Wilden PX1500 Engineering, Operation & Maintenance

EOM

Engineering

Operation &

Maintenance

PX1500

Advanced™ Series

Metal Pump

Where Innovation Flows

www.wildenpump.com

WI L- 112 30 - E -11

Replaces WIL-11230-E-10

TABLE OF CONTENTS

SECTION 1 CAUTIONS—READ FIRST! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SECTION 2 WILDEN PUMP DESIGNATION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

SECTION 3 HOW IT WORKS—PUMP & AIR DISTRIBUTION SYSTEM . . . . . . . . . . . . . . . . 3

SECTION 4 DIMENSIONAL DRAWINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

SECTION 5 PERFORMANCE

PX1500 Performance

Operating Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

How to Use this EMS Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

PX1500 Aluminum Performance Curves

Rubber-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

TPE-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

PTFE-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Full Stroke PTFE-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Ultra-Flex™-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

PX1500 Stainless Steel Performance Curves

Rubber-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

TPE-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

PTFE-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Full Stroke PTFE-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Ultra-Flex™-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

PX1500 Stainless Steel Drop-In Performance Curves

Rubber-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

TPE-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

PTFE-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Full Stroke PTFE-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Ultra-Flex™-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Suction Lift Curves

PX1500 Aluminum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

PX1500 Stainless Steel & Alloy C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

PX1500 Stainless Steel Drop-In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

SECTION 6 SUGGESTED INSTALLATION, OPERATION & TROUBLESHOOTING . . . . . . .30

SECTION 7 ASSEMBLY / DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

SECTION 8 EXPLODED VIEW & PARTS LISTING

PX1500 Aluminum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

PX1500 Stainless Steel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

PX1500 Stainless Steel Drop-In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

SECTION 9 ELASTOMER OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Section 1

CAUTIONS—READ FIRST!

CAUTION: Do not apply compressed air to the

exhaust port — pump will not function.

CAUTION: Do not over-lubricate air supply —

excess lubrication will reduce pump performance.

Pump is pre-lubed.

TEMPERATURE LIMITS:

Neoprene –17.7°C to 93.3°C 0°F to 200°F

Buna-N –12.2°C to 82.2°C 10°F to 180°F

EPDM –51.1°C to 137.8°C –60°F to 280°F

Viton

Wil-Flex™ –40°C to 107.2°C –40°F to 225°F

Sanifl ex™ –28.9°C to 104.4°C –20°F to 220°F

Polyurethane –12.2°C to 65.6°C 10°F to 150°F

Tetra-Flex™ PTFE w/Neoprene Backed

4.4°C to 107.2°C 40°F to 225°F

Tetra-Flex™ PTFE w/EPDM Backed

-10°C to 137°C 14°F to 280°F

PTFE 4.4°C to 104.4°C 40°F to 220°F

®

–40°C to 176.7°C –40°F to 350°F

CAUTION: When choosing pump materials, be

sure to check the temperature limits for all wetted

components. Example: Viton® has a maximum

limit of 176.7°C (350°F) but polypropylene has a

maximum limit of only 79°C (175°F).

CAUTION: Pumps should be thoroughly fl ushed

before installing into process lines. FDA and

USDA approved pumps should be cleaned and/

or sanitized before being used.

CAUTION: Always wear safety glasses when

operating pump. If diaphragm rupture occurs,

material being pumped may be forced out air

exhaust.

CAUTION: Before any maintenance or repair is

attempted, the compressed air line to the pump

should be disconnected and all air pressure

allowed to bleed from pump. Disconnect all

intake, discharge and air lines. Drain the pump

by turning it upside down and allowing any fl uid

to fl ow into a suitable container.

CAUTION: Blow out air line for 10 to 20 seconds

before attaching to pump to make sure all pipeline

debris is clear. Use an in-line air fi lter. A 5µ (micron)

air fi lter is recommended.

NOTE: When installing PTFE diaphragms, it is

important to tighten outer pistons simultaneously

(t urning in opp osite direc tions) to en sure tight fi t.

(See torque specifi cations in Section 7.)

CAUTION: Maximum temperature limits are

based upon mechanical stress only. Certain

chemicals will signifi cantly reduce maximum

safe operating temperatures. Consult Chemical

Resistance Guide (E4) for chemical compatibility

and temperature limits.

WARNING: Prevention of static sparking — If

static sparking occurs, fi re or explosion could

result. Pump, valves, and containers must be

grounded to a proper grounding point when

handling fl ammable fl uids and whenever

discharge of static electricity is a hazard.

CAUTION: Do not exceed 8.6 bar (125 psig) air

supply pressure.

CAUTION: The process fl uid and cleaning fl uids

must be chemically compatible with all wetted

pump components (see E4).

CAUTION: Do not exceed 82°C (180°F) air inlet

temperature for Pro-Flo X™ models.

NOTE: Cast Iron PTFE-fi tted pumps come

standard from the factory with expanded PTFE

gaskets installed in the diaphragm bead of the

liquid chamber. PTFE gaskets cannot be re-used.

Consult PS-TG for installation instructions during

reassembly.

NOTE: Before starting disassembly, mark a line

from each liquid chamber to its corresponding air

chamber. This line will assist in proper alignment

during reassembly.

CAUTION: Pro-Flo® pumps cannot be used in

submersible applications. Pro-Flo X™ is available

in both submersible and non-submersible

options. Do not use non-submersible Pro-Flo X™

models in submersible applications. Turbo-Flo®

pumps can be used in submersible applications.

CAUTION: Tighten all hardware prior to installation.

WI L-11230-E-11 1 WILDEN PUMP & ENGINEERING, LLC

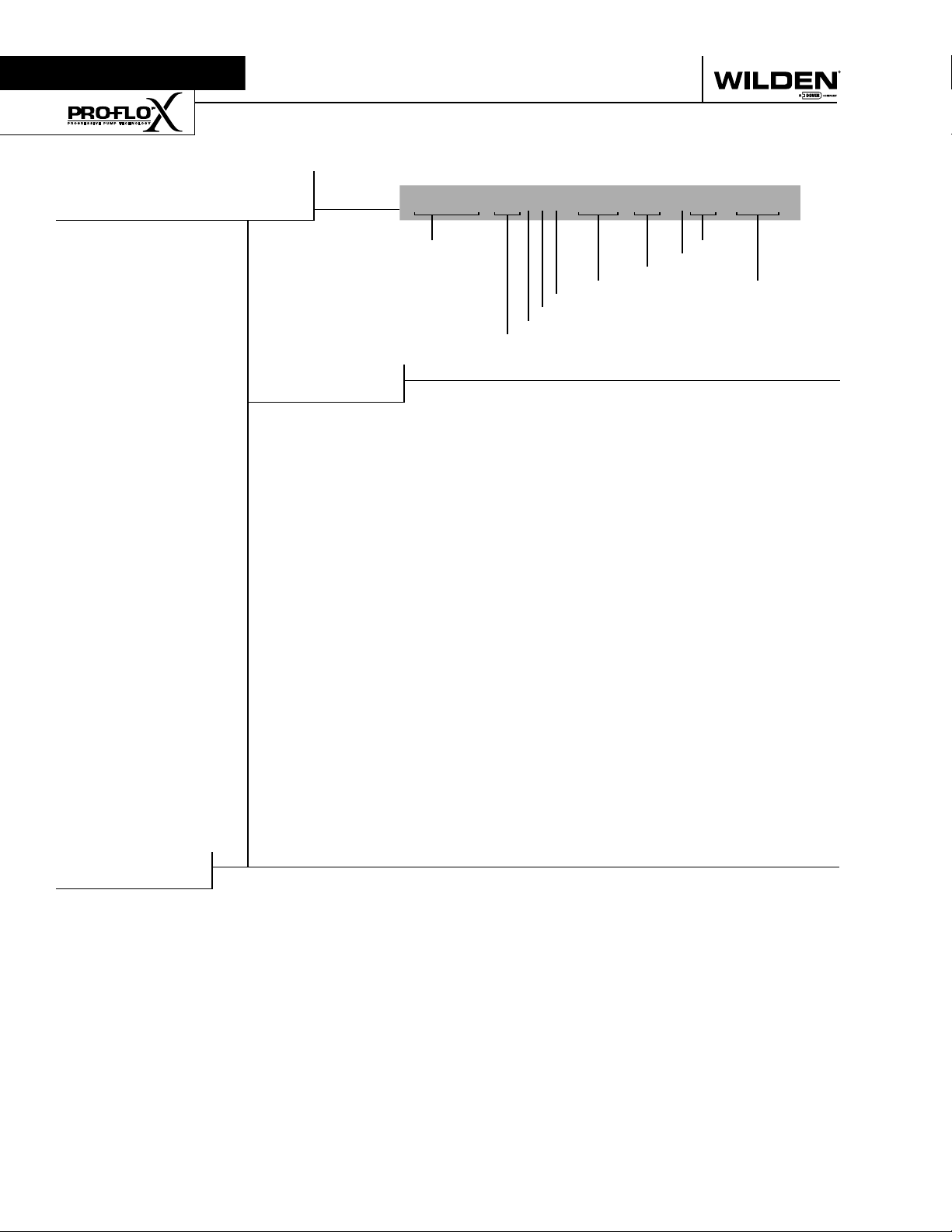

Section 2

WILDEN PUMP DESIGNATION SYSTEM

PX1500 METAL

76 mm (3") Pump

Maximum Flow Rate:

1030 lpm (272 gpm)

LEGEND

PX1500/XXXXX/XXX/XX/XXX/ XXXX

MODEL

AIR CHAMBERS

WETTED PAR TS & OUTER PISTON

MATERIAL CODES

MODEL

PX1500 = 76 mm (3")

XPX150 0 = 76 mm (3 " ) ATEX

WETTED PARTS/OUTER PISTON

AA = ALUMINUM / ALUMINUM

HH = ALL OY C / ALL OY C

SS = STAINLESS STEEL /

STAINLESS STEEL

AIR CHAMBERS

A = ALUMINUM

S = STAINLESS STEEL

C = PFA COATED

CENTER BLOCK

A = ALUMINUM

S = STAINLESS STEEL

P = POLYPROPYLENE

AIR VALVE

A = ALUMINUM

S = STAINLESS STEEL

P = POLYPROPYLENE

NOTE:

1

Reduced stroke PTFE-fitted pumps require stainless outer pistons.

Full Stroke PTFE-fitted pumps can have either stainless or aluminum outer pistons.

2

Meets the requirements of ATEX.

DIAPHRAGMS

BNS = BUNA-N (Red Dot)

XBS = CONDUCTIVE BUNA-N

(Two Red Dots)

1

EPS = EPDM (Blue Dot)

PUS = POLYURETHANE (Clear)

NES = NEOPRENE (Green Dot)

TEU = PTFE w/EPDM

BACK-UP (White)

TNU = PTFE w/NEOPRENE

BACK-UP (White)

FSS = SANIFLEX™ [Hytrel®

(Cream)]

FWS = SANITARY WIL-FLEXTM

VTS = VITON® (White Dot)

WFS = WIL-FLEX™ [Santoprene

(Orange Dot)]

TSU = PTFE W/SANIFLEX™

BACK-UP (White)

BNU = BUNA-N, ULTRA-FLEX™

EPU = EPDM, ULTRA-FLEX™

NEU = NEOPRENE,ULTRA-FLEX™

VTU = VITON®, ULTRA-FLEX™

TSS = FULL STROKE PTFE

W/SANIFLEX™ BACK-UP

TWS = FULL STROKE PTFE

W/WIL-FLEX™ BACK-UP

DIAPHRAGMS

AIR VALVE

CENTER BLOCK

2

2

2

2

O-RINGS

VALVE SEAT

VALVE BALL S

BALL VALVES

BN = BUNA-N (Red Dot)

FS = SANIFLEX™

[Hytrel® (Cream)]

EP = EPDM (Blue Dot)

NE = NEOPRENE (Green Dot)

PU = POLYURETHANE (Brown)

TF = PTFE (White)

VT = VITON® (Silver or White Dot)

WF = WIL-FLEX™ [Santoprene

(Orange Dot)]

VALVE SEAT

BN = BUNA-N (Red Dot)

EP = EPDM (Blue Dot)

®

FS = SANIFLEX™ [Hytrel®

(Cream)]

NE = NEOPRENE (Green Dot)

PU = POLYURETHANE (Brown)

VT = VITON® (Silver or

White Dot)

WF = WIL-FLEX™ [Santoprene®

(Orange Dot)]

M = MILD STEEL

S = STAINLESS STEEL

H = ALLOY C

VALVE SEAT O-RING

TF = PTFE (White)

SPECIALTY

CODE

(if applicable)

2

2

®

2

2

SPECIALTY CODES

Drop-In:

0044 Stallion balls & seats ONLY

0100 Wil-Gard II™ 110V

0102 Wil-Gard II™ sensor wires ONLY

0103 Wil-Gard II™ 220V

0320 Submersible center block

0323 Submersible center block, DIN flange

0540 ANSI flange

0544 DIN flange

NOTE: MOST EL AS TOMERIC MATERIALS USE COLORED DO TS FOR IDENT IFICATION.

NOTE: Not all models are available with all material options.

®

Viton

is a registered trademark of DuPont Dow Elastomers.

WILDEN PUMP & ENGINEERING, LLC 2 WI L-11230-E-11

0677 Center Ported, NPT Inlet & Discharge

0678 Center Ported, BSPT Inlet & Discharge

0685 Center Ported, NPT Inlet & Discharge, PCM Sensor & Wires

0687 Center Ported, NPT Inlet & Discharge, Single-point Exhaust

0688 Center Ported, BSPT Inlet and Discharge manifolds, Single-point Exhaust

0689 Center Ported, NPT inlet and discharge with external SS fasteners

0693 Center Ported, NPT, PFA Coated

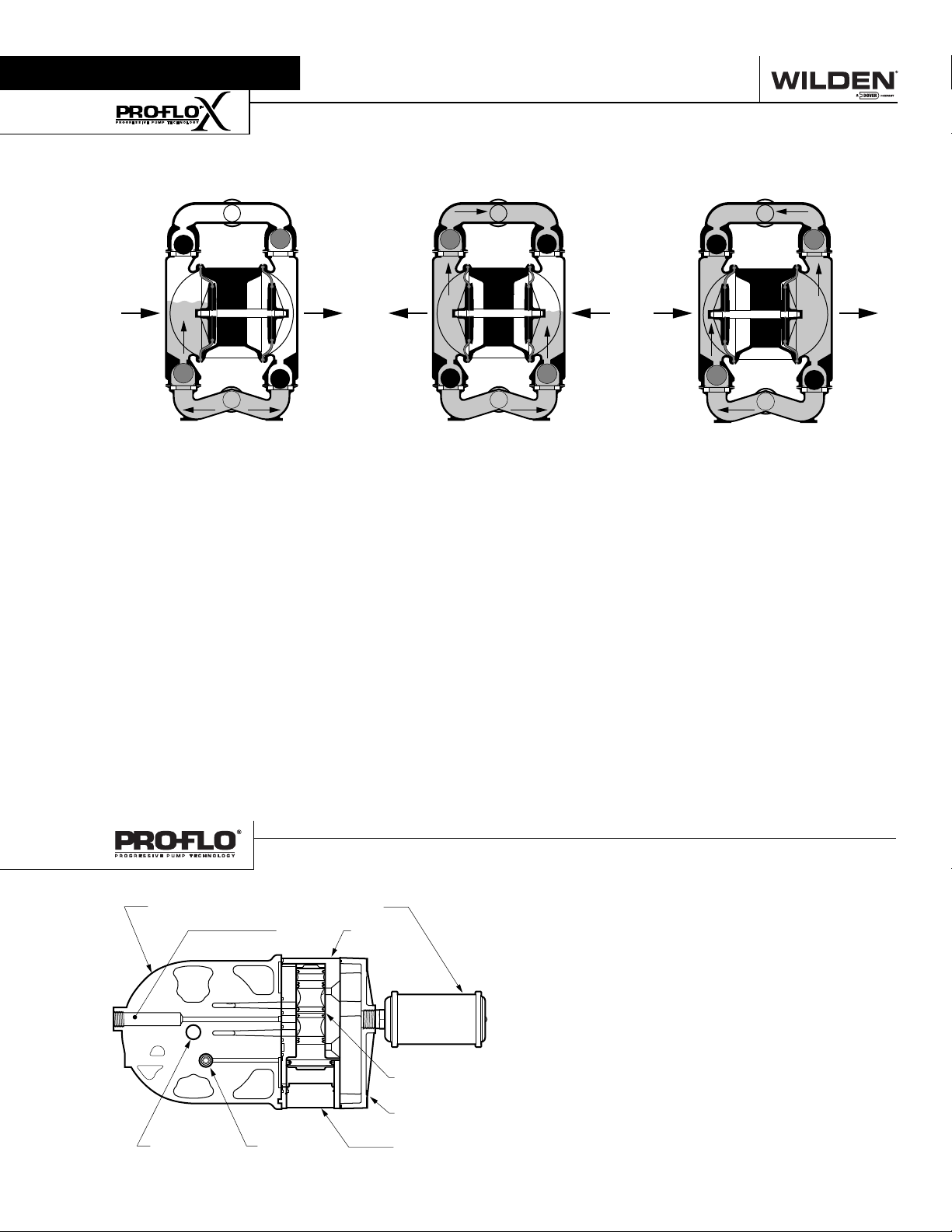

Section 3

HOW IT WORKS—PUMP

The Wilden diaphragm pump is an air-operated, positive displacement, self-priming pump. These drawings show fl ow pattern

through the pump upon its initial stroke. It is assumed the pump has no fl uid in it prior to its initial stroke.

#,/3%$

/54,%4

/0%.

"!

).,%4

FIGURE 1 The air valve dir ects pre ssurized

air to the back side of diaphragm A. The

compressed air is applied directly to the

liquid column separated by elastomeric

diaphragms. The diaphragm acts as

a separation membrane between the

compressed air and liquid, balancing the

load and removing mechanical stress

from the diaphragm. The compressed

air moves the diaphragm away from

the center of the pump. The opposite

diaphragm is pulled in by the shaft

connected to the pressurized diaphragm.

Diaphragm B is on its suction stroke; air

behind the diaphragm has been forced

out to atmosphere through the exhaust

port of the pump. The movement of

diaphragm B toward the center of the

pump creates a vacuum within chamber B.

Atmospheric pressure forces fl uid into

the inlet manifold forcing the inlet valve

ball off its seat. Liquid is free to move

past the inlet valve ball and fi ll the liquid

chamber (see shaded area).

#,/3%$/0%.

#,/3%$ /0%.

FIGURE 2

phragm

of its discharge stroke, the air valve

redirects pressurized air to the back side of

diaphragm B. The pressurized air forces

diaphragm B away from the center

while pulling diaphragm A to the center.

Diaphragm B is now on its discharge

stroke. Diaphragm B forces the inlet valve

ball onto its seat due to the hydraulic

forces developed in the liquid chamber

and manifold of the pump. These same

hydraulic forces lift the discharge valve

ball off its seat, while the opposite

discharge valve ball is forced onto its seat,

forcing fl uid to fl ow through the pump

discharge. The movement of diaphragm A

toward the center of the pump creates a

vacuum within liquid chamber A. Atmospheric pressure forces fl uid into the inlet

manifold of the pump. The inlet valve ball

is forced off its seat allowing the fl uid

being pumped to fi ll the liquid chamber.

/0%.

/54,%4

#,/3%$

"!

).,%4

When the pressurized dia-

, diaphragm A, reaches the limit

#,/3%$ /0%.

"!

/0%.

FIGURE 3 At completion of the stroke,

the air valve again redirects air to the

back side of diaphragm A, which starts

diaphragm B on its exhaust stroke. As

the pump reaches its original starting

point, each diaphragm has gone through

one exhaust and one discharge stroke.

This constitutes one complete pumping

cycle. The pump may take several cycles

to completely prime depending on the

conditions of the application.

/54,%4

).,%4

#,/3%$

HOW IT WORKS—AIR DISTRIBUTION SYSTEM

-5&&,%2#%.4%23%#4)/.

!)2).,%4 !)26!,6%

!)26!,6%30//,

-5&&,%20,!4%

-!).3(!&4

WI L-11230-E-11 3 WILDEN PUMP & ENGINEERING, LLC

0),/430//,

%.$#!0

The Pro -Flo

moving parts: the air valve spool and the pilot spool. The heart of

the system is the air valve spool and air valve. This valve design

incorporates an unbalanced spool. The smaller end of the spool

is pressurized continuously, while the large end is alternately

pressurized then exhausted to move the spool. The spool directs

pressurized air to one air chamber while exhausting the other.

The air causes the main shaft /diaphragm assembly to shift to

one side — discharging liquid on that side and pulling liquid in

on the other side. When the shaft reaches the end of its stroke,

the inner piston actuates the pilot spool, which pressurizes and

exhausts the large end of the air valve spool. The repositioning

of the air valve spool routes the air to the other air chamber.

®

patented air distribution system incorporates two

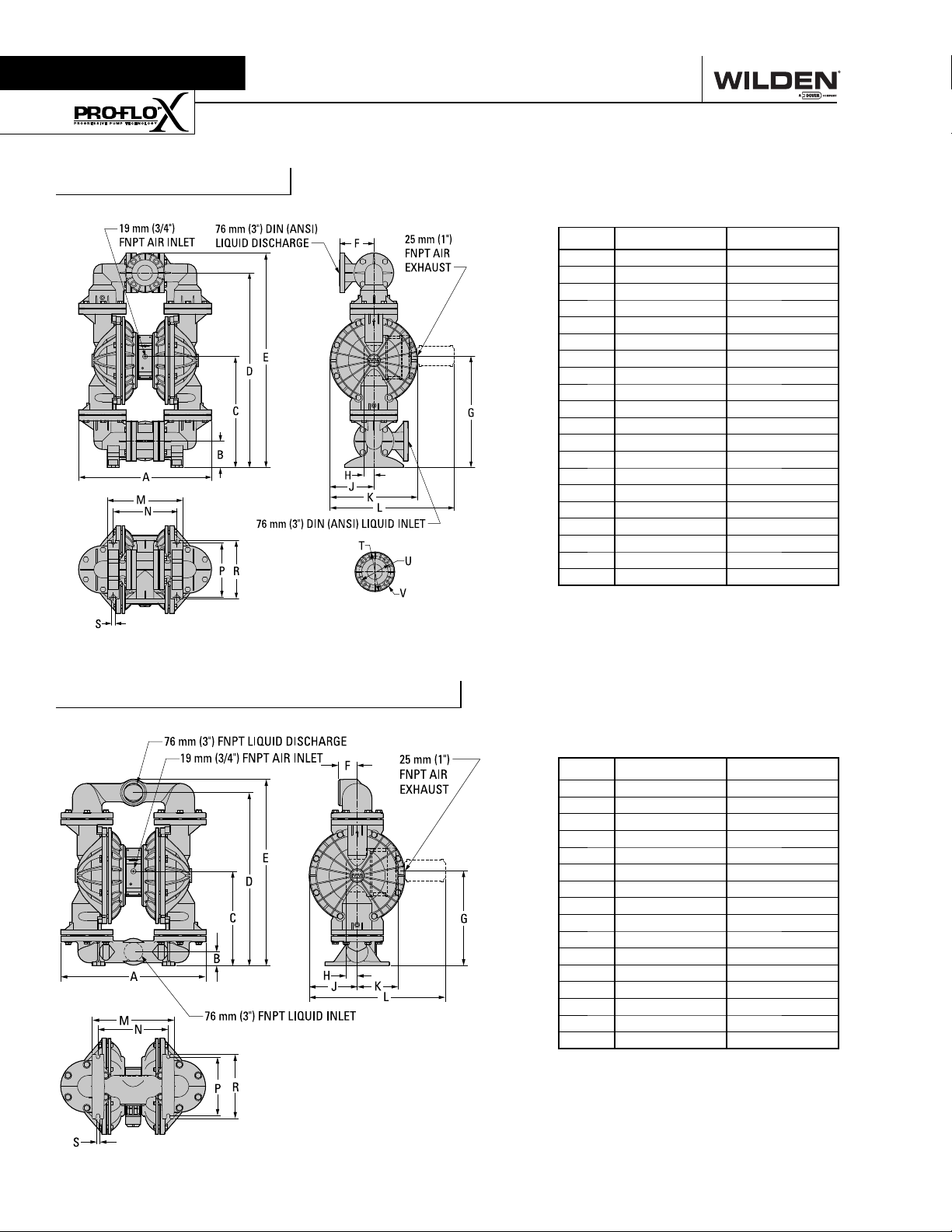

Section 4

DIMENSIONAL DRAWINGS

PX1500 Aluminum

DIMENSIONS

ITEM METRIC (mm) STANDARD (inch)

A 615 24.2

B 127 5.0

C 533 21.0

D 934 36.8

E 1031 40.6

F 165 6.5

G 536 21.1

H 48 1.9

J 211 8.3

K 422 16.6

L 597 23.5

M 363 14.3

N 307 12.1

P 259 10.2

R 282 11.1

S 18 0.7

DIN (mm) ANSI (inch)

T 200 DIA. 7.5 DIA.

U 160 DIA. 6.0 DIA.

V 18 DIA. 0.8 DIA.

PX1500 Aluminum Drop-In Type

DIMENSIONS

ITEM METRIC (mm) STANDARD (inch)

A 635 25.0

B 61 2.4

C 414 16.3

D 760 29.9

E 818 32.2

F 84 3.3

G 417 16.4

H 48 1.9

J 211 8.3

K 178 7.0

L 597 23.5

M 358 14.1

N 307 12.1

P 257 10.1

R 282 11.1

S 15 0.6

WILDEN PUMP & ENGINEERING, LLC 4 WI L-11230-E-11

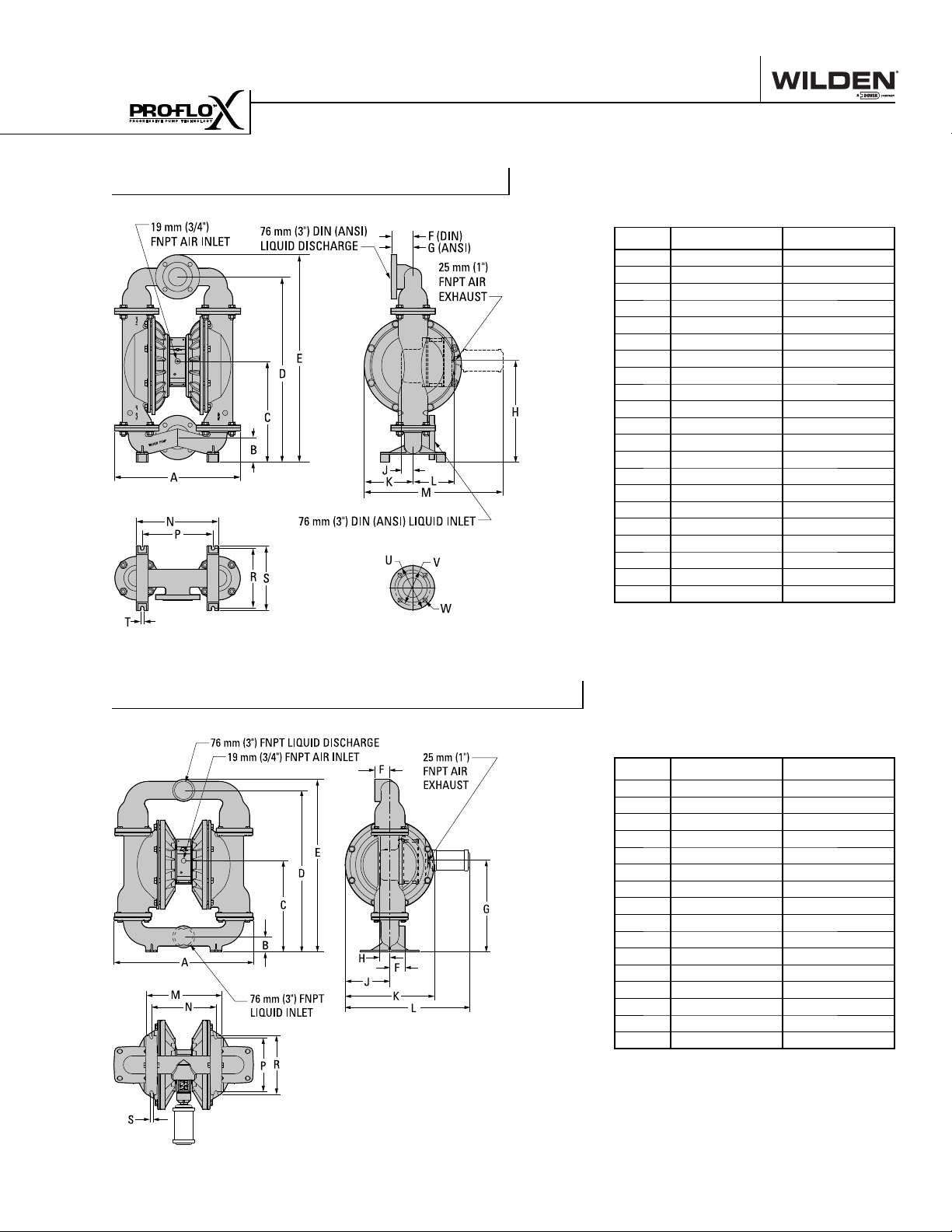

DIMENSIONAL DRAWINGS

PX1500 Stainless Steel/Alloy C

DIMENSIONS

ITEM METRIC (mm) STANDARD (inch)

A 541 21.3

B 107 4.2

C 434 17.1

D 798 31.4

E 894 35.2

F 89 3.5

G 91 3.6

H 437 17.2

J 48 1.9

K 211 8.3

L 178 7.0

M 597 23.5

N 356 14.0

P 305 12.0

R 257 10.1

S 279 11.0

T 15 0.6

DIN (mm) ANSI (inch)

U 200 DIA. 7.5 DIA.

V 160 DIA. 6.0 DIA.

W 18 DIA. 0.8 DIA.

PX1500 Stainless Steel Drop-In Type

DIMENSIONS

ITEM METRIC (mm) STANDARD (inch)

A 650 25.6

B 71 2.8

C 432 17

D 765 30.1

E 815 32.1

F 71 2.8

G 434 17.1

H 48 1.9

J 211 8.3

K 422 16.6

L 589 23.2

M 356 14

N 305 12

P 257 10.1

R 279 11

S 15 0.6

REV A

WI L-11230-E-11 5 WILDEN PUMP & ENGINEERING, LLC

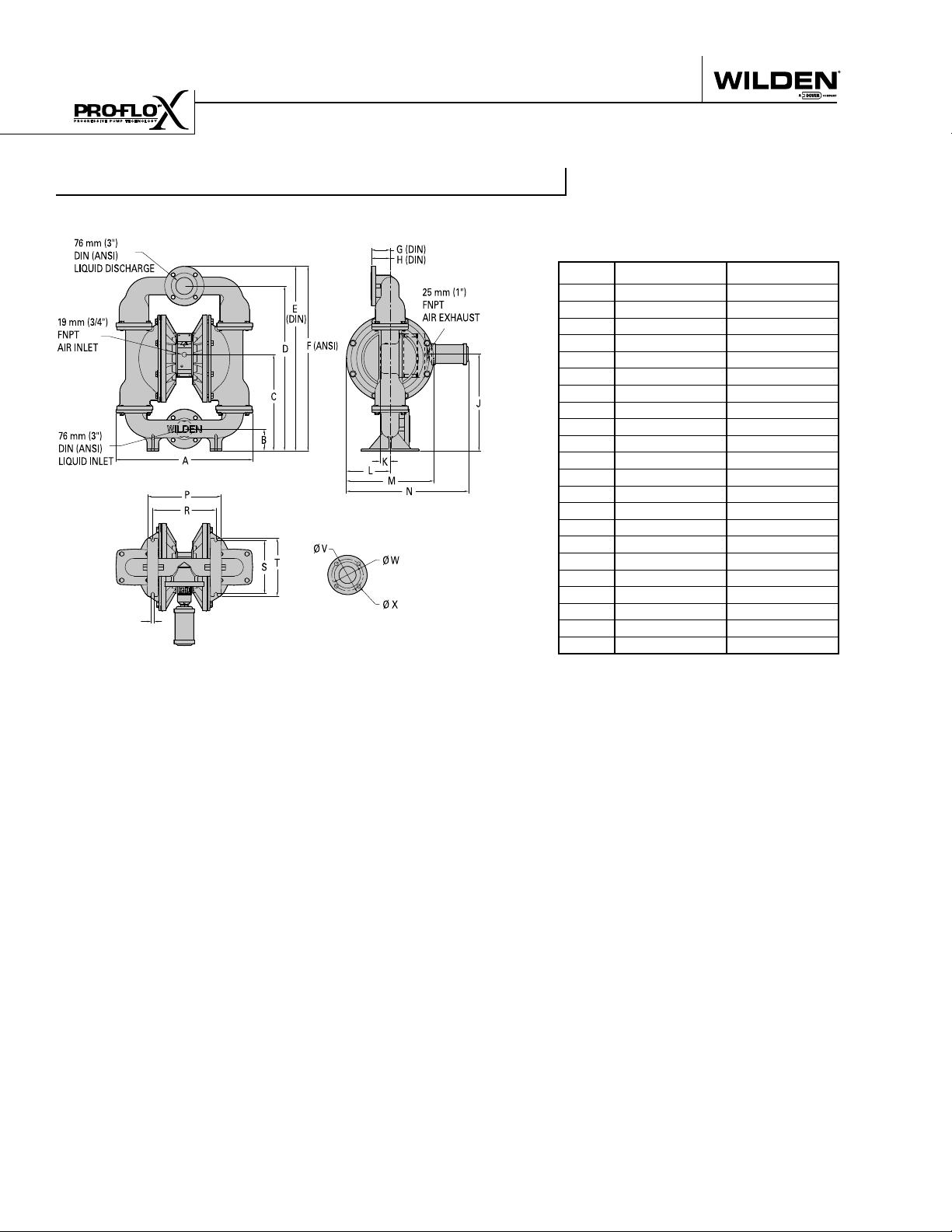

DIMENSIONAL DRAWINGS

PX1500 Stainless Steel Drop-In Flanged

DIMENSIONS

ITEM METRIC (mm) STANDARD (inch)

A 659 26.0

B 105 4.1

C 465 18.3

D 796 31.3

E 896 35.3

F 890 35.1

G 88 3.5

H 90 3.6

J 467 18.4

K 49 1.9

L 211 8.3

M 422 16.6

N 591 23.3

P 356 14.0

R 305 12.0

S 256 10.1

T 279 11.0

U14 .6

DIN (mm) ANSI (inch)

V 200 DIA. 7.5 DIA.

W 160 DIA. 6.0 DIA.

X 18 DIA. 0.8 DIA.

REV A

WILDEN PUMP & ENGINEERING, LLC 6 WI L-11230-E-11

PX1500

M E T A L

PX1500 PERFORMANCE

Section 5

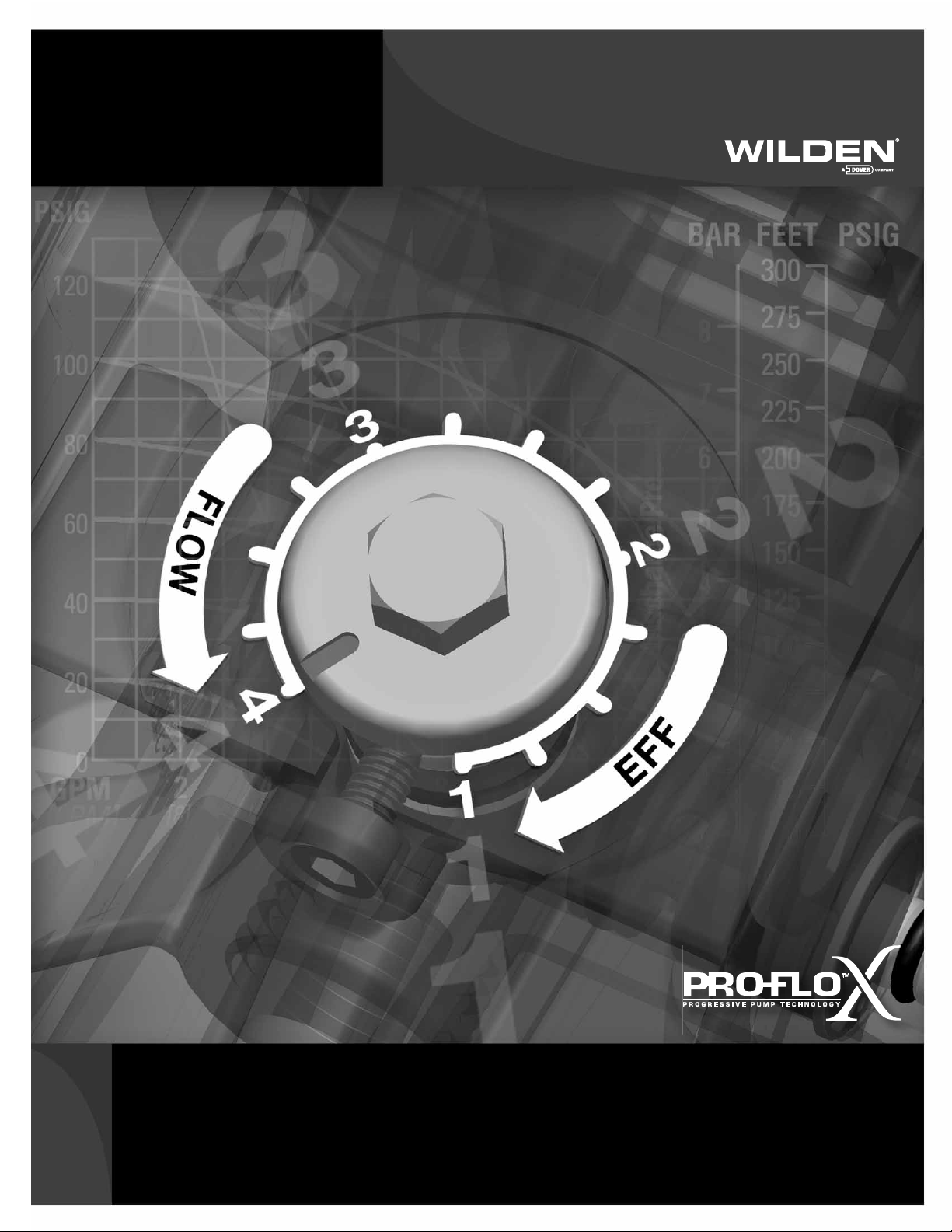

Pro-Flo X

The Pro-Flo X™ air distribution system with the

revolutionary Effi ciency Management System (EMS)

offers fl exibility never before seen in the world of

AODD pumps. The

patent-pending EMS

is simple and easy

to use. With the

turn of an integrated

TM

Operating Principle

control dial, the operator can select the optimal

balance of fl ow and effi ciency that best meets the

application needs. Pro-Flo X™ provides higher

performance, lower

operational costs

and fl exibility that

exceeds previous

industry standards.

AIR CONSUMPTION

$

$

$

Turning the dial

changes the

relationship

between air inlet

and exhaust

porting.

WILDEN PUMP & ENGINEERING, LLC 8 PX1500 Performance

Each dial setting

represents an

entirely different

fl ow curve

Pro-Flo X™ pumps

are shipped from

the factory on

setting 4, which

is the highest

fl ow rate setting

possible

Moving the dial

from setting 4

causes a decrease

in fl ow and an even

greater decrease in

air consumption.

When the air

consumption

decreases more

than the fl ow

rate, effi ciency

is improved and

operating costs

are reduced.

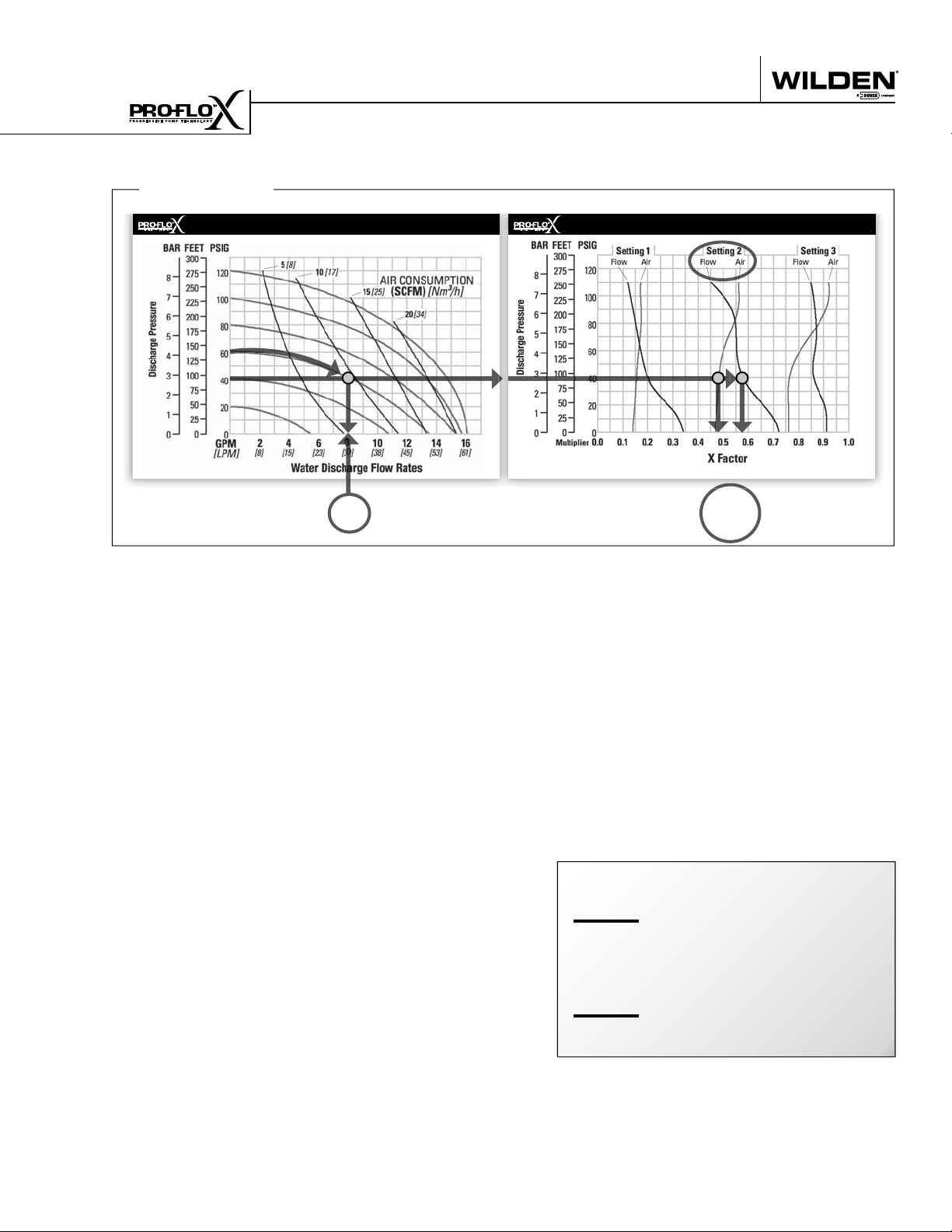

Example 1

HOW TO USE THIS EMS CURVE

SETTING 4 PERFORMANCE CURVE

Figure 1 Figure 2

Example data point = Example data point =

This is an example showing how to determine fl ow rate and

air consumption for your Pro-Flo X™ pump using the Effi ciency Management System (EMS) curve and the performance

curve. For this example we will be using 4.1 bar (60 psig) inlet

air pressure and 2.8 bar (40 psig) discharge pressure and EMS

setting 2.

Step 1:

Identifying performance at setting 4. Locate

the curve that represents the fl ow rate of the

pump with 4.1 bar (60 psig) air inlet pressure.

Mark the point where this curve crosses the

horizontal line representing 2.8 bar (40 psig)

discharge pressure. (Figure 1). After locating

your performance point on the fl ow curve,

draw a vertical line downward until reaching

the bottom scale on the chart. Identify the fl ow

rate (in this case, 8.2 gpm). Observe location

of performance point relative to air consumption curves and approximate air consumption

value (in this case, 9.8 scfm).

8.2

GPM

curve, draw vertical lines downward until

reaching the bottom scale on the chart. This

identifi es the fl ow X Factor (in this case, 0.58)

and air X Factor (in this case, 0.48).

Step 3:

Calculating performance for specific EMS

setting. Multiply the fl ow rate (8.2 gpm)

obtained in Step 1 by the fl ow X Factor multiplier (0.58) in Step 2 to determine the fl ow rate

at EMS setting 2. Multiply the air consumption (9.8 scfm) obtained in Step 1 by the air

X Factor multiplier (0.48) in Step 2 to determine the air consumption at EMS setting 2

(Figure 3).

8.2

gpm

.58

4.8

gpm

0.58

0.48

(fl ow rate for Setting 4)

(Flow X Factor setting 2)

(Flow rate for setting 2)

EMS CURVE

fl ow multiplier

air multiplier

Step 2:

Determining flow and air X Factors. Locate

your discharge pressure (40 psig) on the vertical axis of the EMS curve (Figure 2). Follow

along the 2.8 bar (40 psig) horizontal line until

intersecting both fl ow and air curves for your

desired EMS setting (in this case, setting 2).

Mark the points where the EMS curves intersect the horizontal discharge pressure line.

After locating your EMS points on the EMS

PX1500 Performance 9 WILDEN PUMP & ENGINEERING, LLC

9.8

scfm

(air consumption for setting 4)

.48

4.7

Figure 3

The fl ow rate and air consumption at Setting

2 are found to be 18.2 lpm (4.8 gpm) and 7.9

Nm3/h (4.7 scfm) respectively.

(Air X Factor setting 2)

scfm

(air consumption for setting 2)

HOW TO USE THIS EMS CURVE

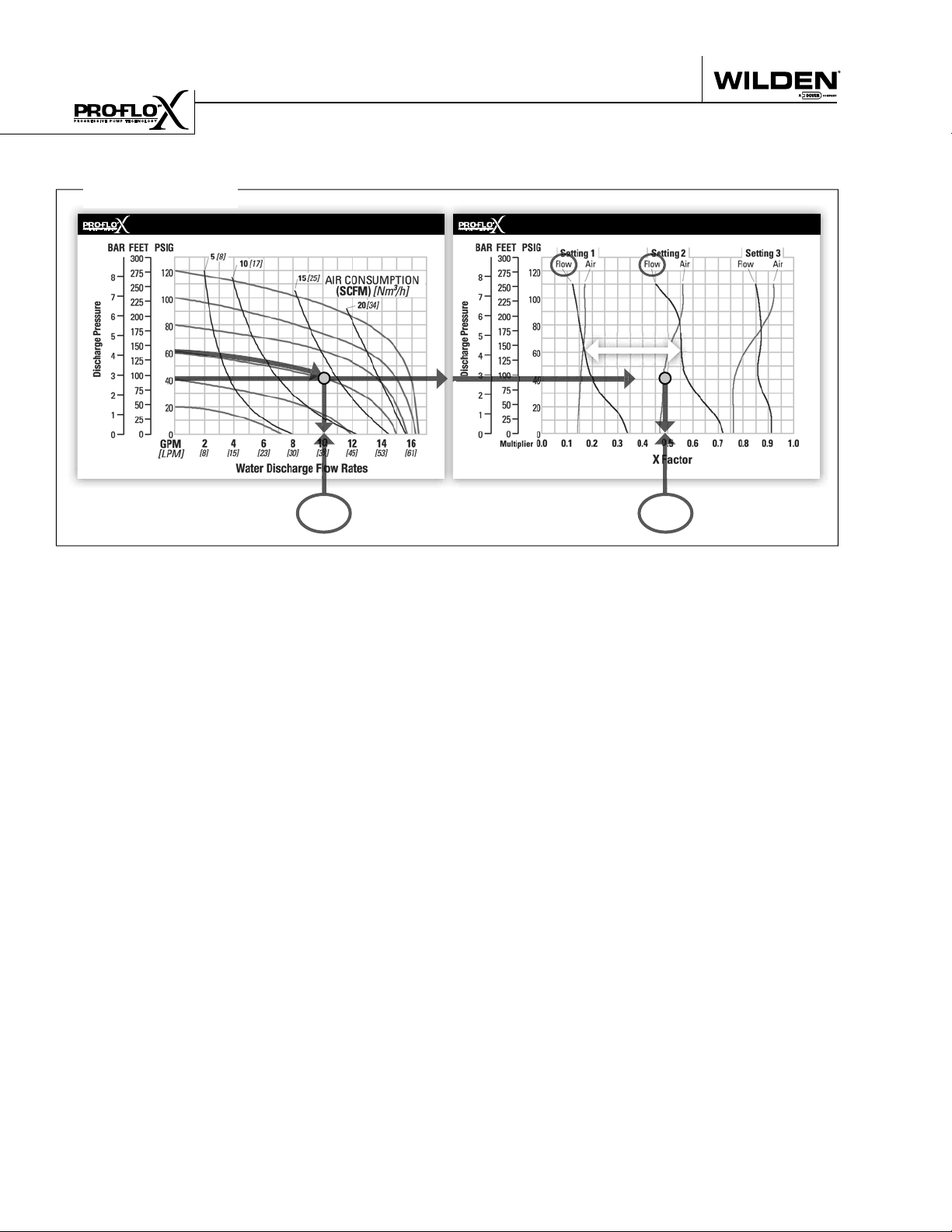

Example 2.1

SETTING 4 PERFORMANCE CURVE

Figure 4

Example data point =

This is an example showing how to determine the inlet air

pressure and the EMS setting for your Pro-Flo X™ pump to

optimize the pump for a specifi c application. For this example we will be using an application requirement of 18.9 lpm

(5 gpm) fl ow rate against 2.8 bar (40 psig) discharge pressure.

This example will illustrate how to calculate the air consumption that could be expected at this operational point.

10.2

gpm

DETERMINE EMS SETTING

Step 1

: Establish inlet air pressure. Higher air pres-

sures will typically allow the pump to run

more effi ciently, however, available plant air

pressure can vary greatly. If an operating

pressure of 6.9 bar (100 psig) is chosen when

EMS Flow

Settings 1 & 2

0.49

In our example it is 38.6 lpm (10.2 gpm). This

is the setting 4 fl ow rate. Observe the location of the performance point relative to air

consumption curves and approximate air

consumption value. In our example setting

4 air consumption is 24 Nm3/h (14 scfm).

See fi gure 4.

Step 3

: Determine flow X Factor. Divide the required

fl ow rate 18.9 lpm (5 gpm) by the setting 4 fl ow

rate 38.6 lpm (10.2 gpm) to determine the fl ow

X Factor for the application.

5

gpm / 10.2 gpm = 0.49 (flow X Factor)

EMS CURVE

Figure 5

fl ow multiplier

plant air frequently dips to 6.2 bar (90 psig)

Step 4

pump performance will vary. Choose an operating pressure that is within your compressed

air system's capabilities. For this example we

will choose 4.1 bar (60 psig).

: Determine EMS setting from the flow

X Factor. Plot the point representing the fl ow

X Factor (0.49) and the application discharge

pressure 2.8 bar (40 psig) on the EMS curve.

This is done by following the horizontal 2.8

Step 2

: Determine performance point at setting 4. For

this example an inlet air pressure of 4.1 bar

(60 psig) inlet air pressure has been chosen.

Locate the curve that represents the performance of the pump with 4.1 bar (60 psig) inlet

air pressure. Mark the point where this curve

crosses the horizontal line representing 2.8

bar (40 psig) discharge pressure. After locating this point on the fl ow curve, draw a vertical line downward until reaching the bottom

scale on the chart and identify the fl ow rate.

bar (40 psig) psig discharge pressure line until

it crosses the vertical 0.49 X Factor line. Typically, this point lies between two fl ow EMS

setting curves (in this case, the point lies between the fl ow curves for EMS setting 1 and

2). Observe the location of the point relative

to the two curves it lies between and approximate the EMS setting (fi gure 5). For more precise results you can mathematically interpolate between the two curves to determine the

optimal EMS setting.

For this example the EMS setting is 1.8.

WILDEN PUMP & ENGINEERING, LLC 10 PX1500 Performance

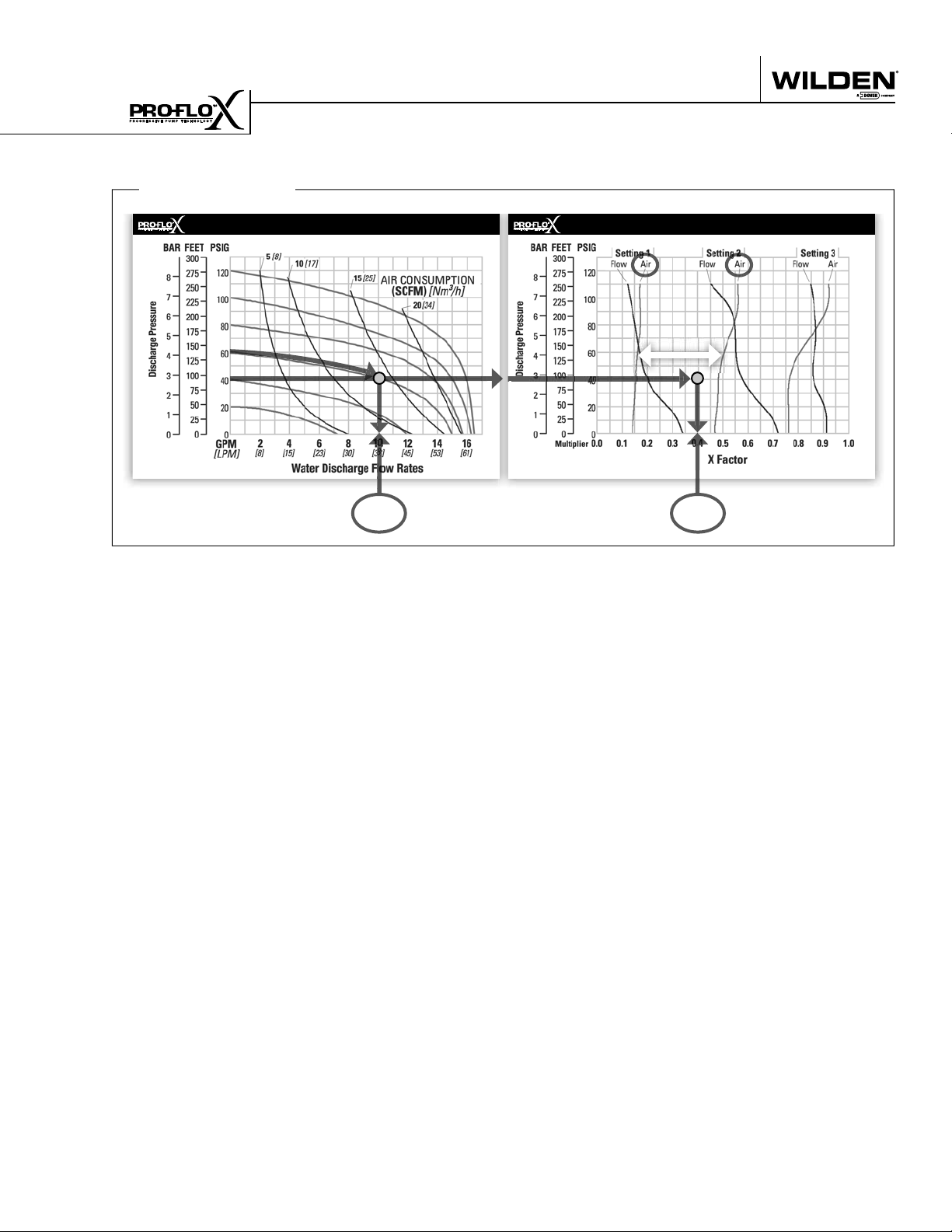

HOW TO USE THIS EMS CURVE

Example 2.2

SETTING 4 PERFORMANCE CURVE

Figure 6

Example data point =

10.2

gpm

Determine air consumption at a specific

EMS setting.

Step 1

: Determine air X Factor. In order to determine

the air X Factor, identify the two air EMS setting curves closest to the EMS setting established in example 2.1 (in this case, the point lies

between the air curves for EMS setting 1 and

2). The point representing your EMS setting

(1.8) must be approximated and plotted on the

EMS curve along the horizontal line representing your discharge pressure (in this case, 40

psig). This air point is different than the fl ow

point plotted in example 2.1. After estimating

(or interpolating) this point on the curve, draw

a vertical line downward until reaching the

bottom scale on the chart and identify the air

X Factor (fi gure 7).

EMS CURVE

EMS Air

Settings 1 & 2

Figure 7

Example data point =

Step 2

: Determine air consumption. Multiply your

setting 4 air consumption (14 scfm) value by

the air X Factor obtained above (0.40) to determine your actual air consumption.

1

4 scfm x 0.40 = 5.6 SCFM

In summary, for an application requiring 18.9 lpm

(5 gpm) against 2.8 bar (40 psig) discharge pressure,

the pump inlet air pressure should be set to 4.1 bar

(60 psig) and the EMS dial should be set to 1.8. The

pump would then consume 9.5 Nm3/h (5.6 scfm) of

compressed air.

0.40

air multiplier

For this example the air X Factor is 0.40

PX1500 Performance 11 WILDEN PUMP & ENGINEERING, LLC

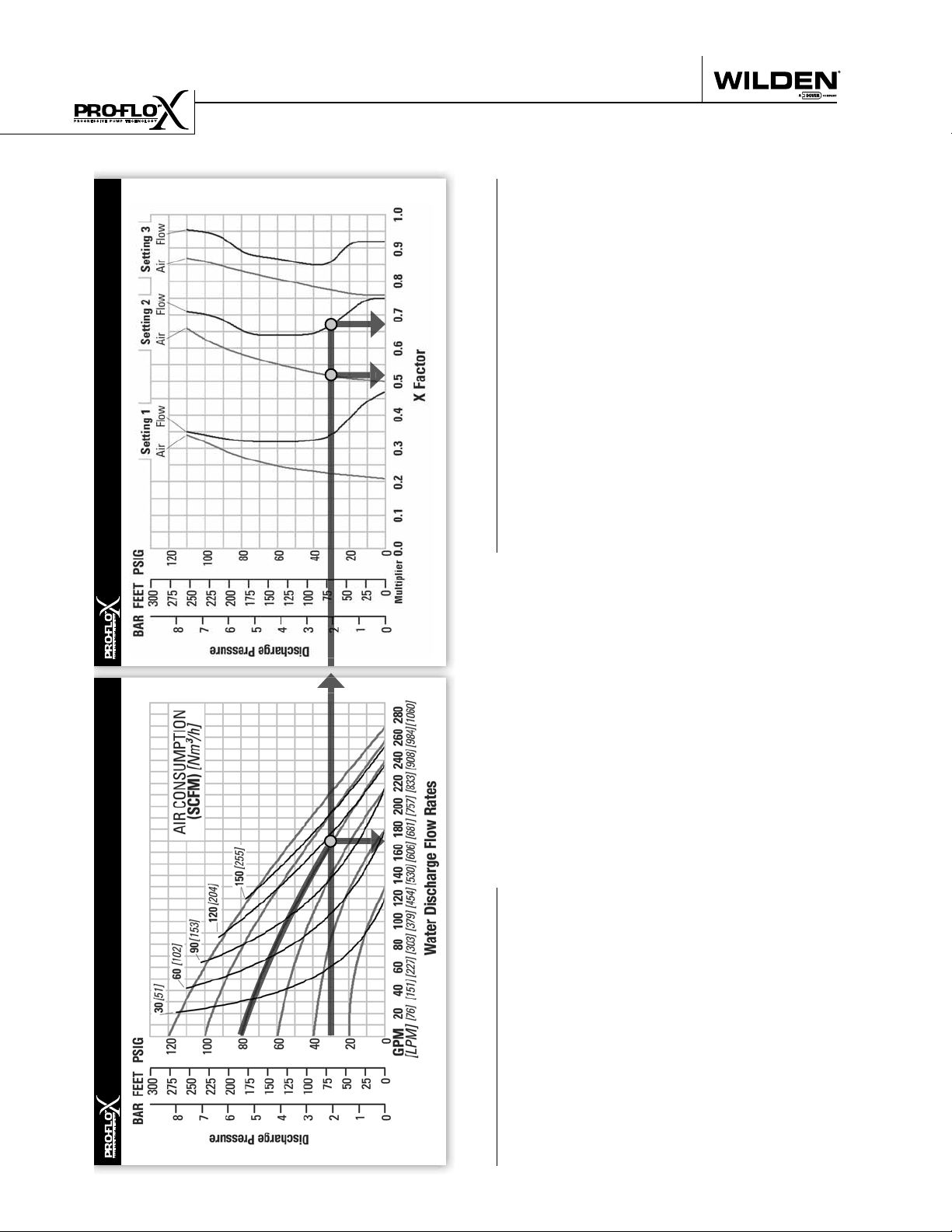

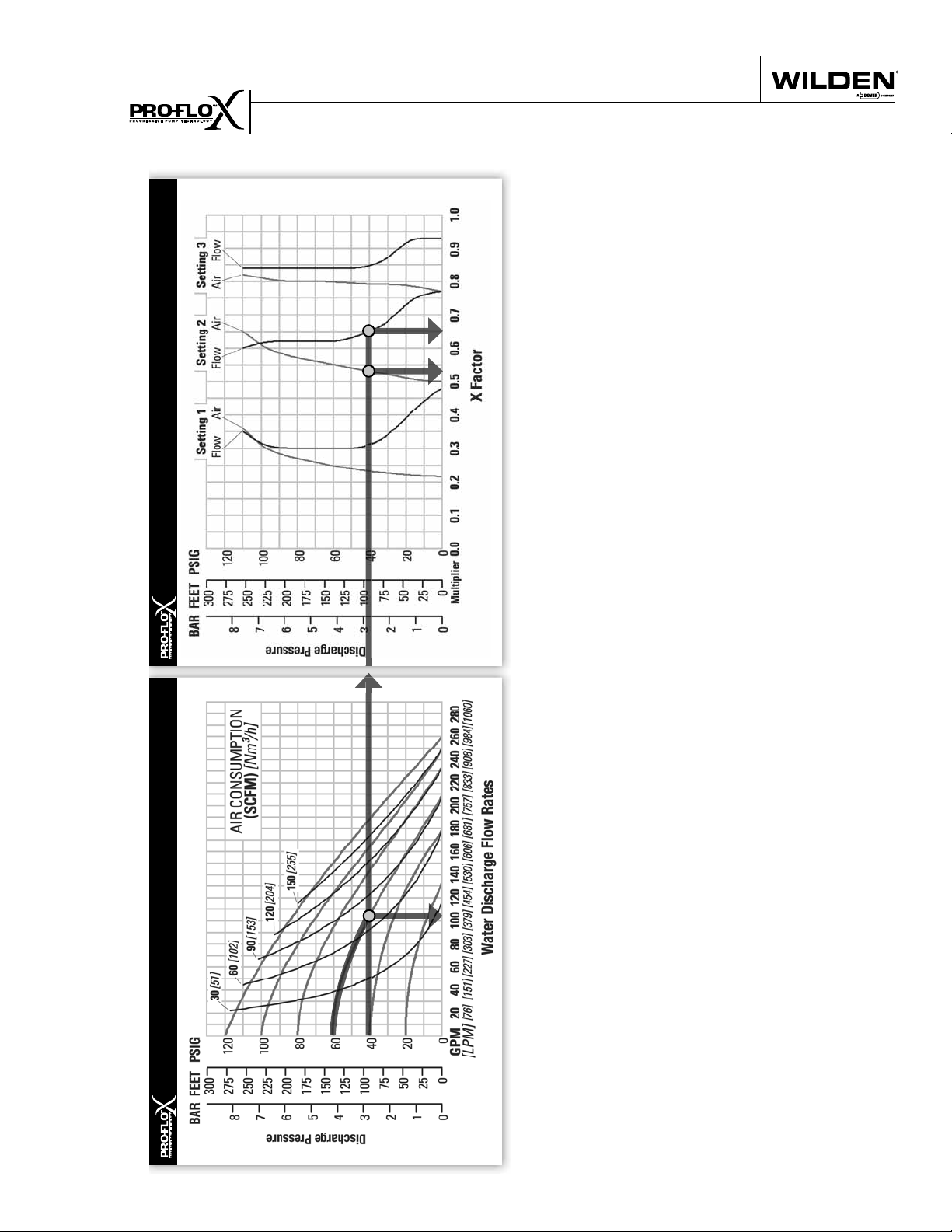

EMS CURVE

PERFORMANCE

/h (113 scfm)

3

EXAMPLE

A PX1500 aluminum, Rubber-fi tted pump operating at EMS setting 4,

achieved a fl ow rate of 640 lpm (169 gpm) using 192 Nm

of air when run at 5.5 bar (80 psig) air inlet pressure and 2.1 bar

(30 psig) discharge pressure (See dot on performance curve).

The end user did not require that much fl ow and wanted to reduce

air consumption at his facility. He determined that EMS setting 2

would meet his needs. At 2.1 bar (30 psig) discharge pressure and

EMS setting 2, the fl ow “X factor” is 0.67 and the air “X factor” is

0.52 (see dots on EMS curve).

/h (59 scfm). The fl ow rate was reduced by 33% while

3

Multiplying the original setting 4 values by the “X factors” provides

the setting 2 fl ow rate of 429 lpm (113 gpm) and an air consumption

of 100 Nm

the air consumption was reduced by 48%, thus providing increased

effi ciency.

For a detailed example for how to set your EMS, see beginning of

performance curve section.

Caution: Do not exceed 8.6 bar (125 psig) air supply pressure.

The Effi ciency Management System (EMS)

can be used to optimize the performance of

your Wilden pump for specifi c applications.

The pump is delivered with the EMS adjusted

to setting 4, which allows maximum fl ow.

The EMS curve allows the pump user to deter-

mine fl ow and air consumption at each EMS

setting. For any EMS setting and discharge

pressure, the “X factor” is used as a multi-

plier with the original values from the setting

4 performance curve to calculate the actual

fl ow and air consumption values for that spe-

cifi c EMS setting. Note: you can interpolate

between the setting curves for operation at

intermediate EMS settings.

1

SETTING 4 PERFORMANCE CURVE

Displacement per stroke was calculated at 4.8 bar (70 psig)

TECHNICAL DATA

Height . . . . . . . . . . . . . . . . . . . . . . . . .1031 mm (40.6”)

Width. . . . . . . . . . . . . . . . . . . . . . . . . . .615 mm (24.2”)

Depth. . . . . . . . . . . . . . . . . . . . . . . . . . .422 mm (16.6”)

Ship Weight . . . . . . . . . . . Aluminum 83 kg (182 lbs.)

Aluminum Drop-In 70 kg (152 lbs.)

Air Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . 19 mm (3/4”)

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76 mm (3”)

Outlet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76 mm (3”)

Suction Lift . . . . . . . . . . . . . . . . . . . . .6.1 m Dry (19.9’)

8.8 m Wet (28.9’)

Disp. Per Stroke. . . . . . . . . . . . . . . . 5.22 l (1.38 gal.)

Max. Flow Rate . . . . . . . . . . . . . .1021 lpm (270 gpm)

PX1500 ALUMINUM RUBBER-FITTED

WILDEN PUMP & ENGINEERING, LLC 12 PX1500 Performance

Max. Size Solids . . . . . . . . . . . . . . . . . 12.7 mm (1/2”)

air inlet pressure against a 2 bar (30 psig) head pressure.

1

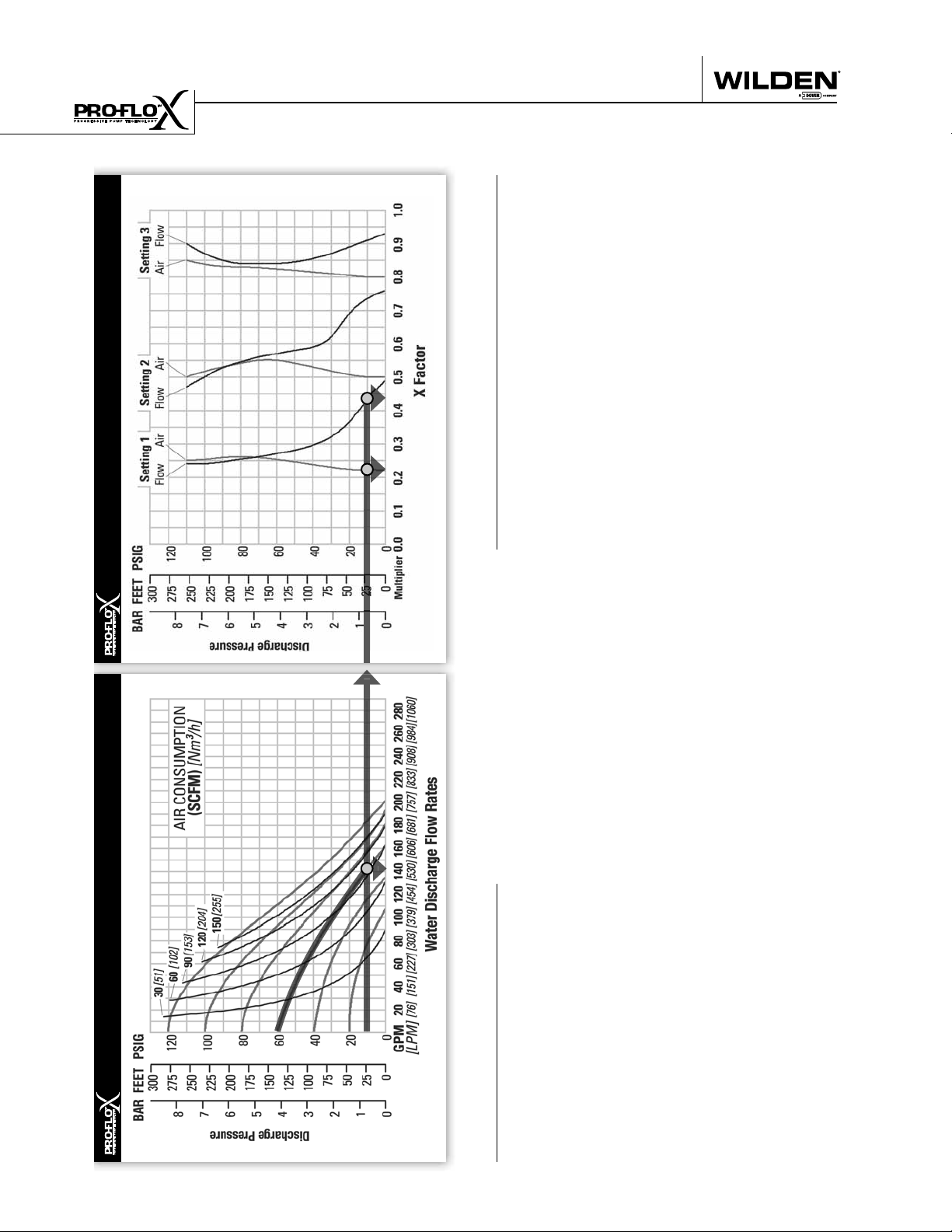

EMS CURVE

PERFORMANCE

/h (72 scfm)

3

of air when run at 4.1 bar (60 psig) air inlet pressure and 2.8 bar (40

psig) discharge pressure (See dot on performance curve).

The end user did not require that much fl ow and wanted to reduce

air consumption at his facility. He determined that EMS setting 2

would meet his needs. At 2.8 bar (40 psig) discharge pressure and

EMS setting 2, the fl ow “X factor” is 0.65 and the air “X factor” is

EXAMPLE

A PX1500 aluminum, TPE-fi tted pump operating at EMS setting 4,

achieved a fl ow rate of 394 lpm (104 gpm) using 122 Nm

0.53 (see dots on EMS curve).

/h (38 scfm). The fl ow rate was reduced by 35% while

3

Multiplying the original setting 4 values by the “X factors” provides

the setting 2 fl ow rate of 256 lpm (68 gpm) and an air consumption

of 65 Nm

the air consumption was reduced by 47%, thus providing increased

effi ciency.

For a detailed example for how to set your EMS, see beginning of

performance curve section.

Caution: Do not exceed 8.6 bar (125 psig) air supply pressure.

The Effi ciency Management System (EMS)

can be used to optimize the performance of

your Wilden pump for specifi c applications.

The pump is delivered with the EMS adjusted

to setting 4, which allows maximum fl ow.

The EMS curve allows the pump user to deter-

mine fl ow and air consumption at each EMS

setting. For any EMS setting and discharge

pressure, the “X factor” is used as a multi-

plier with the original values from the setting

4 performance curve to calculate the actual

fl ow and air consumption values for that spe-

cifi c EMS setting. Note: you can interpolate

between the setting curves for operation at

intermediate EMS settings.

1

SETTING 4 PERFORMANCE CURVE

Displacement per stroke was calculated at 4.8 bar (70 psig)

TECHNICAL DATA

Height . . . . . . . . . . . . . . . . . . . . . . . . .1031 mm (40.6”)

Width. . . . . . . . . . . . . . . . . . . . . . . . . . .615 mm (24.2”)

Depth. . . . . . . . . . . . . . . . . . . . . . . . . . .422 mm (16.6”)

Ship Weight . . . . . . . . . . . Aluminum 83 kg (182 lbs.)

Aluminum Drop-In 70 kg (152 lbs.)

Air Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . 19 mm (3/4”)

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76 mm (3”)

Outlet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76 mm (3”)

Suction Lift . . . . . . . . . . . . . . . . . . . . .6.6 m Dry (21.7’)

8.8 m Wet (28.9’)

Disp. Per Stroke. . . . . . . . . . . . . . . . 4.47 l (1.18 gal.)

Max. Flow Rate . . . . . . . . . . . . . . .984 lpm (260 gpm)

PX1500 ALUMINUM TPE-FITTED

PX1500 Performance 13 WILDEN PUMP & ENGINEERING, LLC

Max. Size Solids . . . . . . . . . . . . . . . . . 12.7 mm (1/2”)

air inlet pressure against a 2 bar (30 psig) head pressure.

1

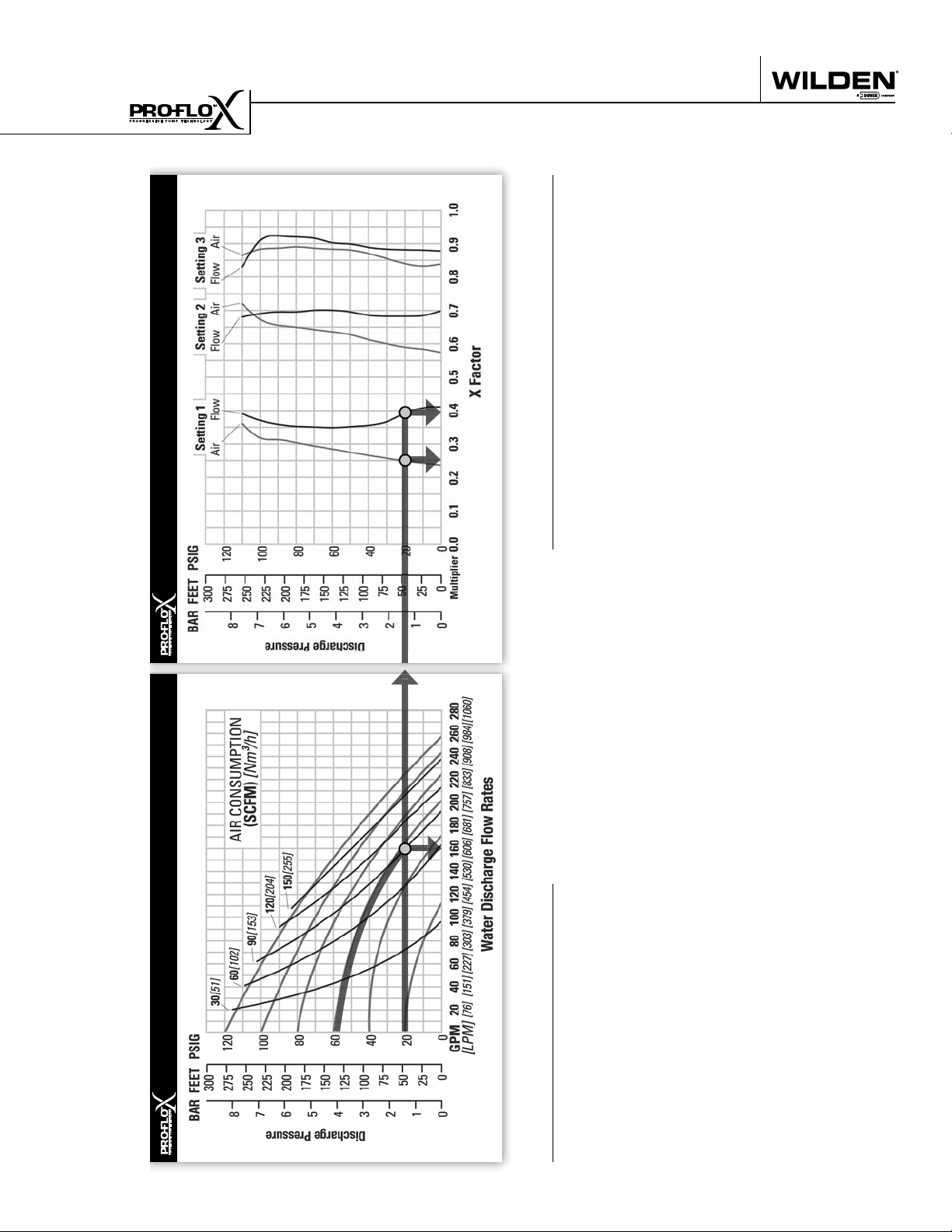

EMS CURVE

PERFORMANCE

/h (94 scfm)

3

of air when run at 4.1 bar (60 psig) air inlet pressure and 0.7 bar (10

psig) discharge pressure (See dot on performance curve).

The end user did not require that much fl ow and wanted to reduce

air consumption at his facility. He determined that EMS setting 1

would meet his needs. At 0.7 bar (10 psig) discharge pressure and

EMS setting 1, the fl ow “X factor” is 0.43 and the air “X factor” is

EXAMPLE

A PX1500 aluminum, PTFE-fi tted pump operating at EMS setting 4,

achieved a fl ow rate of 538 lpm (142 gpm) using 160 Nm

0.22 (see dots on EMS curve).

/h (21 scfm). The fl ow rate was reduced by 57% while the

3

air consumption was reduced by 78%, thus providing increased ef-

fi ciency.

For a detailed example for how to set your EMS, see beginning of

performance curve section.

Multiplying the original setting 4 values by the “X factors” provides

the setting 1 fl ow rate of 231 lpm (61 gpm) and an air consumption

of 35 Nm

Caution: Do not exceed 8.6 bar (125 psig) air supply pressure.

The Effi ciency Management System (EMS)

can be used to optimize the performance of

your Wilden pump for specifi c applications.

The pump is delivered with the EMS adjusted

to setting 4, which allows maximum fl ow.

The EMS curve allows the pump user to deter-

mine fl ow and air consumption at each EMS

setting. For any EMS setting and discharge

pressure, the “X factor” is used as a multi-

plier with the original values from the setting

4 performance curve to calculate the actual

fl ow and air consumption values for that spe-

cifi c EMS setting. Note: you can interpolate

between the setting curves for operation at

intermediate EMS settings

1

SETTING 4 PERFORMANCE CURVE

Displacement per stroke was calculated at 4.8 bar (70 psig)

TECHNICAL DATA

Height . . . . . . . . . . . . . . . . . . . . . . . . .1031 mm (40.6”)

Width. . . . . . . . . . . . . . . . . . . . . . . . . . .615 mm (24.2”)

Depth. . . . . . . . . . . . . . . . . . . . . . . . . . .422 mm (16.6”)

Ship Weight . . . . . . . . . . . Aluminum 83 kg (182 lbs.)

Aluminum Drop-In 70 kg (152 lbs.)

Air Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . 19 mm (3/4”)

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76 mm (3”)

Outlet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76 mm (3”)

Suction Lift . . . . . . . . . . . . . . . . . . . . .4.4 m Dry (14.4’)

7.8 m Wet (25.6’)

Disp. Per Stroke. . . . . . . . . . . . . . . . 3.48 l (0.92 gal.)

Max. Flow Rate . . . . . . . . . . . . . . .765 lpm (202 gpm)

PX1500 ALUMINUM PTFE-FITTED

WILDEN PUMP & ENGINEERING, LLC 14 PX1500 Performance

Max. Size Solids . . . . . . . . . . . . . . . . . 12.7 mm (1/2”)

air inlet pressure against a 2 bar (30 psig) head pressure.

1

EMS CURVE

PERFORMANCE

/h

3

EXAMPLE

A PX1500 aluminum, Full Flow PTFE fi tted pump operating at EMS

setting 4, achieved a fl ow rate of 606 lpm (160 gpm) using 153 Nm

(90 scfm) of air when run at 4.0 bar (58 psig) air inlet pressure and 1.4

bar (20 psig) discharge pressure (See dot on performance curve).

The end user did not require that much fl ow and wanted to reduce

air consumption at his facility. He determined that EMS setting 1

would meet his needs. At 1.4 bar (20 psig) discharge pressure and

EMS setting 1, the fl ow “X factor” is 0.39 and the air “X factor” is

0.25 (see dots on EMS curve).

/h (23 scfm). The fl ow rate was reduced by 61% while

3

the air consumption was reduced by 75%, thus providing increased

effi ciency.

For a detailed example for how to set your EMS, see beginning of

performance curve section.

Multiplying the original setting 4 values by the “X factors” provides

the setting 1 fl ow rate of 236 lpm (62 gpm) and an air consumption

of 38 Nm

Caution: Do not exceed 8.6 bar (125 psig) air supply pressure.

The Effi ciency Management System (EMS)

can be used to optimize the performance of

your Wilden pump for specifi c applications.

The pump is delivered with the EMS adjusted

to setting 4, which allows maximum fl ow.

The EMS curve allows the pump user to deter-

mine fl ow and air consumption at each EMS

setting. For any EMS setting and discharge

pressure, the “X factor” is used as a multi-

plier with the original values from the setting

4 performance curve to calculate the actual

fl ow and air consumption values for that spe-

cifi c EMS setting. Note: you can interpolate

between the setting curves for operation at

intermediate EMS settings

1

SETTING 4 PERFORMANCE CURVE

Displacement per stroke was calculated at 4.8 bar (70 psig)

TECHNICAL DATA

Height . . . . . . . . . . . . . . . . . . . . . . . . .1031 mm (40.6”)

Width. . . . . . . . . . . . . . . . . . . . . . . . . . .615 mm (24.2”)

Depth. . . . . . . . . . . . . . . . . . . . . . . . . . .422 mm (16.6”)

Ship Weight . . . . . . . . . . . Aluminum 83 kg (182 lbs.)

Aluminum Drop-in 70 kg (152 lbs.)

Air Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . 19 mm (3/4”)

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76 mm (3”)

Outlet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76 mm (3”)

Suction Lift . . . . . . . . . . . . . . . . . . . . .6.4 m Dry (21.0’)

9.0 m Wet (29.5’)

Disp. Per Stroke. . . . . . . . . . . . . . . . . 5.3 l (1.39 gal.)

Max. Flow Rate . . . . . . . . . . . . . 974 lpm (257.3 gpm)

PX1500 ALUMINUM FULL STROKE PTFE-FITTED

PX1500 Performance 15 WILDEN PUMP & ENGINEERING, LLC

Max. Size Solids . . . . . . . . . . . . . . . . . 12.7 mm (1/2”)

air inlet pressure against a 2 bar (30 psig) head pressure.

1

Loading...

Loading...