Page 1

P1/PX1

Original™ Series METAL Pumps

Simplify your process

Engineering

Operation &

Maintenance

LISTED

79

WIL-103 00 -E -10

REPLACES WIL-10300- E-09

Page 2

TABLE OF CONTENTS

SECTION 1 CAUTIONS—READ FIRST! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SECTION 2 WILDEN PUMP DESIGNATION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SECTION 3 HOW IT WORKS—PUMP & AIR DISTRIBUTION SYSTEM . . . . . . . . . . . . . . . . 3

SECTION 4 DIMENSIONAL DRAWINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

SECTION 5 PERFORMANCE

A. P1 Performance Curves

Rubber-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

TPE-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

PTFE-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

B. PX1 Performance

Operating Principal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

How to Use this EMS Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Performance Curves

Rubber-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

TPE-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

PTFE-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

C. Suction Lift Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

SECTION 6 SUGGESTED INSTALLATION, OPERATION & TROUBLESHOOTING . . . . . . . 20

SECTION 7 ASSEMBLY / DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Grounding Strap for CSA Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

SECTION 8 EXPLODED VIEW & PARTS LISTING

P1 Rubber/TPE-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

P1 PTFE-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

PX1 Rubber-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

PX1 PTFE-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

SECTION 9 ELASTOMER OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

O

z

o

I

I

n

USE

e

t

i

n

g

e

s

e

c

n

a

t

s

b

u

S

&

I

s

s

a

l

C

NON

U.S. Clean Air Act

Amendments of 1990

D

e

p

l

Page 3

Section 1

CAUTIONS—READ FIRST!

CAUTION: Do not apply compressed air to the exhaust port

— pump will not function.

CAUTION: Do not over-lubricate air supply — excess

lubrication will reduce pump performance. Pump is pre-lubed.

CAUTION: Do not under any circums tance loosen the set

screw located at the adjuster dial of the Pro-Flo X ™ pump. If

the set screw is loose when the pump is pressurized, it could

eject and cause injury to anyone in the area.

TEMPERATURE LIMITS:

Neoprene –17.7°C to 93.3°C 0°F to 200°F

Buna-N –12.2°C to 82.2°C 10°F to 180°F

EPDM –51.1°C to 137.8°C –60°F to 280°F

Viton

®

–40°C to 176.7°C –40°F to 350°F

Sanifl ex™ –28.9°C to 104.4°C –20°F to 220°F

Polytetrafl uoroethylene (PTFE)

4.4°C to 104.4°C 40°F to 220°F

Polyurethane –12.2°C to 65.6°C 10°F to 150°F

Tetr a - Flex™ P T FE w/ Neop r ene B acke d

4.4°C to 107.2°C 40°F to 225°F

Tetr a - Flex™ P T FE w/ EPDM Backe d

-10°C to 137°C 14°F to 280°F

NOTE: Not all materials are available for all models. Refer to

Section 2 for material options for your pump.

NOTE: Canadian Standards Association ( CSA) confi gured

pumps should not be used in temperatures lower than 0.0ºC to

51.6 ºC ( 32 ºF to 125ºF).

NOTE: UL listed confi gured pumps have the following

temperature limits:

UL 79 Buna- -12.2 °C (10 °F) to 52°C (12 5°F)

CAUTION: When choosing pump materials, be sure to check

the temperature limits for all wetted components. Example:

®

Viton

has a max imum limi t of 176 .7°C ( 350 °F) b ut poly propyle ne

has a maximum limit of only 79 °C (17 5°F).

CAUTION: Maximum temperature limits are based upon

mechanical stress only. Certain chemicals will signi fi cantly

reduce maximum safe operating temperatures. Consult

Chemical Resis tance Guide (E4) for chemical compatibility and

temperature limits.

WARNING: Prevention of stat ic sparking — If static sparking

occurs, fi re or explosion could result. Pump, valves, and

containers must be grounded to a proper grounding point when

handling fl ammable fl uids and whenever discharge of static

electricity is a hazard.

CAUTION: Canadian St andards Association (C SA) confi gured

pumps must be electrically grounded using the grounding

location identifi ed. Improper grounding can cause improper

and dangerous operation.

CAUTION: Do not exceed 8.6 bar (12 5 psig ) air supply

pressure.

CAUTION: Canadian St andards Association (C SA) confi gured

pumps should not exceed 6.9 bar (10 0 psig ) sweet gas supply

pressure.

CAUTION: For U.L. listed pumps, do not exceed 3.4 bar (50

psig) air supply pressure.

CAUTION: The process fl uid and cleaning fl uids must be

chemically compatible with all wetted pump components.

Consult Chemical Resistance Guide (E4).

CAUTION: Do not exceed 82°C (180°F) air inlet temperature

for Pro-Flo X™ models.

CAUTION: Pumps should be thoroughly fl ushed before

installing into process lines. FDA and USDA approved pumps

should be cleaned and/or sanitized before being used.

CAUTION: Always wear safety glasses when operating

pump. If diaphragm rupture occurs, material being pumped may

be forced out air exhaust.

CAUTION: Before any maintenance or repair is attempted,

the compressed air line to the pump should be disconnected

and all air pressure allowed to bleed from pump. Disconnect

all intake, discharge and air lines. Drain the pump by turning

it upside down and allowing any fl uid to fl ow into a suitable

container.

CAUTION: Blow out air line for 10 to 20 seconds before

attaching to pump to make sure all pipeline debris is clear. Use

an in-line air fi l ter. A 5µ ( micron) air fi lter is recommended.

NOTE: When installing PTFE diaphragms, it is important

to tighten outer pistons simultaneously (turning in opposite

directions) to ensure tight fi t. (See torque specifi cations in

Section 7.)

NOTE: Cast Iron PTFE-fi tted pumps come standard from the

factory with expanded P TFE gaskets ins talled in the diaphragm

bead of the liquid chamber. PTFE gaskets cannot be re-used.

Consult PS-TG for installation instructions during reassembly.

NOTE: Before starting disassembly, mark a line from each

liquid chamber to i ts corresponding air chamber. This line will

assis t in proper alignment during reassembly.

CAUTION: Pro-Flo® pumps cannot be used in submersible

applications. Pro-Flo X™ is available in both submersible and

non-submersible options. Do not use non-submersible Pro-Flo

X™ models in submersible applications. Turbo-Flo

also be used in submersible applications.

CAUTION: Tighten all hardware prior to installation.

CAUTION: The gas outlet of CSA confi gured pumps must be

vented to a safe location in accordance with local codes or, in

the absence of local codes, an industry or nationally recognized

code having jurisdiction over the specifi ed ins tallation.

CAUTION: Fo r U.L. li sted pum ps, all pipe co nnectio ns are to be

made using U.L. classi fi ed gasoline-resis tant pipe compound.

CAUTION: F or U. L . l i st ed pu m ps al l i ns t al la t io ns mu s t co n fo rm

to NFPA 30, NFPA 30A, and all other applicable codes.

CAUTION: For U.L. listed pumps, air exhaust port is to be

connected to pipe or tubing to be routed outdoors or other

location determined to be equivalent.

CAUTION: For U.L. listed pumps, pump is to be grounded

using the jam-nut located at the top of the long vertical carriage

bolt . The ground connection is marked with a tag having the

grounding symbol.

®

pumps can

Grounding Symbol

WIL-10300-E-09 1 WILDEN PUMP & ENGINEERING, LLC

Page 4

Section 2

WILDEN PUMP DESIGNATION SYSTEM

P1/PX1 ORIGINAL™

METAL

13 mm (½") Pump

Maximum Flow Rate:

62.8 lpm (16.6 gpm)

MATERIAL CODES

MODEL

P1 = Pro-Flo

PX1 = Pro-Flo X™

XPI = ATEX Pro-Flo

WETTED PARTS & OUTER PISTON

AA = ALUMINUM / ALUMINUM

AZ = ALUMINUM / NO PISTON

SS = STAINLESS STEEL /

SZ = STAINLESS STEEL /

CENTER SECTION

AA = ALUMINUM (PX1 only)

GG = CONDUCTIVE ACETAL

(P1 only)

JJ = CONDUCTIVE

LL = ACETAL (P1 only)

PP = POLYPROPYLENE (P1 only)

LEGEND

®

®

STAINLESS STEEL

NO PISTON

POLYPROPYLENE (P1 only)

xPX1 / XXXXX / XXX /XX/ XXX / XXXX

MODEL VALVE SEAT

ATEX DIAPHRAGMS

WETTED PARTS & OUTER PISTON

AIR VALVE

A = ALUMINUM (PX1 only)

G =

CONDUCTIVE ACETAL

only)

J = CONDUCTIVE

POLYPROPYLENE (P1 only)

L = ACETAL (P1 only)

P = POLYPROPYLENE (P1 only)

DIAPHRAGMS

XBS = CONDUCTIVE BUNA-N

(Two Red Dots)

BNS = BUNA-N (Red Dot)

FSS = SANIFLEX™

[Hytrel

PUS = POLYURETHANE (Clear)

TEU = PTFE w/EPDM

BACK-UP (White)

THU = PTFE W/HIGH-TEMP

BUNA-N BACK-UP (White)

TNU = PTFE W/NEOPRENE

BACK-UP (White)

TNL = PTFE W/NEOPRENE

BACK-UP O-RING,

IPD (White)

VTS = VITON

WFS = WIL-FLEX™ [Santoprene

(Orange Dot)]

ESD = BUNA-N

AIR VALVE

CENTER SECTION

(P1

®

(Cream)]

®

(White Dot)

VALVE BALLS

VALVE BALL

BN = BUNA-N (Red Dot)

FS = SANIFLEX™

PU = POLYURETHANE (Brown)

TF = PTFE (White)

VT = VITON

WF = WIL-FLEX™ [Santoprene

VALVE SEAT

A = ALUMINUM

S = STAINLESS STEEL

V = VITON

VALVE SEAT O-RING

BN = BUNA-N

FS = SANIFLEX™

PU = POLYURETHANE (Brown)

TF = PTFE (White)

WF = WIL-FLEX™ [Santoprene

®

O-RINGS

®

[Hytrel

(Cream)]

®

(White Dot)

(Orange Dot)]

®

(White Dot)

®

[Hytrel

(Cream)]

SPECIALTY

CODE

(if applicable)

®

®

]

SPECIALTY CODES

0023 Wing nuts

0067 Saniflo™ FDA, Wil-Gard II™ 220V

0070 Saniflo™ FDA

0079 Tri-clamp fittings, wing nuts

0080 Tri-clamp fittings ONLY

0100 Wil-Gard II™ 110V

0102 Wil-Gard II™ sensor wires ONLY

0103 Wil-Gard II™ 220V

NOTE: The Wilden UL 79 Listed products covered by this manual are PX1 models followed by AA or SS, followed by AA, followed by A, followed by

BNS, followed by BN, followed by A or S, followed by BN, followed by 0495. Wilden UL Listed pumps have been evaluated for use at a

25 C (77F ) ambient temperature with a maximum inlet pressure of 3.4 Bar (50 PSI)..

WILDEN PUMP & ENGINEERING, LLC 2 WIL-10300-E-10

0120 Saniflo™ FDA, Wil-Gard II™ 110V

0206 PFA coated hardware, Wil-Gard II™

sensor wires ONLY

0495 U.L. Approved

0502 PFA coated hardware

0603 PFA coated hardware, Wil Gard 110V

0608 PFA coated hardware, Wil Gard 220V

Page 5

Section 3

HOW IT WORKS

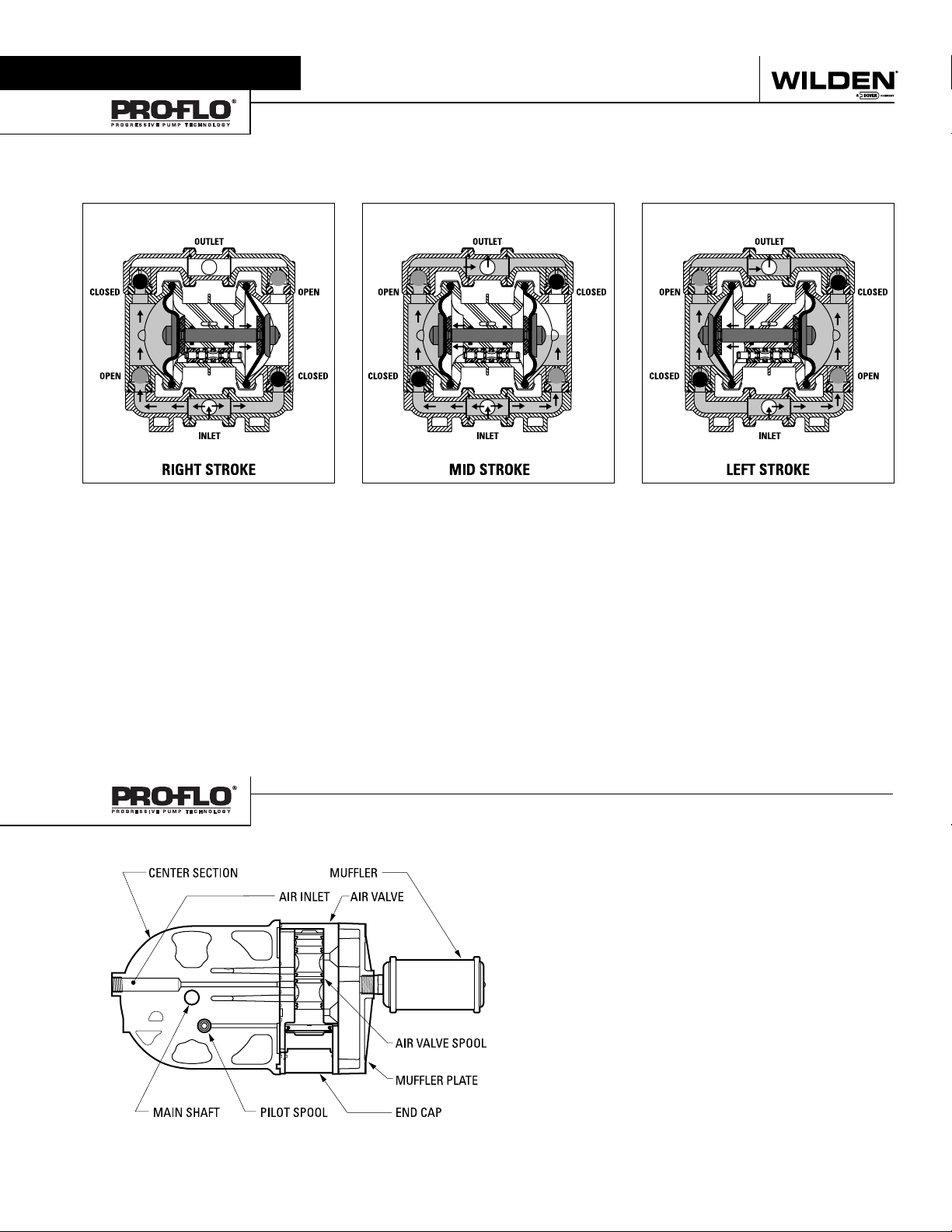

The Wilden diaphragm pump is an air-operated, positive displacement, self-priming pump. These drawings show the flow pattern

through the pump upon its initial stroke. It is assumed the pump has no fluid in it prior to its initial stroke.

BA B A BA

OPEN

FIGURE 1 The air valve directs pressurized air to

the back side of diaphragm A. The compressed air

is applied directly to the liquid column separated by

elastomeric diaphragms. The diaphragm acts as a

separation membrane between the compressed air

and liquid, balancing the load and removing mechanical stress from the diaphragm. The compressed air

moves the diaphragm away from the center block of

the pump. The opposite diaphragm is pulled in by

the shaft connected to the pressurized diaphragm.

Diaphragm B is on its suction stroke; air behind the

diaphragm has been forced out to the atmosphere

through the exhaust port of the pump. The movement of diaphragm B toward the center block of the

pump creates a vacuum within chamber B. Atmospheric pressure forces fluid into the inlet manifold

forcing the inlet valve ball off its seat. Liquid is free

to move past the inlet valve ball and fill the liquid

chamber (see shaded area).

HOW IT WORKS—AIR DISTRIBUTION SYSTEM

FIGURE 2 When the pressurized diaphragm,

diaphragm A, reaches the limit of its discharge

stroke, the air valve redirects pressurized air to the

back side of diaphragm B. The pressurized air forces

diaphragm B away from the center block while pulling diaphragm A to the center block. Diaphragm B

is now on its discharge stroke. Diaphragm B forces

the inlet valve ball onto its seat due to the hydraulic

forces developed in the liquid chamber and manifold of the pump. These same hydraulic forces

lift the discharge valve ball off its seat, while the

opposite discharge valve ball is forced onto its seat,

forcing fluid to flow through the pump discharge.

The movement of diaphragm A toward the center

block of the pump creates a vacuum within liquid

chamber A. Atmospheric pressure forces fluid into

the inlet manifold of the pump. The inlet valve ball is

forced off its seat allowing the fluid being pumped

to fill the liquid chamber.

®

The Pro -Flo

patented air distribution system incorporates two

moving parts : the air valve spool and the pilot spool. The hear t of

the system is the air valve spool and air valve. This valve design

incorporates an unbalanced spool. The smaller end of the spool

is pressurized continuously, while the large end is alternately

pressurized then exhausted to move the spool. The spool direc ts

pressurized air to one air chamber while exhausting the other.

The air causes the main shaft/diaphragm assembly to shift to

one side — discharging liquid on that side and pulling liquid in

on the other side. When the shaft reaches the end of its stroke,

the inner piston actuates the pilot spool, which pressurizes and

exhausts the large end of the air valve spool. The repositioning

of the air valve spool routes the air to the other air chamber.

FIGURE 3 At completion of the stroke, the air valve

again redirects air to the back side of diaphragm A,

which starts diaphragm B on its exhaust stroke. As

the pump reaches its original starting point, each

diaphragm has gone through one exhaust and one

discharge stroke. This constitutes one complete

pumping cycle. The pump may take several cycles

to completely prime depending on the conditions of

the application.

WIL-10300-E-10 3 WILDEN PUMP & ENGINEERING, LLC

Page 6

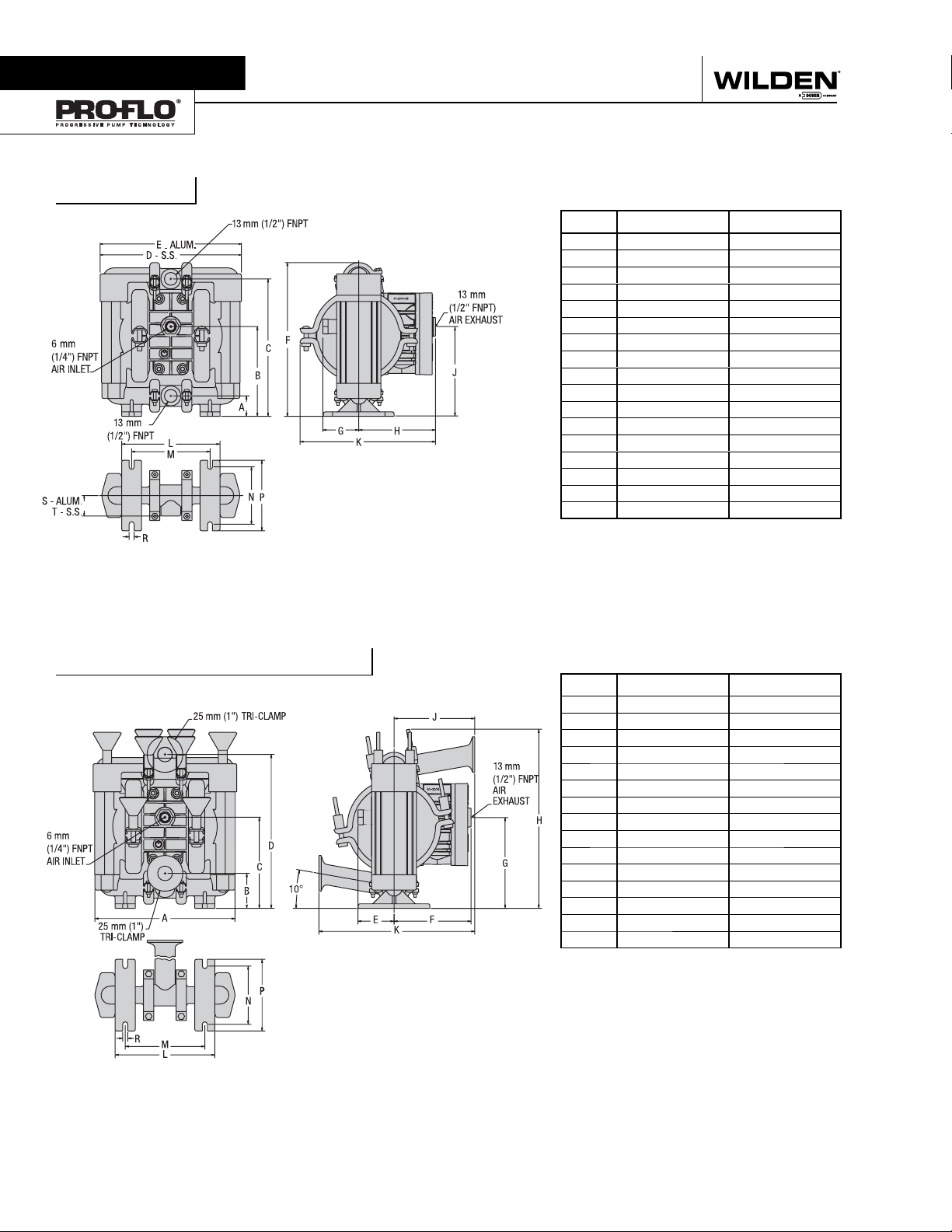

Section 4

DIMENSIONAL DRAWINGS

P1 METAL

DIMENSIONS

ITEM METRIC (mm) STANDARD (inch)

A 29 1.1

B 129 5.1

C 199 7.8

D 203 8.0

E 207 8.2

F 222 8.8

G 56 2.2

H 115 4.5

J 129 5.1

K 205 8.1

L 140 5.5

M 112 4.4

N 83 3.3

P 102 4.0

R 7 0.3

S 30 1.2

T 30 1.2

BSP threads available.

P1 METAL SANIFLO

FDA

DIMENSIONS

ITEM METRIC (mm) STANDARD (inch)

A 204 8.0

B 48 1.9

C 132 5.2

D 221 8.7

E 53 2.1

F 115 4.5

G 125 4.9

H 258 10.2

J 116 4.6

K 229 9.0

L 143 5.6

M 114 4.5

N 83 3.3

P 102 4.0

R 7 0.3

WILDEN PUMP & ENGINEERING, LLC 4 WIL-10300-E-10

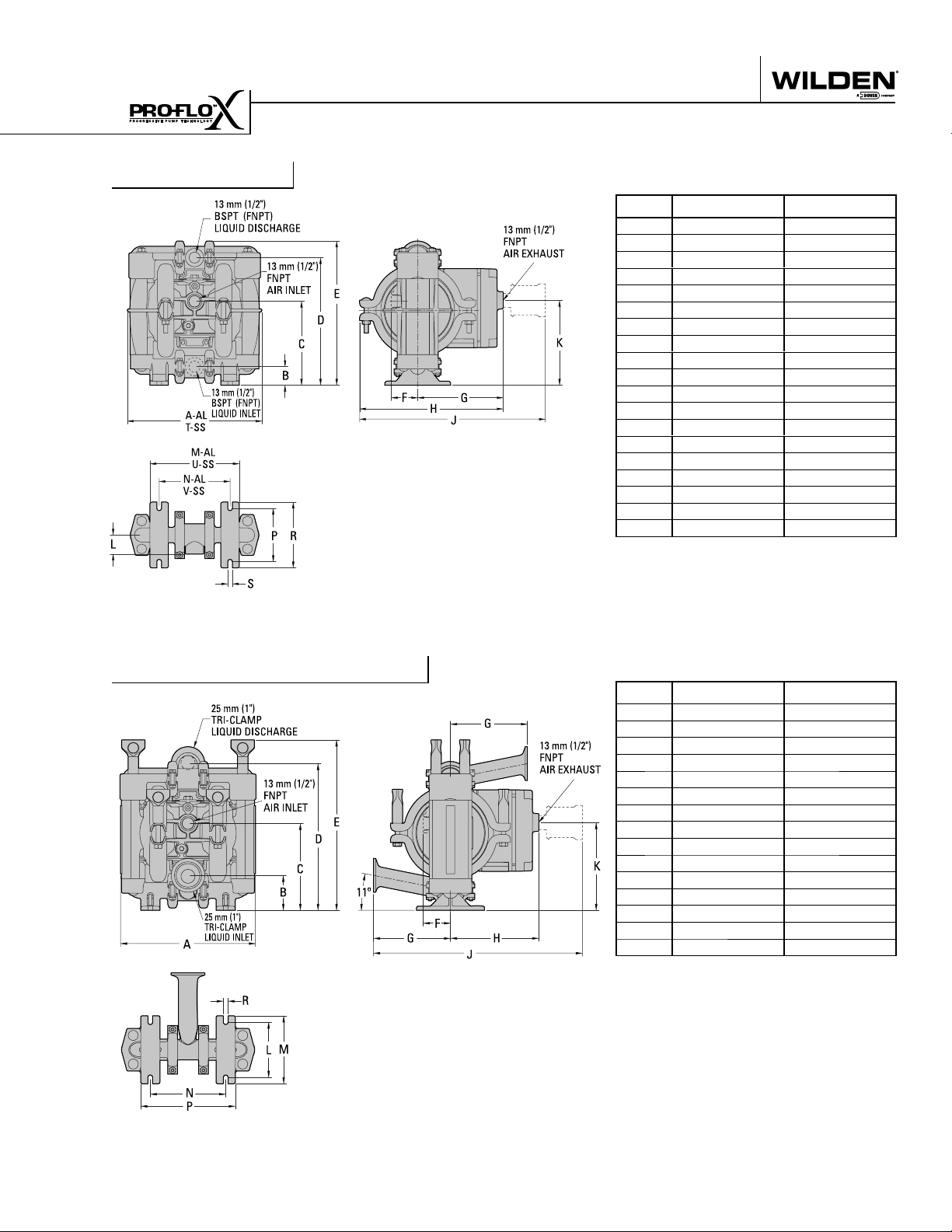

Page 7

DIMENSIONAL DRAWINGS

PX1 METAL

DIMENSIONS

ITEM METRIC (mm) STANDARD (inch)

A 208 8.2

B 28 1.1

C 130 5.1

D 198 7.8

E 224 8.8

F 41 1.6

G 132 5.2

H 221 8.7

J 361 14.2

K 132 5.2

L 30 1.2

M 137 5.4

N 109 4.3

P 84 3.3

R 102 4.0

S 8 0.3

T 203 8.0

U 142 5.6

V 112 4.4

BSP threads available.

PX1 METAL SANIFLO

FDA

DIMENSIONS

ITEM METRIC (mm) STANDARD (inch)

A 203 8.0

B 53 2.1

C 130 5.1

D 218 8.6

E 257 10.1

F 41 1.6

G 114 4.5

H 132 5.2

J 386 15.2

K 132 5.2

L 84 3.3

M 102 4.0

N 112 4.4

P 142 5.6

R 8 0.3

WIL-10300-E-10 5 WILDEN PUMP & ENGINEERING, LLC

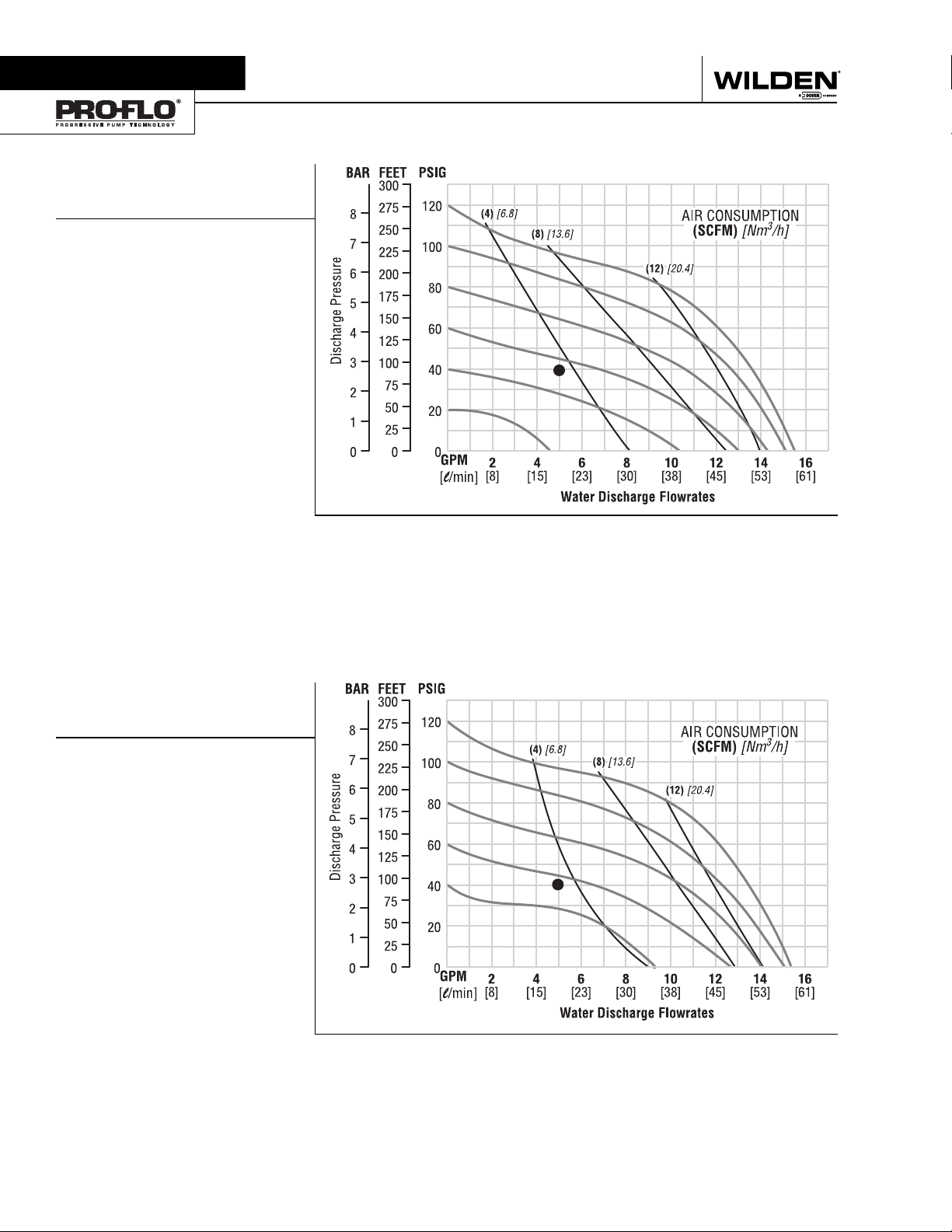

Page 8

Section 5A

PERFORMANCE

P1 METAL

RUBBER-FITTED

Height .................................... 222 mm (8.8")

Width .....................................207 mm (8.2")

Depth .................................... 205 mm (8.1")

Ship Weight .................

Air Inlet ......................................6 mm (1/4")

Inlet .........................................13 mm (1/2")

Outlet ......................................13 mm (1⁄2")

Suction Lift ........................ 5.8 m Dry (19.0')

Displacement per Stroke . .11 l (0.029 gal.)

Max. Flow Rate ........... 58.67 lpm (15.5 gpm)

Max. Size Solids ................. 1.59 mm (1/16")

1

Displacement per stroke was calculated at 4.8 Bar

(70 psig) air inlet pressure against a 2 Bar (30 psig)

head pressure.

Example: To pump 18.9 lpm (5 gpm) against

a discharge pressure head of 2.7 Bar (40

psig) requires 4 Bar (60 psig) and 5.92 Nm

(3.5 scfm) air consumption. (See dot on

chart.)

Caution: Do not exceed 8.6 Bar (125 psig) air

supply pressure.

Aluminum 6 kg (13 lbs)

Stainless Steel 9 kg (20 lbs)

9.5 m Wet (31.0')

1

3

/h

Flow rates indicated on chart were determined by pumping water.

For optimum life and performance, pumps should be specified so that daily operation parameters

will fall in the center of the pump performance curve.

P1 METAL

TPE-FITTED

Height .................................... 222 mm (8.8")

Width .....................................207 mm (8.2")

Depth .................................... 205 mm (8.1")

Ship Weight .................

Air Inlet ......................................6 mm (1/4")

Inlet .........................................13 mm (1/2")

Outlet ......................................13 mm (1/2")

Suction Lift ........................ 5.2 m Dry (17.0')

Displacement per Stroke . .11 l (0.029 gal.)

Max. Flow Rate ........... 58.30 lpm (15.4 gpm)

Max. Size Solids ................. 1.59 mm (1/16")

1

Displacement per stroke was calculated at 4.8 Bar

(70 psig) air inlet pressure against a 2 Bar (30 psig)

head pressure.

Example: To pump 18.9 lpm (5 gpm) against

a discharge pressure head of 2.7 Bar (40

psig) requires 4 Bar (60 psig) and 5.92 Nm

(3.5 scfm) air consumption. (See dot on

chart.)

Caution: Do not exceed 8.6 Bar (125 psig) air

supply pressure.

Aluminum 6 kg (13 lbs)

Stainless Steel 9 kg (20 lbs)

9.5 m Wet (31.0')

3

/h

1

Flow rates indicated on chart were determined by pumping water.

For optimum life and performance, pumps should be specified so that daily operation parameters

will fall in the center of the pump performance curve.

WILDEN PUMP & ENGINEERING, LLC 6 WIL-10300-E-10

Page 9

PERFORMANCE

P1 METAL

PTFE-FITTED

Height .................................... 222 mm (8.8")

Width .....................................207 mm (8.2")

Depth .................................... 205 mm (8.1")

Ship Weight .................

Air Inlet ......................................6 mm (1/4")

Inlet .........................................13 mm (1/2")

Outlet ......................................13 mm (1/2")

Suction Lift ........................ 4.9 m Dry (16.0')

Displacement per Stroke . .09 l (0.025 gal.)

Max. Flow Rate ........... 54.41 lpm (14.4 gpm)

Max. Size Solids ................. 1.59 mm (1/16")

1

Displacement per stroke was calculated at 4.8 Bar

(70 ) air inlet pressure against a 2 Bar (30 psig)

head pressure.

Example: To pump 18.9 lpm (5 gpm) against

a discharge pressure head of 2.7 Bar (40

psig) requires 4 Bar (60 psig) and 5.92 Nm

(3.5 scfm) air consumption. (See dot on

chart.)

Caution: Do not exceed 8.6 Bar (125 psig) air

supply pressure.

Aluminum 6 kg (13 lbs)

Stainless Steel 9.2 kg (20 lbs)

9.5 m Wet (31.0')

1

3

/h

Flow rates indicated on chart were determined by pumping water.

For optimum life and performance, pumps should be specified so that daily operation parameters

will fall in the center of the pump performance curve.

WIL-10300-E-10 7 WILDEN PUMP & ENGINEERING, LLC

Page 10

Finding

Spares

A

Nightmare

?

Sleep easier with

Spectrom is not your typical after market part

supplier. We do not simply sell pump parts; we

PRODUCTS:

AODDP

(Air Operated Double

Diaphragm Pumps)

• Warren-Rupp

®

• ARO

• Other

PUMP PARTS

(Low Cost)

• Diaphragms

• Valve balls

• Valve seats

®

provide value added procurement solutions.

Our unique network enables us to purchase effectively, resulting in low cost

solutions. We also know that low purchase

price is not enough - quality, integrity and

inventory are also important. Spectrom is struc-

tured to provide Pre and Post sales support, giving

our customers value added application and pump

knowledge.

Contact us to have a procurement solution

developed for you. We don’t just fit you

into a generic system, we develop specific

solutions that achieve results.

Spectrom will ship your order from

our facility within 3 working days!

KNOWLEDGE

& SERVICE

• Competitive pricing

• Delivery

• Service

• Inventory

1-909-512-1261 www.spectromparts.com

WILDEN PUMP & ENGINEERING, LLC 8 WIL-10300-E-10

WARNING: These parts may exhibit

better life than OEM parts.

Page 11

PX1

M E T A L

PX1 PERFORMANCE

Page 12

Section 5B

Pro-Flo X

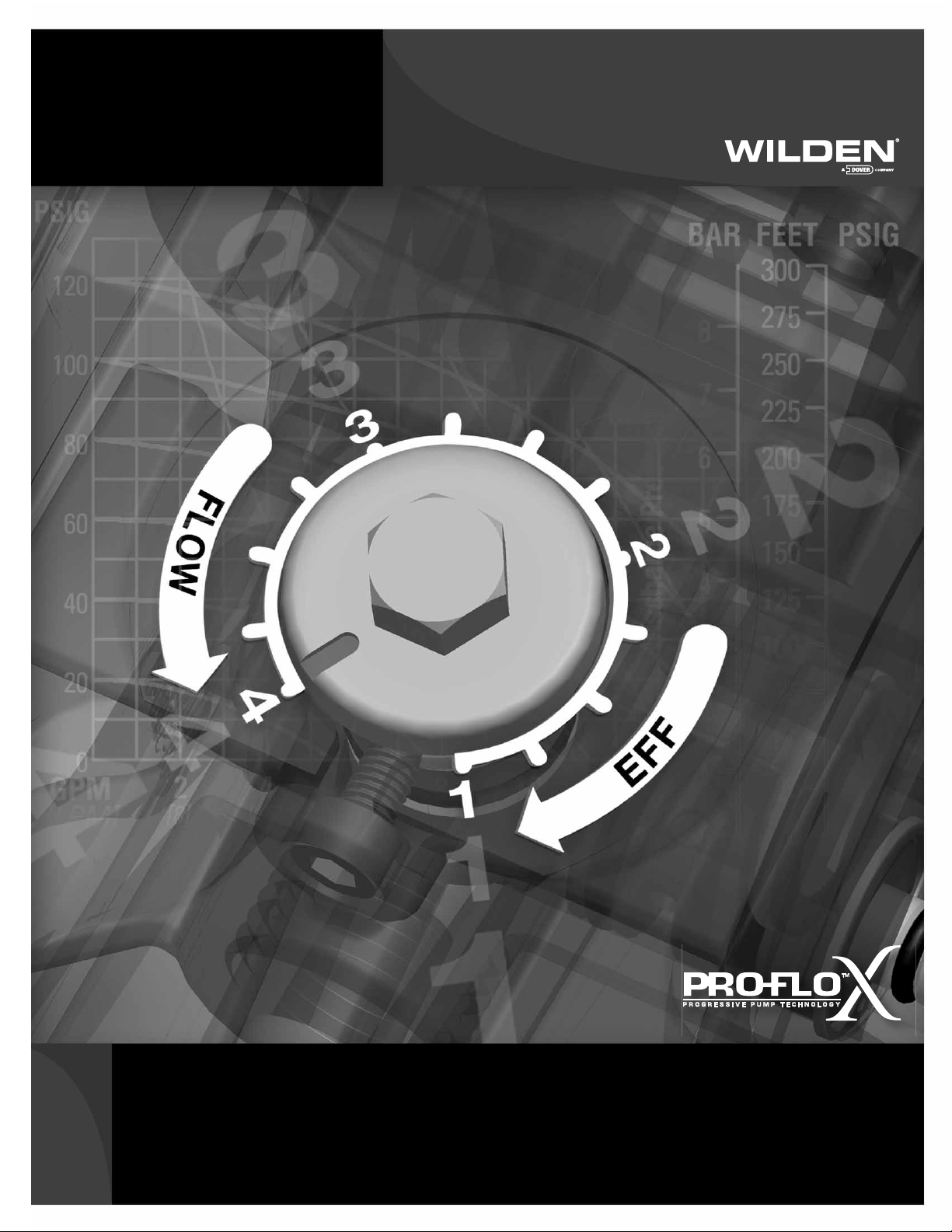

The Pro-Flo X™ air distribution system with the

revolutionary Effi ciency Management System (EMS)

offers fl exibility never before seen in the world of

AODD pumps. The

patent-pending EMS

is simple and easy

to use. With the

turn of an integrated

TM

Operating Principal

control dial, the operator can select the optimal

balance of fl ow and effi ciency that best meets the

application needs. Pro-Flo X™ provides higher

performance, lower

operational costs

and fl exibility that

exceeds previous

industry standards.

AIR CONSUMPTION

$

$

$

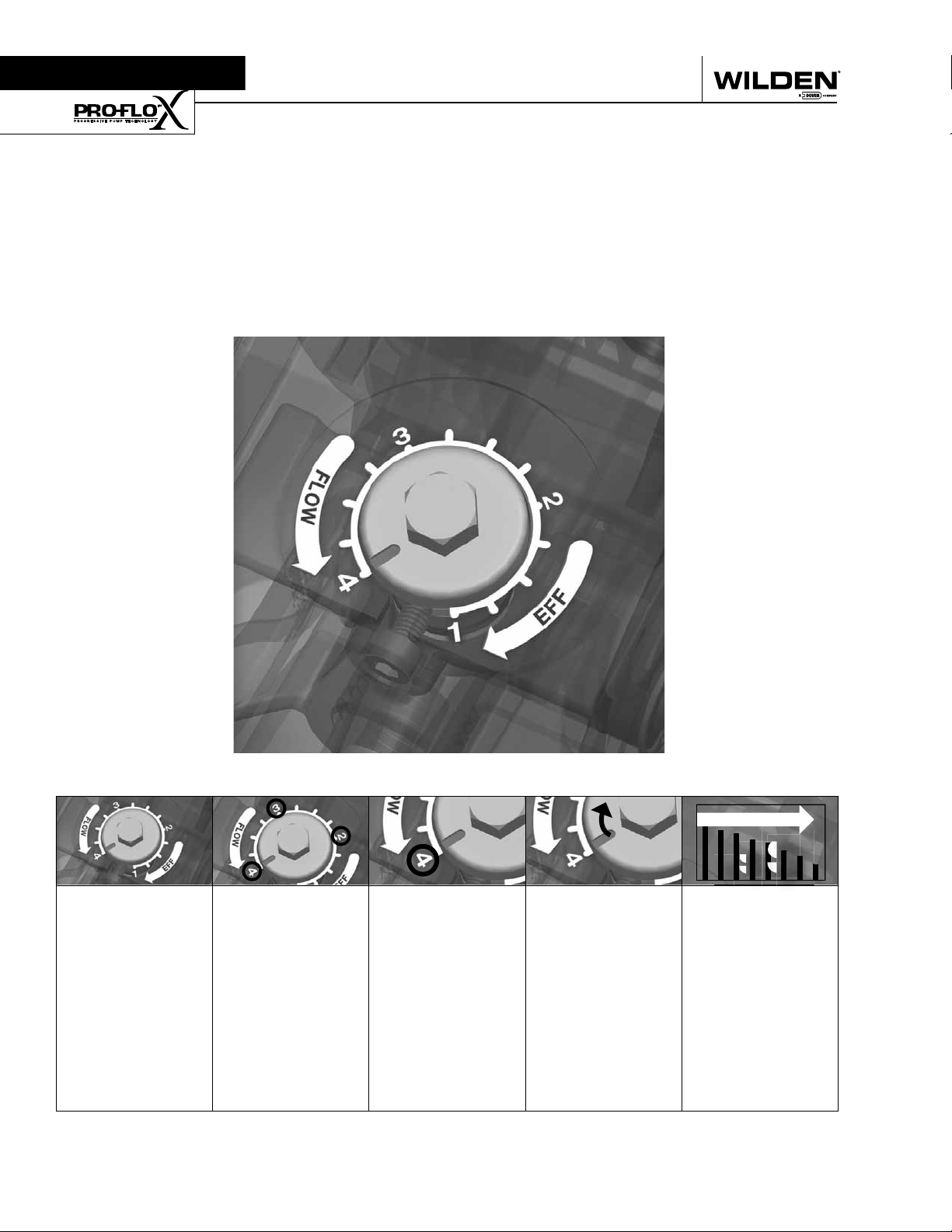

Turning the dial

changes the

relationship

between air inlet

and exhaust

porting.

WILDEN PUMP & ENGINEERING, LLC 10 PX1 Performance

Each dial setting

represents an

entirely different

fl ow curve

Pro-Flo X™ pumps

are shipped from

the factory on

setting 4, which

is the highest

fl ow rate setting

possible

Moving the dial

from setting 4

causes a decrease

in fl ow and an even

greater decrease in

air consumption.

When the air

consumption

decreases more

than the fl ow

rate, effi ciency

is improved and

operating costs

are reduced.

Page 13

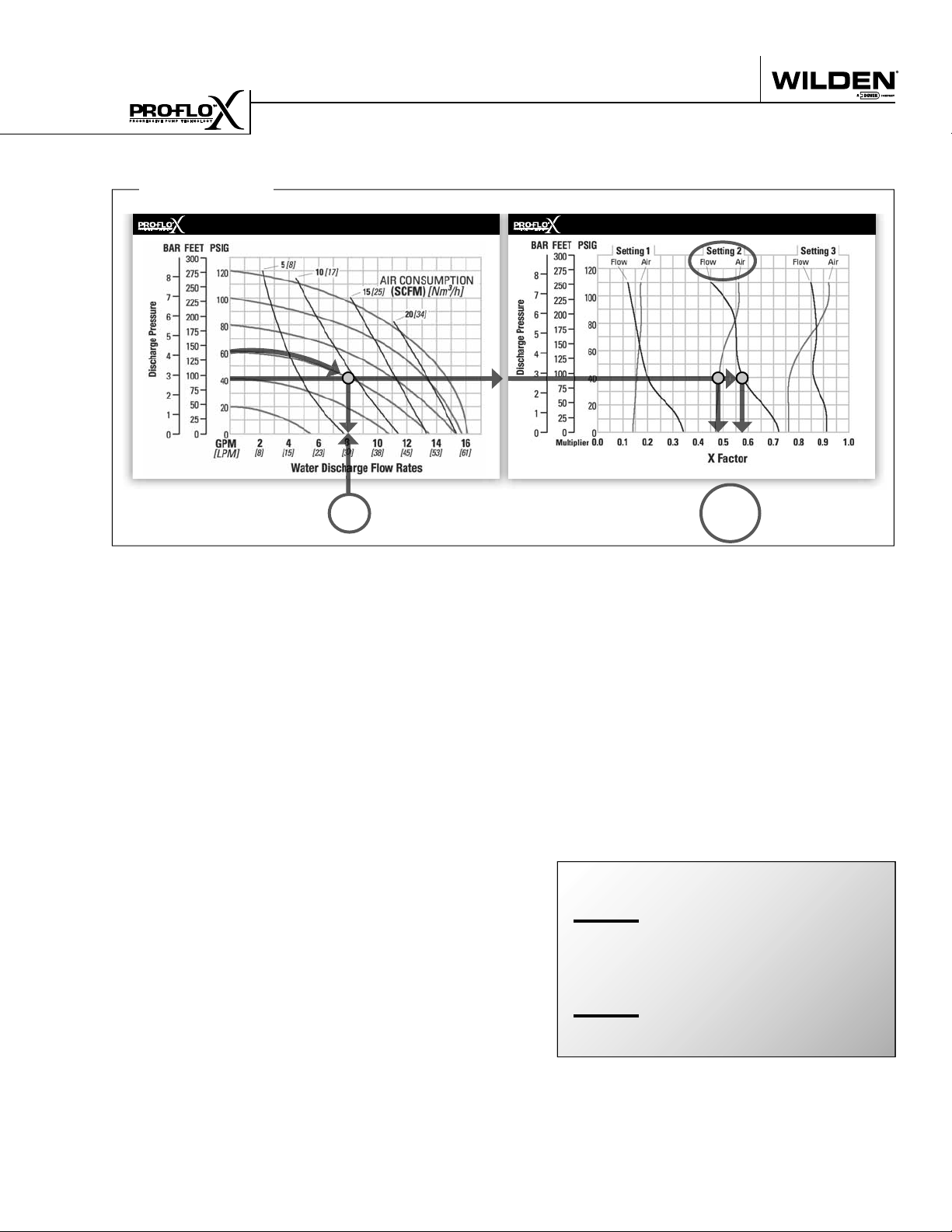

Example 1

HOW TO USE THIS EMS CURVE

SETTING 4 PERFORMANCE CURVE

Figure 1 Figure 2

Example data point = Example data point =

This is an example showing how to determine fl ow rate and

air consumption for your Pro-Flo X™ pump using the Effi ciency Management System (EMS) curve and the performance

curve. For this example we will be using 4.1 bar (60 psig) inlet

air pressure and 2.8 bar (40 psig) discharge pressure and EMS

setting 2.

Step 1:

Identifying performance at setting 4. Locate

the curve that represents the fl ow rate of the

pump with 4.1 bar (60 psig) air inlet pressure.

Mark the point where this curve crosses the

horizontal line representing 2.8 bar (40 psig)

discharge pressure. (Figure 1). After locating

your performance point on the fl ow curve,

draw a vertical line downward until reaching

the bottom scale on the chart. Identify the fl ow

rate (in this case, 8.2 gpm). Observe location

of performance point relative to air consumption curves and approximate air consumption

value (in this case, 9.8 scfm).

8.2

GPM

curve, draw vertical lines downward until

reaching the bottom scale on the chart. This

identifi es the fl ow X Factor (in this case, 0.58)

and air X Factor (in this case, 0.48).

Step 3:

Calculating performance for specific EMS

setting. Multiply the fl ow rate (8.2 gpm)

obtained in Step 1 by the fl ow X Factor multiplier (0.58) in Step 2 to determine the fl ow rate

at EMS setting 2. Multiply the air consumption (9.8 scfm) obtained in Step 1 by the air

X Factor multiplier (0.48) in Step 2 to determine the air consumption at EMS setting 2

(Figure 3).

8.2

gpm

.58

4.8

gpm

0.58

0.48

(fl ow rate for Setting 4)

(Flow X Factor setting 2)

(Flow rate for setting 2)

EMS CURVE

fl ow multiplier

air multiplier

Step 2:

Determining flow and air X Factors. Locate

your discharge pressure (40 psig) on the vertical axis of the EMS curve (Figure 2). Follow

along the 2.8 bar (40 psig) horizontal line until

intersecting both fl ow and air curves for your

desired EMS setting (in this case, setting 2).

Mark the points where the EMS curves intersect the horizontal discharge pressure line.

After locating your EMS points on the EMS

PX1 Performance 11 WILDEN PUMP & ENGINEERING, LLC

9.8

scfm

(air consumption for setting 4)

.48

4.7

Figure 3

The fl ow rate and air consumption at Setting

2 are found to be 18.2 lpm (4.8 gpm) and 7.9

Nm3/h (4.7 scfm) respectively.

(Air X Factor setting 2)

scfm

(air consumption for setting 2)

Page 14

HOW TO USE THIS EMS CURVE

Example 2.1

SETTING 4 PERFORMANCE CURVE

Figure 4

Example data point =

This is an example showing how to determine the inlet air

pressure and the EMS setting for your Pro-Flo X™ pump to

optimize the pump for a specifi c application. For this example we will be using an application requirement of 18.9 lpm

(5 gpm) fl ow rate against 2.8 bar (40 psig) discharge pressure.

This example will illustrate how to calculate the air consumption that could be expected at this operational point.

10.2

gpm

DETERMINE EMS SETTING

Step 1

: Establish inlet air pressure. Higher air pres-

sures will typically allow the pump to run

more effi ciently, however, available plant air

pressure can vary greatly. If an operating

pressure of 6.9 bar (100 psig) is chosen when

EMS Flow

Settings 1 & 2

0.49

In our example it is 38.6 lpm (10.2 gpm). This

is the setting 4 fl ow rate. Observe the location of the performance point relative to air

consumption curves and approximate air

consumption value. In our example setting

4 air consumption is 24 Nm3/h (14 scfm).

See fi gure 4.

Step 3

: Determine flow X Factor. Divide the required

fl ow rate 18.9 lpm (5 gpm) by the setting 4 fl ow

rate 38.6 lpm (10.2 gpm) to determine the fl ow

X Factor for the application.

5

gpm / 10.2 gpm = 0.49 (flow X Factor)

EMS CURVE

Figure 5

fl ow multiplier

plant air frequently dips to 6.2 bar (90 psig)

Step 4

pump performance will vary. Choose an operating pressure that is within your compressed

air systems capabilities. For this example we

will choose 4.1 bar (60 psig).

: Determine EMS setting from the flow

X Factor. Plot the point representing the fl ow

X Factor (0.49) and the application discharge

pressure 2.8 bar (40 psig) on the EMS curve.

This is done by following the horizontal 2.8

Step 2

: Determine performance point at setting 4. For

this example an inlet air pressure of 4.1 bar

(60 psig) inlet air pressure has been chosen.

Locate the curve that represents the performance of the pump with 4.1 bar (60 psig) inlet

air pressure. Mark the point where this curve

crosses the horizontal line representing 2.8

bar (40 psig) discharge pressure. After locating this point on the fl ow curve, draw a vertical line downward until reaching the bottom

scale on the chart and identify the fl ow rate.

bar (40 psig) psig discharge pressure line until

it crosses the vertical 0.49 X Factor line. Typically, this point lies between two fl ow EMS

setting curves (in this case, the point lies between the fl ow curves for EMS setting 1 and

2). Observe the location of the point relative

to the two curves it lies between and approximate the EMS setting (fi gure 5). For more precise results you can mathematically interpolate between the two curves to determine the

optimal EMS setting.

For this example the EMS setting is 1.8.

WILDEN PUMP & ENGINEERING, LLC 12 PX1 Performance

Page 15

HOW TO USE THIS EMS CURVE

Example 2.2

SETTING 4 PERFORMANCE CURVE

Figure 6

Example data point =

10.2

gpm

Determine air consumption at a specific

EMS setting.

Step 1

: Determine air X Factor. In order to determine

the air X Factor, identify the two air EMS setting curves closest to the EMS setting established in example 2.1 (in this case, the point lies

between the air curves for EMS setting 1 and

2). The point representing your EMS setting

(1.8) must be approximated and plotted on the

EMS curve along the horizontal line representing your discharge pressure (in this case, 40

psig). This air point is different than the fl ow

point plotted in example 2.1. After estimating

(or interpolating) this point on the curve, draw

a vertical line downward until reaching the

bottom scale on the chart and identify the air

X Factor (fi gure 7).

EMS CURVE

EMS Air

Settings 1 & 2

Figure 7

Example data point =

Step 2

: Determine air consumption. Multiply your

setting 4 air consumption (14 scfm) value by

the air X Factor obtained above (0.40) to determine your actual air consumption.

1

4 scfm x 0.40 = 5.6 SCFM

In summary, for an application requiring 18.9 lpm

(5 gpm) against 2.8 bar (40 psig) discharge pressure,

the pump inlet air pressure should be set to 4.1 bar

(60 psig) and the EMS dial should be set to 1.8. The

pump would then consume 9.5 Nm3/h (5.6 scfm) of

compressed air.

0.40

air multiplier

For this example the air X Factor is 0.40

PX1 Performance 13 WILDEN PUMP & ENGINEERING, LLC

Page 16

EMS CURVE

PERFORMANCE

/h (21.0

3

EXAMPLE

A PX1 metal, Rubber-fi tted pump operating at EMS setting 4,

achieved a fl ow rate of 56.8 lpm (15.0 gpm) using 35.7 Nm

scfm) of air when run at 5.5 bar (80 psig) air inlet pressure and 1.4

bar (20 psig) discharge pressure (See dot on fl ow chart).

The end user did not require that much fl ow and wanted to reduce

air consumption at his facility. He determined that EMS setting

2 would meet his needs. At 1.4 bar (20 psig) discharge pressure

and EMS setting 2, the fl ow “X factor” is .66 and the air “X factor”

is .48.

Multiplying the original setting 4 values by the “X factors” provides

/h (10.1 scfm). The fl ow rate was reduced by 34%

3

the setting 2 fl ow rate of 37.5 lpm (9.9 gpm) and an air consump-

tion of 17.2 Nm

while the air consumption was reduced by 52%, thus providing

increased effi ciency.

For a detailed example for how to set your EMS, see beginning of

performance curve section.

Caution: Do not exceed 8.6 bar (125 psig) air supply pressure.

The Effi ciency Management System (EMS)

can be used to optimize the performance of

your Wilden pump for specifi c applications.

The pump is delivered with the EMS adjusted

to setting 4, which allows maximum fl ow.

The EMS curve allows the pump user to deter-

mine fl ow and air consumption at each EMS

setting. For any EMS setting and discharge

pressure, the “X factor” is used as a multi-

plier with the original values from the setting

4 performance curve to calculate the actual

fl ow and air consumption values for that spe-

cifi c EMS setting. Note: you can interpolate

between the setting curves for operation at

intermediate EMS settings.

1

SETTING 4 PERFORMANCE CURVE

Displacement per stroke was calculated at 4.8

bar (70 psig) air inlet pressure against a 2 bar

Air Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . 13 mm (1/2”)

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 mm (1/2”)

Outlet. . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 mm (1/2”)

TECHNICAL DATA

Height . . . . . . . . . . . . . . . . . . . . . . . . . . .224 mm (8.8”)

Width. . . . . . . . . . . . . . . . . . . . . . . . . . . .208 mm (8.2”)

Depth. . . . . . . . . . . . . . . . . . . . . . . . . . .287 mm (11.3”)

Ship Weight . . . . . . . . . . . . . Aluminum 6 kg (13 lbs.)

PX1 METAL RUBBER-FITTED

WILDEN PUMP & ENGINEERING, LLC 14 PX1 Performance

. . . . . . . . . . . . . . . . 316 Stainless Steel 9 kg (20 lbs.)

Suction Lift . . . . . . . . . . . . . . . . . . . . .5.9 m Dry (19.3’)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.0 m Wet (26.1’)

Disp. Per Stroke. . . . . . . . . . . . . . . 0.09 l (0.023 gal.)

Max. Flow Rate . . . . . . . . . . . . . .62.5 lpm (16.5 gpm)

Max. Size Solids . . . . . . . . . . . . . . . . . 1.6 mm (1/16”)

(30 psig)head pressure.

1

The Effi ciency Management System (EMS) can be used to optimize the performance of your Wilden pump for

specifi c applications. The pump is delivered with the EMS adjusted to setting 4, which allows maximum fl ow.

Page 17

EMS CURVE

PERFORMANCE

/h (2.5 scfm). The fl ow rate was reduced by 68% while

3

the air consumption was reduced by 86%, thus providing increased

effi ciency.

EXAMPLE

A PX1 metal, TPE-fi tted pump operating at EMS setting 4, achieved

a fl ow rate of 56.0 lpm (14.8 gpm) using 29.7 Nm3/h (17.5 scfm) of air

when run at 4.8 bar (70 psig) air inlet pressure and 0.7 bar (10 psig)

discharge pressure (See dot on fl ow chart).

The end user did not require that much fl ow and wanted to reduce

air consumption at his facility. He determined that EMS setting

1 would meet his needs. At 0.7 bar (10 psig) discharge pressure

and EMS setting 1, the fl ow “X factor” is .32 and the air “X factor”

is .14.

Multiplying the original setting 4 values by the “X factors” provides

the setting 1 fl ow rate of 17.8 lpm (4.7 gpm) and an air consumption

of 4.2 Nm

For a detailed example for how to set your EMS, see beginning of

performance curve section.

Caution: Do not exceed 8.6 bar (125 psig) air supply pressure.

The Effi ciency Management System (EMS)

can be used to optimize the performance of

your Wilden pump for specifi c applications.

The pump is delivered with the EMS adjusted

to setting 4, which allows maximum fl ow.

The EMS curve allows the pump user to deter-

mine fl ow and air consumption at each EMS

setting. For any EMS setting and discharge

pressure, the “X factor” is used as a multi-

plier with the original values from the setting

4 performance curve to calculate the actual

fl ow and air consumption values for that spe-

cifi c EMS setting. Note: you can interpolate

between the setting curves for operation at

intermediate EMS settings.

1

SETTING 4 PERFORMANCE CURVE

Displacement per stroke was calculated at 4.8

bar (70 psig) air inlet pressure against a 2 bar

Air Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . 13 mm (1/2”)

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 mm (1/2”)

Outlet. . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 mm (1/2”)

TECHNICAL DATA

Height . . . . . . . . . . . . . . . . . . . . . . . . . . .224 mm (8.8”)

Width. . . . . . . . . . . . . . . . . . . . . . . . . . . .208 mm (8.2”)

Depth. . . . . . . . . . . . . . . . . . . . . . . . . . .287 mm (11.3”)

Ship Weight . . . . . . . . . . . . . Aluminum 6 kg (13 lbs.)

PX1 METAL TPE-FITTED

PX1 Performance 15 WILDEN PUMP & ENGINEERING, LLC

. . . . . . . . . . . . . . . . 316 Stainless Steel 9 kg (20 lbs.)

Suction Lift . . . . . . . . . . . . . . . . . . . . .5.7 m Dry (18.7’)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.3 m Wet (30.6’)

Disp. Per Stroke. . . . . . . . . . . . . . . 0.11 l (0.029 gal.)

Max. Flow Rate . . . . . . . . . . . . . .62.8 lpm (16.6 gpm)

Max. Size Solids . . . . . . . . . . . . . . . . . 1.6 mm (1/16”)

(30 psig)head pressure.

1

The Effi ciency Management System (EMS) can be used to optimize the performance of your Wilden pump for

specifi c applications. The pump is delivered with the EMS adjusted to setting 4, which allows maximum fl ow.

Page 18

PERFORMANCE

EMS CURVE

/h (4.0 scfm). The fl ow rate was reduced by 14% while

3

EXAMPLE

A PX1 metal, PTFE-fi tted pump operating at EMS setting 4, achieved

a fl ow rate of 18.9 lpm (5 gpm) using 8.83 Nm3/h (5.2 SCFM) of air

when run at 3.2 bar (47 psig) air inlet pressure and 2.8 bar (40 psig)

discharge pressure (See dot on fl ow chart).

The end user did not require that much fl ow and wanted to reduce

air consumption at his facility. He determined that EMS setting 3

would meet his needs. At 2.8 bar (40 psig) discharge pressure and

EMS setting 3, the fl ow “X factor” is .86 and the air “X factor” is

.76.

Multiplying the original setting 4 values by the “X factors” provides

the setting 3 fl ow rate of 16.3 lpm (4.3 gpm) and an air consumption

of 6.8 Nm

the air consumption was reduced by 24%, thus providing increased

effi ciency.

For a detailed example for how to set your EMS, see beginning of

performance curve section.

Caution: Do not exceed 8.6 bar (125 psig) air supply pressure.

The Effi ciency Management System (EMS)

can be used to optimize the performance of

your Wilden pump for specifi c applications.

The pump is delivered with the EMS adjusted

to setting 4, which allows maximum fl ow.

The EMS curve allows the pump user to deter-

mine fl ow and air consumption at each EMS

setting. For any EMS setting and discharge

pressure, the “X factor” is used as a multi-

plier with the original values from the setting

4 performance curve to calculate the actual

fl ow and air consumption values for that spe-

cifi c EMS setting. Note: you can interpolate

between the setting curves for operation at

intermediate EMS settings.

1

SETTING 4 PERFORMANCE CURVE

Displacement per stroke was calculated at 4.8

bar (70 psig) air inlet pressure against a 2 bar

Air Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . 13 mm (1/2”)

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 mm (1/2”)

Outlet. . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 mm (1/2”)

TECHNICAL DATA

Height . . . . . . . . . . . . . . . . . . . . . . . . . . .224 mm (8.8”)

Width. . . . . . . . . . . . . . . . . . . . . . . . . . . .208 mm (8.2”)

Depth. . . . . . . . . . . . . . . . . . . . . . . . . . .287 mm (11.3”)

Ship Weight . . . . . . . . . . . . . Aluminum 6 kg (13 lbs.)

PX1 METAL PTFE-FITTED

WILDEN PUMP & ENGINEERING, LLC 16 PX1 Performance

. . . . . . . . . . . . . . . . 316 Stainless Steel 9 kg (20 lbs.)

Suction Lift . . . . . . . . . . . . . . . . . . . . .4.7 m Dry (15.3’)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.0 m Wet (26.1’)

Disp. Per Stroke. . . . . . . . . . . . . . . 0.09 l (0.024 gal.)

Max. Flow Rate . . . . . . . . . . . . . .60.9 lpm (16.1 gpm)

Max. Size Solids . . . . . . . . . . . . . . . . . 1.6 mm (1/16”)

(30 psig)head pressure.

1

The Effi ciency Management System (EMS) can be used to optimize the performance of your Wilden pump for

specifi c applications. The pump is delivered with the EMS adjusted to setting 4, which allows maximum fl ow.

Page 19

NOTES

PX1 Performance 17 WILDEN PUMP & ENGINEERING, LLC

Page 20

T

a

k

e

c

o

n

t

r

o

l

o

f

y

o

u

r

p

r

o

c

e

s

s

t

o

d

a

y

w

i

t

h

22069 Van Buren St. • Grand Terrace, CA 92313-5651

Tel 909-422-1730 • Fax 909-783-3440 • www.wildenx.com

Page 21

Section 5C

SUCTION LIFT CURVE

P1 METAL

PX1 METAL

SUCTION LIFT CURVE

Suction lift curves are calibrated for pumps operating at 305

m (1,000’) above sea level. This chart is meant to be a guide

only. There are many variables which can affect your pump’s

operating characteristics. The number of intake and dis-

WIL-10300-E-10 19 WILDEN PUMP & ENGINEERING, LLC

charge elbows, viscosity of pumping fluid, elevation (atmospheric pressure) and pipe friction loss all affect the amount

of suction lift your pump will attain.

Page 22

Section 6

SUGGESTED INSTALLATION

Wilden pumps are designed to meet the performance requirements

of even the most demanding pumping applications. They have

been designed and manufactured to the highest standards and are

available in a variety of liquid path materials to meet your chemical

resistance needs. Refer to the performance section of this manual

for an in-depth analysis of the performance characteristics of your

pump. Wilden offers the widest variety of elastomer options in the

industry to satisfy temperature, chemical compatibility, abrasion

resistance and fl ex concerns.

The suction pipe size should be at least the equivalent or larger

than the diameter size of the suction inlet on your Wilden pump.

The suction hose must be non-collapsible, reinforced type as these

pumps are capable of pulling a high vacuum. Discharge piping

should also be the equivalent or larger than the diameter of the

pump discharge which will help reduce friction losses. It is critical

that all fi ttings and connections are airtight or a reduction or loss of

pump suction capability will result.

INSTALLATION: Months of careful planning, study, and selection

efforts can result in unsatisfactory pump performance if installation

details are left to chance.

Premature failure and long term dissatisfaction can be avoided if

reasonable care is exercised throughout the installation process.

LOCATION: Noise, safety, and other logistical factors usually dictate

where equipment will be situated on the production fl oor. Multiple

installations with confl icting requirements can result in congestion

of utility areas, leaving few choices for additional pumps.

Within the framework of these and other existing conditions, every

pump should be located in such a way that six key factors are

balanced against each other to maximum advantage.

ACCESS: First of all, the location should be accessible. If it’s easy

to reach the pump, maintenance personnel will have an easier time

carrying out routine inspections and adjustments. Should major

repairs become necessary, ease of access can play a key role in

speeding the repair process and reducing total downtime.

AIR SUPPLY: Every pump location should have an air line large

enough to supply the volume of air necessary to achieve the desired

pumping rate. Use air pressure up to a maximum of 8.6 bar (125

psig) depending on pumping requirements.

For best results, the pumps should use a 5µ (micron) air fi lter,

needle valve and regulator. The use of an air fi lter before the pump

will ensure that the majority of any pipeline contaminants will be

eliminated.

NOTE: Canadian Standards Association (CSA) confi gured pumps

should not exceed 6.9 bar (100 psig) sweet gas supply pressure.

ONLY CSA confi gured pumps should be operated using gas.

SOLENOID OPERATION: When operation is controlled by a solenoid

valve in the air line, three-way valves should be used. This valve

allows trapped air between the valve and the pump to bleed off

which improves pump performance. Pumping volume can be

estimated by counting the number of strokes per minute and then

multiplying the fi gure by the displacement per stroke.

MUFFLER: Sound levels are reduced below OSHA specifi cations

using the standard Wilden muffl er. Other muffl ers can be used

to further reduce sound levels, but they usually reduce pump

performance.

ELEVATION: Selecting a site that is well within the pump’s dynamic

lift capability will assure that loss-of-prime issues will be eliminated.

In addition, pump effi ciency can be adversely affected if proper

attention is not given to site location.

PIPING: Final determination of the pump site should not be made

until the piping challenges of each possible location have been

evaluated. The impact of current and future installations should be

considered ahead of time to make sure that inadvertent restrictions

are not created for any remaining sites.

For U.L. listed pumps, all installation must conform with NFPA 30,

NFPA 30A, and other applicable codes. All pipe connections are

to be made using U.L. classifi ed gasoline-resistant pipe compound.

Exhaust port is to be connected to pipe or tubing to be routed

outdoors or other location determined to be equivalent.

The best choice possible will be a site involving the shortest and

straightest hook-up of suction and discharge piping. Unnecessary

elbows, bends, and fi ttings should be avoided. Pipe sizes should

be selected to keep friction losses within practical limits. All piping

should be supported independently of the pump. In addition, the

piping should be aligned to avoid placing stress on the pump

fi ttings.

Flexible hose can be installed to aid in absorbing the forces created

by the natural reciprocating action of the pump. If the pump is to be

bolted down to a solid location, a mounting pad placed between the

pump and the foundation will assist in minimizing pump vibration.

Flexible connections between the pump and rigid piping will also

assist in minimizing pump vibration. If quick-closing valves are

installed at any point in the discharge system, or if pulsation within

a system becomes a problem, a surge suppressor (SD Equalizer®)

should be installed to protect the pump, piping and gauges from

surges and water hammer.

If the pump is to be used in a self-priming application, make sure

that all connections are airtight and that the suction lift is within

the model’s ability. Note: Materials of construction and elastomer

material have an effect on suction lift parameters. Please refer to the

performance section for specifi cs.

When pumps are installed in applications involving fl ooded suction

or suction head pressures, a gate valve should be installed in the

suction line to permit closing of the line for pump service.

Pumps in service with a positive suction head are most effi cient

when inlet pressure is limited to 0.5–0.7 bar (7–10 psig). Premature

diaphragm failure may occur if positive suction is 0.7 bar (10 psig)

and higher.

SUBMERSIBLE APPLICATIONS: Pro-Flo X™ pumps can

be used for submersible applications, when using the

Pro-Flo X™ submersible option. Turbo-Flo™ pumps can also be

used for submersible applications.

NOTE: Pro-Flo® and Accu-Flo™ pumps are not submersible.

ALL WILDEN PUMPS ARE CAPABLE OF PASSING SOLIDS. A

STRAINER SHOULD BE USED ON THE PUMP INTAKE TO ENSURE

THAT THE PUMP'S RATED SOLIDS CAPACITY IS NOT EXCEEDED.

CAUTION: DO NOT EXCEED 8.6 BAR (125 PSIG) AIR SUPPLY

PRESSURE.

CAUTION: CANADIAN STANDARDS ASSOCIATION (CSA)

CONFIGURED PUMPS SHOULD NOT EXCEED 6.9 BAR (100 PSIG)

SWEET GAS SUPPLY PRESSURE.

CAUTION: FOR U.L. LISTED PUMPS, DO NOT EXCEED 3.4 BAR (50

PSIG) AIR SUPPLY PRESSURE.

WILDEN PUMP & ENGINEERING, LLC 20 WIL-10300-E-10

Page 23

SUGGESTED INSTALLATION

This illustration is a generic

representation of an air-operated

double-diaphragm pump.

NOTE: In the event of a power failure, the shut off valve

should be closed, if the restarting of the pump is not

desirable once power is regained.

AIR OPERATED PUMPS: To stop the pump from

operating in an emergency situation, simply close the

shut off valve (user supplied) installed in the air supply

line. A properly functioning valve will stop the air supply

to the pump, therefore stopping output. This shut off

valve should be located far enough away from the

pumping equipment such that it can be reached safely

in an emergency situation.

WIL-10300-E-10 21 WILDEN PUMP & ENGINEERING, LLC

Page 24

SUGGESTED OPERATION & MAINTENANCE

OPERATION: P1 and PX1 pumps are pre-lubricated, and

do not require in-line lubrication. Additional lubrication

will not damage the pump, however if the pump is

heavily lubricated by an external source, the pump’s

internal lubrication may be washed away. If the pump is

then moved to a non-lubricated location, it may need to

be disassembled and re-lubricated as described in the

ASSEMBLY/DISASSEMBLY INSTRUCTIONS.

Pump discharge rate can be controlled by limiting the

volume and/or pressure of the air supply to the pump. A

regulator is used to control air pressure while a needle

valve is used to control volume. Pump discharge rate

can also be controlled by throttling the pump discharge

by partially closing a valve in the discharge line of the

pump. This action increases friction loss which reduces

fl ow rate. (See Section 5.) This is useful when the need

exists to control the pump from a remote location.

When the pump discharge pressure equals or exceeds

the air supply pressure, the pump will stop; no bypass

or pressure relief valve is needed, and pump damage

will not occur. The pump has reached a “deadhead”

situation and can be restarted by reducing the fl uid

discharge pressure or increasing the air inlet pressure.

TROUBLESHOOTING

The P1 and PX1 pumps run solely on compressed air

and do not generate heat, therefore your process fl uid

temperature will not be affected.

NOTE: Canadian Standards Association (CSA) confi gured

pumps run solely on gas and do not generate heat.

MAINTENANCE AND INSPECTIONS: Since each

application is unique, maintenance schedules may be

different for every pump. Frequency of use, line pressure,

viscosity and abrasiveness of process fl uid all affect

the parts life of a Wilden pump. Periodic inspections

have been found to offer the best means for preventing

unscheduled pump downtime. Personnel familiar with

the pump’s construction and service should be informed

of any abnormalities that are detected during operation.

RECORDS: When service is required, a record should be

made of all necessary repairs and replacements. Over

a period of time, such records can become a valuable

tool for predicting and preventing future maintenance

problems and unscheduled downtime. In addition,

accurate records make it possible to identify pumps

that are poorly suited to their applications.

Pump will not run or runs slowly.

1. Ensure that the air inlet pressure is at least 0.3 Bar

(5 psig) above startup pressure and that the differential

pressure (the difference between air inlet and liquid

discharge pressures) is not less than 0.7 Bar (10 psig).

2. Check air inlet fi lter for debris (see recommended

installation).

3. Check for extreme air leakage (blow by) which

would indicate worn seals /bores in the air valve,

pilot spool, main shaft.

4. Disassemble pump and check for obstructions

in the air passageways or objects which would

obstruct the movement of internal parts.

5. Check for sticking ball check valves. If material being

pumped is not compatible with pump elastomers,

swelling may occur. Replace ball check valves and

seals with proper elastomers. Also, as the check

valve balls wear out, they become smaller and can

become stuck in the seats. In this case, replace balls

and seats.

6. Check for broken inner piston which will cause the

air valve spool to be unable to shif t.

7. Remove plug from pilot spool exhaust.

Pump runs but little or no product fl ows.

1. Check for pump cavitation; slow pump speed down

to allow thick material to fl ow into liquid chambers.

WILDEN PUMP & ENGINEERING, LLC 22 WIL-10300-E-10

2. Verify that vacuum required to lift liquid is not

greater than the vapor pressure of the material

being pumped (cavitation).

3. Check for sticking ball check valves. If material being

pumped is not compatible with pump elastomers,

swelling may occur. Replace ball check valves and

seats with proper elastomers. Also, as the check

valve balls wear out, they become smaller and can

become stuck in the seats. In this case, replace balls

and seats.

Pump air valve freezes.

1. Check for excessive moisture in compressed

air. Either install a dryer or hot air generator for

c o m p r e s s e d a i r . A l t e r n a t i v e l y , a c o a l e s c i n g fi lter may

be used to remove the water from the compressed

air in some applications.

Air bubbles in pump discharge.

1. Check for ruptured diaphragm.

2. Check tightness of outer pistons (refer to Section 7).

3. Check tightness of fasteners and integrity of

o-rings and seals, especially at intake manifold.

4. Ensure pipe connections are airtight.

Product comes out air exhaust.

1. Check for diaphragm rupture.

2. Check tightness of outer pistons to shaft.

Page 25

Section 7

P1 METAL

PUMP DISASSEMBLY

TOOLS REQUIRED:

• 3/8" Box Wrench

• 7/16" Wrench

• Adjustable Wrench

• Vise equipped with soft

jaws (such as plywood,

plastic or other suitable

material)

CAUTION: Before any maintenance or repair is attempted, the compressed air line

to the pump should be disconnected and all air pressure allowed to bleed from the

pump. Disconnect all intake, discharge, and air lines. Drain the pump by turning it

upside down and allowing any fl uid to fl ow into a suitable container. Be aware of

any hazardous effects of contact with your process fl uid.

NOTE: The model photographed for these instructions is a Pro-FloX™ version and

incorporates rubber diaphragms, balls, and seats.

Step 1

Prior to disassembly, alignment

marks should be placed on the

liquid chambers and air chamber to

assist with proper alignment during

reassembly.

WIL-10300-E-10 23 WILDEN PUMP & ENGINEERING, LLC

Step 2

Using a 7/16" box wrench, remove

the nuts that connect the inlet and

discharge manifolds to the center

section assembly.

Step 3

Next, remove the discharge manifold

from the pump.

Page 26

PUMP DISASSEMBLY

Step 4

Remove the discharge valve ball,

valve seat and valve seat o-ring

and inspect for signs of wear and

replace if necessary.

Step 5

Now the center section assembly

can be removed from the inlet

manifold.

Step 6

Remove the inlet valve ball, valve

seat and valve seat o-ring and inspect

for signs of wear and/or chemical

attack. Replace if necessary.

Step 7

Using a 3/8" wrench, remove the

small clamp band that connects the

manifold elbows to the tee section.

WILDEN PUMP & ENGINEERING, LLC 24 WIL-10300-E-10

Step 8

Remove the tee section o-rings

and inspect for signs of wear and/

or chemical attack. Replace if

necessary.

Step 9

Using a 7/16" box end wrench,

remove the large clamp bands.

With the clamp bands removed, lift

the liquid chamber away from the

center section.

Page 27

PUMP DISASSEMBLY

Step 10

Using an adjustable wrench or

rotating the diaphragm by hand,

remove the diaphragm assembly

from the center section.

Step 11A

Due to varying torque values, one

of the two situations will occur:

A) The outer piston, diaphragm

and inner piston will separate

from the shaft which remains

connected to the opposite side

diaphragm assembly.

Step 11B

B) The diaphragm assembly and

shaft remain connected leaving

the opposite side diaphragm

assembly within the opposite

side of the center section

assembly.

GROUNDING STRAP FOR CSA PX1 PUMPS

Step 12

To remove the diaphragm assembly

from the shaft, secure shaft with

soft jaws (a vise fi tted with plywood

or other suitable material) to ensure

shaft is not nicked, scratched,

or gouged. Using an adjustable

wrench, remove the diaphragm

assembly from shaft. Inspect all

parts for wear and replace with

genuine Wilden parts if necessary.

WIL-10300-E-10 25 WILDEN PUMP & ENGINEERING, LLC

Canadian Standards Association (CSA) confi gured pumps must be

electrically grounded using the grounding strap provided (fi gure 1).

Improper grounding can cause improper and dangerous operation.

To properly attach the grounding strap to a CSA confi gured PX1 pump,

position the grounding strap eyelet between the two 7/16" clamp band nuts

and tighten to secure the grounding strap (fi gure 2). NOTE: Two 7/16" nuts

must be used when securing the grounding strap to the pump. This is

done to avoid loosening the large clamp band and possibly creating a gas

leak. Grounding the pump must be done in accordance with local codes,

or in the absence of local codes, an industry or nationally recognized code

having jurisdiction over the specifi ed installation.

Page 28

AIR VALVE/CENTER SECTION DISASSEMBLY

TOOLS REQUIRED:

• 3/16" Hex Head Wrench

• 7/32" Hex Head Wrench

• Snap Ring Pliers

• O-Ring Pick

CAUTION: Before any maintenance or repair is attempted, the compressed air line

to the pump should be disconnected and all air pressure allowed to bleed from the

pump. Disconnect all intake, discharge, and air lines. Drain the pump by turning it

upside down and allowing any fl uid to fl ow into a suitable container. Be aware of

hazardous effects of contact with your process fl uid.

Step 1

Using a 3/16” hex head wrench,

loosen the air valve bolts.

WILDEN PUMP & ENGINEERING, LLC 26 WIL-10300-E-10

Step 2

Remove the air valve and muffl er

plate from the center section.

Step 3

Remove the air valve gasket

and inspet for nicks, gouges and

chemical attack. Replace if necessary

with genuine Wilden parts. Note:

When installing the air valve gasket

onto the center section assembly,

position gasket with the grooved

side facing away from the center

section.

Page 29

AIR VALVE/CENTER SECTION DISASSEMBLY

Step 4

Remove muffl er plate gasket and

inspect. Replace if necessary.

Step 5

Remove air valve end cap to expose

air valve spool. NOTE: The end cap

cannot be removed until removing

air valve bolts.

Step 6

Remove air valve spool from air

valve body by threading one air valve

bolt into the end of the spool and

gently sliding the spool out of the air

valve body. Inspect seals for signs of

wear and replace entire assembly if

necessary. Use caution when handling

air valve spool to prevent damaging

seals. NOTE: Seals should not be

removed from assembly. Seals are not

sold separately.

Step 7

Remove pilot spool retaining snap

ring on both sides of center section

with snap ring pliers.

WIL-10300-E-10 27 WILDEN PUMP & ENGINEERING, LLC

Step 8

Remove pilot spool assembly from

center section.

Step 9

Using an o-ring pick, gently

remove the pilot spool retaining

o-ring from the opposite side of the notched

end of the spool. Gently remove the pilot

spool from pilot spool sleeve and inspect

for nicks, gouges and other signs of wear.

Replace pilot spool assembly or outer sleeve

o-rings if necessary. During re-assembly

never insert the pilot spool into the sleeve

with the “notched” end side fi rst, this end

incorporates the urethane o-ring and will be

damaged as it slides over the ports cut in

the pilot spool sleeve.

Page 30

AIR VALVE/CENTER SECTION DISASSEMBLY

Step 10

Check center section shaft seals

for signs of wear. If necessary,

remove the shaft seals with an

o-ring pick and replace.

SUBMERSIBLE PRO-FLO X™

Step 1

Install a 1/4" NPT pipe plug (00-7010-

08) into the pilot spool bleed port

located at the front of the center

section.

Step 2

Next, install an optional submersible air valve gasket (01-2621-

52). The submersible air valve gasket can be purchased as a

spare part or included with the purchase of a new Pro-Flo X™

pump.

WILDEN PUMP & ENGINEERING, LLC 28 WIL-10300-E-10

Page 31

REASSEMBLY HINT & TIPS

ASSEMBLY:

Upon performing applicable maintenance to the air distribution system, the pump can now be reassembled. Please

refer to the disassembly instructions for photos and parts

placement. To reassemble the pump, follow the disassembly

instructions in reverse order. The air distribution system needs

to be assembled first, then the diaphragms and finally the

wetted path. Please find the applicable torque specifications

on this page. The following tips will assist in the assembly

process.

• Clean the inside of the center section shaft bore to ensure

no damage is done to new seals.

• Stainless bolts should be lubed to reduce the possibility of

seizing during tightening.

• Level the water chamber side of the intake/discharge

manifold to ensure a proper sealing surface. This is most

easily accomplished by placing them on a flat surface

prior to tightening their clamp bands to the desired torque

(see this page for torque specs).

• Be sure to tighten outer pistons simultaneously on PTFEfitted pumps to ensure proper torque values.

• Ensure proper mating of liquid chambers to manifolds

prior to tightening vertical bolts. Overhang should be

equal on both sides.

• Apply a small amount of Loctite 242 to the shaft interval

threads before the diaphragm assembly.

• Concave side of disc spring in diaphragm assembly faces

toward shaft.

PRO-FLO® MAXIMUM TORQUE SPECIFICATIONS

Description of Part Maximum Torque

Air Valve, Pro-Flo

Outer Piston 14.1 N•m (125 in)

Small Clamp Band 1.7 N•m (15 in)

Large Clamp Band (Rubber/TPE-Fitted) 9.0 N•m (80 in)

Large Clamp Band (PTFE-Fitted) 13.6 N•m (120 in)

Vertical Bolts 14.1 N•m (125 in)

®

3.1 N•m (27 in-lbs.)

PRO-FLO X™ MAXIMUM TORQUE SPECIFICATIONS

Description of Part Maximum Torque

Air Valve, Pro-Flo X™ 11.3 N•m (100 in-lbs.)

Outer Piston 14.1 N•m (125 in)

Small Clamp Band 1.7 N•m (15 in)

Large Clamp Band (Rubber/TPE-Fitted) 9.0 N•m (80 in)

Large Clamp Band (PTFE-Fitted) 13.6 N•m (120 in)

Vertical Bolts 14.1 N•m (125 in)

ELASTOMER KITS

Program Details:

• Elastomer & ADS Repair Kits

• All Sizes Available

• PTFE, Rubber & TPE Elastomers

• One Part Number Simplifi es Inventory

• Eliminates Order Errors

• Reduces Re-Build Time

• Rejuvenates Your Pump

NOTE: See Section 9.

WIL-10300-E-10 29 WILDEN PUMP & ENGINEERING, LLC

Page 32

Section 8

EXPLODED VIEW & PARTS LISTING

P1 METAL

RUBBER/TPE-FITTED EXPLODED VIEW

WILDEN PUMP & ENGINEERING, LLC 30 WIL-10300-E-10

Page 33

EXPLODED VIEW & PARTS LISTING

P1 METAL

Item Part Description

1 Pro-Flo™ Air Valve Assembly

2 End Cap 1 01-2332-20 01-2332-20 01-2332-20

3 O-Ring, End Cap 1 01-2395-52 01-2395-52 01-2395-52

4 Gasket, Air Valve 1 01-2615-52 01-2615-52 01-2615-52

5 Screw, HSHC, Air Valve 1⁄4-20 4 01-6001-03 01-6001-03 01-6001-03

6 Nut, Hex, 1⁄4”-20 4 04-6400-03 04-6400-03 04-6400-03

7 Center Section Assembly 1 01-3140-20 01-3140-20 01-3140-20

8 Bushing, Reducer 1 01-6950-20 01-6950-20 01-6950-20

9 Removable Pilot Sleeve Assembly 1 01-3880-99 01-3880-99 01-3880-99

10 Glyd™ Ring II 2 01-3220-55 01-3220-55 01-3220-55

11 Retaining Ring 2 00-2650-03 00-2650-03 00-2650-03

12 Muffler Plate 1 01-3181-20 01-3181-20 01-3181-20

13 Gasket, Muffler Plate 1 01-3505-52 01-3505-52 01-3505-52

14 Muffler 1 02-3510-99 02-3510-99 02-3510-99

15 Shaft, Pro-Flo™ 1 01-3810-03 01-3810-03 01-3810-03

16 Disc Spring 2 01-6802-08 01-6802-08 01-6802-08

17 Inner Piston 2 01-3711-08 01-3711-08 01-3711-08

18 Outer Piston 2 01-4570-01 01-4570-03 01-4570-03

19 Liquid Chamber 2 01-5000-01 01-5000-03 01-5000-03

20 Manifold Tee Section 2 01-5160-01 01-5160-03 01-5160-03-70

21 Inlet Manifold Elbow 2 01-5220-01 01-5220-03 01-5220-03

22 Discharge Manifold Elbow 2 01-5230-01 01-5230-03 01-5230-03

23 Screw, SHCS (Chamber Bolt) 4 01-6080-03 01-6080-03 01-6080-03

24 Vertical Bolt Washer 4 01-6730-03 01-6730-03 01-6730-03

25 Vertical Bolt Nut 4 04-6400-03 04-6400-03 04-6650-03-70

26 Diaphragm 2 * * 01-1010-56

27 Valve Ball 4 * * 01-1080-56

28 Valve Seat 4 01-1120-01 01-1120-01 01-1120-03

29 Valve Seat O-Ring 4 * * 01-1200-56

30 Manifold O-Ring 4 * * 01-1300-56

31 Small Clamp Band Assy. 4 01-7100-03 01-7100-03 01-7100-03

32 Small Clamp Band Bolt 8 01-6101-03 01-6101-03 01-6101-03

33 Small Clamp Band Nut 8 01-6400-03 01-6400-03 01-6400-03

34 Large Clamp Band Assy. 2 01-7300-03 01-7300-03 01-7300-03

35 Large Clamp Band Bolt 4 01-6070-03 01-6070-03 01-6070-03

36 Large Clamp Band Nut 4 04-6400-03 04-6400-03 04-6650-03-70

1

Air Valve Assembly includes items 2 and 3.

*Refer to corresponding elastomer chart in Section 10.

070 Specialty Code = Saniflo

All boldface items are primary wear parts.

RUBBER/TPE-FITTED PARTS LISTING

Qty. Per

Pump

1

FDA

1 01-2010-20 01-2010-20 01-2010-20

P1/APPP

P/N

P1/SPPP

P/N

P1/SPPP/070

P/N

WIL-10300-E-10 31 WILDEN PUMP & ENGINEERING, LLC

Page 34

EXPLODED VIEW & PARTS LISTING

P1 METAL

PTFE-FITTED EXPLODED VIEW

WILDEN PUMP & ENGINEERING, LLC 32 WIL-10300-E-10

Page 35

EXPLODED VIEW & PARTS LISTING

P1 METAL

Item Part Description

1 Pro-Flo™ Air Valve Assembly

2 End Cap 1 01-2332-20 01-2332-20 01-2332-20

3 O-Ring, End Cap 1 01-2395-52 01-2395-52 01-2395-52

4 Gasket, Air Valve 1 01-2615-52 01-2615-52 01-2615-52

5 Screw, HSHC, Air Valve 1⁄4-20 4 01-6001-03 01-6001-03 01-6001-03

6 Nut, Hex, 1⁄4”-20 4 04-6400-03 04-6400-03 04-6400-03

7 Center Section Assembly 1 01-3140-20 01-3140-20 01-3140-20

8 Bushing, Reducer 1 01-6950-20 01-6950-20 01-6950-20

9 Removable Pilot Sleeve Assembly 1 01-3880-99 01-3880-99 01-3880-99

10 Glyd™ Ring II 2 01-3220-55 01-3220-55 01-3220-55

11 Retaining Ring 2 00-2650-03 00-2650-03 00-2650-03

12 Muffler Plate 1 01-3181-20 01-3181-20 01-3181-20

13 Gasket, Muffler Plate 1 01-3505-52 01-3505-52 01-3505-52

14 Muffler 1 02-3510-99 02-3510-99 01-3510-99

15 Shaft, Pro-Flo™ 1 01-3810-03 01-3810-03 01-3810-03

16 Disc Spring (Belleville Washer) 2 01-6802-08 01-6802-08 01-6802-08

17 Inner Piston 2 01-3711-08 01-3711-08 01-3711-08

18 Outer Piston 2 01-4570-01 01-4570-03 01-4570-03

19 Liquid Chamber 2 01-5000-01 01-5000-03 01-5000-03

20 Manifold Tee Section 2 01-5160-01 01-5160-03 01-5160-03-70

21 Inlet Manifold Elbow 2 01-5220-01 01-5220-03 01-5220-03

22 Discharge Manifold Elbow 2 01-5230-01 01-5230-03 01-5230-03

23 Screw, SHCS (Chamber Bolt) 4 01-6080-03 01-6080-03 01-6080-03

24 Vertical Bolt Washer 4 01-6730-03 01-6730-03 01-6730-03

25 Vertical Bolt Nut 4 04-6400-03 04-6400-03 04-6650-03-70

26 PTFE Primary Diaphragm 2 01-1010-55 01-1010-55 01-1010-55

27 Neoprene Backup Diaphragm 2 01-1060-51 01-1060-51 01-1060-51

28 Valve Ball 4 01-1080-55 01-1080-55 01-1080-55

29 Valve Seat 4 01-1120-01 01-1120-03 01-1120-03

30 Valve Seat O-Ring 4 01-1200-55 01-1200-55 01-1200-55

31 Manifold O-Ring 4 01-1300-55 01-1300-55 01-1300-55

32 Small Clamp Band Assy. 4 01-7100-03 01-7100-03 01-7100-03

33 Small Clamp Band Bolt 8 01-6101-03 01-6101-03 01-6101-03

34 Small Clamp Band Nut 8 01-6400-03 01-6400-03 01-6400-03

35 Large Clamp Band Assy. 2 01-7300-03 01-7300-03 01-7300-03

36 Large Clamp Band Bolt 4 01-6070-03 01-6070-03 01-6070-03

37 Large Clamp Band Nut 4 04-6400-03 04-6400-03 04-6650-03-70

1

Air Valve Assembly includes items 2 and 3.

*Refer to corresponding elastomer chart in Section 10.

070 Specialty Code = Saniflo

All boldface items are primary wear parts.

PTFE-FITTED PARTS LISTING

Qty Per.

Pump

1

FDA

1 01-2010-20 01-2010-20 01-2010-20

P1/APPP

P/N

P1/SPPP

P/N

P1/SPPP/070

P/N

WIL-10300-E-10 33 WILDEN PUMP & ENGINEERING, LLC

Page 36

Section 9D

EXPLODED VIEW & PARTS LISTING

PX1 METAL

RUBBER-FITTED EXPLODED VIEW

ALL CIRCLED PART IDENTIFIERS ARE INCLUDED IN REPAIR KITS.

WILDEN PUMP & ENGINEERING, LLC 34 WIL-10300-E-10

Page 37

EXPLODED VIEW & PARTS LISTING

PX1 METAL

No. Part Description Qty,

1 Pro-Flo X™ Air Valve Assembly

2 End Cap 1 01-2340-01 01-2340-01 01-2340-06

3 O-Ring (-126), End Cap (1.362 x .103) 1 01-2395-52 01-2395-52 01-2395-52

4 Gasket, Air Valve, Pro-Flo X™ 1 01-2620-52 01-2620-52 01-2620-52

5 Gasket, Muffl er Plate, Pro-Flo X™ 1 01-3502-52 01-3502-52 01-3502-52

6 Muffl er Plate, Pro-Flo X™ 1 01-3185-01 01-3185-01 01-3185-06

7 Screw, SHC, Air Valve (1/4”-20 x 3”) 4 01-6001-03 01-6001-03 01-6001-03

8 Muffler* 1 02-3512-99 02-3512-99 02-3512-99

9 Center Block Assembly, Pro-Flo X™ 1 01-3146-01 01-3146-01 01-3146-06

10 Adjuster, Air Inlet, Pro-Flo X™ 1 01-3560-01 01-3560-01 01-3560-06

11 O-Ring (-206), Air Adjustment Pin (.484 x .139) 1 00-1300-52 00-1300-52 00-1300-52

12 Set Screw, Air Adjustment, Pro-Flo X™ 1 01-6342-03 01-6342-03 01-6342-03

13 Shaft Seal 2 01-3220-55 01-3220-55 01-3220-55

14 Pilot Sleeve Assembly 1 01-3880-99 01-3880-99 01-3880-99

15 Pilot Spool Retaining O-Ring 2 04-2650-49-700 04-2650-49-700 04-2650-49-700

16 Retaining Ring 2 00-2650-03 00-2650-03 00-2650-03

17 Shaft 1 01-3810-03 01-3810-03 01-3810-03

18 Disc Spring 2 01-6802-08 01-6802-08 01-6802-08

19 Inner Piston 2 01-3711-08 01-3711-08 01-3711-08

20 Diaphragm 2 * * 01-1010-56

21 Outer Piston 1 01-4570-01 01-4570-03 01-4570-03

22 Liquid Chamber 2 01-5000-01 01-5000-03 01-5000-03

23 Inlet Manifold Elbow 2 01-5220-01 01-5220-03 01-5220-03

24 Manifold Tee Section 2 01-5160-01 01-5160-03 01-5160-03-70

25 Discharge Manifold Elbow 2 01-5230-01 01-5230-03 01-5230-03

26 Ball, Valve 4 * * 01-1080-56

27 Seat, Valve 4 01-1120-03 01-1120-03 01-1120-03

28 Valve Seat O-Ring 4 * * 01-1200-56

29 Bolt, Carriage (1/4”-20 x 7-3/8”) 4 01-6080-03 01-6080-03 01-6080-03

30 Washer (1/4”) 4 01-6730-03 01-6730-03 01-6730-03

31 Hex Nut (1/4”-20) 4 04-6400-03 04-6400-03 04-6651-10

32 O-Ring (-120), Manifold (.987 x .103) 4 * * 01-1300-56

33 Large Clamp Band 4 01-7300-03 01-7300-03 01-7300-03

34 Bolt, Carriage (1/4”-20 x 2”) 4 01-6070-03 01-6070-03 01-6070-03

35 Hex Nut (1/4”-20) 4 04-6400-03 04-6400-03 N/A

36 Small Clamp Band 8 01-7100-03 01-7100-03 01-7100-03

37 Screw, HHC (#10-24 x 1”) 8 01-6101-03 01-6101-03 01-6101-03

38 Hex Nut (#10-24) 8 04-6400-03 04-6400-03 04-6400-03

Wing Nut (not shown) 4 N/A N/A 04-6651-10

39 Grounding Strap, CSA 1 02-8303-99 02-8303-99 N/A

1

Air Valve Assembly includes item numbers 2 and 3.

For a submersible Pro-Flo X™ pump, use air valve gasket 01-2621-52 and pipe plug 00-7010-08 or 00-7010-03.

070 Specialty Code = Saniflo

All boldface items are primary wear parts.

*NOTE: Muffl er should not be used with Canadian Standards Association (CSA) pumps. The gas outlet of CSA confi gured pumps must be vented to a safe

location in accordance with local codes or, in the absence of local codes, an industry or nationally recognized code having jurisdiction over the specifi ed

installation.

RUBBER-FITTED PARTS LISTING

PX1/AAAAA

P/N

1

FDA

1 01-2030-01 01-2030-01 01-2030-06

PX1/SSAAA

P/N

PX1/SSNNN/0070

P/N

WIL-10300-E-10 35 WILDEN PUMP & ENGINEERING, LLC

Page 38

EXPLODED VIEW & PARTS LISTING

PX1 METAL

PTFE-FITTED EXPLODED VIEW

ALL CIRCLED PART IDENTIFIERS ARE INCLUDED IN REPAIR KITS.

WILDEN PUMP & ENGINEERING, LLC 36 WIL-10300-E-10

Page 39

EXPLODED VIEW & PARTS LISTING

PX1 METAL

No. Part Description Qty.

1 Pro-Flo X™ Air Valve Assembly

2 End Cap 1 01-2340-01 01-2340-01 01-2340-06

3 O-Ring (-126), End Cap (1.362 x .103) 1 01-2395-52 01-2395-52 01-2395-52

4 Gasket, Air Valve, Pro-Flo X™ 1 01-2620-52 01-2620-52 01-2620-52

5 Gasket, Muffl er Plate, Pro-Flo X™ 1 01-3502-52 01-3502-52 01-3502-52

6 Muffl er Plate, Pro-Flo X™ 1 01-3185-01 01-3185-01 01-3185-06

7 Screw, SHC, Air Valve (1/4”-20 x 3”) 4 01-6001-03 01-6001-03 01-6001-03