Page 1

© Wikora GmbH Page 1 As of 5/9/2014

Errors excepted.

WIKORA GmbH

Friedrichstr. 9

89568 Hermaringen

Phone: (07322) 9605-0

Fax: (07322) 9605-30

email: contact@wikora.de

Installation manual

Operating instructions

DHW storage tank

WBO 305 UNO/DUO/H/WPSOL

Installation and commissioning must be

undertaken by a specialist.

General terms and conditions of warranty state that

all installations must be carried out by a suitably

trained and qualified plumber who observes the

local norms and regulations.

The installation and maintenance record must

be entirely completed and the user has to be

instructed accordingly.

Efficient operation can only be guaranteed if the

instructions of this manual are followed.

Warranty does not cover any damage caused due

to non-observance of this manual and the technical

rules in force.

The system is to be checked annually by a

specialized company. In addition, occurring defects

must be repaired immediately.

This document should be handed over to the

client on completion of the installation.

.

Index

1 General ................................................................................................................................................................................... 2

2 Transport and installation ....................................................................................................................................................... 2

3 Dimensions and connections .................................................................................................................................................. 3

4 Technical data ........................................................................................................................................................................ 4

5 Installation .............................................................................................................................................................................. 5

6 Commissioning ....................................................................................................................................................................... 6

7 Maintenance and wear parts .................................................................................................................................................. 6

8 Warranties and guarantee ...................................................................................................................................................... 7

9 Installation record ................................................................................................................................................................... 8

Page 2

© Wikora GmbH Page 2 As of 5/9/2014

Errors excepted.

1 General

Depending on the type and design, W IKORA tanks are suitable for heating and / or storing DHW and / or heating water. The

heating is achieved indirectly via heat generators, if applicable, from different heat sources. The maximum working pressure

and working temperature can be found in the technical data.

Set-up, installation and commissioning must be undertaken by a qualified specialist, who must observe these instructions.

The site of installation must be frost-protected according to DIN 4753 and should be in direct proximity to the heat

generator.

When setting-up and installing the tank, the following regulations should be considered:

In addition to the technical rules in force DIN 1988, DIN 18160, DIN 4753, DIN 4109, DIN 4708, DIN 4751 section 2-4 energy

conservation law and VDE regulations are to be observed. Moreover, the relevant regulations of the suppliers as well as legal

building regulations are to be considered.

DHW requirements:

• Minimum hardness:

- 2° dh (sum of alkaline earths 0,4 mmol/l)

• Conductivity

- if external current anode is used ≥ 100 µs/cm

- if Mg-anode is used 130 µs/cm – 1500 µs/cm

• pH-value according to Drinking Water Ordinance (6,5-9,5)

Important: The exhaust pipe must be at least as big as the safety valve outlet in width. It may not have more than 2 bends and

should not be longer than 2 m. If for any compelling reasons 3 bends or a length up to 4 m are required, then the entire exhaust

line must be designed one nominal size larger. More than 3 bends, or a length exceeding 4 m is prohibited. The exhaust pipe

must be installed with downward gradient. The drain line behind the funnel must feature at least the double width of the valve

entrance. A sign is to be attached close to the exhaust pipe of the safety valve or on the safety valve itself. „For safety reasons

water may leak from the exhaust pipe during the heating process! Do not lock! "The operability of the safety valve is to be

checked at regular intervals by means of de-ventilation.

2 Transport and installation

In order to prevent damage during transport, the packaging should only be removed at the site of installation. During shipment,

it should be ensured that the tank does not come in contact with any spiky or sharp items, nor is damaged through dropping or

knocks.

During installation, the tank must be disconnected from any humidity carrying components. Moreover, sufficient space for

maintenance and cleaning purposes should be kept free in front of, beside, above and behind the tank.

Important information for the specialist:

1. Screw the provided anode loosely in the corresponding socket before tank installation. Once the tank is filled

and vented, the anode must be screwed tightly and hermetically sealed.

2. If the tank is not equipped with an electric heating element, the corresponding IG 11/2“ socket must be sealed

on site with a red brass screw plug. Please remove the existing protection cap and replace it with this plug.

Page 3

© Wikora GmbH Page 3 As of 5/9/2014

Errors excepted.

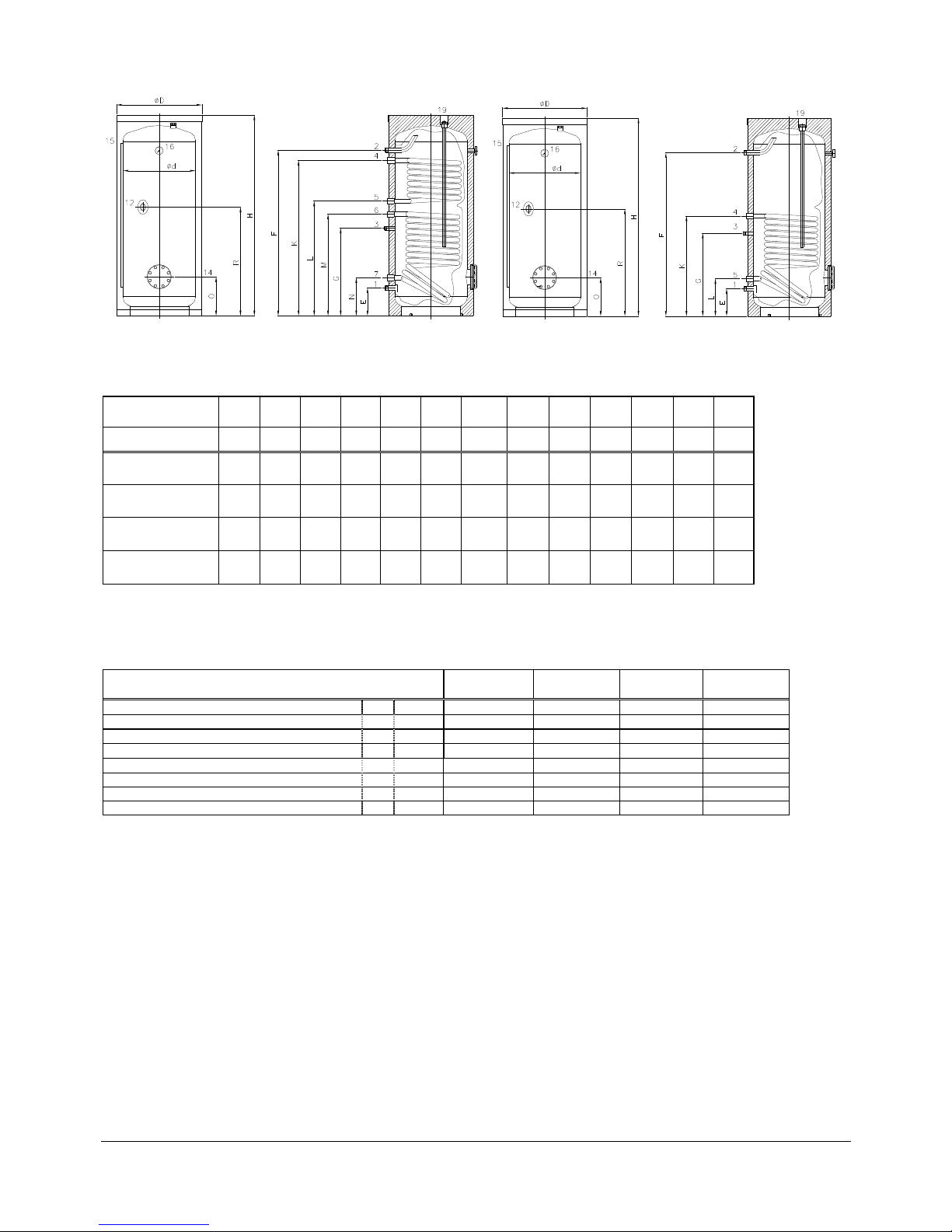

3 Dimensions and connections

Illustration1

Dimensions:

Type

∅ d ∅ D

E F G H K L M N O R W

[mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm]

[mm]

[mm] [mm]

WBO 305 UNO

500 610 215 1422 758 1740 858 243 - - 290 905 1750

WBO 305 DUO

500 610 215 1422 758 1740 1397 958 858 243 290 905 1750

WBO 305 H

500 610 215 1422 758 1740 858 243 - - 290 905 1750

WBO 305 WPSOL

500 610 215 1422 758 1740 1397 958 858 243 290 905 1750

Chart1

W = Tilting dimension

Connections:

Type WBO 305

UNO

WBO 305

DUO

WBO 305 H WBO 305

WPSOL

Cold water / hot water 1/2 Ga 1 1 1 1

Circulation 3 Ga ¾ ¾ ¾ ¾

Aux boiler flow / return 4/5 Gi 1 1 5/4 5/4

Solar flow / return 6/7 Gi - 1 - 1

Plug for electric heater 12 Gi 6/4 6/4 6/4 6/4

Inspection flange 14 NW 116 116 116 116

Sensor tube 15 Ømm

10 10 10 10

Anode 19 Gi 5/4 5/4 5/4 5/4

Chart 2

Ga = male thread

Gi = female thread

NW = nominal size

Page 4

© Wikora GmbH Page 4 As of 5/9/2014

Errors excepted.

4 Technical data

Description

WBO 305

UNO

WBO305

DUO

WBO305 H WBO 305

WPSOL

Capacity

[litre] ca. 293 ca. 285 ca. 278

ca. 275

Max. working temperature DHW / Heating

[°C] 95 / 130 95 / 130 95 / 110

95 / 110

Max. working pressure DHW / Heating

[bar] 10 / 16 10 / 16 10 / 16

10 / 16

Capacity of heat exchanger lower / upper

[litre] 8,6 8,6 / 5,7 19,5

8,6 / 13,5

Surface of heat exchanger lower / upper

[m²] 1,45 1,45 / 0,85 3,00

1,45 / 2,1

Flow rate of heat exchanger lower / upper

[m³/h] 2,4 2,4 / 2,4 2,4

2,4 / 2,4

Pressure drop of heat exchanger lower / upper [mbar] 48 48 / 42 22

48 / 13

Insulation [mm] 60 - Neodul / fleece

Performance lower heat exchanger

DHW 80 °C / 60 °C / 10 °C upper heat exchanger

[l/h (kW)] 560 (32)

560 (32)

350 (21)

1070 (62)

560 (32)

844 (49)

Energy loss

[kWh/24h]

2,6 2,8 2,6

2,8

Weight (empty)

[kg] ca. 93 ca. 105 ca. 122

ca.131

Chart 3

Page 5

© Wikora GmbH Page 5 As of 5/9/2014

Errors excepted.

5 Installation

All pipes connecting to the tank should have removable connections (fitting/flange). Pipe thread seals with teflon are

to be avoided.

All tank connecting pipes are to be planned, constructed and tested according to the technical rules in force, as well as to the

corresponding norms and regulations in accordance with their application and supply medium.

Appropriate filters should be used to prevent dirt or particles from entering the tanks. Moreover, the tank should be ensured

against pressure fluctuations and excess pressure through the installation of tested pressure reducing valves and safety

valves.

Sensors and thermostats necessary for temperature control must be securely and permanently positioned on the tank

(immersion sleeve and sensor rail).

The tank’s venting and draining facilities must have the appropriate dimensions and be correctly installed.

The installation company is responsible for the correct execution of work and for the safe and careful insulation of the pipes.

• When connecting to a solar plant, a temperature limiter is required and must be installed on site at the hot water outlet

in order to prevent scalding.

SF

SR

Connection Scheme

(according to DIN 1988)

BR

BF

Water plug

Drain

CW

Circlation

HW

Pressure reducing valve

Test valve

Backflow preventer

Manometer conn.

Stop valve

Stop valve

Safety group according to

DIN 1988

Drian pipe

Safety valve

HW

BF

Circulation

BR

Drain

Safety valve

Drain pipe

Connection Scheme

(according to DIN 1988)

Stop valve

Manometer conn.

Backflow preventer

Test valve

Pressure reducing valve

Safety group according to

DIN 1988

water pipe

Stop valve

CW

Illustration 2 (Schematic diagram)

The size of the DHW safety valve is shown below:

Content of DHW space Min. valve size Max. heating performance

up to 200 l NW 15 (1/2“) 75 kW

above 200 to 1000 l NW 20 (3/4“) 150 kW

Illustration 3 (Schematic drawing– example hydraulic system heating)

Page 6

© Wikora GmbH Page 6 As of 5/9/2014

Errors excepted.

6 Commissioning

Before putting into operation, the entire system should be flushed through. Particles in the system compromise the

operating reliability.

Fill the heating system slowly with water and vent all the air.

Open the cold water stop valve and all hot water nozzles. The hot water heat exchanger is full when water leaks out

of all hot water nozzles. Then close all nozzles again.

Start-up the heating system.

Set the DHW temperature and supervise the system while heating up.

While the System is heating up, water will leak out of the safety valve.

Before the handover of the system to the end user/owner, the plumbing contractor should ensure that the

system is tested to full load, controls are set and that pipe work and connections are without leaks. Afterwards,

the end user has to be instructed in the operation and handling of the tank, as well as the system. The instruction must

to be documented in the installation and maintenance record.,

Please note that the operation and lifetime of the system depend decisively on a regular maintenance.

7 Maintenance and wear parts

Regular maintenance increases the lifetime and operation reliability of the system.

Decalcification at regular intervals may be

necessary in highly calcareous water areas.

1 . Close the cold water stop valve and drain the tank to check the inner tank as

well as the heat exchanger. Disconnect any

electrical devices from the appliance. Then, carefully remove the insulation of the flange cover and unscrew the flange

cover. Limescale and rough residues can be crushed by a wooden bar. Only use an approved deca

lcifier. Screw the

flange cover hermetically after the cleaning process by using a new flange seal. Fill the tank and check all connections for

tightness. Finally, replace the insulation and, if necessary, remount the electrical devices accordingly.

A chem

ical decalcification can be carried out by a specialist using an approved decalcifier and taking the appropriate

precautions.

Please note that the tank must be disconnected from the DHW installation (cold water / hot water /

circulation).

2. For protection

purposes, the tank is equipped with a magnesium protection anode. Its transmission depends on the local

water properties. It should be

examined for the first time after 2 years and afterwards annually in order to check its

transmission. The diameter shoul

d be at least 1/3 of the original diameter, the surface should be homogenous and without

any limescale crust. If necessary, it should be replaced by an original W ikora anode to protect the tank against corrosion.

2.a. Alternatively, the tanks can be equipped with an external current anode

. Please note that a protection against

corrosion is only guaranteed if the anode is energized and connected accordingly.

If the protection anode is neglected, this can cause damage through corrosion and lead to a loss of warranty.

3.

The safety valve protects the tank against excess pressure. The functional capacity must be checked at regular intervals

by venting. If an expansion vessel is used, the safety valve is not, or only rarely, required. Over a longer period of ti

me

therefore, it can become blocked and not function when needed.

4. If there is a danger of freezing, the DHW tank should be permanently heated or completely emptied.

5. A damp cloth is sufficient to clean the outer parts. Please avoid using any abrasive or solvent cleaning agents.

Page 7

© Wikora GmbH Page 7 As of 5/9/2014

Errors excepted.

8 Warranties and guarantee

The warranty for our products is based on the legal provisions of the general Civil Code and the Consumer Protection Act.

In addition, defective appliances are replaced within the framework of our full warranty

within 1 year, as of the date of the

invoice, including the replacement, procurement and incidental costs. As far as our hot-

water heaters and pressurized boilers

are concerned, the warranty amounts for 6 months, as of the date of the invoice.

Subsequent to the full warranty, defective tanks are replaced within the framework of our guarantee. The guarantee

of the

different products and the conditions are shown in the table below.

All other claims are excluded. Repairs and costs which occur due to damage, inappropriate

installation, chemical,

electrochemical or electrical influences, incorrect operation or

improper manipulation, are excluded. Furthermore, the warranty

becomes invalid if th eappliance has been modified through the installation of externally supplied parts or

through irregular

professional maintenance.

Subject to our general terms and conditions.

Legal

warranty

2 years

Guarantee

years*

Conditions

WBO T/ToF ● 5 20 / 27

WBL ● 5 20 / 27

WBO Uno ● 5 20 / 27

WBO Duo ● 5 20 / 27

WP/Sol ● 5 20 / 27

WBO H ● 5 20 / 27

GS ● 5 20 / 27

Wikos ol Twin ● 10 27

Wikos ol ● 10 27

WPKR H Twin ● 5 20 / 27

WPKR Twin ● 5 20 / 27

WPKR ● 5 20 / 27

WPK ● 5 20 / 27

WPH-FW (tank) ● 5 27

WPR-FW (tank) ● 5 27

WPS ● 5 20 / 27

WPH ● 5 WPR ● 5 WPRR ● 5 WKS ● 5 -

Cu-finned tube heat exchanger ● - 27

Electric heating elem ent ● - -

Conditions:

20

27

Coverage Germany:

Com pliance with the limits of the valid DHW regulations(TrinkwV 2001), especially the

lim its in accordance with Appendix 2, Part 1-2 and Appendix 3

Coverage EU :

Com pliance with the limits of the EG-Regulations 83/98

* Start of guarantee at date of invoice

Products

DHW storage tanks

Combi buffer tanks

Buffer tanks

Tank accessories

Under condition that the lim its of the valid DHW regulations have been respected, the

anode has been examined for the first time after 2 years and afterwards annually and that

the anode has been replaced by an original Wikora anode (individual receipts needed) by

a specialized company.

Page 8

© Wikora GmbH Page 8 As of 5/9/2014

Errors excepted.

9 Installation record

The installation has been completed according to DIN and the technical rules in force. In addition, the customer has received

instruction concerning the operation and maintenance.

Place……………………………………………….. Date…………………………………………………………

Customer Installer

……………………………………………………. ……………………………………………………………….

Signature Signature

Place of installation: ………………………………………………………………………………………………………………………

Name: ……………………………………………………………………………………………………………………...

ZIP Code/Place: …………………………………………………..………………………………………………………………….

Street: ……………………………………………………………………...………………………………………………

Phone: ……………………………………………………………………………...……………………………………...

Tank model: ………………………………. Serial number …………….………………..………………

Date of invoice ………………………………………………………...…………………………………………………………..

Anode maintenance record

Date Visual examination

of anode

Exchange of

anode

Signature + stamp of installer

In the case of reclamation, the receipts for maintenance must be provided as proof. Please complete the data sheet, including

the reason for reclamation, and submit to W ikora.

Submitting the maintenance record does not ensure any promise of guarantee or claim.

Loading...

Loading...