Wilbur Curtis Company SHG, DHG Service Manual

Fi n d o u t m o r e

o n t h e w e b .

WILBURCURTIS.COM

Models Included

SHG

DHG

Wi l b u r Cu r t i s Co m p a n y , in C .

Service Manual – Single and Dual Hopper Grinders

Important Safeguards/Conventions

This appliance is designed for commercial use. Any servicing other than cleaning and maintenance should be performed by an authorized Wilbur Curtis service center.

• Do NOT immerse the unit in water or any other liquid

• To reduce the risk of re or electric shock, do NOT open top panel. No user serviceable parts inside. Repair should be done

only by authorized service personnel.

• Keep hands and other items away from hot parts of unit during operation.

• Never clean with scouring powders or harsh implements.

Conventions

WARNINGS – To help avoid personal injury Important Notes/Cautions – from the factory

CAUTION: Please use

this setup procedure

before attempting to

use this grinder. Failure to follow

the instructions can result in injury

or the voiding of the warranty.

WARNING TO AVOID

SCALDING, Do not

remove brewcone whil

brew light is ashing.

QUICK START & SETUP

SETUP

1. Install the grinder on a rm, level base in a location where it can be connected to a grounded electrical outlet of 120VAC, rated at 15

amps minimum.

2. Test the unit by running some whole bean coffee through the grinder. If any problems are encountered, refer to the troubleshooting

section complete at www.wilburcurtis.com or call Technical Support at 800-995-0417.

OPERATING INSTRUCTIONS

1. Lift open the top cover of the grinder and ll with fresh whole bean coffee. Close the cover.

2. Place a new paper lter into the brewcone.

3. Insert the brewcone into the basket holder arms on the grinder.

4. Press the grind switch. The grinder will start to grind coffee. Allow the motor to come to a

complete stop before removing the brewcone.

5. Transfer the lled brewcone to the brewer and press the desired brew button. The brew

cycle is complete when the brew light stops ashing.

ADJUSTING THE GRINDS

1. Empty hopper of coffee beans. Run grinder to clear grinding burrs of coffee.

2. Open housing cover to locate adjustment screw (8) and lock nut (7). Loosen lock nut.

3. Run motor during adjustment. Turning adjustment screw clockwise will result in a ner

grind (if, while turning, you hear the grinding burrs starting to touch, immediately, back

off 1/8th turn). Turning counter clockwise will produce a coarser grind.

4. With a screwdriver holding the adjustment screw in place, tighten the locknut.

5. Run some coffee beans through the machine to check the grind adjustment.

6. Replace front cover on machine.

*This adjustment may change the amount of ground coffee dispensed.

C

ISO 9001 REGISTERED

WILBUR CURTIS COMPANY

Montebello, CA 90640

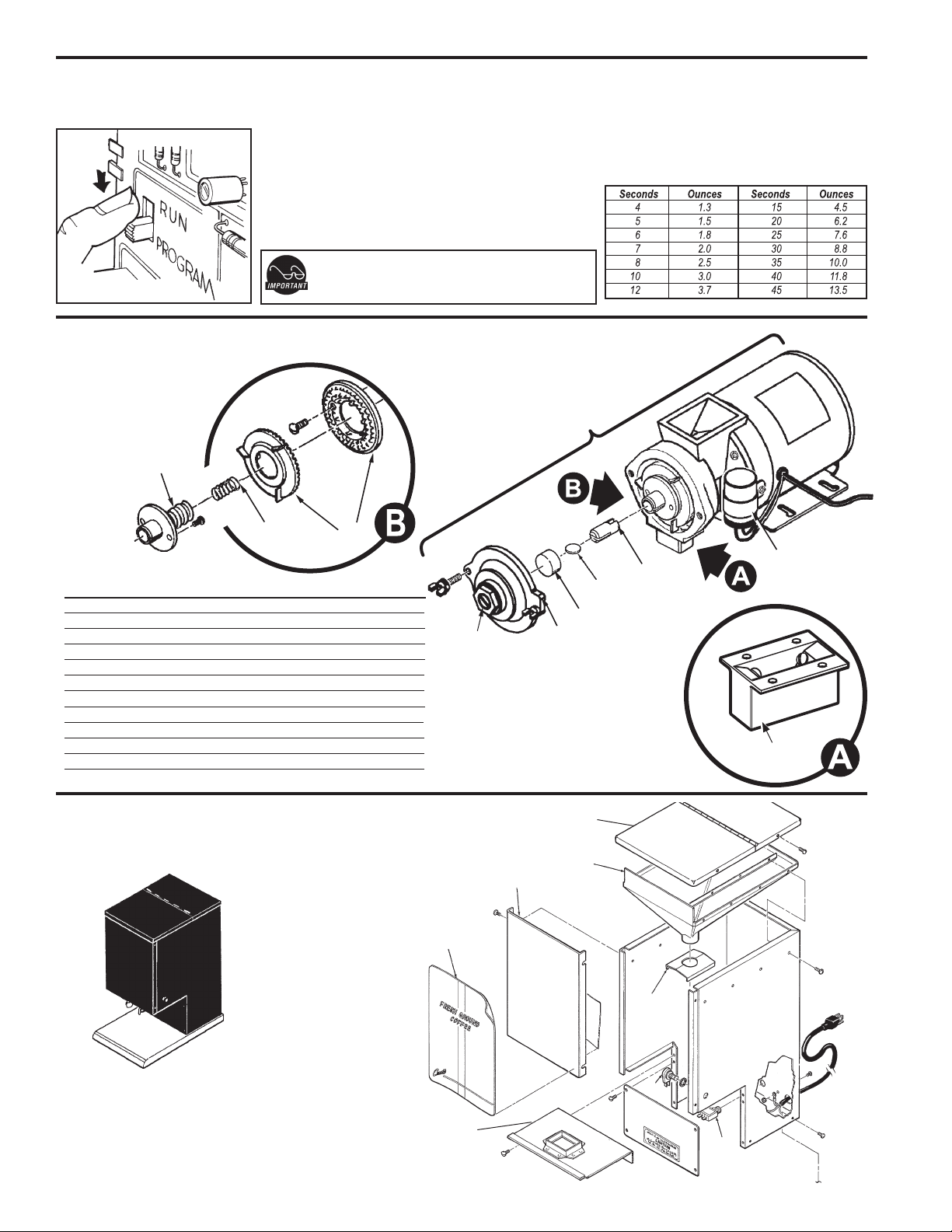

CHANGING A BROKEN SHEAR DISK

1. Unplug the power cord.

2. Empty the hopper of beans.

3. Take out the thumb screws (10) to remove the grind cap (6).

4. Pull out the grinding burr/feed worm assembly (2). The inner half of the grinding burr set

will remain in the housing.

5. Separate the shear cap (5) and shear drive (3). The snapped shear disk (4) should fall

out of it’s slot on the shear drive.

6. Inspect and clean housing (1) of any coffee or debris. Especially look for anything that may have broken the shear disk.

7. Re-insert the feed worm and grinding burr on to the motor shaft.

8. Push shear drive through burr/feed worm assembly and align large slot with tongue on the motor shaft.

9. Rotate burr/feed worm assembly to align slot with narrow slot on shear drive.

10. Insert a new shear disk into slot. Cover with the shear cap.

11. Replace grind cap and thumb screws.

For the Latest speciFications and inFormation go to www.wiLburcurtis.com

1

TIMER SETTING – DHG

PARTS

DIAGRAM

MOTOR ASSY

11

1. To set the timer, place an empty lter paper below the chute. Pour whole bean coffee into the hopper.

2. Open the lower cover to reveal the timer.

3. On the timer control board, locate the programming switch. Switch from RUN to PROG (see illustration, left).

4. On the front cover, select the desired switch to program, REGULAR or DECAF. Press and hold this switch.

5. The grinder motor and auger motor will start grinding coffee. When the desired ground coffee output is reached, release the grind

switch. The auger motor will shut off, stopping the ow of coffee from the hopper. The grind motor will continue to run until the

delay has elapsed.

6. Press the other grind button or move the program switch to RUN.

This will save the time setting.

7. Repeat steps 1 to 7 for the other grind switch.

NOTE: Time settings in this table are only approximate.

Amounts will vary with grind texture and specic coffee bean.

Weigh your output, then make adjustments as necessary.

1

INDEX

NUMBER

1

2

3

4

5

6

7

8

9

10

11

PART

NUMBER

WC-9135

WC-37283

WC-91026

WC-91024

WC-9107-6

WC-91016

WC-91017

WC-91015

WC-91045

WC-91021

WC-91020

PARTS

DIAGRAMS

10

DESCRIPTION

MOTOR CRUSHING GRINDER ASSY 120VAC

KIT, GRINDER CHUTE NEW STYLE

CAPACITOR, COFFEE GRINDER ASSY

SHEAR DRIVE COFFEE GRINDER

DISC, SHEAR COFFEE GRINDER 6PCS

CAP, SHEAR DISK GRINDERS

COVER, GRINDER HOUSING W/LABEL

SCREW & THRUST PIN ADJUSTING ASSY

BURRS, SET CRUSH HIGH FLOW

SPRING, TENSION COFFEE GRINDER

WORM FEEDING ASSY CCG

9

SHG Hopper & Covers

3

4

5

6

8

7

2

1

2

3

4

19

34

22

21

2 3

Loading...

Loading...