Wilden P.025 Operation & Maintenance Manual

P.025

Original™ Series PLASTIC Pumps

Simplify your process

Engineering

Operation &

Maintenance

WIL-10090-E-0 4

REPLACES WIL-10090 -E-03

TABLE OF CONTENTS

SECTION 1 CAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SECTION 2 PUMP DESIGNATION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

SECTION 3 HOW IT WORKS (PUMP & AIR SYSTEMS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

SECTION 4 DIMENSIONAL DRAWING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

SECTION 5 PERFORMANCE CURVES

A. P.025 PLASTIC Rubber-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

B. P.025 PLASTIC TPE-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

B. P.025 PLASTIC PTFE-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

B. Suction Lift Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

SECTION 6 SUGGESTED INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Suggested Operation and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

SECTION 7 PUMP DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Air Valve/Cleaning & Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

SECTION 8 EXPLODED VIEW & PARTS LISTING

P.025 PLASTIC Rubber/TPE-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

P.025 PLASTIC PTFE-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

SECTION 9 ELASTOMER OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

O

z

o

I

I

n

&

I

s

s

a

l

C

NON

U.S. Clean Air Act

Amendments of 1990

D

e

p

l

e

e

USE

u

S

t

i

n

g

s

e

c

n

a

t

s

b

Section 1

CAUTIONS—READ FIRST!

TEMPERATURE LIMITS:

Polypropylene 0°C to 79°C +32°F to 175°F

PVDF –12°C to 107°C +10°F to 225°F

Buna-N –12.2°C to 82.2°C +10°F to +180°F

Viton® –40°C to 176.7°C –40°F to +350°F

Wil-Flex™ –40°C to 107.2°C –40°F to +225°F

PTFE +4.4°C to 104.4°C +40°F to +220°F

CAUTION: When choosing pump materials, be

sure to check the temperature limits for all wetted

components. Example: Viton

limit of 176.7°C (350°F) but polypropylene has a

maximum limit of only 79°C (175°F ).

CAUTION: Maximum temperature limits are based

upon mechanical stress only. Certain chemicals

will signifi cantly reduce maximum safe operating

temperatures. Consult engineering guide for

chemical compatibility and temperature limits.

CAUTION: Always wear safety glasses when

operating pump. If diaphragm rupture occurs,

material being pumped may be forced out air

exhaust.

WARNING: Prevention of static sparking — If

static sparking occurs, fi re or explosion could

result. Pump, valves, and containers must be

properly grounded when handling fl ammable

fl uids and whenever discharge of static electricity

is a hazard.

CAUTION: Do not exceed 8.6 bar (125 psig) air

supply pressure.

®

has a maximum

CAUTION: Before any maintenance or repair is

attempted, the compressed air line to the pump

should be disconnected and all air pressure

allowed to bleed from pump. Disconnect all intake,

discharge and air lines. Drain the pump by turning

it upside down and allowing any fl uid to fl ow into

a suitable container.

CAUTION: Blow out air line for 10 to 20 seconds

before attaching to pump to make sure all pipe line

debris is clear. Use an in-line air fi lter. A 5µ (micron)

air fi lter is recommended.

NOTE: Tighten clamp bands and retainers

prior to installation. Fittings may loosen during

transportation.

NOTE: When installing PTFE diaphragms, it is

important to tighten outer pistons simultaneously

(turning in opposite directions) to ensure tight fi t.

NOTE: Before starting disassembly, mark a line

from each liquid chamber to its corresponding air

chamber. This line will assist in proper alignment

during reassembly.

CAUTION: Verify the chemical compatibility of

the process and cleaning fl uid to the pump’s

component materials in the Chemical Resistance

Guide. (see E4).

NOTE: Plastic series pumps are made of virgin

plastic and are not UV stabilized. Direct sunlight

for prolonged periods can cause deterioration of

plastics.

CAUTION: The P.025 pump is not submersible.

WIL-10090-E-04

1

WILDEN PUMP & ENGINEERING, LLC

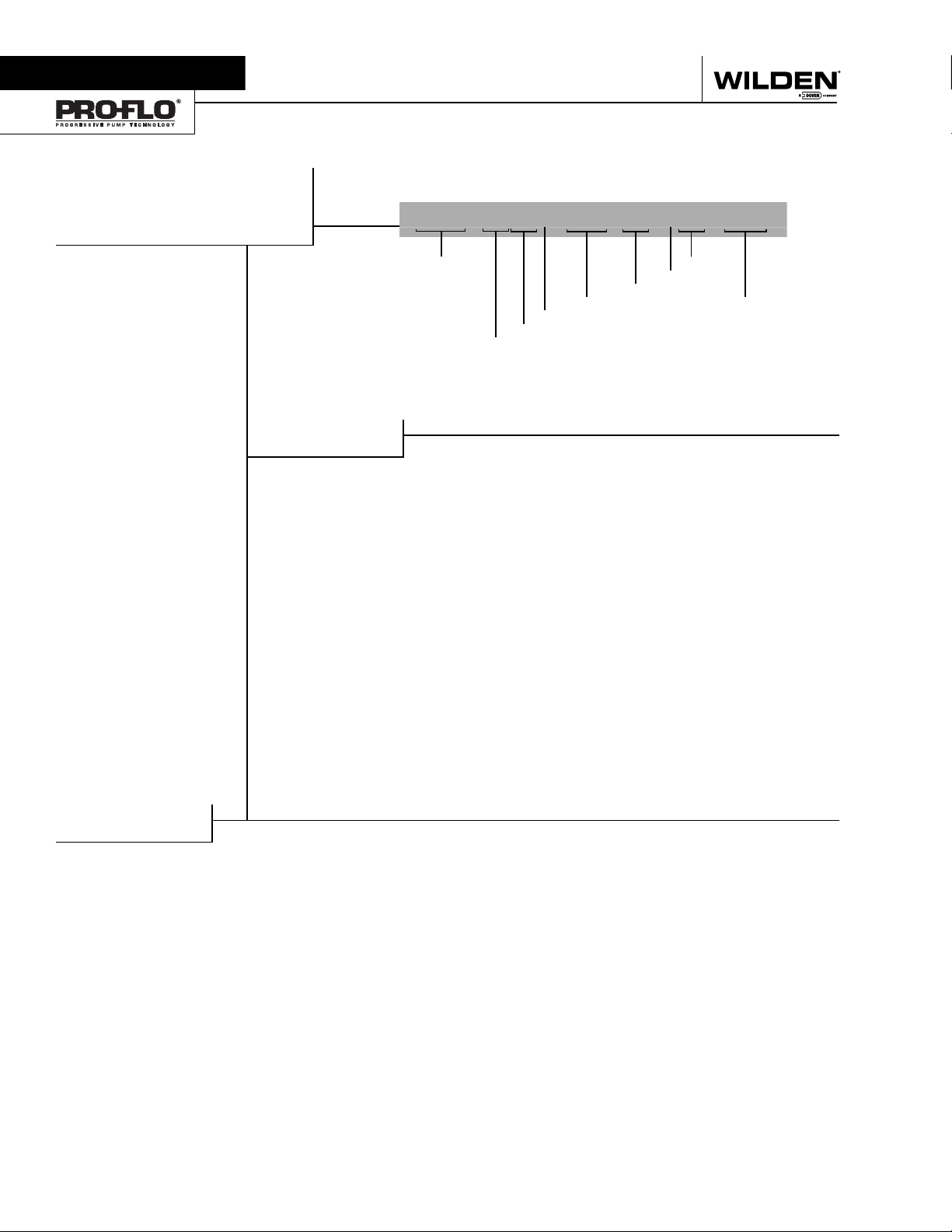

Section 2

WILDEN PUMP DESIGNATION SYSTEM

P.025 ORIGINAL™

PLASTIC

6 mm (1/4") Pump

Maximum Flow Rate:

18.2 lpm (4.8 gpm)

LEGEND

MODEL

MATERIAL CODES

WETTED PARTS & OUTER PISTON

KK = PVDF / PVDF

KZ = PVDF / NO PISTON

PP = POLYPROPYLENE /

POLYPROPYLENE

PZ = POLYPROPYLENE /

NO PISTON

CENTER SECTION

LL = ACETAL

PP = POLYPROPYLENE

AIR VALVE

L = ACETAL

P = POLYPROPYLENE

P.025 / XXXXX / XXX / XX / XXX / XXXX

O-RINGS

DIAPHRAGMS

AIR VALVE

CENTER SECTION

WETTED PAR TS & OUTER PISTON

DIAPHRAGMS

BNS = BUNA-N (Red Dot)

TNL = PTFE W/ NEOPRENE

BACK-UP O-RING,

IPD (White)

WFS = WIL-FLEX™ [Santoprene®

(Orange Dot)]

VALVE BALL

TF = PTFE (White)

VALVE SEAT

VALVE BALL S

VALVE SEAT

K = PVDF

P = POLYPROPYLENE

VALVE SEAT O-RING

BN = BUNA-N (Red Dot)

TV = PTFE ENCAP. VITON

WF = WIL-FLEX™ [Santoprene®]

SPECIALTY

CODE

(if applicable)

®

SPECIALTY CODES

0502 PFA coated hardware

0512 Adapter block, no muffler, Pro-Flo

center section

Viton® is a registered trademark of Dupont Dow Elastomers.

WILDEN PUMP & ENGINEERING, LLC

®

,

2

WIL-10090-E-04

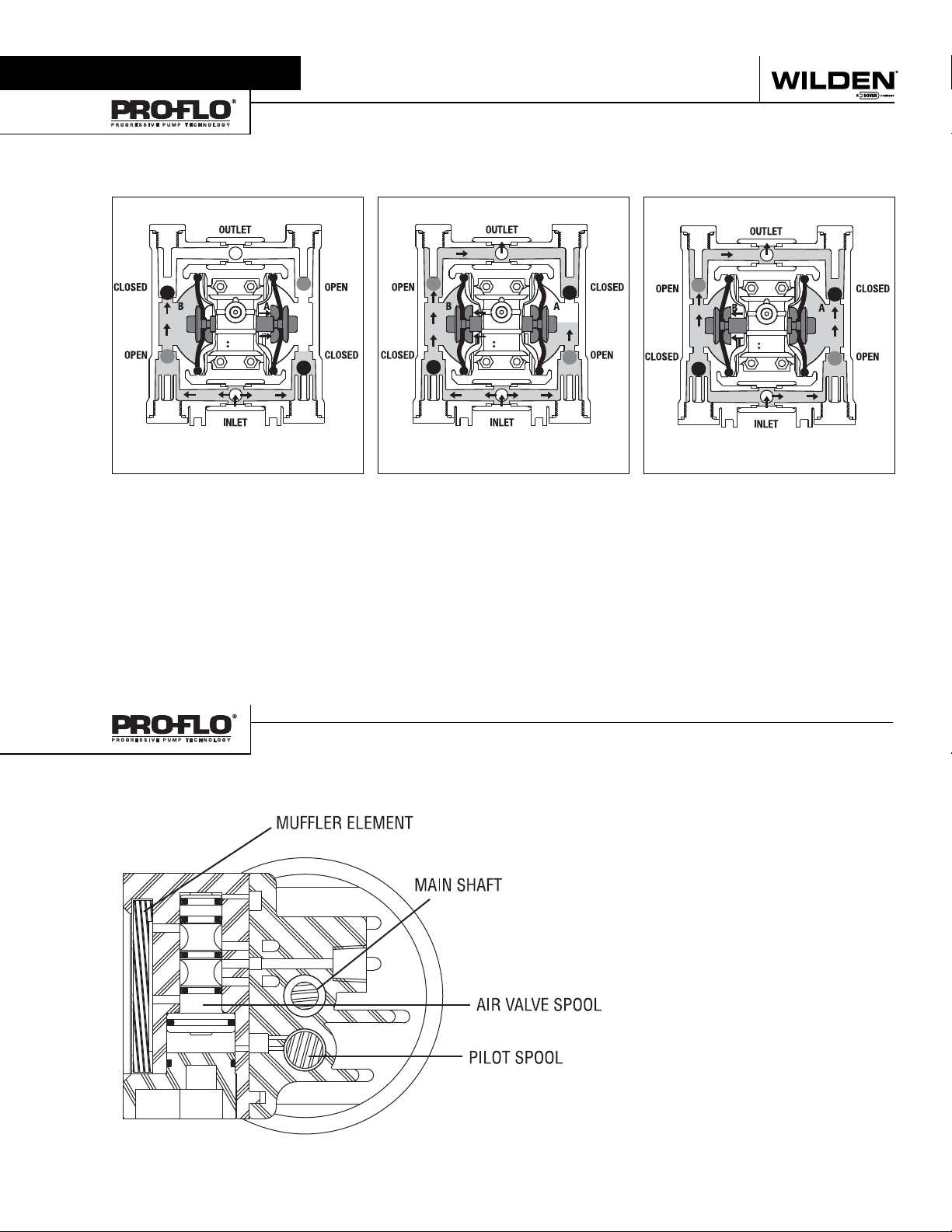

Section 3

HOW IT WORKS

The Wilden diaphragm pump is an air-operated, positive displacement, self-priming pump. These drawings show fl ow pattern through

the pump upon its initial stroke. It is assumed the pump has no fl uid in it prior to its initial stroke.

RIGHT STROKE MID STROKE LEFT STROKE

FIGURE 1 The air valve directs pressurized air to the back

side of diaphragm A. The compressed air is applied directly

to the liquid column separated by elastomeric diaphragms.

The diaphragm acts as a separation membrane between the

compressed air and liquid, balancing the load and removing

mechanical stress from the diaphragm. The compressed

air moves the diaphragm away from the center block of

the pump. The opposite diaphragm is pulled in by the shaft

connected to the pressurized diaphragm. Diaphragm B is

on its suction stroke; air behind the diaphragm has been

forced out to the atmosphere through the exhaust port

of the pump. The movement of diaphragm B toward the

center block of the pump creates a vacuum within chamber

B. Atmospheric pressure forces fluid into the inlet manifold

forcing the inlet valve ball off its seat. Liquid is free to move

past the inlet valve ball and fill the liquid chamber (see

shaded area).

FIGURE 2 When the pressurized diaphragm, diaphragm

A, reaches the limit of its discharge stroke, the air valve

redirects pressurized air to the back side of diaphragm

B. The pressurized air forces diaphragm B away from the

center block while pulling diaphragm A to the center block.

Diaphragm B is now on its discharge stroke. Diaphragm B

forces the inlet valve ball onto its seat due to the hydraulic

forces developed in the liquid chamber and manifold of the

pump. These same hydraulic forces lift the discharge valve

ball off its seat, while the opposite discharge valve ball is

forced onto its seat, forcing fluid to flow through the pump

discharge. The movement of diaphragm A toward the center

block of the pump creates a vacuum within liquid chamber

A. Atmospheric pressure forces fluid into the inlet manifold

of the pump. The inlet valve ball is forced off its seat allowing

the fluid being pumped to fill the liquid chamber.

FIGURE 3 At completion of the stroke, the air valve again

redirects air to the back side of diaphragm A, which starts

diaphragm B on its exhaust stroke. As the pump reaches

its original starting point, each diaphragm has gone through

one exhaust and one discharge stroke. This constitutes

one complete pumping cycle. The pump may take several

cycles to completely prime depending on the conditions of

the application.

WIL-10090-E-04

HOW IT WORKS—AIR DISTRIBUTION SYSTEM

Figure 1

3

The Pro-Flo® patented air distribution system incorporates three moving parts: the

air valve spool, the pilot spool, and the

main shaft/diaphragm assembly. The heart

of the system is the air valve spool and

air valve. As shown in Figure 1, this valve

design incorporates an unbalanced spool.

The smaller end of the spool is pressurized

continuously, while the large end is alternately pressurized and exhausted to move

the spool. The spool directs pressurized

air to one chamber while exhausting the

other. The air causes the main shaft/

diaphragm assembly to shift to one side

— discharging liquid on one side and

pulling liquid in on the other side. When

the shaft reaches the end of its stroke, it

actuates the pilot spool, which pressurizes and exhausts the large end of the

air valve spool. The pump then changes

direction and the same process occurs in

the opposite direction, thus reciprocating

the pump.

WILDEN PUMP & ENGINEERING, LLC

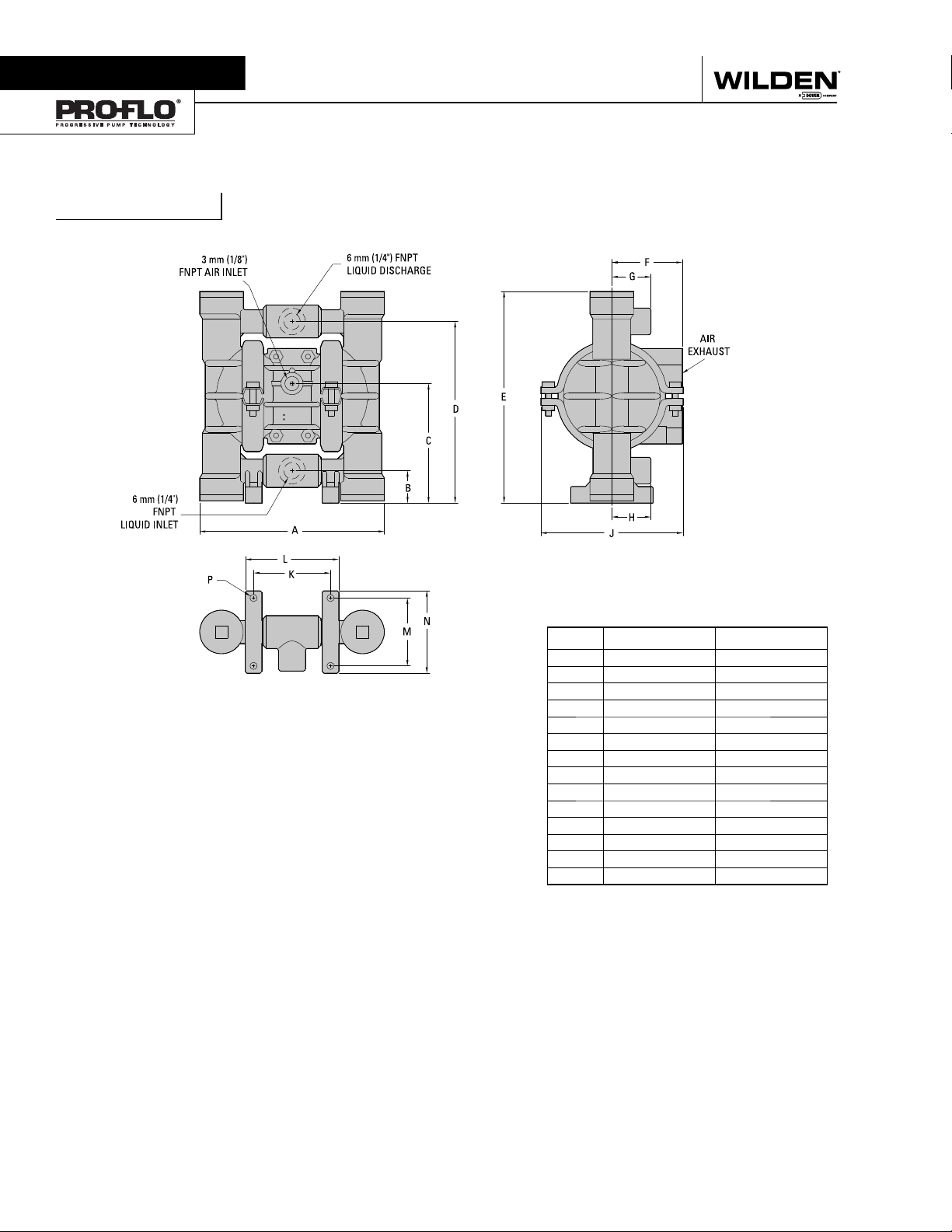

Section 4

P.025 M eta l

DIMENSIONAL DRAWINGS

DIMENSIONS

ITEM METRIC (mm) STANDARD (inch)

A 145 5.7

B 25 1.0

C 94 3.7

D 140 5.5

E 163 6.4

F 56 2.2

G 30 1.2

H 30 1.2

J 114 4.5

K 61 2.4

L 74 2.9

M 53 2.1

N 64 2.5

P Ø5 Ø.2

REV. B

WILDEN PUMP & ENGINEERING, LLC

4

WIL-10090-E-04

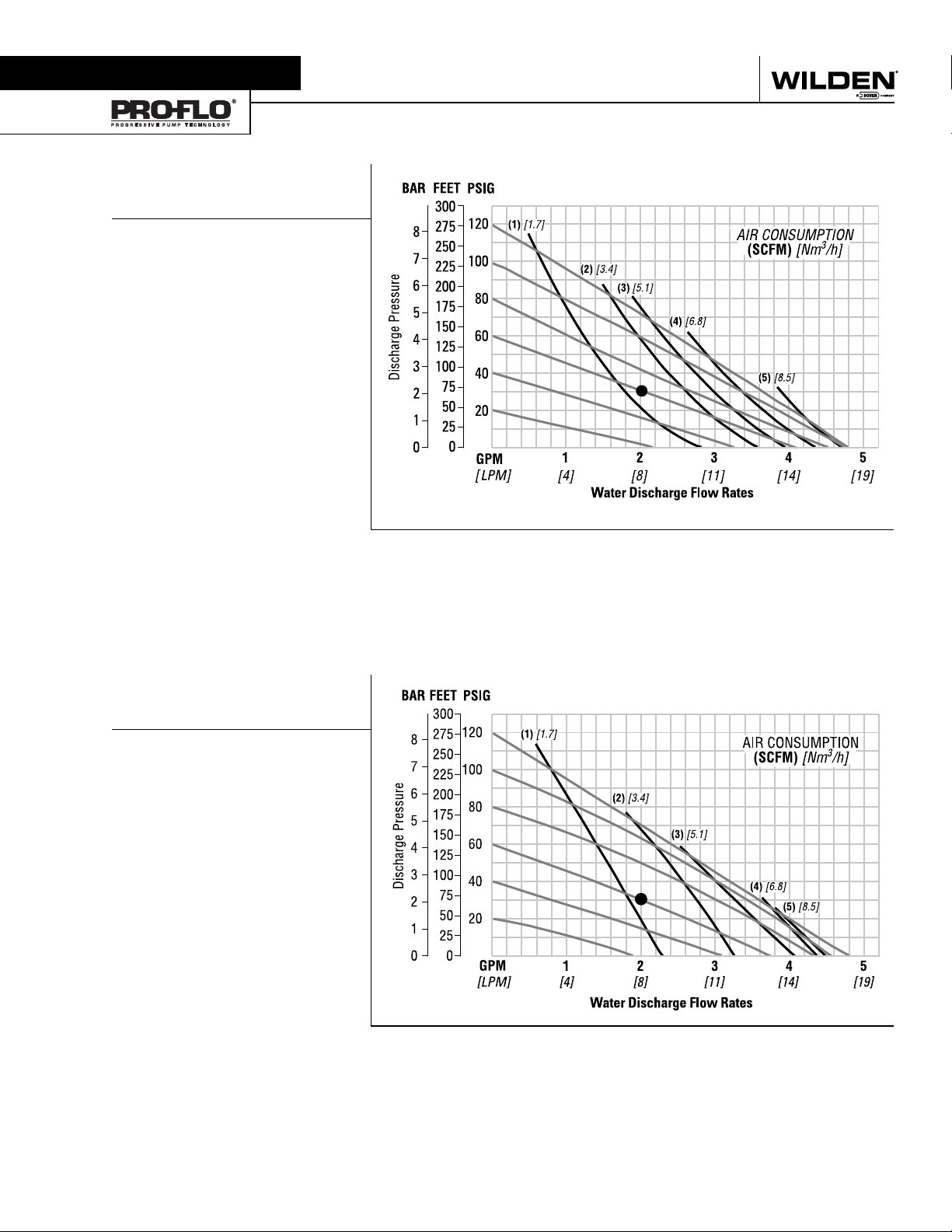

Section 5A

PERFORMANCE

P.025 PLASTIC

RUBBER-FITTED

Height ....................................163 mm (6.4")

Width .....................................145 mm (5.7")

Depth ....................................115 mm (4.5")

Est. Ship Weight .....

PVDF 1.4 kg (3 lbs)

Air Inlet ..................................... 3 mm (1/8")

Inlet .......................................... 6 mm (1/4")

Outlet ....................................... 6 mm (1/4")

Suction Lift ........................... 2.74 m Dry (9')

9.45 m Wet (31')

Displacement per

Stroke .........................0.02 l (0.004 gal.)

Max. Flow Rate ...............18.1 lpm (4.8 gpm)

Max. Size Solids .................. 0.4 mm (1/64")

1

Displacement per stroke was calculated at 4.8 bar

(70 psig) air inlet pressure against a 2 bar (30 psig)

head pressure.

Example: To pump 7.6 lpm (2 gpm) against

a discharge pressure head of 2 bar (30 psig)

requires 4.1 bar (60 psig) and 2.0 Nm

(1.2 scfm) air consumption. (See dot on

chart.)

Caution: Do not exceed 8.6 bar (125 psig) air

supply pressure.

Polypropylene 1.4 kg (3 lbs)

1

3

/h

Flow rates indicated on chart were determined by pumping water.

For optimum life and performance, pumps should be specified so that daily operation parameters

will fall in the center of the pump performance curve.

P.025 PLASTIC

TPE-FITTED

Height ....................................163 mm (6.4")

Width .....................................145 mm (5.7")

Depth ....................................115 mm (4.5")

Est. Ship Weight .....

PVDF 1.4 kg (3 lbs)

Air Inlet ..................................... 3 mm (1/8")

Inlet .......................................... 6 mm (1/4")

Outlet ....................................... 6 mm (1/4")

Suction Lift ......................... 3.05 m Dry (10')

8.84 m Wet (29')

Displacement per

Stroke ....................... 0.02 l gal. (0.005)

Max. Flow Rate ...............18.1 lpm (4.8 gpm)

Max. Size Solids .................. 0.4 mm (1/64")

1

Displacement per stroke was calculated at 4.8 bar

(70 psig) air inlet pressure against a 2 bar (30 psig)

head pressure.

Example: To pump 7.6 lpm (2 gpm) against

a discharge pressure head of 2 bar (30 psig)

requires 4.1 bar (60 psig) and 2.0 Nm

(1.2 scfm) air consumption. (See dot on

chart.)

Caution: Do not exceed 8.6 bar (125 psig) air

supply pressure.

Polypropylene 1.4 kg (3 lbs)

1

3

/h

Flow rates indicated on chart were determined by pumping water.

For optimum life and performance, pumps should be specified so that daily operation parameters

will fall in the center of the pump performance curve.

WIL-10090-E-04

5

WILDEN PUMP & ENGINEERING, LLC

Loading...

Loading...