Wildeboer FR90 User Manual

Maintenance-free

FR90 re dampers

■ Sizes ∅ 100 mm to ∅ 800 mm

■ For universal use with a wide range of applications

■ Fire classication: EI 30/60/90/120 (ve - ho, i ↔ o) S C

■ Hygiene certicate

■ Environmental Product Declaration according to ISO 14025 and EN 15804

The German original version of this document shall prevail

10ooo

User Manual 5.3 (2018-07) 1

FR90 re dampers

Features and characteristics

Single-piece sheet steel casing

galvanized - longitudinal seam welded - extremely robust

airtight, smoke-proof

Leak tightness class C

according to EN 1751

Option: Epoxy resin powder coating

Nominal sizes [mm]

DN 100 to DN 800

Break-resistant

damper blade

with elastomer lip seal

airtight, leak tightness class 3

according to EN 1751

Options:

• Metal cover made of galvanized steel

• Metal cover made of 1.4301 stainless steel

Two control openings (inspection openings)

for viewing both sides of the damper blade

Lip seals

Large free cross-section

Maximum volume ows

Minimum pressure drop

Extremely low sound power level

Release mechanism and axis of

the damper blade rotatable 360°

Fully enclosed:

• Operation unit

• Release mechanism

• Release element

Thermal-mechanical

release mechanism

for single handed operation

Option:

Electric actuators, also explosion-protected

All-round enclosed

thermal release elements 70°C or 95°C

Option:

Corrosion-resistant release element 70°C

User Manual 5.3 (2018-07) 2 Subject to change

Series FR92

FR90 re dampers

Description

Maintenance-free FR90 re dampers according to EN 15650

Fire classications: EI 30/60/90/120 (v

- ho, i ↔ o) S C

e

10ooo

Declaration of performance: DoP no.: CPR/FR90/003

EU Declaration of Conformity according to Directive 2014/34/EU for

use in potentially explosive atmospheres

Environmental Product Declaration ISO 14025, EN 15804:

EPD-WWB-20130082-IBA1-DE

All-round single-piece galvanized sheet steel casing.

Casing tightness class C according to EN 1751.

Moulded push-t connections with lip seals for spiral

duct according to DIN 24145, for exible pipe and for

similar ducts of ventilation and air conditioning systems.

All-round press-moulded beading over the whole length

of casing ensures necessary strength and free movement of the damper blade even with large dimensions.

Low pressure drop and a very low noise level are thus

achieved.

Replaceable damper blade made of high-temperature-resistant, abrasion-proof calcium silicate with

wear-resistant elastomer seals. Damper blade leak tightness class 3 according to EN 1751.

Option: Casing with powder coating. ⇒ see page 6

Option: Damper blade with metal cover (not replaceable)

made of galvanized steel or 1.4301 stainless steel.

Enclosed, maintenance-free drive mechanism in the

area of the casing wall as a self-locking transmission

for break-proof torque transmission. Sealed drive axles

made of stainless steel, with red metal bearings. Thermal release mechanisms for 70°C or 95°C nominal temperature. The operation units can be actuated manually

or electrically. ⇒ see pages 4 and 5

Release mechanisms, operation units and electric actuators are enclosed and with a spring return. They are

maintenance-free, can be connected in a form-locking

or force-tting manner, are easy to replace and can be

easily retrotted as required.

For installation with horizontal or vertical damper blade

axles and in intermediate positions. Air ows are possible from each connection side.

Connection to ventilation ducts made from non-combustible or combustible materials is possible, also protective

grille.

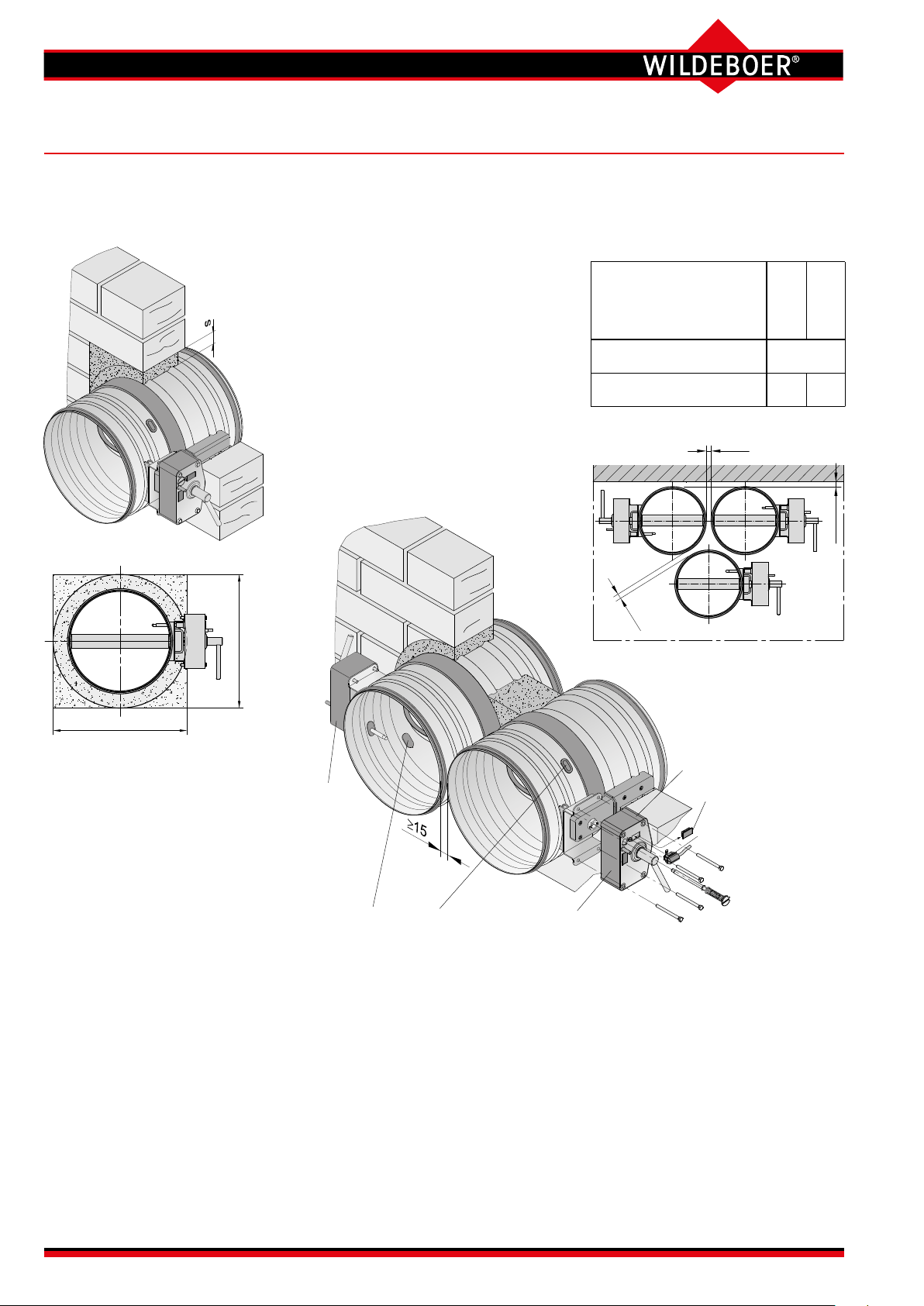

Installation spacings from 15 mm possible.

Additional national approvals in

Germany:

• Building materials: Z-56.4212-993

FR90 re dampers are essentially

made from non-combustible building materials.

• Air transfer applications:

Z-6.50-2133

Z-19.18-2241

Nominal sizes [mm] DN:

100 - 125 - 140 - 160 - 180 - 200 - 224 - 250 - 280 - 315 - 355 - 400 - 450 - 500 - 560 - 630 - 710 - 800

FR90 re dampers in these sizes achieve re resistance periods of up to 120 minutes if they are installed in accordance with

the following stipulations. Installation types in, on or remote from rigid walls and ceilings or metal stud walls, in wooden walls and

ceilings and in ceilings with steel frames with a minimum thickness and re resistance period. If the walls, ceilings have a re

resistance period of less than 120, 90 or 60 minutes, the re resistance period of the FR90 re dampers is reduced accordingly;

partly if the minimum thickness is lower.

Options:

• Circular installation subframe RR (RR100, RR150) for

simplied installation in circular installation openings.

Only up to DN 315! ⇒ see pages 7, 8, 13, 14, 22, 42 to 44

•

Rectangular installation subframe RE (RE100,

RE150) for simplied installation in rigid walls and

ceilings and in metal stud walls with cladding on both

sides.

⇒ see pages 7, 8, 13, 14, 20 to 22, 42 to 44

• With rectangular installation subframe RH (RH100,

RH150) for installation in wooden walls and wooden

ceilings. ⇒ see pages 7, 8, 28 to 31, 42 to 45

• Rectangular installation subframe RH150 for installation in ceilings with steel frames.

⇒ see pages 7, 8, 33, 34, 42 to 45

• Mounting frame AE for mounting on rigid walls and

ceilings and walls with cladding on one side and with

or without metal studs.

⇒ see pages 7, 8, 15, 26, 27, 35, 42 to 44

• Installation subframe ER6 for sliding ceiling connec-

tions with drops of up to 40 mm in metal stud walls

with cladding on both sides.

⇒ see pages 7, 8, 23 to 25, 42, 43

• Mounting frame RV for connection to ventilation

ducts with re resistance period. Installation remote

from rigid walls and ceilings and metal stud walls.

⇒ see pages 7, 8, 36 to 39, 42 to 45

Series FR92

User Manual 5.3 (2018-07) 3Subject to change

FR90 re dampers

Release mechanisms and actuators (1)

FR90 re dampers, series FR92, are tted with maintenance-free thermal-mechanical release mechanisms or with

thermal-electrical release mechanisms on the spring return actuators. Release occurs at a nominal temperature of

70°C or 95°C. Coated release elements provide increased corrosion protection.

Electric spring return actuators also close the re dampers if the supply voltage is interrupted. They reopen the re

dampers as soon as the voltage is present again.

Release mechanisms and operation units can be replaced on site!

Thermal-mechanical release mechanism - Standard -

with 70°C release element, protection class IP54.

Option: with coated 70°C release element.

Option: with coated 95°C release element.

Option: with limit switch

E Changeover with gold-plated contacts for 5 A at

250 V AC or 24 V DC; protection class IP67;

1 m silicone free connection cable 3 x 0.34 mm².

One or two can be plugged in for the CLOSED and/or OPEN

position indicator instead of blind caps.

Option: with additional remote release based on the:

closed circuit principle. The re dampers must be opened man-

ually, and close after the electrical supply voltage is interrupted.

WU220 with magnetic clamp 230 V AC; 4 VA;

GU24 with magnetic clamp 24 V DC; 1.6 W;

100% duty cycle; IP42.

100% duty cycle; IP42.

Open circuit principle. The re dampers must be opened man-

ually, and close by means of electrical or pneumatic stimulus.

P with lift cylinder 4 to 8 bar.

P2 with lift cylinder 1.2 to 8 bar.

G24 with lifting solenoid 24 V DC; 3.5 W; 100% duty

cycle; IP42.

W220 with lifting solenoid 230 V AC; 5.5 VA; 100% duty

cycle; IP42.

Manual release

“Red button”

Blind cap can

be replaced with

the OPEN limit

switch.

Lever for opening

the re damper.

Release mechanism and remote release with lift cylinder

Button for function check

Enclosed release

element can be

replaced from the

front.

Inserted

CLOSED limit

switch.

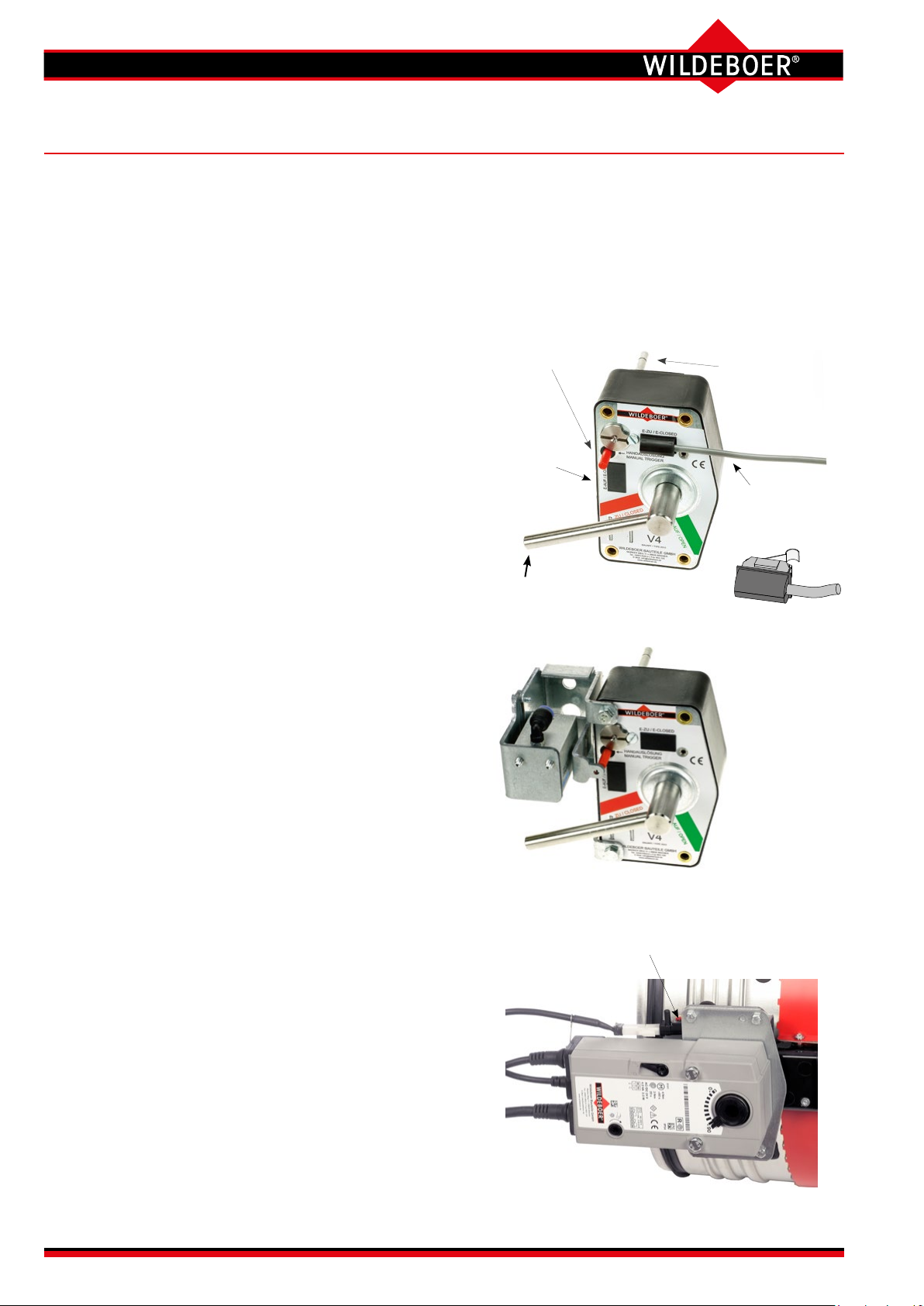

Option: Electric spring return actuator - Standard up to DN 315 -

only for sizes DN ≤ 315 mm

with 70°C release element; protection class IP54.

M220-10/F 230 V AC; 6.5 VA / 3 W; I

M24-10/F 24 V AC/DC; 4 VA / 2.5 W; I

Runtime: Opening < 60 s, closing ≈ 20 s

CLOSED/OPEN position indicators via limit switches for 0.5 A

at ≤ 250 V AC or for 1 mA up to 3 A at 5 up to 250 V DC.

Halogen-free connection cable; 1 m long; 2 x 0.75 mm² and

6 x 0.75 mm². The AMP connector plugs are detachable.

Option: with 95°C release element.

User Manual 5.3 (2018-07) 4 Subject to change

max ≤ 5 ms

max ≤ 5 ms

= 4 A

= 8.3 A

Figure shows M220-10/F or

M24-10/F.

Series FR92

FR90 re dampers

Release mechanisms and actuators (2)

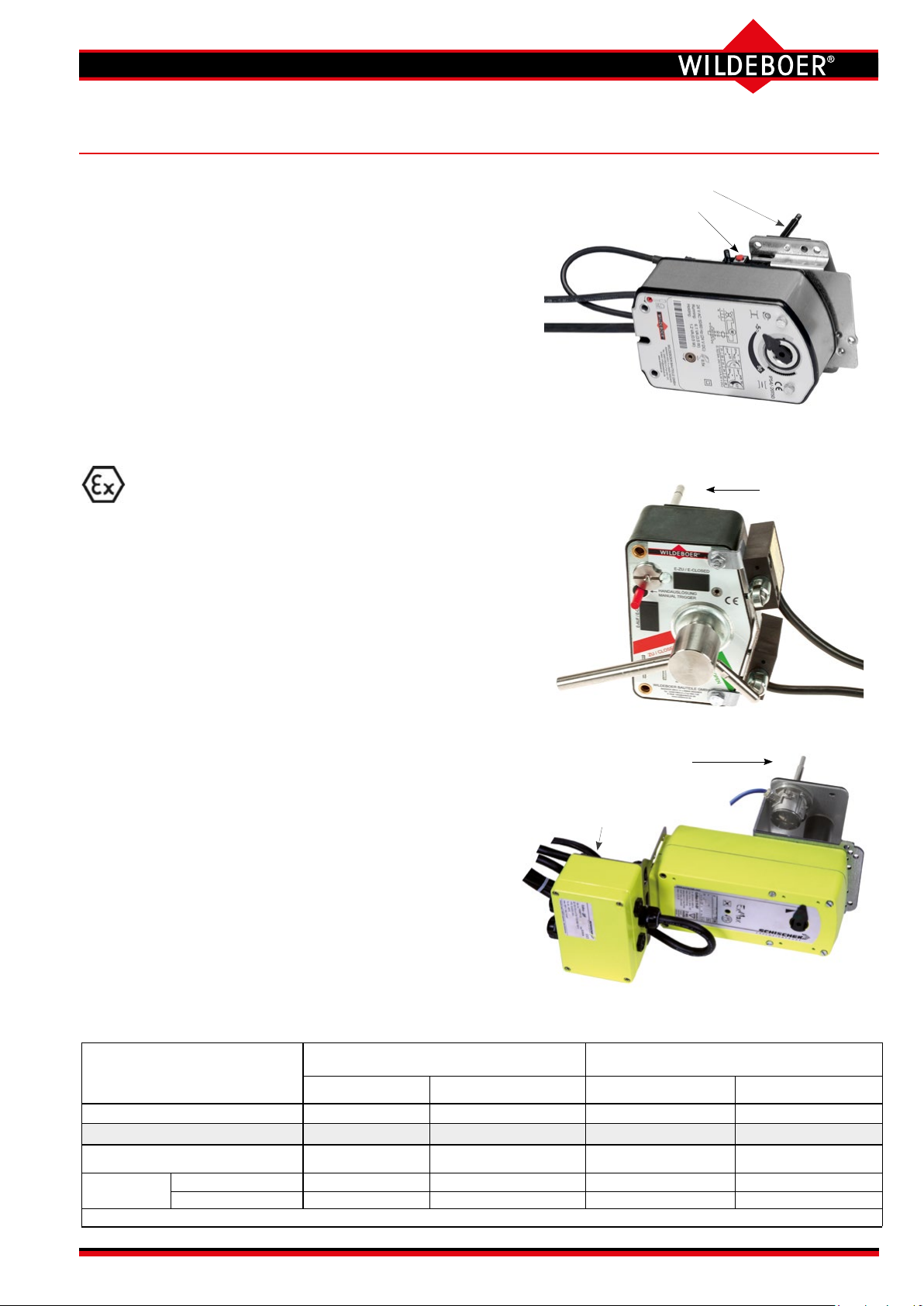

Option: Electric spring return actuator

- Standard from DN 355 -

with 70°C release element; protection class IP54.

M24-9/H 24 V AC/DC; 6.1 VA / 3.5 W; I

Runtime: Opening ≈ 60 s, closing ≈ 21 s.

CLOSED/OPEN position indicators via limit switch for

Halogen-free connection cable; 0.9 m long;

Option: with 95°C release element.

M220-9/H 230 V AC; 9,2 VA; I

max ≤ 2 ms

= 0.27 A.

max ≤ 2 ms

= 3.5 A.

5 A at ≤ 240 V AC.

2 x 0.75 mm² and 6 x 0.75 mm². The AMP connector

plugs are detachable.

- designs

Thermal-mechanical release mechanism

with 70°C release element; protection class IP54.

Option: with coated 70°C release element.

Option: with explosion-protected limit switch

E-Ex with normally open contact and normally closed

contact for 6 A at ≤ 250 V AC or 0.25 A at

≤ 230 V DC; protection class IP65;

2 m connection cable 4 x 0.75 mm².

One or two can be attached for the CLOSED and/or OPEN

position indicator.

Option: Electric spring return actuator

with 70°C release element and terminal box.

EM-1 10 Nm

EM-2 15 Nm

24 to 240 V AC/DC;

protection class IP66.

}

RM-1 10 Nm

Power consumption up to 20 W including heating;

I

nominal

≤ 0.7 A; I

max ≤ 1 s

≈ 2.5 A

Runtime: Opening ≈ 30 s, closing ≈ 10 s.

CLOSED and OPEN position indicators via limit

switches for ≤ 3 A at 24 V AC/DC and ≤ 0.25 A at

250 V AC/DC;at least 5 V, 10 mA.

The 12 x 0.5 mm² halogen-free connection cable must be wired in

the terminal box! All of the contained voltages must be the same!

Use of explosion-protected designs

Enclosed release element

Button for function check

Enclosed

release element

Enclosed release element

Terminal box

The actuators can be rotated into

suspended and vertical positions on site.

... as a mixture of air and

Building area where a dangerous, potentially explo-

sive atmosphere may occur in normal operation...

Zone 1 2 21 22

Identication of the re damper II 2 G c IIc T6/T5 II 3 G c IIc T6/T5 II -/2 D c T80°C/T95°C II -/3 D c T80°C/T95°C

Thermal-mechanical release mechanism with or

without explosion-protected limit switch

Motor drive

Ambient temperatures: -20 … +40°C for T6 and T80°C/-20 … +50°C for T5 and T95°C *) Also to be used in this zone!

EM-1 or EM-2 X X

RM-1 - X - X

... can form occasionally. ... occurs temporarily or not at all. ... can form occasionally. ... occurs temporarily or not at all.

combustible gases, mists or vapours...

X X *

)

)

*

Series FR92

... in the form of a cloud of

combustible dust contained in the air...

X X

X X

User Manual 5.3 (2018-07) 5Subject to change

)

*

)

*

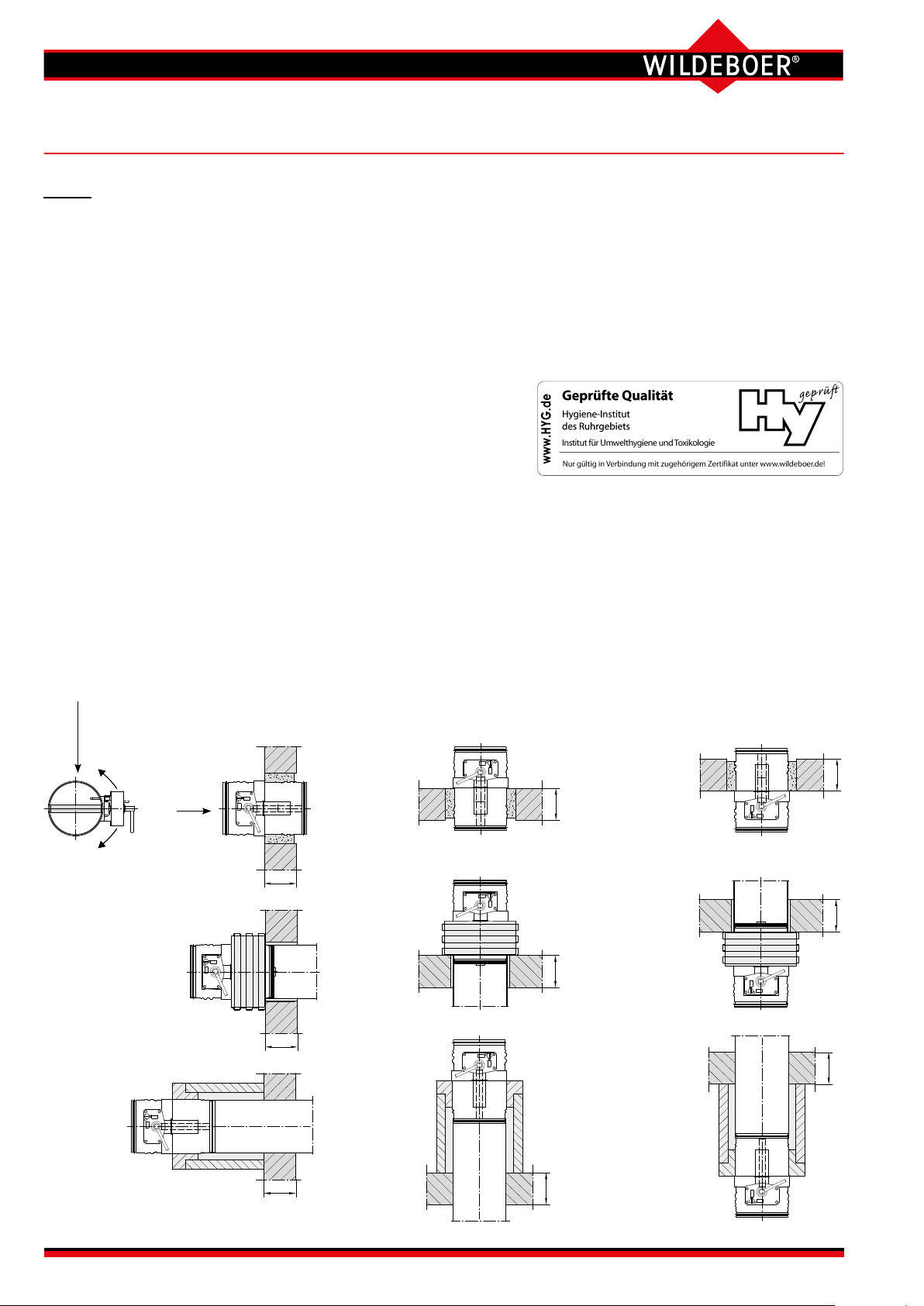

FR90 re dampers

Powder coating/hygiene /installation positions

Option: Powder coating

For FR90 re damper casings with inner and outer epoxy resin coating

• damper blades with metal cover made of 1.4301 stainless steel

• thermal-mechanical release mechanisms with corrosion-resistant (coated) release element 70°C

should be used. This allows for additional corrosion protection for higher stresses.

FR90 re dampers

• meet the hygiene requirements according to VDI 6022-1, VDI 3803-1, DIN 1946-4, DIN EN 13779

• do not promote the growth of microorganisms 1) (fungi, bacteria). This

reduces the risk of infection for people and also the necessary cleaning and

disinfection work!

• are resistant to disinfectants 2)

• are suitable for use in hospitals and similar facilities!

•

permanently perform their function under high corrosion conditions.

Tested according to EN 15650, annex B with 20% saline solution.

1)

The corresponding resistance of the materials to fungi and bacteria has been veried by testing the microbial metabolic potential according to

DIN EN ISO 846 for all materials in the FR90 re dampers.

2)

The resistance to disinfectants of the materials in the FR90 re dampers was tested with the disinfectant groups of active ingredients alcohol and

quaternary compounds. These disinfectants are on the list by the Robert Koch Institute, and were used in accordance with the specications in

the list of disinfectants by the Disinfectants Commission in the German Association for Applied Hygiene (VAH). It has been veried that FR90 re

dampers can withstand normal use of disinfectants and disinfection methods.

Installation positions

Damper blade axle and drive can be installed

to rotate up to 360°!

Horizontal installation positions W = wall

Operation side

Visible side

Installation in walls

Installation

directly on walls

W

W

Vertical installation positions D = ceiling

Non-operation side

Vertical installation in ceilings

Installation directly on ceilings

D

Installation in suspended position ceilings

D

Installation directly under ceilings

Installation remote from

and above ceilings

D

D

D

W

Installation remote from walls

User Manual 5.3 (2018-07) 6 Subject to change

Series FR92

D

Installation remote from

and below ceilings

FR90 re dampers

Installation subframes/mounting frames

With circular installation subframe RR100 or RR150

for simplied installation in circular openings such as

core holes in rigid walls and ceilings or holes in metal

stud walls with cladding on both sides.

Only up to DN 315!

⇒ see pages 8, 13, 14, 22,

42 to 44

With installation subframe ER6 made from calcium

silicate for sliding ceiling connections with a drop of

up to 40 mm in metal stud walls with cladding on both

sides.

The drop can be

single or recurring

(settlement and

changing loads).

⇒ see pages 8,

23 to 25

, 42, 43

Rectangular installation subframe RE100 or RE150

made of calcium silicate for simplied – also multiple –

installation in rigid walls and ceilings and in

walls

with cladding on both sides.

⇒ see pages 8, 13, 14, 20 to 22, 42 to 44

metal stud

With rectangular instal-

lation subframe

RH100 or RH150

made of calcium silicate for dry instal-

lation in wooden

walls and in wooden

ceilings

⇒ see pages 8, 28 to 31,

42 to 45

With rectangular installation

subframe RH150 for installation in ceilings with steel

frames.

⇒ see pages 8, 33, 34, 42 to 45

With mounting frame AE made of calcium silicate

for mounting on rigid walls and ceilings and on walls

with cladding on one side

(shaft walls) and with

and without metal

studs.

⇒ see pages 8, 15, 26,

27, 35,

42 and 44

With Mounting frame RV for connection to ventilation

ducts with re resistance period.

Particularly for installation remote from rigid walls and ceilings

and from metal stud walls with

cladding on both sides.

⇒ see pages 8,

36 to 39, 42 to 45

Series FR92

Accessories for mounting frame:

Connecting frame for attaching the ventilation duct

with re resistance period to walls and ceilings.

⇒ see pages 8, 36 to 39, 42 to 44

Featured: Size for DN ≤ 315

User Manual 5.3 (2018-07) 7Subject to change

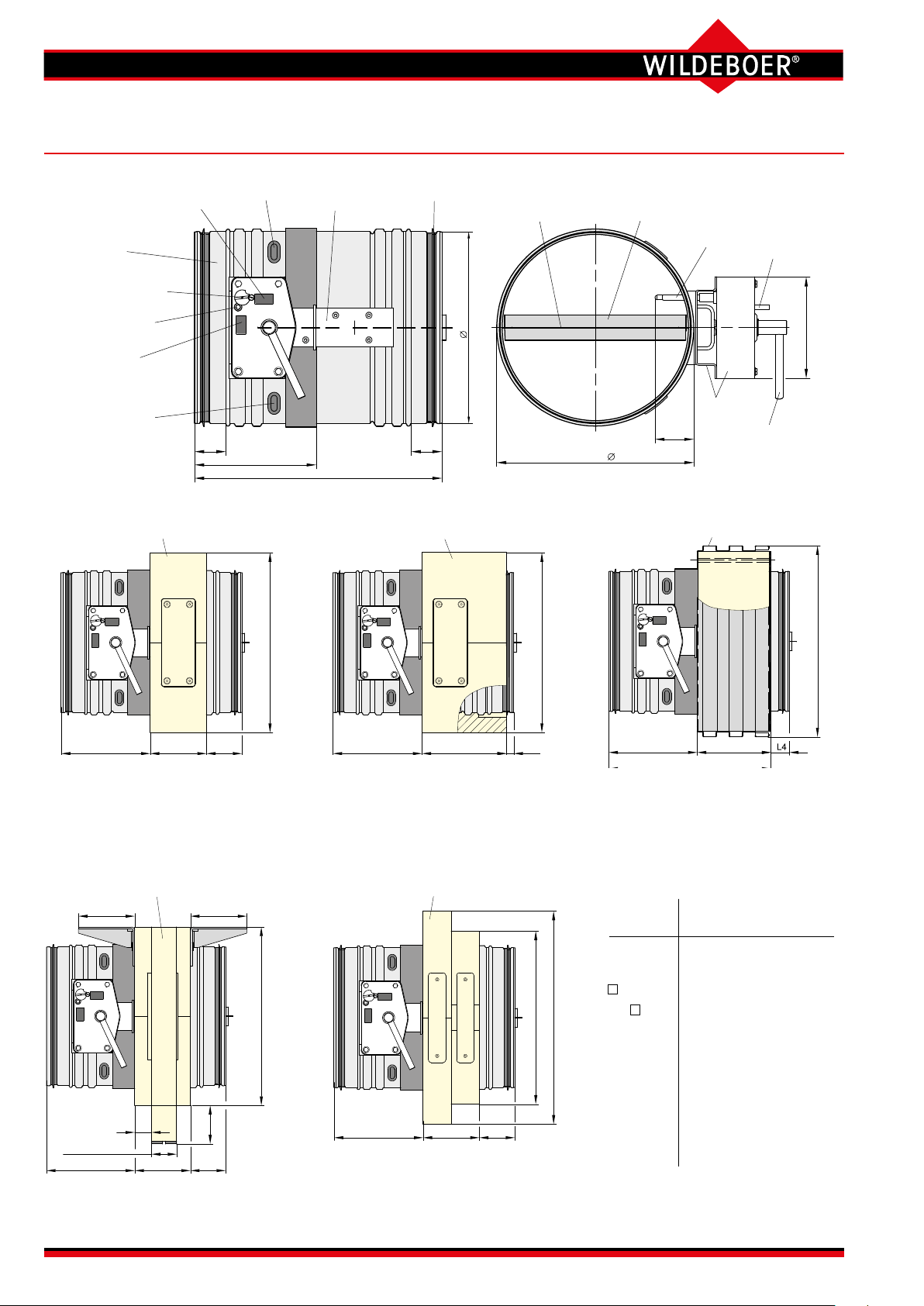

L2

Control opening

Limit switch

E-OPEN (optional)

Control opening

Limit switch

Lip seal

Mounting frame AE

Installation subframe ER6 (only available assembled)

Mounting frame RV

FR90 re dampers

Data sheet (1)

E-CLOSED (optional)

Casing

Thermal-mechanical

release mechanism

Manual release

L1

L2

Installation subframe RR / RE / RH (100mm long)

RR

□ RE/RH

Enclosed transmission

L1

L

Installation subframe RR / RE / RH (150mm long)

Damper bladeDamper blade seal

Release element

1D

50

Outer dimension = DN+8

RR

□ RE/RH

Manual release

231

Operation unit

Manual lever

□ AE

L2

100

L3

With installation subframe RR100, RR150 (circular) or RE100, RE150,

RH100, RH150 (rectangular)

Installation lengths 100 mm and 150 mm.

⇒ see pages 3, 7, 13, 14, 20 to 22, 28 to 34, 42 to 44

101 101

Stud profile

depths S:

50 to 125 mm

L2 100 L3

30

68

With installation subframe ER6

⇒ see pages 3, 7, 23 to 25, 42, 43

□ RE

L2

With mounting frame RV

⇒ see pages 3, 7, 36 to 39, 42 to 45

150

100 L3

L6

□ DN + 59

□ DN + 130

L2

128

L5

With mounting frame AE

⇒ see pages 3, 7, 15, 26, 27, 35, 42 to 44

DN from 100 355

to 315 800

Ø D1 DN - 1 DN - 1

Ø RR DN + 99 -

RE/RH DN + 89 DN + 99

AE DN + 110 DN + 120

L 320 340

L1 40 50

L2 155 160

L3 65 80

L4 37 52

L5 283 288

L6 15 30

All dimensions in mm

User Manual 5.3 (2018-07) 8 Subject to change

Series FR92

FR90 re dampers

Data sheet (2)

Maximum excess lengths of mechanical and electrical equipment parts.

Additional space must be provided for

assembly, electrical connections and maintenance; observe the cable entry points!

In addition to the "T" measurement,

it is recommended that a distance of

400 mm be kept from adjacent walls,

ceilings or other re dampers, in order

to ensure that the release mechanisms

and actuators can be accessed for

operational purposes.

Damper blade

Operation side: X

Non-operation side: Y

Actuators

U Horizontal (delivery condition)

J Vertical

J3

EM-1, RM-1, EM-2

Rotated to vertical or suspended

position

J4

M220-11/H, M24-11/H

rotated to suspended position

J3

J3, J4

U

X

L

Y

DN T

Size-independent

excess lengths

T U

Thermal-mechanical

release mechanism 130 -

with: • W220, WU220 155

• G24, GU24 155 -

• P, P2 140 -

• E-Ex limit switch 140 -

M220-9/H, M24-9/H 125 60

M220-10/F, M24-10/F 85 80

M220-11/H, M24-11/H 110 110

EM-1, EM-2, RM-1 310 216

Size-dependent excess lengths

DN Ø D1 L J3 J4 X Y

100 99 320 220 160 - 125 124 320 210 150 - 140 139 320 200 140 - 160 159 320 190 130 - -

180 179 320 180 120 - -

200 199 320 170 110 - 224 223 320 160 100 - -

250 249 320 150 90 - 10

280 279 320 130 70 - 25

315 314 320 115 55 - 43

355 354 340 95 35 - 52

400 399 340 70 10 - 75

450 449 340 45 - 12 100

500 499 340 20 - 37 126

560 559 340 - - 68 156

-

630 629 340 - - 104 192

710 709 340 - - 144 233

800 799 340 - - 190 279

Operating area, closing and opening

• FR90 re dampers are quick-closing, apart from the versions with electric

actuators. Due to the ow dynamics, if the re damper is triggered at high

inow velocities, this may cause pressure surges accompanied by multiplication of operating pressures, which in turn may lead to considerable damage

to the ventilation and air conditioning system. When shut-o dampers are

closed, the volume ows are distributed to other parallel dampers that are still

open. This may lead to excessive stress, in particular at high operating pressures, large volume ows and large cross-sections. Electric actuators should

be used under such conditions. They close re dampers relatively slowly. In

addition, the fan switch-o can also be triggered via the OPEN limit switch.

• The application limits marked in the nomograms must be complied with!

⇒ see page 9

• For large re dampers that are subjected to an unfavourable ow, actuators

with large torques may be necessary in order to open the re dampers when

the fan is running and there are very large volume ows. These actuators are

available on request. Alternatively, it is also possible to switch on the fans

once the re dampers are fully open.

• It must be ensured that the inows and outows are as equal as possible.

• FR90 Fire dampers with electric actuator can be used for OPEN/CLOSED

volume ow control.

Thermal-mechanical release mechanisms are marked with V3-1, V4,

V5-1. The allocations dependent on DN nominal sizes must not be changed!

DN

≤ 200 V5-1

≥ 224 up to ≤ 315 V3-1

≥ 355 V4

All dimensions in mm

Series FR92

User Manual 5.3 (2018-07) 9Subject to change

Sound power level

500

560

630

710

800

Pressure drop

Flow velocity va [m/s]

Relative sound power level ∆L [dB]

FR90 re dampers

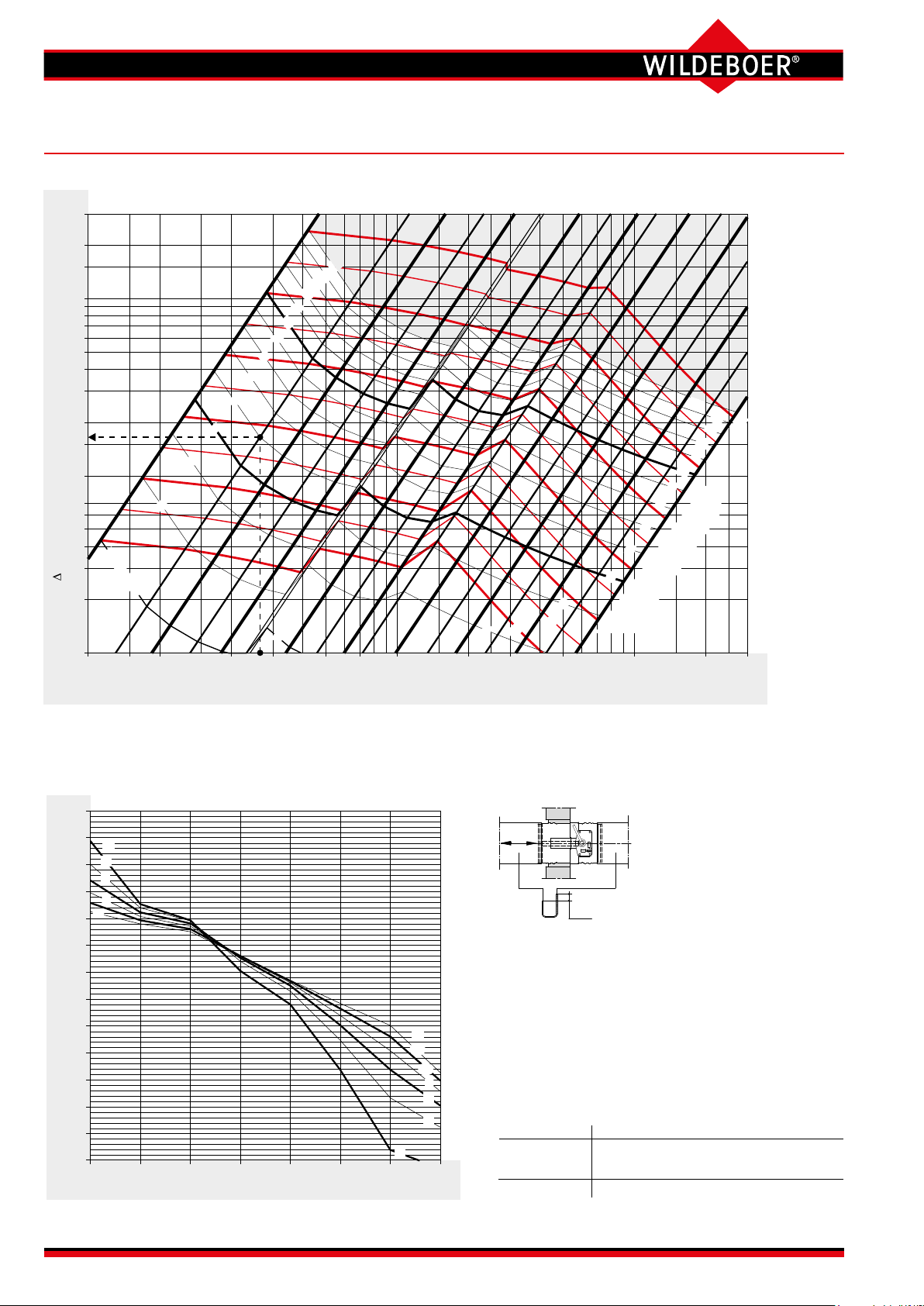

Dimensioning (1) pressure drop, sound power level with ventilation duct connection on both sides

300

200

150

100

70

50

40

30

20

15

10

7

6

5

]aP[p

4

v = 2 m/s

A

S

3

2

1

Volume flow V [m³/h]

Nominal size DN [mm]

6

5

4

3

200 300 500 700 1000 2000 3000 5000 10000 20000100 3000050 75

140

100

15

14

13

12

11

10

9

8

7

2

125

160

3

20

180

200

25

224

4

250

5

30

280

6

40

7

315

8

355

10

9

50

400

15

14

13

12

11

60

WA

L [dB(A)]

450

70

FR90 re dampers can be used up to 15 m/s velocity in the inow cross-section AA and up to 2500 Pa operating pressure.

Relative sound power level

+25

+20

v

A

2

+15

4

+10

8

12

+5

5

0

0

-5

-10

-15

-20

-25

-30

-35

-40

63

Oktav-Mittenfrequenz [Hz]

125

Octave mid frequency [Hz]

250

v

A

12

10

8

6

4

2

500 1000 2000 4000 8000

LR

p

S

Example: Both sides with ventilation duct connection

V = 265 m³/h

DN = 125 mm

vA = 6 m/s

Dps = 16 Pa

LWA = 38 dB(A)

Sound power level L

f [Hz] 63 125 250 500 1000 2000 4000 8000

LWA [dB(A)] 38 38 38 38 38 38 38 38

DL

L

[dB] +12 +6 +4 -2 -7 -15 -23 -30

6 m/s

[dB] 50 44 42 36 31 23 - -

W-Oct

for the octave mid frequencies

W-Oct

Nomenclature

⇒

see page 11

User Manual 5.3 (2018-07) 10 Subject to change

Series FR92

FR90 re dampers

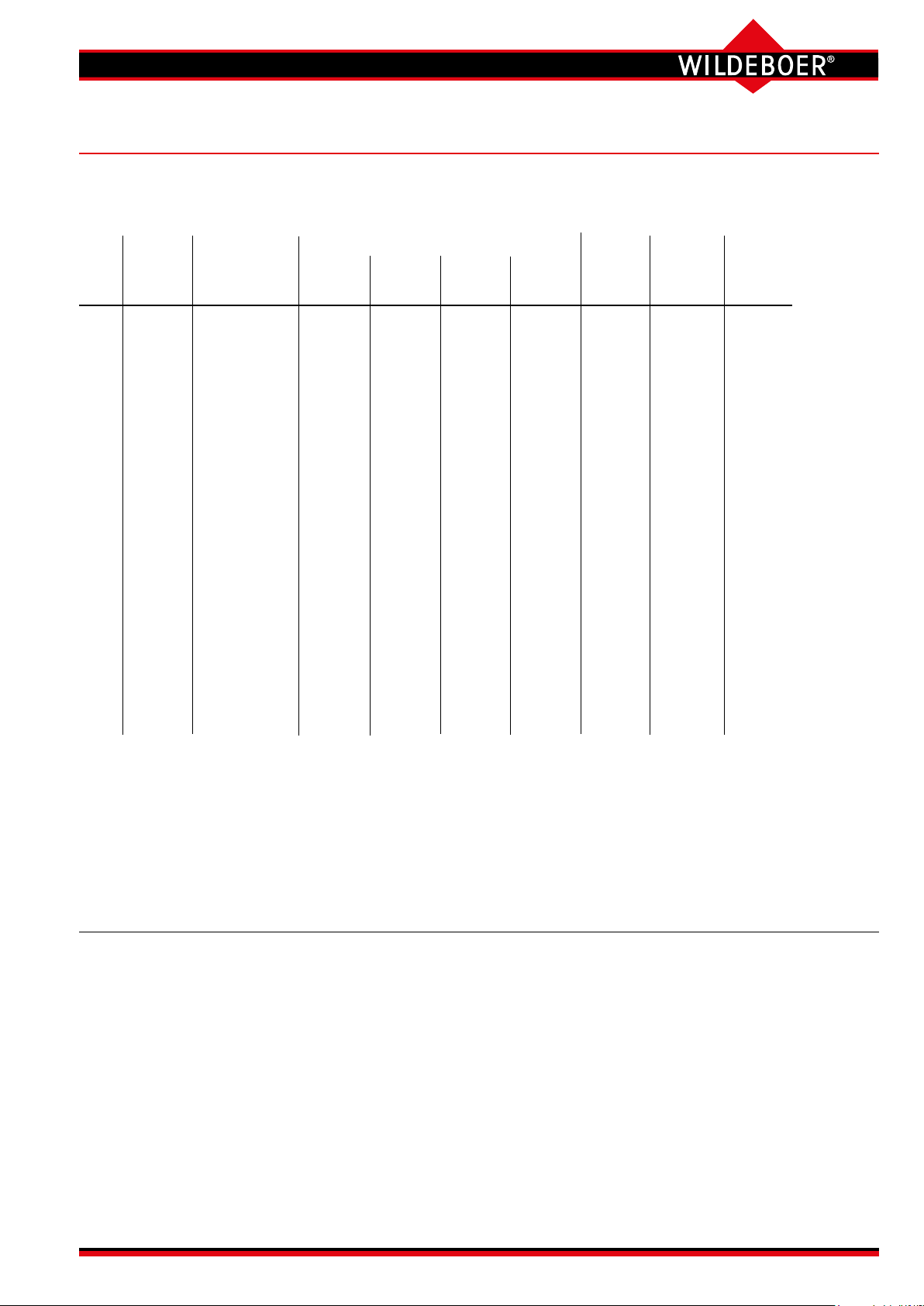

Dimensioning (2) Free cross-sections, weights, nomenclature

Free cross-sections A

DN A

free

[m²] RE100 RE150

[m²], weights [kg]

free

Fire

damper

Installation subframe

Mounting

frame

Installation

subframe

Mounting

frame

[m²] FR90 FR90 RH100 RH150 RR100 RR150 AE ER6 RV

100 0.0047 2.3 2.0 3.0 1.4 2.2 3.5 4.9 2.1

125 0.0082 2.5 2.4 3.6 1.7 2.5 4.1 5.7 2.5

140 0.0108 2.6 2.6 3.9 1.8 2.7 4.5 6.1 2.7

160 0.0149 2.7 3.0 4.5 2.0 3.0 5.0 6.8 3.1

180 0.0195 2.9 3.3 5.0 2.2 3.3 5.5 7.4 3.4

200 0.0248 3.1 3.7 5.5 2.4 3.6 6.1 8.1 3.8

224 0.0298 3.6 4.1 6.2 2.7 4.0 6.8 8.2 4.2

250 0.0383 3.9 4.7 7.0 2.9 4.4 7.6 9.0 4.8

280 0.0494 4.3 5.3 7.9 3.2 4.8 8.5 9.9 5.4

315 0.0642 4.9 6.0 9.0 3.6 5.3 9.6 11.0 6.1

355 0.0806 7.9 7.6 11.4 - - 11.8 14.3 7.0

400 0.1051 9.0 8.7 13.1 - - 13.4 16.2 8.1

450 0.1356 10.4 10.0 15.1 - - 15.3 18.5 9.4

500 0.1702 11.8 11.5 17.2 - - 17.3 20.9 10.7

560 0.2169 13.7 13.3 19.9 - - 19.9 23.9 12.4

630 0.2786 16.1 15.5 23.2 - - 23.0 27.7 14.6

710 0.3584 19.1 18.2 27.3 - - 26.8 32.3 17.2

800 0.4603 22.8 21.5 32.3 - - 31.3 37.9 20.3

The weight of the re dampers must factor in the weight of the

• installation subframes RE, RH, RR, ER6, the mounting frame AE or the mounting frame RV;

• The following must be added for actuators:

- M220-10/F; M24-10/F: 1.5 kg

- M220-9/H; M24-9/H: 2 kg

- M220-11/H; M24-11/H: 2 kg

- EM-1, RM-1; EM-2: 5 kg

Nomenclature

DN [mm] Nominal size

AA [m²] Inow cross-section

A

[m²] Free cross-section

free

V [m³/h] Volume ow

vA [m/s] Flow velocity in inow cross-section (inow velocity)

Dps [Pa] Static pressure drop

L

[dB] Octave sound power level L

W-Oct

DL [dB] Relative sound power level to L

W-Oct

= L

WA

WA

+ DL

f [Hz] Octave mid frequency

LWA [dB(A)] A-weighted, area-corrected sound power level

Series FR92

User Manual 5.3 (2018-07) 11Subject to change

s 15≥

s 15≥

s 15≥

CLOSED

release mechanism

FR90 re dampers

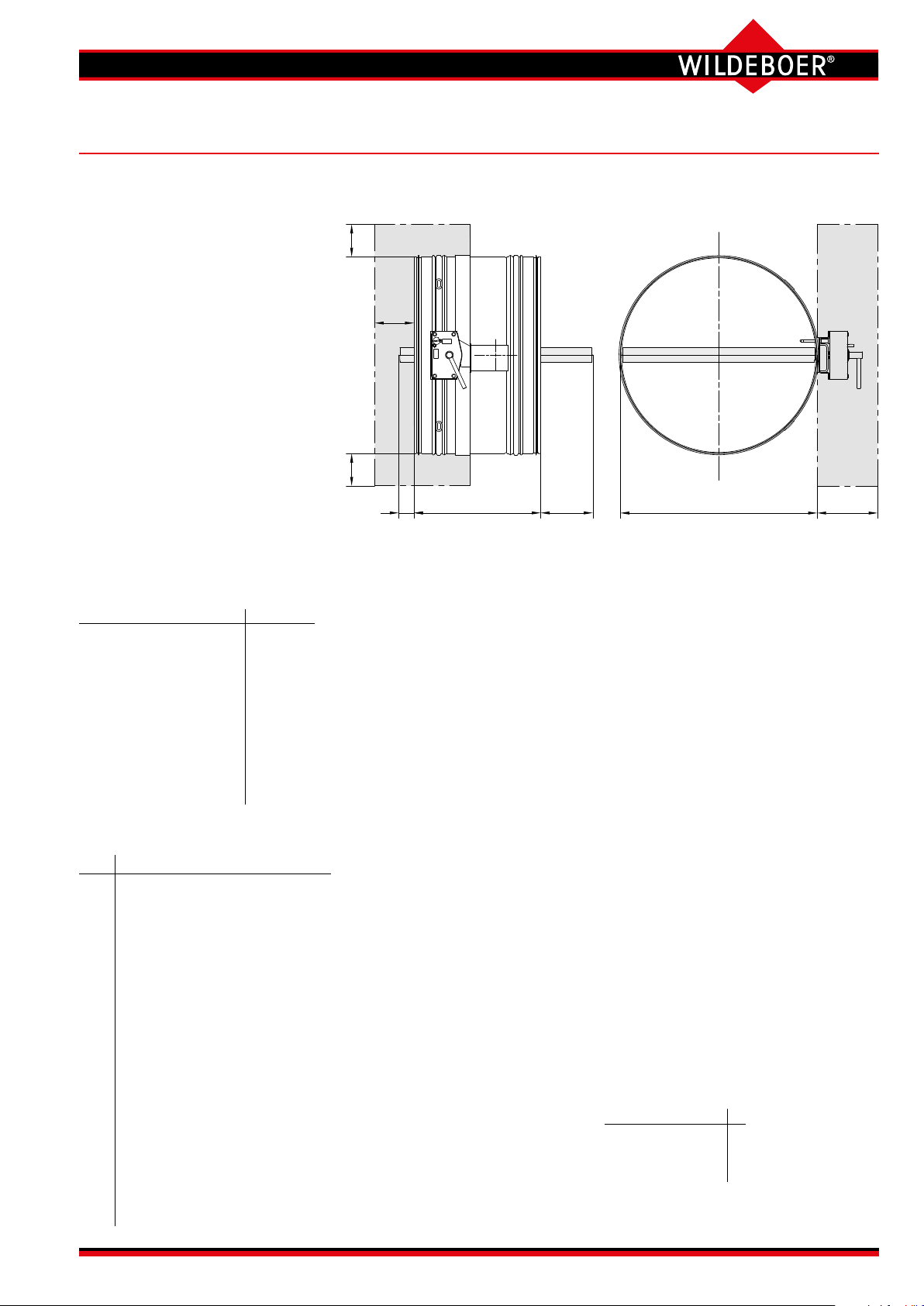

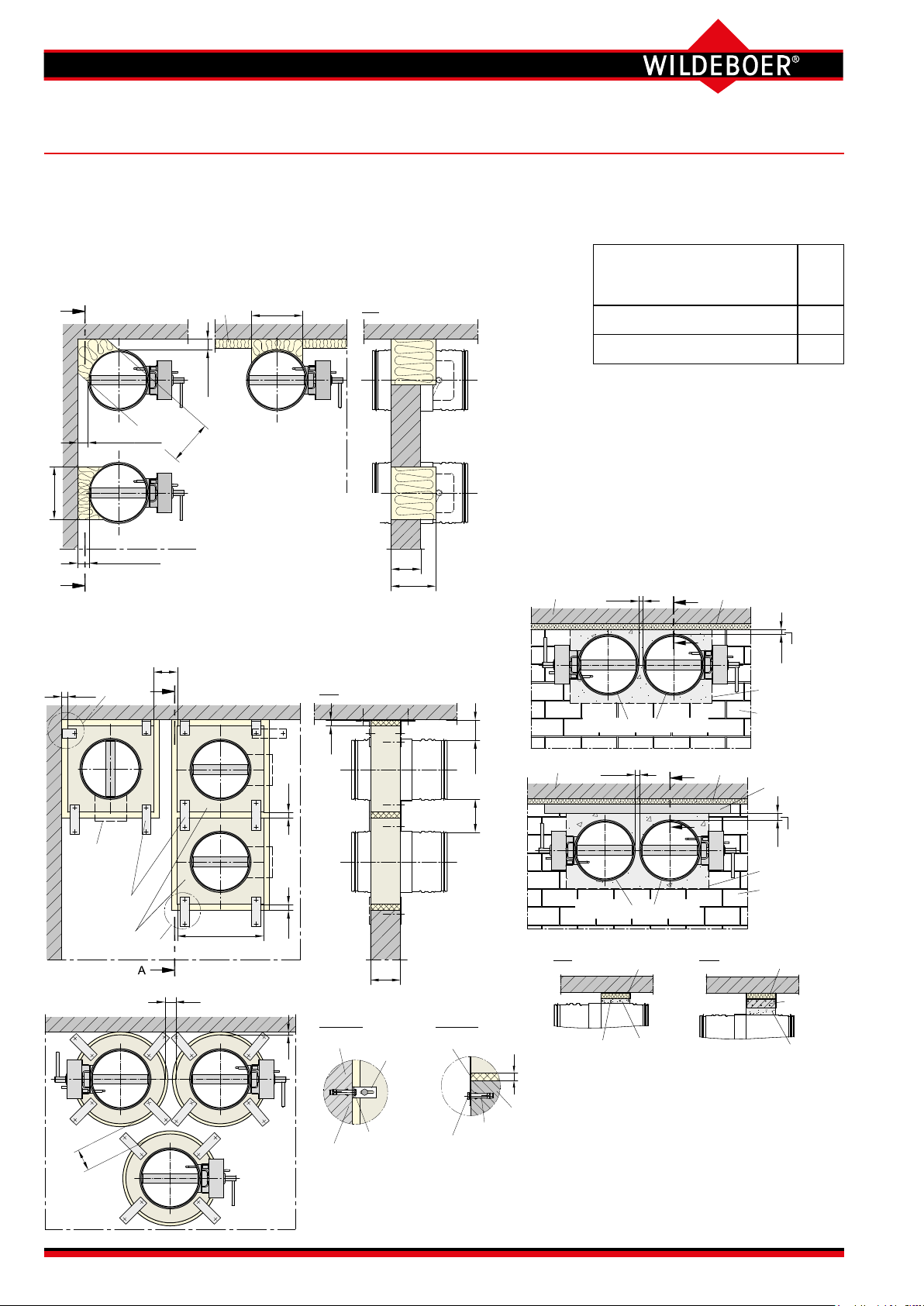

Installation in rigid walls and ceilings (1)

Installation without installation

subframe (standard installation)

The rigid walls and ceilings can

be made of concrete, lightweight

concrete, porous concrete (aerated

concrete) or plaster. They can be a

masonry or wallboard construction

and must have a bulk density of

≥ 450 kg/m³. Walls can also be re

walls, shaft walls, shafts or ducts.

The all-round ≥ 15 mm wide gap "s"

should be lled ≥

100 mm deep

with

mortar of group II or III according to

DIN 1053 or classes M2.5, M5, M10

or M20 according to EN 998-2, or

with the corresponding re-protection

mortar or gypsum mortar.

To install the FR90 re dampers in

rigid walls and ceilings, the mini-

mum thicknesses W, D [mm] are

required:

Fire resistance period

in minutes

Rigid walls 95

Rigid ceilings

100 115

30

60

90

30

60

90

120

d or. a

b

Installation opening a x b or ∅ d

a ≥ DN + 30 mm, b ≥ DN + 75 mm,

d ≥ DN + 75 mm

Clearance between FR90 re

dampers≥ 15 mm.

Installation does not require a

specic opening when the wall or

ceiling is built.

Actuator

on the left

Control openings

(inspection openings)

Installation with mortar

in walls and ceilings with

only 15 mm spacing.

Operation

unit on right

Blind cap

E-

Thermal-mechanical

User Manual 5.3 (2018-07) 12 Subject to change

Series FR92

RE 100 / 150

Installation

FR90 connection

brackets for attachment

Installation

alternative

FR90 connection

brackets for attachment

Installation

subframe

RR

100 / 150

FR90 connection

brackets for attachment

Screw M6x20

Installation

subframe

100 / 150

Fill on both sides

FR90 connection

brackets for attachment

FR90 re dampers

Installation in rigid walls and ceilings (2)

Installation with rectangular

installation subframes RE100, RE150

Screw M6x20

subframe

RE

100 / 150

Installation with mortar

Screw M6x20

subframe

RE

100 / 150

alternative

Installation with

mineral wool

Fill on

both sides

alternative

Screw

M6x20

Installation

subframe

Installation with circular installation sub-

frames RR100, RR150 (only DN ≤ 315 mm)

Screw M6x20

Installation

subframe

RR

100 / 150

RR

Screw

M6x20

For installation in rigid walls and

ceilings, the minimum thicknesses

W, D [mm] are required:

Fire resistance period

in minutes

30

60

30

60

90

Rigid walls 70*)100

Rigid ceilings

*) This installation must be performed with

installation subframe RE100 or RR100.

b

- 100

a

b

Installation openings

• Installation with mortar

DN ≤ 315: a x b = DN + 120 to 190

DN ≥ 355: a x b = DN + 130 to 200

DN ≤ 315: ∅ d = DN + 130 to 170

DN ≤ 200: a x b = DN + 130

Fill gap s with mortar! ⇒ see page 12

Mortaring in ceilings must be secured

from falling out by roughening the

reveals or using mortar anchors!

• Installation with mineral wool

DN ≤ 315: a x b = DN + 110 to 130

DN ≥ 355: a x b = DN + 120 to 140

DN ≤ 315: ∅ d = DN + 120 to 140

Design gap s ≤ 20 mm and ll with

mineral wool! ⇒ see page 14

Mineral wool must be prevented from

falling out by using a non-combustible

adhesive! A sheet metal cover is rec-

ommended when using mineral wool!

• Filled installation

DN ≤ 315: a x b = DN + 93 mm

DN ≥ 355: a x b = DN + 103 mm

DN ≤ 315: ∅ d = DN + 103 mm

Joints must be designed approx. 2 mm

and sealed on both sides of the wall

or ceiling with gypsum ller or with

non-combustible adhesive!

Adhesive ⇒ see page 44

d bzw. a

Filled installation

Series FR92

All dimensions in mm

User Manual 5.3 (2018-07) 13Subject to change

Settlement joint

s 15≥

Rigid ceiling

B

Settlement joint

s 15≥

C

Rigid ceiling

FR90 connection

bracket

RE

Release

mechanism

or actuator

W, D

09≥

54≥

s

s

s

A

A X

s

s

c

A-A

Y

Installation

subframe RE

ND x 9.0≤

0.9 x DN≤

A-A

Settlement joint possible

A

C-C

Lintel

Mortar

Settlement joint

B-B

Mortar

Reinforcement

Metal dowel

corner bracket

Wall / ceiling

s

FR90 connection bracket

Metal anchor M6

Screw M6

Wall

FR90 re dampers

Installation in rigid walls and ceilings (3)

In hard-to access corners and directly on walls and ceilings, gaps "s" on

FR90 re dampers without installation subframe can be lled with two layers

and 150 mm deep with mineral wool

"Knauf

Insulation

TPD"

or equivalent.

They must be secured with non-combustible adhesive. A sheet metal cover

is recommended when using insulation wool. IMortaring in ceilings must be

prevented from falling out by roughening the reveals or using mortar anchors!

05s51

≤≤

15 s 50≤ ≤

15 s 50≤ ≤

A

Multiple installation of up to 4 x FR90 re dampers of the same size

side-by-side, above each other or in a combined manner is possible

without any weight restriction. Assembly of frames RE

0.9 x DN≤

Partial mortaring

Mineral wool:

Bulk density ≥ 150 kg/m³

Melting point ≥ 1000°C

Adhesive ⇒ see page 44

W, D

150

⇒ see page 21

Settlement joints (sliding ceiling connection)

above non-load-bearing rigid walls and under ceilings are lled on site, with mineral wool for example. The illustration shows the installation of FR90

re dampers immediately under such settlement

joints. A reinforcement should be inserted into the

mortar bed or a lintel to prevent cracks from forming later.

For installation in rigid walls and

ceilings, the minimum thicknesses

W, D [mm] are required:

Fire resistance period

in minutes

30

60

90

Rigid walls 100

Rigid ceilings

Types of walls and ceilings

⇒ see page 12

B

FR90 fire dampers

100

Overlap

15 mm≥

Installation opening

Non-load-bearing

rigid wall

≥ 100 mm thick

C

FR90 fire dampers

Settlement joint

User Manual 5.3 (2018-07) 14 Subject to change

c

c

Detail X

s

FR90

Screw M6

M6

Detail Y

Spacings c between subframes RE or RR that are not directly next to each other depend

on the structural properties of the wall or ceiling. C ≥ 50 mm is normally sucient. For

installation in walls, 4 x FR90 connection brackets or FR90 corner brackets are

required on one side; for installation in ceilings, they are necessary on both sides (8 x).

Series FR92

Lintel

Overlap

15 mm≥

Installation opening

Non-load-bearing

rigid wall

≥ 100 mm thick

A-A

Pass-through

FR90 re dampers

Mounting on rigid walls and ceilings

Mounting with mounting frame AE

Types of walls and ceilings ⇒ see page 12

Mounting

frame

AE

Mounting on masonry (example)

Mounting frames AE should be

secured with threaded rods which

pass through the wall or ceiling,

and washers and nuts on both

sides.

Dowels with verication of re protection suitability can be used in

suitable walls and ceilings.

Factory-produced holes in the

mounting frames AE indicate the

number of the fastenings.

DN pc pc

[mm] per corner in total

To mount the FR90 re

dampers, the opposite

Minimum thickness

Fire resistance period

in minutes

30

60

90

W, D [mm] is required:

Rigid walls and ceilings 100

128

threaded bolt M6

or dowel

Ventilation duct

as required

W, D

160W, D ≥

s

Mounting frame AE

A

A

FR90

DN 100 125 140 160 180 200 224 250 280 315 355 400 450 500 560 630 710 800

AE 210 235 250 270 290 310 334 360 390 425 475 520 570 620 680 750 830 920

x1 - - - - - - - - - - 228 250 275 300 330 365 405 450

x2 120 145 160 180 200 220 244 270 300 335 385 430 480 530 590 660 740 830

A

A-A

d

x1

x2

AE

AE washerHexagon nut M6

1x

2x

EA

≤ 315 1 4

≥ 355 2 8

d

Installation opening

∅d = DN + 10 to 15 mm

The gap between ventilation duct

and wall or ceiling does not need

to be lled.

55≥

011≥

AEAE

Release mechanism

or actuator

A

EA

EA≥

EA

W, D

Spacing between the mounting frames AE of the FR90 re dampers and from

the adjacent walls and ceilings is not required.

Ventilation ducts on the non-operation side of the FR90 re damper can

be fed through the wall or ceiling and should lie ush. The connection of the

FR90 re damper on the non-operation side can be fully inserted in these.

Connections can be made to the casing of missing re dampers if it is

ensured that the damper blade can move freely! ⇒ see page 9

All dimensions in mm

Series FR92

User Manual 5.3 (2018-07) 15Subject to change

Loading...

Loading...