Page 1

Tel: +1 (301) 330-8811

Tel: +1 800 WILCOXON

Fax: +1 (301) 330-8873

www.wilcoxon.com

91457 Rev. C

Please read this manual thoroughly before making electrical connections and applying

power to the module. Following the instructions in this manual will ensure the transmitter

delivers optimum performance.

Newer versions of firmware may occasionally be released to address known bugs or add

new features. Make sure you always use the latest firmware version and product

documentation. Both can be found at www.wilcoxon.com.

iT300 Series

Intelligent Configurable Transmitters

Installation and Operating Manual

Models iT300 and iT301

Wilcoxon Sensing Technologies

an Amphenol Company

Germantown, MD 20876 USA Page 1 of 59

Page 2

Tel: +1 (301) 330-8811

Tel: +1 800 WILCOXON

Fax: +1 (301) 330-8873

www.wilcoxon.com

91457 Rev. C

Table of Contents

1 Introduction ........................................................................................................................................ 7

2 Description .......................................................................................................................................... 7

3 Key features ........................................................................................................................................ 7

3.1 General features (all models) ...................................................................................................................................................7

3.2 iT301 advanced features ..........................................................................................................................................................7

4 Abbreviations used in this manual ...................................................................................................... 8

5 Safety Regulations and Installation Notes ........................................................................................... 8

5.1 Safety summary ........................................................................................................................................................................8

5.2 Declaration of conformity ........................................................................................................................................................8

6 iT300 family overview ......................................................................................................................... 9

7 System diagrams ................................................................................................................................. 9

7.1 Major system components ......................................................................................................................................................9

7.2 Basic circuit diagram .................................................................................................................................................................9

7.3 Isolation diagram ......................................................................................................................................................................9

8 Front panel LEDs ............................................................................................................................... 10

8.1 Operating modes ................................................................................................................................................................... 10

9 IO ports and signal assignments ........................................................................................................ 11

9.1 Terminal block locations and pin numbers ........................................................................................................................... 11

9.2 Terminal block pin and signal assignments .......................................................................................................................... 11

10 Electrical connections and wiring ...................................................................................................... 12

10.1 ESD precaution .................................................................................................................................................................. 12

10.2 Pluggable terminal blocks ................................................................................................................................................. 12

10.3 Sensor/transducer connections ....................................................................................................................................... 12

10.4 4-20 mA current loop connections ................................................................................................................................... 13

10.5 Dynamic output connections ........................................................................................................................................... 13

10.6 Signal relay connections (iT301) ....................................................................................................................................... 13

10.7 Power supply input connections ...................................................................................................................................... 13

10.8 Cable shielding and earth ground connections ............................................................................................................... 14

11 Power-up .......................................................................................................................................... 14

12 IO ports – detailed description .......................................................................................................... 15

12.1 Vibration sensor input ....................................................................................................................................................... 15

12.1.1 Constant current IEPE power source ........................................................................................................................... 15

12.1.2 BOV acceptable range and sensor fault detection ...................................................................................................... 15

12.2 Temperature sensor input ................................................................................................................................................ 16

12.3 4-20 mA current loop outputs .......................................................................................................................................... 16

12.3.1 Loop error state when sensor fault detected .............................................................................................................. 16

12.3.2 Loop force mode (test mode) ...................................................................................................................................... 16

12.4 Power supply input ........................................................................................................................................................... 16

12.5 BNC dynamic signal output............................................................................................................................................... 16

13 TBUS ................................................................................................................................................. 17

13.1 Stacking modules .............................................................................................................................................................. 17

13.2 Powering via the TBUS ...................................................................................................................................................... 17

Wilcoxon Sensing Technologies

an Amphenol Company

Germantown, MD 20876 USA Page 2 of 59

Page 3

Tel: +1 (301) 330-8811

Tel: +1 800 WILCOXON

Fax: +1 (301) 330-8873

www.wilcoxon.com

91457 Rev. C

14 DIN rail assembly and removal .......................................................................................................... 17

14.1 Requirements for installation ........................................................................................................................................... 17

14.2 DIN rail mounting .............................................................................................................................................................. 17

14.3 Preparing the DIN rail TBUS connectors........................................................................................................................... 18

14.4 Installing the module onto the DIN rail ............................................................................................................................ 18

14.5 Removing the module from the DIN rail .......................................................................................................................... 18

15 HTTP web server ............................................................................................................................... 19

15.1 10/100 Ethernet ................................................................................................................................................................ 19

15.2 Browser support ................................................................................................................................................................ 19

15.3 Establishing a network connection (PC, Laptop) ............................................................................................................. 19

15.3.1 Adjusting network adapter settings ............................................................................................................................. 20

15.4 Establishing a network connection .................................................................................................................................. 21

15.5 Accessing the web server ................................................................................................................................................. 21

16 User Interface (UI) ............................................................................................................................. 21

16.1 Overview ............................................................................................................................................................................ 21

16.2 Layout................................................................................................................................................................................. 21

16.3 Sample UI ........................................................................................................................................................................... 21

16.4 Configurable parameters .................................................................................................................................................. 24

16.5 Default configuration ........................................................................................................................................................ 24

17 Configuring the transmitter ............................................................................................................... 25

17.1 Access control .................................................................................................................................................................... 25

17.2 Restoring factory defaults ................................................................................................................................................. 25

17.3 Typical configuration flow ................................................................................................................................................. 25

17.4 Parameter interdependencies .......................................................................................................................................... 26

17.5 Highlighting of altered settings ......................................................................................................................................... 26

18 User-configurable parameters ........................................................................................................... 27

18.1 Machine information ........................................................................................................................................................ 27

18.2 Sensor input and averaging time ...................................................................................................................................... 27

18.2.1 Sensor type.................................................................................................................................................................... 27

18.2.2 Sensitivity ...................................................................................................................................................................... 27

18.2.3 Averaging time .............................................................................................................................................................. 27

18.2.4 Sensor power source .................................................................................................................................................... 27

18.2.5 Serial number ................................................................................................................................................................ 27

18.3 Frequency range ................................................................................................................................................................ 27

18.3.1 F

18.3.2 F

18.4 Processing bands ............................................................................................................................................................... 28

18.4.1 Output type ................................................................................................................................................................... 28

18.4.2 F

18.4.3 F

18.4.4 Detector type ................................................................................................................................................................ 28

18.5 True peak detection .......................................................................................................................................................... 29

18.5.1 Overview ....................................................................................................................................................................... 29

18.5.2 True peak detector response and decay times ........................................................................................................... 29

18.6 Measurement results ........................................................................................................................................................ 30

18.6.1 Vibration measurement results ................................................................................................................................... 30

18.6.2 Temperature measurement ......................................................................................................................................... 30

18.6.3 BOV monitor ................................................................................................................................................................. 30

................................................................................................................................................................................ 27

MAX

................................................................................................................................................................................. 27

MIN

............................................................................................................................................................................... 28

START

................................................................................................................................................................................ 28

STOP

Wilcoxon Sensing Technologies

an Amphenol Company

Germantown, MD 20876 USA Page 3 of 59

Page 4

Tel: +1 (301) 330-8811

Tel: +1 800 WILCOXON

Fax: +1 (301) 330-8873

www.wilcoxon.com

91457 Rev. C

18.7 4-20 mA current loops ...................................................................................................................................................... 30

18.7.1 Loop driving source ....................................................................................................................................................... 30

18.7.2 Loop full scale ................................................................................................................................................................ 31

18.7.3 Destination .................................................................................................................................................................... 31

18.7.4 Loop status .................................................................................................................................................................... 31

18.7.5 Testing the loops using force mode ............................................................................................................................. 31

18.8 Alerts and alarms (iT301) .................................................................................................................................................. 32

18.8.1 Overview ....................................................................................................................................................................... 32

18.8.2 Result status alerts ........................................................................................................................................................ 32

18.8.3 Alert limits ..................................................................................................................................................................... 32

18.8.4 Alarm Delay time .......................................................................................................................................................... 32

18.8.5 Alarm Hold time ............................................................................................................................................................ 33

18.8.6 Alarm Status .................................................................................................................................................................. 33

18.8.7 Clearing alarms ............................................................................................................................................................. 33

18.9 Signal relay (iT301) ............................................................................................................................................................ 33

18.9.1 Mapping alarms to the relay ........................................................................................................................................ 33

18.9.2 Testing the relay using force mode .............................................................................................................................. 33

18.9.3 Example – Alarm behavior ........................................................................................................................................... 34

19 User-action controls .......................................................................................................................... 35

19.1 Overview ............................................................................................................................................................................ 35

19.2 Saving the current configuration to a file ......................................................................................................................... 35

19.3 Loading a configuration from a file ................................................................................................................................... 35

19.4 Changing the user name and password ........................................................................................................................... 35

19.5 Restoring factory default settings ..................................................................................................................................... 36

19.6 Updating the module firmware ........................................................................................................................................ 36

20 Troubleshooting ................................................................................................................................ 37

20.1 Fault conditions ................................................................................................................................................................. 37

20.2 Unexpected behavior ........................................................................................................................................................ 37

21 Application example ......................................................................................................................... 39

22 Maintenance and calibration ............................................................................................................ 40

23 Warranty ........................................................................................................................................... 40

24 Technical assistance and customer service ........................................................................................ 40

24.1 Module information .......................................................................................................................................................... 40

24.2 Technical assistance........................................................................................................................................................... 40

24.3 Customer service ............................................................................................................................................................... 40

25 Accessories ....................................................................................................................................... 40

Appendix A: Technical data ........................................................................................................................ 41

Wilcoxon Sensing Technologies

an Amphenol Company

Germantown, MD 20876 USA Page 4 of 59

Page 5

Tel: +1 (301) 330-8811

Tel: +1 800 WILCOXON

Fax: +1 (301) 330-8873

www.wilcoxon.com

91457 Rev. C

Appendix B: Modbus (iT301) ..................................................................................................................... 44

Overview ......................................................................................................................................................................................... 44

Modbus-TCP ............................................................................................................................................................................... 44

RS485 serial interface modes .................................................................................................................................................... 44

RTU mode .............................................................................................................................................................................. 44

ASCII mode ............................................................................................................................................................................. 45

RS485 serial data bus ..................................................................................................................................................................... 45

RS485 connections ..................................................................................................................................................................... 45

Activating the RS485 termination resistor ................................................................................................................................ 46

Line Polarization ......................................................................................................................................................................... 47

RS485 serial interface configuration .............................................................................................................................................. 47

Slave address .............................................................................................................................................................................. 47

RTU/ASC II format ...................................................................................................................................................................... 47

Baud rate .................................................................................................................................................................................... 47

Parity ........................................................................................................................................................................................... 47

Stop bits ...................................................................................................................................................................................... 48

Object types .................................................................................................................................................................................... 48

Discrete Inputs ........................................................................................................................................................................... 48

Input Registers ............................................................................................................................................................................ 48

Holding Registers ........................................................................................................................................................................ 48

Function Codes ............................................................................................................................................................................... 48

02 - Read input status ................................................................................................................................................................ 48

03 - Read holding registers ........................................................................................................................................................ 48

04 - Read input registers ............................................................................................................................................................ 48

Data types ....................................................................................................................................................................................... 49

Boolean ....................................................................................................................................................................................... 49

Binary .......................................................................................................................................................................................... 49

Bitwise ........................................................................................................................................................................................ 49

ASCII ............................................................................................................................................................................................ 49

Floating point ............................................................................................................................................................................. 49

Byte ordering .................................................................................................................................................................................. 49

Examples – reading Modbus registers........................................................................................................................................... 50

Reading a discrete input ............................................................................................................................................................ 50

Reading discrete inputs.............................................................................................................................................................. 51

Reading input registers .............................................................................................................................................................. 51

Reading holding registers .......................................................................................................................................................... 52

Reading holding registers .......................................................................................................................................................... 52

Reading the module IP address ................................................................................................................................................. 53

Reading the module IP address via Modbus-TCP ..................................................................................................................... 54

RS485 Modbus troubleshooting guide.......................................................................................................................................... 55

Modbus Register tables.................................................................................................................................................................. 56

Discrete Inputs (1X references) - Alerts, Alarms, Status ........................................................................................................... 56

Input Registers (3X references) - Measurement results, module information ....................................................................... 56

Holding Registers (4X references) - User configurable parameters ......................................................................................... 57

Wilcoxon Sensing Technologies

an Amphenol Company

Germantown, MD 20876 USA Page 5 of 59

Page 6

Tel: +1 (301) 330-8811

Tel: +1 800 WILCOXON

Fax: +1 (301) 330-8873

www.wilcoxon.com

91457 Rev. C

Diagrams & Figures

Figure 1 - Major system components .................................................................................................................................................................9

Figure 2 - Basic circuit diagram ..........................................................................................................................................................................9

Figure 3 - Isolation diagram................................................................................................................................................................................9

Figure 4 - IO port and terminal block locations .............................................................................................................................................. 11

Figure 5 - Sensor connections .......................................................................................................................................................................... 12

Figure 6 - 4-20 mA current loop connections .................................................................................................................................................. 13

Figure 7 - Dynamic output connections .......................................................................................................................................................... 13

Figure 8 - Relay connections ............................................................................................................................................................................ 13

Figure 9 - Power supply connections ............................................................................................................................................................... 13

Figure 10 - Maximum input signal swing with 12V BOV................................................................................................................................ 15

Figure 11 - RC coupling circuit ......................................................................................................................................................................... 15

Figure 12 - Stacking modules ........................................................................................................................................................................... 17

Figure 13 - User Interface (1 of 2) .................................................................................................................................................................... 22

Figure 14 - True Peak detector behavior ......................................................................................................................................................... 29

Figure 15 - Effect of Alarm Delay and Hold times on alarm behavior ........................................................................................................... 34

Figure 16 - Application example ...................................................................................................................................................................... 39

Figure 17 - RS485 terminal block connections ................................................................................................................................................ 45

Figure 18 - RS485 TBUS terminal locations ..................................................................................................................................................... 45

Figure 19 - Proper RS485 terminations ........................................................................................................................................................... 46

Figure 20 - RS485 termination DIP switch location ........................................................................................................................................ 46

Figure 21 - Big endian byte ordering ............................................................................................................................................................... 49

Wilcoxon Sensing Technologies

an Amphenol Company

Germantown, MD 20876 USA Page 6 of 59

Page 7

Tel: +1 (301) 330-8811

Tel: +1 800 WILCOXON

Fax: +1 (301) 330-8873

www.wilcoxon.com

91457 Rev. C

1 Introduction

This document contains information on the installation,

configuration and operation of the iT300 Series of Intelligent

Transmitters. The vibration transmitters are designed and

manufactured in the USA by Wilcoxon Sensing Technologies,

Germantown, Maryland.

2 Description

The iT300 Series of configurable transmitter modules perform

acquisition and processing of dynamic vibration signals. The

transmitters are field configurable. Configurable parameters

include: input signal type, measurement bandwidth, detector

type, output type, English or metric measurement units, 4-20

mA driving source and full-scale range. Configuration may be

performed in the field, using a common web browser. No

custom or proprietary software is required. There are no

hardware jumpers to set.

The iT300/301 transmitters accept vibration signals from

piezoelectric (IEPE-type) accelerometers, piezovelocity

transducers (PVT™) and other sensors with comparable electrical

characteristics. They also feature an input for connection to a

Model 786T-type (or compatible) temperature sensor.

The iT300/301 transmitter module conditions, digitizes and

processes the input signal using powerful DSP technology. All

filtering, frequency selection, sub-sampling and power detection

is performed digitally, for consistent, reliable results. Selected

measurement results are then scaled and converted to dual 4-20

mA analog outputs. On iT301 models, measurement results and

operational status are also mapped to Modbus digital outputs.

iT300/301 transmitters are housed in a durable plastic enclosure

with a 35 mm DIN rail mount. The transmitter front panel

features multiple LEDs, a BNC connector for the buffered sensor

output, a “factory restore” push-button switch, and a standard

RJ45 jack for the Ethernet connection. The LEDs provide at-aglance operational status and indicate when power, sensor and

4-20 mA loops are correctly connected to the transmitter and

working properly. Removable, uniquely-keyed terminal blocks

allow for easy wiring and ensure correct terminal block

installation into the various transmitter IO ports.

3 Key features

3.1 General features (all models)

Field configurable via standard web browser

0.2 Hz – 20 kHz signal bandwidth (-3.0 dB, -0.1 dB)

20 V p-p sensor input range, >90 dB dynamic range

DSP signal processing with 1,600-line FFT

Built-in 4.5 mA constant current source for IEPE sensors

Buffered sensor output on the front-panel BNC connector

Buffered, dynamic signal outputs on terminal block

RMS, peak and peak-to-peak detection

Fast, true-peak detector for capturing short transients and

impulses

Dual, 4-20 mA active current loop outputs with diagnostic

test mode

Two configurable frequency bands

Digital acceleration-to-velocity or velocity-to-displacement

conversion, based on sensor type

Selectable English or metric measurement units

6-way isolated (500 VAC) IO ports to prevent ground loops

Wide, 11-32 VDC power supply input with reverse polarity

and transient protection

TBUS power and data buses

ESD and short circuit protection on all ports

Pluggable, individually-keyed terminal blocks with screw

terminals on all ports

Multiple front panel LED status indicators

Front panel factory restore switch

Auto-MDIX 10/100 Ethernet with HTTP web server

Field upgradable firmware

35 mm DIN rail mounting, stackable on TBUS

4-terminal wide (22.5 mm) modular housing

Wide operating temperature range of -40 °C to +70 °C

CE approvals, RoHS compliant

3.2 iT301 advanced features

Configurable alarms

Relay output with NO/NC contacts and test mode

Modbus over RS485

Modbus TCP over Ethernet

Wilcoxon Sensing Technologies

an Amphenol Company

Germantown, MD 20876 USA Page 7 of 59

Page 8

Tel: +1 (301) 330-8811

Tel: +1 800 WILCOXON

Fax: +1 (301) 330-8873

www.wilcoxon.com

91457 Rev. C

4 Abbreviations used in this manual

ASCII American Standard Code for Information Interchange

BOV Bias Output Voltage (DC)

BPS Bits Per Second

DCS Distributed Control System

DHCP Dynamic Host Configuration Protocol

DIN Deutsches Institut für Normung

DSP Digital Signal Processor/Processing

EMC Electromagnetic Compatibility

ESD Electrostatic Discharge

FFT Fast Fourier Transform

HTTP Hypertext Transfer Protocol

IEEE Institute of Electrical and Electronics Engineers

IEPE Integrated Electronics Piezo Electric

IO Input-Output

IPS Inches Per Second

LAN Local Area Network

LED Light Emitting Diode

mA milliamps

ms milliseconds

mV millivolts

MDIX Medium Dependent Interface Crossover

NC Normally closed

NO Normally open

PLC Programmable Logic Controller

RMS Root-mean-square

RoHS Restriction of Hazardous Substances Directive

RTU Remote Terminal Unit

SCADA Supervisory Control and Data Acquisition

SNR Signal-to-Noise-Ratio

UI User Interface

5 Safety Regulations and Installation

Notes

WARNING: This symbol indicates a caution or warning

that, if ignored, could cause damage to the product or connected

equipment.

This symbol indicates a technical tip or advice on operation

that provides helpful information on how to use or configure the

module.

WARNING: Risk of electric shock

During operation, certain parts of this device may carry

hazardous voltages. Disregarding this warning may result in

damage to equipment and/or serious personal injury.

Provide a switch/circuit breaker close to the device, which is

labeled as the disconnect device for this device or the entire

control cabinet.

Provide overcurrent protection (I ≤ 6 A) in the installation.

Disconnect the device from all power sources during

maintenance work and configuration (the device can remain

connected to SELV or PELV circuits).

5.1 Safety summary

Because this product is designed to be used in an industrial

environment, personnel involved with the installation,

operation and maintenance of this instrument should be

familiar with all plant safety requirements before using this

product. Only qualified personnel should perform

installation and service.

The transmitter must not be opened. There are no user

serviceable parts within the product. Do not attempt to

repair or modify the module. Replace the module only with

an equivalent device.

The IP20 ingress protection rating (IEC 60529/EN 60529)

implies the module is intended for installation and use only

in a clean and dry environment. The module must not be

subjected to stresses or thermal conditions which exceed

the specified limits.

The device is not designed for use in atmospheres with a

danger of dust explosions. If dust is present, the module

must be installed within an approved housing, whereby the

surface temperature of the housing must be taken into

consideration.

Use common sense and avoid haste during installation and

operation of this product.

5.2 Declaration of conformity

This product complies with the standards for:

Electrical safety according to EN61010-1

Limits and methods of measurement of radio

disturbance characteristics

Limits for harmonic current emissions

RoHS Directive, 2011/65/EU

Wilcoxon Sensing Technologies

an Amphenol Company

Germantown, MD 20876 USA Page 8 of 59

Page 9

Tel: +1 (301) 330-8811

Tel: +1 800 WILCOXON

Fax: +1 (301) 330-8873

www.wilcoxon.com

91457 Rev. C

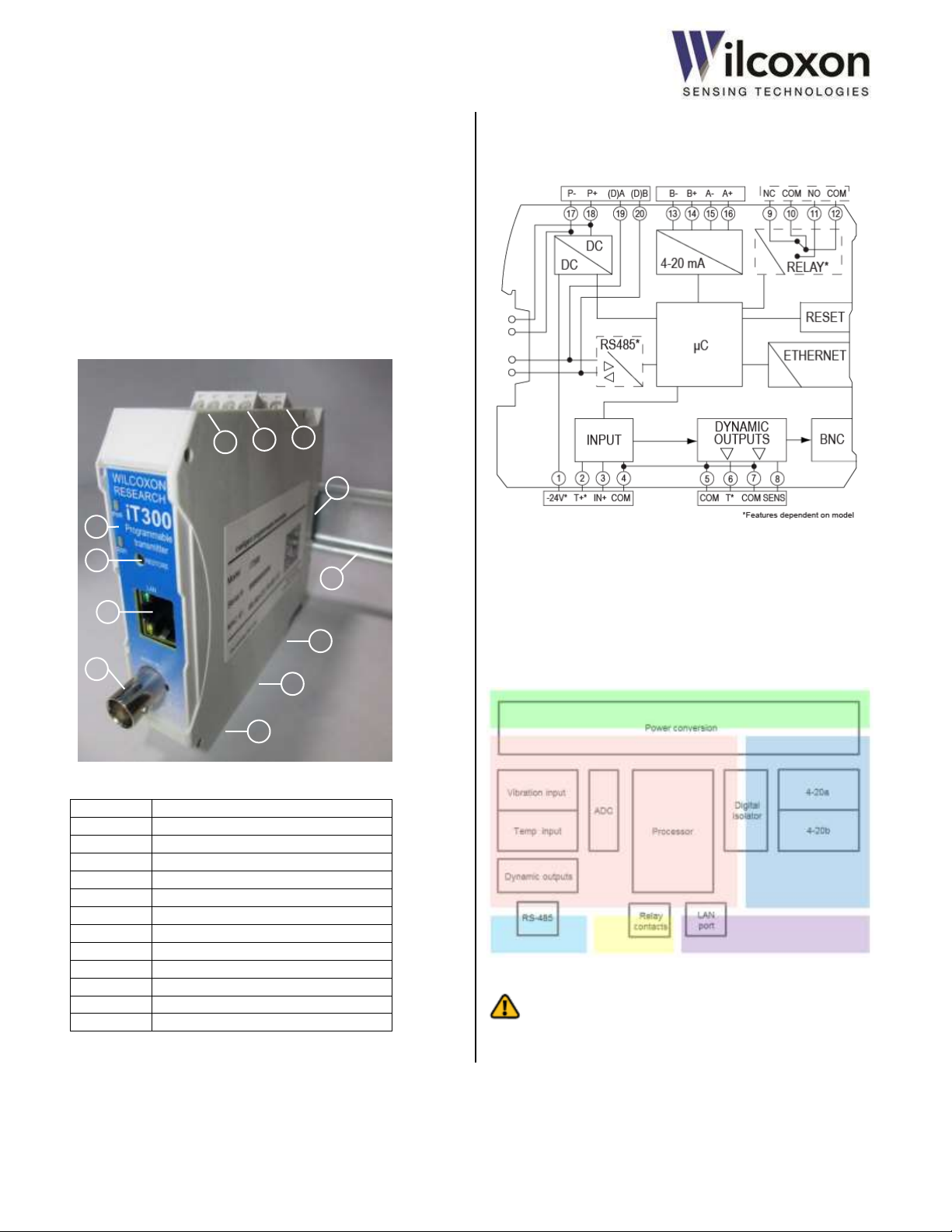

#

Description

1

Sensor/transducer inputs

2

(Empty)

3

Buffered, dynamic outputs

4

Signal relay contacts*

5

4-20 mA current loop outputs

6

Power input / RS485 serial interface*

7

LED indicators

8

Factory restore / alarm clear button

9

Ethernet connection

10

Buffered sensor output BNC connection

11

TBUS card-edge connector

12

DIN rail

8

12 3 4

2

1

7

9

10

11

5

6

6 iT300 family overview

iT300 Base model. Accepts input from IEPE

accelerometers or velocity transducers.

Temperature sensor input.

iT301 Same as iT300, but adds: alarm capability, signal

relay output, Modbus over RS485, Modbus-TCP.

7 System diagrams

7.1 Major system components

Figure 1 - Major system components

7.2 Basic circuit diagram

Shown below are the major functional blocks of the transmitter.

Figure 2 - Basic circuit diagram

7.3 Isolation diagram

The transmitter features 500 VAC functional isolation between

six zones: 1.) power input, 2.) sensor input, 3.) 4-20 mA outputs,

4.) Ethernet-LAN, 5.) RS485, 6.) signal relay. Figure 3 shows the

isolation zones.

*iT301 only

Wilcoxon Sensing Technologies

an Amphenol Company

Germantown, MD 20876 USA Page 9 of 59

Figure 3 - Isolation diagram

CAUTION! Functional or operational isolation is necessary

only for the correct functioning of the product. It does not

protect or isolate against electrical shock.

Page 10

Tel: +1 (301) 330-8811

Tel: +1 800 WILCOXON

Fax: +1 (301) 330-8873

www.wilcoxon.com

91457 Rev. C

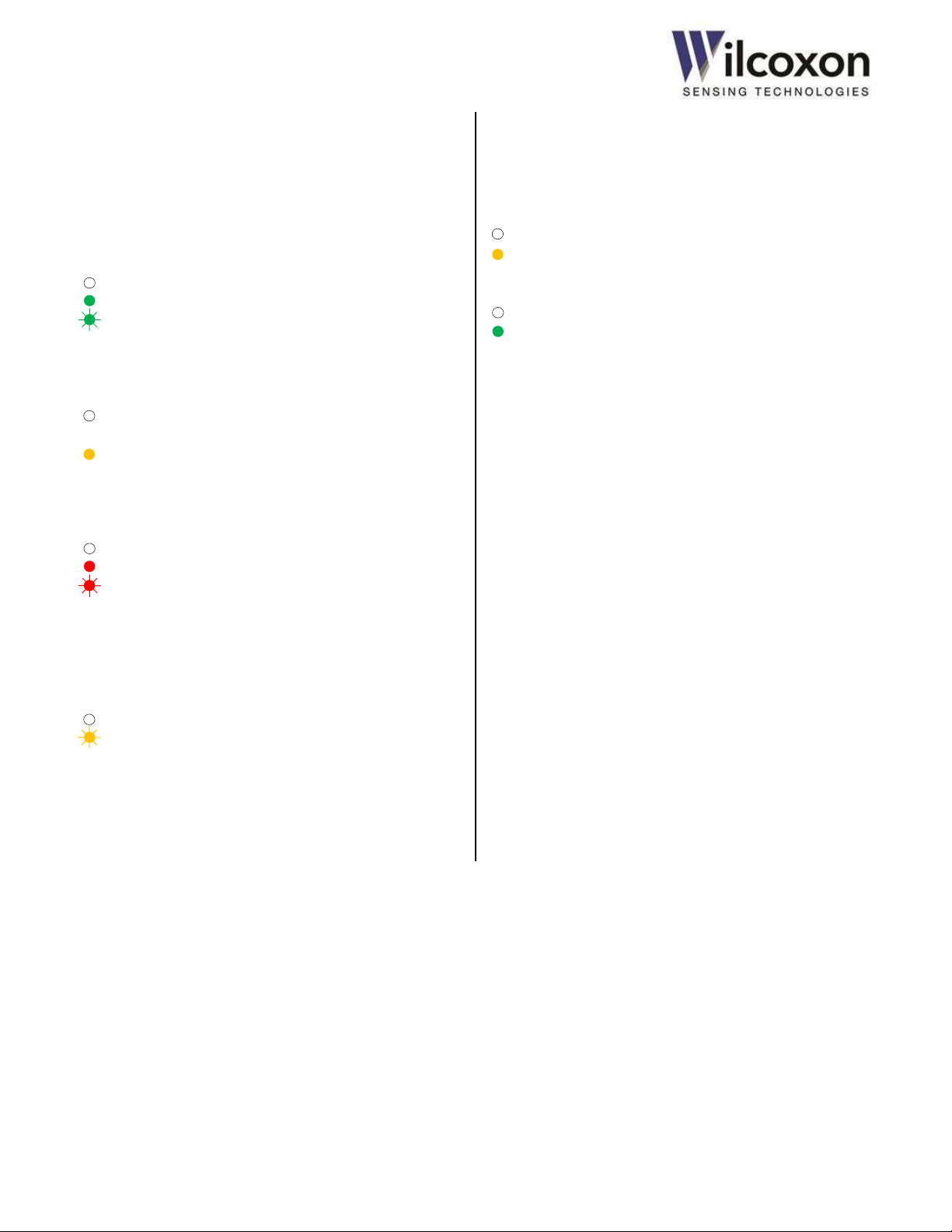

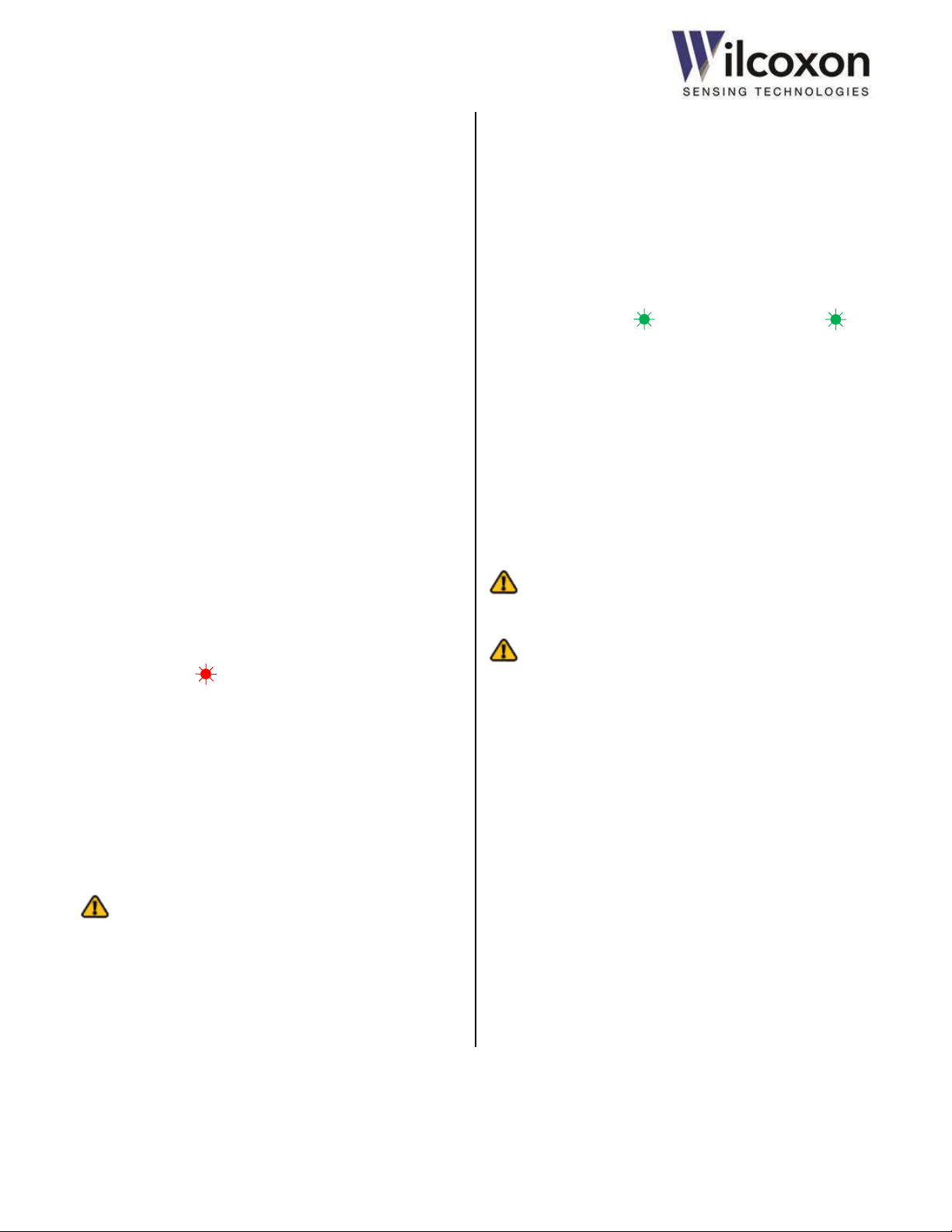

8 Front panel LEDs

8.1 Operating modes

Multiple LEDs, located on the front panel, indicate the module’s

operating modes.

PWR

The green PWR LED indicates power and test mode status.

OFF Unit not powered

ON Normal operating mode

BLINKING One or more test modes active (4-20 mA

loops or signal relay)

RLY (iT301)

The yellow RLY LED indicates the relay status.

OFF Relay not energized

(NO contacts = open, NC contacts = closed)

ON Relay energized

(NO contacts = closed, NC contacts = open)

ERR

The red ERR LED indicates system and connection faults.

OFF No faults – normal operation

ON Sensor fault (priority)

BLINKING 4-20 mA loop fault

See section 20 “Troubleshooting” for information about

correcting fault conditions.

RS485 (iT301)

The yellow RS485 LED indicates RS485 data activity.

OFF Non-matching address/RS485 idle

FLASH RS485 Modbus packet with matching slave

address received

The RS485 LED will flash each time the module receives a

Modbus packet that contains a matching slave address. Data

packets not addressed to the module are ignored and do not

cause LED activity.

Ethernet Status

Green and yellow LEDs, located on the RJ45 jack, provide status

of the Ethernet interface.

Yellow (Link speed)

OFF 10 Mbps

ON 100 Mbps

Green (Link/activity)

OFF No link

ON Link established (blinks with link activity)

Wilcoxon Sensing Technologies

an Amphenol Company

Germantown, MD 20876 USA Page 10 of 59

Page 11

Tel: +1 (301) 330-8811

Tel: +1 800 WILCOXON

Fax: +1 (301) 330-8873

www.wilcoxon.com

91457 Rev. C

IO Port

Terminal numbers and

signal assignments

Vibration sensor

1 – No connection

2 – Temperature sensor in (T+)

3 – Signal in / Sensor Power (IN+)

4 – Circuit Common (COM)

Temperature

dynamic output

5 – Circuit Common (COM)

6 – Temperature out (T)

Sensor dynamic output

7 – Circuit Common (COM)

8 – Sensor out (SENS)

Signal relay*

9 – Normally closed (NC)

10 – Relay common (COM)

11 – Normally open (NO)

12 – Relay common (COM)

4-20 mA Loop B

13 – B14 – B+

4-20 mA Loop A

15 – A16 – A+

Power input

17 – P18 – P+

RS485*

19 – (D)A

20 – (D)B

SENSOR IN

PWR

RLY

ERR

RS485

CLR / RESTORE

DYNAMIC OUT

5 8 6

7

1 4 2

3

12 9 11

10

16

13

15

14

20

17

19

18

SIGNAL RELAY*

CURRENT LOOPS

RS485* / POWER INPUT

WILCOXON

iT301

P+

P-

(D)A*

(D)B*

REAR

FRONT

FRONT

REAR

MIDDLE

TBUS

ETHERNET

MONITOR

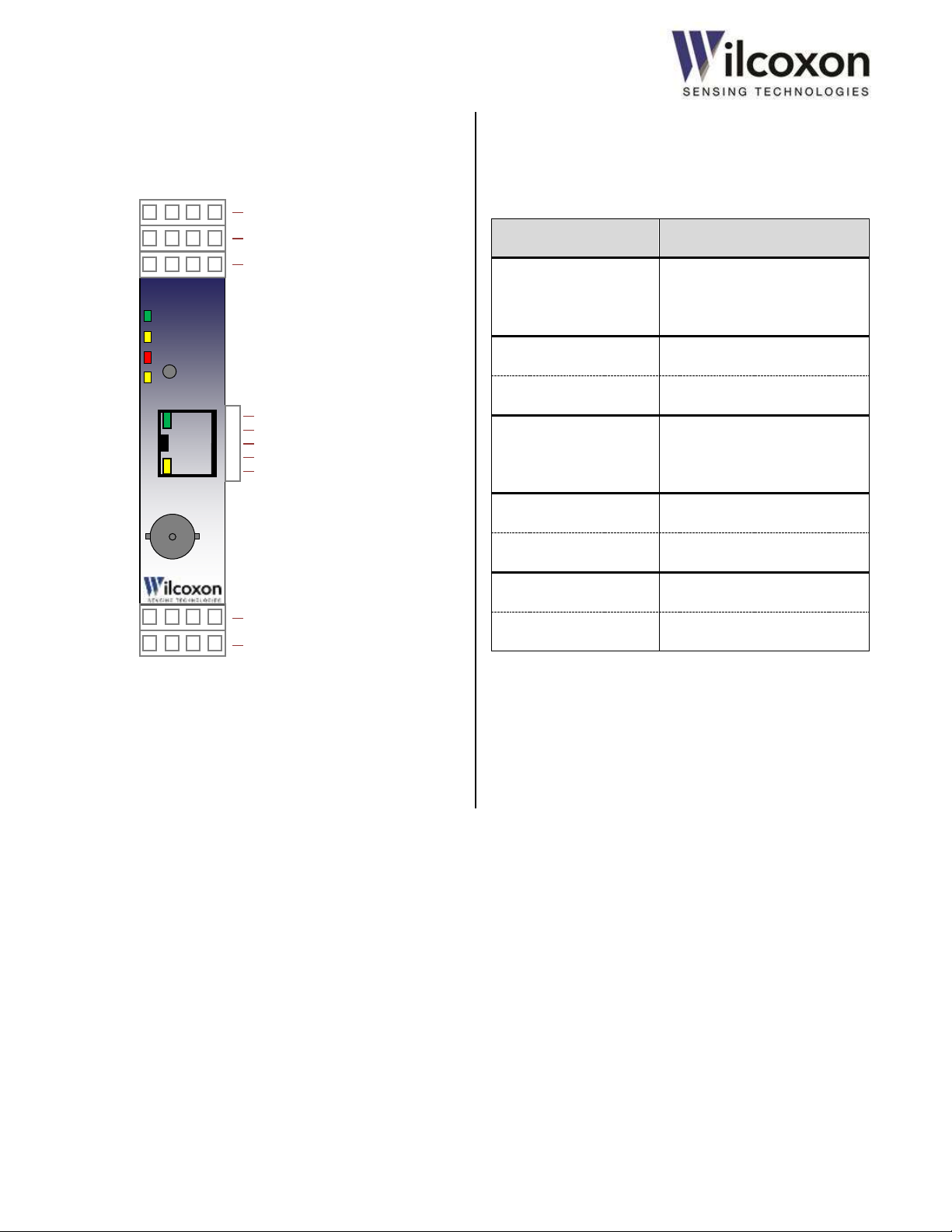

9 IO ports and signal assignments

9.1 Terminal block locations and pin numbers

*iT301 only

Figure 4 - IO port and terminal block locations

9.2 Terminal block pin and signal assignments

* iT301 only

Table 1 - Terminal numbers and signal assignments

Wilcoxon Sensing Technologies

an Amphenol Company

Germantown, MD 20876 USA Page 11 of 59

Page 12

Tel: +1 (301) 330-8811

Tel: +1 800 WILCOXON

Fax: +1 (301) 330-8873

www.wilcoxon.com

91457 Rev. C

Sensor

Signal Out/Power in (A)

Common (B)

Temperature out (C)

iT300/301

(3) Signal in/Sensor power

(4) Common

(2) Temperature in

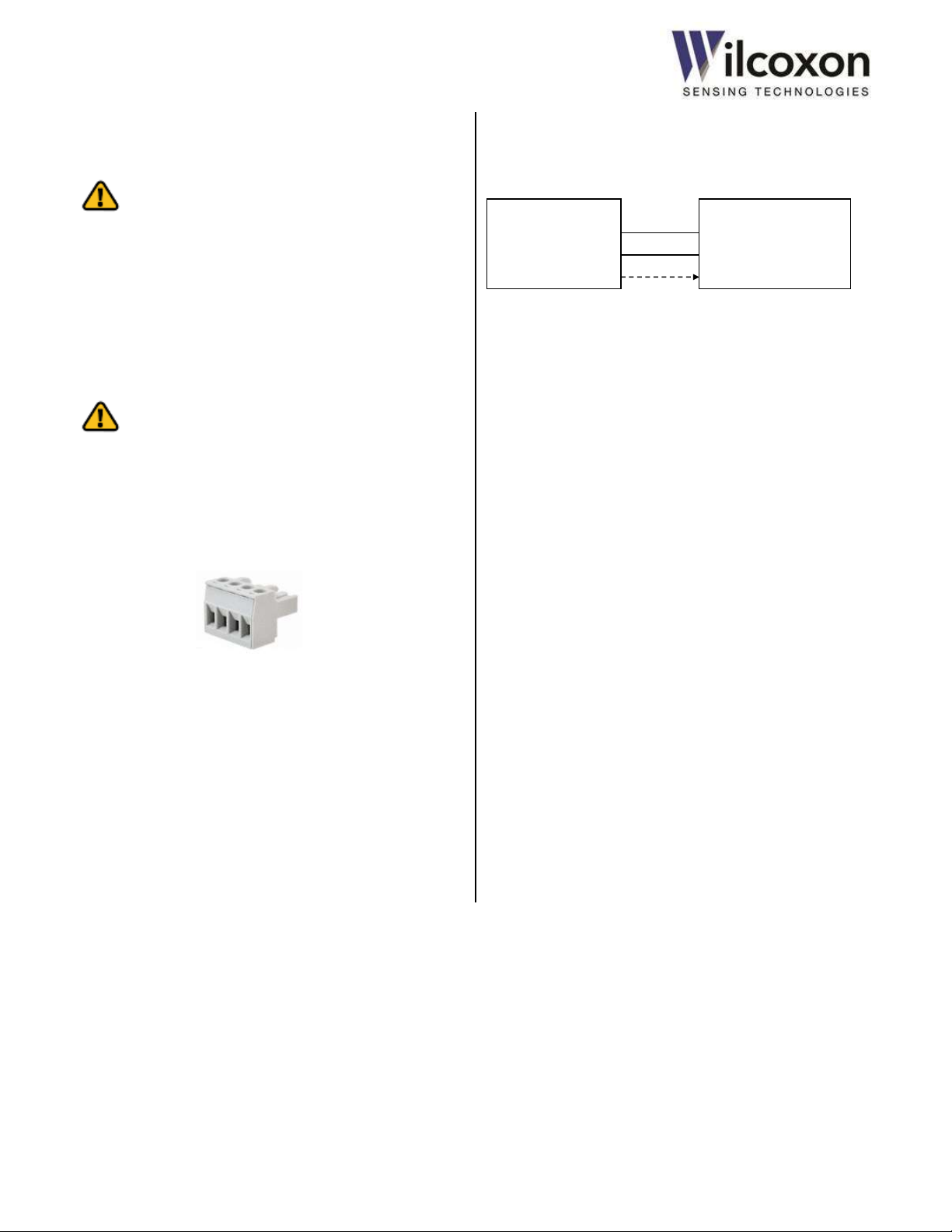

10 Electrical connections and wiring

10.1 ESD precaution

CAUTION! electrostatic discharge

Although the transmitter contains ESD suppression devices on all

IO ports, components still can be damaged or destroyed by large

magnitude electrostatic discharge. When handling the module or

making electrical connections, observe the necessary safety

precautions against ESD according to EN 61340-5-1 and IEC

61340-5-1. This will reduce the possibility of damage caused by

ESD.

10.2 Pluggable terminal blocks

CAUTION! Electrical connections should not be made

with power applied to the module.

All electrical connections to the transmitter are made using

pluggable terminal blocks. The removable terminal blocks have

screw terminals for easy wiring and are uniquely keyed to ensure

correct installation into the various transmitter IO ports.

10.3 Sensor/transducer connections

Connect the IEPE vibration sensor as shown in ”Figure 5 - Sensor

connections”.

Figure 5 - Sensor connections

A 786T accelerometer with a temperature output utilizes the

temperature input on terminal #2. The temperature portion of

the sensor is powered by the accelerometer circuit.

Note: Connection of a temperature sensor is optional.

The terminal blocks accept 12 AWG through 24 AWG size wire

(cable cross section: 0.2...2.5 mm²).

To make a connection to a terminal block:

1. Strip wire to 0.25” (6.4 mm)

2. Optionally, install a ferrule onto the wire and crimp securely

3. Insert the wire into the terminal block

4. Use a flat-blade screwdriver to tighten the screw to a torque

of 0.6 Nm (2.1 oz/in)

Wilcoxon Sensing Technologies

an Amphenol Company

Germantown, MD 20876 USA Page 12 of 59

Page 13

Tel: +1 (301) 330-8811

Tel: +1 800 WILCOXON

Fax: +1 (301) 330-8873

www.wilcoxon.com

91457 Rev. C

iT300/301

(16) LOOP A OUT+

(15) LOOP A OUT−

(14) LOOP B OUT+

(13) LOOP B OUT−

PLC, DCS, etc

(9) NC

(10) COM

(11) NO

(12) COM

Monitoring Equipment

(8) SENS OUT

(7) COM

(6) TEMP OUT

(5) COM

Monitoring Equipment

Power Supply

24 VDC+

COM

iT300/301

(18) P+

(17) P−

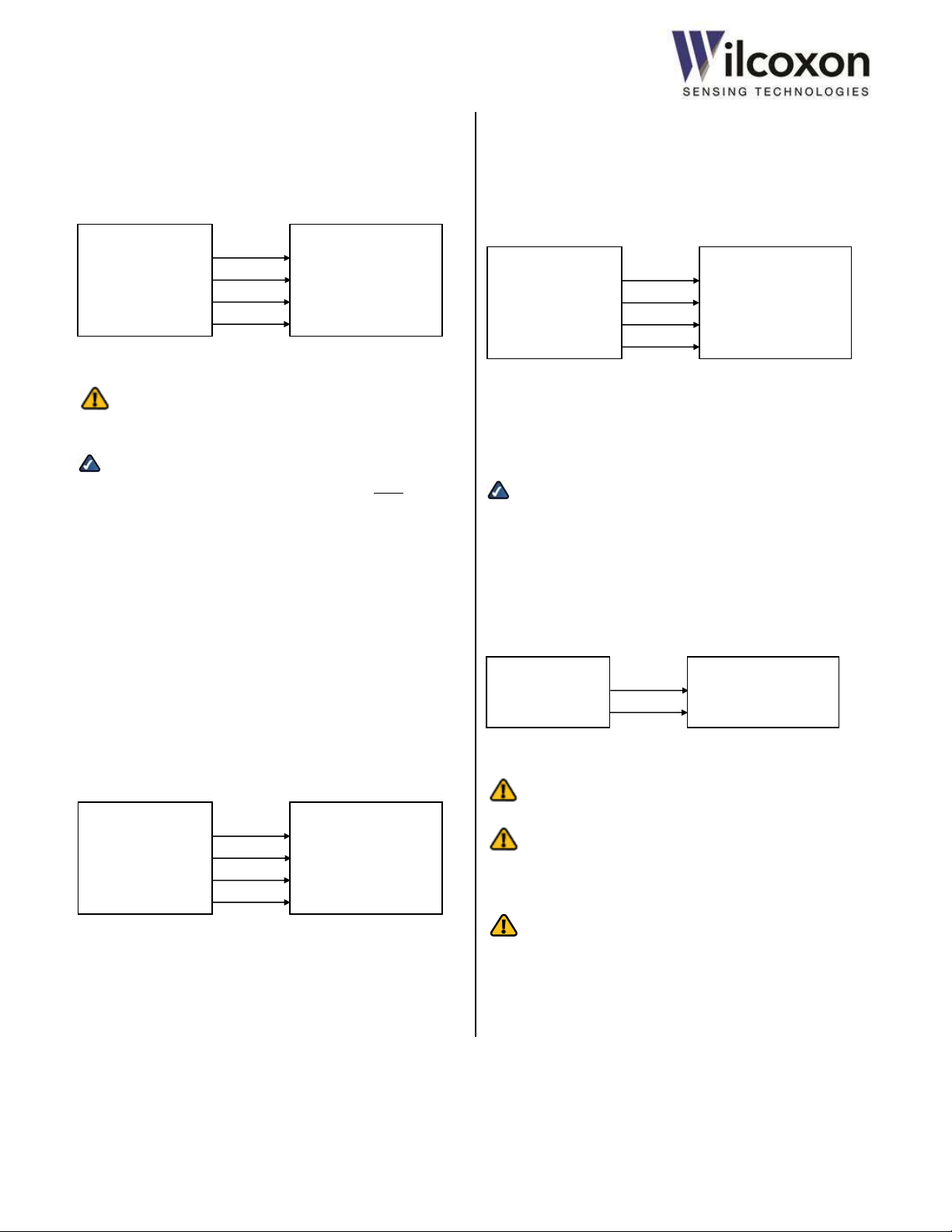

10.4 4-20 mA current loop connections

Route the Loop A and Loop B 4-20 mA outputs to a compatible

monitoring system as shown, being careful to use a properly

sized load resistor. The transmitter sources the voltage and

current for both loops.

Figure 6 - 4-20 mA current loop connections

Caution: The 4-20 mA outputs will not work with

externally powered loops.

Tech tip! If a 4−20 mA output is not required by the

application or is to remain unconnected, the loop must be

disabled, via the UI, to prevent a current loop fault from being

indicated by the transmitter. By default, Loop A is enabled and

Loop B is disabled. See section 18.7, “4-20 mA current loops” for

information on how to configure the current loop outputs.

10.5 Dynamic output connections

A buffered, unfiltered version of the AC vibration sensor signal,

riding on the BOV, is available as a terminal block output. This

output is in parallel with the front-panel BNC connector.

A buffered and low-pass-filtered version of temperature sensor

signal is also available as a terminal block output.

All dynamic outputs are short circuit protected and have a 50 Ω

output impedance.

iT300/301

Figure 7 - Dynamic output connections

10.6 Signal relay connections (iT301)

A mechanical relay provides both normally open (NO) and

normally closed (NC) contacts on a single terminal block.

The contacts can be wired to the monitoring equipment, as

required by the application. The operation of the relay is

configured via the UI.

iT301

Figure 8 - Relay connections

The relay contacts are rated 30 volts DC, 2A and are electrically

isolated from all other internal circuits.

Tech tip! The relay “COM” terminals are simply the center

pole of the relay contacts. They are not connected to any other

circuit “common.”

10.7 Power supply input connections

Connect a 24-volt DC (11 – 32 volts, allowable) power source to

the power input terminals, as shown. Optionally, the module

may be powered via the TBUS.

Figure 9 - Power supply connections

WARNING: The supply voltage must not exceed 33 volts or

damage to the module may occur.

WARNING: The maximum current handling capacity of the

power supply input terminals is 4 amps. When using these

terminals to supply power to the TBUS, do not exceed the 4-amp

rating.

WARNING: The iT300 TBUS is NOT compatible with older

Wilcoxon Research iT100/200, iT401 or iT501 series modules.

When connecting modules via the TBUS, connect only iT300

series modules together on the same bus. Do not connect any

other types of modules or devices to an iT300 TBUS. Doing so

may result in damage to the modules.

Wilcoxon Sensing Technologies

an Amphenol Company

Germantown, MD 20876 USA Page 13 of 59

Page 14

Tel: +1 (301) 330-8811

Tel: +1 800 WILCOXON

Fax: +1 (301) 330-8873

www.wilcoxon.com

91457 Rev. C

10.8 Cable shielding and earth ground connections

Shielding and proper earth grounding are important for the

mitigation of interference and proper operation of the

transmitter. A good shield connection prevents egress of

transmitted signals and ingress of interfering sources. Faulty

shield connections, along with the presence of external sources

of interference, can adversely affect signal integrity. Ensure all

cable shields are properly terminated and connected correctly, as

required by the application.

There is no “shield” or earth ground connection on the

transmitter module. Cable shields should be properly connected

to protective earth (PE) ground external to the transmitter, as

called for by the application. For best electrical performance,

cable shields should be terminated as close as possible to the

transmitter.

Wilcoxon provides enclosures with integrated grounding bus

bars that are located in proximity with the DIN rail. The bus bar

should be connected to a central earthing point using short, lowimpedance connections with a large surface area.

To facilitate connecting cable shields to earth ground, DIN-mount

shield connection clamps and grounding terminal blocks are

available from Wilcoxon. See section 25, “Accessories” for a

complete list of items to complement the installation and

operation of the transmitter.

The type of shield connection should be determined by the

expected operating environment:

Connecting the shield at only one equipment end works to

suppress interference caused by electrical fields.

Connecting the shield at both equipment ends works to

suppress interference caused by dynamic magnetic

fields. When connecting the shield at both ends, the

possibility of ground loops must be considered; galvanic

disturbances along the reference potential can interfere

with the signal, thereby reducing the effectiveness of the

shielding.

11 Power-up

After all wires are connected, power can be applied to the

module. The module begins its power-up sequence immediately

after power is applied. There is no on-off switch.

During power-up, all front-panel LED indicators will illuminate for

three seconds while a self-check is performed. After the unit has

completed its self-check, the green PWR LED will remain on. If

the transmitter passes its self-test and the sensor and primary 420 mA loop are connected correctly, the red ERR LED will be off.

See section 8, “Front panel LEDs” for detailed explanation of

LEDs and unit operating status.

Wilcoxon Sensing Technologies

an Amphenol Company

Germantown, MD 20876 USA Page 14 of 59

Page 15

Tel: +1 (301) 330-8811

Tel: +1 800 WILCOXON

Fax: +1 (301) 330-8873

www.wilcoxon.com

91457 Rev. C

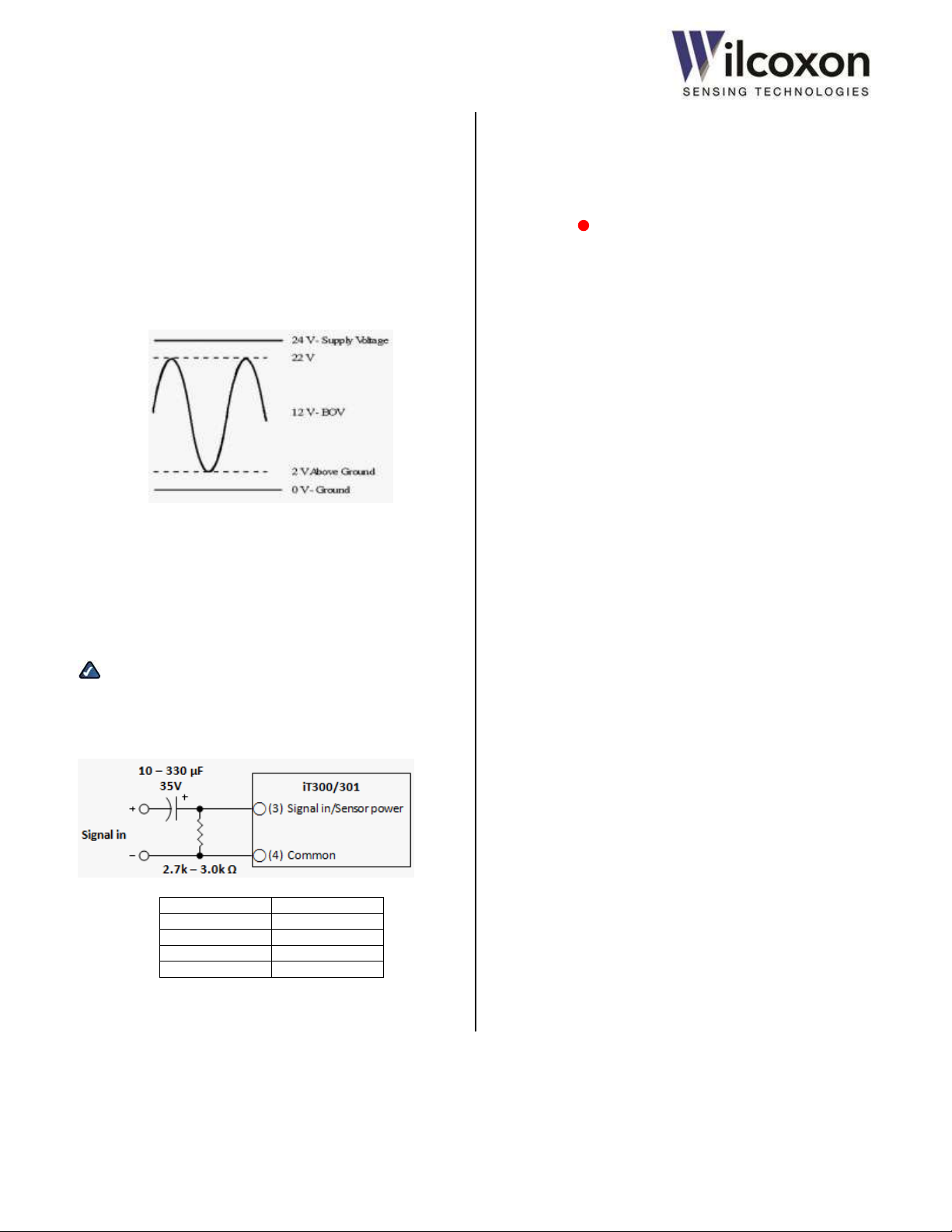

Capacitance

-3dB frequency

10 µF

6 Hz

47 µF

1.2 Hz

100 µF

0.6 Hz

330 µF

0.2 Hz

12 IO ports – detailed description

12.1 Vibration sensor input

The transmitter has been designed to accept signals from

piezoelectric (IEPE-type) accelerometers, velocity transducers

and other compatible sensors that have a BOV of approximately

12 volts. This allows the maximum input signal swing without

clipping. If the BOV deviates significantly from 12 volts, the

maximum allowable input signal swing and dynamic range will

be reduced accordingly. The analog input circuitry is powered by

+24 VDC.

Figure 10 - Maximum input signal swing with 12V BOV

12.1.1 Constant current IEPE power source

12.1.2 BOV acceptable range and sensor fault detection

The module continuously monitors and reports the BOV of the

sensor signal. If the DC level falls outside the acceptable range, a

sensor fault will be indicated. When a sensor fault is detected,

the UI will display “Fault” next to the BOV reading and the front-

panel ERR LED will illuminate. A sensor fault will cause the 4-

20 mA loop current to be set to 2 mA on each enabled loop. A

loop current of less than 4 mA conveys the fault condition to the

4-20 mA monitoring equipment. This complies with NAMUR

NE43.

For the iT300, the acceptable range for the BOV is 5 to 16 volts

and is not user adjustable. For the iT301, the acceptable range

for the sensor BOV can be adjusted via UI.

If a sensor fault is indicated, the sensor BOV should be checked

with an isolated (hand-held) DC voltmeter at the BNC connector

and verified it is within the acceptable range. The BOV is also

displayed on the UI. See section 20, ”Troubleshooting” for more

information on sensor faults.

The built-in current source (IEPE Power) is enabled by default

and supplies a nominal 4.5 mA to the attached sensor. The

current source can be disabled, via the UI, to allow the

connection of an external voltage.

Tech tip! In all cases, the input signal must have a DC bias of

at least +5.5 volts. Signal sources not compliant with this

requirement can use the biasing circuit shown below. If more

information is required, contact Wilcoxon technical support.

Figure 11 - RC coupling circuit

Wilcoxon Sensing Technologies

an Amphenol Company

Germantown, MD 20876 USA Page 15 of 59

Page 16

Tel: +1 (301) 330-8811

Tel: +1 800 WILCOXON

Fax: +1 (301) 330-8873

www.wilcoxon.com

91457 Rev. C

12.2 Temperature sensor input

The transmitter supports a 786T-type (or similar) accelerometer

with temperature sensor with a sensitivity of 10 mV/°C. The

input range for the temperature signal is 0 VDC to +1.2 VDC.

Before being passed to the processing circuitry and dynamic

output terminals, the temperature input signal is low-pass

filtered to remove noise and high frequency content.

Connection of a temperature sensor is optional. If a temperature

sensor is not connected, the transmitter will read a temperature

of approximately 0 °C (32 °F).

12.3 4-20 mA current loop outputs

The transmitter provides two analog, 4-20 mA current loop

outputs. The outputs are usually wired to a Programmable Logic

Controller (PLC) or a Distributed Control System (DCS). The loop

current is proportional to the measurement result that is

mapped as the loop driving source. Measurement results

(process variables) are mapped to the current loops via the UI.

Both current loop outputs are “active.” That is, the outputs

source the voltage and current for the loops and are designed to

be connected to a passive, resistive load. The total loop

resistance, including the load resistor, should not exceed 500 Ω.

If the loop resistance is too high or if an output is unconnected, a

loop fault will be detected by the module. When a loop fault is

detected, “Fault” will be displayed in the Level (mA) field on the

UI and the ERR LED on the front panel will blink. If a loop is

not needed in the application or is to remain unconnected, it

should be disabled via the UI. Disabling the loop will set the

current to 0 mA and prevent a loop fault from being indicated.

By default, the primary loop (Loop A) is enabled and the

secondary loop (Loop B) is disabled. These settings may be

changed via the UI.

Loop compliance voltage is 15 volts, ±5%. The current loop

outputs are electrically isolated from all other internal circuitry

and are protected from short circuits.

Caution: The 4-20 mA outputs will not work with

externally powered loops.

12.3.1 Loop error state when sensor fault detected

The transmitter complies with Namur NE43 recommendations

for indicating a sensor fault to a control system by means of the

4-20 mA signal. If the transmitter detects a fault with the

vibration sensor input, the current in the enabled loops will be

set to 2 mA. This conveys the condition of a sensor fault to the 420 mA monitoring equipment. See section 12.1.2, “BOV

acceptable range and sensor fault detection”.

12.3.2 Loop force mode (test mode)

A loop test function is provided to allow loop current to be

forced to any value between zero and 20 mA. This feature

permits testing of the loops and receiving equipment using

various, user-defined currents. When either loop is placed in test

mode, a green indicator on the UI and the PWR LED on

the front panel will both blink. Test mode is controlled via the UI.

See section 18.7.5 for details.

12.4 Power supply input

A 24-volt DC power source is normally used to power the

transmitter. To provide greater installation flexibility, the power

source voltage may range from 11 volts to 32 volts DC. This

allows the use of power supplies with outputs other than 24

volts. The power inputs are protected from a reverse polarity

condition and are electrically isolated from all other internal

circuitry.

WARNING: The power supply voltage must not exceed 33

volts or damage to the module may occur.

WARNING: The maximum current handling capacity of the

power supply input terminals is 4 amps. When using these

terminals to supply power to the TBUS, do not exceed the 4-amp

rating.

12.5 BNC dynamic signal output

A buffered sensor output is available on the front-panel BNC

connector. This allows live, on-line signal analysis and testing of

the sensor. This analog output is a buffered version of the raw,

unfiltered sensor signal allowing full spectrum analysis.

The BNC output is short circuit protected and has an output

impedance of 50 Ω.

Note: When connecting a portable data collector or online

monitoring system to the dynamic outputs the external meter’s

internal constant current source, if so equipped, should be

turned off. Failure to do so may result in a corrupted waveform.

Wilcoxon Sensing Technologies

an Amphenol Company

Germantown, MD 20876 USA Page 16 of 59

Page 17

Tel: +1 (301) 330-8811

Tel: +1 800 WILCOXON

Fax: +1 (301) 330-8873

www.wilcoxon.com

91457 Rev. C

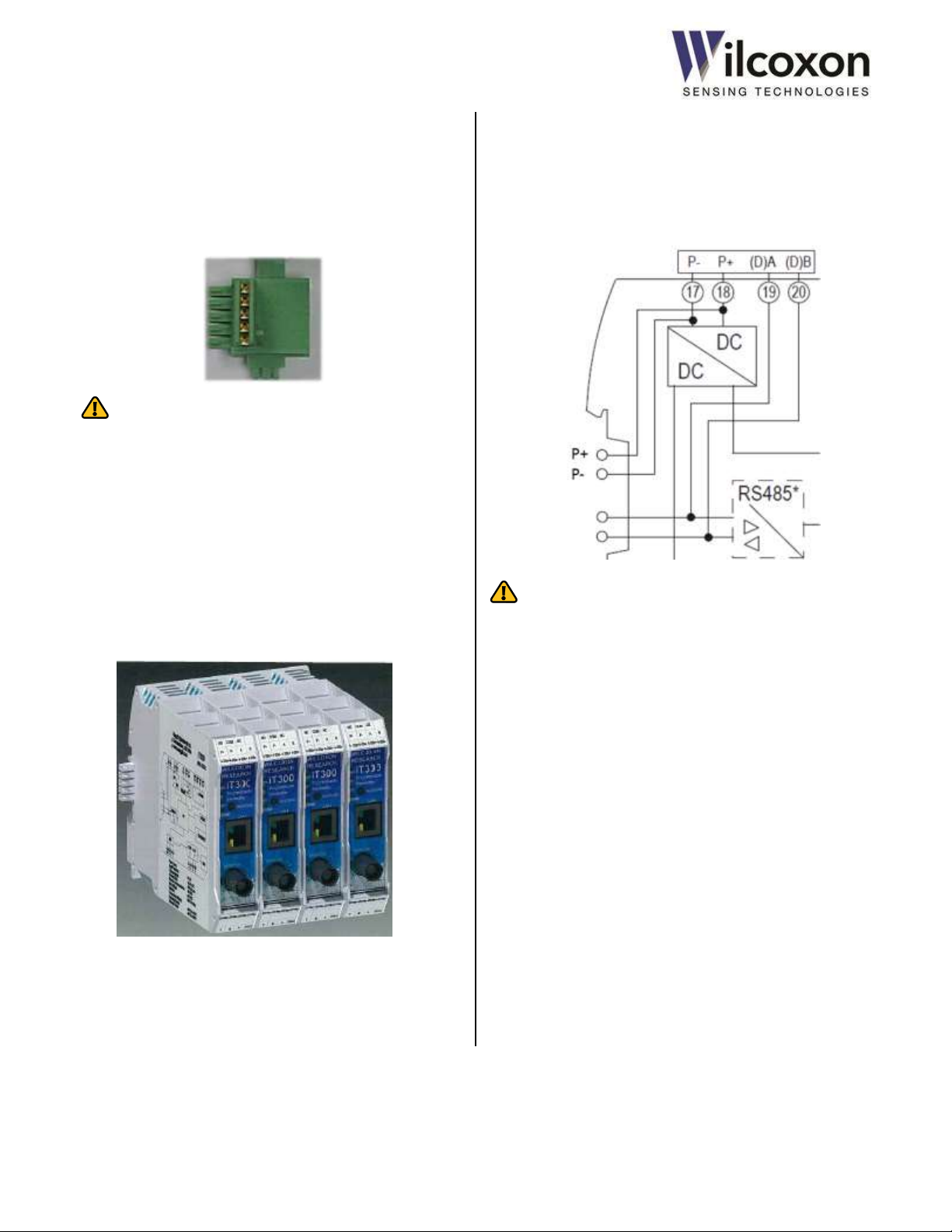

13 TBUS

The TBUS allows multiple modules to be interconnected without

the need for external wiring. Connection to the TBUS is made via

a recessed board-edge connector, located on the rear of the

module, and a IT032 connector. The board-edge fingers plug

directly into the connector.

WARNING: The iT300 TBUS is NOT compatible with older

iT100/200, iT401 or iT501 series modules. When connecting

modules via the TBUS, connect only iT300 series modules

together on the same bus. Do not connect any other types of

modules or devices to an iT300 TBUS. Doing so may result in

damage to the modules.

13.1 Stacking modules

Multiple modules can be connected together through the TBUS.

This allows power to be supplied to all modules on the bus. For

iT301 models, the RS485 serial interface is also available on the

TBUS.

Figure 12 - Stacking modules

13.2 Powering via the TBUS

Power can be bused to all modules via shared P+ and P- supply

rails on the TBUS card-edge connector. This allows one module

to supply power to other modules on the bus. The location of

the terminal is shown below. The positive TBUS terminal (P+) is

nearest the power input terminal block.

WARNING: The maximum current handling capacity of the

power supply input terminals is 4 amps. When using these

terminals to supply power to the TBUS, ensure the 4 amp rating

is not exceeded.

14 DIN rail assembly and removal

14.1 Requirements for installation

To protect the module from harsh conditions, it is recommended

to install the unit in a suitable enclosure (NEMA 4 type, or

equivalent) with the appropriate degree of environmental

protection. In all cases, the enclosure must meet the

requirements of the installation.

14.2 DIN rail mounting

The iT300 Series of modules are designed to mount to a

standard 35 mm DIN rail. The rear of the module has a springloaded metal foot catch that holds the module securely in place.

The module is installed onto the rail by simply snapping it into

place.

Each module is 22.5 mm wide and therefore occupies 22.5 mm

of DIN rail space.

Wilcoxon Sensing Technologies

an Amphenol Company

Germantown, MD 20876 USA Page 17 of 59

Page 18

Tel: +1 (301) 330-8811

Tel: +1 800 WILCOXON

Fax: +1 (301) 330-8873

www.wilcoxon.com

91457 Rev. C

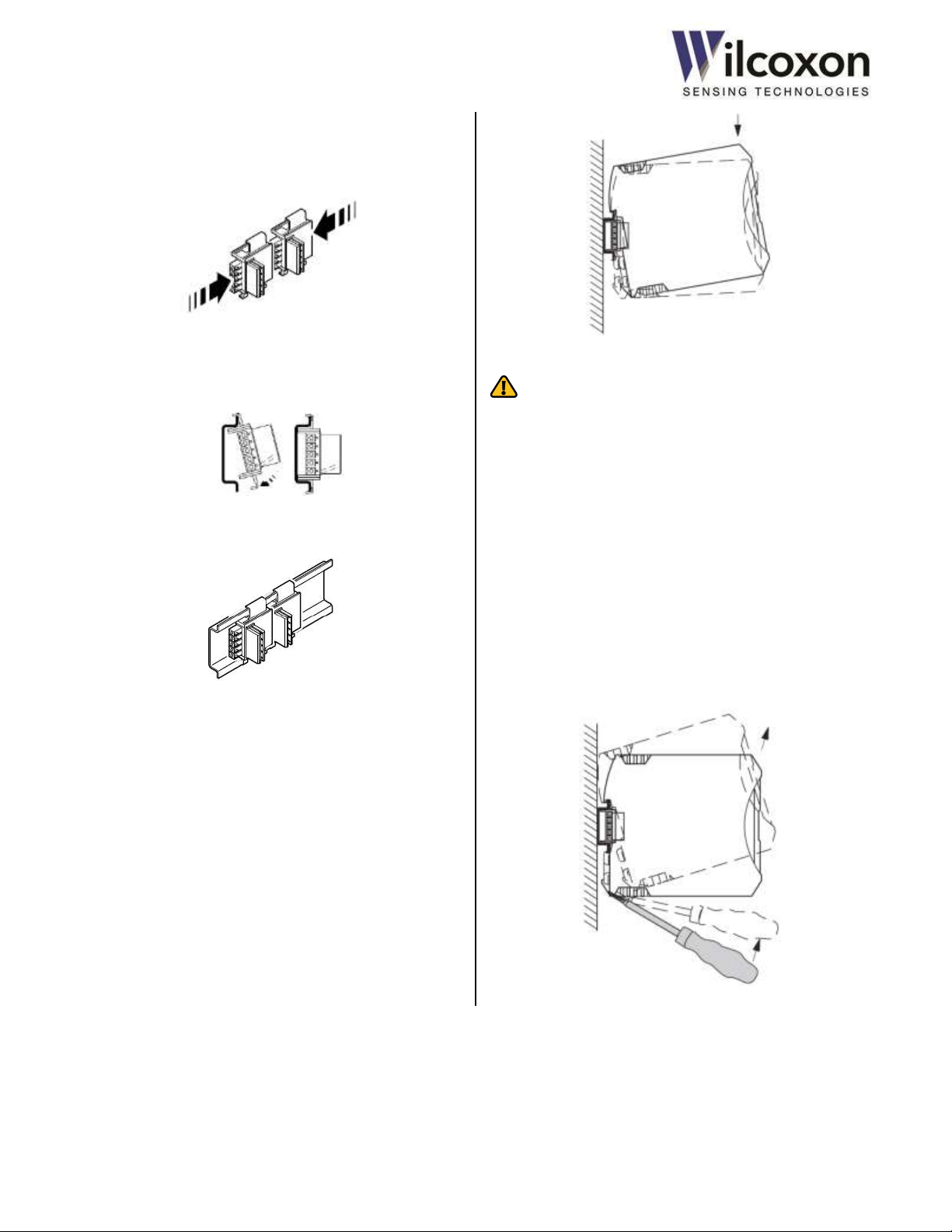

14.3 Preparing the DIN rail TBUS connectors

Connect the required number of connectors by pushing them

together, as shown.

Attach the connectors to the DIN rail by hooking the latch of the

connectors over the top of the rail and then snapping the

bottom of the connectors onto the rail.

The completed connector assembly on the rail.

14.4 Installing the module onto the DIN rail

With the module tilted up, as shown, hook the top lip of the

module onto the top of the rail while carefully aligning the DIN

rail connector with the card edge slot on the rear of the module.

Gently push the module downward and toward the rail. Firmly

seat the module so the DIN TBUS connector fully engages the

module card edge connector. The metal foot catch should

audibly snap onto the rail. The module is now mechanically

secured to the rail.

WARNING: The iT300 TBUS is NOT compatible with older

iT100/200, iT401 and iT501 series modules. When connecting

modules via the TBUS, connect only iT300 series modules

together on the same bus. Do not connect any other types of

modules or devices to an iT300 TBUS. Doing so may result in

damage to the modules.

14.5 Removing the module from the DIN rail

Locate the metal foot catch on the bottom rear of the module.

The catch is spring loaded. To remove the module from the rail,

insert a small, flat-blade screwdriver or other suitable tool into

the foot catch slot. (The blade must be less than ¼ inch (6 mm)

in width to fit into the slot on the latch.) Using the screwdriver as

a lever, gently push the screwdriver upward, as shown, to release

the locking mechanism. With the catch released, tilt the module

upward and remove it from the rail and connector.

Wilcoxon Sensing Technologies

an Amphenol Company

Germantown, MD 20876 USA Page 18 of 59

Page 19

Tel: +1 (301) 330-8811

Tel: +1 800 WILCOXON

Fax: +1 (301) 330-8873

www.wilcoxon.com

91457 Rev. C

15 HTTP web server

The transmitter is field-configurable via a built-in HTTP web

server. The server features an intuitive, easy-to-use, one-page

interface that can be accessed with any modern web browser.

No custom or proprietary software is required.

15.1 10/100 Ethernet

Connection to a 10/100 Ethernet device or network is made via a

standard RJ45 connector located on the front panel of the unit.

To eliminate cabling complications, the Ethernet transceiver

utilizes an Auto-MDIX function to detect the type of cable being

used (straight-through or crossover). The transceiver will

automatically swap the transmit and receive pairs, as necessary,

to ensure the proper transmission and reception of data in

accordance with IEEE 802.3 auto-negotiation and crossover

specifications.

The transmitter supports four different Ethernet protocols: 10

Mb/s Half Duplex, 10 Mb/s Full Duplex, 100 Mb/s Half Duplex,

and 100 Mb/s Full Duplex. The transceiver is configured for

Auto-Negotiation. The Auto-Negotiation function provides a

mechanism for exchanging configuration information between

two ends of a link segment to automatically select the highest

performance mode of operation supported by both devices. It

ensures that the highest performance protocol will be selected

based on the advertised ability of the Link Partner (the Ethernet

device connected to the transmitter).

If the Link Partner does not support Auto-Negotiation or it has

been administratively disabled, the transmitter still can

determine and match speed with the Link Partner. However, the

presence of full duplex cannot be detected, so the transmitter

will default to half duplex. In this case, the Link Partner should

also be configured for half duplex operation.

For optimum performance, the Link Partner should have AutoNegotiation enabled.

For further details regarding Auto-Negotiation, refer to Clause 28

of the IEEE 802.3u specification.

15.2 Browser support

The following browsers are supported and have been verified

compatible with the web server:

Mozilla Firefox

Microsoft Internet Explorer

Google Chrome

The most recent version of each browser, at time of firmware

release, has been tested. As newer firmware revisions are

released, additional browser support may be added. Visit

www.wilcoxon.com for the latest firmware revision and

downloads.

CAUTION! Proper functionality and operability cannot be

guaranteed with older versions of the supported browsers or

browsers not listed.

15.3 Establishing a network connection (PC, Laptop)

iT300 series modules support the Internet Protocol version 4

(IPv4) network addressing architecture. The default IPv4

network settings are as follows:

IP address 192.168.0.100

Subnet mask 255.255.255.0

Default gateway 192.168.0.1

Only static IP addressing is permitted. The module does not

support DHCP.

To establish a connection between the iT300/301 and a

standalone PC or laptop computer, the computer’s network

settings will, most likely, need to be adjusted. The IPv4

connection must be configured by disabling DHCP (if enabled)

and manually entering the IP address and subnet mask. This is

because the PC must belong to the same subnet as the

iT300/301 and have the same network prefix. The prefix

occupies the most-significant bits of the address. In this case,

the prefix is 192.168.0.

If the networking settings are not correct, communication with

the transmitter will not be possible. An example of how to

configure the network settings on a PC running the Windows

operating system is presented in the next section.

Wilcoxon Sensing Technologies

an Amphenol Company

Germantown, MD 20876 USA Page 19 of 59

Page 20

Tel: +1 (301) 330-8811

Tel: +1 800 WILCOXON

Fax: +1 (301) 330-8873

www.wilcoxon.com

91457 Rev. C

15.3.1 Adjusting network adapter settings

In the following example, we will adjust a PC’s network adapter

settings to be compatible with the iT300/301. The operating

system is Windows 7. The procedure will differ for other

operating systems. Consult a network administrator if you are

unsure about making changes to network settings.

To adjust the network adapter settings:

Open the Control Panel and access the Network and Sharing

Center. Then click on Change Adapter Settings:

If more than one network adapter or LAN connection is

available, choose the desired connection which to modify. In this

example, we will modify Local Area Connection 2:

After selecting the desired network connection to modify, click

Properties:

Select Internet Protocol Version 4 (TCP/IPv4) and then click

Properties.

Wilcoxon Sensing Technologies

an Amphenol Company

Germantown, MD 20876 USA Page 20 of 59

Page 21

Tel: +1 (301) 330-8811

Tel: +1 800 WILCOXON

Fax: +1 (301) 330-8873

www.wilcoxon.com

91457 Rev. C

Select “Use the following IP address:”

Change the IP address to 192.168.0.1.

Change the Subnet mask to 255.255.255.0.

The Default gateway field should be left blank.

NOTE: Enabling ‘Use the following IP address’ will disable your

PC from communicating with other networks.

Save the changes by clicking “OK.”

15.4 Establishing a network connection

The transmitter also may be accessed via a LAN or other

network. If the module is intended to be connected to a

network, consult the network administrator to obtain

information regarding the proper network settings.

15.5 Accessing the web server

16 User Interface (UI)

16.1 Overview

The transmitter is field-configurable via the built-in web server

and User Interface (UI). The UI allows configuration to be

performed in the field or from a remote location, using any

common web browser.

16.2 Layout

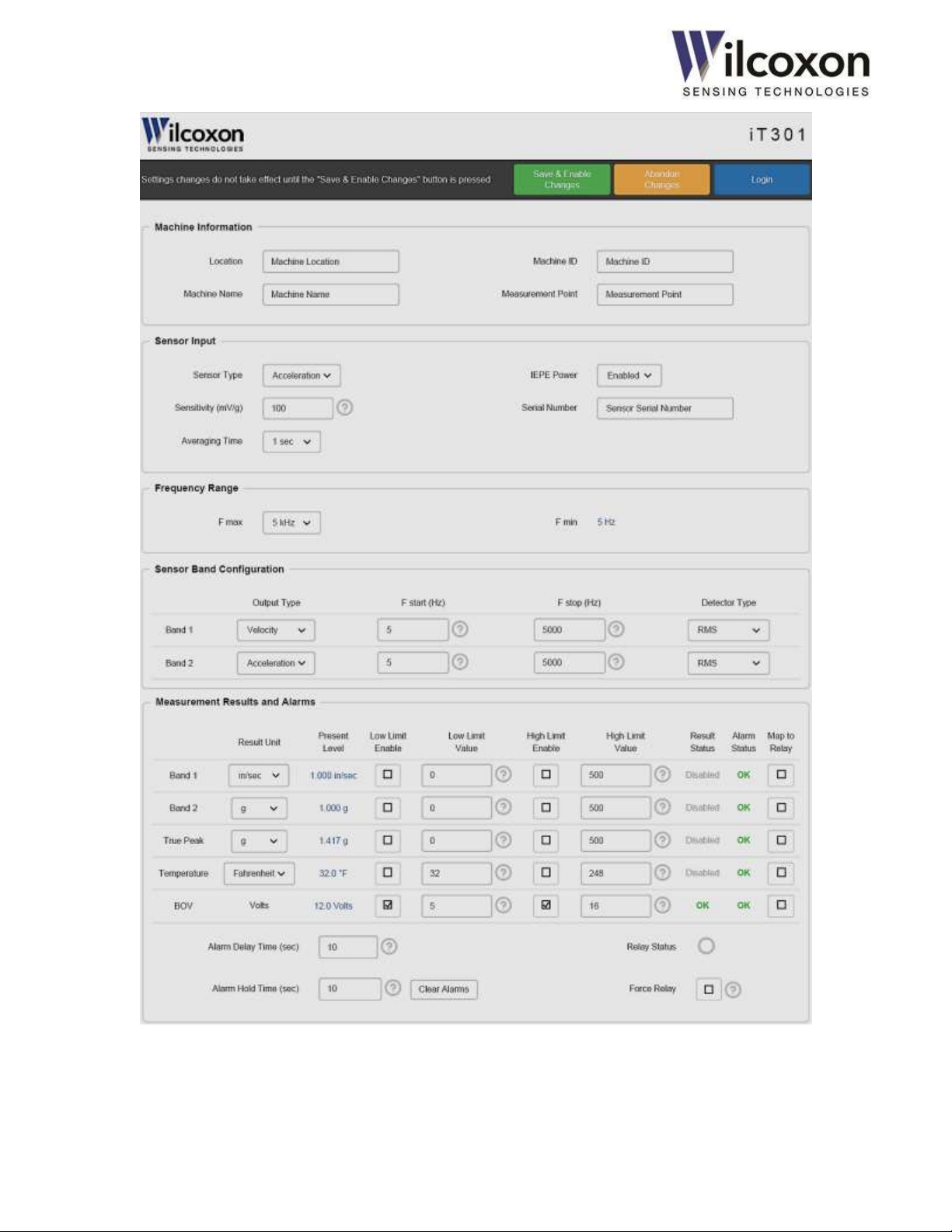

For simplicity and ease-of-use, the UI consists of a single web

page. The layout of the page positions the various fields in an

intuitive, logical order. Configurable parameters are grouped into

nine sections:

1. Machine Information

2. Sensor Input Configuration

3. Frequency Range

4. Band Configuration

5. Measurement Results and Alarms

6. 4-20 mA Loops

7. Network Configuration

8. Modbus/RS485

9. User-action Controls.

In addition to allowing configuration of the transmitter, the UI

also displays all measurement results and current status in real

time.

16.3 Sample UI

A representative sample of the iT301 User Interface is shown in

Figure 13. Actual page layout will vary by model.

After ensuring the network settings of the Link Partner are

correct, a connection to the web server can be established.

To access the web server, launch the web browser on your

computer and enter the module’s IP address

(default is 192.168.0.100) in the Address field. Then, press Enter.