Wilden P820, P830 Engineering, Operation & Maintenance

EOM

Engineering

Operation &

Maintenance

P820/P830

FIT Metal Pump

Where Innovation Flows

wildenpump.com

TABLE OF CONTENTS

SECTION 1 CAUTIONS—READ FIRST! ..............................................1

SECTION 2 WILDEN PUMP DESIGNATION SYSTEM .................................2

SECTION 3 HOW IT WORKS—PUMP & AIR DISTRIBUTION SYSTEM ................3

SECTION 4 DIMENSIONAL DRAWINGS .............................................4

SECTION 5 PERFORMANCE

P820/P830 Metal Rubber-Fitted ..............................................6

P820/P830 Metal EZ-Install TPE-Fitted .........................................6

P820/P830 Metal Reduced-Stroke PTFE-Fitted ..................................7

P820/P830 Metal Full-Stroke PTFE-Fitted ......................................7

Suction-Lift Curves ........................................................8

SECTION 6 SUGGESTED INSTALLATION, OPERATION & TROUBLESHOOTING .......10

SECTION 7 DISASSEMBLY / REASSEMBLY ........................................13

Air Valve / Center Section Disassembly ......................................16

Reassembly Hints & Tips ..................................................19

SECTION 8 EXPLODED VIEW & PARTS LISTING

P820/P830 Metal .........................................................20

SECTION 9 ELASTOMER OPTIONS .................................................22

Section 1

CAUTIONS—READ FIRST!

CAUTION : Do not apply compressed air to the

exhaust port — pump will not function.

CAUTION: Do not over-lubricate air supply —

excess lub rication will reduce pump p erformance .

Pump is pre-lubed.

TEMPERATURE LIMITS:

Acetal –29°C to 82°C –20°F to 180°F

Buna-N –12°C to 82°C 10°F to 180°F

Geolast

®

–40°C to 82°C –40°F to 180°F

Neoprene –18°C to 93°C 0°F to 200°F

Nordel

®

EPDM –51°C to 138°C –60°F to 280°F

Nylon –18°C to 93°C 0°F to 200°F

PFA –7°C to 107°C 45°F to 225°F

Polypropylene 0°C to 79°C 32°F to 175°F

Polyurethane –12°C to 66°C 10°F to 150°F

PVDF –12°C to 107°C 10°F to 225°F

Saniflex™ –29°C to 104°C –20°F to 220°F

SIPD PTFE with EPDM-backed

SIPD PTFE with Neoprene-backed

PTFE

Viton

1

4°C to 104°C 40°F to 220°F

®

FKM –40°C to 177°C –40°F to 350°F

4°C to 137°C 40°F to 280°F

4°C to 93°C 40°F to 200°F

Wil-Flex™ –40°C to 107°C –40°F to 225°F

1

4°C to 149°C (40°F to 300°F) - 13 mm (1/2") and 25 mm (1") models only.

CAUTION: Do not exceed 82°C (180°F) air inlet

®

temperature for Pro-Flo

models.

CAUTION: Pumps should be thoroughly flushed

before installing into process lines. FDA- and

USDA-approved pumps should be cleaned and /

or sanitized before being used.

CAUTION: Always wear safety glasses when

operating pump. If diaphragm rupture occurs,

material being pumped may be forced out air

exhaust.

CAUTION: Before any maintenance or repair is

attempted, the compressed air line to the pump

should be disconnected and all air pressure

allowed to bleed from pump. Disconnect all

intake, discharge and air lines. Drain the pump

by turning it upside down and allowing any fluid

to flow into a suitable container.

CAUTION: Blow out air line for 10 to 20 seconds

before attaching to pump to make sure all pipeline

debris is clear. Use an in-line air filter. A 5μ

(micron) air filter is recommended.

NOTE:

Not all materials are available for all models.

Refer to Section 2 for material options for your pump.

CAUTION: When choosing pump materials, be

sure to check the temperature limits for all wet-

ted components. Example: Viton® has a maxi-

mum limit of 177°C (350°F), but polypropylene

has a maximum limit of only 79°C (175°F).

CAUTION: Maximum temperature limits are

based upon mechanical stress only. Certain

chemicals will significantly reduce maximum

safe operating temperatures. Please consult the

Wilden Chemical Resistance Guide.

WARNING : Prevent static sparking — If static

sparking occurs, fire or explosion could result.

Pump, valves and containers must be grounded

to a proper grounding point when handling

flammable fluids and whenever discharge of

static electricity is a hazard.

CAUTION: Do not exceed 8.6 bar (125 psig) air

supply pressure.

CAUTION: The process fluid and cleaning fluids

must be chemically compatible with all wetted

pump components. Please consult the Wilden

Chemical Resistance Guide.

NOTE: When installing PTFE diaphragms, it is

important to tighten outer pistons simultaneously

(turning in opposite directions) to ensure tight fit.

(See torque specifications in Section 7.)

NOTE: Some PTFE-fitted pumps come standard

from the factory with expanded PTFE gaskets

installed in the diaphragm bead of the liquid

chamber. PTFE gaskets cannot be re-used.

NOTE: Before starting disassembly, mark a line

from each liquid chamber to its corresponding air

chamber. This line will assist in proper alignment

during reassembly.

CAUTION: Pro-Flo® pumps cannot be used

in submersible applications. Pro-Flo® SHIFT

pumps do have a single-point exhaust option

for submersible applications. Do not use

®

standard Pro-Flo

SHIFT models in submersible

applications.

CAUTION : Tighten all hardware prior to installation.

WIL-115 9 0 -E- 01 1 WILDEN PUMP & ENGINEERING, LLC

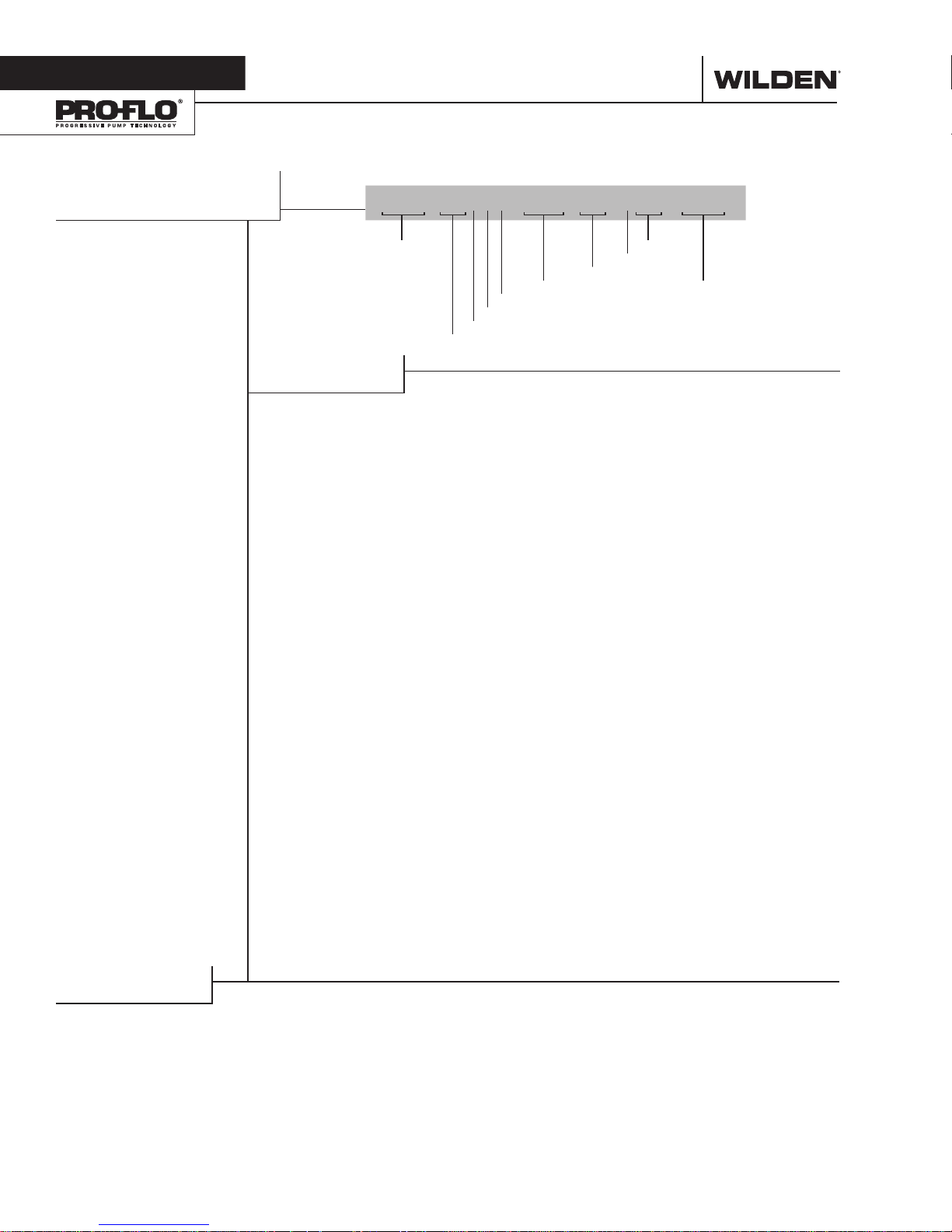

Section 2

WILDEN PUMP DESIGNATION SYSTEM

P820/P830 METAL

51 mm (2") Pump

Maximum Flow Rate:

609 lpm (161 gpm)

MATERIAL CODES

LEGEND

MODEL

XP 8 2 0 = PRO-FLO® THREADED

XP83 0 = PRO-FLO® FL ANGED

WETTED PARTS/OUTER PISTON

AA = ALUMINUM / ALUMINUM

SS = STAINLESS ST EEL /

STAINLESS STEEL

WW

AIR CHAMBERS

A = ALUMINUM

CENTER BLOCK

P = POLYPROP YLENE

AIR VALVE

P = POLYPROPYL ENE

PORTS

PORTS

= DUC TILE IRON /

DUCTILE IRON

P820 / XXX XX / XXX / XX / XXX / XXXX

MODEL

DIAPHRAGMS

VALVE BALLS

AIR VALVE

CENTER BLOCK

AIR CHAMBERS

WETTED PARTS & OUTER PISTON

DIAPHRAGMS

BNS = BUNA-N (Red Dot)

EPS = EPDM (Blue Dot)

FWS = SANITARY WIL-FLEXTM,

EZ-INSTALL [Santoprene®

(Two Black Dots)]

NES = NEOPRENE (Green Dot)

TEU = PTFE W/EPDM BACKUP

(White)

TNU = PTFE W/NEOPRENE

BACKUP (White)

TSS = FULL-STROKE PTFE W/

SANIFLEX™ BACK-UP

TSU = PTFE W/SANIFLEX™

BACKUP (White)

TWS = FULL-STROKE PTFE W/WIL-

FLEX™ BACKUP

VTS = VITON® (White Dot)

XBS = CONDUCTIVE BUNA-N

(Two Red Dots)

ZGS = GEOLAST®, EZ-INSTALL

(Black)

ZPS = POLYURETHANE, EZ-INSTALL

(Clear)

ZSS = SANIFLEX™, EZ-INSTALL

[Hytrel® (Cream)]

ZWS = WIL-FLEX™, EZ-INSTALL

[Santoprene® (Three Black

Dots)]

O-RINGS

VALVE SE ATS

VALVE BALLS

BN = BUNA-N (Red Dot)

FS = SANIFLEX™ [Hytrel® (Cream)]

FW = SANITARY WIL-FLEXTM

[Santoprene®

(Two Black Dots)]

EP = EPDM (Blue Dot)

NE = NEOPRENE (Green Dot)

PU = POLYURETHANE (Brown)

TF = PTFE (White)

VT = VITON® (Silver or White Dot)

WF = WIL-FLEX™ [Santoprene®

VALVE SEATS

A = ALUMINUM

BN = BUNA-N (Red Dot)

EP = EPDM (Blue Dot)

FS = SANIFLEX™ [Hytrel® (Cream)]

FW = SANITARY WIL-FLEXTM

[Santoprene®

(Two Black Dots)]

M = MILD STEEL

NE = NEOPRENE (Green Dot)

PU = POLYURETHANE (Brown)

S = STAINLESS STEEL

VT = VITON® (White Dot)

WF = WIL-FLEX™ [Santoprene®

SPECIALT Y

CODE

(if applicable)

(Three Black Dots)]

(Three Black Dots)]

SPECIALTY CODES

0014 BSPT

0100 Wil-Gard 110V

0102 Wil-Gard sensor wires ONLY

0103 Wil-Gard 220V

NOTE: Most elastomeric materials use colored dots for identification.

NOTE: Not all models are available with all material options.

Viton® is a registered trademark of DuPont Dow Elastomers.

WILDEN PUMP & ENGINEERING, LLC 2 WIL-115 9 0 -E- 01

0480 Pump Cycle Monitor (sensor & wires)

0483 Pump Cycle Monitor (module, sensor & wires)

0485 Pump Cycle Monitor (module, sensor & wires), DIN flange

0504 DIN flange

VALVE SEAT O-RINGS

TF = PTFE

Section 3

HOW IT WORKS—PUMP

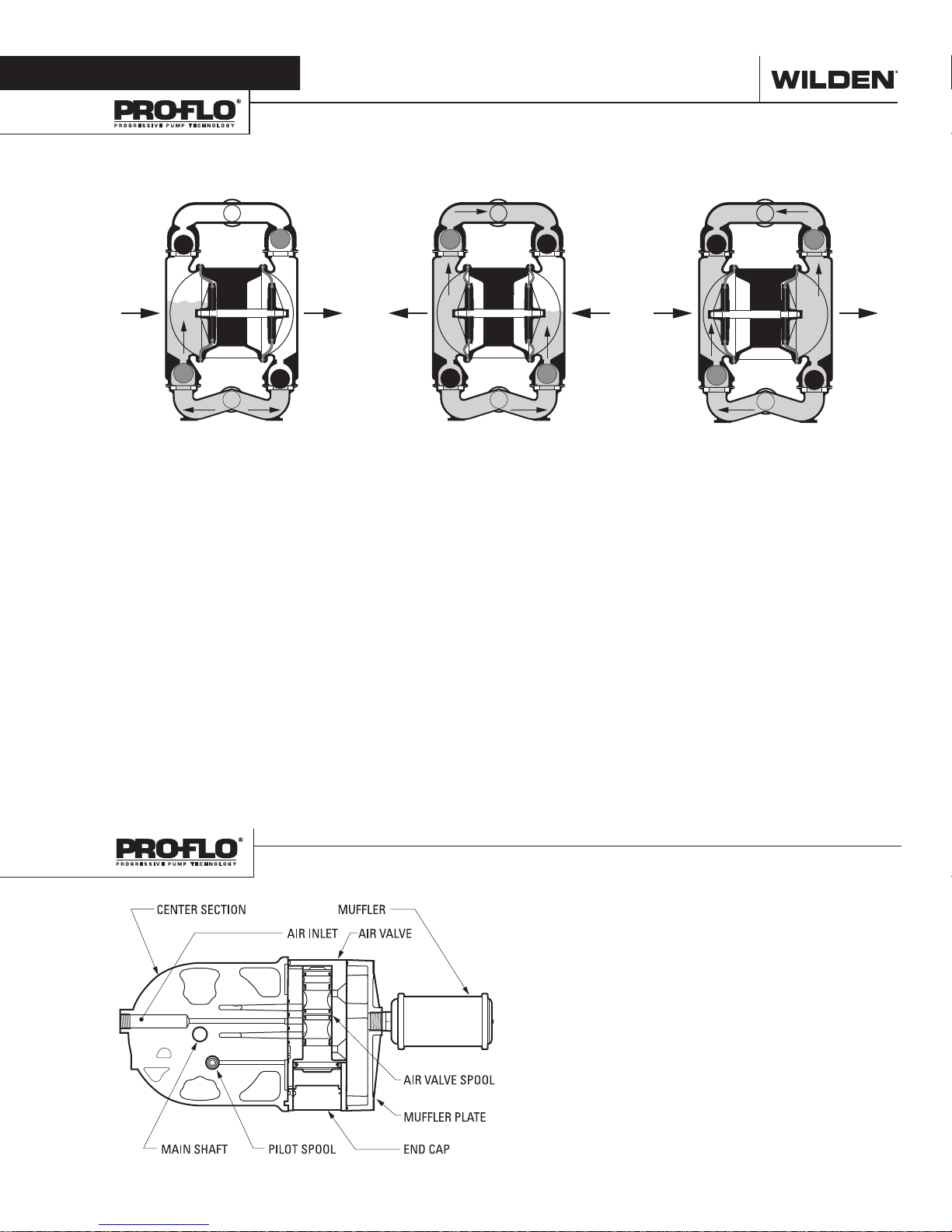

The Wilden diaphragm pump is an air-operated, positive displacement, self-priming pump. These drawings show flow pattern

through the pump upon its initial stroke. It is assumed the pump has no fluid in it prior to its initial stroke.

CLOSED

OUTLET

OPEN

B A

INLET

FIGUR E 1 The air valve dire cts pre ssurized

air to the back side of diaphragm A. The

compressed air is applied directly to the

liquid column separated by elastomeric

diaphragms. The diaphragm ac ts as

a separation membrane bet ween the

compressed air and liquid; a balanced

load removes mechanical stress from the

diaphragm. The compressed air moves

the diaphragm away from the center

of the pump. The opposite diaphragm

is pulled in by the shaft connected to

the pressurized diaphragm. Diaphragm

B is on its suction stroke; air behind

the diaphragm has been forced out to

atmosphere through the exhaust port of

the pump. The movement of diaphragm

B toward the center of the pump creates

a vacuum within chamber B. A tmosphe ric

pressure forces fluid into the inlet

manifold forcing the inlet valve ball off its

seat. Liquid is free to move past the inlet

valve ball and fill the liquid chamber (see

shaded area).

CLOSEDOPEN

OPEN

OUTLET

CLOSED

B A

CLOSED OPEN

FIGURE 2

phragm

, diaphragm A, reaches the limit

of its discharge stroke, the air valve

redirects pressurized air to the back side of

diaphragm B. The pressurized air forces

diaphragm B away from the center

while pulling diaphragm A to the center.

Diaphragm B is now on its discharge

stroke. Diaphragm B forces the inlet valve

ball onto its seat due to the hydraulic

forces developed in the liquid chamber

and manifold of the pump. These same

hydraulic forces lift the discharge valve

ball off its seat, while the opposite

discharge valve ball is forced onto its seat,

forcing fluid to flow through the pump

discharge. The movement of diaphragm A

toward the center of the pump creates a

vacuum within liquid chamber A. Atmospheric pressure forces fluid into the inlet

manifold of the pump. The inlet valve ball

is forced off its seat allowing the fluid

being pumped to fill the liquid chamber.

INLET

When the pressurized dia-

CLOSED OPEN

OUTLET

B A

OPEN

FIGURE 3 At completion of the stroke,

the air valve again redirects air to the

back side of diaphragm A, which starts

diaphragm B on its exhaust stroke. As

the pump reaches its original star ting

point, each diaphragm has gone through

one exhaust and one discharge stroke.

This constitutes one complete pumping

cycle. The pump may take several cycles

to completely prime depending on the

conditions of the application.

INLET

CLOSED

HOW IT WORKS—AIR DISTRIBUTION SYSTEM

WIL-115 9 0 -E- 01 3 WILDEN PUMP & ENGINEERING, LLC

The Pro-Flo® patented air distribution system incorporates

two moving par ts : the air valve spool and the pilot spool. The

heart of the system is the air valve spool and air valve. This

valve design incorporates an unbalanced spool. The smaller

end of the spool is pressurized continuously, while the large

end is alternately pressurized then exhausted to move the

spool. The spool directs pressurized air to one air chamber

while exhausting the other. The air causes the main shaft/

diaphragm assembly to shif t to one side — discharging liquid

on that side and pulling liquid in on the other side. When the

shaft reaches the end of its stroke, the inner piston actuates

the pilot spool, which pressurizes and exhausts the large end

of the air valve spool. The repositioning of the air valve spool

routes the air to the other air chamber.

Section 4

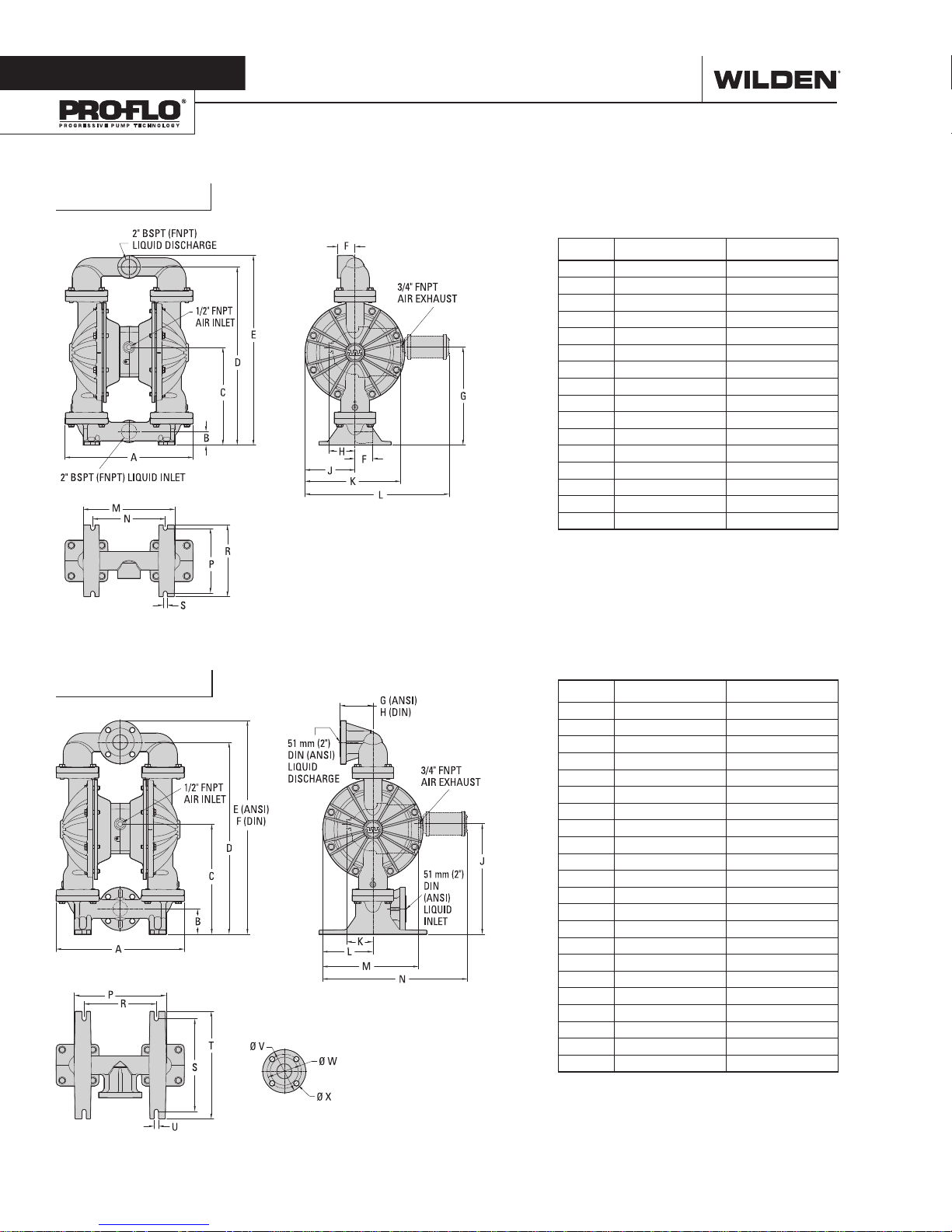

P820 Metal

DIMENSIONAL DRAWINGS

DIMENSIONS

ITEM METRIC (mm) STANDARD (Inch)

A 453 17.9

B 48 1.9

C 346 13.6

D 630 24.8

E 670 26.4

F 62 2.4

G 347 13.7

H 93 3.7

J 177 7.0

K 338 13.3

L 510 20.1

M 324 12.8

N 257 10.1

P 229 9.0

R 254 10.0

S 14 0.6

LW0369 REV. A

P830 Metal

DIMENSIONS

ITEM METRIC (mm) STANDARD (Inch)

A 452 17.8

B 89 3.5

C 387 15.3

D 675 26.6

E 752 29.6

F 758 29.8

G 116 4.6

H 117 4.6

J 389 15.3

K 93 3.7

L 177 7.0

M 338 13.3

N 510 20.1

P 324 12.8

R 254 10.0

S 326 12.8

T 378 14.9

U 16 0.6

DIN (mm) ANSI (Inch)

V 165 DIA. 6.0 DIA.

W 125 DIA. 4.8 DIA.

X 18 DIA. 0.8 DIA.

LW0370 REV. A

WILDEN PUMP & ENGINEERING, LLC 4 WIL-115 9 0 -E- 01

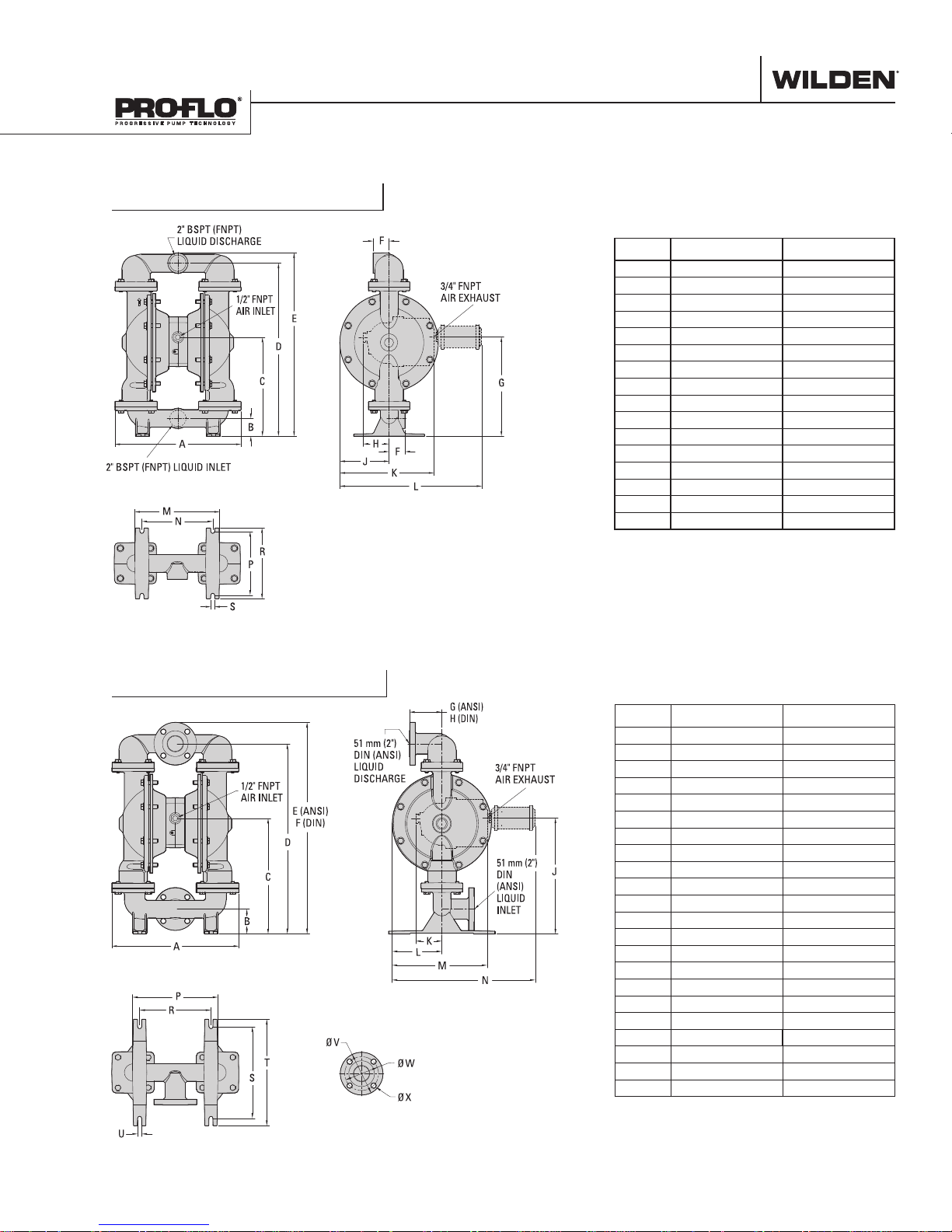

DIMENSIONAL DRAWINGS

P820 Stainless Steel

DIMENSIONS

ITEM METRIC (mm) STANDARD (Inch)

A 452 17.8

B 64 2.5

C 354 14.0

D 620 24.4

E 658 25.9

F 58 2.3

G 356 14.0

H 93 3.7

J 178 7.0

K 338 13.3

L 510 20.1

M 305 12.0

N 254 10.0

P 229 9.0

R 254 10.0

S 15 0.6

LW0371 REV. A

P830 Stainless Steel

DIMENSIONS

ITEM METRIC (mm) STANDARD (Inch)

A 452 17.8

B 89 3.5

C 412 16.2

D 678 26.7

E 754 29.7

F 760 29.9

G 116 4.6

H 115 4.5

J 413 16.3

K 93 3.7

L 177 7.0

M 338 13.3

N 510 20.1

P 304 12.0

R 254 10.0

S 325 12.8

T 379 14.9

U 14 0.6

DIN (mm) ANSI (Inch)

V 165 DIA. 6.0 DIA.

W 125 DIA. 4.8 DIA.

X 18 DIA. 0.8 DIA.

LW0372 REV. A

WIL-115 9 0 -E- 01 5 WILDEN PUMP & ENGINEERING, LLC

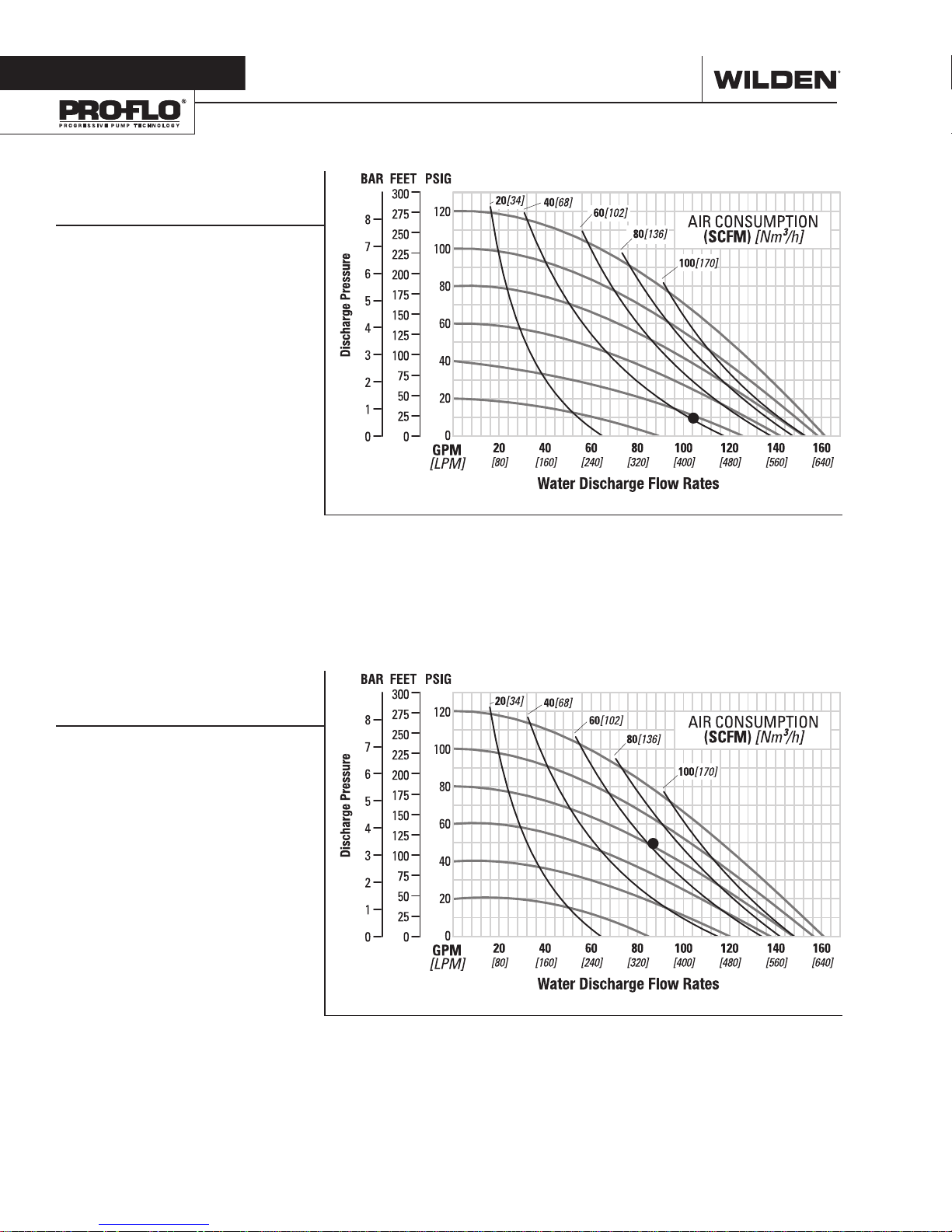

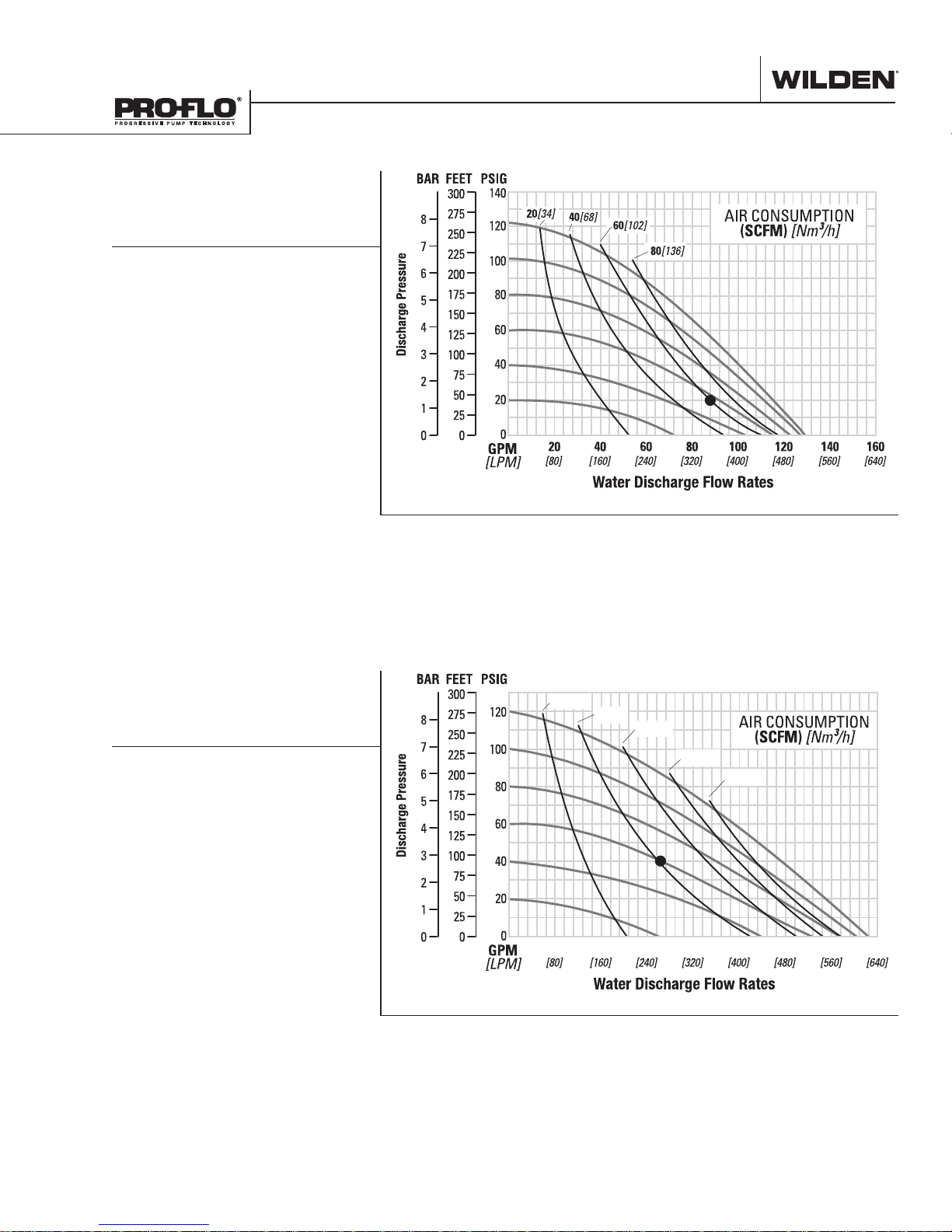

Section 5

PERFORMANCE

P820/P830 METAL

RUBBER-FITTED

Ship Weight ... 820 Threaded AL 47 kg (104 lb)

820 Threaded SS 73 kg (161 lb)

820 Threaded Iron 71 kg (156 lb)

830 Flanged AL 54 kg (118 lb)

830 Flanged SS 81 kg (178 lb)

830 Flanged Iron 82 Kg (181 lb)

Air Inlet ........................................19 mm (3/4”)

Inlet .................................................51 mm (2”)

Outlet ..............................................51 mm (2”)

Suction Lift .............................7.4 m Dry (24.3’)

9.0 m Wet (29.5’)

Disp. per Stroke1 ...................... 2.8 L (0.74 gal)

Max. Flow Rate ................. 609 lpm (161 gpm)

Max. Size Solids .........................6.4 mm (1/4”)

1

Displacement per stroke was calculated at

4.8 bar (70 psig) air inlet pressure against

2 bar (30 psig) head pressure.

Example: To pump 394 lpm (104 gpm) against

a discharge head of 0.69 bar (10 psig) requires

2.8 bar (40 psig) and 63 Nm3/h (40 scfm) air

consumption.

Caution: Do not exceed 8.6 bar (125 psig) air

supply pressure.

Flow rates indicated on chart were determined by pumping water.

For optimum life and performance, pumps should be specified so that daily operation

parameters will fall in the center of the pump's performance curve.

P820/P830 METAL

EZ-INSTALL TPE-FITTED

Ship Weight ... 820 Threaded AL 47 kg (104 lb)

820 Threaded SS 73 kg (161 lb)

820 Threaded Iron 71 kg (156 lb)

830 Flanged AL 54 kg (118 lb)

830 Flanged SS 81 kg (178 lb)

830 Flanged Iron 82 Kg (181 lb)

Air Inlet ........................................19 mm (3/4”)

Inlet .................................................51 mm (2”)

Outlet ..............................................51 mm (2”)

Suction Lift ............................ 6.7 m Dry (21.9’)

9.0 m Wet (29.5’)

Disp. per Stroke

Max. Flow Rate ................. 605 lpm (160 gpm)

Max. Size Solids .........................6.4 mm (1/4”)

1

Displacement per stroke was calculated at

4.8 bar (70 psig) air inlet pressure against

2 bar (30 psig) head pressure.

Example: To pump 326 lpm (86 gpm) against

a discharge head of 3.4 bar (50 psig) requires

5.5 bar (80 psig) and 98 Nm3/h (62 scfm) air

consumption.

Caution: Do not exceed 8.6 bar (125 psig) air

supply pressure.

1

...................... 2.5 L (0.67 gal)

Flow rates indicated on chart were determined by pumping water.

For optimum life and performance, pumps should be specified so that daily operation

parameters will fall in the center of the pump's performance curve.

WILDEN PUMP & ENGINEERING, LLC 6 WIL-115 9 0 -E- 01

PERFORMANCE

P820/P830 METAL

REDUCED-STROKE

PTFE-FITTED

Ship Weight ... 820 Threaded AL 47 kg (104 lb)

820 Threaded SS 73 kg (161 lb)

820 Threaded Iron 71 kg (156 lb)

830 Flanged AL 54 kg (118 lb)

830 Flanged SS 81 kg (178 lb)

830 Flanged Iron 82 Kg (181 lb)

Air Inlet ........................................19 mm (3/4”)

Inlet .................................................51 mm (2”)

Outlet ..............................................51 mm (2”)

Suction Lift ............................ 4.6 m Dry (15.1’)

9.0 m Wet (29.5’)

Disp. per Stroke

Max. Flow Rate ................. 492 lpm (130 gpm)

Max. Size Solids .........................6.4 mm (1/4”)

1

Displacement per stroke was calculated at

4.8 bar (70 psig) air inlet pressure against

2 bar (30 psig) head pressure.

Example: To pump 326 lpm (86 gpm) against

a discharge head of 1.4 bar (20 psig) requires

4.1 bar (60 psig) and 95 Nm3/h (60 scfm) air

consumption.

Caution: Do not exceed 8.6 bar (125 psig) air

supply pressure.

1

.......................1.7 L (0.46 gal)

Flow rates indicated on chart were determined by pumping water.

For optimum life and performance, pumps should be specified so that daily operation

parameters will fall in the center of the pump's performance curve.

P820/P830 METAL

FULL-STROKE

PTFE-FITTED

Ship Weight ... 820 Threaded AL 47 kg (104 lb)

820 Threaded SS 73 kg (161 lb)

820 Threaded Iron 71 kg (156 lb)

830 Flanged AL 54 kg (118 lb)

830 Flanged SS 81 kg (178 lb)

830 Flanged Iron 82 Kg (181 lb)

Air Inlet ........................................19 mm (3/4”)

Inlet .................................................51 mm (2”)

Outlet ..............................................51 mm (2”)

Suction Lift ............................6.9 m Dry (22.6’)

9.0 m Wet (29.5’)

Disp. per Stroke1 ...................... 2.5 L (0.65 gal)

Max. Flow Rate ................. 590 lpm (156 gpm)

Max. Size Solids .........................6.4 mm (1/4”)

1

Displacement per stroke was calculated at

4.8 bar (70 psig) air inlet pressure against

2 bar (30 psig) head pressure.

Example: To pump 250 lpm (66 gpm) against

a discharge head of 2.8 bar (40 psig) requires

4.1 bar (60 psig) and 65 Nm3/h (41 scfm) air

consumption.

Caution: Do not exceed 8.6 bar (125 psig) air

supply pressure.

20[34]

40[68]

60[102]

80[136]

100[170]

20 40 60 80 100 120 140 160

Flow rates indicated on chart were determined by pumping water.

For optimum life and performance, pumps should be specified so that daily operation

parameters will fall in the center of the pump's performance curve.

WIL-115 9 0 -E- 01 7 WILDEN PUMP & ENGINEERING, LLC

Loading...

Loading...