Wilden H800 Operation & Maintenance Manual

EOM

Engineering

Operation &

Maintenance

H800

Advanced

Metal Pump

™

Series

Where Innovation Flows

www.wildenpump.com

REPLACES WI L-11150 -E -0 9

WI L-11150 -E -10

TABLE OF CONTENTS

SECTION 1 CAUTIONS—READ FIRST! ..............................................1

SECTION 2 WILDEN PUMP DESIGNATION SYSTEM .................................2

SECTION 3 HOW IT WORKS—PUMP & AIR DISTRIBUTION SYSTEM ................3

SECTION 4 DIMENSIONAL DRAWINGS .............................................4

SECTION 5 PERFORMANCE ........................................................5

SECTION 6 SUGGESTED INSTALLATION, OPERATION & TROUBLESHOOTING ........6

SECTION 7 ASSEMBLY / DISASSEMBLY ............................................9

SECTION 8 EXPLODED VIEW & PARTS LISTING

H800 Metal - Ductile Iron .............................................18

H800 Metal - Stainless Steel ...........................................19

Center Section ......................................................20

SECTION 9 ELASTOMER OPTIONS .................................................22

Section 1

CAUTIONS—READ FIRST!

TEMPERATURE LIMITS:

Neoprene –17.7°C to 93.3°C 0°F to 200°F

Buna-N –12.2°C to 82.2°C 10°F to 180°F

Nordel

Viton® –40°C to 176.7°C –40°F to 350°F

Saniflex™ –28.9°C to 104.4°C –20°F to 220°F

Wil-Flex™ -40ºC to 107.2ºC –40ºF to 225ºF

Polytetrafluoroethylene (PTFE)

4.4°C to 104.4°C 40°F to 220°F

Polyurethane –12.2°C to 65.6°C 10°F to 150°F

NOTE: Not all materials are available for all

models. Refer to Section 2 for material options

for your pump.

CAUTION: When choosing pump materials, be

sure to check the temperature limits for all wetted

components. Example: Viton® has a maximum

limit of 177°C (350°F) but polypropylene has a

maximum limit of only 79°C (175°F).

CAUTION: Maximum temperature limits are

based upon mechanical stress only. Certain

chemicals will significantly reduce maximum

safe operating temperatures. Consult Chemical

Resistance Guide for chemical compatibility and

temperature limits.

WARNING: Prevent static sparking — If static

sparking occurs, fire or explosion could result.

Pump, valve and containers must be grounded

to a proper grounding point when handling

flammable fluids and whenever discharge of

static electricity is a hazard.

®

–51.1°C to 137.8°C –60°F to 280°F

CAUTION: Always wear safety glasses when

operating pump. If diaphragm rupture occurs,

material being pumped may be forced out air

exhaust.

CAUTION: Before any maintenance or repair is

attempted, the compressed air line to the pump

should be disconnected and all air pressure

allowed to bleed from pump. Disconnect all

intake, discharge and air lines. Drain the pump

by turning it upside down and allowing any fluid

to flow into a suitable container.

CAUTION: Blow out air line for 10 to 20 seconds

before attaching to pump to make sure all pipeline

debris is clear. Use an in-line air filter. A 5μ (micron)

air filter is recommended.

NOTE: Before starting disassembly, mark a line

from each liquid chamber to its corresponding air

chamber. This line will assist in proper alignment

during reassembly.

CAUTION: Wilden H800 High Pressure pumps

cannot be used in submersible applications.

CAUTION: Tighten all hardware prior to installation.

CAUTION: Do not exceed 5.9 bar (85 psig) air

supply pressure.

CAUTION: All piping, valves, gauges and other

components installed on the liquid discharge must

have a minimum pressure rating of 20.7 bar (300 psig).

CAUTION: The discharge pressure generated by

this pump is 3X the inlet pressure supplied.

CAUTION: The process fluid and cleaning fluids

must be chemically compatible with all wetted

pump components. Consult Chemical Resistance

Guide.

CAUTION: Pumps should be thoroughly flushed

before installing into process lines. FDA- and

USDA- approved pumps should be cleaned and /

or sanitized before being used.

WIL-1115 0 - E-10

1

WILDEN PUMP & ENGINEERING, LLC

Section 2

WILDEN PUMP DESIGNATION SYSTEM

H800 METAL

51 mm (2") Pump

Maximum Flow Rate:

360 lpm (95 gpm)

LEGEND

MATERIAL CODES

MODEL

H800 = 51 mm (2" ) HIGH

PRESSURE

WETTED PARTS

& OUTER PISTON

SS = STAINLESS STEEL/

STAINLESS STEEL

WW = DUCTILE IRON/

DUCTILE IRON

AIR CHAMBERS

S = S TAINLESS STEEL

W = DUCTILE IRON

H800 / X X X X X / XXX / XX / X XX / XXXX

MODEL

CENTER BLOCK

AIR CHAMBERS

WETTED PARTS & OUTER PISTON

CENTER BLOCK

A = ALUMINUM

AIR VALVE

A = ALUMINUM

DIAPHRAGMS

FWL = FUL L-STROKE

SANITARY

WIL-FLE X™ IPD

FWS = SANITARY

WIL-FLE X ™

TWS = FULL-STROKE PTFE

W/WIL-FLEX™

BACKUP

DIAPHRAGMS

VALVE BALLS

AIR VALVE

1

1

O-RINGS

VALVE SEAT

VALVE BALL

TF = PTFE (WHITE)

WF = WIL-FLEX™

VALVE SEAT

S = S TAINLESS STEEL

M = MILD STEEL

VALVE SEAT O-RING

TF = PT FE (WHITE)

WF = WIL-FLEX™

SPECIA LTY

CODE

(if applicable)

[SANTOPRENE

(ORANGE DOT)]

[SANTOPRENE

(ORANGE DOT)]

®

®

Notes: 1 Meets Requirement s of FDA CFR21.177

SPECIALTY CODES

0504 DIN flange

NOTE: MOST EL ASTOMERIC MATERIALS USE COLORED DOTS FOR IDENTIFICATION.

NOTE: Not all models are available with all material options.

WILDEN PUMP & ENGINEERING, LLC

2

WIL-1115 0 - E-10

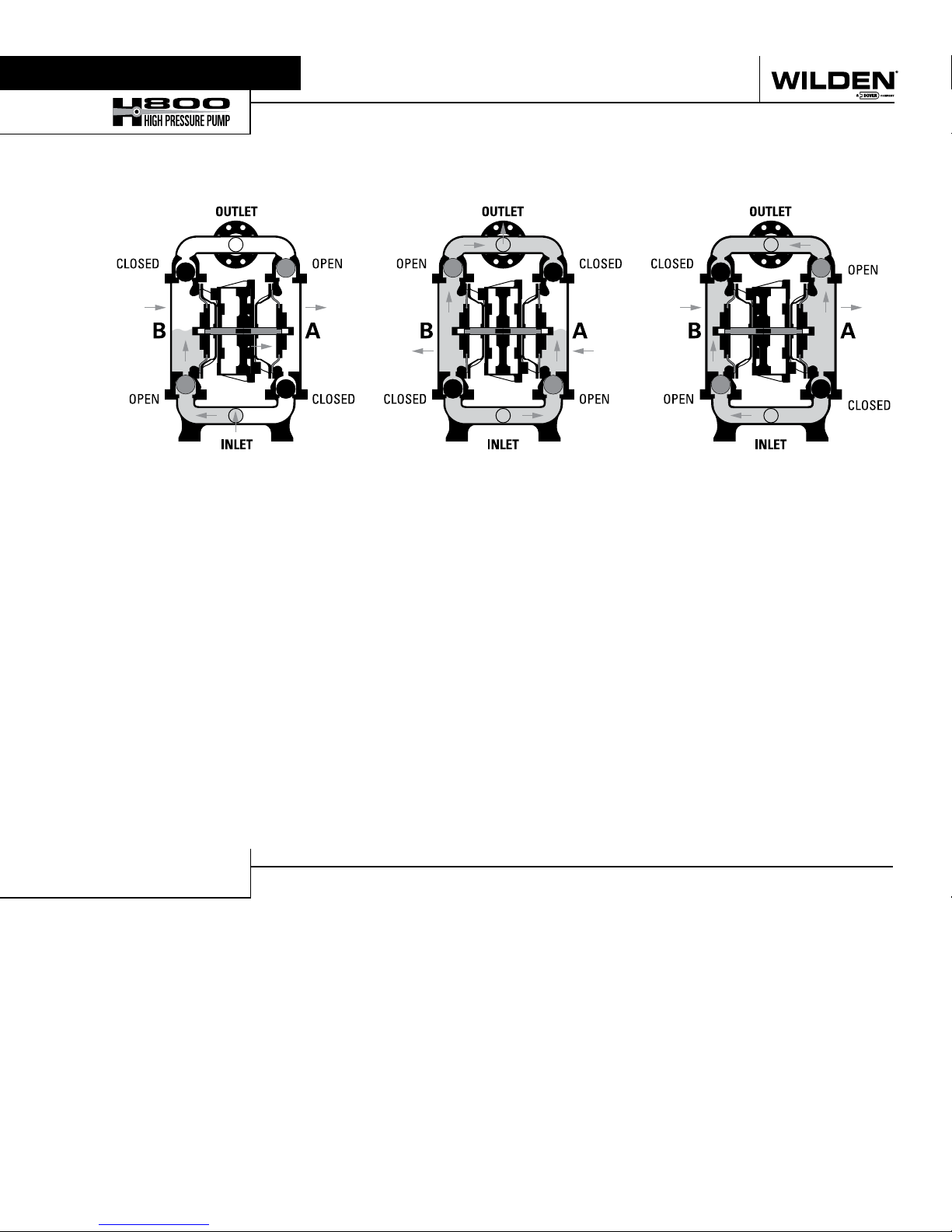

Section 3

HOW IT WORKS—PUMP

The Wilden diaphragm pump is an air-operated, positive displacement, self-priming pump. These drawings show flow pattern

through the pump upon its initial stroke. It is assumed the pump has no fluid in it prior to its initial stroke.

FIGURE 1 When air pressure is supplied

to the pump, the air valve directs pressure

to the back side of diaphragm A. The

compressed air moves the diaphragm

away from the center section of the pump.

The opposite diaphragm is pulled in by

the shaft connected to the pressurized

diaphragm. Diaphragm B is on its suction

stroke; air behind the diaphragm has been

forced out to the atmosphere through

the exhaust port. The movement of

diaphragm B towards the center section

of the pump creates a vacuum within

chamber B. Atmospheric pressure forces

fluid into the inlet manifold forcing the

inlet valve ball off of its seat. Liquid is free

to move past the inlet valve ball and fill

the liquid chamber (see shaded area).

FIGURE 2 Once the shaft has reached the

end of its stroke, the air valve redirects

pressurized air to the back side of

diaphragm B.

FIGURE 3 At completion of the stroke,

the air valve again redirects air to the

back side of diaphragm A, which star ts

diaphragm B on its exhaust stroke. As

the pump reaches its original star ting

point, each diaphragm has gone through

one exhaust and one discharge stroke.

This constitutes one complete pumping

cycle. The pump may take several cycles

to completely prime depending on the

condition of the application.

HOW IT WORKS—THE POWER PRINCIPLE

The H800 uses an integral power amplifier piston together with two diaphragms to yield a pressure ratio of 3:1 (e.g. 85 psig air

inlet will develop pump discharge pressures up to 250 psig). Air is simultaneously directed behind the amplifier piston as well as

one of the diaphragms via specialized air manifold porting. The sum of the two sur face areas is three times that of the diaphragm.

Therefore, the discharge is amplified by a 3:1 pressure output ratio.

WIL-1115 0 - E-10

3

WILDEN PUMP & ENGINEERING, LLC

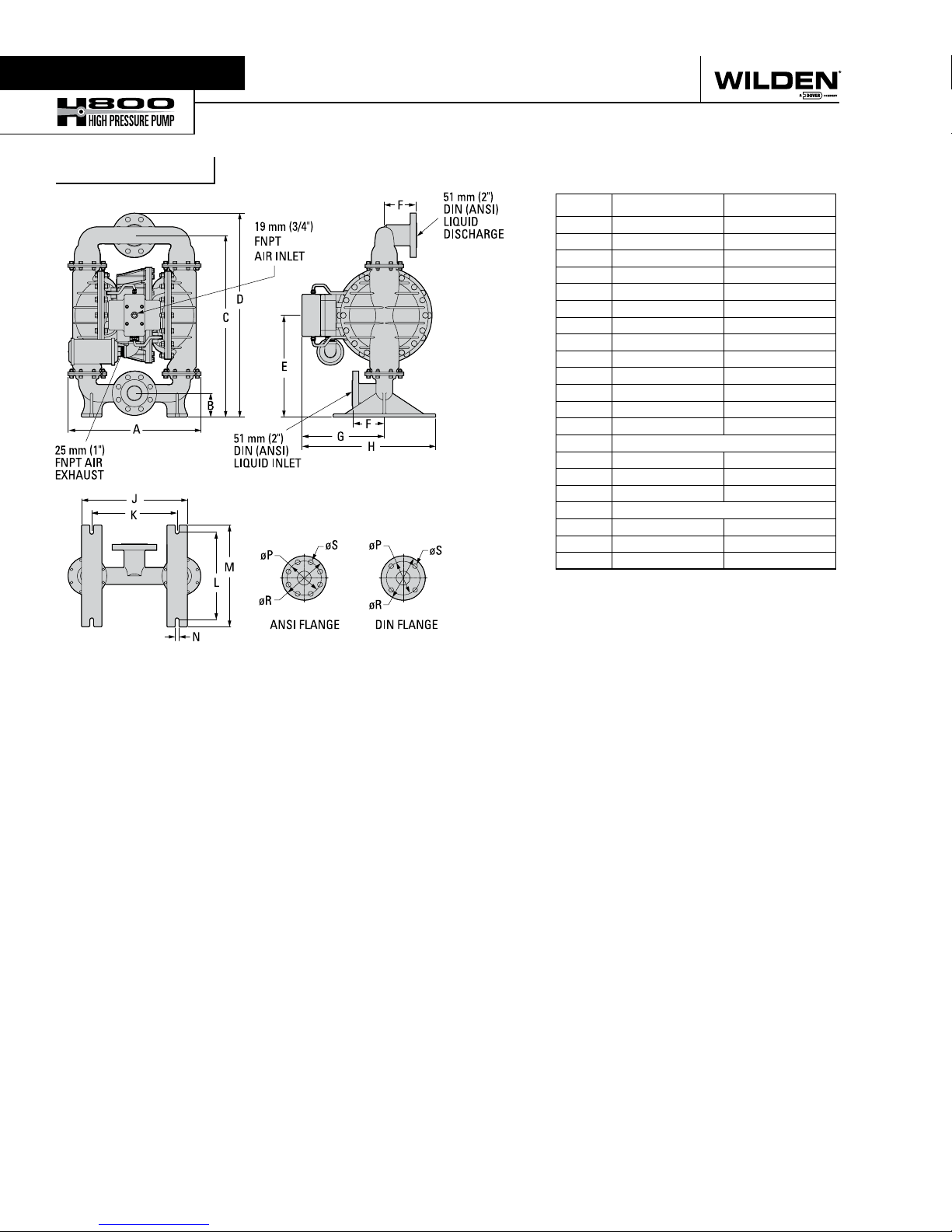

Section 4

DIMENSIONAL DRAWINGS

H800 Metal

DIMENSIONS

ITEM Metric (mm) Standard (inch)

A 490 19.3

B 89 3.5

C 677 26.7

D 760 29.9

E 378 14.9

F 120 4.7

G 307 12.1

H 498 19.6

J 394 15.5

K 318 12.5

L 325 12.8

M 379 14.9

N 14 0.6

DIN FLANGE

P 125 DIA. 4.9 DIA.

R 165 DIA. 6.5 DIA.

S 18 DIA. 0.7 DIA.

ANSI FLANGE

P 125 DIA. 5.0 DIA.

R 165 DIA. 6.5 DIA.

S 19 DIA. 0.8 DIA.

REV B

WILDEN PUMP & ENGINEERING, LLC

4

WIL-1115 0 - E-10

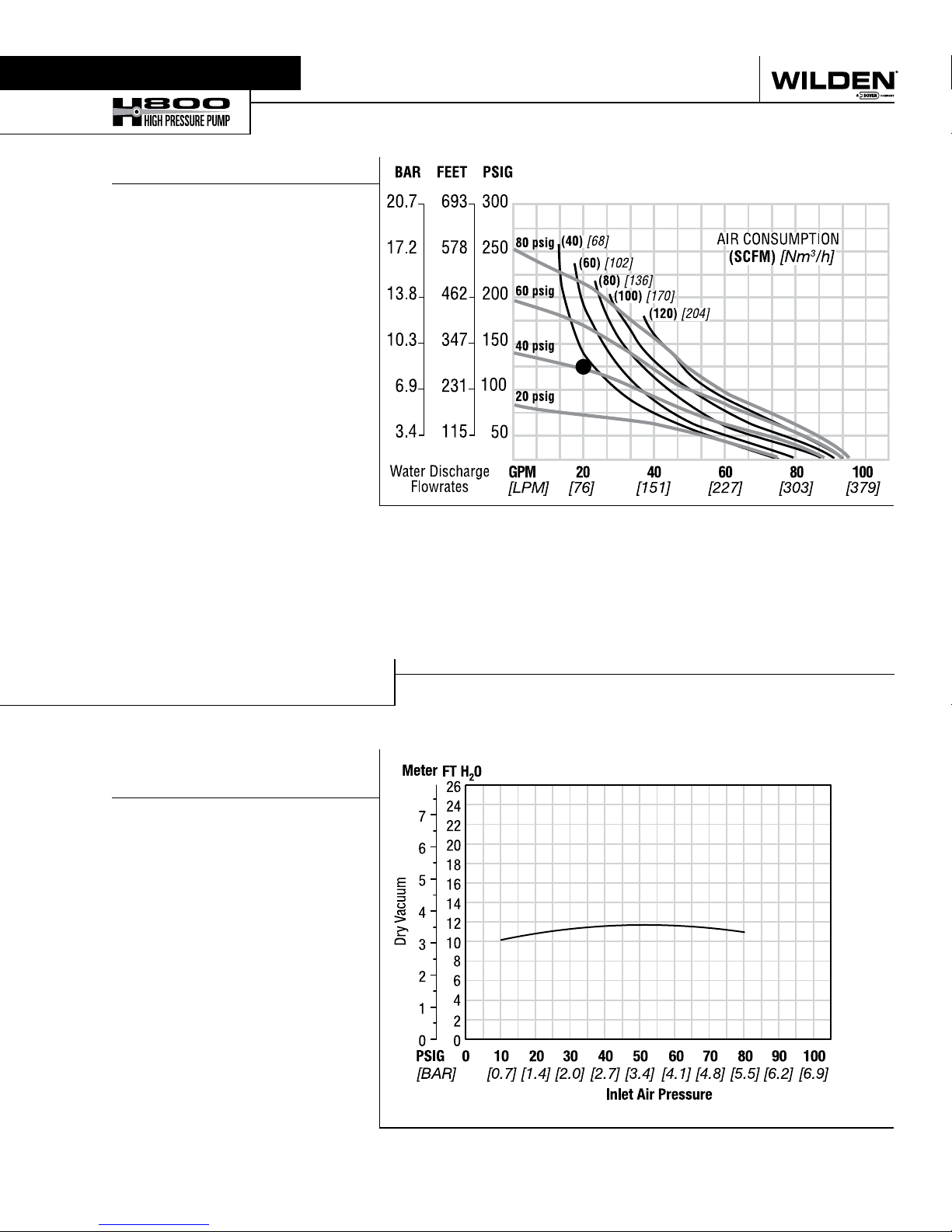

Section 5

H800 High Pressure Suction Lift Capability

PERFORMANCE (TPE/FULL STROKE PTFE)

A. P400 Aluminum performance

Curves

H800 METAL

Height………………… . ……759 mm (29.9")

Width ...................................490 mm (19.3")

Depth ...................................546 mm (21.5")

Est. Ship Weight ...... Stainless Steel 128 kg (283 lb)

Ductile Iron 128 kg (283 lb)

Air Inlet ....................................19 mm (3/4")

Inlet ........................................... 51 mm (2")

Outlet ........................................ 51 mm (2")

Suction Lift ...................... 3.7 m Dry (12.0')

9.0 m Wet (29.5')

Displacement Per Stroke ...1.67 L (0.44 gal)

Max. Flow Rate .............. 360 lpm (95 gpm)

Max. Size Solids .................. 12.7 mm (1/2")

1

Displacement per stroke was calculated at

4.8 bar (70 psig) air inlet pressure against a

5.1 bar (75 psig) head pressure.

Example: To pump 76 lpm (20 gpm)

against a discharge pressure head of 8.6

bar (125 psig) requires 2.9 bar (42 psig)

and 65 Nm3/h (38 scfm) air consumption.

Caution: Do not exceed 5.9 bar (85 psig) air

supply pressure.

Flow rates indicated on chart were determined by pumping water.

For optimum life and performance, pumps should be specified so that daily operation

parameters will fall in the center of the pump's performance curve.

SUCTION-LIFT CURVE

H800 METAL HIGH PRESSURE

SUCTION-LIFT CAPABILITIES

Suction lift curves are calibrated for

pumps operating at 305 m (1,000')

above sea level. This chart is meant

to be a guide only. There are many

variables that can affect your pump’s

operating characteristics. The number of

intake and discharge elbows, viscosity

of pumping fluid, elevation (atmospheric

pressure) and pipe friction loss all affect

the amount of suction lift your pump will

attain.

WIL-1115 0 - E-10

5

WILDEN PUMP & ENGINEERING, LLC

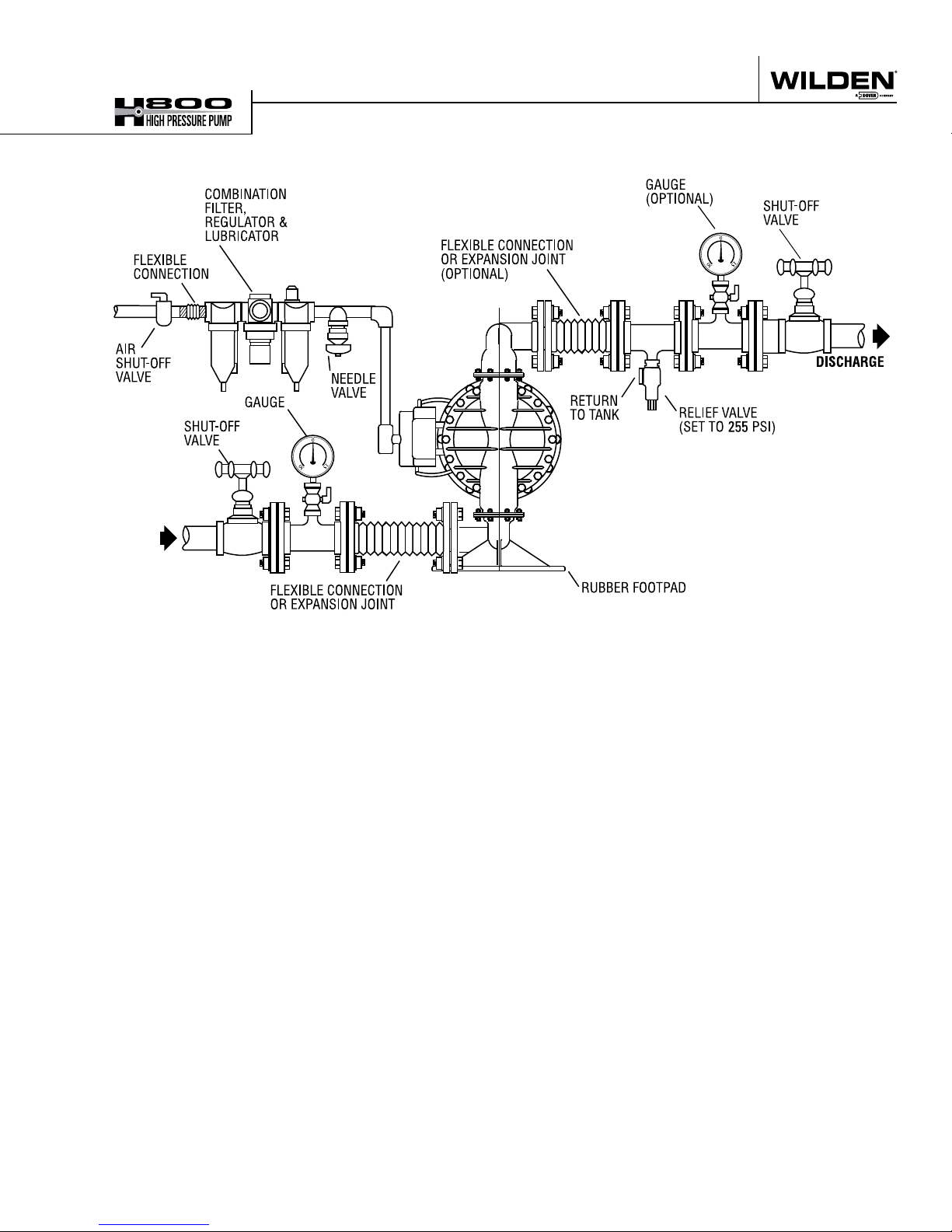

Section 6

SUGGESTED INSTALLATION

Wilden pumps are designed to meet the performance

requirements of even the most demanding pumping

applications. They have been designed and manufactured

to the highest standards and are available in a variety of

liquid path materials to meet your chemical resistance

needs. Refer to the performance section of this manual for

an in-depth analysis of the performance characteristics of

your pump. Wilden offers the widest variety of elastomer

options in the industry to satisfy temperature, chemical

compatibility, abrasion resistance and flex concerns.

The suction pipe size should be at least the equivalent or

larger than the diameter size of the suction inlet on your

Wilden pump. The suction hose must be non-collapsible,

reinforced type as these pumps are capable of pulling a high

vacuum. Discharge piping should also be the equivalent

or larger than the diameter of the pump discharge, which

will help reduce friction losses. It is critical that all fittings

and connections are airtight or a reduction or loss of pump

suction capability will result.

INSTALLATION: Months of careful planning, study

and selection efforts can result in unsatisfactory pump

performance if installation details are left to chance.

Premature failure and long-term dissatisfaction can be

avoided if reasonable care is exercised throughout the

installation process.

LOCATION: Noise, safety and other logistical factors usually

dictate where equipment will be situated on the production

floor. Multiple installations with conflicting requirements

can result in congestion of utility areas, leaving few choices

for additional pumps.

Within the framework of these and other existing conditions,

every pump should be located in such a way that six key

factors are balanced against each other to maximum

advantage.

ACCESS: First of all, the location should be accessible. If

it’s easy to reach the pump, maintenance personnel will

have an easier time carrying out routine inspections and

adjustments. Should major repairs become necessary, ease

of access can play a key role in speeding the repair process

and reducing total downtime.

AIR SUPPLY: Every pump location should have an air line

large enough to supply the volume of air necessary to

achieve the desired pumping rate. Use air pressure up to

a maximum of 5.9 bar (85 psig) depending on pumping

requirements.

For best results, the pumps should use a 5μ (micron) air

filter, needle valve and regulator. The use of an air filter

before the pump will ensure that the majority of any pipeline

contaminants will be eliminated.

SOLENOID OPERATION: When operation is controlled by a

solenoid valve in the air line, three-way valves should be

used. This valve allows trapped air between the valve and the

pump to bleed off, after which improves pump performance.

Pumping volume can be estimated by counting the number

of strokes per minute and then multiplying the figure by the

displacement per stroke.

MUFFLER: Sound levels are reduced below OSHA

specifications using the standard Wilden muffler. Other

mufflers can be used to further reduce sound levels, but

they usually reduce pump performance.

ELEVATION: Selecting a site that is well within the pump’s

dynamic lift capability will assure that loss-of-prime issues will

be eliminated. In addition, pump efficiency can be adversely

affected if proper attention is not given to site location.

PIPING: Final determination of the pump site should not be

made until the piping challenges of each possible location

have been evaluated. The impact of current and future

installations should be considered ahead of time to make

sure that inadvertent restrictions are not created for any

remaining sites.

The best choice possible will be a site involving the

shortest and straightest hook-up of suction and discharge

piping. Unnecessary elbows, bends and fittings should

be avoided. Pipe sizes should be selected to keep friction

losses within practical limits. All piping should be supported

independently of the pump. In addition, the piping should

be aligned to avoid placing stress on the pump fittings.

Flexible hose can be installed to aid in absorbing the forces

created by the natural reciprocating action of the pump. If the

pump is to be bolted down to a solid location, a mounting

pad placed between the pump and the foundation will assist

in minimizing pump vibration. Flexible connections between

the pump and rigid piping will also assist in minimizing

pump vibration. If quick-closing valves are installed at any

point in the discharge system, or if pulsation within a system

becomes a problem, a surge suppressor (SD Equalizer

should be installed to protect the pump, piping and gauges

from surges and water hammer.

If the pump is to be used in a self-priming application, make

sure that all connections are airtight and that the suction lift is

within the model’s ability. Note: Materials of construction and

elastomer material have an effect on suction lift parameters.

Please refer to the performance section for specifics.

When pumps are installed in applications involving flooded

suction or suction head pressures, a gate valve should be

installed in the suction line to permit closing of the line for

pump service.

Pumps in service with a positive suction head are most efficient

when inlet pressure is limited to 0.5–0.7 bar (7–10 psig).

Premature diaphragm failure may occur if positive suction

is 0.7 bar (10 psig) and higher.

ALL WILDEN PUMPS ARE CAPABLE OF PASSING SOLIDS.

A STRAINER SHOULD BE USED ON THE PUMP INTAKE TO

ENSURE THAT THE PUMP'S RATED SOLIDS CAPACITY IS

NOT EXCEEDED.

CAUTION: DO NOT EXCEED 5.9 BAR (85 PSIG) AIR SUPPLY

PRESSURE.

®

)

WILDEN PUMP & ENGINEERING, LLC

6

WIL-1115 0 - E-10

SUGGESTED INSTALLATION

NOTE: In the event of a power failure, the shut-off

valve should be closed, if the restarting of the pump is

not desirable once power is regained.

AIR-OPERATED PUMPS: To stop the pump from

operating in an emergency situation, simply close

the shut-off valve (user-supplied) installed in the air

supply line. A properly functioning valve will stop the

air supply to the pump, therefore stopping output. This

shut-off valve should be located far enough away from

the pumping equipment such that it can be reached

safely in an emergency situation.

WIL-1115 0 - E-10

7

WILDEN PUMP & ENGINEERING, LLC

Loading...

Loading...