Wildeboer EK90 User Manual

User Manual 5.32 (2018-05) 1

Subject to change

The German original version of this document shall prevail

Maintenance-free

EK90 smoke control dampers

meet all requirements in accordance with European

standards and are universal for all applications.

Further uses and extended fire classification

EI 90 (v

edw

- h

odw

- i ↔ o) S1500 C

mod

HOT400/30 MA multi

E

A

A

A

A

E

E

E

D

D

C

A

B

1

2

3

4

5

User Manual 5.32 (2018-05) 2

Subject to change

Series EK92

EK90 smoke control dampers

Application examples for smoke extraction and for ventilation, as required, in the form of "combi-dampers"

A

B

C

D

E

Closed smoke control damper

Opened smoke control damper

Ventilator for smoke extraction and also for ventilation

Smoke extraction duct with fire resistance period

Smoke extraction duct without fire resistance period

Smoke control damper in an air intake

Smoke control damper suspended underneath ceilings

Smoke control damper in a shaft wall

Smoke control damper in a vertical smoke extraction duct

Smoke control damper in a horizontal smoke extraction duct

A

B

C

D

E

1

2

3

4

5

User Manual 5.32 (2018-05) 3

Subject to change

Series EK92

EK90 smoke control dampers

Description, properties, sizes

Fire classification

EI 90 (v

edw

- h

odw

- i ↔ o) S1500 C

mod

HOT400/30 MA multi

• EI90 Fire resistance period of 90 minutes

Installation:

v

e d

in and on horizontal smoke extraction ducts.

h

o d

in and on vertical smoke extraction ducts.

v

e w

in rigid walls and in flexible walls.

h

o w

in rigid ceilings.

i ↔ o Fire exposure has been verified on both sides.

• S1500 For smoke extraction systems with operating pressures

between

1500 Pa negative pressure and 500 Pa overpres-

sure (pressure class 3).

Smokeproof at up to 1500 Pa differ-

ential pressure.

• C

mod

For systems designed only for smoke extraction and also for

combined ventilation systems that was as heating, ventila-

tion and air conditioning systems.Intermediate damper blade

positions for volume flow adjustment are permitted (modulation mode).

The service life is verified by 20,000 weight-loaded cycles.

• HOT The smoke control dampers close and open again at least

after 30 minutes of fire exposure at 400°C.

• MA

Closed smoke control dampers can be opened after 25 min-

utes of full exposure to fire (> 800°C).

• multi The smoke control dampers may be used between fire com-

partments (multi) and in individual areas (single).

Maintenance-free

EK90 smoke control dampers EN 12101-8 – Series EK92 –

With casing and damper blades made from abrasion-proof, safe,

corrosion-resistant calcium silicate that is suitable for higher

temperatures. The edge protection profiles are made from galvanized steel and include connection holes.

Opening and closing is carried out by means of stainless steel

shafts using electric motor drives for 24 V AC/DC or 230 V AC

even when the fan is running and at inflow velocities of up to

20 m/s.

Special seals without any additional stops allow for large free

cross-sections and thus extremely low pressure drops and

sound power levels.

Widths B: 200 mm to 1500 mm

Heights H:: 200 mm to 800 mm

Lengths L: 350 mm to 850 mm

All dimensions are available in 5-mm

increments!

Installation with horizontal or vertical damper

blade:

• in rigid walls and ceilings, ≥ 100 mm thick and

≥ 450 kg/m³ bulk density.Wet installation with

mortar or a dry installation with mineral wool

≥ 100 kg/m³ are possible.

• in metal stud walls, ≥ 95 mm thick, with or with-

out mineral wool ≤ 100 kg/m³ inside.

• on and between horizontal or vertical smoke

extraction ducts.

Can be connected:

• in single or double-sided arrangement on

smoke extraction ducts with fire resistance

period,

• in single-sided arrangement on smoke extrac-

tion ducts without fire resistance period,

• in single or double-sided arrangement on protective grille

⇒see also page 34

Declaration of performance DoP no. CPR/EK90/003

German approval Z 56.4212 – 1007

Environmental Product Declaration according to ISO 14025 and

EN 15804 EPD-WIL-20160047-ICC1-DE

Casing leak tightness class C according to EN 1751

B+100

H+100

B

H

User Manual 5.32 (2018-05) 4

Subject to change

Series EK92

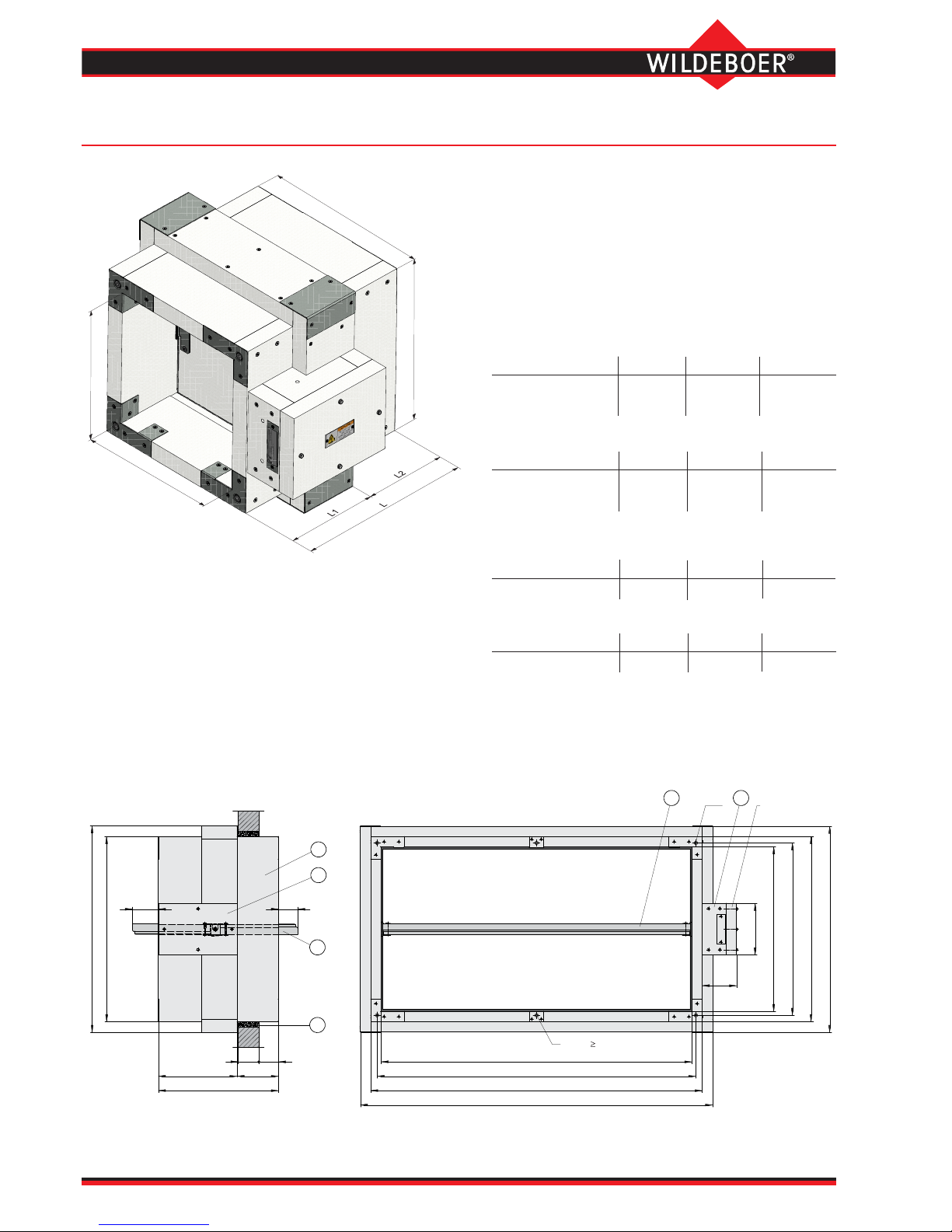

1 Casing

2 Damper blade

3 Protective casing with opening for motor drive cover

4 Installation gap filled with mortar or mineral wool ≥100 kg/m³

W: Wall thickness / D: Ceiling thickness / Z: Casing excess length

EK90 smoke control dampers

Data sheet

Calculating damper blade excess lengths:

• Ü1 = ½ · H - L1 + 105 mm; Ü2 = ½ · H - L2 - 107 mm

• If Ü1 ≤0 or Ü2 ≤0, there is no damper blade excess length!

If protective grilles are mounted directly on the casings,

then Ü1 or Ü2 should be at least -20 mm, which equates to a

20-mm freedom of movement. Hence, L1 ≥ ½ · H + 125 mm and

L2 ≥ ½ · H - 87 mm should be applied!

L2 ≥ W(D) + Z is also necessary! Here, W = thickness of the wall,

D = thickness of the ceiling. Z is the necessary casing excess

length.

Examples: • Fitting of shear protection brackets A.⇒see page 19

• Connection of smoke extraction ducts.⇒see page 23

Smallest lengths for lateral mounting on smoke extraction ducts

for heights H Length L Length L1 Length L2

up to 450 mm: 350 mm 330 mm 20 mm

larger than 450 mm: 400 mm 380 mm 20 mm

Standard widths B [mm]

200 - 225 - 250 - 275 - 300 - 325 - 350 - 375 - 400 - 450

500 - 550 - 600 - 650 - 700 - 750 - 800 - 850 - 900 - 950

1000 - 1050 - 1100 - 1150 - 1200 - 1250 - 1300 - 1400 - 1500

Standard heights H [mm]

200 - 225 - 250 - 275 - 300 - 325 - 350 - 375 - 400 - 450

500 - 550 - 600 - 650 - 700 - 750 - 800

Lengths for double-sided mounting of protective

grilles

⇒see page 34

Standard lengths [mm]

for heights H Length L Length L1 Length L2

up to 450 mm: 500 mm 330 mm 170 mm

larger than 450 mm: 550 mm 380 mm 170 mm

Intermediate dimensions for B, H, L, L1 and L2 are available in 5 mm increments. L is always = L1 + L2.

All dimensions in mm

Smallest lengths for lateral mounting on smoke extraction ducts

for all heights H Length L Length L1 Length L2

200 to 800 mm 400 mm 380 mm 20 mm

Standard lengths of special electrical connection

design

for all heights H Length L Length L1 Length L2

200 to 800 mm: 550 mm 380 mm 170 mm

1

3

2

3

L1

L2

W, D

L

2Ü1Ü

B+38

B+200

B

from B 1000

165

250

H

83+H

001+H

Cover

M10

Z

)001+B( x )001+H(

)002+B( x )002+H(

2

4

002+H

B+100

User Manual 5.32 (2018-05) 5

Subject to change

Series EK92

H B = 750 800 850 900 950 1000 1050 1100 1150 1200 1250 1300 1400 1500

200 0.842 0.837 0.832 0.828 0.824 0.821 0.818 0.815 0.812 0.810 0.808 0.806 0.803 0.800

225 0.670 0.666 0.662 0.658 0.655 0.652 0.649 0.647 0.645 0.643 0.641 0.639 0.636 0.634

250 0.556 0.552 0.548 0.545 0.542 0.539 0.537 0.535 0.533 0.531 0.530 0.528 0.525 0.523

275 0.475 0.471 0.467 0.464 0.462 0.459 0.457 0.455 0.454 0.452 0.451 0.449 0.447 0.445

300 0.414 0.411 0.408 0.405 0.402 0.400 0.398 0.397 0.395 0.393 0.392 0.391 0.389 0.387

325 0.368 0.365 0.362 0.359 0.357 0.355 0.353 0.351 0.350 0.348 0.347 0.346 0.344 0.342

350 0.331 0.328 0.325 0.323 0.321 0.319 0.317 0.315 0.314 0.312 0.311 0.310 0.308 0.306

375 0.301 0.298 0.296 0.293 0.291 0.289 0.288 0.286 0.285 0.284 0.282 0.281 0.279 0.278

400 0.277 0.274 0.271 0.269 0.267 0.265 0.264 0.262 0.261 0.260 0.259 0.257 0.256 0.254

450 0.239 0.236 0.233 0.231 0.229 0.228 0.226 0.225 0.224 0.223 0.221 0.221 0.219 0.217

500 0.210 0.208 0.205 0.203 0.202 0.200 0.199 0.197 0.196 0.195 0.194 0.193 0.192 0.190

550 0.189 0.186 0.184 0.182 0.180 0.179 0.178 0.176 0.175 0.174 0.173 0.172 0.171 0.169

600 0.172 0.169 0.167 0.165 0.164 0.162 0.161 0.160 0.158 0.157 0.157 0.156 0.154 0.153

650 0.158 0.155 0.153 0.151 0.150 0.148 0.147 0.146 0.145 0.144 0.143 0.142 0.141 0.140

700 0.146 0.144 0.142 0.140 0.139 0.137 0.136 0.135 0.134 0.133 0.132 0.131 0.130 0.129

750 0.137 0.134 0.132 0.131 0.129 0.128 0.127 0.125 0.124 0.123 0.123 0.122 0.120 0.119

800 0.128 0.126 0.124 0.123 0.121 0.120 0.119 0.117 0.116 0.116 0.115 0.114 0.113 0.111

H B = 200 225 250 275 300 325 350 375 400 450 500 550 600 650 700

200 1.118 1.071 1.035 1.006 0.983 0.964 0.948 0.934 0.922 0.902 0.887 0.875 0.864 0.856 0.849

225 0.908 0.868 0.837 0.812 0.792 0.775 0.761 0.749 0.739 0.722 0.709 0.698 0.689 0.682 0.676

250 0.768 0.732 0.704 0.682 0.664 0.649 0.637 0.626 0.617 0.602 0.590 0.581 0.573 0.566 0.561

275 0.669 0.636 0.610 0.590 0.574 0.560 0.549 0.539 0.531 0.517 0.506 0.497 0.490 0.484 0.479

300 0.595 0.564 0.540 0.521 0.506 0.494 0.483 0.474 0.466 0.453 0.443 0.435 0.429 0.423 0.418

325 0.537 0.508 0.486 0.469 0.454 0.442 0.432 0.424 0.417 0.405 0.395 0.388 0.381 0.376 0.372

350 0.492 0.464 0.443 0.427 0.413 0.402 0.392 0.384 0.377 0.366 0.357 0.350 0.344 0.339 0.335

375 0.455 0.429 0.409 0.393 0.380 0.369 0.360 0.352 0.345 0.335 0.326 0.319 0.314 0.309 0.305

400 0.425 0.399 0.380 0.365 0.352 0.342 0.333 0.326 0.319 0.309 0.300 0.294 0.288 0.284 0.280

450 0.377 0.354 0.335 0.321 0.309 0.299 0.291 0.284 0.278 0.269 0.261 0.255 0.250 0.245 0.242

500 0.342 0.320 0.302 0.289 0.277 0.268 0.260 0.254 0.248 0.239 0.231 0.226 0.221 0.217 0.213

550 0.315 0.294 0.277 0.264 0.253 0.244 0.237 0.230 0.225 0.216 0.209 0.203 0.199 0.195 0.191

600 0.294 0.273 0.257 0.244 0.234 0.225 0.218 0.212 0.207 0.198 0.191 0.186 0.181 0.177 0.174

650 0.277 0.256 0.240 0.228 0.218 0.210 0.203 0.197 0.192 0.183 0.177 0.171 0.167 0.163 0.160

700 0.262 0.242 0.227 0.215 0.205 0.197 0.190 0.184 0.179 0.171 0.165 0.160 0.155 0.152 0.149

750 0.250 0.231 0.216 0.204 0.194 0.186 0.180 0.174 0.169 0.161 0.155 0.150 0.145 0.142 0.139

800 0.240 0.221 0.206 0.194 0.185 0.177 0.171 0.165 0.160 0.152 0.146 0.141 0.137 0.134 0.131

EK90 smoke control dampers

Pressure drop coefficients z/ nomenclature

B [mm] Clear width of the smoke control damper

H [mm] Clear height of the smoke control damper

AA [m²] Inflow cross-section AA = B [m] · H [m]

A

free

[m²] Free cross-section ⇒ see table on page 16

v0 [m/s] Flow velocity in A

free

vA [m/s] Flow velocity in AA

Inflow velocity

V [m³/h] Volume flow

z Pressure drop coefficient

DpS [Pa] Pressure drop with smoke control damper fully open

DpS [Pa] = ½ · 1.2 [kg/m³] · z · vA [m/s] ²

LWA [dB(A)] A-weighted sound power level (area-corrected)

L

W-Oct

[dB] Octave sound power level L

W-Oct

= LWA + DL

DL [dB] Relative sound power level

f [Hz] Octave mid frequency

Nomenclature

User Manual 5.32 (2018-05) 6

Subject to change

Series EK92

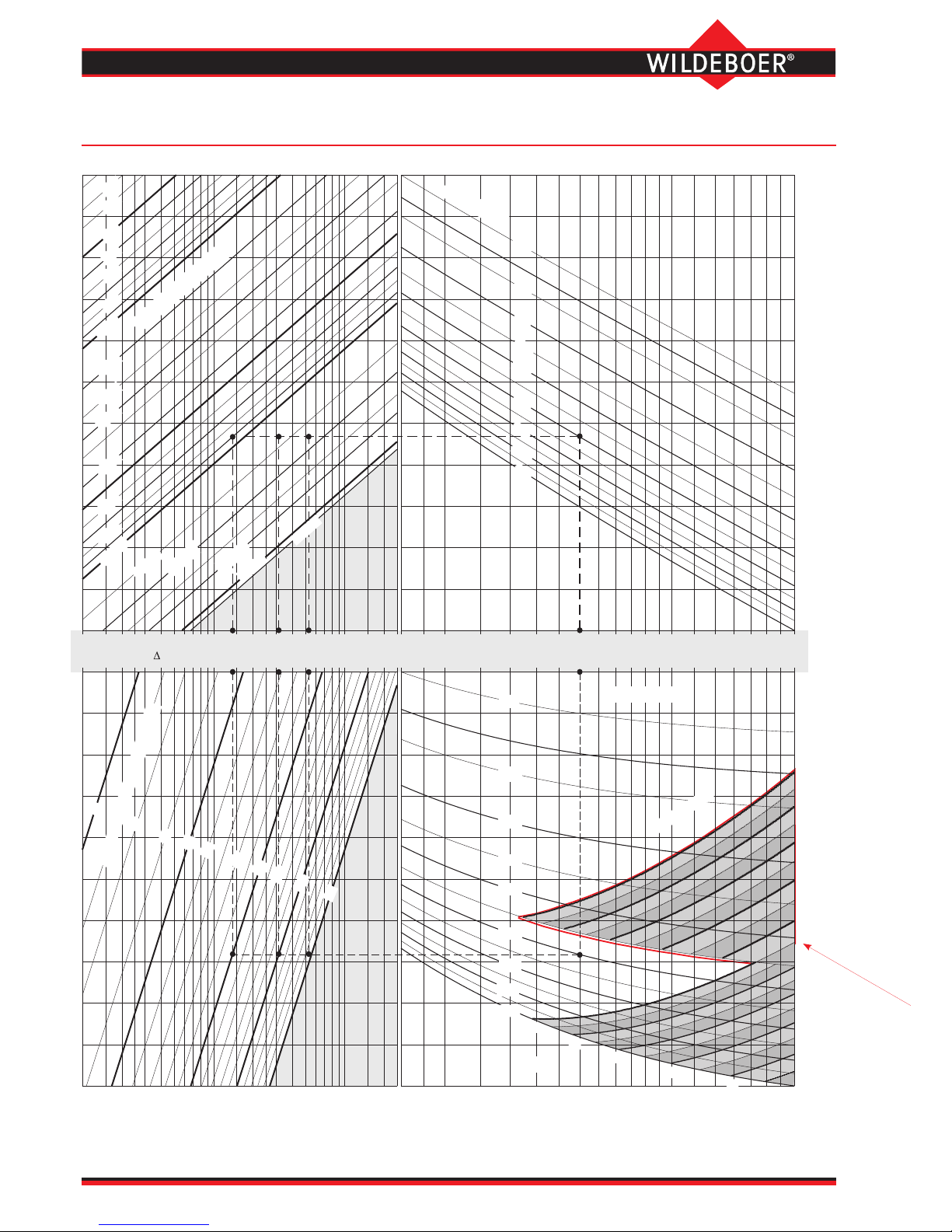

EK90 smoke control dampers

Volume flow V, pressure drop Dp, inflow velocity v

A

With inflow velocities v

A Max

= 10 to 20 m/s, depending on the width and height of the EK90 smoke control damper,

the inflow velocity limits the opening of the smoke control damper. It may need to be reduced temporarily!

Example: The intersection point B = 500 mm with H = 500 mm lies in the field

A Max

= 20 m/s. There is no restriction here! ⇒see also table on page 7!

v

A Max

[m/s]

6

5

5

5

3

2

1

20

30

70

100

7

200

250

300

350 400 500 600 700 800 1000

1200

1500

Height H [mm]

Pressure drop p [Pa]

S

3

4

8

10

12

2

Inflow velocity v [m/s]

A

200

250

300

350

400

800

500

600

Width B [mm]

200

250

300

350

400

500

600

700

800

Height H [mm]

Volume flow V [m³/h]

225

300

400

500

600

800

1000

2000

2500

4000

6000

8000

10000

20000

30000

40000

43200

250

1500

50

150 250

700

15

15000

20

v = 20 m/s

A Max

20

18

16

14

12

10

20

18

16

14

12

10

v

[m/s]

A Max

H \ B 400 450 500 550 600 650 700 750 800 850 900 950 1000 1050 1100 1150 1200 1250 1300 1400 1500

250 19 19 18

275 19 19 18 18 18 17 16

300 19 19 18 18 17 17 17 16 16 15 15

325 19 18 18 17 17 17 16 16 15 15 15 14 14

350 19 19 18 18 17 17 16 16 15 15 15 14 14 14 13 13

375 19 18 18 17 16 16 15 15 15 14 14 14 13 13 13 12 12

400 19 19 18 17 16 16 15 15 14 14 14 13 13 13 13 12 12 12 11

450 19 18 17 16 16 15 15 14 14 13 13 13 12 12 12 11 11 11 11 10 10

500 19 19 18 18 18 17 16

550 19 19 18 18 17 17 17 16 16 15 15

600 19 19 18 18 17 17 16 16 16 15 15 15 14 14

650 19 18 18 17 17 16 16 15 15 15 14 14 14 13 13 13

700 19 18 18 17 16 16 15 15 15 14 14 14 13 13 13 13 12 12

750 19 18 17 17 16 15 15 14 14 14 13 13 13 12 12 12 12 11 11

800 19 18 17 16 16 15 14 14 14 13 13 12 12 12 12 11 11 11 11 10

User Manual 5.32 (2018-05) 7

Subject to change

Series EK92

Example 63 125 250 500 1000 2000 4000 8000 Hz

1 59 53 50 45 43 40 37 33 [dB]

2 65 62 60 56 54 53 49 45 [dB]

3 70 67 66 63 62 61 57 54 [dB]

EK90 smoke control dampers

Sound power level LWA / examples / inflow velocities v

A

Relative sound power level DL [dB]

f [Hz] 63 125 250 500 1000 2000 4000 8000

vA = 5 m/s 16 8 2 -4 -8 -12 -15 -19

vA = 10 m/s 10 4 1 -4 -6 -9 -12 -16

vA = 15 m/s 5 2 0 -4 -6 -7 -11 -15

vA = 20 m/s 2 -1 -2 -5 -6 -7 -11 -14

Examples 1 2 3

Width B x height H =

Inflow velocity v

A

= 10 15 20 m/s

Volume flow V = 9000 13500 18000 m³/h

Pressure drop DpS = 14 31 56 Pa

Sound power level L

WA

= 49 60 68 dB(A)

Sound power level L

W-Oct

= LWA + DL =

Inflow velocity vA = 10 m/sInflow velocity vA = 5 m/s

Inflow velocity vA = 15 m/s

v

A

≤

20 m/s

EK90 smoke control dampers can be used, opened and closed with inflow velocities of vA ≤20 m/s.

The inflow velocities for opening are limited to the values given in the table and in the diagrams:

Nomenclature ⇒see page 5

500 mm x 500 mm

Example

In these ranges surrounded by the red border, opening is possible at an inflow velocity of vA up to 20 m/s with a specially designed electrical connection! ⇒ see page 34

v

A

≤

20 m/s

250

200 250 300 400 500 600

700

Width B [mm]

700

300

900

600

200

500

]mm[ H Height

400

800

1200

1000800 1500

29

31

33

34

35

36

37

30

Sound

power level

L

W

= 32

dB(A)

A

250

200 250 300 400 500 600

700

Width B [mm]

700

300

900

600

200

500

]mm[ H ehöH

Height

400

800

1200

1000800 1500

48

49

51

52

53

54

47

A

Sound

power level

250

200 250 300 400 500 600

700

Width [mm]

700

300

900

600

200

500

]mm[ H ehöH

400

800

1200

1000800 1500

58

61

62

63

64

450

64

65

L

W

=

6

0

d

B

(

A

)

59

A

Sound

power level

Height

User Manual 5.32 (2018-05) 8

Subject to change

Series EK92

H B = 200 225 250 275 300 325 350 375 400 450 500 550 600 650 700

200 m³/h 720 810 900 990 1080 1170 1260 1350 1440 1620 1800 1980 2160 2340 2520

Pa 17 16 16 15 15 15 14 14 14 14 13 13 13 13 13

dB(A) 38 37 37 37 37 37 37 37 37 37 37 37 37 36 36

225 m³/h 810 911 1013 1114 1215 1316 1418 1519 1620 1823 2025 2228 2430 2633 2835

Pa 14 13 13 12 12 12 11 11 11 11 11 11 10 10 10

dB(A) 37 37 36 36 36 36 36 36 36 36 36 36 36 36 36

250 m³/h 900 1013 1125 1238 1350 1463 1575 1688 1800 2025 2250 2475 2700 2925 3150

Pa 12 11 11 10 10 10 10 9 9 9 9 9 9 9 8

dB(A) 36 36 36 36 35 35 35 35 35 35 35 35 35 35 35

275 m³/h 990 1114 1238 1361 1485 1609 1733 1856 1980 2228 2475 2723 2970 3218 3465

Pa 10 10 9 9 9 8 8 8 8 8 8 7 7 7 7

dB(A) 35 35 35 35 35 35 35 35 35 34 34 34 34 34 34

300 m³/h 1080 1215 1350 1485 1620 1755 1890 2025 2160 2430 2700 2970 3240 3510 3780

Pa 9 8 8 8 8 7 7 7 7 7 7 7 6 6 6

dB(A) 35 35 35 34 34 34 34 34 34 34 34 34 34 34 34

325 m³/h 1170 1316 1463 1609 1755 1901 2048 2194 2340 2633 2925 3218 3510 3803 4095

Pa 8 8 7 7 7 7 7 6 6 6 6 6 6 6 6

dB(A) 35 34 34 34 34 34 34 34 34 34 33 33 33 33 33

350 m³/h 1260 1418 1575 1733 1890 2048 2205 2363 2520 2835 3150 3465 3780 4095 4410

Pa 7 7 7 6 6 6 6 6 6 6 5 5 5 5 5

dB(A) 34 34 34 34 34 34 33 33 33 33 33 33 33 33 33

375 m³/h 1350 1519 1688 1856 2025 2194 2363 2531 2700 3038 3375 3713 4050 4388 4725

Pa 7 6 6 6 6 6 5 5 5 5 5 5 5 5 5

dB(A) 34 34 34 33 33 33 33 33 33 33 33 33 33 33 33

400 m³/h 1440 1620 1800 1980 2160 2340 2520 2700 2880 3240 3600 3960 4320 4680 5040

Pa 6 6 6 5 5 5 5 5 5 5 5 4 4 4 4

dB(A) 34 33 33 33 33 33 33 33 33 33 32 32 32 32 32

450 m³/h 1620 1823 2025 2228 2430 2633 2835 3038 3240 3645 4050 4455 4860 5265 5670

Pa 6 5 5 5 5 5 4 4 4 4 4 4 4 4 4

dB(A) 33 33 33 33 33 32 32 32 32 32 32 32 32 32 32

500 m³/h 1800 2025 2250 2475 2700 2925 3150 3375 3600 4050 4500 4950 5400 5850 6300

Pa 5 5 5 4 4 4 4 4 4 4 3 3 3 3 3

dB(A) 33 33 33 32 32 32 32 32 32 32 32 32 31 31 31

550 m³/h 1980 2228 2475 2723 2970 3218 3465 3713 3960 4455 4950 5445 5940 6435 6930

Pa 5 4 4 4 4 4 4 3 3 3 3 3 3 3 3

dB(A) 33 32 32 32 32 32 32 32 32 31 31 31 31 31 31

600 m³/h 2160 2430 2700 2970 3240 3510 3780 4050 4320 4860 5400 5940 6480 7020 7560

Pa 4 4 4 4 4 3 3 3 3 3 3 3 3 3 3

dB(A) 32 32 32 32 32 32 31 31 31 31 31 31 31 31 31

650 m³/h 2340 2633 2925 3218 3510 3803 4095 4388 4680 5265 5850 6435 7020 7605 8190

Pa 4 4 4 3 3 3 3 3 3 3 3 3 3 2 2

dB(A) 32 32 32 32 31 31 31 31 31 31 31 31 31 31 31

700 m³/h 2520 2835 3150 3465 3780 4095 4410 4725 5040 5670 6300 6930 7560 8190 8820

Pa 4 4 3 3 3 3 3 3 3 3 2 2 2 2 2

dB(A) 32 32 32 31 31 31 31 31 31 31 31 31 30 30 30

750 m³/h 2700 3038 3375 3713 4050 4388 4725 5063 5400 6075 6750 7425 8100 8775 9450

Pa 4 3 3 3 3 3 3 3 3 2 2 2 2 2 2

dB(A) 32 32 31 31 31 31 31 31 31 31 30 30 30 30 30

800 m³/h 2880 3240 3600 3960 4320 4680 5040 5400 5760 6480 7200 7920 8640 9360 10080

Pa 4 3 3 3 3 3 3 2 2 2 2 2 2 2 2

dB(A) 32 31 31 31 31 31 31 31 31 30 30 30 30 30 30

EK90 smoke control dampers

Volume flow, pressure drop, sound power level at 5 m/s inflow velocity (1)

User Manual 5.32 (2018-05) 9

Subject to change

Series EK92

H B = 750 800 850 900 950 1000 1050 1100 1150 1200 1250 1300 1400 1500

200 m³/h 2700 2880 3060 3240 3420 3600 3780 3960 4140 4320 4500 4680 5040 5400

Pa 13 13 13 12 12 12 12 12 12 12 12 12 12 12

dB(A) 36 36 36 36 36 36 36 36 36 36 36 36 36 36

225 m³/h 3038 3240 3443 3645 3848 4050 4253 4455 4658 4860 5063 5265 5670 6075

Pa 10 10 10 10 10 10 10 10 10 10 10 10 10 10

dB(A) 35 35 35 35 35 35 35 35 35 35 35 35 35 35

250 m³/h 3375 3600 3825 4050 4275 4500 4725 4950 5175 5400 5625 5850 6300 6750

Pa 8 8 8 8 8 8 8 8 8 8 8 8 8 8

dB(A) 35 35 35 35 35 35 35 35 35 35 35 35 35 34

275 m³/h 3713 3960 4208 4455 4703 4950 5198 5445 5693 5940 6188 6435 6930 7425

Pa 7 7 7 7 7 7 7 7 7 7 7 7 7 7

dB(A) 34 34 34 34 34 34 34 34 34 34 34 34 34 34

300 m³/h 4050 4320 4590 4860 5130 5400 5670 5940 6210 6480 6750 7020 7560 8100

Pa 6 6 6 6 6 6 6 6 6 6 6 6 6 6

dB(A) 34 34 34 34 34 33 33 33 33 33 33 33 33 33

325 m³/h 4388 4680 4973 5265 5558 5850 6143 6435 6728 7020 7313 7605 8190 8775

Pa 6 5 5 5 5 5 5 5 5 5 5 5 5 5

dB(A) 33 33 33 33 33 33 33 33 33 33 33 33 33 33

350 m³/h 4725 5040 5355 5670 5985 6300 6615 6930 7245 7560 7875 8190 8820 9450

Pa 5 5 5 5 5 5 5 5 5 5 5 5 5 5

dB(A) 33 33 33 33 33 33 33 33 33 33 33 33 33 33

375 m³/h 5063 5400 5738 6075 6413 6750 7088 7425 7763 8100 8438 8775 9450 10125

Pa 5 4 4 4 4 4 4 4 4 4 4 4 4 4

dB(A) 33 32 32 32 32 32 32 32 32 32 32 32 32 32

400 m³/h 5400 5760 6120 6480 6840 7200 7560 7920 8280 8640 9000 9360 10080 10800

Pa 4 4 4 4 4 4 4 4 4 4 4 4 4 4

dB(A) 32 32 32 32 32 32 32 32 32 32 32 32 32 32

450 m³/h 6075 6480 6885 7290 7695 8100 8505 8910 9315 9720 10125 10530 11340 12150

Pa 4 4 4 3 3 3 3 3 3 3 3 3 3 3

dB(A) 32 32 32 32 32 32 32 32 32 32 32 31 31 31

500 m³/h 6750 7200 7650 8100 8550 9000 9450 9900 10350 10800 11250 11700 12600 13500

Pa 3 3 3 3 3 3 3 3 3 3 3 3 3 3

dB(A) 31 31 31 31 31 31 31 31 31 31 31 31 31 31

550 m³/h 7425 7920 8415 8910 9405 9900 10395 10890 11385 11880 12375 12870 13860 14850

Pa 3 3 3 3 3 3 3 3 3 3 3 3 3 3

dB(A) 31 31 31 31 31 31 31 31 31 31 31 31 31 31

600 m³/h 8100 8640 9180 9720 10260 10800 11340 11880 12420 12960 13500 14040 15120 16200

Pa 3 3 3 2 2 2 2 2 2 2 2 2 2 2

dB(A) 31 31 31 31 31 31 31 31 31 31 30 30 30 30

650 m³/h 8775 9360 9945 10530 11115 11700 12285 12870 13455 14040 14625 15210 16380 17550

Pa 2 2 2 2 2 2 2 2 2 2 2 2 2 2

dB(A) 31 30 30 30 30 30 30 30 30 30 30 30 30 30

700 m³/h 9450 10080 10710 11340 11970 12600 13230 13860 14490 15120 15750 16380 17640 18900

Pa 2 2 2 2 2 2 2 2 2 2 2 2 2 2

dB(A) 30 30 30 30 30 30 30 30 30 30 30 30 30 30

750 m³/h 10125 10800 11475 12150 12825 13500 14175 14850 15525 16200 16875 17550 18900 20250

Pa 2 2 2 2 2 2 2 2 2 2 2 2 2 2

dB(A) 30 30 30 30 30 30 30 30 30 30 30 30 30 30

800 m³/h 10800 11520 12240 12960 13680 14400 15120 15840 16560 17280 18000 18720 20160 21600

Pa 2 2 2 2 2 2 2 2 2 2 2 2 2 2

dB(A) 30 30 30 30 30 30 30 30 30 30 30 30 30 30

EK90 smoke control dampers

Volume flow, pressure drop, sound power level at 5 m/s inflow velocity (2)

User Manual 5.32 (2018-05) 10

Subject to change

Series EK92

H B = 200 225 250 275 300 325 350 375 400 450 500 550 600 650 700

200 m³/h 1440 1620 1800 1980 2160 2340 2520 2700 2880 3240 3600 3960 4320 4680 5040

Pa 67 64 62 61 59 58 57 56 56 54 53 53 52 52 51

dB(A) 55 55 55 55 55 55 55 55 55 54 54 54 54 54 54

225 m³/h 1620 1823 2025 2228 2430 2633 2835 3038 3240 3645 4050 4455 4860 5265 5670

Pa 55 52 50 49 48 47 46 45 44 43 43 42 41 41 41

dB(A) 54 54 54 54 54 54 54 54 54 53 53 53 53 53 53

250 m³/h 1800 2025 2250 2475 2700 2925 3150 3375 3600 4050 4500 4950 5400 5850 6300

Pa 46 44 42 41 40 39 38 38 37 36 36 35 34 34 34

dB(A) 54 54 53 53 53 53 53 53 53 53 53 53 53 53 52

275 m³/h 1980 2228 2475 2723 2970 3218 3465 3713 3960 4455 4950 5445 5940 6435 6930

Pa 40 38 37 36 35 34 33 32 32 31 30 30 30 29 29

dB(A) 53 53 53 53 53 52 52 52 52 52 52 52 52 52 52

300 m³/h 2160 2430 2700 2970 3240 3510 3780 4050 4320 4860 5400 5940 6480 7020 7560

Pa 36 34 33 31 30 30 29 29 28 27 27 26 26 25 25

dB(A) 53 53 52 52 52 52 52 52 52 52 52 52 51 51 51

325 m³/h 2340 2633 2925 3218 3510 3803 4095 4388 4680 5265 5850 6435 7020 7605 8190

Pa 32 31 29 28 27 27 26 26 25 24 24 23 23 23 22

dB(A) 52 52 52 52 52 52 51 51 51 51 51 51 51 51 51

350 m³/h 2520 2835 3150 3465 3780 4095 4410 4725 5040 5670 6300 6930 7560 8190 8820

Pa 30 28 27 26 25 24 24 23 23 22 21 21 21 20 20

dB(A) 52 52 52 51 51 51 51 51 51 51 51 51 51 51 51

375 m³/h 2700 3038 3375 3713 4050 4388 4725 5063 5400 6075 6750 7425 8100 8775 9450

Pa 27 26 25 24 23 22 22 21 21 20 20 19 19 19 18

dB(A) 52 51 51 51 51 51 51 51 51 51 50 50 50 50 50

400 m³/h 2880 3240 3600 3960 4320 4680 5040 5400 5760 6480 7200 7920 8640 9360 10080

Pa 26 24 23 22 21 21 20 20 19 19 18 18 17 17 17

dB(A) 51 51 51 51 51 51 51 50 50 50 50 50 50 50 50

450 m³/h 3240 3645 4050 4455 4860 5265 5670 6075 6480 7290 8100 8910 9720 10530 11340

Pa 23 21 20 19 19 18 18 17 17 16 16 15 15 15 15

dB(A) 51 51 51 50 50 50 50 50 50 50 50 50 50 49 49

500 m³/h 3600 4050 4500 4950 5400 5850 6300 6750 7200 8100 9000 9900 10800 11700 12600

Pa 21 19 18 17 17 16 16 15 15 14 14 14 13 13 13

dB(A) 51 50 50 50 50 50 50 50 50 49 49 49 49 49 49

550 m³/h 3960 4455 4950 5445 5940 6435 6930 7425 7920 8910 9900 10890 11880 12870 13860

Pa 19 18 17 16 15 15 14 14 14 13 13 12 12 12 12

dB(A) 50 50 50 50 50 49 49 49 49 49 49 49 49 49 49

600 m³/h 4320 4860 5400 5940 6480 7020 7560 8100 8640 9720 10800 11880 12960 14040 15120

Pa 18 16 15 15 14 14 13 13 12 12 12 11 11 11 10

dB(A) 50 50 50 49 49 49 49 49 49 49 49 49 48 48 48

650 m³/h 4680 5265 5850 6435 7020 7605 8190 8775 9360 10530 11700 12870 14040 15210 16380

Pa 17 15 14 14 13 13 12 12 12 11 11 10 10 10 10

dB(A) 50 50 49 49 49 49 49 49 49 49 48 48 48 48 48

700 m³/h 5040 5670 6300 6930 7560 8190 8820 9450 10080 11340 12600 13860 15120 16380 17640

Pa 16 15 14 13 12 12 11 11 11 10 10 10 9 9 9

dB(A) 50 49 49 49 49 49 49 49 48 48 48 48 48 48 48

750 m³/h 5400 6075 6750 7425 8100 8775 9450 10125 10800 12150 13500 14850 16200 17550 18900

Pa 15 14 13 12 12 11 11 10 10 10 9 9 9 9 8

dB(A) 50 49 49 49 49 49 48 48 48 48 48 48 48 48 48

800 m³/h 5760 6480 7200 7920 8640 9360 10080 10800 11520 12960 14400 15840 17280 18720 20160

Pa 14 13 12 12 11 11 10 10 10 9 9 8 8 8 8

dB(A) 49 49 49 49 49 48 48 48 48 48 48 48 48 48 48

EK90 smoke control dampers

Volume flow, pressure drop, sound power level at 10 m/s inflow velocity (1)

User Manual 5.32 (2018-05) 11

Subject to change

Series EK92

H B = 750 800 850 900 950 1000 1050 1100 1150 1200 1250 1300 1400 1500

200 m³/h 5400 5760 6120 6480 6840 7200 7560 7920 8280 8640 9000 9360 10080 10800

Pa 51 50 50 50 50 49 49 49 49 49 49 49 48 48

dB(A) 54 54 54 54 54 54 54 54 54 54 54 54 54 54

225 m³/h 6075 6480 6885 7290 7695 8100 8505 8910 9315 9720 10125 10530 11340 12150

Pa 40 40 40 40 39 39 39 39 39 39 39 38 38 38

dB(A) 53 53 53 53 53 53 53 53 53 53 53 53 53 53

250 m³/h 6750 7200 7650 8100 8550 9000 9450 9900 10350 10800 11250 11700 12600 13500

Pa 33 33 33 33 33 32 32 32 32 32 32 32 32 31

dB(A) 52 52 52 52 52 52 52 52 52 52 52 52 52 52

275 m³/h 7425 7920 8415 8910 9405 9900 10395 10890 11385 11880 12375 12870 13860 14850

Pa 29 28 28 28 28 28 28 27 27 27 27 27 27 27

dB(A) 52 52 52 52 52 52 52 52 52 52 52 52 52 52

300 m³/h 8100 8640 9180 9720 10260 10800 11340 11880 12420 12960 13500 14040 15120 16200

Pa 25 25 25 24 24 24 24 24 24 24 24 24 23 23

dB(A) 51 51 51 51 51 51 51 51 51 51 51 51 51 51

325 m³/h 8775 9360 9945 10530 11115 11700 12285 12870 13455 14040 14625 15210 16380 17550

Pa 22 22 22 22 21 21 21 21 21 21 21 21 21 21

dB(A) 51 51 51 51 51 51 51 51 51 51 51 51 51 51

350 m³/h 9450 10080 10710 11340 11970 12600 13230 13860 14490 15120 15750 16380 17640 18900

Pa 20 20 20 19 19 19 19 19 19 19 19 19 19 18

dB(A) 51 50 50 50 50 50 50 50 50 50 50 50 50 50

375 m³/h 10125 10800 11475 12150 12825 13500 14175 14850 15525 16200 16875 17550 18900 20250

Pa 18 18 18 18 18 17 17 17 17 17 17 17 17 17

dB(A) 50 50 50 50 50 50 50 50 50 50 50 50 50 50

400 m³/h 10800 11520 12240 12960 13680 14400 15120 15840 16560 17280 18000 18720 20160 21600

Pa 17 16 16 16 16 16 16 16 16 16 16 16 15 15

dB(A) 50 50 50 50 50 50 50 50 50 50 50 50 50 50

450 m³/h 12150 12960 13770 14580 15390 16200 17010 17820 18630 19440 20250 21060 22680 24300

Pa 14 14 14 14 14 14 14 14 13 13 13 13 13 13

dB(A) 49 49 49 49 49 49 49 49 49 49 49 49 49 49

500 m³/h 13500 14400 15300 16200 17100 18000 18900 19800 20700 21600 22500 23400 25200 27000

Pa 13 13 12 12 12 12 12 12 12 12 12 12 12 11

dB(A) 49 49 49 49 49 49 49 49 49 49 49 49 49 49

550 m³/h 14850 15840 16830 17820 18810 19800 20790 21780 22770 23760 24750 25740 27720 29700

Pa 11 11 11 11 11 11 11 11 11 10 10 10 10 10

dB(A) 49 49 49 49 48 48 48 48 48 48 48 48 48 48

600 m³/h 16200 17280 18360 19440 20520 21600 22680 23760 24840 25920 27000 28080 30240 32400

Pa 10 10 10 10 10 10 10 10 10 9 9 9 9 9

dB(A) 48 48 48 48 48 48 48 48 48 48 48 48 48 48

650 m³/h 17550 18720 19890 21060 22230 23400 24570 25740 26910 28080 29250 30420 32760 35100

Pa 9 9 9 9 9 9 9 9 9 9 9 9 8 8

dB(A) 48 48 48 48 48 48 48 48 48 48 48 48 48 48

700 m³/h 18900 20160 21420 22680 23940 25200 26460 27720 28980 30240 31500 32760 35280 37800

Pa 9 9 9 8 8 8 8 8 8 8 8 8 8 8

dB(A) 48 48 48 48 48 48 48 48 48 48 48 48 47 47

750 m³/h 20250 21600 22950 24300 25650 27000 28350 29700 31050 32400 33750 35100 37800 40500

Pa 8 8 8 8 8 8 8 8 7 7 7 7 7 7

dB(A) 48 48 48 47 47 47 47 47 47 47 47 47 47 47

800 m³/h 21600 23040 24480 25920 27360 28800 30240 31680 33120 34560 36000 37440 40320 43200

Pa 8 8 7 7 7 7 7 7 7 7 7 7 7 7

dB(A) 47 47 47 47 47 47 47 47 47 47 47 47 47 47

EK90 smoke control dampers

Volume flow, pressure drop, sound power level at 10 m/s inflow velocity (2)

Loading...

Loading...