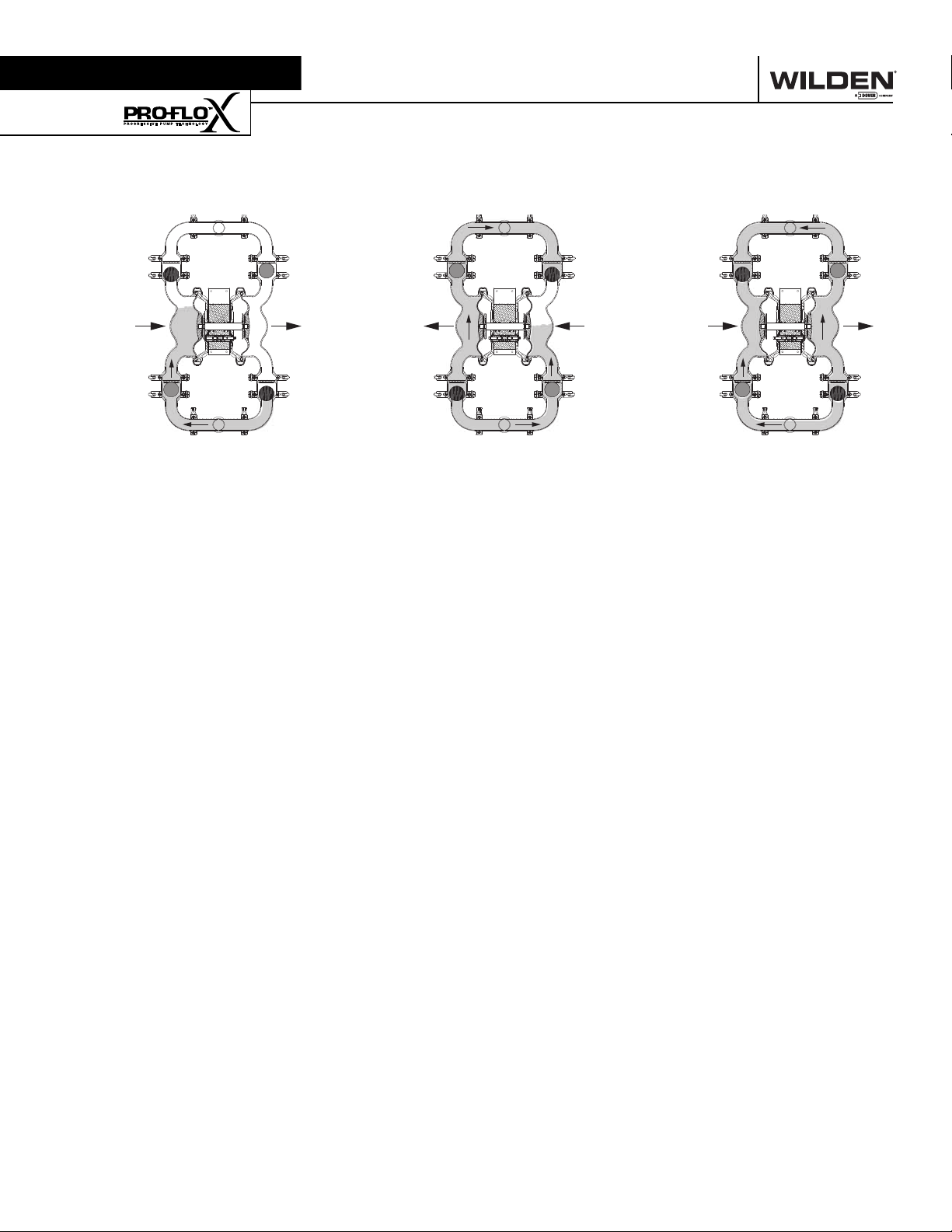

Section 3

The Wilden diaphragm pump is an air-operated, positive displacement, self-priming pump. These drawings show fl ow pattern

through the pump upon its initial stroke. It is assumed the pump has no fl uid in it prior to its initial stroke.

CLOSED

OUTLET

BA

INLET

FIGURE 1 The air valve dir ects pre ssurized

air to the back side of diaphragm A. The

compressed air is applied directly to the

liquid column separated by elastomeric

diaphragms. The diaphragm acts as

a separation membrane between the

compressed air and liquid, balancing the

load and removing mechanical stress

from the diaphragm. The compressed

air moves the diaphragm away from

the center of the pump. The opposite

diaphragm is pulled in by the shaft

connected to the pressurized diaphragm.

Diaphragm B is on its suction stroke; air

behind the diaphragm has been forced

out to atmosphere through the exhaust

port of the pump. The movement of

diaphragm B toward the center of the

pump creates a vacuum within chamber B.

Atmospheric pressure forces fl uid into

the inlet manifold forcing the inlet valve

ball off its seat. Liquid is free to move

past the inlet valve ball and fi ll the liquid

chamber (see shaded area).

HOW IT WORKS—PUMP

OPEN

OPEN

OUTLET

BA

CLOSEDOPEN

FIGURE 2 When the pressurized diaphragm,

diaphra gm A, re aches t he limit of it s disc harge

stroke, the air valve redirects pressurized

air to the back side of diaphragm B. T he

pressurized air forces diaphragm B away

from the center while pulling diaphragm A

to the center. Diaphragm B is now on its

discharge stroke. Diaphragm B forces the

inlet valve ball onto its seat due to the

hydraulic forces developed in the liquid

chamber and manifold of the pump. These

same hydraulic forces lift the discharge

valve ball off its seat, while the opposite

discharge valve ball is forced onto its seat,

forcing fl uid to fl ow through the pump

discharge. The movement of diaphragm A

toward the center of the pump creates a

vacuum within liquid chamber A. Atmospheric pressure forces fl uid into the inlet

manifold of the pump. The inlet valve ball

is forced off its seat allowing the fl uid being

pumped to fi ll the liquid chamber.

INLET

CLOSED

OPENCLOSED

CLOSED

OUTLET

OPEN

BA

INLET

FIGURE 3 At completion of the stroke,

the air valve again redirects air to the

back side of diaphragm A, which star ts

diaphragm B on its exhaust stroke. As

the pump reaches its original starting

point, each diaphragm has gone through

one exhaust and one discharge stroke.

This constitutes one complete pumping

cycle. The pump may take several cycles

to completely prime depending on the

conditions of the application.

CLOSEDOPEN

WIL-12310-E-04 3 WILDEN PUMP & ENGINEERING, LLC

Page 6

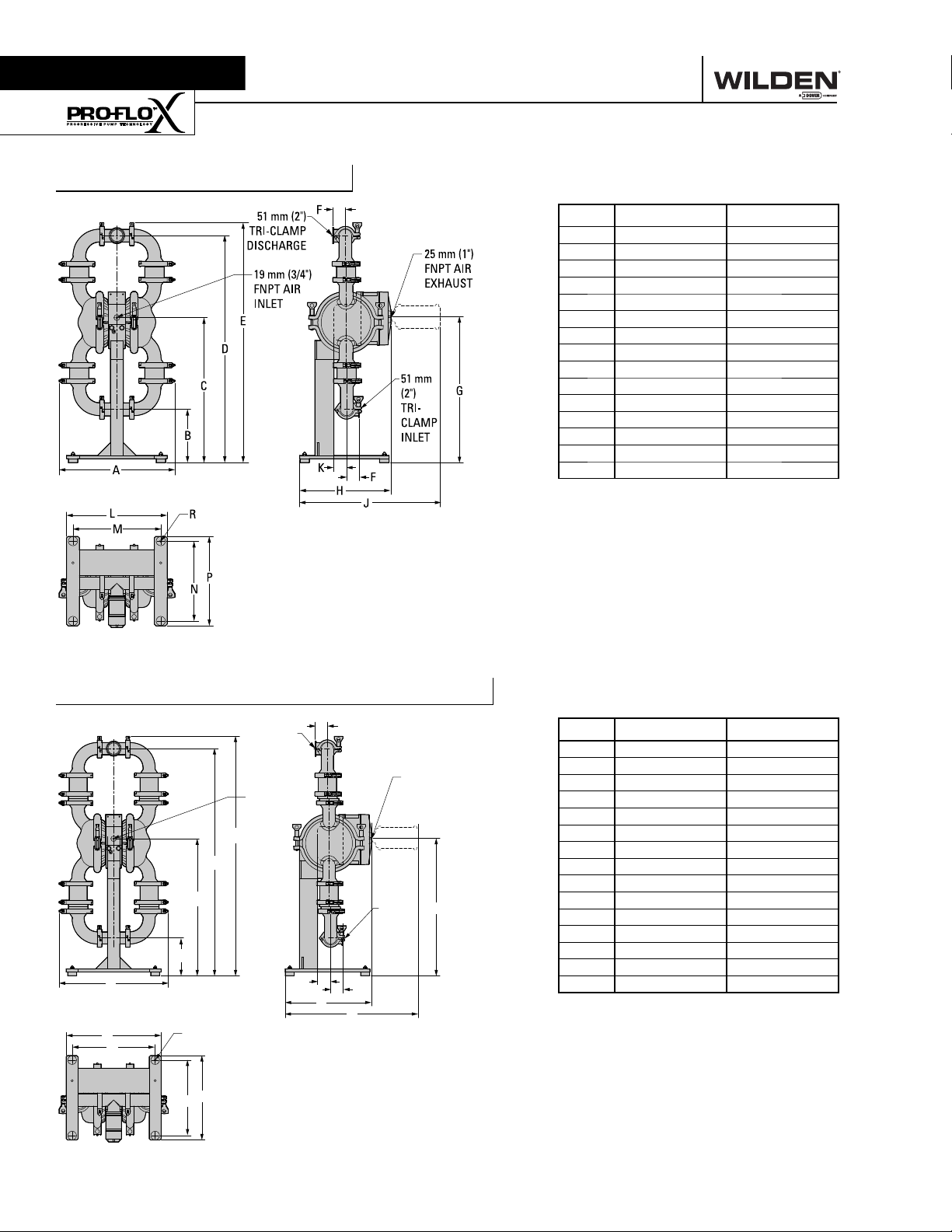

Section 4

DIMENSIONAL DRAWINGS

PX8 Saniflo™ HS Fixed

DIMENSIONS

ITEM METRIC (mm) STANDARD (inch)

A 460 18.1

B 213 8.4

C 577 22.7

D 902 35.5

E 955 37.6

F 51 2.0

G 579 22.8

H 363 14.3

J 559 22.0

K 46 1.8

L 401 15.8

M 351 13.8

N 318 12.5

P 356 14.0

R

ø10 ø0.4

Rev A

PX8 Saniflo™ HS Flap Valve Fixed

51 mm (2")

TRI-CLAMP

DISCHARGE

19 mm (3/4")

FNPT AIR

INLET

E

D

C

B

A

L

M

R

P

N

F

25 mm (1")

FNPT AIR

EXHAUST

51 mm

(2")

TRICLAMP

INLET

K

F

H

J

G

DIMENSIONS

ITEM METRIC (mm) STANDARD (inch)

A 460 18.1

B 160 6.3

C 577 22.7

D 955 37.6

E 1008 39.7

F 51 2.0

G 579 22.8

H 363 14.3

J 559 22.0

K 56 2.2

L 401 15.8

M 351 13.8

N 318 12.5

P 356 14.0

R

ø10 ø0.4

Rev A

WILDEN PUMP & ENGINEERING, LLC 4 WIL-12310-E-04

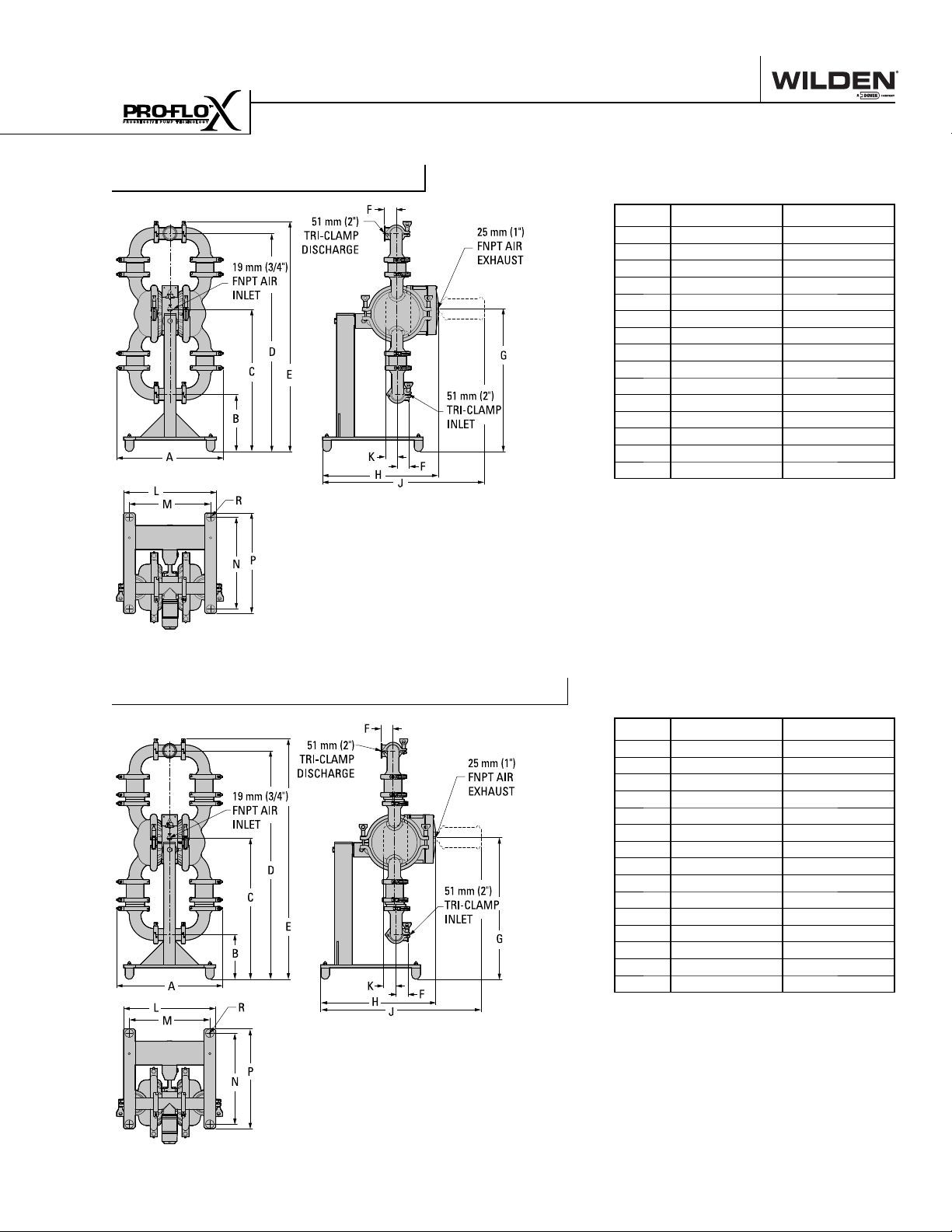

Page 7

Section 4

DIMENSIONAL DRAWINGS

PX8 Saniflo™ HS Swivel

DIMENSIONS

ITEM METRIC (mm) STANDARD (inch)

A 460 18.1

B 247 9.7

C 612 24.1

D 938 36.9

E 989 38.9

F 51 2.0

G 615 24.2

H 498 19.6

J 693 27.3

K 46 1.8

L 401 15.8

M 351 13.8

N 394 15.5

P 432 17.0

R ø10 ø0.4

Rev B

PX8 Saniflo™ HS Flap Valve Swivel

DIMENSIONS

ITEM METRIC (mm) STANDARD (inch)

A 460 18.1

B 194 7.6

C 612 24.1

D 990 39.0

E 1042 41.0

F 51 2.0

G 615 24.2

H 498 19.6

J 693 27.3

K 56 2.2

L 401 15.8

M 351 13.8

N 394 15.5

P 432 17.0

R ø10 ø0.4

Rev B

WIL-12310-E-04 5 WILDEN PUMP & ENGINEERING, LLC

Page 8

Pump Solids

Maximize Your Yield

Is your process limping along with a pump that wasn't

designed to transfer sanitary solids? Are your inspection,

cleaning, and maintenance costs too high? Are you looking

for a pump that is actually designed for your application?

Wilden has your answer. The Saniflo™ VC pump can trans-

fer your product without damage from bruising or shearing.

The pump is specifically designed to meet your performance

needs while minimizing cleaning and inspection time. Contact

us for a unique perspective and proven results. The Saniflo™

VC will handle any food product that you can dish out.

• 3 sizes available

• Solids passage to 152 mm (6")

• Stainless steel construction

• Only 2 moving parts

• Low liquid content requirement

• Complies with

USDA requirements

• Variable fl ow

• CE marked

• Low voltage directive by TÜV

• PED & machinery directive

WILDEN PUMP & ENGINEERING, LLC 6 WIL-12310-E-04

Page 9

PX8

SANIFLO

PX8 SANIFLO HS PERFORMANCE

Page 10

Section 5A

Pro-Flo X

The Pro-Flo X™ air distribution system with the

revolutionary Effi ciency Management System (EMS)

offers fl exibility never before seen in the world of

AODD pumps. The

patent-pending EMS

is simple and easy

to use. With the

turn of an integrated

TM

Operating Principle

control dial, the operator can select the optimal

balance of fl ow and effi ciency that best meets the

application needs. Pro-Flo X™ provides higher

performance, lower

operational costs

and fl exibility that

exceeds previous

industry standards.

AIR CONSUMPTION

$

$

$

Turning the dial

changes the

relationship

between air inlet

and exhaust

porting.

WILDEN PUMP & ENGINEERING, LLC 8 PX8 HS Performance

Each dial setting

represents an

entirely different

fl ow curve

Pro-Flo X™ pumps

are shipped from

the factory on

setting 4, which

is the highest

fl ow rate setting

possible

Moving the dial

from setting 4

causes a decrease

in fl ow and an even

greater decrease in

air consumption.

When the air

consumption

decreases more

than the fl ow

rate, effi ciency

is improved and

operating costs

are reduced.

Page 11

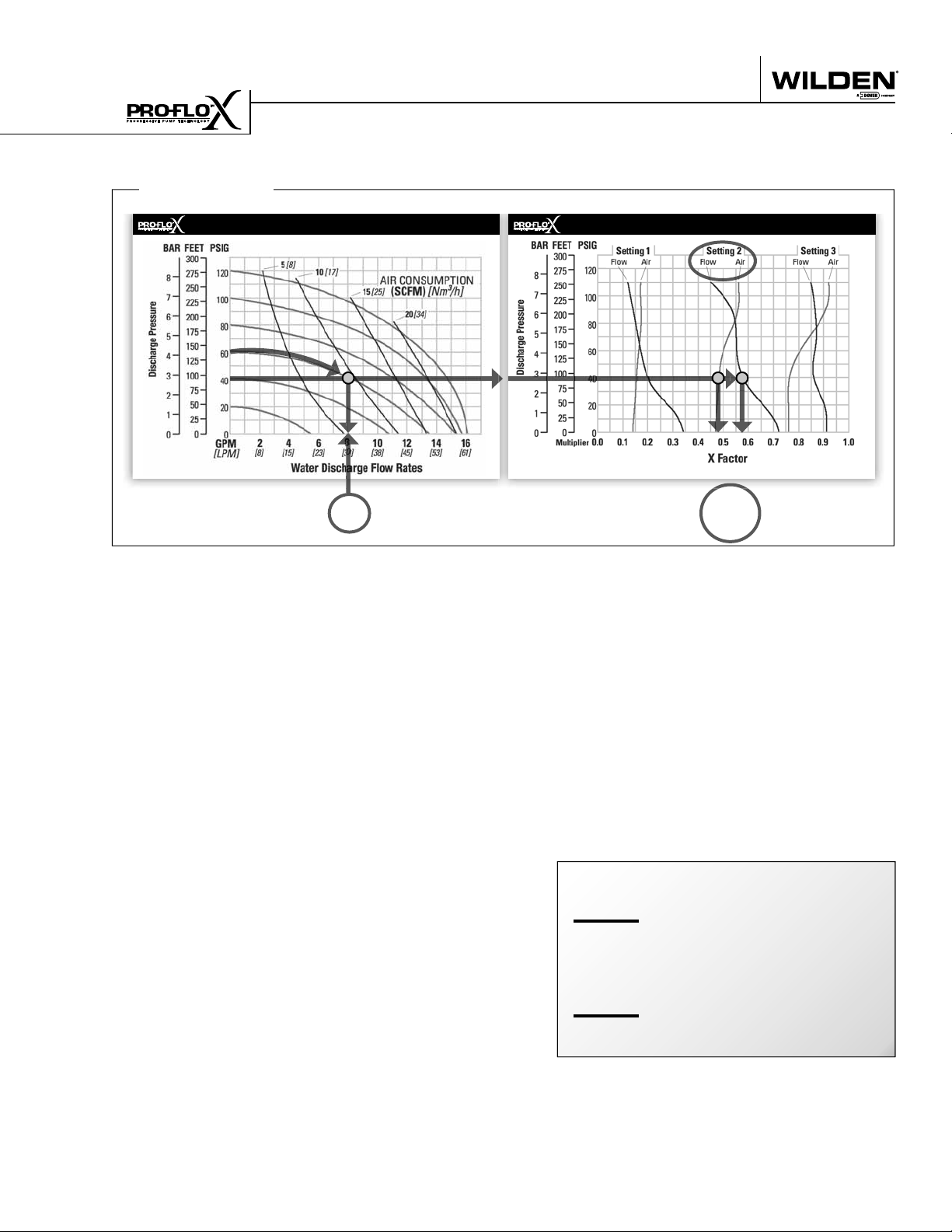

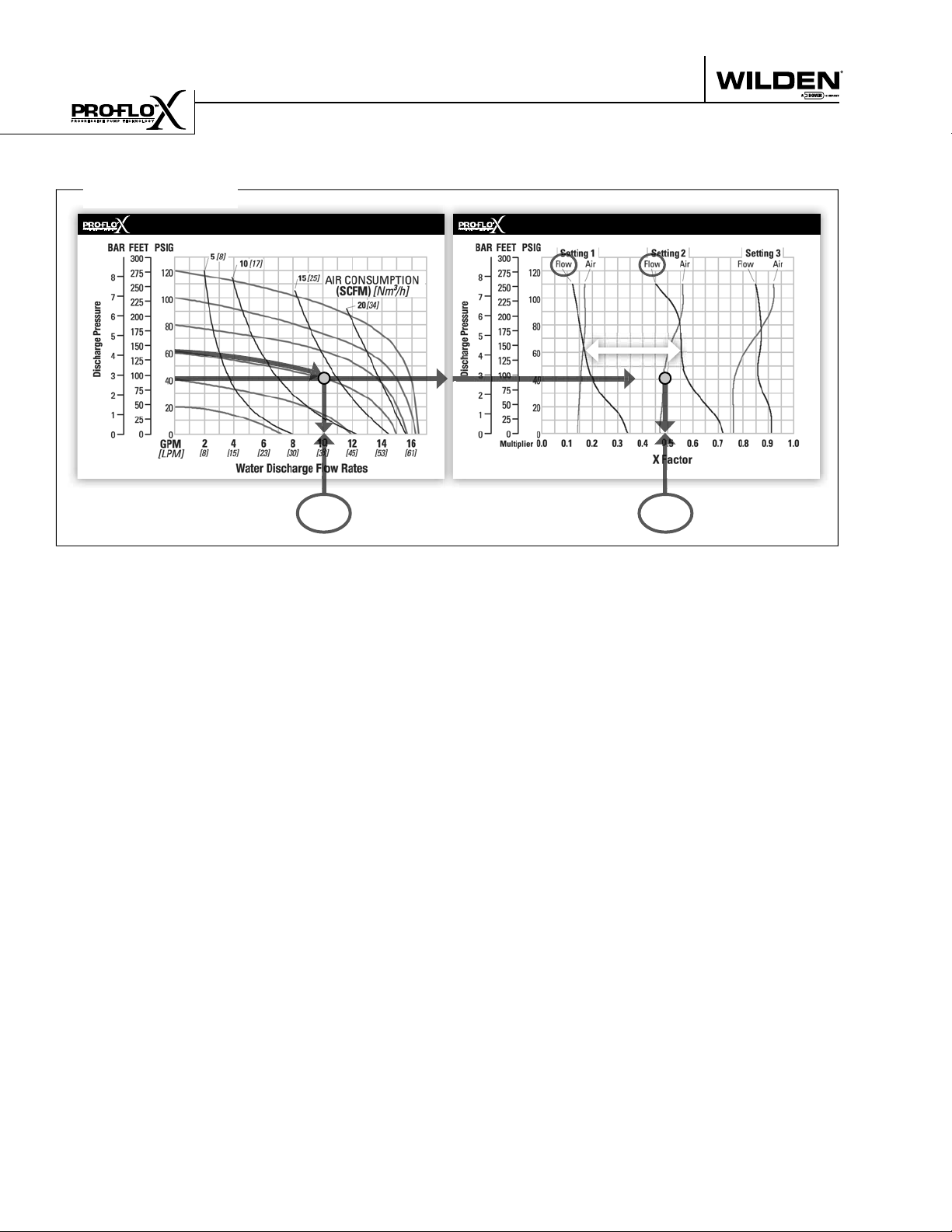

Example 1

HOW TO USE THIS EMS CURVE

SETTING 4 PERFORMANCE CURVE

Figure 1 Figure 2

Example data point = Example data point =

This is an example showing how to determine fl ow rate and

air consumption for your Pro-Flo X™ pump using the Effi ciency Management System (EMS) curve and the performance

curve. For this example we will be using 4.1 bar (60 psig) inlet

air pressure and 2.8 bar (40 psig) discharge pressure and EMS

setting 2.

Step 1:

Identifying performance at setting 4. Locate

the curve that represents the fl ow rate of the

pump with 4.1 bar (60 psig) air inlet pressure.

Mark the point where this curve crosses the

horizontal line representing 2.8 bar (40 psig)

discharge pressure. (Figure 1). After locating

your performance point on the fl ow curve,

draw a vertical line downward until reaching

the bottom scale on the chart. Identify the fl ow

rate (in this case, 8.2 gpm). Observe location

of performance point relative to air consumption curves and approximate air consumption

value (in this case, 9.8 scfm).

8.2

GPM

curve, draw vertical lines downward until

reaching the bottom scale on the chart. This

identifi es the fl ow X Factor (in this case, 0.58)

and air X Factor (in this case, 0.48).

Step 3:

Calculating performance for specific EMS

setting. Multiply the fl ow rate (8.2 gpm)

obtained in Step 1 by the fl ow X Factor multiplier (0.58) in Step 2 to determine the fl ow rate

at EMS setting 2. Multiply the air consumption (9.8 scfm) obtained in Step 1 by the air

X Factor multiplier (0.48) in Step 2 to determine the air consumption at EMS setting 2

(Figure 3).

8.2

gpm

.58

4.8

gpm

0.58

0.48

(fl ow rate for Setting 4)

(Flow X Factor setting 2)

(Flow rate for setting 2)

EMS CURVE

fl ow multiplier

air multiplier

Step 2:

Determining flow and air X Factors. Locate

your discharge pressure (40 psig) on the vertical axis of the EMS curve (Figure 2). Follow

along the 2.8 bar (40 psig) horizontal line until

intersecting both fl ow and air curves for your

desired EMS setting (in this case, setting 2).

Mark the points where the EMS curves intersect the horizontal discharge pressure line.

After locating your EMS points on the EMS

PX8 HS Performance 9 WILDEN PUMP & ENGINEERING, LLC

9.8

scfm

(air consumption for setting 4)

.48

4.7

Figure 3

The fl ow rate and air consumption at Setting

2 are found to be 18.2 lpm (4.8 gpm) and 7.9

Nm3/h (4.7 scfm) respectively.

(Air X Factor setting 2)

scfm

(air consumption for setting 2)

Page 12

HOW TO USE THIS EMS CURVE

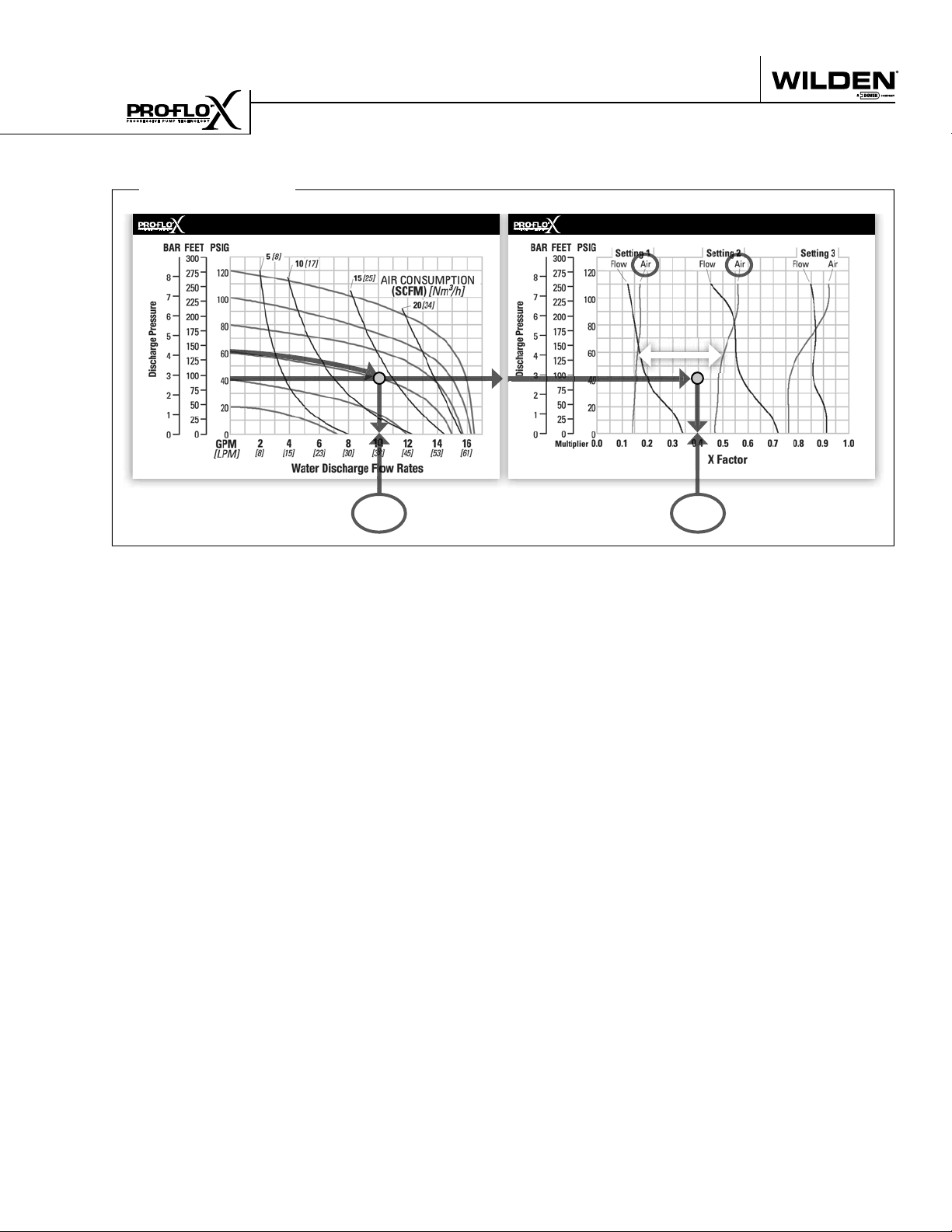

Example 2.1

SETTING 4 PERFORMANCE CURVE

Figure 4

Example data point =

This is an example showing how to determine the inlet air

pressure and the EMS setting for your Pro-Flo X™ pump to

optimize the pump for a specifi c application. For this example we will be using an application requirement of 18.9 lpm

(5 gpm) fl ow rate against 2.8 bar (40 psig) discharge pressure.

This example will illustrate how to calculate the air consumption that could be expected at this operational point.

10.2

gpm

DETERMINE EMS SETTING

Step 1

: Establish inlet air pressure. Higher air pres-

sures will typically allow the pump to run

more effi ciently, however, available plant air

pressure can vary greatly. If an operating

pressure of 6.9 bar (100 psig) is chosen when

EMS Flow

Settings 1 & 2

0.49

In our example it is 38.6 lpm (10.2 gpm). This

is the setting 4 fl ow rate. Observe the location of the performance point relative to air

consumption curves and approximate air

consumption value. In our example setting

4 air consumption is 24 Nm3/h (14 scfm).

See fi gure 4.

Step 3

: Determine flow X Factor. Divide the required

fl ow rate 18.9 lpm (5 gpm) by the setting 4 fl ow

rate 38.6 lpm (10.2 gpm) to determine the fl ow

X Factor for the application.

5

gpm / 10.2 gpm = 0.49 (flow X Factor)

EMS CURVE

Figure 5

fl ow multiplier

plant air frequently dips to 6.2 bar (90 psig)

Step 4

pump performance will vary. Choose an operating pressure that is within your compressed

air system's capabilities. For this example we

will choose 4.1 bar (60 psig).

: Determine EMS setting from the flow

X Factor. Plot the point representing the fl ow

X Factor (0.49) and the application discharge

pressure 2.8 bar (40 psig) on the EMS curve.

This is done by following the horizontal 2.8

Step 2

: Determine performance point at setting 4. For

this example an inlet air pressure of 4.1 bar

(60 psig) inlet air pressure has been chosen.

Locate the curve that represents the performance of the pump with 4.1 bar (60 psig) inlet

air pressure. Mark the point where this curve

crosses the horizontal line representing 2.8

bar (40 psig) discharge pressure. After locating this point on the fl ow curve, draw a vertical line downward until reaching the bottom

scale on the chart and identify the fl ow rate.

bar (40 psig) psig discharge pressure line until

it crosses the vertical 0.49 X Factor line. Typically, this point lies between two fl ow EMS

setting curves (in this case, the point lies between the fl ow curves for EMS setting 1 and

2). Observe the location of the point relative

to the two curves it lies between and approximate the EMS setting (fi gure 5). For more precise results you can mathematically interpolate between the two curves to determine the

optimal EMS setting.

For this example the EMS setting is 1.8.

WILDEN PUMP & ENGINEERING, LLC 10 PX8 HS Performance

Page 13

HOW TO USE THIS EMS CURVE

Example 2.2

SETTING 4 PERFORMANCE CURVE

Figure 6

Example data point =

10.2

gpm

Determine air consumption at a specific

EMS setting.

Step 1

: Determine air X Factor. In order to determine

the air X Factor, identify the two air EMS setting curves closest to the EMS setting established in example 2.1 (in this case, the point lies

between the air curves for EMS setting 1 and

2). The point representing your EMS setting

(1.8) must be approximated and plotted on the

EMS curve along the horizontal line representing your discharge pressure (in this case, 40

psig). This air point is different than the fl ow

point plotted in example 2.1. After estimating

(or interpolating) this point on the curve, draw

a vertical line downward until reaching the

bottom scale on the chart and identify the air

X Factor (fi gure 7).

EMS CURVE

EMS Air

Settings 1 & 2

Figure 7

Example data point =

Step 2

: Determine air consumption. Multiply your

setting 4 air consumption (14 scfm) value by

the air X Factor obtained above (0.40) to determine your actual air consumption.

1

4 scfm x 0.40 = 5.6 SCFM

In summary, for an application requiring 18.9 lpm

(5 gpm) against 2.8 bar (40 psig) discharge pressure,

the pump inlet air pressure should be set to 4.1 bar

(60 psig) and the EMS dial should be set to 1.8. The

pump would then consume 9.5 Nm3/h (5.6 scfm) of

compressed air.

0.40

air multiplier

For this example the air X Factor is 0.40

PX8 HS Performance 11 WILDEN PUMP & ENGINEERING, LLC

Page 14

EMS CURVE

PERFORMANCE

/h

3

EXAMPLE

A PX8 Sanifl o HS, full stroke Rubber-fi tted pump operating at EMS

setting 4, achieved a fl ow rate of 348 lpm (92 gpm) using 119 Nm

(70 scfm) of air when run at 5.5 bar (80 psig) air inlet pressure and 2.1

bar (30 psig) discharge pressure (See dot on performance curve).

The end user did not require that much fl ow and wanted to reduce

air consumption at his facility. He determined that EMS setting 2

would meet his needs. At 2.1 bar (30 psig) discharge pressure and

EMS setting 2, the fl ow “X factor” is 0.74 and the air “X factor” is

0.48 (see dots on EMS curve).

/h (34 scfm). The fl ow rate was reduced by 26% while

3

the air consumption was reduced by 52%, thus providing increased

effi ciency.

For a detailed example for how to set your EMS, see beginning of

performance curve section.

Multiplying the original setting 4 values by the “X factors” provides

the setting 2 fl ow rate of 258 lpm (68 gpm) and an air consumption

of 57 Nm

Caution: Do not exceed 8.6 bar (125 psig) air supply pressure.

The Effi ciency Management System (EMS)

can be used to optimize the performance of

your Wilden pump for specifi c applications.

The pump is delivered with the EMS adjusted

to setting 4, which allows maximum fl ow.

The EMS curve allows the pump user to deter-

mine fl ow and air consumption at each EMS

setting. For any EMS setting and discharge

pressure, the “X factor” is used as a multi-

plier with the original values from the setting

4 performance curve to calculate the actual

fl ow and air consumption values for that spe-

cifi c EMS setting. Note: you can interpolate

between the setting curves for operation at

intermediate EMS settings

1

SETTING 4 PERFORMANCE CURVE

Displacement per stroke was calculated at 4.8 bar (70 psig)

Flow rates indicated on chart were determined by pumping water with a vertically mounted, center ported ball check confi guration.

TECHNICAL DATA

Height . . . . . . . . . . . . . . . . . . . . . . . . . 1008 mm (39.7”)

Width. . . . . . . . . . . . . . . . . . . . . . . . . . . 460 mm (18.1”)

Depth. . . . . . . . . . . . . . . . . . . . . . . . . . . 498 mm (19.6”)

Ship Weight . . . . . . . . . . . . . . . . . . . . . 49 kg (109 lbs.)

Air Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 mm (3/4”)

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 mm (2”)

Outlet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 mm (2”)

Suction Lift . . . . . . . . . . . . . . . . . . . . . 5.3 m Dry (17.3’)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.0 m Wet (29.5’)

Disp. Per Stroke. . . . . . . . . . . . . . . . . . 1.1 l (0.28 gal.)

Max. Flow Rate . . . . . . . . . . . . . . . .579 lpm (153 gpm)

Max. Size Solids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mushroom Valve . . . . . . . . . . . . . . . . . 6.4 mm (1/4”)

Ball Valve. . . . . . . . . . . . . . . . . . . . . . . 12.7 mm (1/2”)

PX8 SANIFLO HS FULL STROKE RUBBER-FITTED

Flap Valve (compressible solids). 47.5 mm (1-7/8”)

WILDEN PUMP & ENGINEERING, LLC 12 PX8 HS Performance

air inlet pressure against a 2 bar (30 psig) head pressure.

Surface Finish . . . . . . . . . . . . . . . . Ra 0.8 µm (32 µ-in)

1

When alternate check valve options are used, multiply fl ow rate by appropriate factor: Flap check valve = 83%. For optimum life and

performance, pumps should be specifi ed so that daily operation parameters fall in the center of the pump performance curve.

Page 15

EMS CURVE

PERFORMANCE

/h (60

3

scfm) of air when run at 4.1 bar (60 psig) air inlet pressure and 1.4

bar (20 psig) discharge pressure (See dot on performance curve).

The end user did not require that much fl ow and wanted to reduce

air consumption at his facility. He determined that EMS setting 2

would meet his needs. At 1.4 bar (20 psig) discharge pressure and

EXAMPLE

A PX8 Sanifl o HS, full stroke TPE-fi tted pump operating at EMS set-

ting 4, achieved a fl ow rate of 367 lpm (97 gpm) using 102 Nm

EMS setting 2, the fl ow “X factor” is 0.66 and the air “X factor” is

/h (28 scfm). The fl ow rate was reduced by 34% while

3

0.47 (see dots on EMS curve).

Multiplying the original setting 4 values by the “X factors” provides

the setting 2 fl ow rate of 242 lpm (64 gpm) and an air consumption

of 48 Nm

the air consumption was reduced by 53%, thus providing increased

effi ciency.

For a detailed example for how to set your EMS, see beginning of

performance curve section.

Caution: Do not exceed 8.6 bar (125 psig) air supply pressure.

The Effi ciency Management System (EMS)

can be used to optimize the performance of

your Wilden pump for specifi c applications.

The pump is delivered with the EMS adjusted

to setting 4, which allows maximum fl ow.

The EMS curve allows the pump user to deter-

mine fl ow and air consumption at each EMS

setting. For any EMS setting and discharge

pressure, the “X factor” is used as a multi-

plier with the original values from the setting

4 performance curve to calculate the actual

fl ow and air consumption values for that spe-

cifi c EMS setting. Note: you can interpolate

between the setting curves for operation at

intermediate EMS settings.

1

SETTING 4 PERFORMANCE CURVE

Displacement per stroke was calculated at 4.8 bar (70 psig)

Flow rates indicated on chart were determined by pumping water with a vertically mounted, center ported ball check confi guration.

TECHNICAL DATA

Height . . . . . . . . . . . . . . . . . . . . . . . . .1008 mm (39.7”)

Width. . . . . . . . . . . . . . . . . . . . . . . . . . .460 mm (18.1”)

Depth. . . . . . . . . . . . . . . . . . . . . . . . . . .498 mm (19.6”)

Ship Weight . . . . . . . . . . . . . . . . . . . . .49 kg (109 lbs.)

Air Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . 19 mm (3/4”)

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 mm (2”)

Outlet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 mm (2”)

Suction Lift . . . . . . . . . . . . . . . . . . . . . .1.9 m Dry (6.2’)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.0 m Wet (29.5’)

Disp. Per Stroke. . . . . . . . . . . . . . . . . 1.2 l (0.33 gal.)

Max. Flow Rate . . . . . . . . . . . . . . .587 lpm (155 gpm)

Max. Size Solids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mushroom Valve . . . . . . . . . . . . . . . . 6.4 mm (1/4”)

Ball Valve. . . . . . . . . . . . . . . . . . . . . . 12.7 mm (1/2”)

PX8 SANIFLO HS FULL STROKE TPE-FITTED

Flap Valve (compressible solids) 47.5 mm (1-7/8”)

PX8 HS Performance 13 WILDEN PUMP & ENGINEERING, LLC

air inlet pressure against a 2 bar (30 psig) head pressure.

Surface Finish . . . . . . . . . . . . . . . Ra 0.8 µm (32 µ-in)

1

When alternate check valve options are used, multiply fl ow rate by appropriate factor: Flap check valve = 83%. For optimum life and

performance, pumps should be specifi ed so that daily operation parameters fall in the center of the pump performance curve.

Page 16

EMS CURVE

PERFORMANCE

/h

3

EXAMPLE

A PX8 Sanifl o HS, Full Stroke PTFE -fi tted pump operating at EMS

setting 4, achieved a fl ow rate of 201 lpm (53 gpm) using 93 Nm

(55 scfm) of air when run at 5.5 bar (80 psig) air inlet pressure and 4.1

bar (60 psig) discharge pressure (See dot on performance curve).

The end user did not require that much fl ow and wanted to reduce

air consumption at his facility. He determined that EMS setting 2

would meet his needs. At 4.1 bar (60 psig) discharge pressure and

EMS setting 2, the fl ow “X factor” is 0.70 and the air “X factor” is

0.60 (see dots on EMS curve).

/h (33 scfm). The fl ow rate was reduced by 30% while

3

the air consumption was reduced by 40%, thus providing increased

effi ciency.

For a detailed example for how to set your EMS, see beginning of

performance curve section.

Multiplying the original setting 4 values by the “X factors” provides

the setting 2 fl ow rate of 140 lpm (37 gpm) and an air consumption

of 56 Nm

Caution: Do not exceed 8.6 bar (125 psig) air supply pressure.

The Effi ciency Management System (EMS)

can be used to optimize the performance of

your Wilden pump for specifi c applications.

The pump is delivered with the EMS adjusted

to setting 4, which allows maximum fl ow.

The EMS curve allows the pump user to

determine fl ow and air consumption at

each EMS setting. For any EMS setting and

discharge pressure, the “X factor” is used

as a multiplier with the original values from

the setting 4 performance curve to calculate

the actual fl ow and air consumption values

for that specifi c EMS setting. Note: you can

interpolate between the setting curves for

operation at intermediate EMS settings.

1

SETTING 4 PERFORMANCE CURVE

Displacement per stroke was calculated at 4.8 bar (70 psig)

Flow rates indicated on chart were determined by pumping water with a vertically mounted, center ported ball check confi guration.

When alternate check valve options are used, multiply fl ow rate by appropriate factor: For optimum life and performance, pumps

TECHNICAL DATA

Height . . . . . . . . . . . . . . . . . . . . . . . . . 1008 mm (39.7”)

Width. . . . . . . . . . . . . . . . . . . . . . . . . . . 460 mm (18.1”)

Depth. . . . . . . . . . . . . . . . . . . . . . . . . . . 398 mm (15.7”)

Ship Weight . . . . . . . . . . . . . . . . . . . . . 49 kg (109 lbs.)

Air Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 mm (3/4”)

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 mm (2”)

Outlet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 mm (2”)

Suction Lift . . . . . . . . . . . . . . . . . . . . . 4.8 m Dry (15.9’)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.6 m Wet (28.4’)

Disp. Per Stroke. . . . . . . . . . . . . . . . . . 1.1 l (0.28 gal.)

Max. Flow Rate . . . . . . . . . . . . . . . .556 lpm (147 gpm)

Max. Size Solids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mushroom Valve . . . . . . . . . . . . . . . . . 6.4 mm (1/4”)

PX8 SANIFLO HS FULL STROKE PTFE-FITTED

Ball Valve. . . . . . . . . . . . . . . . . . . . . . . 12.7 mm (1/2”)

WILDEN PUMP & ENGINEERING, LLC 14 PX8 HS Performance

air inlet pressure against a 2 bar (30 psig) head pressure.

Surface Finish . . . . . . . . . . . . . . . . Ra 0.8 µm (32 µ-in)

1

should be specifi ed so that daily operation parameters fall in the center of the pump performance curve.

Page 17

PERFORMANCE

EMS CURVE

(Full Stroke Integral Piston Diaphragm)

/h

3

EXAMPLE

A PX8 Sanifl o HS, Full Stroke SIPD -fi tted pump operating at EMS

setting 4, achieved a fl ow rate of 390 lpm (103 gpm) using 105 Nm

(62 scfm) of air when run at 4.1 bar (60 psig) air inlet pressure and 1.4

bar (20 psig) discharge pressure (See dot on performance curve).

The end user did not require that much fl ow and wanted to reduce

air consumption at his facility. He determined that EMS setting 2

would meet his needs. At 1.4 bar (20 psig) discharge pressure and

EMS setting 2, the fl ow “X factor” is 0.79 and the air “X factor” is

0.54 (see dots on EMS curve).

/h (33 scfm). The fl ow rate was reduced by 21% while

3

the air consumption was reduced by 46%, thus providing increased

effi ciency.

For a detailed example for how to set your EMS, see beginning of

performance curve section.

Multiplying the original setting 4 values by the “X factors” provides

the setting 2 fl ow rate of 308 lpm (81 gpm) and an air consumption

of 57 Nm

Caution: Do not exceed 8.6 bar (125 psig) air supply pressure.

The Effi ciency Management System (EMS)

can be used to optimize the performance of

your Wilden pump for specifi c applications.

The pump is delivered with the EMS adjusted

to setting 4, which allows maximum fl ow.

The EMS curve allows the pump user to

determine fl ow and air consumption at

each EMS setting. For any EMS setting and

discharge pressure, the “X factor” is used

as a multiplier with the original values from

the setting 4 performance curve to calculate

the actual fl ow and air consumption values

for that specifi c EMS setting. Note: you can

interpolate between the setting curves for

operation at intermediate EMS settings.

1

SETTING 4 PERFORMANCE CURVE

PX8 SANIFLO HS FULL STROKE SIPD-FITTED

TECHNICAL DATA

Height . . . . . . . . . . . . . . . . . . . . . . . . . 1008 mm (39.7”)

Width. . . . . . . . . . . . . . . . . . . . . . . . . . . 460 mm (18.1”)

Depth. . . . . . . . . . . . . . . . . . . . . . . . . . . 398 mm (15.7”)

Ship Weight . . . . . . . . . . . . . . . . . . . . . 49 kg (109 lbs.)

Air Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 mm (3/4”)

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 mm (2”)

Outlet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 mm (2”)

Suction Lift . . . . . . . . . . . . . . . . . . . . . 4.7 m Dry (15.3’)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.6 m Wet (28.4’)

Disp. Per Stroke. . . . . . . . . . . . . . . . . . 1.1 l (0.28 gal.)

Max. Flow Rate . . . . . . . . . . . . . . . .556 lpm (147 gpm)

Max. Size Solids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mushroom Valve . . . . . . . . . . . . . . . . . 6.4 mm (1/4”)

PX8 HS Performance 15 WILDEN PUMP & ENGINEERING, LLC

Displacement per stroke was calculated at 4.8 bar (70 psig)

Flow rates indicated on chart were determined by pumping water with a vertically mounted, center ported ball check confi guration.

Ball Valve. . . . . . . . . . . . . . . . . . . . . . . 12.7 mm (1/2”)

air inlet pressure against a 2 bar (30 psig) head pressure.

Surface Finish . . . . . . . . . . . . . . . . Ra 0.8 µm (32 µ-in)

1

When alternate check valve options are used, multiply fl ow rate by appropriate factor: For optimum life and performance, pumps

should be specifi ed so that daily operation parameters fall in the center of the pump performance curve.

Page 18

EMS CURVE

PERFORMANCE

SETTING 4 PERFORMANCE CURVE

/h (100 scfm) of air when run at 6.9 bar (100 psig) air inlet pres-

3

sure and 1.4 bar (20 psig) discharge pressure (See dot on perfor-

mance curve).

The end user did not require that much fl ow and wanted to reduce

air consumption at his facility. He determined that EMS setting 1

would meet his needs. At 1.4 bar (20 psig) discharge pressure and

EMS setting 1, the fl ow “X factor” is 0.33 and the air “X factor” is

EXAMPLE

A PX8 Sanifl o HS, reduced stroke PTFE-fi tted pump operating at

EMS setting 4, achieved a fl ow rate of 257 lpm (68 gpm) using 170

Nm

The Effi ciency Management System (EMS)

can be used to optimize the performance of

your Wilden pump for specifi c applications.

The pump is delivered with the EMS adjusted

to setting 4, which allows maximum fl ow.

The EMS curve allows the pump user to deter-

mine fl ow and air consumption at each EMS

0.21 (see dots on EMS curve).

setting. For any EMS setting and discharge

pressure, the “X factor” is used as a multi-

plier with the original values from the setting

4 performance curve to calculate the actual

fl ow and air consumption values for that spe-

1

/h (21 scfm). The fl ow rate was reduced by 67% while the air con-

3

Multiplying the original setting 4 values by the “X factors” provides

sumption was reduced by 79%, thus providing increased effi ciency.

the setting 1 fl ow rate of 85 lpm (22 gpm) and an air consumption of 36

Nm

For a detailed example for how to set your EMS, see beginning of

performance curve section.

Caution: Do not exceed 8.6 bar (125 psig) air supply pressure.

cifi c EMS setting. Note: you can interpolate

between the setting curves for operation at

intermediate EMS settings.

PX8 SANIFLO HS REDUCED STROKE PTFE-FITTED

TECHNICAL DATA

Height . . . . . . . . . . . . . . . . . . . . . . . . .1008 mm (39.7”)

Width. . . . . . . . . . . . . . . . . . . . . . . . . . .460 mm (18.1”)

Depth. . . . . . . . . . . . . . . . . . . . . . . . . . .498 mm (19.6”)

Ship Weight . . . . . . . . . . . . . . . . . . . . .49 kg (109 lbs.)

Air Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . 19 mm (3/4”)

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 mm (2”)

Outlet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 mm (2”)

Suction Lift . . . . . . . . . . . . . . . . . . . . . .2.8 m Dry (9.1’)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.0 m Wet (29.5’)

Disp. Per Stroke. . . . . . . . . . . . . . . . . 0.5 l (0.13 gal.)

Max. Flow Rate . . . . . . . . . . . . . . . .353 lpm (96 gpm)

Max. Size Solids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mushroom Valve . . . . . . . . . . . . . . . . 6.4 mm (1/4”)

Displacement per stroke was calculated at 4.8 bar (70 psig)

Ball Valve. . . . . . . . . . . . . . . . . . . . . . 12.7 mm (1/2”)

air inlet pressure against a 2 bar (30 psig) head pressure.

Surface Finish . . . . . . . . . . . . . . . Ra 0.8 µm (32 µ-in)

1

Flow rates indicated on chart were determined by pumping water with a vertically mounted, center ported ball check confi guration.

WILDEN PUMP & ENGINEERING, LLC 16 PX8 HS Performance

When alternate check valve options are used, multiply fl ow rate by appropriate factor: For optimum life and performance, pumps

should be specifi ed so that daily operation parameters fall in the center of the pump performance curve.

Page 19

PERFORMANCE

EMS CURVE

(Sanitary Integrate Piston Diaphragm)

EXAMPLE

A PX8 Sanifl o HS, reduced stroke PTFE SIPD-fi tted pump operating

at EMS setting 4, achieved a fl ow rate of 197 lpm (52 gpm) using 93

Nm3/h (55 scfm) of air when run at 4.1 bar (60 psig) air inlet pressure

and 1.4 bar (20 psig) discharge pressure (See dot on performance

curve).

The end user did not require that much fl ow and wanted to reduce

air consumption at his facility. He determined that EMS setting 3

would meet his needs. At 1.4 bar (20 psig) discharge pressure and

EMS setting 3, the fl ow “X factor” is 0.87 and the air “X factor” is

0.74 (see dots on EMS curve).

Multiplying the original setting 4 values by the “X factors” provides the

setting 3 fl ow rate of 171 lpm (45 gpm) and an air consumption of 69

Nm3/h (41 scfm). The fl ow rate was reduced by 13% while the air con-

sumption was reduced by 26%, thus providing increased effi ciency.

For a detailed example for how to set your EMS, see beginning of

performance curve section.

Caution: Do not exceed 8.6 bar (125 psig) air supply pressure.

The Effi ciency Management System (EMS)

can be used to optimize the performance of

your Wilden pump for specifi c applications.

The pump is delivered with the EMS adjusted

to setting 4, which allows maximum fl ow.

The EMS curve allows the pump user to

determine fl ow and air consumption at

each EMS setting. For any EMS setting and

discharge pressure, the “X factor” is used

as a multiplier with the original values from

the setting 4 performance curve to calculate

the actual fl ow and air consumption values

for that specifi c EMS setting. Note: you can

interpolate between the setting curves for

operation at intermediate EMS settings.

1

SETTING 4 PERFORMANCE CURVE

PX8 SANIFLO HS REDUCED STROKE PTFE SIPD-FITTED

PX8 HS Performance 17 WILDEN PUMP & ENGINEERING, LLC

TECHNICAL DATA

Height . . . . . . . . . . . . . . . . . . . . . . . . . 1008 mm (39.7”)

Width. . . . . . . . . . . . . . . . . . . . . . . . . . . 460 mm (18.1”)

Depth. . . . . . . . . . . . . . . . . . . . . . . . . . . 498 mm (19.6”)

Ship Weight . . . . . . . . . . . . . . . . . . . . . 49 kg (109 lbs.)

Air Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 mm (3/4”)

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 mm (2”)

Outlet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 mm (2”)

Suction Lift . . . . . . . . . . . . . . . . . . . . . . 2.3 m Dry (7.4’)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.0 m Wet (29.5’)

Disp. Per Stroke. . . . . . . . . . . . . . . . . . 0.4 l (0.11 gal.)

Max. Flow Rate . . . . . . . . . . . . . . . .405 lpm (107 gpm)

Max. Size Solids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mushroom Valve . . . . . . . . . . . . . . . . . 6.4 mm (1/4”)

Displacement per stroke was calculated at 4.8 bar (70 psig)

Flow rates indicated on chart were determined by pumping water with a vertically mounted, center ported ball check confi guration.

Ball Valve. . . . . . . . . . . . . . . . . . . . . . . 12.7 mm (1/2”)

air inlet pressure against a 2 bar (30 psig) head pressure.

Surface Finish . . . . . . . . . . . . . . . . Ra 0.8 µm (32 µ-in)

1

When alternate check valve options are used, multiply fl ow rate by appropriate factor: For optimum life and performance, pumps

should be specifi ed so that daily operation parameters fall in the center of the pump performance curve.

Page 20

EMS CURVE

-FITTED

TM

PERFORMANCE

EXAMPLE

A PX8 Sanifl o HS, reduced stroke Ultra-Flex-fi tted pump operating at

EMS setting 4, achieved a fl ow rate of 250 lpm (66 gpm) using 97 Nm3/h

(57 scfm) of air when run at 4.1 bar (60 psig) air inlet pressure and 2.1

bar (30 psig) discharge pressure (See dot on performance curve).

The end user did not require that much fl ow and wanted to reduce

air consumption at his facility. He determined that EMS setting 1

would meet his needs. At 2.1 bar (30 psig) discharge pressure and

EMS setting 1, the fl ow “X factor” is 0.34 and the air “X factor” is

0.20 (see dots on EMS curve).

Multiplying the original setting 4 values by the “X factors” provides

the setting 1 fl ow rate of 85 lpm (22 gpm) and an air consumption

of 19 Nm3/h (11 scfm). The fl ow rate was reduced by 66% while

the air consumption was reduced by 80%, thus providing increased

effi ciency.

For a detailed example for how to set your EMS, see beginning of

performance curve section.

Caution: Do not exceed 8.6 bar (125 psig) air supply pressure.

The Effi ciency Management System (EMS)

can be used to optimize the performance of

your Wilden pump for specifi c applications.

The pump is delivered with the EMS adjusted

to setting 4, which allows maximum fl ow.

The EMS curve allows the pump user to

determine fl ow and air consumption at

each EMS setting. For any EMS setting and

discharge pressure, the “X factor” is used

as a multiplier with the original values from

the setting 4 performance curve to calculate

the actual fl ow and air consumption values

for that specifi c EMS setting. Note: you can

interpolate between the setting curves for

operation at intermediate EMS settings.

1

SETTING 4 PERFORMANCE CURVE

Displacement per stroke was calculated at 4.8 bar (70 psig)

Flow rates indicated on chart were determined by pumping water with a vertically mounted, center ported ball check confi guration.

When alternate check valve options are used, multiply fl ow rate by appropriate factor: For optimum life and performance, pumps

TECHNICAL DATA

Height . . . . . . . . . . . . . . . . . . . . . . . . . 1008 mm (39.7”)

Width. . . . . . . . . . . . . . . . . . . . . . . . . . . 460 mm (18.1”)

Depth. . . . . . . . . . . . . . . . . . . . . . . . . . . 498 mm (19.6”)

Ship Weight . . . . . . . . . . . . . . . . . . . . . 49 kg (109 lbs.)

Air Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 mm (3/4”)

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 mm (2”)

Outlet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 mm (2”)

Suction Lift . . . . . . . . . . . . . . . . . . . . . 3.8 m Dry (12.5’)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.0 m Wet (29.5’)

Disp. Per Stroke. . . . . . . . . . . . . . . . . . 0.9 l (0.23 gal.)

Max. Flow Rate . . . . . . . . . . . . . . . .534 lpm (141 gpm)

Max. Size Solids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mushroom Valve . . . . . . . . . . . . . . . . . 6.4 mm (1/4”)

PX8 SANIFLO HS REDUCED STROKE ULTRA-FLEX

WILDEN PUMP & ENGINEERING, LLC 18 PX8 HS Performance

Ball Valve. . . . . . . . . . . . . . . . . . . . . . . 12.7 mm (1/2”)

air inlet pressure against a 2 bar (30 psig) head pressure.

Surface Finish . . . . . . . . . . . . . . . . Ra 0.8 µm (32 µ-in)

1

should be specifi ed so that daily operation parameters fall in the center of the pump performance curve.

Page 21

Section 5B

SUCTION LIFT CURVES

PX8 SANIFLO™ HS

REDUCED STROKE

SUCTION LIFT CAPABILITY

PX8 SANIFLO™ HS FULL

STROKE SUCTION LIFT

CAPABILITY

Suction lift curves are calibrated for pumps operating

at 305 m (1,000') above sea level. This chart is meant

to be a guide only. There are many variables which

can affect your pump’s operating characteristics. The

number of intake and discharge elbows, viscosity of

pumping fl uid, elevation (atmospheric pressure) and

pipe friction loss all affect the amount of suction lift

your pump will attain.

PX8 HS Performance 19 WILDEN PUMP & ENGINEERING, LLC

Page 22

NOTES

Page 23

Section 6

SUGGESTED INSTALLATION

Wilden pumps are designed to meet the performance

requirements of even the most demanding pumping

applications. They have been designed and manufactured

to the highest standards and are available in a variety of

liquid path materials to meet your chemical resistance

needs. Refer to the performance section of this manual for

an in-depth analysis of the performance characteristics of

your pump. Wilden offers the widest variety of elastomer

options in the industry to satisfy temperature, chemical

compatibility, abrasion resistance and fl ex concerns.

The suction pipe size should be equivalent or larger than

the diameter of the suction inlet on your Wilden pump.

The suction hose must be non-collapsible, reinforced type

as these pumps are capable of pulling a high vacuum.

Discharge piping should also be equivalent or larger than the

diameter of the pump discharge to minimize friction losses.

It is critical that all fi ttings and connections are airtight or a

reduction or loss of pump suction capability will result.

INSTALLATION: Months of careful planning, study,

and selection efforts can result in unsatisfactory pump

performance if installation details are left to chance.

Premature failure and long term dissatisfaction can be

avoided if reasonable care is exercised throughout the

installation process.

LOCATION: Noise, safety, and other logistical factors usually

dictate where equipment will be situated on the production

fl oor. Multiple installations with confl icting requirements

can result in congestion of utility areas, leaving few choices

for additional pumps.

Within the framework of these and other existing conditions,

every pump should be located in such a way that six key

factors are balanced against each other to maximum

advantage.

ACCESS: First of all, the location should be accessible. If

it’s easy to reach the pump, maintenance personnel will

have an easier time carrying out routine inspections and

adjustments. Should major repairs become necessary, ease

of access can play a key role in speeding the repair process

and reducing total downtime.

AIR SUPPLY: Every pump location should have an air

line large enough to supply the volume of air necessary

to achieve the desired pumping rate. Do not exceed the

maximum rated air pressure.

For best results, the pumps should use a 5µ (micron) air

fi lter, needle valve and regulator. The use of an air fi lter

before the pump will ensure that the majority of any pipeline

contaminants will be eliminated.

SOLENOID OPERATION: When operation is controlled by a

solenoid valve in the air line, three-way valves should be

used. This valve allows trapped air between the valve and

the pump to bleed off which improves pump performance.

MUFFLER: Sound levels are reduced below OSHA

specifi cations using the standard Wilden muffl er. Other

muffl ers can be used to further reduce sound levels, but

they usually reduce pump performance.

ELEVATION: Selecting a site that is well within the pump’s

dynamic lift capability will assure that loss-of-prime issues will

be eliminated. In addition, pump effi ciency can be adversely

affected if proper attention is not given to site location.

PIPING: Final determination of the pump site should not be

made until the piping challenges of each possible location

have been evaluated. The impact of current and future

installations should be considered ahead of time to make

sure that inadvertent restrictions are not created for any

remaining sites.

The best choice possible will be a site involving the shortest

and straightest hook-up of suction and discharge piping.

Unnecessary elbows, bends, and fi ttings should be avoided.

Pipe sizes should be selected to keep friction losses within

practical limits. All piping should be supported independently

of the pump. In addition, the piping should be aligned to

avoid placing stress on the pump fi ttings.

Flexible hose can be installed to aid in absorbing the forces

created by the natural reciprocating action of the pump. If the

pump is to be bolted down to a solid location, a mounting

pad placed between the pump and the foundation will assist

in minimizing pump vibration. Flexible connections between

the pump and rigid piping will also assist in minimizing

pump vibration. If quick-closing valves are installed at any

point in the discharge system, or if pulsation within a system

becomes a problem, a surge suppressor (SD Equalizer

should be installed to protect the pump, piping and gauges

from surges and water hammer.

If the pump is to be used in a self-priming application, make

sure that all connections are airtight and that the suction lift is

within the model’s ability. NOTE: Materials of construction and

elastomer material have an effect on suction lift parameters.

Please refer to the performance section for specifi cs.

When pumps are installed in applications involving fl ooded

suction or suction head pressures, a gate valve should be

installed in the suction line to permit closing of the line for

pump service.

Pumps in service with a positive suction head are most effi cient

when inlet pressure is limited to 0.5–0.7 bar (7–10 psig).

Premature diaphragm failure may occur if positive suction

is 0.7 bar (10 psig) and higher.

SUBMERSIBLE APPLICATIONS: Pro-Flo X™ pumps can be

used for submersible applications, when using the Pro-Flo

X™ submersible option.

ALL WILDEN PUMPS ARE CAPABLE OF PASSING SOLIDS.

A STRAINER SHOULD BE USED ON THE PUMP INTAKE TO

ENSURE THAT THE PUMP´S RATED SOLIDS CAPACITY IS

NOT EXCEEDED.

®

)

WIL-12310-E-04 21 WILDEN PUMP & ENGINEERING, LLC

Page 24

SUGGESTED INSTALLATION

NOTE: In the event of a power failure, the air shut off valve should

be closed, if restarting of the pump is not desirable once power

is regained.

AIR OPERATED PUMPS: To stop the pump from operating in an

emergency situation, simply close the air shut off valve (user

supplied) installed in the air supply line. A properly functioning

valve will stop the air supply to the pump, therefore stopping

output. This air shut off valve should be located far enough away

from the pumping equipment such that it can be reached safely in

an emergency situation.

WILDEN PUMP & ENGINEERING, LLC 22 WIL-12310-E-04

Page 25

SUGGESTED OPERATION & MAINTENANCE

OPERATION: The Pro-Flo

®

and Pro-Flo X™ pumps are

pre-lubricated, and do not require in-line lubrication.

Additional lubrication will not damage the pump,

however if the pump is heavily lubricated by an

external source, the pump’s internal lubrication may

be washed away. If the pump is then moved to a nonlubricated location, it may need to be disassembled

and re-lubricated as described in the ASSEMBLY/

DISASSEMBLY INSTRUCTIONS.

Pump discharge rate can be controlled by limiting the

volume and/or pressure of the air supply to the pump.

An air regulator is used to regulate air pressure. A needle

valve is used to regulate volume. Pump discharge rate

can also be controlled by throttling the pump discharge

by partially closing a valve in the discharge line of the

pump. This action increases friction loss which reduces

fl ow rate. (See Section 5.) This is useful when the need

exists to control the pump from a remote location.

When the pump discharge pressure equals or exceeds

the air supply pressure, the pump will stop; no bypass

or pressure relief valve is needed, and pump damage

will not occur. The pump has reached a “deadhead”

situation and can be restarted by reducing the fl uid

discharge pressure or increasing the air inlet pressure.

The Wilden Pro-Flo

®

and Pro-Flo X™ pumps run solely

on compressed air and do not generate heat, therefore

your process fl uid temperature will not be affected.

MAINTENANCE AND INSPECTIONS: Since each

application is unique, maintenance schedules may

be different for every pump. Frequency of use, line

pressure, viscosity and abrasiveness of process fl uid

all affect the parts life of a Wilden pump. Periodic

inspections have been found to offer the best

means for preventing unscheduled pump downtime.

Personnel familiar with the pump’s construction and

service should be informed of any abnormalities that

are detected during operation.

RECORDS: When service is required, a record should

be made of all necessary repairs and replacements.

Over a period of time, such records can become a

valuable tool for predicting and preventing future

maintenance problems and unscheduled downtime. In

addition, accurate records make it possible to identify

pumps that are poorly suited to their applications.

TROUBLESHOOTING

Pump will not run or runs slowly.

1. Ensure that the air inlet pressure is at least 0.4 bar

(5 psig) above startup pressure and that the differential

pressure (the difference between air inlet and liquid

discharge pressures) is not less than 0.7 bar (10 psig).

2. Check air inlet fi lter for debris (see recommended

installation).

3. Check for extreme air leakage (blow by) which

would indicate worn seals/bores in the air valve,

pilot spool, main shaft.

4. Disassemble pump and check for obstructions

in the air passageways or objects which would

obstruct the movement of internal parts.

5. Check mating surfaces of fl ap valve assembly.

6. Check for sticking ball check valves. If material being

pumped is not compatible with pump elastomers,

swelling may occur. Replace ball check valves and

seats with proper elastomers. Also, as the check

valve balls wear out, they become smaller and can

become stuck in the seats. In this case, replace balls

and seats.

7. Check for broken inner piston which will cause the

air valve spool to be unable to shift.

8. Remove plug from pilot spool exhaust.

2. Verify that vacuum required to lift liquid is not

greater than the vapor pressure of the material

being pumped (cavitation).

3. Check for sticking ball check valves. If material being

pumped is not compatible with pump elastomers,

swelling may occur. Replace ball check valves and

seats with proper elastomers. Also, as the check

valve balls wear out, they become smaller and can

become stuck in the seats. In this case, replace balls

and seats.

Pump air valve freezes.

1. Check for excessive moisture in compressed

air. Either install a dryer or hot air generator for

compressed air. Alternatively, a coalescing fi lter

may be used to remove the water from the

compressed air in some applications.

Air bubbles in pump discharge.

1. Check for ruptured diaphragm.

2. Check tightness of outer pistons (refer to Section 7).

3. Check tightness of fasteners and integrity of o-rings

and seals, especially at intake manifold.

4. Ensure pipe connections are airtight.

Pump runs but little or no product fl ows.

1. Check for pump cavitation; slow pump speed down to

allow thick material to fl ow into liquid chambers.

WIL-12310-E-04 23 WILDEN PUMP & ENGINEERING, LLC

Product comes out air exhaust.

1. Check for diaphragm rupture.

2. Check tightness of outer pistons to shaft.

Page 26

Section 7 Assembly / Disassembly

Section 7

PUMP DISASSEMBLY

Tools Required :

• Adjustable Wrench

• Vise equipped with

soft jaws (such as

plywood, plastic

or other suitable

material)

CAUTION: Before any maintenance or repair is attempted, the compressed air line

to the pump should be disconnected and all air pressure allowed to bleed from the

pump. Disconnect all intake, discharge, and air lines. Drain the pump by turning it

upside down and allowing any fl uid to fl ow into a suitable container. Be aware of

any hazardous effects of contact with your process fl uid.

NOTE: The model photographed for these instructions incorporates PTFE

diaphragms.

Step 1

Prior to assembly, alignment marks

should be placed on the liquid

chambers and air chambers to

assist with proper alignment during

reassembly.

WILDEN PUMP & ENGINEERING, LLC 24 WIL-12310-E-04

Step 2

Loosen the wing nut and remove

both discharge manifold clamp

bands.

Step 3

Remove the discharge manifold and

manifold gaskets.

Page 27

PUMP DISASSEMBLY

Step 4

Next, remove the clamp bands that

secure the ball valve housing to the

liquid chamber.

Step 5A

Next, remove the ball valve housing,

valve ball and gasket.

Step 5B

If your pump is fi tted with a

mushroom valve, remove the

mushroom valve housing,

mushroom valve and gasket.

Step 6

Loosen the wing nut and remove

the inlet manifold clamp bands.

WIL-12310-E-04 25 WILDEN PUMP & ENGINEERING, LLC

Step 7

Next, remove the clamp bands that

secure the ball valve housing to the

liquid chamber.

Step 8

Next, remove the ball valve

housing, valve ball and gasket from

liquid chamber. To ensure proper

alignment during reassembly of

manifold/liquid chamber interface,

turn off-set portion of valve

housing to the left or to the right.

This procedure works for the inlet

manifold and discharge manifold

connections.

Page 28

PUMP DISASSEMBLY

Step 9

Now the large clamp bands can be

removed. NOTE: Prior to assembly,

alignment marks should be placed

on the liquid chambers and air

chambers to assist with proper

alignment during reassembly.

Step 10A

Next, remove the liquid chamber

from the center section assembly.

Step 10B

If your pump is fi tted with an integral

piston diaphragm (IPD), when you

remove the liquid chamber you will

notice that there is no outer piston.

Step 11A

Using two adjustable wrenches,

turning in the opposite direction,

loosen and remove one of the two

outer pistons.

WILDEN PUMP & ENGINEERING, LLC 26 WIL-12310-E-04

Step 11B

If your pump is fi tted with an IPD,

the procedure for removing the

diaphragm is slightly different.

In this case, simply grasp the

diaphragm in two locations and turn

in a counter-clockwise direction.

Step 12A

After loosening and removing

the outer piston, the remaining

diaphragm assembly and shaft can

be removed from the center section

assembly.

Page 29

PUMP DISASSEMBLY

Step 12B

If your pump is fi tted with an IPD,

the procedure for removing the

diaphragm is the same.

WIL-GARD™ DIAPHRAGM SENSOR

Wil-Gard™ Diaphragm Sensor Removal

Step 1

After removing the inlet and

discharge manifold assemblies,

disconnect the Wil-Gard™ module

from the sensor wires.

Step 2

Next, remove the large clamp bands

and the liquid chamber on either

side of the pump.

Step 3

The Wil-Gard™ sensor cables can be

easily removed from the diaphragm

assembly by simply pulling them

from between the primary and backup diaphragm.

WIL-12310-E-04 27 WILDEN PUMP & ENGINEERING, LLC

Page 30

WIL-GARD™ DIAPHRAGM SENSOR

Wil-Gard™ Diaphragm Sensor Installation

Step 1

The Wil-Gard™ sensor wires must

be installed between the primary

diaphragm and the back-up

diaphragm, on both sides of the

pump, at the 6 o’clock position. They

should be positioned approximately

half the distance to the shaft from

the edge of the diaphragm.

Step 2

Prior to installing the liquid chamber,

and after positioning the Wil-Gard™

sensor cable between the primary

and back-up diaphragms, run the

sensor cable along the diaphragm

bead but outside the pump. Now

install the liquid chamber and large

clamp band.

Step 3

When installing the liquid chamber

and large clamp band, route the WilGard™ sensor cable to the inside of

the large clamp band fastener. Next,

reconnect the Wil-Gard™ module.

NOTE: Use caution to ensure that

the sensor wires are not damaged

or pinched by the clamp band.

WILDEN PUMP & ENGINEERING, LLC 28 WIL-12310-E-04

Page 31

AIR VALVE / CENTER SECTION DISASSEMBLY

Tools Required :

Tools Required:

• 3/16" Hex Head Wrench

• 1/4" Hex Head Wrench

• Snap Ring Pliers

• O-Ring Pick

CAUTION: Before any maintenance or repair is attempted, the compressed air line

to the pump should be disconnected and all air pressure allowed to bleed from the

pump. Disconnect all intake, discharge, and air lines. Drain the pump by turning it

upside down and allowing any fl uid to fl ow into a suitable container. Be aware of

hazardous effects of contact with your process fl uid.

Step 1

Using a 9/16” wrench, loosen the

bolts that connect the center section

to the stand. CAUTION: With bolts

removed, the center section is no

longer attached to the stand and

must be supported so that it does

not fall from the stand.

WIL-12310-E-04 29 WILDEN PUMP & ENGINEERING, LLC

Step 2

Remove the center section from the

stand.

Step 3

Using a 3/16” hex wrench, loosen

air valve bolts.

Page 32

AIR VALVE / CENTER SECTION DISASSEMBLY

Air Valve Gasket

Muffl er Gasket

Step 4

Remove muffl er plate and air valve

bolts from air valve assembly

exposing muffl er gasket for

inspection. Replace if necessary.

Step 5

Lift away air valve assembly

and remove air valve gasket for

inspection. Replace if necessary.

Step 6

Remove air valve end cap to expose

air valve spool by simply lifting up

on end cap once air valve bolts are

removed. NOTE: Pro-Flo V™ air

valve incorporates an end cap at

both ends of the air valve.

Step 7

Remove the air valve spool from the

air valve body by threading one air

valve bolt into the end of the air valve

spool and gently sliding the spool

out of the air valve body. Inspect

seals for signs of wear and replace

entire assembly if necessary. Use

caution when handling air valve

spool to prevent damaging seals.

NOTE: seals should not be removed

from assembly. Seals are not sold

separately.

WILDEN PUMP & ENGINEERING, LLC 30 WIL-12310-E-04

Step 8

Remove pilot sleeve retaining snap

ring on both sides of center section

with snap ring pliers.

Step 9

Remove pilot spool sleeve from

center section.

Page 33

AIR VALVE / CENTER SECTION DISASSEMBLY

Notched EndNotched End

Step 10

Using an o-ring pick, gently remove the o-ring from the opposite

side of the “notched end” on one side of the pilot spool. Gently

remove the pilot spool from pilot spool sleeve and inspect for nicks,

gouges and wear. Replace pilot sleeve or outer sleeve o-rings if

necessary. During re-assembly, never insert the pilot spool into the

sleeve with the “notched end” fi rst, this end incorporates the urethane

o-ring and will be damaged as it slides over the ports cut in the sleeve.

NOTE: seals should not be removed from pilot spool. Seals are not sold

separately.

Finding spares a nightmare?

Sleep easier with

PRODUCTS: AODDP

(Air Operated Double Diaphragm Pumps)

• Warren-Rupp

• ARO

• Other

PUMP PARTS

(Low Cost)

• Diaphragms

• Valve balls

• Valve seats

KNOWLEDGE & SERVICE

• Competitive pricing

• Delivery

• Service

• Inventory

These parts may exhibit

WARNING:

better life than OEM parts.

WIL-12310-E-04 31 WILDEN PUMP & ENGINEERING, LLC

Spectrom is not your typical after market part supplier. We do not

simply sell pump parts; we provide value added procurement solutions.

Our unique network enables us to purchase effectively, resulting in low

cost solutions. We also know that low purchase price is not enough

- quality, integrity and inventory are also important. Spectrom is

structured to provide Pre and Post sales support, giving our customers

value added application and pump knowledge.

Contact us to have a procurement solution developed for you. We don’t

just fit you into a generic system, we develop specific solutions that

achieve results.

Spectrom will ship your order from

our facility within 3 working days!

1-909-512-1261 www.spectromparts.com

Page 34

REASSEMBLY HINTS & TIPS

ASSEMBLY:

Upon performing applicable maintenance to the air

distrib ution system, the p ump can now be reass embled.

Please refer to the disassembly instructions for photos

and parts placement. To reassemble the pump, follow

the disassembly instructions in reverse order. The

air distribution system needs to be assembled fi rst,

then the diaphragms and fi nally the wetted path. The

following tips will assist in the assembly process.

• Lubricate air valve bore, center section shaft and pilot

spool bore with NLGI grade 2 white EP bearing grease

or equivalent.

• Clean the inside of the center section shaft bore to

ensure no damage is done to new shaft seals.

• A small amount of NLGI grade 2 white EP bearing

grease can be applied to the muffl er and air valve

gaskets to locate gaskets during assembly.

• Make sure that the exhaust port on the muffl er plate

is centered between the two exhaust ports on the

center section.

• Stainless bolts should be lubed to reduce the

possibility of seizing during tightening.

• Use a mallet to tap lightly on the large clamp bands

to seat the diaphragm before tightening.

MAXIMUM TORQUE SPECIFICATIONS

Description of Part Max. Torque

Air Valve 13.6 N·m (120 in-lbs)

Air Chamber Bolts 27.1 N·m (20 ft-lbs)

Outer Pistons, All 54.2 N·m (40 ft-lbs)

Center Block-to-Stand Bolt 44.7 N·m (33 ft-lbs)

Center Block-to-Bushing Bolt 44.7 N·m (33 ft-lbs)

Locking Pin 44.7 N·m (33 ft-lbs)

Anti-Rotation Bolt 67.8 N·m (50 ft-lbs)

Twist

Off-Set

Valve

Housing

NOTE: To ensure prop e r

alignment during reassembly of manifold/liquid

chamber interface, turn

off-set portion of valve

housing to the left or to

the right. This procedure

works for the inlet manifold and discharge manifold connections.

SHAFT SEAL INSTALLATION:

PRE-INSTALLATION

• Once all of the old seals have been removed, the

inside of the bushing should be cleaned to ensure

no debris is left that may cause premature damage

to the new seals.

INSTALLATION

The following tools can be used to aid in the installation

of the new seals:

Needle Nose Pliers

Phillips Screwdriver

Electrical Tape

• Wrap electrical tape around each leg of the needle nose

pliers (heat shrink tubing may also be used). This is done

to prevent damaging the inside surface of the new seal.

• With a new seal in hand, place the two legs of the needle

nose pliers inside the seal ring. (See Figure A.)

• Open the pliers as wide as the seal diameter will allow,

then with two fi ngers pull down on the top portion of

the seal to form kidney bean shape. (See Figure B.)

• Lightly clamp the pliers together to hold the seal into

the kidney shape. Be sure to pull the seal into as tight

of a kidney shape as possible, this will allow the seal to

travel down the bushing bore easier.

• With the seal clamped in the pliers, insert the seal into

the bushing bore and position the bottom of the seal

into the correct groove. Once the bottom of the seal is

seated in the groove, release the clamp pressure on the