EdgeGard™ Dock Gate, Folding-Rail

Installation Instructions

WG-EFR

Table of Contents

General Specifications ………………………………………………………………… 1

Product Description ……………………………………………………………………. 2

Installation Procedure …………………………………………………………………. 3

Component Parts ………………………………………………………………………. 9

Warranty ………………………………………………………………………………...10

Thank you

We know that in today’s competitive marketplace, customers have many choices

when purchasing safety products. We appreciate your choosing Wildeck’s high

quality EdgeGard™ dock gate and know you have made a wise decision.

Our continued reputation as one of the top manufacturers of industrial products

rests with the satisfaction of each and every customer. Wildeck products are

Crafted with Confidence by employee owners in Waukesha, Wisconsin, USA.

Should you have any questions or require installation assistance, please do not

hesitate to contact your local Wildeck representative or Wildeck’s customer

service department at 1-800-325-6939.

Thank you for allowing Wildeck to serve your needs.

General Specifications

Features and Benefits:

► EdgeGard™ Gate top rails are 42” high (above floor Level) when

closed.

► Requires minimal floor space and is easily assembled and installed.

► Strong balanced construction withstands 200 lbs. top rail pressure.

Meets OSHA 1910.23 load force protection requirement.

► Counterbalanced gas cylinder(s) allow easy lifting and safe gate

operation.

► Black safety stripe on bright yellow paint finish ensures high visibility.

► Quality Wildeck® gates are manufactured in the USA and provide a

lone service life.

Specifications:

► Weight:

Straight-Rail Gate 71 lbs (8 ft.)

77 lbs (10 ft.)

Folding-Rail Gate 110 lbs (10 ft.)

116 lbs (12 ft.)

► Installation Footprint:

(overall width and height clearance when raised)

Straight-Rail Gate 110”W x 143”H (8 ft.)

134”W x 167”H (10 ft.)

Folding-Rail Gate 141”W x 104”H (10 ft.)

165”W x 116”H (12 ft.)

NOTE: The gate sizes listed above are Wildeck’s standard product, other gate sizes available on request.

1

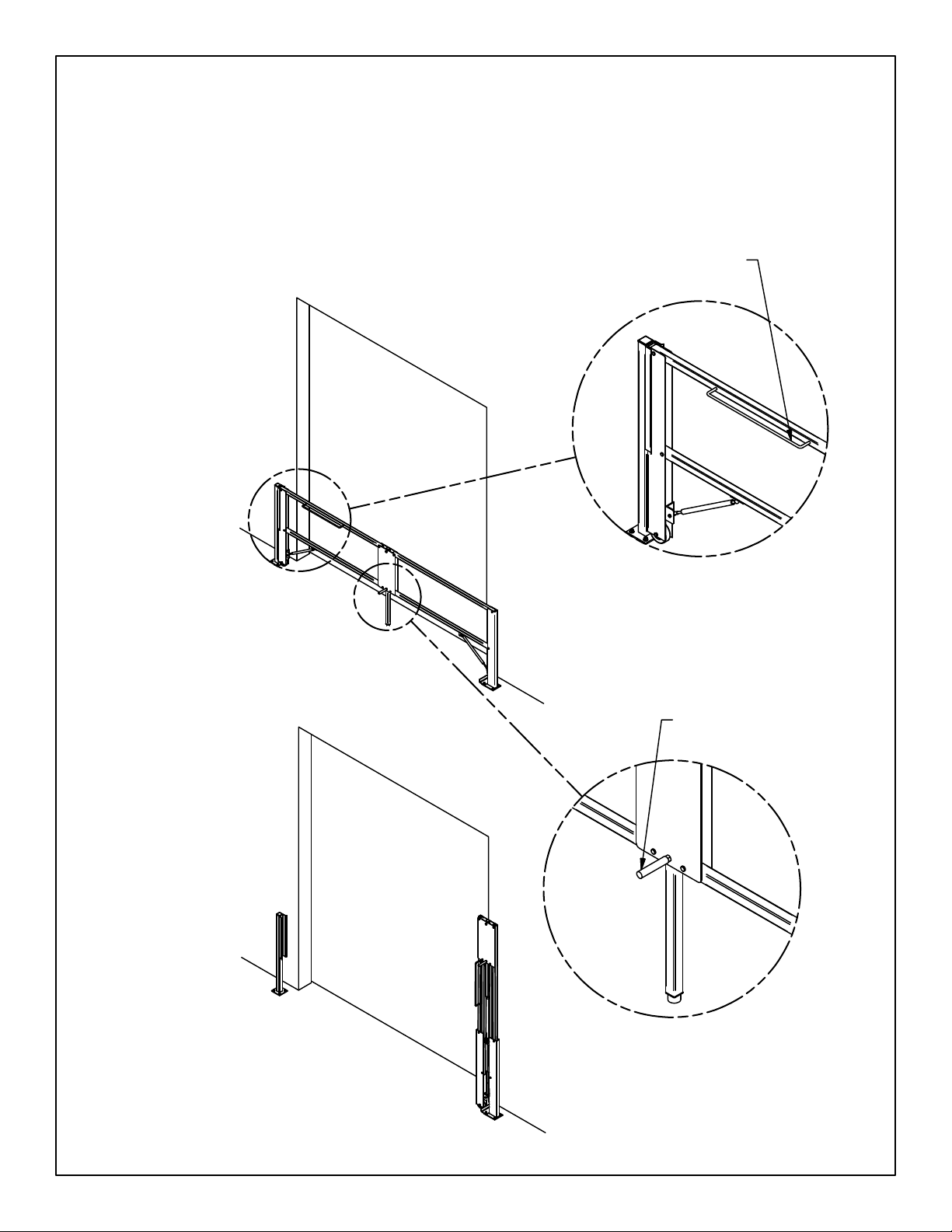

Product Description

The Folding-Rail EdgeGard™ Dock Gate is a personnel barrier, protecting the open

edge of a dock door, truck loading pit, or other hazardous area. The gate can be

installed so that the gate slides open from right-to-left or from left-to-right. Below

depicts the gate opening from left-to-right.

Slide gate open or closed

using handle on top rail

Gate Closed

Gate Open

Lift up on handle grip

when opening gate

2

Installation Procedure

It is recommended to start installation of

gate from the pivot post and work towards

the receiver post. The gas springs to be

the last items assembled onto the gate.

1. Position pivot post in desired location.

Before anchoring to floor, place gate

stop on top of base plate aligned with

holes along inside edge of base plate,

as shown. Utilize anchors to secure

gate stop in place.

Pivot Post

(SP0110)

NOTES:

Dimension A to match on page 7.

Refer to the assembly drawing # SP0103

at the end of these instructions to aid in

assembly of the gate.

Anchors not provided

by Wildeck, use Ø3/8"

anchors

Gate Stop

(SP0127)

s

ee

p

a

ge

7

3

Installation Procedure

2. Slide top and bottom rails into pivot post

and secure with clevis pins. Plastic washers

are used between the rails and the post

(both sides of tubes).

NOTES:

The bottom rail with spring attachment bracket

must be oriented as shown below.

Make sure that the top rail closest to the pivot

post does not

handle is assembled to the rolling pivot post

at the opposite end of gate, see following steps.

have a handle. The top rail with

Cotter Pin

(HWM1130)

Plastic Washers

(HWM1480)

Top Rail

(SP0126)

Bottom Rail

(SP0125)

Clevis Pin

(HWM1100)

Cotter Pin

(HWM1130)

Plastic Washers

(HWM1480)

Clevis Pin

(HWM1100)

4

Installation Procedure

3. Install tube insert into bottom of center

tube and then thread on rubber bumper.

Cap other end of tube with plastic plug.

Note orientation of the holes in the center

tube.

4. Attach center plates to center tube.

Secure the top of the plates to the tube

with 1/2" bolt, washers & nut and secure

the bottom of the plates with bolt, washers

and handle grip. Steel washers are used

between the center tube and the center

plates (both sides of tube).

Bottom Rail

(SP0125)

Handle

Note orientation of the center plates, the

holes at the top should be at the corners.

5. Attach top and bottom rails to the center

plate assembly secured with clevis pins.

Plastic washers are used between the

rails and the center plates (both sides

of tubes).

NOTE: The orientation of the spring

attachment brackets on the bottom rails are

mirror images of each other.

The top rail with handle must be oriented as

shown below.

Top Rail w/Handle

(SP0124)

Plastic Plug

(HWF0630)

1/2" Nylock Nut

(HWN12L)

Plastic Washers

(HWM1480)

Steel Washers

(HWW12ST)

1/2" x 2-3/4" bolt

(HWB12X275GR5)

Center Plate

(SP0123)

Handle Grip

(SP0128)

Tube Insert

(HWF0710)

Clevis Pins

(HWM1100)

(4 places)

Top Rail

(SP0126)

1/2" x 2-3/4" bolt

(HWB12X275GR5)

Center Plate

(SP0123)

Bottom Rail

(SP0125)

Pivot post (SP0110)

located this end

Center Tube

(SP0122)

Rubber Bumper

(HWM1310)

5

Installation Procedure

6. Assemble wheel onto rolling end post

with 3/8" bolt, washers and nut.

NOTE: It may be advantageous to have a

second person help with the following.

7. Slide top and bottom rails into post and

secure with clevis pins. Plastic washers

are used between the rails and the post

(both sides of tubes).

Plastic Washers

(HWM1480)

Clevis Pin

(HWM1100)

NOTE: The bottom rail with spring

attachment bracket must be oriented as

shown below. It should be a mirror image

of the bottom rail at the other end.

Cotter Pin

(HWM1130)

Top Rail w/Handle

(SP0124)

Clevis Pin

(HWM1100)

3/8" x 2-3/4" bolt

(HWB38X275GR5)

Washers

(HWW38FL)

Cotter Pin

(HWM1130)

Plastic Washers

(HWM1480)

Bottom Rail

(SP0125)

3/8" Nylock Nut

(HWN38L)

Wheel

(HWM1320)

6

Installation Procedure

8. Place gate into its fully closed position.

9. Position receiver post next to rolling

end post and anchor to floor.

NOTE: Before anchoring receiver post,

double check that the base plate is aligned

with the pivot post base plate, Dimension A.

Plastic Plug

(HWF0640)

10. Cap receiver post with plastic plug.

Receiver Post

(SP0121)

Anchors not provided

by Wildeck, use Ø3/8"

anchors

3

e

g

a

p

e

e

s

7

Installation Procedure

NOTE: It may be advantageous to have a

second person help with the following steps.

11. Attach ball studs to spring attachment

brackets on both the bottom rails and

the pivot posts (4 places). Secure the

studs with jam nuts.

NOTE: orientation of ball studs as shown

in Assembled View.

12. Thread ball sockets onto gas springs.

13. Remove clips from the ball sockets.

14. Slide the gate open until it's approx.

6" from fully open to allow room to

install springs.

Jam Nut

(HWN51618J)

15. Attach gas springs to ball stu d s wi th

the rod pointing down as shown.

16. Secure ball sockets onto studs with

the retaining clips.

17. After the springs are attached, double

check that the springs are aligned with

the centerline of the post, adjust

accordingly.

18. Close and open gate to make sure

nothing binds, fix accordingly.

19. Apply striped tape to rails as desired.

NOTE: below diagrams show attaching

gas springs to rolling pivot post; same

arrangement applies to stationary pivot

post.

Ball Stud

(HWM1050)

Ball Stud

(HWM1050)

Jam Nut

(HWN51618J)

Ball Socket

(HWM1040)

Ball Socket

(HWM1040)

Retaining Ring

Spring must be aligned

with centerline of post

and rails, as shown.

Gas Spring

(HWM1150)

Ball Socket

(HWM1040)

Ball Socket

(HWM1040)

Retaining Ring

Assembled

View

8

PART #

DESCRIPTIONQTY

BILL OF MATERIALS

JOB #:

SP0110

SP0120

SP0121

SP0122Center Post14SP0123Center Connection Plate

SP0124Top Rail w/ Handle16SP0125Bottom Rail27SP0126

SP0127Gate Stop19

SP0128Handle with Grip

HWM1150

HWM1040

HWM1050

HWN51618JJam Nut, 5/16-18 UNC414

HWN12L

HWM1100

HWM1480

HWM1130

HWW12STWasher, 1/2"

HWM1320

HWB12X275GR5Bolt, 1/2-13 x 2 3/4"

HWB38X275GR5Bolt, 3/8-16 x 2 3/4"

HWW38FL

HWN38L

HWF0710Tube Insert125

HWF0630

HWF0640Plastic Cap for 2" Square Tube128

HWM1310Vibration Mount w/ Stud126

HWM1410

QTY:

SP0103

TM

ITEM

Rubber Wheel, 4" Dia.

121

122

Washer, 3/8"

223

Lock Nut, 3/8-16 UNC

124

Plastic Cap for 1-1/2" Square Tube

127

Striped Tape, YELLOW/BLACK

129

215

4

16

Lock Nut, 1/2-13 UNC

117

Clevis Pin, 1/2" DIA. x 2 1/4" Long

Plastic Washer, 1/2" ID x 1 1/4" OD

818

1619

Cotter Pin, 1/8 x 3/4"

820

Gas Spring w/M8 Threaded Ends

Ball Socket

211

412

Ball Stud

413

Pivot Post11

End Post, Rolling

Receiver Post13

12

2

Rail Tube18

110

5

1

8 29

9

11121314

15 16 17

5

729

Bill of Material

18 19 20

5

Folding EdgeGard Gate (WG-EFR)

3 28

6 29

11

7

2

12

29

13

21

14

22

23

101516

24

4

252627

3/27/2009

REV

DATE:

BRT

DRN BY: DATE:

REV:

w

EdgeGard™ Dock Gates

WARRANTY

Wildeck EdgeGard™ Dock Gates are warranted to be free of material defects

and workmanship for a period of one (1) year. When properly anchored,

EdgeGard™ Dock Gates are also warranted to meet the 200 lb. OSHA 1910.23 load

force protection requirement.

The warranty begins at time of shipment from Wildeck’s factory. Labor to install,

adjust, maintain or replace the warranted gate, or any component part, is not

included.

This warranty is valid only if the Wildeck EdgeGard™ Dock Gate has been installed

in complete accordance with Wildeck’s Installation Instructions. Improprieties

including but not limited to abuse, negligence, or failure to install, maintain or adjust

the equipment properly, will void the warranty.

The warranty is also voided if unauthorized parts, hardware or equipment are

installed, or modifications are made to the Wildeck EdgeGard™ Dock Gate without

prior written authorization. Wildeck reserves the right to change, at any time, the

material, design or specifications of its products without obligation to subsequent

purchases, or add improvements without making corresponding changes to products

previously manufactured.

WILDECK SHALL NOT IN ANY EVENT BE LIABLE FOR ANY DAMAGES, WHETHER

BASED ON CONTRACT, WARRANTY, NEGLIGENCE, STRICT LIABILITY OR

OTHERWISE, INCLUDING WITHOUT LIMITATION ANY CONSEQUENTIAL,

INCIDENTAL OR SPECIAL DAMAGES, ARISING WITH RESPECT TO THE EQUIPMENT

OR ITS FAILURE TO OPERATE, EVEN IF WILDECK HAS BEEN ADVISED OF THE

POSSIBILITY THEREOF.

WILDECK MAKES NO OTHER WARRANTY OR REPRESENTATION OF ANY KIND,

EXCEPT THAT OF TITLE, AND ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING WARRANTIES OR MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, ARE HEREBY EXPRESSLY DISCLAIMED.

Order No._______________________________

P.O. Box 89 • 405 Commerce Street

Waukesha, WI USA 53186

262-549-4000 • 800-325-6939

FAX 262-549-3466 • info@wildeck.com

© Wildeck, Inc. 2011 Printed in USA • WG-EFR-IN 1109

ww.wildeck.com

Loading...

Loading...