Page 1

hand-held optical fiber identifier

Operating Instructions

Introduction

The Wilcom OFI Model F6222C Probe is a rugged, hand-held, easy-to-use maintenance and installation instrument that identifies optical fibers by detecting the optical signals that are transmitted through a singlemode fiber. The F6222C utilizes

non-destructive macro-bend detection, which eliminates the need to identify a fiber

by opening it at the splice point. Thus, the probability of interrupting service is

eliminated.

Signals that the F6222C detect include continuous wave live optical transmission,

and low frequency modulated tones at 270, 1000, and 2000 Hz. When the F6222C

detects traffic on a fiber being tested, one of two LEDs on the F6222C illuminates to

indicate the presence and direction of transmission. The presence of tone is indicated by illumination of one of three LEDs (Figure 1). The relative level of core

power within the fiber is also displayed on the two-digit seven-segment LED dis-

Figure 1

tion

play. The F6222C also has an easy to use thumb lock feature for hands-free opera-

F6222C

Operating the F6222C

Operation of the F6222C is simple, as outlined in the

following steps:

1. Choose an adapter head for the type of fiber to be tested.

The F6222C is supplied with three adapters (as shown in

Figure 2): (A) foam-covered, to accommodate 900 µm buffered fiber; (B) smooth-surfaced with foam perimeter, for

use with ribbon fiber or a 250 µm coated fiber; and (C) slot-

ted, for 3 mm and optional 2 mm jacketed fiber (i.e., pigtails

and jumpers) or loose tube fiber.

2. Select the appropriate adapter and slide it into the mating

slotted channel of the F6222C with slight downward pressure, as shown in Figure 3.

3. Insert the fiber to be tested between the adapter and the top

of the clamp (refer to Figure 4). Slide the thumb switch

upward and ensure that the fiber is installed properly in the

alignment groove.

Figure 2

4. For hands-free operation, slide the thumb switch upward and

“rock” forward to lock, and the fiber will be held in place

( refer to Figure 4 ) “rock” backward to unlock.

04/04

813-219-000

Figure 3

Page 2

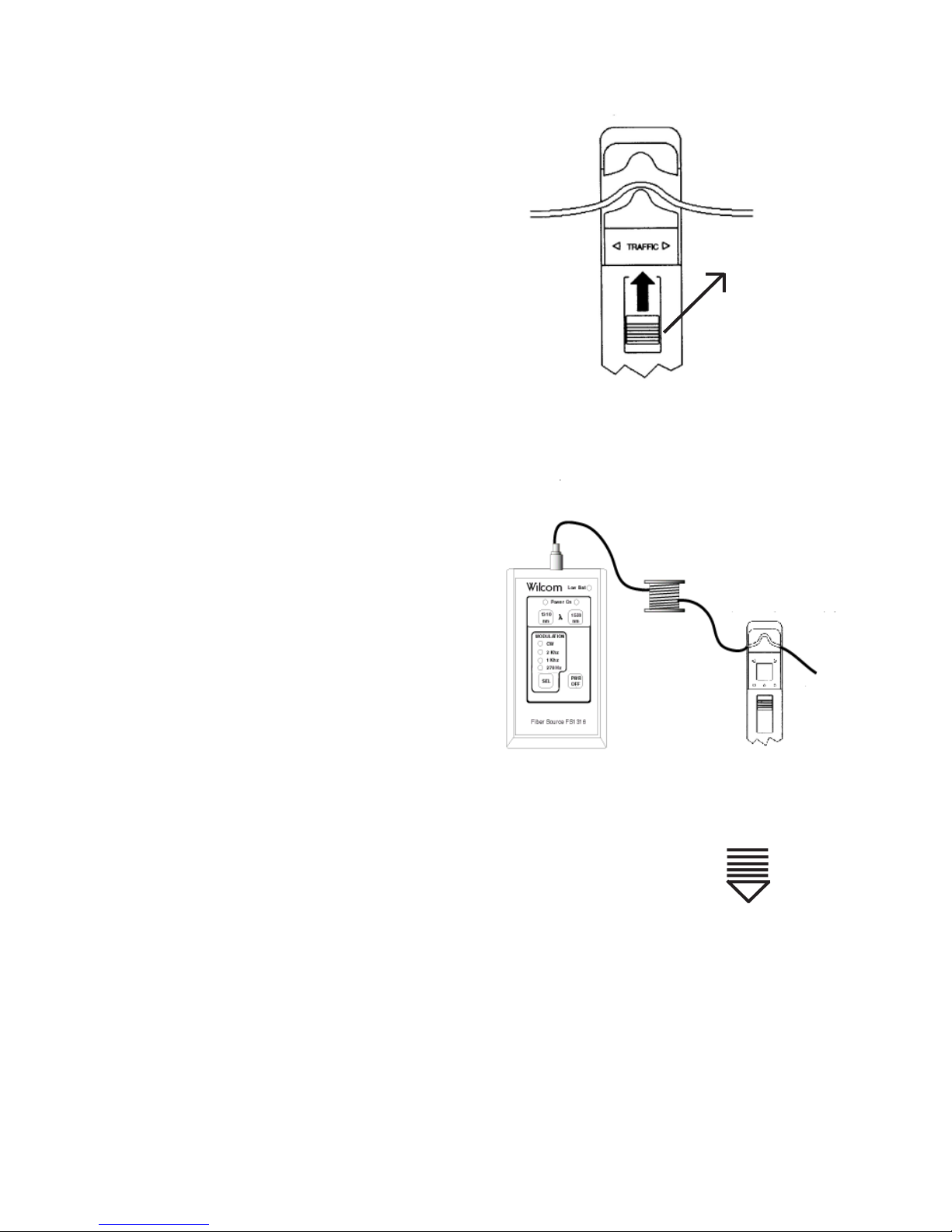

Presence of Traffic. Illumination of either Traffic LED

indicates the detection and direction of traffic. This is useful in determining whether the fiber is transmitting or receiving at equipment terminal locations. The F6222C also

provides an audible tone alert when traffic is detected.

Test Tone Detection. Illumination of any one of the 2

kHz, 1 kHz, or 270 Hz LEDs indicates that a test tone is

being detected, which ensures accurate identi-fication of

the fiber that is under test.

The 2 kHz tone can be generated by a source such as

Wilcom Models FS1316 (includes also 1kHz and 270 Hz),

FS1317 (includes also 1kHz and 270 Hz), and FS8514A

(includes also 1kHz and 270 Hz). The F6222C can be used

with all three units, as shown in Figure 5. The recommended wavelength is 1550nm for tone identification.

Relative Power Level . The relative core power in the fiber is displayed as a dB value between +14 and -19 dBm.

The F6222C will operate with core powers greater than

+15 dBm. Under these conditions the F6222C displays a

“HI” and the Traffic LED indications remain valid. When

the core powers are below -19 dB, the F6222C displays

a “LO” and the Traffic LED indications are no longer valid.

The signal level is below the range of the F6222C.

slide the thumb switch upward

and “rock” forward to lock,

and “rock” backward to unlock

Figure 4

Fiber under test

Self Test. Each time the thumb switch is operated, the

F6222C performs a self test. When this occurs all LEDs

will illuminate and then after approximately one-half second turn off.

Figure 5

Low Battery Indication. When the battery voltage be-

comes low, “Lb” is diplayed after the selftest. The unit will continue to operate for some time, but the battery

should be replaced with a fresh 9-volt alkaline battery as soon as possible.

Battery Replacement. To replace battery hold probe in hand, and with thumb on grip, slide cover

downward. Replace battery. To re-install cover reverse the steps. Gently place cover on

probe and align cover keys with probe keyways. Slide cover forward.

Maintenance. It is important that the optical ports remain clean and free of dust, dirt, grease, or other foreign

matter. Cleaning with lint-free swabs and isopropyl alcohol is recommended for optimum performance.

Loading...

Loading...