Page 1

Operating instructions

Betriebsanleitung

Version Standard

Version Ex nA ic

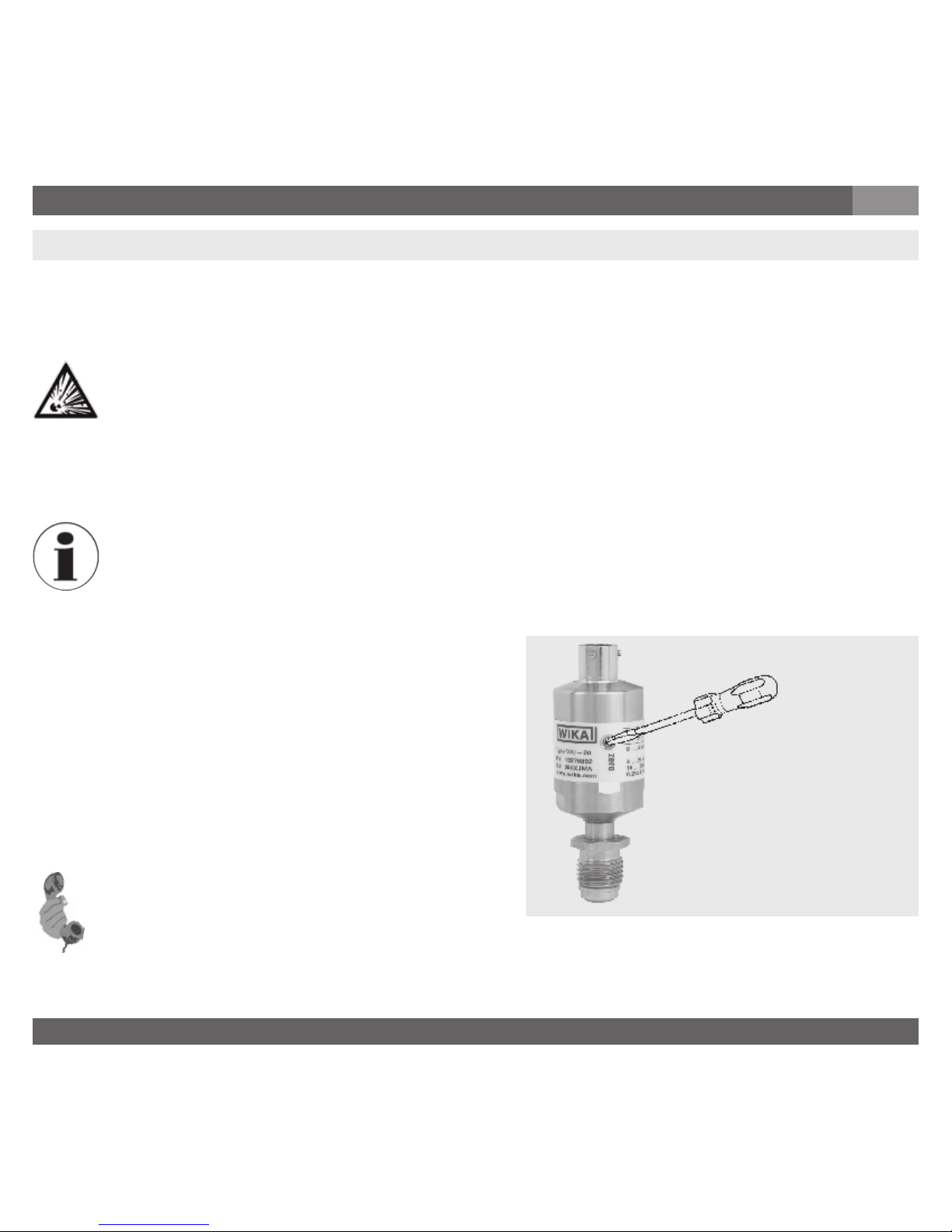

Ultra High Purity Transducer, models WU-20, WU-25, WU-26

WU-25

WU-20

WU-26

Page 2

2 WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

Contents Page 3 - 21 EN

1. Important details for your information

2. A quick overview for you

3. Signs, symbols and abbreviations

4. Function

5. For your safety

6. Packaging

7. Starting, operation

8. Adjustment of zero point

9. Maintenance, accessories

10. Trouble shooting

11. Storage, disposal

12. EU declaration of conformity

13 FM certicate of compliance

14 FM control drawing

Inhalt Seite 22 - 40 DE

1. Wichtiges zu Ihrer Information

2. Der schnelle Überblick für Sie

3. Zeichenerklärungen, Abkürzungen

4. Funktion

5. Zu Ihrer Sicherheit

6. Verpackung

7. Inbetriebnahme, Betrieb

8. Einstellung Nullpunkt

9. Wartung, Zubehör

10. Störbeseitigung

11. Lagerung, Entsorgung

12. EU-Konformitätserklärung

13 FM-Zertikat

14 FM-Control drawing

ENContents

Page 3

3WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

1. Important details for your information

Read these operating instructions without fail before installing and starting the pressure

transducer

1. Important details for your information

Read these operating instructions before installing and starting the pressure transducer. Keep the operating

instructions in a place that is accessible to all users at any time.

The following installation and operating instructions have been compiled by us with great care but it is not

feasible to take all possible applications into consideration. These installation and operation instructions

should meet the needs of most pressure measurement applications. If questions remain regarding a specic

application, you can obtain further information:

■

Via our Internet address www.wika.de / www.wika.com

■

The product data sheet is designated as PE 87.07

■

Contact WIKA for additional technical support (+49) 9372 / 132-0

If the serial number on the product label gets illegible (e.g. by mechanical damage or repainting), the retraceability of the instrument is not possible any more.

WIKA transducers are carefully designed and manufactured using state-of-the-art technology. Every component undergoes strict quality and e)vironmental inspection before assembly and each instrument is fully

tested prior to shipment. Our environmental management system is certied to DIN EN ISO 14001.

Use of the product in accordance with the intended use WU-20, WU-25 and WU-26:

Use the transducer to transform the pressure into an electrical signal.

For transducer with Ex-marking:

Use the nonincendive transducer of category 3G to transform the pressure into an electrical signal in hazardous areas of zone 2.

Certicate for transducer with Ex-marking:

Transducer for operation in hazardous areas.

ATEX marking: II 3G Ex nA ic IIC T6/T5/T4 Gc X

IECEx marking: IECEx BVS 13.0070 X, Ex nA ic IIC T6/T5/T4 Gc

EN

Page 4

4 WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

WARNING!

Potential danger of life or of severe

injuries.

1. Important details for your information / ... / 3. Signs and symbols

Certicate for transducer with FM-marking:

Transducer for operation in hazardous areas in compliance with the respective certicate (see Control

drawing No. 11537885, page 24).

FM Approval ratings: Non-incendive for Class I Division 2 Groups A, B, C and D

Knowledge required: Install and start the transducer only if you are familiar with the relevant regulations

and directives of your country and if you have the qualication required. You have to be acquainted with the

rules and regulations on hazardous areas (if transducer with Ex-marking), measurement and control techno-

logy and electric circuits. Depending on the operating conditions of your application you have to have the

corresponding knowledge, e.g. of aggressive media.

2. A quick overview for you

If you want to get a quick overview, read Chapters 3, 5, 7 and 11. There you will get some short safety

instructions and important information on your product and its starting. Read these chapters in any case.

3. Signs, symbols and abbreviations

EN

WARNING!

For transducer with Ex-marking:

Instructions for hazardous areas:

Potential danger of life or of severe

injuries.

WARNING!

Potential danger of life or of severe

injuries due to catapulting parts.

CAUTION!

Potential danger of burns due to hot

surfaces.

Notice, important information,

malfunction.

The product complies with the

applicable European directives.

Page 5

5WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

3. Signs and symbols / 4. Function

2-wire Two connection lines are intended for the voltage supply.

The supply current is the measurement signal.

3-wire Two connection lines are intended for the voltage supply.

One connection line is intended for the measurement signal.

U+ Positive supply connection

U- Negative supply connection

S+ Positive measurement connection

4. Function

Ultra High Purity Transducer

WU-20: Single End

WU-25: Flow Through

WU-26: Modular Surface Mount

Function: The pressure prevailing within the application is transformed into a standardised electrical signal

through the deection of the diaphragm, which acts on the sensor element with the power supply fed to the

transducer. This electric signal changes in proportion to the pressure and can be evaluated correspondingly

For transducer with Ex-marking ATEX

European guideline for explosion

protection. The product complies with

the requirements for the European

directive 2014/34/EU on explosion

protection

V DC direct voltage

EN

For transducer with FM (Factory

Mutual) marking:

The product was tested and certied

by FM Approvals. It complies with the

applicable US-American standards

on safety (including explosion protection).

Page 6

6 WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

5. For your safety

5. For your safety

WARNING!

■

Select the appropriate transducer with regard to scale range, performance and specic

measurement conditions prior to installing and starting the instrument.

■

Consider the relevant national regulations (e.g.: EN/IEC 60079-14) and observe the applicable

standards and directives for special applications (e.g. with dangerous media such as

acetylene, ammable gases or liquids and toxic gases or liquids and with compressors).

Non-observance can result in serious injury and/or damage to equipment.

■

Open pressure connections only after the system is without pressure!

■

Please make sure that the transducer is only used within the overload threshold limit all the

time!

■

Observe the ambient and working conditions outlined in section 7 „Technical data”.

■

Ensure that the transducer is only operated in accordance with the provisions i.e. as described

in the following instructions.

■

Do not interfere with or change the transducer in any other way than described in these

operating instructions.

■

Remove the pressure transducer from service and mark it to prevent it from being used again

accidentally, if it becomes damaged or unsafe for operation

■

Take precautions with regard to remaining media in removed pressure transducers.

Remaining media in the pressure port may be hazardous or toxic!

■

Have repairs performed by the manufacturer only.

■

The operator is responsible for the material compatibility as well as correct handling, operation

and maintenance.

Information about material consistency against corrosion and diusion can be found in our WIKA-Handbook,

"Pressure and Temperature Measurement".

WARNING!

For transducer with Ex-/FM-marking: Consider the relevant safety instructions as well as

the respective country specic regulations for installation and operation in hazardous areas

(e.g.: IEC 60079-14, NEC). If you do not observe these stipulations, serious injuries and/or

damage may occur.

EN

Page 7

7WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

6. Packaging

6. Packaging

Has everything been supplied?

Check the scope of supply:

■

Completely assembled transducer

■

Inspect the transducer for possible damage during transportation. Should there be any

obvious damage, inform the transport company and WIKA without delay.

■

The UHP transducers are puried, evacuated and double-packed in clean rooms in a protective atmosphere (clean room class 5 according to ISO 14644). Special plastic protective

caps are used to protect the high-quality threaded connections (ttings). The gauges should

remain in this special packaging until installation in order to prevent damage and contamina-

tion. Therefore remove the ESD (Electro-Static-Discharge) protective foil only at the place of

installation.

■

Keep the packaging, as it oers optimal protection during transportation (e.g. changing

installation location, shipment for repair).

■

Ensure that the pressure connection thread and the connection contacts will not be damaged.

■

Remove this protection cap only just before installing the transducer.

■

Mount the protection cap when removing and transporting the instrument.

Unpack the transducer

1. Remove the transducer from the box.

2. Remove the outer protective bag and discard.

3. Carry the transducer (sealed in the inner bag), into the clean area.

EN

Page 8

8 WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

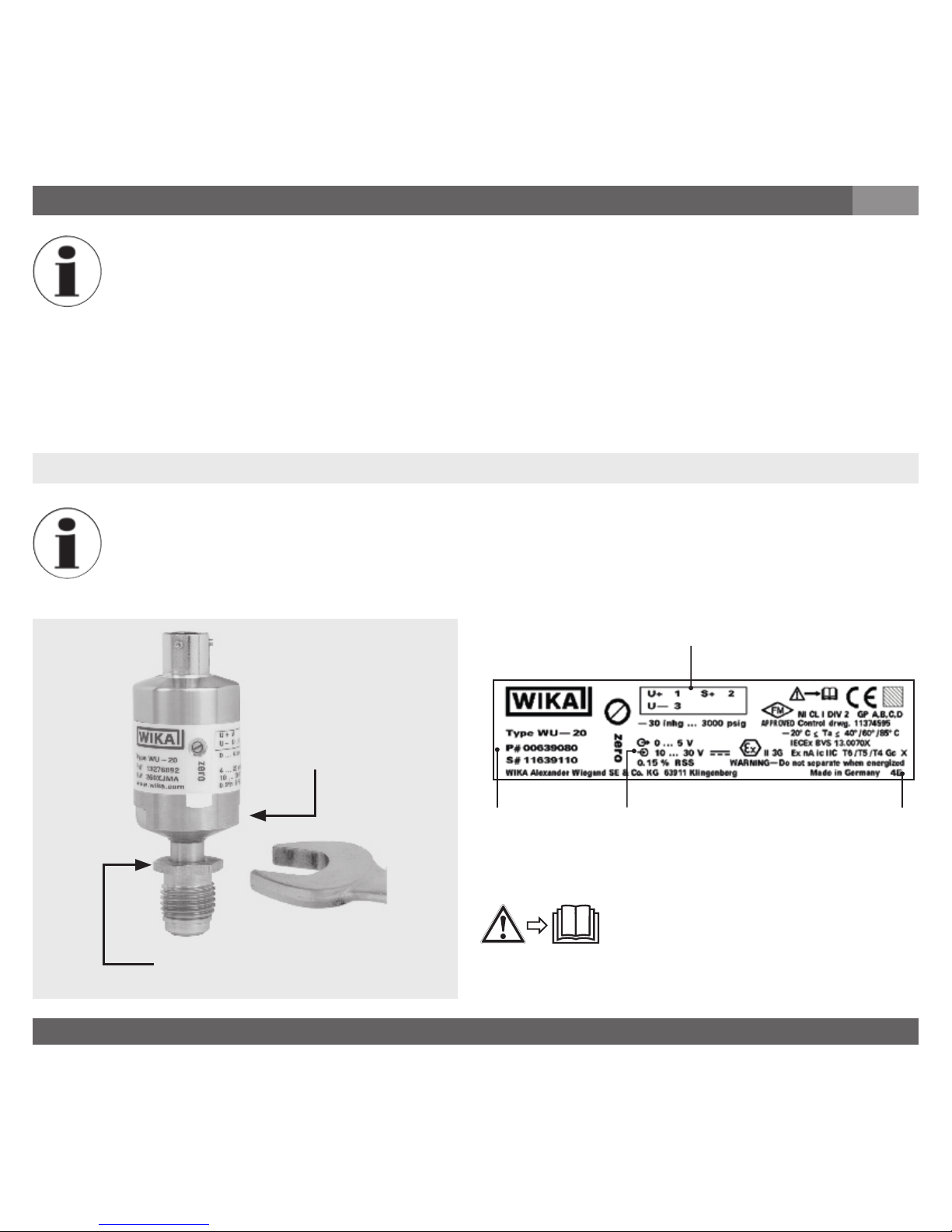

7. Starting, operation

7. Starting, operation

Required tools: wrench (ats 19 and 16), screw driver (0.040" to 0.060" / 1 to 1.5 mm) and a pair

of scissors, allen key for WU-26

Mechanical connection Product label (example)

Signal

Power Supply

EN

PIN assignment

P # Product No.

S # Serial No.

Coded manufacture date

Before mounting and commissioning the instrument, ensure you

read the operating instructions!

Use this wrench at

for screwing in!

Don't use this

wrench at!

Page 9

9WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

7. Starting, operation

EN

■

Remove the protection cap only just before installation.

■

When mounting the instrument, ensure that the sealing faces of the instrument and the

measuring point are clean and undamaged.

■

Do not scratch or nick the bead. Do not over tighten. Damage to the bead will aect the

tting's performance and may cause leakage in the system.

■

Screw in or unscrew the instrument only via the ats using a suitable tool and the prescribed

torque. The appropriate torque depends on the dimension of the pressure connection and on

the sealing element used (form/material). Do not use the case as working surface for screwing

in or unscrewing the instrument.

■

When screwing the transmitter in, ensure that the threads are not jammed.

WARNING!

For transducer with Ex-/FM-marking:

■

Protect the inner diaphragm against any contact with abrasive substances and pressure

peaks and do not touch it with tools. Damage of the diaphragm may result in losing the

explosion protection.

■

Observe the technical data for the use of the transducer in connection with aggressive /

corrosive media and for the avoidance of mechanical hazards.

Mechanical Connection

■

Prepare the gas line connections appropriately.

■

You should blow clean all tting components (such as sealing gaskets, for example) using a clean/ltered

gas. Please refer to the specic technical guides furnished by the gasket manufacturers for additional

specications.

■

You can then remove the protective lm, as well as any plastic caps there may be for protecting high-quality

ttings.

Page 10

10 WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

7. Starting, operation

Face Seal Connections (only WU-20, WU-25)

For connections compatible with VCR®-ttings:

1. Hold the swivel female face seal / swivel male face seal, mounting part (valve etc.) or case hexagon. Tighten the swivel female face seal hand-tight and adjust the instrument to the desired position. When tighten-

ing or untightening at mounting parts (valves etc.) or ttings, ensure that the threads do not get jammed.

2. Hold the swivel female face seal with a suitable open-end wrench. Tighten the swivel female face seal /

swivel male face seal or mounting part (valve etc.) by a 1/8 or 1/4 turn (depending on the sealing elements

used) beyond the hand-tight position.

3. Please refer to the specic technical guides furnished by the tting manufacturers for additional specications.

4. With that the transducer is mechanically connected. Electrical connection possibilities are described in the

following section.

Welding Connections (only WU-20, WU-25)

The weld needs to be fully penetrating, but amperage and heat need to be minimised. We recommend

owing Argon gas through the transducer during welding. This will help to cool the transducer. Prior to

welding tubing to the transducer, it is recommended that a few test welds be made.

WARNING!

■

Make sure the transducer is not connected to any other device, prior to arc welding.

■

Disconnect the transducer from any electrical device.

■

The operator is responsible for the material compatibility as well as correct handling, operation and maintenance.

Prepare the transducer for use

1. Adjust the zero point (please refer to chapter Zero Adjustment).

2. Verify integrity of the weld or seal by appropriate helium leak-testing procedures.

3. Turn the gas ow ON then OFF, 10 times to remove any particles generated during

installation. (The ow rate used should at least equal the process ow specications.)

MSM, Modular Surface Mount (only WU-26)

Please observe the corresponding technical specications, such as torques and mounting position of the

contact components.

EN

Page 11

11WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

7. Starting, operation

Electrical connection

WARNING!

Connect the enclosure to ground through the process connection, against electromagnetic elds

and electrostatic discharge.

WARNING!

Specic conditions for safe use in explosive atmosphere:

■

External earthing connection shall be established by end-user via pressure connection

minimum 4 mm² required. External earthing connection shall be corrosion resist and locked

against rotation.

■

The connector provided by the end user in the end use application shall be in accordance with

all applicable clauses of IEC 60079-0 and IEC 60079-15. A minimum degree of protection IP54

according to IEC 60529 shall be ensured.

■

Cable provided by end-user shall be suitable for the ambient temperature.

■

The Sub-D version has to be installed in a way that it is protected against an impact energy

> 4 J. The connector as well as the corresponding sealing are provided by the end user in the

end use application and shall be in accordance with all applicable clauses of IEC 60079-0 and

IEC 60079-15. A minimum degree of protection IP54 according to IEC 60529 shall be ensured.

■

Use only shielded cables. Note that with connectors no connection between cable shield and

housing is possible.

For instruments with cable outputs, the cable is always shielded. Depending upon the design

(ordered version) the screen may or may not be connected with the enclosure. An additional

equipotential bonding maybe required.

■

Ensure that the cable diameter you select ts to the cable gland of the connector Ensure that

the cable gland of the mounted connector is positioned correctly and that the sealings are

available and undamaged. Tighten the threaded connection and check the correct position of

the sealings in order to ensure the ingress protection

■

Cover ying leads with ne wires by an end splice (cable preparation).

■

Please make sure that the ends of cables with ying leads do not allow any ingress of moisture.

■

The transducer must be connected and operated in accordance with the approriate regulations.

Take care to ensure that the electrical connection (e.g. M12 connector) is correctly made (fully

sealed).

EN

Page 12

12 WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

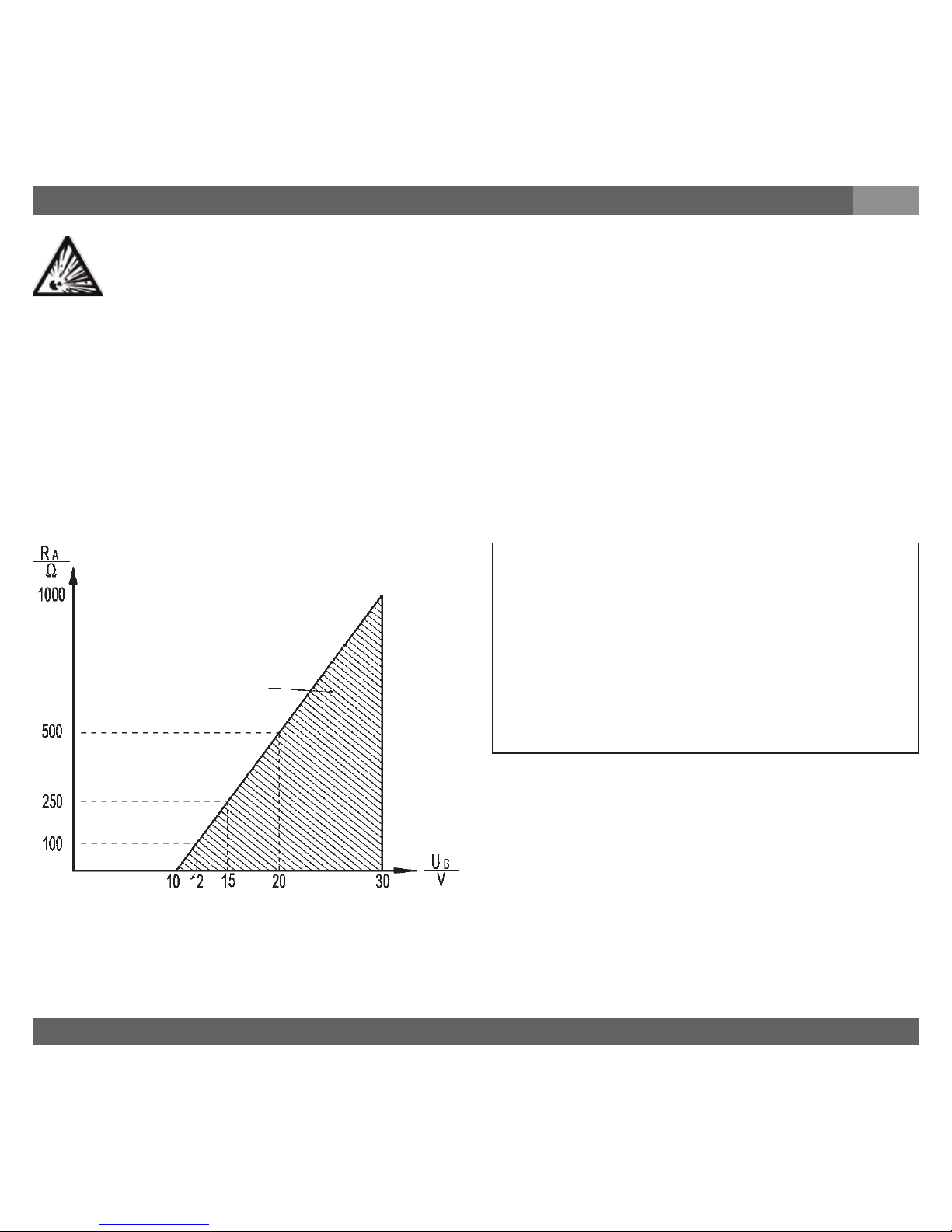

Current output (2-wire)

4 ... 20 mA:

RA ≤ (U+ – 10 V) / 0,02 A

Voltage output (3-wire)

0 ... 5 V: RA > 5 kOhm

0 ... 10 V: RA > 10 kOhm

with RA in Ohm and U+ in Volt

Current for external display- or evaluation equipment can be supplied directly from the circuit, when operating

a transducer with current output. A voltage drop specic to the display unit is to be considered. The transducers are short-circuit-proof for a short time, but anyhow any incorrect connection of the instrument should be

avoided.

WARNING!

■

For equipment with Ex nA ic certication, or if operated under nA ic conditions: Do not

separate when energized.

■

For products with FM Approval: The connection between cable and connector shall

withstand a tensile force of min. 15 N

The transducer is designed to operate with an input voltage of DC 10 ... 30 V / DC 14 ... 30 V with output

signal 0 ... 10 V. The voltage value Ui = DC 30 V shall not be exceeded in the current loop circuit. The inter-

relationship between voltage supply and load resistor (RA) is illustrated by the following diagram.

Signal output and allowed load

4 ... 20 mA, 2-wire

7. Starting, operation

EN

permitted range

Page 13

13WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

Wiring details

Bayonet connector, 4-pin Circular connector M12 x 1, 4-pin Flying leads, 1.5 m

2-wire U+ = A U- = D U+ = 1 U- = 3 U+ = red U- = black

3-wire U+ = A U- = D S+ = B U+ = 1 U- = 3 S+ = 4 U+ = red U- = black S+ = brown

Wire gauge - - 0.22 mm

2

(AWG 24)

Diameter of cable - - 4.8 mm

Torque required for

mounting counterconnector should be

ensured:

1 Nm 1 Nm -

Ingress Protection

per IEC 60529

IP 67 (NEMA 4) IP 67 (NEMA 4) IP 67 (NEMA 4)

The ingress protection classes specied only apply while the pressure transmitter is connected with female connectors

that provide the corresponding ingress protection.

Refer to remark for IP-protection at clause 7 “Specic conditions for safe use in explosive atmosphere”

7. Starting, operation

EN

4

3

1

2

Page 14

14 WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

Wiring details

Sub-D HD connector, 15-pin Sub-D connector, 9-pin

2-wire U+ = 7

U- = 5

U- = 12

U+ = 4 U- = 8

U-

= 9

3-wire U+ = 7

U- = 5

U- = 12

S+ = 2

U+ = 4 U- = 8

U-

= 9

S+ = 1

Wire gauge - Diameter of cable - Torque required for moun-

ting counter-connector

should be ensured:

0.3 Nm (both srews) 0.3 Nm (both srews)

Ingress Protection per IEC

60529

IP 54 IP 54

The ingress protection classes specied only apply while the pressure transmitter is connected with female

connectors that provide the corresponding ingress protection.

Refer to remark for IP-protection at clause 7 “Specic conditions for safe use in explosive atmosphere”

7. Starting, operation

EN

Page 15

15WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

Specications Models WU-20, WU-25 and WU-26

WU-20 / WU-25

WU-26

Pressure ranges psi 30 60 100 160 250 350 500 1000 1500

bar 2 4 7 11 17 25 36 70 100

Over pressure safety *

)

psi 120 120 210 320 500 750 1100 2100 3000

Burst pressure *

)

psi 1800 1800 2200 2600 4800 6200 5800 8000 10500

Pressure ranges psi 2000 3000 5000

bar 145 225 360

Over pressure safety *

)

psi 4200 6600 10500

Burst pressure *

)

psi 10500 10500 12000

Other pressure ranges, pressure units (e.g. MPa, kg/cm

2

) and absolute pressure on request

*

)

1 psi = 0.069 bar

Measuring principle Metal thin-lm sensor

Materials

■

Wetted parts

- Pressure Connection 316L stainless steel, according to SEMI F20 (option: 316L VIM/VAR)

- Pressure sensor 2.4711 / UNSR 30003

■

Case 304 SS

Inboard helium leak test < 1 x 10

-9

mbar l/sec (atm STD cc/sec) according to Semi F1

Surface nish Electropolished, typical Ra ≤ 0.13 µm (RA 5); max. Ra ≤ 0.18 µm (RA 7) exceeds Semi F19

Dead volume cm

3

WU-20 < 1.5, WU-25 < 1, WU-26 < 1

Permissible Medium Speciality gases, vapours, liquids

Power supply U+ U+ in VDC 10 ... 30 with output signal 4 ... 20 mA / 0 ... 5 V

14 ... 30 with output signal 0 ... 10 V

Signal output and RA in Ohm 4 … 20 mA, 2-wire RA ≤ (U+ – 10 V) / 0.02 A

maximum ohmic load RA 0 ... 5 V, 3-wire RA > 5 k

0 ... 10 V, 3-wire RA > 10 k

Power Pmax W 1

Adjustability zero % of span -3.5 up to +3.5 (via potentiometer) Current output signal

-2 up to +3.5 (via potentiometer) Voltage output signal

7. Starting, operation

EN

Page 16

16 WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

Specications Models WU-20, WU-25 and WU-26

Response time (10 ... 90 %) ms ≤ 300

Insulation voltage VDC 500

Accuracy % of span ≤ 0.15 (≤ 0.4 with pressure ranges ≤ 2 bar) RSS (Root Sum Squares)

≤ 0.3

1)

(≤ 0.6 1) with pressure ranges ≤ 2 bar) per IEC 61298-2

Non-linearity % of span ≤ 0.1 (≤ 0.15 for pressure ranges ≤ 2 bar) (BFSL) per IEC 61298-2

Hysteresis % of span ≤ 0.14

Non-repeatability % of span ≤ 0.12

1-year stability % of span ≤ 0.25 % (typ.), at reference conditions (≤ 0.4 % with measuring ranges ≤ 2 bar)

Permissible temperature of non-Ex T4 T5 T6

■

Medium -20 ... +100 °C

-4 ... +212 °F

-20 ... +85 °C

-4 ... +185 °F

-20 ... +60 °C

-4 ... +140 °F

-20 ... +40 °C

-4 ... +104 °F

■

Ambient 20 ... +85 °C

-4 ...+185 °F

-20 ... +85 °C

-4 ... +185 °F

-20 ... +60°C

-4 ... +140 °F

-20 ... +40 °C

-4 ... +104 °F

■

Storage -40 ... +100 °C

-40 ... +212 °F

-40 ... +100 °C

-40 ... +212 °F

-40 ... +100 °C

-40 ... +212 °F

-40 ... +100 °C

-40 ... +212 °F

Rated temperature range -20 ... +80 °C / -4 ... +176 °F (actively compensated)

Temperature coecients within rated tempera-

ture range (actively compensated)

■

Mean TC of zero % of span ≤ 0.1 / 10 K

■

Mean TC of span % of span

≤

0.15 / 10 K

RoHS-conformity Yes

CE- conformitiy

■

Pressure equipment directive 2014/68/EU

■

EMC directive 2014/30/EU, EN 61326-1 Emission (Group 1, Class B) and interference immunity

(industrial application)

■

ATEX directive of equipment intended for

use in potentially explosive atmospheres

2014/34/EU (for transducer with Ex-marking)

Ex-protection ATEX Category 3G (for transducer with Ex-marking)

Ignition protection type II 3G Ex nA ic IIC T6/T5/T4 Gc X (for transducer with Ex-marking)

Ex-protection IECEx

Ignition protection type IECEx BVS 13.0070 X, Ex nA ic IIC T6/T5/T4 Gc

7. Starting, operation

EN

Page 17

17WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

Specications Models WU-20, WU-25 and WU-26

Ex-protection FM Class I (for transducer with FM-marking)

Ignition protection type Nonincendive for Use in Class I, Division 2, Groups A, B, C & D, and Class I, Zone 2,

Group IIC, Hazardous (Classied) Locations

Assembly and packing area Clean room class 5 per ISO 14644

Packaging Double bagging per SEMI E49.6

Shock resistance g 500 (1.5 ms) per IEC 60068-2-27

Vibration resistance mm 0.35 mm (10 - 58 Hz) / 5 g (58.1 - 2000 Hz) per IEC 60068-2-6

Wiring protection

■

Short-circuit proofness S+ vs. U- (short time)

■

Reverse polarity protection U+ vs. U-

Weight kg Approx. 0.1

1) Including non-linearity, hysteresis, zero oset and end value deviation (corresponds to measured error per IEC 61298-2

7. Starting, operation

EN

When designing your plant, take into account that the stated values (e.g.burst pressure, over

pressure safety) apply depending on the material, thread and sealing element used.

Functional test

The output signal must be proportional to the pressure. If not, this might point to a damage of the diaphragm.

In that case refer to chapter 10 „Troubleshooting“.

WARNING!

■

Open pressure connections only after the system is without pressure!

■

Observe the ambient and working conditions outlined in section 7 „Technical data.

■

Please make sure that the transducer is only used within the over load threshold limit at all

times!

CAUTION!

When touching the transducer, keep in mind that the surfaces of the instrument components

might get hot during operation.

Page 18

18 WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

8. Adjustment of zero point

8. Adjustment of zero point

The UHP-Transducers are maintenance free. The transducer is factory calibrated and does not normally need

eld adjustment.

WARNING!

For equipment with Ex nA ic marking, or if operated under nA ic conditions: Do not separate

when energised.

For verication and adjustment of the zero point, vent the transducer to zero (0)PSI for gauge reference

transducers. Use a 0.040" to 0.060" (1 to 1.5 mm) jeweler's screwdriver for adjustment.

■

For instruments with absolute pressure measuring ranges or +/- measuring ranges, a

sucient calibration equipment as well as a vacuum pump are also necessary for the zero

point adjustment.

■

Span adjustment is not necessary after zero point correction.

Procedure

1. Restore power to the transducer.

2. Lift the sticker.

3. Adjust the zero point by means of the potentiometer

in pressureless state. Check the zero point by means

of a suitable instrument. Clockwise rotation means an

upward zero oset, anti-clockwise rotation means a

downward zero oset.

4. Push the sticker on.

EN

For further information

(+49) 9372/132-8976

Page 19

19WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

9. Maintenance, accessories / 10. Trouble shooting

9. Maintenance, accessories

■

WIKA transducers require no maintenance.

■

Have repairs performed by the manufacturer only.

Accessories: For details about the accessories (e. g. connectors), please refer to WIKA‘s price list, WIKA‘s

product catalog on CD or or contact our sales department.

10.Trouble shooting

WARNING!

Open pressure connections only after the system is without pressure!

WARNING!

■

Take precautions with regard to remaining media in removed transducers. Remaining media

in the pressure port may be hazardous or toxic!

■

Remove the transducer from service and mark it to prevent it from being used again accidentally, if it becomes damaged or unsafe for operation.

■

Have repairs performed by the manufacturer only.

Do not insert any pointed or hard objects into the pressure port for cleaning to prevent damage

to the diaphragm of the pressure connection.

Please verify in advance if pressure is being applied (valves/ ball valve etc. open) and if the right voltage

supply and the right type of wiring (2-wire/3-wire) has been chosen?

EN

Page 20

20 WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

Failure Possible cause Procedure

Output signal unchanged after change in

pressure

Mechanical overload through overpressure

Wrong supply voltage or current spike

Replace instrument; if failure reoccurs, consult

the manufacturer *)

Replace instrument

No output signal No/incorrect voltage supply or current spike

Cable break

Adjust the voltage supply to correspond with

the Operating Instructions *)

Check connections and cable

No/False output signal Incorrectly wired (e.g. Connected as 2-wire

instead of 3-wire system)

Follow pin assignment (see Instrument Label /

Operating Instructions)

Abnormal output signal or abnormal zero point

signal

Zero point set wrongly Adjust zero point correctly (see chapter 8); a

suciently accurate current/volt meter should

be used

Abnormal zero point signal Medium or ambient temperature too high/

too low

Diaphragm is damaged, e.g. through impact,

abrasive/agressive media; corrosion of

diaphragm/pressure connector.

Control the internal temperature of the instru-

ment within the permissible range; observe the

allowable temperature error (see Operating

Instructions)

Replace instrument

Signal span dropping o/too small Diaphragm is damaged, e.g. through impact,

abrasive/agressive media; corrosion of

diaphragm/pressure connector

Contact the manufacturer and replace the

instrument

Signal span too small Power supply too high/too low

Mechanical overload through overpressure

Correct the power supply in line with the

Operating Instructions

Re-calibrate the instrument *)

*) Make sure that after the setting the unit is working properly. In case the error continues to exist send in the instrument for reparation (or replace

the unit).

In case of unjustied reclamation we charge the reclamation handling expenses.

10. Trouble shooting

EN

Page 21

21WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

10. Trouble shooting / 11. Storage, disposal

If the problem persists, contact our sales department.

USA, Canada: If the problem continues, contact WIKA or an authorized agent for assistance. If the pressure

transducer must be returned obtain an RMA (return material authorization) number and shipping instructions

from the place of purchase. Be sure to include detailed information about the problem. Pressure transducers

received by WIKA without a valid RMA number will not be accepted.

Process material certicate (Contamination declaration for returned goods)

Purge / clean dismounted instruments before returning them in order to protect our employees and the

environment from any hazard caused by adherent remaining media.

Service of instruments can only take place safely when a Product Return Form has been submitted and

fully lled-in. This Return Form contains information on all materials with which the instrument has come into

contact, either through installation, test purposes, or cleaning. You can nd the Product Return Form on our

internet site (www.wika.de).

11. Storage, disposal

WARNING!

When storing or disposing of the transducer, take precautions with regard to remaining media in

removed transducers. We recommend cleaning the transducer properly and carefully. Remaining media in the pressure port may be hazardous or toxic!

Storage

Mount the protection cap when storing the transducer.

Disposal

Dispose of instrument components and packaging materials in accordance with the respective

waste treatment and disposal regulations of the region or country to which the instrument is

supplied.

EN

Page 22

22 WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

12. EU declaration of conformity

12. EU declaration of conformity

Declarations of conformity can be found online at www.wika.com.

WIKA reserves the right to alter these technical specications.

EN

Page 23

23WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

13. FM certicate of compliance

EN

13. FM certicate of compliance

Certicate of compliance can be found online at www.wika.com.

Page 24

24 WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

14. FM control drawing

EN

14. FM control drawing

Page 25

25WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

1. Wichtiges zu Ihrer Information

DE

Lesen Sie unbedingt diese Betriebsanleitung vor Montage und Inbetriebnahme des Druckmessgerätes.

1. Wichtiges zu Ihrer Information

Lesen Sie diese Betriebsanleitung vor Montage und Inbetriebnahme des Druckmessgerätes.

Bewahren Sie die Betriebsanleitung an einem für alle Benutzer jederzeit zugänglichen Ort auf.

Die nachfolgenden Einbau- und Betriebshinweise haben wir mit Sorgfalt zusammengestellt. Es ist jedoch

nicht möglich, alle erdenklichen Anwendungsfälle zu berücksichtigen. Sollten Sie

Hinweise für Ihre spezielle

Aufgabenstellung vermissen, können Sie hier weitere Informationen nden:

■

Über unsere Internet-Adresse www.wika.de / www.wika.com

■

Die Bezeichnung des zugehörigen Datenblattes ist PE 87.07

■

Anwendungsberater: (+49) 9372/132-0

Wird die Seriennummer auf dem Typenschild unleserlich (z. B. durch mechanische Beschädigung oder

Übermalen), ist eine Rückverfolgbarkeit nicht mehr möglich.

Die in der Betriebsanleitung beschriebenen WIKA-Transducer werden nach den neuesten Erkenntnissen

konstruiert und gefertigt. Alle Komponenten unterliegen während der Fertigung strengen Qualitäts- und

Umweltkriterien. Unser Umweltmanagementsystem ist nach DIN EN ISO 14001 zertiziert. Das fertige Gerät

wurde vor dem Versand getestet, gereinigt und sorgfältig unter Schutzatmosphäre verpackt.

Bestimmungsgemäße Produktverwendung WU-20, WU-25 and WU-26:

Verwenden Sie den Transducer, um Druck in ein elektrisches Signal zu wandeln.

Für Transducer mit Ex-Kennzeichen: Verwenden Sie den nicht funkenden Transducer der Kategorie 3G, um

in explosionsgefährdeten Bereichen der Zone 2, Druck in ein elektrisches Signal zu wandeln.

Zulassungf ür Transducer mit Ex-Kennzeichen

Transducer zur bestimmungsgemäßen Verwendung in explosionsgefährdeten Bereichen.

ATEX-Kennzeichen: II 3G Ex nA ic IIC T6/T5/T4 Gc X

IECEx-Kennzeichen: IECEx BVS 13.0070 X, Ex nA ic IIC T6/T5/T4 Gc

Page 26

26 WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

1. Wichtiges zu Ihrer Information / ... / 3. Zeichenerklärungen, ...

DE

Zulassung für Transducer mit FM-Kennzeichen

Transducer zur bestimmungsgemäßen Verwendung in explosionsgefährdeten Bereichen (siehe

Control drawing Nr. 11537885, Seite 46)

FM Zulassungseigenschaften: Non-incendive für Class I Division 2 Gruppe A, B, C und D

Ihre erforderlichen Kenntnisse: Montieren und nehmen Sie den Transducer nur in Betrieb, wenn Sie mit

den zutreenden landesspezischen Richtlinien vertraut sind und die entsprechende Qualikation besitzen.

Sie müssen mit den Vorschriften und Kenntnissen für explosionsgefährdete Bereiche (wenn Ex-Kennzeichnung auf dem Transducer), Mess- und Regeltechnik sowie elektrische Stromkreise vertraut sein. Je nach

Einsatzbedingung müssen Sie über entsprechendes Wissen verfügen, z. B. über agressive Medien.

2. Der schnelle Überblick für Sie

Wollen Sie sich einen schnellen Überblick verschaen, lesen Sie Kapitel 3, 5, 7 und 11. Dort erhalten Sie

kurze Hinweise zu Ihrer Sicherheit und wichtige Informationen über Ihr Produkt und zur Inbetriebnahme.

Lesen Sie diese unbedingt.

3. Zeichenerklärungen, Abkürzungen

WARNUNG!

Mögliche Gefahr für Ihr Leben oder

schwerer Verletzungen.

WARNUNG!

Für Transducer mit Ex-Kennzeichen:

Ex-Hinweise: Mögliche Gefahr für Ihr

Leben oder schwerer Verletzungen.

WARNUNG!

Mögliche Gefahr für Ihr Leben

oder schwerer Verletzungen durch

wegschleudernde Teile.

VORSICHT!

Mögliche Gefahr von Verbrennungen

durch heisse Oberächen.

Hinweis, wichtige Information,

Funktionsstörung.

Das Produkt stimmt mit den

zutreenden europäischen Richtlinien

überein.

Page 27

27WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

2-Leiter Zwei Anschlussleitungen dienen zur Spannungsversorgung.

Der Speisestrom ist das Messsignal.

3-Leiter Zwei Anschlussleitungen dienen zur Spannungsversorgung.

Eine Anschlussleitung dient für das Messsignal.

U+ Positiver Versorgungsanschluss

U- Negativer Versorgungsanschluss

S+ Positiver Messanschluss

4. Funktion

Ultra High Purity Transducer

WU-20: Single End

WU-25: Flow Through

WU-26: Modular Surface Mount

Funktion: Mittels Sensorelement und unter Zuführung von Hilfsenergie wird über die Verformung einer

Membran der anstehende Druck in Ihrer Anwendung in ein verstärktes standardisiertes elektrisches Signal

umgewandelt. Dieses elektrische Signal verändert sich proportional zum Druck und kann entsprechend

ausgewertet werden.

Für Transducer mit Ex-Kennzeichen:

ATEX Europäische ExplosionsschutzRichtlinie

Das Produkt stimmt überein mit den

Anforderungen der europäischen

Richtlinie 2014/34/EU zum Explosionsschutz.

Gleichspannung

3. Zeichenerklärungen, Abkürzungen / 4. Funktion

DE

Für Transducer mit FM-Kennzeichen:

FM - Factory Mutual; Das Produkt

wurde von FM Approvals geprüft und

zertiziert. Es stimmt überein mit den

anwendbaren US-amerikanischen

Normen zur Sicherheit (einschließlich

Explosionsschutz).

Page 28

28 WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

5. Zu Ihrer Sicherheit

DE

5. Zu Ihrer Sicherheit

WARNUNG!

■

Wählen Sie den richtigen Transducer hinsichtlich Messbereich, Ausführung und spezischen

Messbedingungen vor Montage oder Inbetriebnahme.

■

Halten Sie die entsprechenden landesspezischen Vorschriften ein (z. B.: EN/IEC 60079-14)

und beachten Sie bei speziellen Anwendungen die geltenden Normen und Richtlinien (z.

B. bei gefährlichen Messstoen wie Acetylen, brennbaren oder giftigen Stoen sowie bei

Kompressoren). Wenn Sie die entsprechenden Vorschriften nicht beachten, können schwere

Körperverletzungen und Sachschäden entstehen!

■

Önen Sie Anschlüsse nur im drucklosen Zustand!

■

Betreiben Sie den Transducer immer innerhalb des Überlastgrenzbereiches!

■

Beachten Sie die Betriebsparameter gemäß Punkt 7 „Technische Daten“.

■

Stellen Sie sicher, dass der Transducer nur bestimmungsgemäß -also wie in der folgenden

Anleitung beschrieben- betrieben wird.

■

Unterlassen Sie unzulässige Eingrie und Änderungen am Transducer, welche nicht in

dieser Betriebsanleitung beschrieben sind.

■

Setzen Sie den Transducer außer Betrieb und schützen Sie ihn gegen versehentliche

Inbetriebnahme, wenn Sie Störungen nicht beseitigen können.

■

Ergreifen Sie Vorsichtsmaßnahmen für Messstoreste in ausgebauten Transducern.

Messstoreste können zur Gefährdung von Menschen, Umwelt und Einrichtung führen!

Page 29

29WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

5. Zu Ihrer Sicherheit / 6. Verpackung

DE

WARNUNG!

■

Lassen Sie Reparaturen nur vom Hersteller durchführen.

■

Der Anwender ist für die Materialverträglichkeit sowie die vorschriftsmäßige Handhabung,

Betrieb und Wartung verantwortlich.

Angaben zu Korrosions- bzw. Diusionsbeständigkeit der Gerätewerkstoe entnehmen Sie bitte unserem

WIKA-Handbuch zur Druck- und Temperaturmesstechnik.

WARNUNG!

Für Transducer mit Ex-/FM-Kennzeichen: Beachten Sie die relevanten Sicherheitshinweise,

sowie die jeweiligen landesspezischen Vorschriften zur Installation und Einsatz in explosionsgefährdeten Bereichen (z.B.: IEC 60079-14, NEC). Wenn Sie diese nicht beachten, können

schwere Körperverletzungen und Sachschäden entstehen.

6. Verpackung

Wurde alles geliefert?

Überprüfen Sie den Lieferumfang:

■

Komplett montierte Transducer

■

Untersuchen Sie den Transducer auf eventuell entstandene Transportschäden. Sind

oensichtlich Schäden vorhanden, teilen Sie dies dem Transportunternehmen und WIKA

unverzüglich mit.

■

Die UHP-Transducer wurden in Reinräumen unter Schutzatmosphäre (Reinraumklasse 5

nach ISO 14644) gereinigt, evakuiert und doppelt verpackt. Die hochwertigen Verschraubungen (Fittings) sind mit speziellen Kunststokappen geschützt. Zum Schutz gegen Beschä-

digung und Kontamination sollten Sie die Geräte in dieser Spezialverpackung bis zu ihrem

Einbau lassen. Entfernen Sie daher die ESD-Schutzfolie (Electro-Static-Discharge) erst am

Einsatzort.

■

Bewahren Sie die Verpackung auf, denn diese bietet bei einem Transport einen optimalen

Schutz (z. B. wechselnder Einbauort, Reparatursendung).

■

Achten sie darauf, dass das Druckanschluss-Gewinde und die Anschlusskontakte nicht

beschädigt werden.

Page 30

30 WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

6. Verpackung / 7. Inbetriebnahme, Betrieb

DE

Montage mechanischer Anschluss

Typenschild (Beispiel)

■

Entfernen Sie die Schutzkappe erst kurz vor dem Einbau.

■

Montieren Sie die Schutzkappe bei Ausbau und Transport des Gerätes.

Entpacken der Geräte

1. Nehmen Sie den Transducer aus dem Karton.

2. Entfernen Sie danach vorsichtig die erste durchsichtige Folie ohne die ESD-Schutzfolie zu beschädigen.

3. Bringen Sie das Gerät inkl. ungeöneter ESD-Schutzfolie in den Reinraum.

7. Inbetriebnahme, Betrieb

Benötigtes Werkzeug: Maulschlüssel SW 19 und 16, Schraubendreher der Größe 1 bis 1,5 mm,

Schere, Inbusschlüsselsatz für WU-26

Signal

Spannungsversorgung

Anschlussbelegung

P # Erzeugnis-Nr.

S # Serien-Nr.

Codiertes

Herstelldatum

Vor Montage und Inbetriebnahme

des Gerätes unbedingt die Betriebsanleitung lesen!

Benutzen Sie diese Schlüssel-

äche zum Einschrauben!

Benutzen Sie nicht

diese Schlüsseläche!

Page 31

31WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

7. Inbetriebnahme, Betrieb

DE

■

Entfernen Sie die Schutzkappe erst kurz vor dem Einbau.

■

Achten Sie bei der Montage auf saubere und unbeschädigte Dichtächen am Gerät und

Messstelle.

■

Zerkratzen Sie nicht die Dichtlippen. Ein übermäßiges Anziehen kann die Dichtlippen

beschädigen und zu möglichen Leckagen führen.

■

Schrauben Sie das Gerät nur über die Schlüsselächen mit einem geeigneten Werkzeug

und dem vorgeschriebenen Drehmoment ein bzw. aus. Das richtige Drehmoment ist abhängig von der Dimension des Druckanschlusses sowie der verwendeten Dichtung (Form/

Werksto). Verwenden Sie zum Ein- bzw. Ausschrauben nicht das Gehäuse als Angrisäche.

■

Beachten Sie beim Einschrauben, dass die Gewindegänge nicht verkantet werden.

WARNUNG!

Für Transducer mit Ex-/FM-Kennzeichen:

■

Schützen Sie die innenliegende Membran vor Kontakt mit abrasiven Medien und gegen

Schläge. Eine Beschädigung der Membrane kann zum Verlust des Explosionsschutzes

führen!

■

Beachten Sie die Technischen Daten zur Verwendung des Transducers in Verbindung mit

agressiven / korrosiven Medien und zur Vermeidung von mechanischen Gefährdungen.

Mechanischer Anschluss

■

Bereiten Sie die Anschlüsse der Gasleitungen entsprechend vor.

■

Sie sollten alle Anschlusskomponenten wie z.B. Dichtscheiben mit einem reinen/gelterten Gas reinigen.

Beachten Sie hierbei die entsprechenden Einbauvorschriften der verwendeten herstellerspezischen

Dichtscheiben.

■

Die Schutzfolie sowie evtl. vorhandene Kunststokappen zum Schutz der hochwertigen Anschlüsse

können Sie jetzt entfernen.

Verschraubungen (nur WU-20 / WU-25)

Für Verschraubungen (Fittings) mit Innen- bzw. Außengewinde kompatibel zu VCR® Anschlüssen gilt:

1. Halten Sie die Überwurfmutter/Druckschraube oder Armatur bzw. die Gehäuseschlüsseläche fest. Ziehen

Sie die Überwurfmutter handfest an und richten das Sie Gerät in die gewünschte Position aus. Beachten

Sie beim Ein- bzw. Aufschrauben an Armaturen oder Fittings, dass die Gewindegänge nicht verkantet

werden.

Page 32

32 WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

7. Inbetriebnahme, Betrieb

DE

2. Halten Sie die Überwurfmutter mit einem geeigneten Maulschlüssel fest. Ziehen Sie die Überwurfmutter/

Druckschraube oder Armatur mit einer 1/8 bzw. 1/4 Drehung (abhängigvon den verwendeten Dichtungen)

über die handfeste Stellung hinaus an.

3. Bitte beachten Sie auch die entsprechenden technischen Spezikationen und Hinweise der spezischen

Anschlusshersteller (Glands + Fittings).

4. Der Transducer ist damit mechanisch angeschlossen. Elektrische Anschlussmöglichkeiten

werden im folgenden Abschnitt behandelt.

Schweißanschlüsse (nur WU-20 / WU-25)

Die Schweißnaht muss vollständig und durchgängig geschweißt sein. Achten Sie dennoch auf minimalen

Strom und Hitzeeintrag gegenüber den Geräten. Zum Kühlen empfehlen wir den Durchuss von Argon

während des Schweißprozesses. Es empehlt sich, vor dem eigentlichen Schweißen der Transducer einige

Testschweißungen durchzuführen.

WARNUNG!

■

Stellen Sie vor dem Lichtbogenschweißen sicher, dass der Transducer an keine weiteren

Geräte angeschlossen ist.

■

Trennen Sie alle elektrischen Anschlüsse mit dem Transducer.

■

Vermeiden Sie es strikt, dass Zuleitungen aus der Anschlusslitze mit Metalloberächen in

Berührung kommen.

Nachbearbeitung

1. Der Nullpunkt ist unter Umständen abzugleichen (siehe Punkt Nullpunktabgleich).

2. Prüfen Sie alle mechanischen Anschlüsse (Fittings, Schweißungen) mittels geeignetem Test (z.B. Helium

Leak Test) auf Dichtigkeit.

3. Den Gasdurchuss sollten Sie mindestens 10-mal ein und wieder ausschalten, um eventuell bei der Installation eingedrungene Partikel zu entfernen. Die Durchussrate des Gases sollte hierbei dem späteren

Prozessuss entsprechen.

MSM-Anschlüsse (nur WU-26)

Bitte beachten Sie die entsprechenden technischen Spezikationen wie Drehmomente und Einbauposition

der Anschlusskomponenten.

Page 33

33WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

D

7. Inbetriebnahme, Betrieb

DE

Montage elektrischer Anschluss

WARNUNG!

Erden Sie das Gehäuse über den Prozessanschluss gegen elektromagnetische Felder und

elektrostatische Auadungen.

WARNUNG!

Besondere Bedingungen für die Verwendung im Ex-Bereich

■

Der externe Erdungsanschluss muss über den Prozessanschluss, der einer Mindestquerschnittsäche von 4 mm2 entspricht, hergestellt werden. Die Anschlussteile müssen

so ausgelegt sein, dass sie gegen Lockern und Verdrehen gesichert und wirksam gegen

Korrosion geschützt sind.

■

Der vom Endanwender genutzte Gegenstecker muss übereinstimmen mit allen anwendbaren Paragraphen der IEC 60079-0 and IEC 60079-15. Der minimale Schutzgrad IP54 nach

IEC 60529 muss sichergestellt sein.

■

Es müssen für die Umgebungstemperatur geeignete Anschlussleitungen verwendet werden.

■

Bei elektrischem Anschluss „Sub-D“ muss über die Installation sichergestellt sein, dass der

Transducer vor Schlägen/Stößen mit einer Energie > 4 J geschützt ist. Der Stecker, wie auch

die Dichtung, welche vom Anwender in der Endanwendung zur Verfügung gestellt werden,

müssen mit allen zutreenden Bestimmungen von IEC 60079-0 und IEC 60079-15 überein-

stimmen. Eine minimale Schutzart von IP54 gemäß IEC 60529 muss sichergestellt werden.

■

Verwenden Sie nur geschirmte Leitungen. Beachten Sie, dass bei Steckverbindern keine

Verbindung zwischen Kabelschirm und Gehäuse möglich ist. Bei Geräten mit Kabelausgang

ist das Kabel immer geschirmt. Je nach Ausführung (Bestellmerkmal) ist der Schirm mit dem

Gehäuse verbunden oder nicht. Sorgen Sie hier ggf. für einen Potentialausgleich.

■

Wählen Sie den Kabeldurchmesser passend zur Kabeldurchführung des Steckers. Achten

Sie darauf, dass die Kabelverschraubung des montierten Steckers korrekt sitzt und dass die

Dichtungen vorhanden und nicht beschädigt sind. Ziehen Sie die Verschraubung fest und

überprüfen Sie den korrekten Sitz der Dichtungen, um die Schutzart zu gewährleisten.

■

Versehen Sie feindrahtige Leiterenden mit Aderendhülsen (Kabelkonfektionierung).

■

Stellen Sie bei Kabelausgängen sicher, dass am Ende des Kabels keine Feuchtigkeit eintritt.

■

Der Transducer muss bestimmungsgemäß angeschlossen und betrieben werden. Achten

Sie auf den korrekten (dichten) Verschluss der elektrischen Verbindung (z.B. M12-Kupplung).

Page 34

34 WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

7. Inbetriebnahme, Betrieb

DE

Stromausgang (2-Leiter)

4 ... 20 mA:

RA ≤ (U+ – 10 V) / 0,02 A

Spannungsausgang (3-Leiter)

0 ... 5 V: RA > 5 kOhm

0 ... 10 V: RA > 10 kOhm

mit RA in Ohm und U+ in Volt

Bei Transducern mit Stromausgang können externe Anzeige- und Auswertegeräte direkt aus der Strom-

schleife gespeist werden. Dabei ist ein, durch das Anzeigegerät spezischer zusätzlicher Spannungsabfall

zu beachten. Die Transducer sind kurzzeitig kurzschlussfest; dennoch sollte eine falsche Beschaltung des

Gerätes vermieden werden.

WARNUNG!

■

Für Geräte mit Kennzeichnung Ex nA ic oder wenn unter nA ic-Bedingungen betrieben:

Trennen Sie das Gerät nicht unter Spannung!

■

Bei Produkten mit FM-Zulassung: Der Anschluss zwischen Kabel und Steckverbinder muss

einer Zugkraft von min. 15 N standhalten.

Der elektrische Anschluss der Transducer wird über Stecker hergestellt.

Als Hilfsenergie genügt eine Gleichspannung innerhalb der angegebenen Grenzen.

Hilfsenergie U+: DC 10 ... 30 V / DC 14 ... 30 V bei Ausgang 0 ... 10 V. Der Spannungswert Ui = DC 30 V darf

im Stromschleifenkreis nicht überschritten werden. Den Zusammenhang zwischen Spannungsversorgung

und Bürdenwiderstand (RA) verdeutlicht die folgende Zeichnung:

Ausgangssignal und zulässige Bürde

4 ... 20 mA, 2-Leiter

zulässiger Bereich

Page 35

35WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

Elektrische Anschlüsse

Bajonett-Rundsteckverbinder,

4-polig

Rundsteckverbinder M12 x 1,

4-polig

Kabelausgang, 1,5 m

2-Leiter U+ = A U- = D U+ = 1 U- = 3 U+ = rot U- = schwarz

3-Leiter U+ = A U- = D S+ = B U+ = 1 U- = 3 S+ = 4 U+ = rot U- = schwarz S+ = braun

Aderquerschnitt - - 0,22 mm

2

(AWG 24)

Kabeldurchmesser - - 4,8 mm

Benötiges Anzugsmo-

ment für den Gegenstecker

1 Nm 1 Nm -

Schutzart

nach IEC 60529

IP 67 (NEMA 4) IP 67 (NEMA 4) IP 67 (NEMA 4)

Die angegebenen Schutzarten gelten nur im gesteckten Zustand mit Leitungssteckern entsprechender Schutzart.

Bezugnehmend auf die Hinweise zur IP-Schutzart unter Kapitel 7 "Besondere Bedingungen für die Verwendung im

Ex-Bereich"

7. Inbetriebnahme, Betrieb

DE

4

3

1

2

Page 36

36 WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

Elektrische Anschlüsse

Sub-D HD Stecker, 15-polig Sub-D Stecker, 9-polig

2-Leiter U+ = 7 U- = 5

U- = 12

U+ = 4 U- = 8

U-

= 9

3-Leiter U+ = 7 U- = 5

U- = 12

S+ = 2 U+ = 4 U- = 8

U-

= 9

S+ = 1

Aderquerschnitt - Kabeldurchmesser - Benötiges Anzugs-

moment für den

Gegenstecker

0,3 Nm (beide Schrauben) 0,3 Nm (beide Schrauben)

Schutzart

nach IEC 60529

IP 54 IP 54

Die angegebenen Schutzarten gelten nur im gesteckten Zustand mit Leitungssteckern entsprechender Schutzart.

Bezugnehmend auf die Hinweise zur IP-Schutzart unter Kapitel 7 "Besondere Bedingungen für die Verwendung im

Ex-Bereich"

7. Inbetriebnahme, Betrieb

DE

Page 37

37WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

Technische Daten Typen WU-20, WU-25 und WU-26

WU-20 / WU-25

WU-26

Messbereich psi 30 60 100 160 250 350 500 1000 1500

bar 2 4 7 11 17 25 36 70 100

Überlastgrenze

1)

psi 120 120 210 320 500 750 1100 2100 3000

Berstdruck

1)

psi 1800 1800 2200 2600 4800 6200 5800 8000 10500

Messbereich psi 2000 3000 5000

bar 145 225 360

Überlastgrenze

1)

psi 4200 6600 10500

Berstdruck

1)

psi 10500 10500 12000

Weitere Druckbereiche und Druckeinheiten (z.B. MPa, kg/cm

2

) sowie Absolutdruck auf Anfrage

1)

1 psi = 0,069 bar

Messprinzip Dünnlm-Sensor

Werksto

■

Messstoberührte Teile

- Druckanschluss CrNi-Stahl 316L, nach SEMI F20 (Option: 316L VIM/VAR)

- Drucksensor 2.4711 / UNSR 30003

■

Gehäuse 304 SS

Inboard Helium-Lecktest < 1 x 10-9 mbar l/sec (atm STD cc/sec) nach Semi F1

Oberächengüte Elektropoliert, typ. Ra ≤ 0,13 µm (RA 5); max. Ra ≤ 0,18 µm (RA 7) nach Semi F19

Totraumvolumen cm

3

WU-20 < 1,5, WU-25 < 1, WU-26 < 1

Zulässige Messstoe Spezialgase / Nebel / Flüssigkeiten

Hilfsenergie U+ U+ in VDC 10 ... 30 bei Ausgang 4 ... 20 mA / 0 ... 5 V

14 ... 30 bei Ausgang 0 ... 10 V

Ausgangssignal und zulässige RA in Ohm 4 ... 20 mA, 2-Leiter RA ≤ (U+ – 10 V) / 0,02 A

max. ohmsche Bürde RA 0 ... 5 V, 3-Leiter RA > 5 k

0 ... 10 V, 3-Leiter RA > 10 k

Leistung Pmax W 1

Einstellbarkeit Nullpunkt % d. Spanne

-3,5 bis +3,5 (durch Potentiometer) Ausgangssignal Strom

-2 bis +3,5 (durch Potentiometer) Ausgangssignal Spannung

7. Inbetriebnahme, Betrieb

DE

Page 38

38 WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

Technische Daten Typen WU-20, WU-25 und WU-26

Einstellzeit (10 … 90 %) ms

≤

300

Isolationsspannung VDC 500

Genauigkeit % d. Spanne ≤ 0,15 (≤ 0,4 bei Messbereiche ≤ 2 bar) RSS (Root Sum Squares)

≤ 0,3

1)

(≤ 0,6 1) bei Messbereiche ≤ 2 bar) nach IEC 61298-2

Nichtlinearität % d. Spanne ≤ 0,1 (≤ 0,15 für Messbereiche ≤ 2 bar) (BFSL) nach IEC 61298-2

Hysterese % d. Spanne ≤ 0,14

Nichtwiederholbarkeit % d. Spanne ≤ 0,12

Stabilität pro Jahr % d. Spanne ≤ 0,25 (typ.), bei Referenzbedingungen (≤ 0,4 % für Messbereich ≤ 2 bar)

Zulässige Temperaturbereiche Nicht-Ex T4 T5 T6

■

Messsto -20 ... +100 °C

-4 ... +212 °F

-20 ... +85 °C

-4 ... +185 °F

-20 ... +60 °C

-4 ... +140 °F

-20 ... +40 °C

-4 ... +104 °F

■

Umgebung 20 ... +85 °C

-4 ...+185 °F

-20 ... +85 °C

-4 ... +185 °F

-20 ... +60°C

-4 ... +140 °F

-20 ... +40 °C

-4 ... +104 °F

■

Lagerung -40 ... +100 °C

-40 ... +212 °F

-40 ... +100 °C

-40 ... +212 °F

-40 ... +100 °C

-40 ... +212 °F

-40 ... +100 °C

-40 ... +212 °F

Nenntemperaturbereich -20 ... +80 °C / -4 ... +176 °F (aktiv kompensiert)

Temperaturkoezienten im Nenntempe-

raturbereich (aktiv kompensiert)

■

Mittlerer TK des Nullpunktes % d. Spanne

≤

0,1 / 10 K

■

Mittlerer TK der Spanne % d. Spanne

≤

0,15 / 10 K

RoHS-Konformität Ja

CE- Kennzeichen

■

Druckgeräterichtlinie 2014/68/EU

■

EMV-Richtlinie 2014/30/EU, EN 61326-1 Emission (Gruppe 1, Klasse B) und Störfestigkeit

(industrieller Bereich)

■

ATEX-Richtlinie für Geräte zur

bestimmungsgemäßen Verwendung in

explosionsgefährdeten Bereichen

2014/34/EU (für Transducer mit Ex-Kennzeichen)

Ex -Schutz ATEX Kategorie 3G (für Transducer mit Ex-Kennzeichen)

Zündschutzart II 3G Ex nA ic IIC T6/T5/T4 Gc X

Ex -Schutz IECEx

Zündschutzart IECEx BVS 13.0070 X, Ex nA ic IIC T6/T5/T4 Gc

7. Inbetriebnahme, Betrieb

DE

Page 39

39WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

Technische Daten Typen WU-20, WU-25 und WU-26

Ex-Schutz FM Class I (für Transducer mit FM-Kennzeichen)

Zündschutzart Nonincendive for Use in Class I, Division 2, Groups A, B, C & D, and Class I,

Zone 2, Group IIC, Hazardous (Classied) Locations

Fertigungsumgebung Reinraumklasse 5 nach ISO 14644

Verpackung Doppelt verpackt nach SEMI E49.6

Schockbelastbarkeit g 500 (1,5 ms) nach IEC 60068-2-27

Vibrationsbelastbarkeit mm 0,35 mm (10 - 58 Hz) / 5 g (58,1 - 2000 Hz) nach EN 60068-2-6

Elektrische Schutzarten

■

Kurzschlussfestigkeit S+ gegen U- (kurzzeitig)

■

Verpolschutz U+ gegen U-

Gewicht kg Ca. 0,1

1) Einschließlich Nichtlinearität, Hysterese, Nullpunkt- und Endwertabweichung (entspricht Messabweichung nach IEC 61298-2)

7. Inbetriebnahme, Betrieb

DE

Beachten Sie bei der Auslegung Ihrer Anlage, dass die angegebenen Werte (z. B. Berstdruck,

Überlastgrenze) in Abhängigkeit vom verwendeten Material, Gewinde und Dichtung gelten.

Funktionsprüfung

Das Ausgangssignal muss sich dem anstehenden Druck proportional verhalten. Wenn dies nicht so ist, kann

das ein Hinweis auf eine Beschädigung der Membran sein. Lesen Sie in diesem Fall in Kapitel 10 „Störbeseitigung“ nach.

WARNUNG!

■

Önen Sie Anschlüsse nur im drucklosen Zustand!

■

Beachten Sie die Betriebsparameter gemäß Punkt 7 „Technische Daten“.

■

Betreiben Sie den Transducer immer innerhalb des Überlastgrenzbereichs!

VORSICHT!

Beachten Sie beim Berühren des Transducers, dass die Oberächen der Gerätekomponenten

während des Betriebes heiß werden können.

Page 40

40 WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

8. Einstellung Nullpunkt

DE

8. Einstellung Nullpunkt

Die hier beschriebenen WIKA-Transducer sind wartungsfrei. Sollte dennoch ein Nullpunktversatz auftreten,

kann dieser mittels des eingebauten Potentiometers justiert werden.

WARNUNG!

Für Geräte mit Kennzeichnung Ex nA ic oder wenn unter nA ic-Bedingungen betrieben: Trennen

Sie das Gerät nicht unter Spannung!

Die Überprüfung und Einstellung des Nullpunktes erfolgt im drucklosen Zustand.

Zum Abgleich ist ein Schraubendreher der Größe 1 bis 1,5 mm erforderlich.

■

Für Geräte mit Absolutdruckmessbereichen oder +/- Messbereichen ist auch für die

Nullpunkteinstellung eine ausreichende Kalibrierausstattung sowie eine Vakuumpumpe

erforderlich.

■

Eine Spanneeinstellung (nach der Nullpunktjustage) ist für die hier beschriebenen Transducer

nicht erforderlich.

Ablauf

1. Versorgen Sie das Gerät mit Spannung.

2. Heben Sie das Klebeschild an.

3. Verstellen Sie mit dem Potentiometer denNullpunkt im drucklosen

Zustand. Überprüfen Sie den Nullpunkt mittels geeignetem Gerät.

Drehen im Uhrzeigersinn bedeutet Nullpunktverschiebung nach

oben, drehen entgegen dem Uhrzeigersinn bedeutet Nullpunktver-

schiebung nach unten.

4.Drücken Sie das Klebeschild wieder an.

Bei Rückfragen

(+49) 9372/132-8976

Page 41

41WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

9. Wartung, Zubehör / 10. Störbeseitigung

DE

9. Wartung, Zubehör

■

WIKA Transducer sind wartungsfrei.

■

Lassen Sie Reparaturen nur vom Hersteller durchführen.

Zubehör

Entnehmen Sie bitte Zubehörangaben (z. B. Stecker) unserer aktuellen Standardpreisliste, dem CD-Katalog

oder setzen Sie sich mit unserem Vertriebsmitarbeiter in Verbindung.

10. Störbeseitigung

WARNUNG!

Önen Sie Anschlüsse nur im drucklosen Zustand!

WARNUNG!

■

Ergreifen Sie Vorsichtsmaßnahmen für Messstoreste in ausgebauten Transducern.

Messstoreste können zur Gefährdung von Menschen, Umwelt und Einrichtung führen!

■

Setzen Sie den Transducer außer Betrieb und schützen Sie ihn gegen versehentliche

Inbetriebnahme, wenn Sie Störungen nicht beseitigen können.

■

Lassen Sie Reparaturen nur vom Hersteller durchführen.

Verwenden Sie keine spitzen bzw. harten Gegenstände zur Reinigung, denn die Membran des

Druckanschlusses darf nicht beschädigt werden.

Prüfen Sie bitte vorab, ob Druck ansteht (Ventile/Kugelhahn usw. oen) und ob Sie die richtige Spannungs-

versorgung und die richtige Verdrahtungsart (2-Leiter/3-Leiter) gewählt haben.

Page 42

42 WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

Störung Mögliche Ursache Maßnahme

Gleichbleibendes Ausgangssignal bei

Druckänderung

Mechanische Überlastung durch Überdruck

Falsche Versorgungsspannung oder

Stromstoß

Gerät austauschen; bei wiederholtem Ausfall

Rücksprache mit Hersteller *)

Gerät austauschen

Kein Ausgangssignal Keine/Falsche Versorgungsspannung oder

Stromstoß

Leitungsbruch

Versorgungsspannung gemäß Betriebsanleitung korrigieren *)

Durchgang überprüfen

Kein/Falsches Ausgangssignal Verdrahtungsfehler (z. B. 2-Leiter als

3-Leiter verdrahtet)

Anschlussbelegung beachten (siehe Typenschild / Betriebsanleitung)

Abweichendes Ausgangssignal oder abwei-

chendes Nullpunkt-Signal

Nullpunkt verstellt Nullpunkt korrekt einstellen (siehe Kapitel 8);

ausreichend genaues Strom/Spannungsmessgerät verwenden

Abweichendes Nullpunkt-Signal Medium- bzw. Umgebungstemperatur zu

hoch/niedrig

Membranbeschädigung, z. B. durch

Schläge, abrasives/agressives Medium;

Korrosion an Membran/Druckanschluss

Gerät innerhalb zulässigem Temperaturbe-

reich betreiben; zulässigen Temperaturfehler

beachten (siehe Betriebsanleitung)

Gerät austauschen

Signalspanne fällt/ab/zu klein Membranbeschädigung, z. B. durch

Schläge, abrasives/agressives Medium;

Korrosion an Membran/Druckanschluss

Hersteller kontaktieren und Gerät austauschen

Signalspanne zu klein Versorgungsspannung zu hoch/niedrig

Mechanische Überlastung durch Überdruck

Versorgungsspannung gemäß Betriebsanleitung korrigieren

Gerät neu kalibrieren *)

*) Überprüfen Sie nach dem Justieren die korrekte Arbeitsweise des Systems. Besteht der Fehler weiterhin, senden Sie das Gerät zur Reparatur

ein (oder tauschen Sie das Gerät aus).

Im unberechtigtem Reklamationsfall berechnen wir die Reklamationsbearbeitungs-Kosten.

10. Störbeseitigung

DE

Page 43

43WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

10. Störbeseitigung / 11. Lagerung, Entsorgung

DE

Wenn das Problem bestehen bleibt, setzen Sie sich mit unserem Vertriebsmitarbeiter in Verbindung.

Prozess Material Zertikat (Kontaminationserklärung im Servicefall)

Spülen bzw. säubern Sie ausgebaute Geräte vor der Rücksendung, um unsere Mitarbeiter und die Umwelt

vor Gefährdung durch anhaftende Messstoreste zu schützen.

Eine Überprüfung ausgefallener Geräte kann nur sicher erfolgen, wenn das vollständig ausgefüllte Rücksendeformular vorliegt. Eine solche Erklärung beinhaltet alle Materialien, welche mit dem Gerät in Berührung

kamen, auch solche, die zu Testzwecken, zum Betrieb oder zur Reinigung eingesetzt wurden. Das Rücksendeformular ist über unsere Internet-Adresse (www.wika.de / www.wika.com) verfügbar.

11. Lagerung, Entsorgung

WARNUNG!

Ergreifen Sie bei Lagerung und Entsorgung Vorsichtsmaßnahmen für Messstoreste in ausgebauten Transducern. Wir empfehlen eine geeignete und sorgfältige Reinigung. Messstoreste

können zur Gefährdung von Menschen, Umwelt und Einrichtung führen!

Lagerung

Montieren Sie die Schutzkappe bei Lagerung des Transducers.

Entsorgung

Entsorgen Sie Gerätekomponenten und Verpackungsmaterialien entsprechend den einschlägi-

gen landesspezischen Abfallbehandlungs- und Entsorgungsvorschriften des Anliefergebietes.

Page 44

44 WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

12. EU-Konformitätserklärung

DE

Konformitätserklärungen nden Sie online unter www.wika.com

Technische Änderungen vorbehalten.

12. EU-Konformitätserklärung

Page 45

45WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

13. FM-Zertikat

13. FM-Zertikat

DE

Zertikate nden Sie online unter www.wika.com

Page 46

46 WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

14. FM-Control drawing

14. FM-Control drawing

DE

Page 47

47WIKA Operating instructions/Betriebsanleitung, WU-2X

11553678.05 EN/DE 02/2019

DE

Page 48

11553678.05 EN/DE 02/2019

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/Germany

Tel. +49 9372 132-0

Fax +49 9372 132-406

info@wika.de

www.wika.de

Current terms and conditions apply. Details are available on ...

Es gelten unsere aktuellen Verkaufs- und Lieferbedingungen, siehe unter ...

www.wika.com

Loading...

Loading...