Wilbur Curtis Company TLP Service Manual

MODELS INCLUDED

• TLP

Wi l b u r Cu r t i s Co m p a n y , in C .

Service Manual – TLP Brewer

Important Safeguards/Conventions

This appliance is designed for commercial use. Any servicing other than cleaning and maintenance should be performed by an authorized Wilbur Curtis service center.

• Do NOT immerse the unit in water or any other liquid

• To reduce the risk of re or electric shock, do NOT open top panel. No user serviceable parts inside. Repair should be done only by

authorized service personnel.

• Keep hands and other items away from hot parts of unit during operation.

• Never clean with scouring powders, bleach or harsh implements.

Conventions

WARNINGS – To help avoid personal injury

Important Notes/Cautions – from the factory

CAUTION: Please use this

setup procedure before

attempting to use this

brewer. Failure to follow

the instructions can result in injury

or the voiding of the warranty.

CAUTION: DO NOT

connect this brewer to hot

water. The inlet valve is

not rated for hot water.

IMPORTANT: This equipment is to be installed

to comply with the

applicable federal, state,

or local plumbing and electrical

codes having jurisdiction.

WARNING: To avoid

scalding, do NOT remove

brew cone while brew

indicator light is ashing.

IMPORTANT: The

brewcycle is adjusted

at the factory to ll a

standard 2.5 liter airpot with 2.2

liters of brewed coffee. The dura-

tion of the brewcycle is set from 3

to 4 minutes.

Sanitation Requirements

SYSTEM REQUIREMENTS

• Water Source: 20 ‑ 100 PSI. Must have a Minimum Flow Rate of 1/2 GPM (preferred ow rate is 1 gpm).

• Electrical: See attached schematic for your model.

Setup Steps

The unit should be level (left to right and front to back), located on a solid counter top. Connect a water line from the cold water supply to

the brewer. (NOTE: Some type of water ltration device must be used to maintain a trouble‑free operation). In areas with extremely hard

water, we suggest that a sedimentary and taste & odor lter be installed. These will prolong the life of your brewing system and enhance

coffee quality.

NSF International requires the following water connection:

1. A quick disconnect or additional coiled tubing (at least 2x the depth of the unit) so that the machine can be moved to clean

beneath the unit.

2. This equipment is to be installed with adequate back ow protection to comply with applicable federal, state and local codes..

3. Water pipe connections and xtures directly connected to a potable water supply shall be sized, installed and maintained in accordance with federal, state, and local codes.

1. A 1/4” Flare has been supplied for water line connection. Use tubing sized sufciently to provide a minimum of 1/2 GPM.

2. Connect the unit to an appropriate electrical power circuit.

3. Turn on the toggle (STANDBY/ON) switch behind the unit. The heating tank will start to ll. When the water level in the tank rises to

the correct volume, the heating element will energize automatically. With G3 Systems there is no danger of element burnout caused

by an empty tank.

4. Turn on the control panel by pressing the ON/OFF button.

5. The heating tank will require 20 to 30 minutes to reach operating temperature (200°F). The READY‑TO‑BREW light will come on.

6. Prior to brewing, dispense 12 ounces of hot water through the hot water faucet.

7. Run brew cycle of at least 16 ounces to purge the water line of any air trapped in the lines after lling.

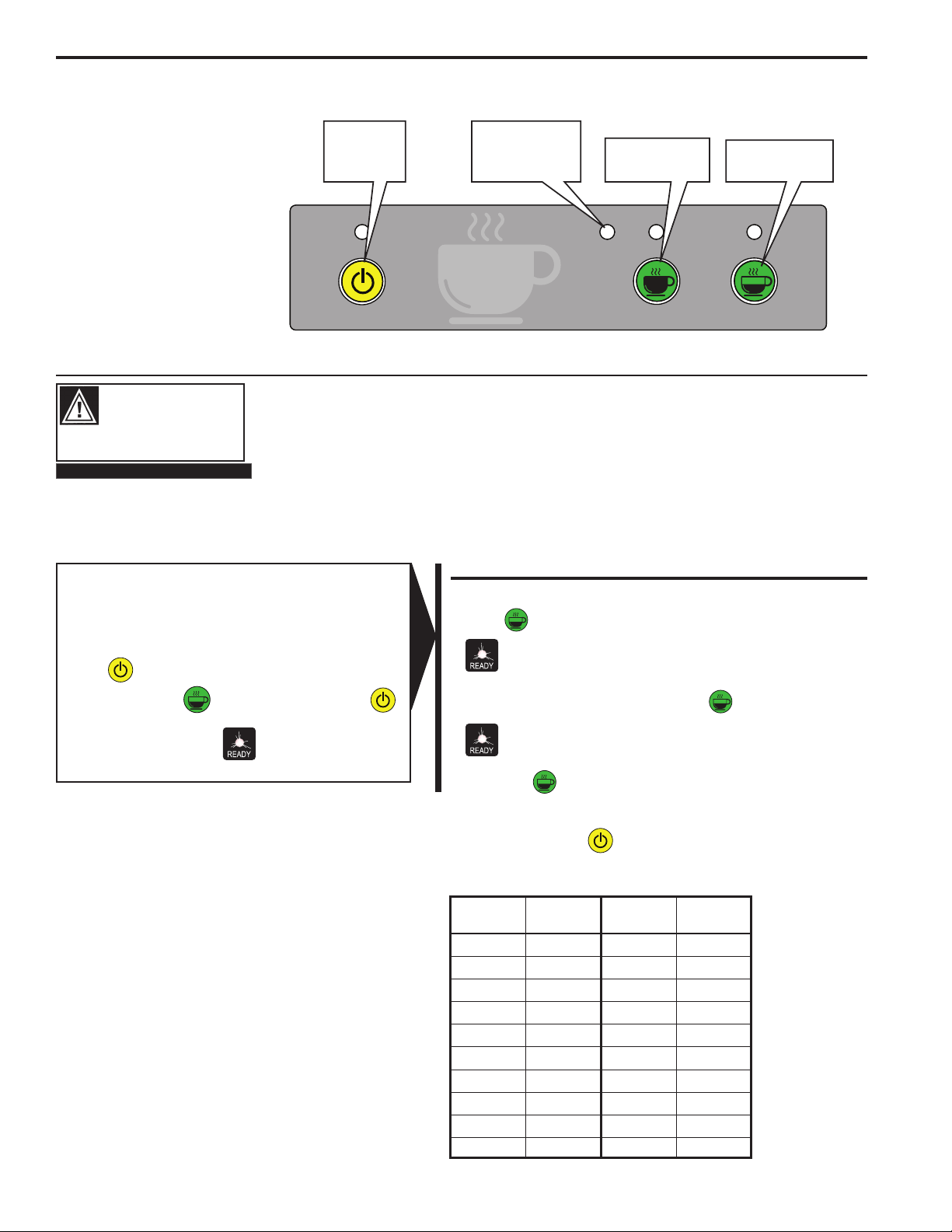

BREWING COFFEE

1

2

3 4

C

PENDING

WILBUR CURTIS COMPANY

Montebello, CA 90640

ISO 9001 REGISTERED

1. Place airpot in

position, under the

sprayhead.

Place a new lter in

the brewcone.

FOR THE LATEST SPECIFICATION INFORMATION GO TO WWW.WILBURCURTIS.COM

2. Pour ground coffee

into the brewbasket.

3. Slide the brewcone

into position on

brew rails.

4. Wait until READY‑

TO‑BREW light appears,

then press the BREW

button. The indicator light

above the selected brew

button will ash durring

the brewcycle.

1

FULL BREW

READY

HALF BREW

TLP

ON/OFF

BUTTON

YELLOW

READY TO

BREW LIGHT

RED

FULL BREW

GREEN

HALF BREW

GREEN

STEPS TO

HALF BREW

ON/OFF

ON/OFF

HALF BREW

ON/OFF

HALF BREW

HALF BREW

PROGRAMMING

Your Curtis TLP system is factory pre‑set for optimum performance. generally, there will not be a

need to change programming.

CAUTION: These steps

involve working with

hot water. Avoid against

splashing and spilling.

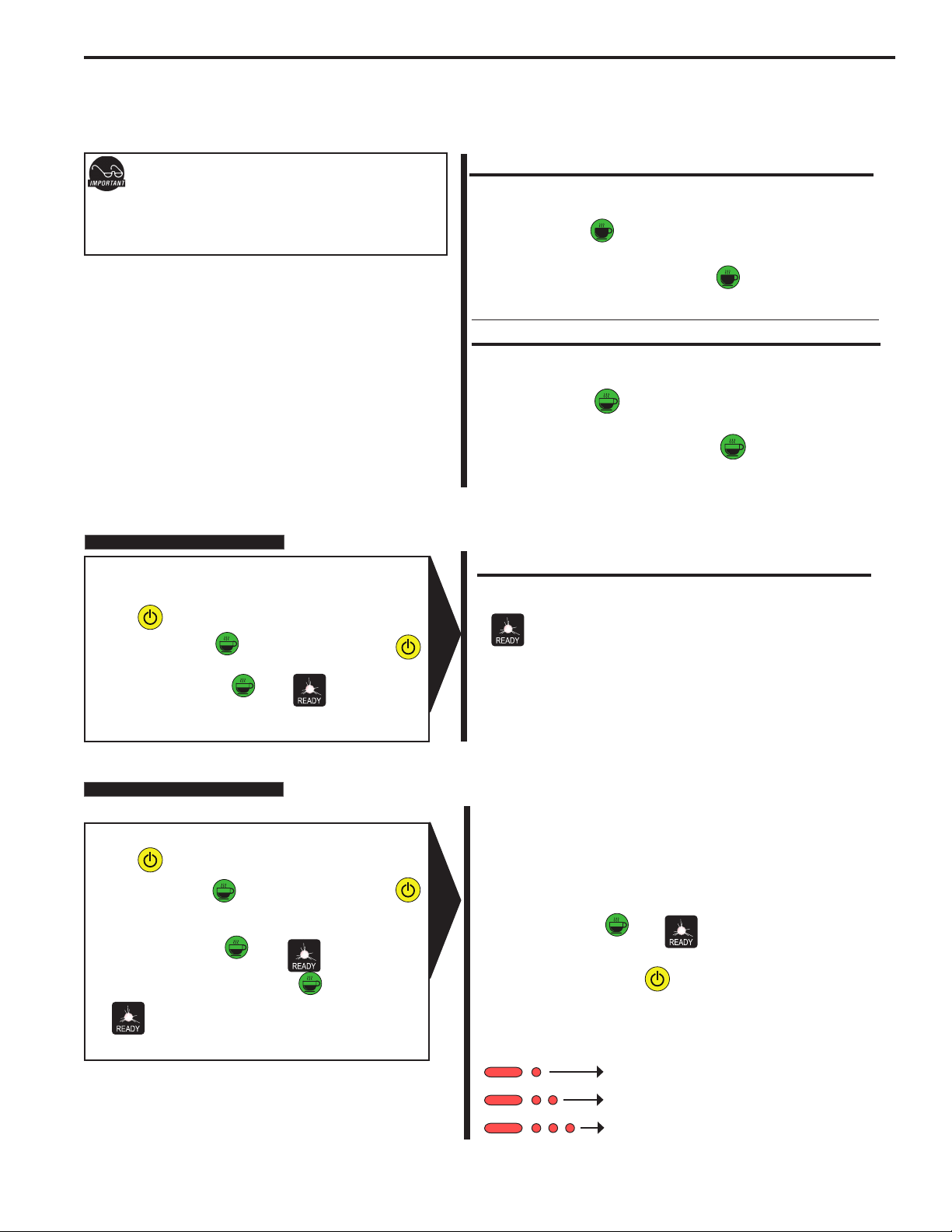

Changing the TLP Program

The TLP features a dynamic memory. In the event of a power loss, it will remember ALL program settings.

Brew Temperature – Factory Pre‑Set to 200°F

Function to set brew temperature, 170° to 206°F. Brew temperature will be indicated by READY‑TO‑BREW

light blinking.

ENTERING THE PROGRAM MODE #1

For ALL functions you must rst enter the programming

mode.

Turn OFF the power from the Control Panel by press-

ing .

Press and HOLD and press and RELEASE .

Continue HOLDING until starts blinking; RE-

LEASE.

CONFIRM/RESET BREW TEMPERATURE ‑ Factory Preset

to 200ºF

ENTER THE PROGRAMMING MODE #1:

Press for two seconds, then RELEASE.

will start blinking. Each blink equals 2º F, starting at 170º (max.

temp. 206º F or 19 blinks).

To change Temperature, press and HOLD .

will start QUICK ashing. Each QUICK ash equals 2º F. After

reaching 206º, temperature starts over at 170º.

RELEASE when the desired temperature is reached (new temp.

will now be displayed).

2

To set and exit, press .

Temperature Table

Nº of

Blinks

1

2

3

4

5

6

7

8

9

10

Temp.

170º F

172º F

174º F

176º F

178º F

180º F

182º F

184º F

186º F

188º F

Nº of

Blinks

11

12

13

14

15

16

17

18

19

Temp.

190º F

192º F

194º F

196º F

198º F

200º F

202º F

204º F

206º F

Brew Volume ‑ Factory Pre‑set Full Brew to 2.2 Liters

ON/OFF

FULL BREW

ON/OFF

FULL BREW

HALF BREW

HALF BREW

HALF BREW

HALF BREW

HALF BREW

ON/OFF

ON/OFF

HALF BREW

HALF BREW

HALF BREW

ON/OFF

When setting the brew volume, place an empty airpot under the brewcone to determine volume level. The factory default for the Half Brew button is half the brew volume of the Full Brew button. The brew volume of the Half Brew button can be set independently (see Half Brew Volume

below)..

Before changing the brew volume, wait until unit

reaches brew temperature (Ready to Brew light comes

on), insert the brewcone into place on the brewer, then

place an airpot or some kind of measuring container

centered beneath the brewcone.

BREW CYCLE COUNTER

ENTER THE PROGRAM MODE #2

Turn OFF the power from the Control Panel by press-

ing .

Press and HOLD and press and RELEASE

Continue HOLDING until STOPS blink-

ing; RELEASE.

CHANGE FULL BREW VOLUME

ENTER THE PROGRAMMING MODE #1

(Be sure to have an empty brewcone & airpot in position).

Press and HOLD until hot water starts running from sprayhead;

then RELEASE.

When desired volume is reached, press again to stop ow and

set. brew volume.

HALF BREW VOLUME

ENTER THE PROGRAMMING MODE #1

Have an empty brewcone & airpot in position under the sprayhead.

Press and HOLD until hot water starts running from sprayhead;

then RELEASE.

When desired volume is reached, press again to stop ow and

set. brew volume.

TO ACCESS BREW CYCLE COUNTER

ENTER THE PROGRAMMING MODE #2:

will now start a pattern of LONG and SHORT blinks.

This pattern identies the number of brew cycles. SHORT blinks indicate

the brew number from one [1] to nine [9]. LONG blinks separate the 1’s,

10’s, 1,000’s and 10,000’s.

PULSE BREW

ENTER THE PROGRAM MODE #3

Turn OFF the power from the Control Panel by press-

ing .

Press and HOLD and press and RELEASE

.

Continue HOLDING until STOPS blinking

and remains on, then RELEASE .

will now blink a pattern of ashes from one to

three.

CHANGING THE PULSE BREW FEATURE

To change:

press and hold the full brew button until the “ready‑to‑brew” light

shows one quick ash. Press power button on the switch panel to

set the desired pulse brew setting and exit programming mode.

Press and HOLD until shows one quick ash, then

RELEASE. You have now added a blink to your blinking light pattern.

By pressing and holding you add another blink.

PULSE OPTIONS:

OFF = One Long Flash

#1 = One Long Flash + 1 Short Flash

#2 = One Long Flash + 2 Short Flash

#3 = One Long Flash + 3 Short Flash

3

Loading...

Loading...