A100

Advanced™ Series PLASTIC Pumps

Advance your process

EOM

Engineering

Operation &

Maintenance

WIL-11040-E-03

REPLACES WIL-11040-E-01

TABLE OF CONTENTS

SECTION 1 CAUTIONS—READ FIRST! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SECTION 2 WILDEN PUMP DESIGNATION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SECTION 3 DIMENSIONAL DRAWINGS

A100 Plastic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

A100B Plastic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

SECTION 4 PERFORMANCE

A100 Plastic Rubber-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

A100 Plastic PTFE-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Suction Lift Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

SECTION 5 EXPLODED VIEW & PARTS LISTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

SECTION 6 ELASTOMER OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Section 1

CAUTION–READ FIRST!

TEMPERATURE LIMITS:

Wetted Path

Polypropylene 0°C to 79.4°C 32°F to 175°F

PVDF –12.2°C to 107.2°C 10°F to 225°F

Elastomers

Buna-N –12.2°C to 82.2°C 10°F to 180°F

Viton

Wil-Flex™ –40°C to 107.2°C –40°F to 225°F

Polyurethane 12.2°C to 65.6°C 10°F to 150°F

PTFE 4.4°C to 104.4°C 40° F to 220°F

Saniflex™ –28.9°C to 104.4°C –20°F to 220°F

®

–40°C to 176.7°C –40°F to 350°F

CAUTION: When choosing pump materials, be sure

to check the temperature limits for all wetted components. Example: Viton

(350°F) but polypropylene has a maximum limit of only

79°C (175°F).

CAUTION: Maximum temperature limits are based

upon mechanical stress only. Certain chemicals will

significantly reduce maximum safe operating temperatures. Consult engineering guide for chemical compatibility and temperature limits.

CAUTION: Always wear safety glasses when operating pump. If diaphragm rupture occurs, material being

pumped may be forced out air exhaust.

WARNING: Prevention of static sparking — If static

sparking occurs, fire or explosion could result. Proper

grounding of pump, valves, and containers is critical when handling flammable fluids and whenever

discharge of static electricity is a hazard.

CAUTION: Do not exceed 8.6 bar (125 psig) air supply

pressure.

CAUTION: Advanced™ series plastic pumps are made

with plastic that is not UV stabilized. Direct sunlight for

prolonged periods can cause deterioration of plastics.

®

has a maximum limit of 176.7°C

CAUTION: Before any maintenance or repair is

attempted, the compressed air line to the pump should

be disconnected and all air pressure allowed to bleed

from pump. Disconnect all intake, discharge and air

lines. Drain the pump by turning it upside down and

allowing any fluid to flow into a suitable container.

CAUTION: Blow out air line for 10 to 20 seconds

before attaching to pump to make sure all pipe line

debris is clear. Use an in-line air filter. A 5μ (micron) air

filter is recommended.

NOTE: Tighten all bolts prior to installation. Fasteners

may loosen during transportation.

NOTE: When installing PTFE diaphragms, it is important to tighten outer pistons simultaneously (turning in

opposite directions) to ensure tight fit.

CAUTION: Verify the chemical compatibility of the

process and cleaning fluid to the pumpʼs component

materials in the Chemical Resistance Guide (see E4).

CAUTION: When removing the end cap using

compressed air, the air valve end cap may come out

with considerable force. Hand protection such as a

padded glove or rag should be used to capture the

end cap.

CAUTION: Do not over-tighten the air inlet reducer

bushing. Additionally, too much torque on the muffler

may damage the air valve muffler plate.

CAUTION: The A100 Advanced™ pump is not

submersible.

CAUTION: Only explosion proof (NEMA 7) solenoid

valve should be used in areas where explosion proof

equipment is required.

1

WILDEN PUMP & ENGINEERING, LLCWIL-11040-E-03

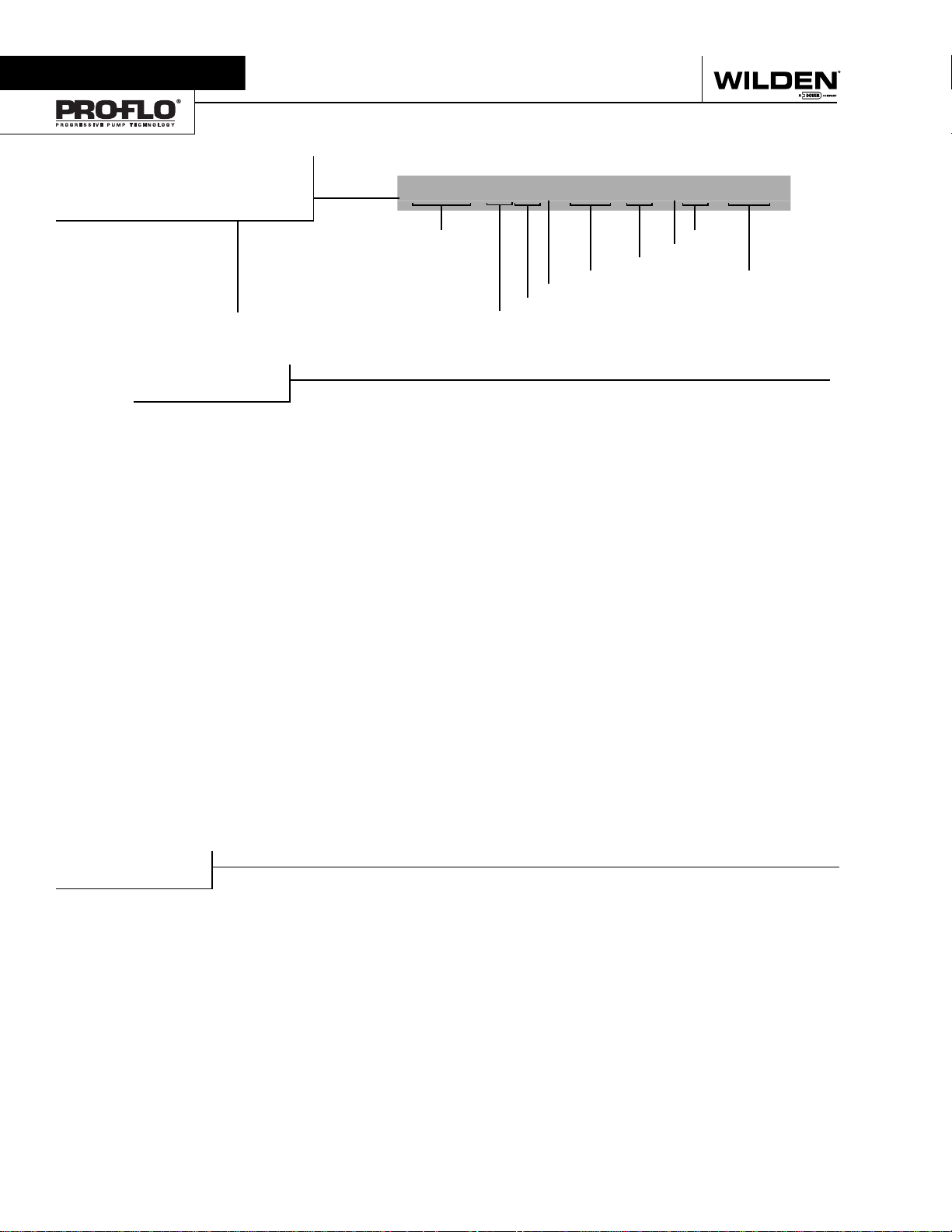

Section 2

WILDEN PUMP DESIGNATION SYSYTEM

A100 ADVANCED™

PLASTIC

13 mm (½") Pump

Maximum Flow Rate:

42.4 LPM (11.2 GPM)

MATERIAL CODES

AIR SYSTEM BASE TYPE

P = PRO-FLO

B = ADAPTER BLOCK

WETTED PARTS & OUTER

PISTON

KK = PVDF / PVDF

PP = POLYPROPYLENE /

POLYPROPYLENE

CENTER SECTION

PP = POLYPROPYLENE

AIR VALVE

P = POLYPROPYLENE

®

LEGEND

DIAPHRAGMS

A100P/ XXXXX / XXX /XX / XXX / XXXX

MODEL

CENTER SECTION

WETTED PARTS & OUTER PISTON

BNS = BUNA-N (Red Dot)

FSS = SANIFLEX™

[Hytrel

®

(Cream)]

PUS = POLYURETHANE (Clear)

THU = PTFE W/HIGH-TEMP BUNA-N

BACK-UP (White)

TNU = PTFE W/NEOPRENE

BACK-UP (White)

TNL = PTFE W/NEOPRENE

BACK-UP O-RING, IPD (White)

®

VTS = VITON

WFS = WIL-FLEX™ [Santoprene

(White Dot)

®

(Orange Dot)]

O-RINGS

VALVE SEAT

DIAPHRAGMS

AIR VALVE

VALVE BALL

VALVE BALLS

BN = BUNA-N (Red Dot)

FS = SANIFLEX™

[Hytrel

®

(Cream)]

PU = POLYURETHANE (Brown)

TF = PTFE (White)

VT = VITON

®

(White Dot)

WF = WIL-FLEX™ [Santoprene

(Orange Dot)]

VALVE SEAT

K = PVDF

P = POLYPROPYLENE

VALVE SEAT O-RING

BN = BUNA-N

FS = SANIFLEX™

[Hytrel

®

(Cream)]

PU = POLYURETHANE (Brown)

TV = PTFE ENCAP. VITON

WF = WIL-FLEX™ (Santoprene®)

SPECIALTY

CODE

(if applicable)

®

®

SPECIALTY CODES

0150 Accu-Flo™, 24V DC coil

0151 Accu-Flo™, 24V AC / 12V DC coil

0155 Accu-Flo™, 110V AC coil

0160 Accu-Flo™, 24V DC coil, BSPT

0512 Adapter block, no muffler, Pro-Flo®, center section

0682 P100 with OEM manifold, Accu-Flo™ 24V DC Coil

NOTE: MOST ELASTOMERIC MATERIALS USE COLORED DOTS FOR IDENTIFICATION.

Viton is a registered trademark of DuPont Dow Elastomers.

WILDEN PUMP & ENGINEERING, LLC WIL-11040-E-03

2

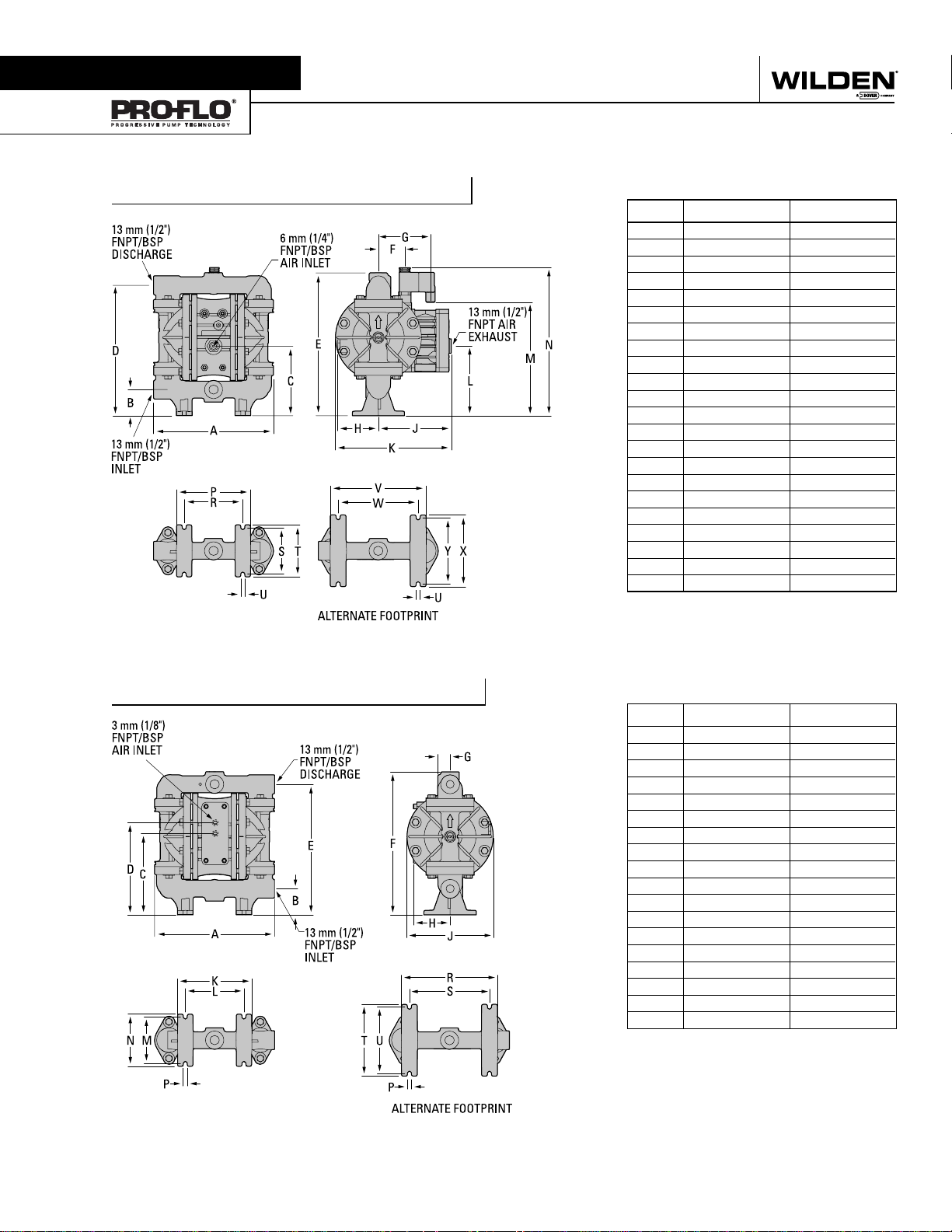

Section 3

DIMENSIONAL DRAWINGS

A100 ADVANCEDTM PLASTIC

DIMENSIONS

ITEM METRIC (mm) STANDARD (inch)

A 234 9.2

B 51 2.0

C 135 5.3

D 254 10.0

E 279 11.0

F 51 2.0

G 102 4.0

H 79 3.1

J 142 5.6

K 226 8.9

L 137 5.4

M 224 8.8

N 277 10.9

P 145 5.7

R 114 4.5

S 91 3.6

T 102 4.0

U 8 0.3

V 188 7.4

W 155 6.1

X 140 5.5

Y 130 5.1

A100B ADVANCED

TM

PLASTIC

DIMENSIONS

ITEM METRIC (mm) STANDARD (inch)

A 234 9.2

B 51 2.0

C 157 6.2

D 180 7.1

E 254 10.0

F 279 11.0

G 25 1.0

H 66 2.6

J 168 6.6

K 145 5.7

L 114 4.5

M 91 3.6

N 102 4.0

P 8 0.3

R 188 7.4

S 155 6.1

T 140 5.5

U 130 5.1

3

WILDEN PUMP & ENGINEERING, LLCWIL-11040-E-03

Section 4

PERFORMANCE

A100 PLASTIC

RUBBER-FITTED

Height ..................................277 mm (10.9")

Width .....................................234 mm (9.2")

Depth .................................... 226 mm (8.9")

Est. Ship Weight ........

Air Inlet ......................................6 mm (1/4")

Inlet .........................................13 mm (1/2")

Outlet ......................................13 mm (1/2")

Suction Lift ........................ Dry 6.6 m (21.5')

Displacement / Stroke ....... 0.11 l (0.03 gal)

Max. Flow Rate ............... 42.4 lpm (11.2 gal)

Max. Size Solids ...................1.6 mm (1/16")

Displacement per stroke was calculated at 4.8 bar

(70 psig) air inlet pressure against a 2.0 bar (30

psig) head pressure.

Example: To pump 17.4 lpm (4.6 gpm)

against a discharge head pressure of 1.4

bar (20 psig) requires 2.8 bar (40 psig) and

3

13.6 Nm

dot on chart.)

Caution: Do not exceed 8.6 bar (125 psig) air

supply pressure.

/hr (8 scfm) air consumption. (See

Polypropylene 4 kg (8 lbs)

PVDF 5 kg (10 lbs)

Wet 9.0 m (29.5')

;.MH=

;,0-=

Flow rates indicated on chart were determined by pumping water.

For optimum life and performance, pumps should be specified so that daily operation parameters

will fall in the center of the pump performance curve.

A100 PLASTIC

PTFE-FITTED

Height ..................................277 mm (10.9")

Width .....................................234 mm (9.2")

Depth .................................... 226 mm (8.9")

Est. Ship Weight ........

Air Inlet ......................................6 mm (1/4")

Inlet .........................................13 mm (1/2")

Outlet ......................................13 mm (1/2")

Suction Lift ........................ Dry 5.7 m (18.7')

Displacement / Stroke ....... 0.11 l (0.03 gal)

Max. Flow Rate ............... 38.2 lpm (10.1 gal)

Max. Size Solids ...................1.6 mm (1/16")

Displacement per stroke was calculated at 4.8 bar

(70 psig) air inlet pressure against a 2.0 bar (30

psig) head pressure.

Example: To pump 11.4 lpm (3.0 gpm)

against a discharge head pressure of 2.1 bar

(30 psig) requires 2.8 bar (40 psig) and 6.8

3

Nm

/hr (4 scfm) air consumption. (See dot

on chart.)

Caution: Do not exceed 8.6 bar (125 psig) air

supply pressure.

Polypropylene 4 kg (8 lbs)

PVDF 5 kg (10 lbs)

Wet 9.3 m (30.6')

;.MH=

;,0-=

Flow rates indicated on chart were determined by pumping water.

For optimum life and performance, pumps should be specified so that daily operation parameters

will fall in the center of the pump performance curve.

WILDEN PUMP & ENGINEERING, LLC WIL-11040-E-03

4

SUCTION LIFT CURVE

These curves demonstrate the flow created when the stroke rate is modified under static air and fluid pressure condition. This

curve can be applied to different pressure conditions to estimate the change in flow due to stroke rate.

A100 PLASTIC

;,0-=

;,0-=

7ATER$ISCHARGE&LOW2ATE

7ATER$ISCHARGE&LOW2ATE

5

WILDEN PUMP & ENGINEERING, LLCWIL-11040-E-03

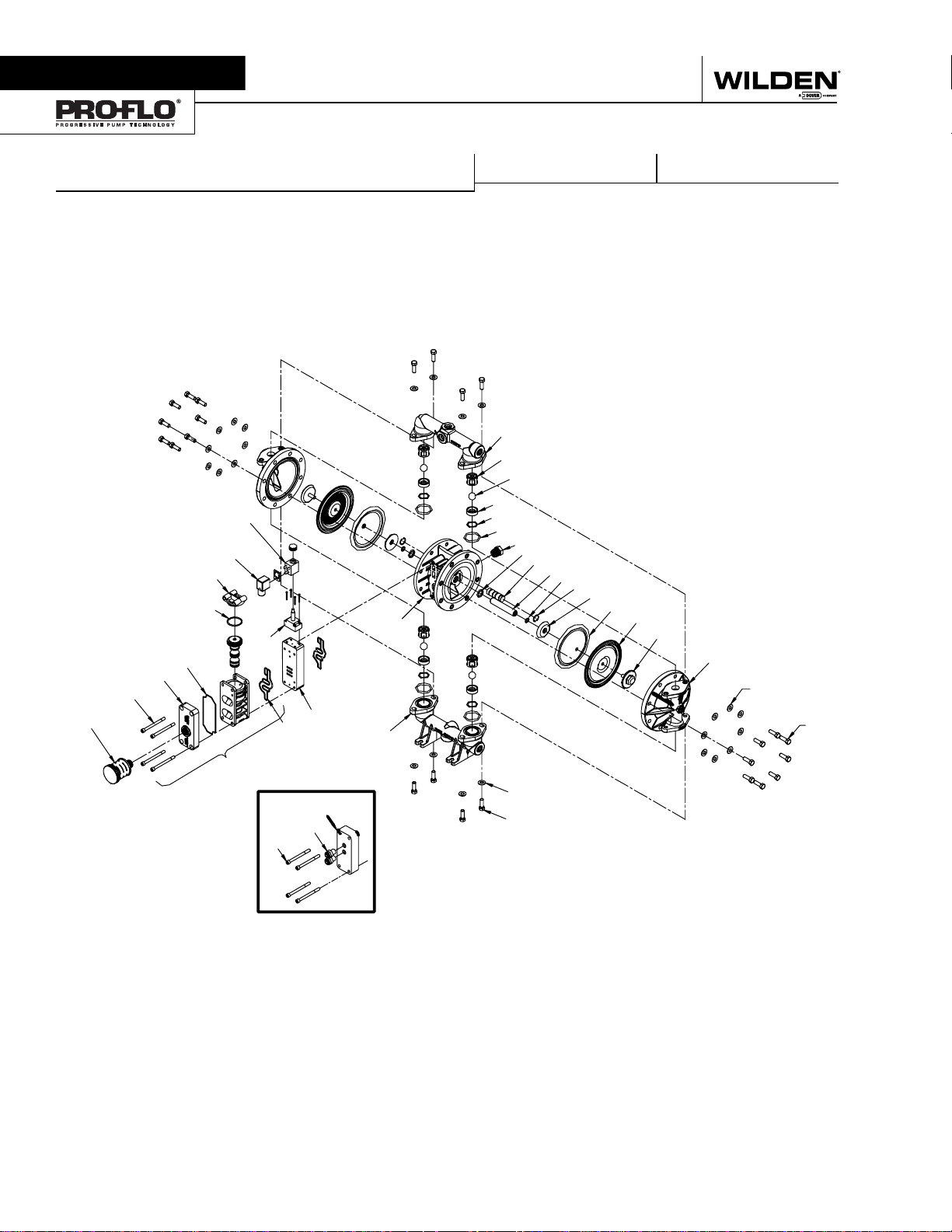

Section 5

EXPLODED VIEW & PARTS LISTING

A100 ADVANCED PLASTIC

10

11

2

3

9

5

6

7

12

8

4

25

13

31

32

33

26

29

30

15

14

16

18

19

17

20

23

EXPLODED VIEW

22

21

24

27

28

1

27

34

35

36

ADAPTER BLOCK VERSION

WILDEN PUMP & ENGINEERING, LLC WIL-11040-E-03

6

28

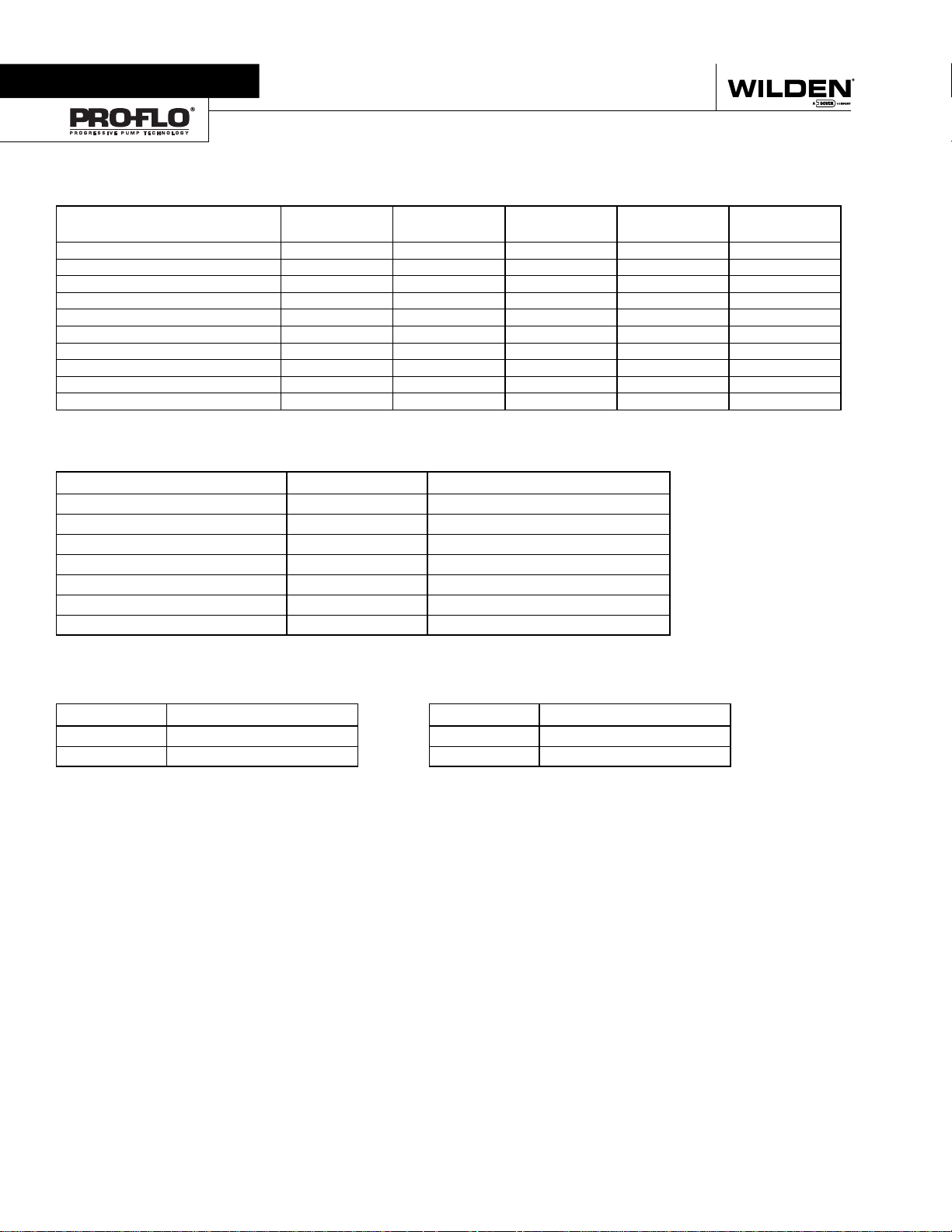

EXPLODED VIEW & PARTS LISTING

A100P & A100B ADVANCED PLASTIC

A100P/PKPPP/0151

Item Description Qty.

1 Air Valve Assembly

2 End Cap 1 01-2332-20 01-2332-20

3 O-ring, (.103 x 1.362) 1 01-2395-52 01-2395-52

4 Gasket, Air Valve 2 01-2615-52 01-2615-52

5 Gasket, Muffler Plate 1 01-3505-52 01-3505-52

6 Muffler Plate 1 01-3181-20 01-3181-20

7 Air Valve Screws, SHC, 1/4-20 x 4.5 4 01-6000-03 01-6000-03

8 Solenoid Spacer Plate 1 01-2160-20 01-2160-20

9 Operator, Solenoid, Nema 4 1 00-2120-99 00-2120-99

10 Coil 1 00-2110-99-151 00-2110-99-151

11 Terminal Connector 1 00-2130-99 00-2130-99

12 Muffler, 1/2” 1 02-3510-99 02-3510-99

13 Center Section 1 01-3141-20 01-3141-20

14 Glyd-Ring II, (.618 x .136) 2 01-3220-55 01-3220-55

15 Reducer Bushing 1 01-6950-20 01-6950-20

16 Pilot Plug Assy 1 01-2285-99 01-2285-99

17 Retaining Ring 2 00-2650-03 00-2650-03

18 Shaft 1 01-3810-03 01-3810-03

19 Disc Spring (.331 x .512) 2 01-6802-08 01-6802-08

20 Piston, Inner, (Combo) 2 01-3711-08 01-3711-08

21 Piston, Outer, (Combo) 2 01-4570-21-500 01-4570-21-500

22 Diaphragm, Primary, PTFE 2 01-1010-55 01-1010-55

23 Diaphragm, Back-Up, Neoprene 2 01-1060-51 01-1060-51

24 Liquid Chamber 2 01-5005-20 01-5005-21

25 Inlet Manifold 1 01-5095-20 01-5095-21

26 Discharge Manifold 1 01-5035-20 01-5035-21

27 Washer (.343 x .750 x .05) 24 01-6732-03 01-6732-03

28 Screw, HHC, 5/16-18 x 1.13 24 01-6191-03 01-6191-03

29 Ball Cage 4 01-5355-20 01-5355-21

30 Valve Ball 4 01-1080-55 01-1080-55

31 Valve Seat 4 01-1125-20 01-1125-21

32 Valve Seat O-ring (.924 x .103) 4 01-1205-60 01-1205-60

33 Manifold O-ring (1.484 x .139) 4 05-1370-60 05-1370-60

34 Adapter Block 1 01-2155-20 01-2155-20

35 Adapter Block Air Fittings 2 00-2170-20 00-2170-20

36 Air Valve Screws, SHC, 1/4-20 x 2 4 04-6000-03 04-6000-03

Alternate OEM Manifold (not shown) 1 01-5097-20 01-5097-21

Drum Pump Manifold (not shown) 1 01-5094-20 01-5094-21

Pipe Plug (not shown) 1 01-7101-20 01-7101-21

v

Air Valve Assembly includes items 2 & 3

All Boldface items are primary wear parts

1

1 01-2010-20 01-2010-20

P/N

PTFE-FITTED PARTS LISTING

A100P/KKPPP/0151

P/N

7

WILDEN PUMP & ENGINEERING, LLCWIL-11040-E-03

Section 6

ELASTOMER OPTIONS

A100P & A100B ADVANCED PLASTIC PUMPS

VALVE SEAT O-

MATERIAL Diaphragm P/N VALVE BALL P/N VALVE SEAT P/N

Polyurethane 01-1010-50 01-1080-50 N/A 01-1200-50 02-1230-50

Buna-N 01-1010-52 01-1080-52 N/A 00-1260-52 02-1230-52

Viton 01-1010-53 01-1080-53 N/A N/A N/A

Wil-Flex™ 01-1010-58 01-1080-58 N/A 00-1260-58 01-1370-58

Sanifl ex™ 01-1010-56 01-1080-56 N/A 01-1200-56 01-1370-56

PTFE 01-1010-55 01-1080-55 N/A N/A N/A

PTFE with Integral Piston 01-1030-55 N/A N/A N/A N/A

Encapsulated/Viton N/A N/A N/A 01-1205-60 05-1370-60

PVDF N/A N/A 01-1125-21 N/A N/A

Polypropylene N/A N/A 01-1125-20 N/A N/A

RING P/N

COIL OPTIONS

Specialty Code Part Number Description

150 01-2110-99-150 24V DC

154 01-2110-99-154 24V DC, NEMA 7

157 01-2110-99-157 24V DC, International

151 01-2110-99-151 24V AC/12V DC

153 01-2110-99-153 24V AC/12V DC, NEMA 7

155 01-2110-99-155 110V AC

156 01-2110-99-156 110V AC, NEMA 7

MANIFOLD O-RING

P/N

ADAPTER BLOCK OPTIONS

Part Number Description

01-2155-13 Acetal

01-2155-20 Polypropylene

OPERATOR OPTIONS

Part Number Description

00-2120-99 Nema 4

00-2121-99 Nema 7

WILDEN PUMP & ENGINEERING, LLC WIL-11040-E-03

8

WARRANTY

Each and every product manufactured by Wilden Pump and Engineering, LLC is built to meet the highest

standards of quality. Every pump is functionally tested to insure integrity of operation.

Wilden Pump and Engineering, LLC warrants that pumps, accessories and parts manufactured or supplied by

it to be free from defects in material and workmanship for a period of five (5) years from date of installation or

six (6) years from date of manufacture, whichever comes first. Failure due to normal wear, misapplication, or

abuse is, of course, excluded from this warranty.

Since the use of Wilden pumps and parts is beyond our control, we cannot guarantee the suitability of any pump

or part for a particular application and Wilden Pump and Engineering, LLC shall not be liable for any consequential

damage or expense arising from the use or misuse of its products on any application. Responsibility is limited

solely to replacement or repair of defective Wilden pumps and parts.

All decisions as to the cause of failure are the sole determination of Wilden Pump and Engineering, LLC.

Prior approval must be obtained from Wilden for return of any items for warranty consideration and must be

accompanied by the appropriate MSDS for the product(s) involved. A Return Goods Tag, obtained from an

authorized Wilden distributor, must be included with the items which must be shipped freight prepaid.

The foregoing warranty is exclusive and in lieu of all other warranties expressed or implied (whether written or oral)

including all implied warranties of merchantability and fitness for any particular purpose. No distributor or other

person is authorized to assume any liability or obligation for Wilden Pump and Engineering, LLC other than expressly

provided herein.

PLEASE PRINT OR TYPE AND FAX TO WILDEN

PUMP INFORMATION

Item # Serial #

Company Where Purchased

YOUR INFORMATION

Company Name

Industry

Name Title

Street Address

City State Postal Code Country

Telephone Fax E-mail Web Address

Number of pumps in facilit y? Number of Wilden pumps?

Types of pumps in facility (check all that apply): Diaphragm Centrifugal Gear Submersible Lobe

Other

Media being pumped?

How did you hear of Wilden Pump? Trade Journal Trade Show Internet/ E-mail Distributor

Other

ONCE COMPLETE, FAX TO (909) 783-3440

NOTE: WARRANTY VOID IF PAGE IS NOT FA XED TO WILDEN

WILDEN PUMP & ENGINEERING, LLC

Loading...

Loading...