Page 1

Operating instructions

Betriebsanleitung

Process transmitter for hazardous areas

Model UPT-20, UPT-21

Prozesstransmitter für explosionsgefährdete Bereiche

Typ UPT-20, UPT-21

EN

DE

Process transmitter, model UPT-20

Page 2

EN

Operating instructions model UPT-2x Page 3 - 70

DE

Betriebsanleitung Typ UPT-2x Seite 71 - 137

© 2015 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

®

WIKA

is a registered trademark in various countries.

®

WIKA

ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

2

WIKA operating instructions process transmitter, model UPT-2x

14111166.02 04/2015 EN/DE

Page 3

Contents

Contents

1. General information ...............................................6

2. Design and function ...............................................7

2.1 Design .................................................................7

2.2 Description..............................................................7

2.3 Scope of delivery.........................................................8

3. Safety ...........................................................9

3.1 Explanation of symbols....................................................9

3.2 Intended use ............................................................9

3.2.1 Special conditions for safe use......................................10

3.3 Personnel qualification ...................................................10

3.4 Risks in hazardous areas .................................................11

3.5 Handling of hazardous media..............................................11

3.6 Labelling, safety marks...................................................11

4. Transport, packaging and storage ..................................13

5. Commissioning, operation ........................................14

5.1 Mechanical mounting ....................................................14

5.1.1 Requirements for mounting point ....................................14

5.1.2 Mounting the process transmitter....................................15

5.2 Electrical installation .....................................................17

5.2.1 Safety instructions ................................................17

5.2.2 Requirements for connection cable ..................................17

5.2.3 Requirements regarding intrinsic voltage supply........................18

5.2.4 Opening the case.................................................18

5.2.5 Shielding and grounding ...........................................18

5.2.6 Connection......................................................19

5.2.7 Pin assignments..................................................20

EN

6. Display and operating unit, model DI-PT-U ...........................21

6.1 Design and description...................................................21

6.2 Accessing/exiting the operating menu.......................................21

6.3 Installation/Removal .....................................................22

6.4 Setting the main display ..................................................23

6.5 Setting the additional display ..............................................24

7. Configuration without display and operating unit .....................25

7.1 Performing a mounting correction (offset)....................................25

7.2 Configuring over HART® interface..........................................26

14111166.02 04/2015 EN/DE

WIKA operating instructions process transmitter, model UPT-2x

3

Page 4

EN

Contents

8. Configuration via display and operating unit .........................27

8.1 Configuring the measuring task . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

8.1.1 Configuring pressure measurement..................................27

8.1.2 Configuring level measurement .....................................28

8.1.3 Configuring the volume measurement ................................29

8.1.4 Characteristic curves..............................................32

8.2 Setting the units.........................................................34

8.2.1 Setting the pressure unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.2.2 Set length unit (for level measurement) ...............................34

8.2.3 Setting the volume unit ............................................35

8.2.4 Setting the density unit and density value .............................36

8.2.5 To set the temperature unit .........................................36

8.3 Scaling the measuring range ..............................................37

8.3.1 Performing a wet adjustment .......................................37

8.3.2 Performing a dry adjustment........................................38

8.4 Setting the mode ........................................................39

8.5 Mounting correction (offset) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.5.1 Performing a wet adjustment .......................................40

8.5.2 Performing a dry adjustment........................................40

8.6 Setting the damping .....................................................41

8.7 Write protection .........................................................42

8.7.1 Activating/deactivating the write protection ............................42

8.7.2 Change PIN .....................................................42

9. Diagnostic functions .............................................43

9.1 Simulations ............................................................43

9.1.1 Performing a pressure simulation....................................43

9.1.2 Performing a current simulation .....................................43

9.2 Display/reset drag pointer.................................................44

9.2.1 Drag pointer P

9.2.2 Drag pointer PV

9.2.3 Drag pointer T

min

min

/ P

............................................44

max

/ PV

min

/ T

.........................................45

max

............................................45

max

9.3 Display/reset operating time...............................................45

10. Detailed settings.................................................46

10.1 Setting the language .....................................................46

10.2 Marking the measuring point (TAG) .........................................46

10.2.1 Setting the TAG short..............................................46

10.2.2 Setting the TAG long ..............................................46

10.3 Setting the alarm signal ..................................................47

10.4 Setting the signal limits ...................................................47

10.5 Setting the contrast of the LC display .......................................48

10.6 Restoring factory setting..................................................48

4

WIKA operating instructions process transmitter, model UPT-2x

14111166.02 04/2015 EN/DE

Page 5

Contents

10.7 Setting the HART® communication .........................................49

10.7.1 Setting the short address (multidrop mode) ...........................49

10.7.2 Activate/deactivate constant current .................................49

11. Instrument information ...........................................50

11.1 Display measuring range .................................................50

11.2 Display settings .........................................................50

11.3 Display date of manufacture...............................................50

11.4 Display firmware version..................................................50

11.5 Display serial number ....................................................51

12. Maintenance and cleaning.........................................51

12.1 Maintenance ...........................................................51

12.2 Cleaning...............................................................51

12.3 Recalibration ...........................................................51

13. Faults ..........................................................52

14. Dismounting, return and disposal ..................................53

15. Specifications ...................................................55

16. Accessories.....................................................62

Appendix 1: EC Declaration of conformity model UPT-2x ..................63

EN

Appendix 2: Menu tree, basic setting...................................64

Appendix 3: Menu tree, display........................................66

Appendix 4: Menu tree, diagnositic ....................................68

Appendix 5: Menu tree, detail setup....................................69

Appendix 6: Menu tree, info...........................................70

Declarations of conformity can be found online at www.wika.com

14111166.02 04/2015 EN/DE

WIKA operating instructions process transmitter, model UPT-2x

5

Page 6

EN

1. General information

1. General information

■

The process transmitter described in the operating instructions has been designed

and manufactured using state-of-the-art technology. All components are subject

to stringent quality and environmental criteria during production. Our management

systems are certied to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the instrument. Working safely requires that all safety instructions and work instructions are

observed.

■

Observe the relevant local accident prevention regulations and general safety regulations for the instrument's range of use.

■

The operating instructions are part of the product and must be kept in the immediate

vicinity of the instrument and readily accessible to skilled personnel at any time.

■

Skilled personnel must have carefully read and understood the operating instructions

prior to beginning any work.

■

The manufacturer's liability is void in the case of any damage caused by using the

product contrary to its intended use, non-compliance with these operating instructions, assignment of insuciently qualied skilled personnel or unauthorised modications to the instrument.

■

The general terms and conditions contained in the sales documentation shall apply.

■

Subject to technical modications.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: PE 86.05

- Application consultant:

Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.com

6

WIKA operating instructions process transmitter, model UPT-2x

14111166.02 04/2015 EN/DE

Page 7

2. Design and function

2. Design and function

2.1 Design

EN

Process connection, thread

Process connection, spanner ats

Sensor housing

Ex-relevant data

Case head

2.2 Description

The process transmitter processes the prevailing pressure and converts it into a current

signal. This current signal can be used for the evaluation, control and monitoring of the

process.

Push-on cap

Product label

Ground screw, outside

Electrical connection, cable gland

Second bore for cable gland (delivered sealed

with blind plug)

®

HART

(option)

The instrument version with HART

Measuring range scaling (turndown)

The start and end of the measuring range can be set within dened ranges.

14111166.02 04/2015 EN/DE

WIKA operating instructions process transmitter, model UPT-2x

®

can communicate with a controller (master).

7

Page 8

2. Design and function

Display and operating unit (accessory)

The display and operating unit model DI-PT-U has a main and an additional display.

The main display and the additional display are able to be set in almost any way. In the

factory setting, the main display shows the pressure value of the output signal.

EN

The process transmitter can be congured via the display and operating unit.

Adaptable to mounting position

The process transmitter is tted with a case head which can be turned through 330°.

The display and operating unit can be attached in 90° steps. Thus the measured value

can be read irrespective of the mounting position.

Rotatable case head

330°

Displaceable display and operating unit

2.3 Scope of delivery

■

Pre-assembled process transmitter

■

Ordered accessories

■

Operating instructions

■

Measured value protocol

Cross-check scope of delivery with delivery note.

8

WIKA operating instructions process transmitter, model UPT-2x

14111166.02 04/2015 EN/DE

Page 9

3. Safety

3. Safety

3.1 Explanation of symbols

DANGER!

... indicates a potentially dangerous situation in the hazardous area that can

result in serious injury or death, if not avoided.

WARNING!

... indicates a potentially dangerous situation that can result in serious injury

or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result in light injuries

or damage to equipment or the environment, if not avoided.

Information

... points out useful tips, recommendations and information for ecient and

trouble-free operation.

3.2 Intended use

The intrinsically safe process transmitter measures gauge pressure, absolute pressure

and vacuum. The physical quantity pressure is converted into an electrical signal.

EN

Only use the intrinsically safe process transmitter in applications that lie within its technical performance limits (e.g. max. ambient temperature, material compatibility, ignition

protection type, ...). Instruments with a ush process connection must not be used with

media which might damage the diaphragm of the process connection.

→ Performance limits see chapter 15 “Specications”.

ATEX and IECEx approval

Process transmitter approved for use in hazardous areas, type tested in accordance

with the following standards:

IEC 60079-0:2011 + Corr.1:2012 + Corr.2:2013 / EN 60079-0:2012 + A11:2013

IEC 60079-11:2011 + Corr.1:2012 / EN 60079-11:2012

IEC 60079-26:2006 + Corr.1:2009 / EN 60079-26:2007 + Corr.1:2009

Approval ratings ATEX and IECEx

■

Gases and mist Mounting to zone 0 (EPL Ga/Gb)

Installation in zone 1 (EPL Gb) and zone 2 (EPL Gc)

■

Dusts

14111166.02 04/2015 EN/DE

WIKA operating instructions process transmitter, model UPT-2x

Mounting to zone 20 (EPL Da/Db); installation in zone 21 (EPL Db)

9

Page 10

3. Safety

The instrument has been designed and built solely for the intended use described here,

and may only be used accordingly.

The manufacturer shall not be liable for claims of any type based on operation contrary

to the intended use.

EN

3.2.1 Special conditions for safe use

For the case “mounting to zone 0 (EPL Ga/Gb)”

The instrument's internal separation (diaphragm) from the wetted area has a wall thickness of < 0.2 mm in order to ensure proper functioning. In operation, it must be ensured

that any impairment of the separation, e.g. by aggressive media or through mechanical

damage, is eliminated.

3.3 Personnel qualication

WARNING!

Risk of injury should qualication be insucient!

Improper handling can result in considerable injury and damage to equipment.

▶

The activities described in these operating instructions may only be

carried out by skilled personnel who have the qualifications described

below.

Skilled personnel

Skilled personnel are understood to be personnel who, based on their technical training,

knowledge of measurement and control technology and on their experience and knowl-

edge of country-specic regulations, current standards and directives, are capable of

carrying out the work described and independently recognising potential hazards.

Special operating conditions require further appropriate knowledge, e.g. of aggressive

media, compatibility of materials.

Special knowledge for working with instruments for hazardous areas:

The skilled personnel must have knowledge of ignition protection types, regulations and

provisions for equipment in hazardous areas.

10

WIKA operating instructions process transmitter, model UPT-2x

14111166.02 04/2015 EN/DE

Page 11

3. Safety

3.4 Risks in hazardous areas

Observe the information given in the type examination certicate and the country-specic

regulations for installation and use in hazardous areas (e.g. IEC 60079-14, NEC, CEC). If

this is not observed, serious injuries and damage could occur.

Do not commission any damaged instruments within hazardous areas. Damaged instruments cannot reliably guarantee any explosion protection. Obvious damage must be

reported immediately.

3.5 Handling of hazardous media

For hazardous media such as oxygen, acetylene, ammable or toxic gases and liquids

and refrigeration plants, compressors, etc., in addition to all standard regulations, the

appropriate existing codes or regulations must also be followed.

Residual media in the dismounted process transmitter can result in a risk to personnel,

the environment and equipment. Take sucient precautionary measures.

3.6 Labelling, safety marks

Product label

EN

Pin assignment

Power supply

Output signal

Measuring range

14111166.02 04/2015 EN/DE

WIKA operating instructions process transmitter, model UPT-2x

Model

Model code

Date of manufacture YYYY-MM

S# Serial no.

P# Product no.

Permissible ambient temperature

Approval ratings

11

Page 12

3. Safety

Symbols

Before mounting and commissioning the instrument, ensure you read the

operating instructions!

EN

Instruments bearing this mark comply with the relevant European directives.

ATEX European Explosion Protection Directive

(Atmosphère = AT, explosible = EX)

Instruments bearing this mark comply with the requirements of the

European directive 94/9/EC (ATEX) on explosion protection.

Output signal

Power supply

12

WIKA operating instructions process transmitter, model UPT-2x

14111166.02 04/2015 EN/DE

Page 13

4. Transport, packaging and storage

4. Transport, packaging and storage

4.1 Transport

Check the process transmitter for any damage that may have been caused by transport.

Obvious damage must be reported immediately.

4.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change

in installation site, return for calibration).

4.3 Storage

Permissible conditions at the place of storage:

■

Storage temperature: -40 ... +80 °C

■

Humidity: 35 ... 93 % relative humidity (no condensation)

Avoid exposure to the following factors:

■

Proximity to hot objects, when permissible storage temperature is exceeded by

radiation.

■

Mechanical vibration, mechanical shock (putting it down hard), when the permissible

values are exceeded, see chapter 15 “Specications”.

■

Soot, vapour, dust and corrosive gases

■

Hazardous areas and ammable atmospheres where the instruments are not suitable

for installation in or mounting to equipment in explosive atmospheres.

EN

Store the process transmitter in its original packaging in a location that fulls the conditions listed above. If the original packaging is not available, then store the instrument

in a container that is similar to the original packaging, so that the instrument cannot be

scratched and is protected against damage if dropped.

14111166.02 04/2015 EN/DE

WIKA operating instructions process transmitter, model UPT-2x

13

Page 14

5. Commissioning, operation

5. Commissioning, operation

The process transmitter should only be commissioned and operated by skilled personnel.

The skilled personnel must have knowledge of ignition protection types, regulations and

provisions for equipment in hazardous areas.

EN

5.1 Mechanical mounting

DANGER!

Danger to life from explosion

Incorrect mounting and non-compliance with the contents of this chapter

can lead to a risk of explosion.

▶

Carefully read and comply with the following sub-chapters.

5.1.1 Requirements for mounting point

The process transmitter can be adjusted to the installation site.

→ see chapter 2.2 “Description”

■

Sucient space for a safe electrical installation.

■

Operating elements can be accessed following the mounting.

■

Permissible ambient and medium temperatures remain within the temperature

classes.

■

Consider possible restrictions on the ambient temperature range caused by mating

connector used.

■

Protect the process transmitter from heat sources (e.g. pipes or tanks).

Additional for instruments with cooling element:

■

Mount the process transmitter as horizontally as possible and ensure an unhindered

air circulation at the cooling element.

■

The cooling element should have as little soiling as possible, otherwise the cooling

action cannot be guaranteed. Ensure as much space as possible so that the cooling

element can be cleaned.

14

WIKA operating instructions process transmitter, model UPT-2x

14111166.02 04/2015 EN/DE

Page 15

5. Commissioning, operation

5.1.2 Mounting the process transmitter

DANGER!

Damaged diaphragm of the ush process connection

If the diaphragm is damaged, the explosion protection is no longer guaranteed. Through any explosion resulting from this, there will be a high danger

to life.

▶

Before commissioning, the diaphragm should be checked for visible

damage. Leaking fluid is indicative of damage.

▶

Protect the diaphragm from contact with abrasive media and against any

impacts.

Sealing

Parallel threads

Seal the sealing face with at gaskets,

sealing rings or WIKA prole sealings.

Tapered threads

Wrap threads with sealing material,

e.g. PTFE tape.

EN

per EN 837 per DIN 3852-E

14111166.02 04/2015 EN/DE

WIKA operating instructions process transmitter, model UPT-2x

NPT, R and PT

15

Page 16

5. Commissioning, operation

Screwing in

CAUTION!

Improper mounting

Process transmitter is damaged.

▶

EN

Screw the process transmitter into the mounting location with a spanner using the

spanner ats.

The tightening torque depends on the dimensions of the process connection and the

gasket used (form/material).

Tighten the process transmitter using the spanner flats.

▶

Do not tighten using the sensor housing or the case head.

▶

Use a suitable open-ended spanner.

▶

Do not cross the threads.

16

Spanner ats

Sensor housing

Case head

For information on tapped holes and welding sockets, see Technical information IN 00.14 at www.wika.com.

WIKA operating instructions process transmitter, model UPT-2x

14111166.02 04/2015 EN/DE

Page 17

5. Commissioning, operation

5.2 Electrical installation

DANGER!

Danger to life from explosion

Incorrect mounting and non-compliance with the contents of this chapter

can lead to a risk of explosion.

▶

Carefully read and comply with the following sub-chapters.

Observe the information given in the type examination certicate and the country-specic

regulations for installation and use in hazardous areas (e.g. IEC 60079-14, NEC, CEC)

this is not observed, serious injuries and damage could occur.

→ Type examination certicate is available for download at www.wika.com.

5.2.1 Safety instructions

■

Only connect with the voltage disconnected.

■

If any overvoltage is expected, install surge protection devices.

■

Exposed cables must not run close to bare metal components. Maintain a minimum

clearance of 5 mm.

■

Ensure that the cables are properly installed and the cable gland or plug connections

are securely closed and sealed.

. If

EN

5.2.2 Requirements for connection cable

■

Use and assemble connection cable that is suitable for the application. For cables

with exible wires, always use ferrules appropriate for the wire cross-section.

■

Where there is electromagnetic radiation above the test values per EN 61326, a

shielded connection cable must be used.

■

When using an M12 x 1 (4-pin) circular connector, the mating connector is supplied

by the customer. Ensure the matching design from the connector manufacturer.

Electrical connections

Cable gland M20 x 1.5 and spring-loaded

terminals

Angular connector DIN 175301-803A with

mating connector

Circular connector M12 x 1 (4-pin) without

mating connector

Ground screw, inside 0.13 ... 2.5 mm²

Ground screw, outside 0.13 ... 4 mm²

14111166.02 04/2015 EN/DE

WIKA operating instructions process transmitter, model UPT-2x

Ingress protection: IP 66/67

Cable diameter: 7 ... 12 mm

Wire cross-section max. 2.5 mm

Single cable: 0.13 ... 2.5 mm²

End splices: 0.13 ... 1.5 mm²

For cable diameters outside of 7 ... 12 mm,

change the seal and cable gland

Ingress protection: IP 65

Cable diameter: 6 ... 8 mm

Wire cross-section: max. 1.5 mm²

Ingress protection: IP 65

Observe manufacturer's specications

2

(AWG 14)

17

Page 18

5. Commissioning, operation

5.2.3 Requirements regarding intrinsic voltage supply

■

Power the process transmitter via an intrinsically safe circuit (Ex ia). Both the internal

capacitance and inductance must be considered (→ see chapter 15 “Specications”).

■

Provide the required voltage supply separation between Ex and non-Ex areas

with a certied isolated barrier or Zener barrier (suitable isolated barrier, model

EN

KFD2-STC4-Ex1).

■

For applications that require EPL Gb or Db, the power supply and signal circuit should

have a protection level of “ib”. Then the interconnections and the transmitter will have

a protection level of II 2G Ex ib IIC T4/T5/T6 Gb or II 2D Ex ib IIIC T4/T5/T6 Db, even if

the process transmitter is marked otherwise (→ see EN 60079-14 section 5.4).

5.2.4 Opening the case

CAUTION!

Ingress of moisture

Moisture can destroy the process transmitter.

▶

Protect the opened process transmitter against moisture.

▶

Screw off the case head cover by hand and pull out the display and operating unit or

push-on cap.

5.2.5 Shielding and grounding

The process transmitter must be shielded and grounded in accordance with the grounding concept of the plant.

▶

Connect the cable shield with the equipotential bonding.

▶

Connect the process connection or the external grounding screw with the equipotential bonding

18

WIKA operating instructions process transmitter, model UPT-2x

14111166.02 04/2015 EN/DE

Page 19

5. Commissioning, operation

5.2.6 Connection

1. Pass the connection cable through the cable gland and connect it.

Ensure that no moisture can enter at the cable end.

→ For pin assignment see chapter 5.2.7 “pin assignments”.

2. Tighten the cable gland.

■

Recommended tightening torque 1.5 Nm

■

Check that the seals are correctly seated in order to guarantee the ingress

protection.

3. Perform a mounting correction.

→ Without display, see chapter 7.1 “Performing a mounting correction (oset)”

→ Via HART

®

, see chapter 7.2 “Conguring the HART® interface”

→ With display, see chapter 8.5 “Mounting correction (oset)”

4. Attach the push-on cap or display and operating unit and screw the case head cover

tight down to the stop.

EN

14111166.02 04/2015 EN/DE

WIKA operating instructions process transmitter, model UPT-2x

19

Page 20

5. Commissioning, operation

1

2

3

4

3

1

2

5.2.7 Pin assignments

Spring-loaded terminal

Pin assignmentOutlet for connection cable

EN

Cable gland

Process connection

Positive power supply terminal +

Angular connector DIN 175301-803 A

+ 1

Negative power supply terminal –

Ground screw, inside (GND)

Circular connector M12 x 1 (4-pin)

+ 1

– 2

Shield GND

The shield connection is located on the inside of the instrument.

20

WIKA operating instructions process transmitter, model UPT-2x

– 3

Shield 4

14111166.02 04/2015 EN/DE

Page 21

6. Display and operating unit, model DI-PT-U

6. Display and operating unit, model DI-PT-U

6.1 Design and description

The display and operating unit model DI-PT-U is available as an accessory.

It can be plugged into the instrument electronics at 90° increments. Thus the display can

be read, whether the process transmitter is mounted laterally or upside down.

Description

Direction key [▲]

Escape key [ESC]

Additional display

Unit

Main display

Trend indication

Bar graph with over/under limit

arrows and drag pointer function

Enter key [↵]

Direction key [▼]

EN

6.2 Accessing/exiting the operating menu

Accessing: Press [↵].

Exiting: Press [ESC] repeatedly until the menu has been exited.

If after 3 min. no entry is made, the menu will automatically be exited and the

last set display mode will be activated.

If there is an invalid entry, the message “Input error” will show in the display

for 2 seconds, and the previous menu will be accessed.

14111166.02 04/2015 EN/DE

WIKA operating instructions process transmitter, model UPT-2x

21

Page 22

6. Display and operating unit, model DI-PT-U

6.3 Installation/Removal

CAUTION!

Ingress of moisture.

Moisture can destroy the process transmitter.

▶

EN

1. Screw o the case head cover by hand.

2. Installation

Pull out the push-on cap and attach the display and

operating unit into any of the locking positions (0°, 90°,

180°, 270°).

Removal

Pull out the display and operating unit and attach the

push-on cap.

Protect the opened process transmitter against moisture.

▶

Close the case head tightly.

3. Screw on the case head cover.

Ensure that the case head is tightly closed.

22

WIKA operating instructions process transmitter, model UPT-2x

14111166.02 04/2015 EN/DE

Page 23

6. Display and operating unit, model DI-PT-U

6.4 Setting the main display

The main display can indicate the following values:

■

Pressure Applied pressure is displayed.

■

Level Level is displayed.

■

Volume Volume is displayed.

■

Current Output signal is displayed.

■

PV percent Output signal is displayed as a percentage.

■

Sensor temperature Temperature at the sensor is displayed.

■

PV (primary value) The value corresponding to the mode will be displayed.

If the mode is changed, then the main display will change.

1. Open the operating menu with [↵].

Select “Display” and conrm with [↵].

2. Select “Main display” and conrm with [↵].

EN

3. Select value and conrm with [↵].

» Main display indicates the selected value.

14111166.02 04/2015 EN/DE

WIKA operating instructions process transmitter, model UPT-2x

23

Page 24

6. Display and operating unit, model DI-PT-U

6.5 Setting the additional display

The additional display can indicate the following values:

■

Pressure Applied pressure is displayed.

■

EN

Level Level is displayed.

■

Volume Volume is displayed.

■

Current Output signal is displayed.

■

PV percent Output signal is displayed as a percentage.

■

Sensor temperature Temperature at the sensor is displayed.

■

PV (primary value) The value corresponding to the mode will be displayed.

If the mode is changed, then the main display will change.

Drag pointer values

■

P

/ P

min

PV

T

min

min

/ T

max

/ PV

max

max

■

■

Further data

■

TAG short (max. 8 capital letters and gures)

■

TAG long (max. 32 alphanumeric characters)

■

Empty (additional display switched o)

1. Open the operating menu with [↵].

Select “Display” and conrm with [↵].

2. Select “Add. display” and conrm with [↵].

3. Select value and conrm with [↵].

» Additional display indicates the selected value.

24

WIKA operating instructions process transmitter, model UPT-2x

14111166.02 04/2015 EN/DE

Page 25

7. Conguration without display and operating unit

7. Conguration without display and operating unit

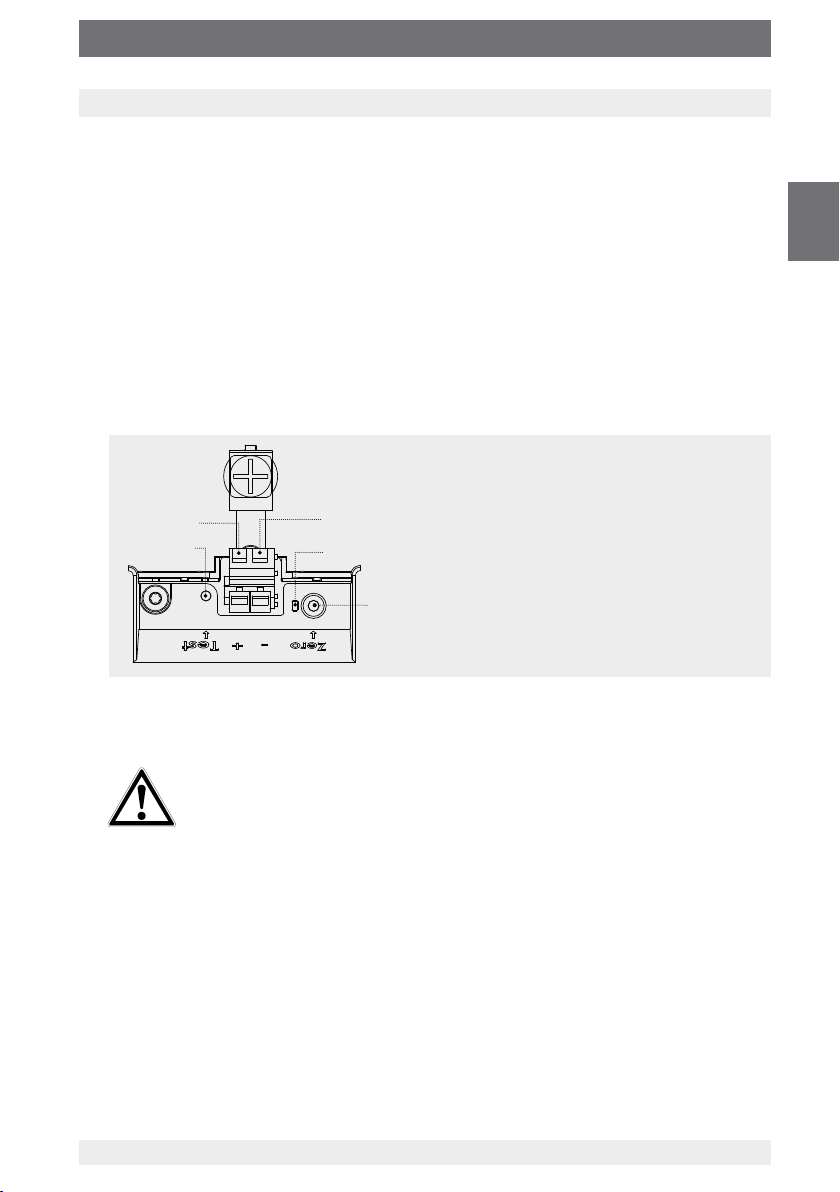

7.1 Performing a mounting correction (oset)

The mounting correction corrects a zero oset in the output signal by dening a new

zero point. The zero oset is caused by the mounting position.

Correction range: ±20 % of maximum measuring range

Required tool: Multimeter (ammeter)

1. Screw o the case head cover and pull out the push-on cap.

2. Press [Zero] for approx. 2 s (e.g. with measuring tip of a multimeter).

» Mounting correction successful: Control diode lights up for 2 s.

» Mounting correction unsuccessful: Control diode blinks 5 times.

EN

3. Check the output signal as follows.

CAUTION!

Incorrect connection

A short circuit will destroy the process transmitter.

▶

Ensure that the multimeter does not come into contact with the

positive power supply terminal.

▶

Set the multimeter to current measurement.

▶

Connect the positive measuring line of the multimeter to the test contact.

▶

Connect the negative measuring line of the multimeter to the negative power

supply terminal.

» The result of the current measurement should give a value between 4 ... 20 mA

in the pressure-free condition. If the ambient atmospheric pressure is outside

the measuring range, the measured current can be < 4 mA or > 20mA.

Control diode

Mounting correction, [Zero] key

Test contact

Positive power supply terminal +

Negative power supply terminal –

14111166.02 04/2015 EN/DE

WIKA operating instructions process transmitter, model UPT-2x

25

Page 26

7. Conguration without display and operating unit

7.2 Conguring over HART® interface

®

HART

-compatible process transmitters can be operated and congured with operat-

ing software (e.g. PACTware

®

), process control software (e.g. AMS or Simatic PDM) or

a hand-held device (e.g. FC475 from Emerson).

The operation of the respective menus is described in the associated online help.

EN

The device drivers are available for download from www.wika.com.

®

Connecting process transmitter to PC (HART

)

Any work should only be carried out in a safe area.

1. Connect HART

2. Connect HART

Ex-Bereich Sicherer Bereich

Hazardous area Non-hazardous area

®

modem to process transmitter.

®

modem to PC or notebook..

HART-Widerstand 250 ohm

HART resistor 250 ohm

HART-Modem

HART modem

RS-232

=

~

Spannungsquelle

Voltage source

26

WIKA operating instructions process transmitter, model UPT-2x

14111166.02 04/2015 EN/DE

Page 27

8. Conguration via display and operating unit

8. Conguration via display and operating unit

8.1 Conguring the measuring task

8.1.1 Conguring pressure measurement

1. Open the operating menu with [↵].

Select “Basic setting” and conrm with [↵].

2. Select “Application” and conrm with [↵].

3. Select “Pressure” and conrm with [↵].

4. Select “Unit” and conrm with [↵].

5. Select pressure unit and conrm with [↵].

» Pressure unit is set.

6. Go back one menu level using [ESC].

Select “Mode” and conrm with [↵].

EN

7. Select “Pressure” and conrm with [↵].

» Mode is set.

8. Scale the measuring range.

→ See chapter 8.3 “Scaling the measuring range”.

9. Perform a mounting correction.

→ See chapter 8.5 “Mounting correction (oset)”.

» Pressure measurement is congured.

14111166.02 04/2015 EN/DE

WIKA operating instructions process transmitter, model UPT-2x

27

Page 28

8. Conguration via display and operating unit

8.1.2 Conguring level measurement

Requirement

■

Length unit for the lling height is known

■

The density of the medium is known

1. Open the operating menu with [↵].

EN

Select “Basic setting” and conrm with [↵].

2. Select “Application” and conrm with [↵].

3. Select “Level” and conrm with [↵].

4. Select “Unit” and conrm with [↵].

5. Select length unit and conrm with [↵].

» Length unit is set.

6. Select “Density” and conrm with [↵].

7. Select “Density unit” and conrm with [↵].

8. Select density unit and conrm with [↵].

» Density unit is set.

9. Select “Density value” and conrm with [↵].

10. Set digit using [▲] [▼] and conrm with [↵].

» The cursor moves to the next digit.

» Repeat for each digit.

» Density value is set.

11. Go back two menu levels using [ESC].

Select “Mode” and conrm with [↵].

12. Select “Level” and conrm with [↵].

» Mode is set.

13. Perform a mounting correction.

→ See chapter 8.5 “Mounting correction (oset)”.

» Level measurement is congured.

28

WIKA operating instructions process transmitter, model UPT-2x

14111166.02 04/2015 EN/DE

Page 29

8. Conguration via display and operating unit

8.1.3 Conguring the volume measurement

Requirement

■

Length unit for the lling height is known

■

Medium density is known

■

Characteristic curve of the tank is known (→ see chapter 8.1.4

“Characteristic curves”)

1. Open the operating menu with [↵].

Select “Basic setting” and conrm with [↵].

2. Select “Application” and conrm with [↵].

3. Select “Level” and conrm with [↵].

4. Select “Unit” and conrm with [↵].

5. Select length unit and conrm with [↵].

» Length unit is set.

6. Select “Density” and conrm with [↵].

7. Select “Density unit” and conrm with [↵].

EN

8. Select density unit and conrm with [↵].

» Density unit is set.

9. Select “Density value” and conrm with [↵].

10. Setting the density of the medium.

Set digits using [▲] [▼] and conrm with [↵].

» The cursor moves to the next digit.

» Repeat for each digit.

» Density value is set.

11. Go back two menu levels using [ESC].

Select “Volume” and conrm with [↵].

12. Select “Scale in” and conrm with [↵].

14111166.02 04/2015 EN/DE

WIKA operating instructions process transmitter, model UPT-2x

29

Page 30

8. Conguration via display and operating unit

13. Select “Low” and conrm with [↵].

14. Select “change” and conrm with [↵].

EN

15. Setting the start of the measuring range referred to the lling

height of the tank.

Set digits using [▲] [▼] and conrm with [↵].

» The cursor moves to the next digit.

» Repeat for each digit.

» Start of the measuring range is set.

16. Go back one menu level using [ESC].

Select “High” and conrm with [↵].

17. Select “change” and conrm with [↵].

18. Setting the end of the measuring range referred to the lling

height of the tank.

Set digits using [▲] [▼] and conrm with [↵].

» The cursor moves to the next digit.

» Repeat for each digit.

» End of the measuring range is set.

19. Go back two menu levels using [ESC].

Select “Characteristic” and conrm with [↵].

20. Select characteristic curve and conrm with [↵].

→ Explanation of characteristic curves, see chapter 8.1.4

“Characteristic curves”

21. Select “Scale out” and conrm with [↵].

22. Select “Unit” and conrm with [↵].

23. Select volume unit and conrm with [↵].

■

Volume unit: Standard units (e.g. litres, m³, ...)

■

Free input: Freely denable unit (selectable under

“Volume unit“)

» Volume unit is set.

30

WIKA operating instructions process transmitter, model UPT-2x

14111166.02 04/2015 EN/DE

Page 31

8. Conguration via display and operating unit

24. Go back one menu level using [ESC].

Select “Low 0%” and conrm with [↵].

25. Set the initial value of the volume measurement with respect

to 0 % of the lling height (e.g. 0 % lling height corresponds

to 3 litres).

» The cursor moves to the next digit.

» Repeat for each digit.

» Initial value is set.

26. Select “High 100%” and conrm with [↵].

27. Set the end value of the volume measurement with respect

to 100 % of the lling height (e.g. 100 % lling height corresponds to 1,000 litres).

» The cursor moves to the next digit.

» Repeat for each digit.

» Initial value is set.

28. Go back one menu level using [ESC].

Select “Mode” and conrm with [↵].

29. Go back one menu levels using [ESC].

Select “Volume” and conrm with [↵].

» Mode is set to volume.

EN

30. Perform a mounting correction.

→ See chapter 8.5 “Mounting correction (oset)”.

» Volume measurement is congured.

14111166.02 04/2015 EN/DE

WIKA operating instructions process transmitter, model UPT-2x

31

Page 32

8. Conguration via display and operating unit

8.1.4 Characteristic curves

Linear

Used for vertical tanks.

EN

Horizontal tank

Used for horizontal tanks.

32

WIKA operating instructions process transmitter, model UPT-2x

14111166.02 04/2015 EN/DE

Page 33

8. Conguration via display and operating unit

Spherical tank

Used for spherical tanks.

Linearisation table

Will be used for special designs. The linearisation table can, as an option, be loaded at

the factory or can be transferred via HART

®

.

EN

14111166.02 04/2015 EN/DE

WIKA operating instructions process transmitter, model UPT-2x

33

Page 34

8. Conguration via display and operating unit

8.2 Setting the units

8.2.1 Setting the pressure unit

1. Open the operating menu with [↵].

EN

Select “Basic setting” and conrm with [↵].

2. Select “Application” and conrm with [↵].

3. Select “Pressure” and conrm with [↵].

4. Select “Unit” and conrm with [↵].

5. Select pressure unit and conrm with [↵].

» Pressure unit is set.

8.2.2 Set length unit (for level measurement)

1. Open the operating menu with [↵].

Select “Basic setting” and conrm with [↵].

2. Select “Application” and conrm with [↵].

3. Select “Level” and conrm with [↵].

4. Select “Unit” and conrm with [↵].

5. Select length unit and conrm with [↵].

» Length unit is set.

34

WIKA operating instructions process transmitter, model UPT-2x

14111166.02 04/2015 EN/DE

Page 35

8. Conguration via display and operating unit

8.2.3 Setting the volume unit

1. Open the operating menu with [↵].

Select “Basic setting” and conrm with [↵].

2. Select “Application” and conrm with [↵].

3. Select “Volume” and conrm with [↵].

4. Select “Scale out” and conrm with [↵].

5. Select “Unit” and conrm with [↵].

6. Select volume unit and conrm with [↵].

■

Volume unit: Standard units (e.g. litres, m³, ...)

■

Free input: Freely denable unit (selectable under

“Volume unit“)

» Volume unit is set.

EN

14111166.02 04/2015 EN/DE

WIKA operating instructions process transmitter, model UPT-2x

35

Page 36

8. Conguration via display and operating unit

8.2.4 Setting the density unit and density value

1. Open the operating menu with [↵].

Select “Basic setting” and conrm with [↵].

2. Select “Application” and conrm with [↵].

EN

3. Select “Level” and conrm with [↵].

4. Select “Density” and conrm with [↵].

5. Select “Density unit” and conrm with [↵].

6. Select unit and conrm with [↵].

» Density unit is set.

7. Select “Density value” and conrm with [↵].

8. Set digit using [▲] [▼] and conrm with [↵]. The cursor

moves to the next digit. Repeat for each digit.

»Density value is set.

8.2.5 To set the temperature unit

Temperature unit °C and °F selectable.

1. Open the operating menu with [↵].

Select “Basic setting” and conrm with [↵].

2. Select “Application” and conrm with [↵].

3. Select “Sensor temp.” and conrm with [↵].

4. Select temperature unit and conrm with [↵].

» Temperature unit is set.

36

WIKA operating instructions process transmitter, model UPT-2x

14111166.02 04/2015 EN/DE

Page 37

8. Conguration via display and operating unit

8.3 Scaling the measuring range

8.3.1 Performing a wet adjustment

For the start of the measuring range and end of the measuring range, the values will be

taken from the running measurement. The respective output signal can be adjusted.

Requirement Measurement is running.

Setting range Start of measuring range: -10 ... +110 % of measuring range

End of measuring range: 1 ... 120 % of measuring range

Max. turndown: 100 : 1 (recommended max. 20 : 1)

1. Open the operating menu with [↵].

Select “Basic setting” and conrm with [↵].

2. Select “Scale setting” and conrm with [↵].

3. Select “Wet adjustm.” and conrm with [↵].

4. Dening the current measured value as start of measuring

range or end of measuring range:

To dene as start of measuring range:

Conrm “min. adjustm.” with [↵].

To dene as end of measuring range:

Conrm “max. adjustm.” with [↵].

5. Change digit using [▲] [▼] and conrm with [↵]. The cursor

moves to the next digit. Repeat for each digit. When the last

digit is exited, the menu moves back to step 2.

EN

With the input of current values that are not

either 4 mA or 20 mA the pressure value is

converted into the standardised current signals

as soon as the current value entered is accepted.

14111166.02 04/2015 EN/DE

WIKA operating instructions process transmitter, model UPT-2x

37

Page 38

8. Conguration via display and operating unit

8.3.2 Performing a dry adjustment

Via the dry adjustment, the values for the start of the measuring range and the end of the

measuring range are entered manually. The respective output signal can be adjusted.

Requirement Process transmitter does not have to be installed.

EN

Setting range Start of measuring range: -10 ... +110 % of measuring range

1. Open the operating menu with [↵].

Select “Basic setting” and conrm with [↵].

2. Select “Scale setting” and conrm with [↵].

3. Select “Dry adjustm.” and conrm with [↵].

4. Dening the start of measuring range or end of measuring

range:

No measurement is running. If there is a running measurement, the

output signal can alter abruptly.

End of measuring range: 1 ... 120 % of measuring range

Max. turndown: 100 : 1 (recommended max. 20 : 1)

To dene start of measuring range

Conrm “min. adjustm.” with [↵].

To dene end of measuring range

Conrm “max. adjustm.” with [↵].

5. Change digit using [▲] [▼] and conrm with [↵]. The cursor

moves to the next digit. Repeat for each digit.

When the last digit is exited, the cursor moves to the output

signal (step 6).

6. Change digit using [▲] [▼] and conrm with [↵]. The cursor

moves to the next digit. Repeat for each digit.

digit is exited, the menu moves back to step 2.

With the input of current values that are not

either 4 mA or 20 mA the pressure value is

converted into the standardised current signals

as soon as the current value entered is accepted.

38

WIKA operating instructions process transmitter, model UPT-2x

When the last

14111166.02 04/2015 EN/DE

Page 39

8. Conguration via display and operating unit

8.4 Setting the mode

The mode denes which measurement parameter will be transmitted via the current

output (pressure, volume).

If the main display is set to PV (primary value), the measurement parameter

set under “Mode” will always be displayed.

1. Open the operating menu with [↵].

Select “Basic setting” and conrm with [↵].

2. Select “Application” and conrm with [↵].

3. Select “Mode” and conrm with [↵].

4. Select measurement parameter and conrm with [↵].

» Mode is set.

EN

14111166.02 04/2015 EN/DE

WIKA operating instructions process transmitter, model UPT-2x

39

Page 40

8. Conguration via display and operating unit

8.5 Mounting correction (oset)

8.5.1 Performing a wet adjustment

Zero point will be taken from measurement in operation.

EN

Requirement:

■

Deviation ≤ 20 % of the measuring range.

■

Absolute vacuum with absolute pressure measuring instruments.

Not to be carried out without suitable equipment.

1. Open the operating menu with [↵].

Select “Basic setting” and conrm with [↵].

2. Select “Application” and conrm with [↵].

3. Select “Pressure” and conrm with [↵].

4. Select “Mounting corr.” and conrm with [↵].

5. Select “apply” and conrm with [↵].

Current measured value will be used as the new zero point.

8.5.2 Performing a dry adjustment

The mounting correction is registered manually via the dry adjustment. For all future

measurements, the mounting correction will be subtracted.

Requirement: Deviation ≤ 20 % of the measuring range.

1. Open the operating menu with [↵].

Select “Basic setting” and conrm with [↵].

2. Select “Application” and conrm with [↵].

3. Select “Pressure” and conrm with [↵].

40

WIKA operating instructions process transmitter, model UPT-2x

14111166.02 04/2015 EN/DE

Page 41

8. Conguration via display and operating unit

4. Select “Mounting corr.” and conrm with [↵].

5. Select “change” and conrm with [↵].

6. Change digit using [▲] [▼] and conrm with [↵]. The cursor

moves to the next digit. Repeat for each digit.

» Entered value will be used as the new zero point.

8.6 Setting the damping

The damping prevents the uctuation of the output signal when there are short-term

uctuations in the measured value. Safety shut-downs due to turbulent processes are

thus prevented.

Pressure spikes will still be registered, e.g. as P

in the menu point

max

“Diagnostic”.

Setting range 0 ... 99.9 s

1. Open the operating menu with [↵].

Select “Basic setting” and conrm with [↵].

2. Select “Damping value” and conrm with [↵].

3. Change digit using [▲] [▼] and conrm with [↵]. The cursor

moves to the next digit. Repeat for each digit.

» Damping is set.

EN

14111166.02 04/2015 EN/DE

WIKA operating instructions process transmitter, model UPT-2x

41

Page 42

8. Conguration via display and operating unit

8.7 Write protection

An active write protection locks the settings so that these cannot be changed via the

display and operating module nor via HART

that the write protection is active.

®

. A key icon above the main display signals

EN

Activation/deactivation of the write protection and changing the PIN is also

possible via HART®.

8.7.1 Activating/deactivating the write protection

1. Open the operating menu with [↵].

Select “Basic setting” and conrm with [↵].

2. Select “Write protect” and conrm with [↵].

3. Select “on/o” and conrm with [↵].

4. Activate write protection:

Select “on” and conrm with [↵].

» Write protection is activated.

Deactivate write protection:

Select “o” and conrm with [↵].

Enter PIN and conrm with [↵].

» Write protection is deactivated.

8.7.2 Change PIN

Factory setting: 0000

1. Open the operating menu with [↵].

Select “Basic setting” and conrm with [↵].

2. Select “Write protect” and conrm with [↵].

3. Select “Change PIN” and conrm with [↵].

4. Change digit using [▲] [▼] and conrm with [↵]. The cursor

moves to the next digit. Repeat for each digit.

» Pin is changed.

42

WIKA operating instructions process transmitter, model UPT-2x

14111166.02 04/2015 EN/DE

Page 43

9. Diagnostic functions

9. Diagnostic functions

Requirement: Display and operating unit tted.

9.1 Simulations

9.1.1 Performing a pressure simulation

A pressure value within the measuring range must be entered and is converted into a

current value and output.

1. Open the operating menu with [↵].

Select “Diagnostic” and conrm with [↵].

2. Select “Simulation” and conrm with [↵].

3. Select “Press. simu.” and conrm with [↵].

4. Change digit using [▲] [▼] and conrm with [↵]. The cursor

moves to the next digit. Repeat for each digit.

» Simulation is active.

5. Ending the simulation. Press [ESC] to do this.

EN

9.1.2 Performing a current simulation

The selected or entered current value will be simulated and output as the PV (primary

value).

1. Open the operating menu with [↵].

Select “Diagnostic” and conrm with [↵].

2. Select “Simulation” and conrm with [↵].

3. Select “Current sim.” and conrm with [↵].

4.

Select the current value or dene via “Input”.

Change digit using [▲] [▼] and conrm with [↵]. The cursor

moves to the next digit. Repeat for each digit.

» Simulation is active.

5. Ending the simulation. Press [ESC] to do this.

14111166.02 04/2015 EN/DE

WIKA operating instructions process transmitter, model UPT-2x

43

Page 44

9. Diagnostic functions

9.2 Display/reset drag pointer

The drag pointer function indicates the limit values reached since the last reset. These

limit values can be displayed and reset.

9.2.1 Drag pointer P

EN

Displays the minimum and maximum pressure that has occurred since the last reset.

min

/ P

max

Displays

1. Open the operating menu with [↵].

Select “Diagnostic” and conrm with [↵].

2. Select “Drag pointer” and conrm with [↵].

3. Select “P min/max” and conrm with [↵].

4. Select “display” and conrm with [↵].

» Limit values are displayed.

P

= P

▼

min

P▲ = P

max

Resetting

1. Open the operating menu with [↵].

Select “Diagnostic” and conrm with [↵].

2. Select “Drag pointer” and conrm with [↵].

3. Select “P min/max” and conrm with [↵].

4. Select “reset” and conrm with [↵].

5. Select limit value and conrm with [↵].

■

P▼ = P

P▲ = P

min

max

■

» Limit value is reset.

44

WIKA operating instructions process transmitter, model UPT-2x

14111166.02 04/2015 EN/DE

Page 45

9. Diagnostic functions

9.2.2 Drag pointer PV

min

/ PV

max

Displays the minimum and maximum value of the primary value since the last reset.

→ For display and reset see chapter 10.2.1 “Drag Pointer P

9.2.3 Drag pointer T

min

/ T

max

min

/ P

max

“

Displays the minimum and maximum temperature of the temperature sensor, measured

since the last reset.

→ For display and reset see chapter 10.2.1 “Drag Pointer P

min

/ P

max

“

9.3 Display/reset operating time

Displays the operating time since the last reset.

Displaying

1. Open the operating menu with [↵].

Select “Diagnostic” and conrm with [↵].

2. Select “Operat. time” and conrm with [↵].

3. Select “display” and conrm with [↵].

» Operating time is displayed.

EN

Resetting

1. Open the operating menu with [↵].

Select “Diagnostic” and conrm with [↵].

2. Select “Operat. time” and conrm with [↵].

3. Select “reset” and conrm with [↵].

4. Conrm operating time with [↵].

» Operating time is reset.

14111166.02 04/2015 EN/DE

WIKA operating instructions process transmitter, model UPT-2x

45

Page 46

10. Detailed settings

10. Detailed settings

Requirement: Display and operating unit tted.

10.1 Setting the language

Available languages: German, English, French, Spanish

EN

1. Open the operating menu with [↵].

Select “Detail setup” and conrm with [↵].

2. Select “Language” and conrm with [↵].

3. Select language and conrm with [↵].

» Language is set.

10.2 Marking the measuring point (TAG)

10.2.1 Setting the TAG short

TAG short enables 8 gures with a limited character set (numbers and capital letters).

TAG short can be displayed in the additional display.

1. Open the operating menu with [↵].

Select “Detail setup” and conrm with [↵].

2. Select “Marking” and conrm with [↵].

3. Select “TAG short” and conrm with [↵].

4. Change gure using [▲] [▼] and conrm with [↵]. The cursor

moves to the next gure. Repeat for each gure.

» TAG short is set.

10.2.2 Setting the TAG long

TAG long enables 32 gures with alphanumeric characters (all characters in accordance

with HART

Setting is made as described in chapter 10.2.1 “TAG short”.

46

®

revision 7). TAG long can be displayed in the additional display.

WIKA operating instructions process transmitter, model UPT-2x

14111166.02 04/2015 EN/DE

Page 47

10. Detailed settings

10.3 Setting the alarm signal

Alarm signal downscale (3.5 mA)

In the event of a failure in the process transmitter, the output signal changes itself to

3.5 mA.

Alarm signal upscale (21.5 mA)

In the event of a failure in the process transmitter, the output signal changes itself to

21.5 mA.

1. Open the operating menu with [↵].

Select “Detail setup” and conrm with [↵].

2. Select “Current out” and conrm with [↵].

3. Select “Alarm signal” and conrm with [↵].

4. Select alarm signal and conrm with [↵].

3.5 mA = alarm signal downscale

21.5 mA = alarm signal upscale

» Alarm signal is set.

10.4 Setting the signal limits

The signal limits dene the current range within which the output signal can be. Above

or below the signal limits are the preset limits for the output signal.

Setting range 3.8 ... 20.5 mA or 4.0 ... 20.0 mA (NAMUR recommendation for process

instruments is 3.8 ... 20.5 mA)

EN

1. Open the operating menu with [↵].

Select “Detail setup” and conrm with [↵].

2. Select “Current out” and conrm with [↵].

3. Select “Limits” and conrm with [↵].

3. Select signal limits and conrm with [↵].

» Signal limits are set.

14111166.02 04/2015 EN/DE

WIKA operating instructions process transmitter, model UPT-2x

47

Page 48

10. Detailed settings

10.5 Setting the contrast of the LC display

Setting range: 1 ... 9 (in steps of 1)

1. Open the operating menu with [↵].

EN

Select “Detail setup” and conrm with [↵].

2. Select “Contrast” and conrm with [↵].

3. Change gure using [▲] [▼] and conrm with [↵].

» Contrast is set.

10.6 Restoring factory setting

1. Open the operating menu with [↵].

Select “Detail setup” and conrm with [↵].

2. Select “Reset” and conrm with [↵].

3. Select the settings that are to be reset and conrm with [↵].

Instrument specications

Instrument settings will be reset to their as-delivered settings.

Drag pointer

The drag pointer values are reset.

4. Conrm reset with [↵].

» The settings are reset.

48

WIKA operating instructions process transmitter, model UPT-2x

14111166.02 04/2015 EN/DE

Page 49

10. Detailed settings

10.7 Setting the HART® communication

10.7.1 Setting the short address (multidrop mode)

Setting range: 0 ... 63

1. Open the operating menu with [↵].

Select “Detail setup” and conrm with [↵].

2. Select “HART” and conrm with [↵].

3. Select “Short addr.” and conrm with [↵].

4. Change digit using [▲] [▼] and conrm with [↵]. The cursor

moves to the next digit. Repeat for each digit.

» Short address is set.

10.7.2 Activate/deactivate constant current

The constant current aects the output of current values, e.g. in the additional

display

1. Open the operating menu with [↵].

Select “Detail setup” and conrm with [↵].

2. Select “HART” and conrm with [↵].

EN

3. Select “Cons. current” and conrm with [↵].

3. Activate/deactivate constant current.

Select “on” or “o” and conrm with [↵].

» Constant current is activated/deactivated.

14111166.02 04/2015 EN/DE

WIKA operating instructions process transmitter, model UPT-2x

49

Page 50

11. Instrument information

11. Instrument information

11.1 Display measuring range

1. Open the operating menu with [↵].

Select “Info” and conrm with [↵].

EN

2. Select “Measuring range” and conrm with [↵].

» Measuring range is displayed.

11.2 Display settings

1. Open the operating menu with [↵].

Select “Info” and conrm with [↵].

2. Select “Setting” and conrm with [↵].

» Mode is displayed.

» Scaling is displayed (4 mA und 20 mA).

11.3 Display date of manufacture

1. Open the operating menu with [↵].

Select “Info” and conrm with [↵].

2. Select “Date manufac.” and conrm with [↵].

» Date of manufacture is displayed.

11.4 Display rmware version

1. Open the operating menu with [↵].

Select “Info” and conrm with [↵].

2. Select “Version” and conrm with [↵].

» Firmware version is displayed.

50

WIKA operating instructions process transmitter, model UPT-2x

14111166.02 04/2015 EN/DE

Page 51

11. Instrument information / 12. Maintenance and cleaning

11.5 Display serial number

1. Open the operating menu with [↵].

Select “Info” and conrm with [↵].

2. Select “Serial number” and conrm with [↵].

» Serial numbers are displayed.

S# = Serial number

H# = HART serial number (the device responds with this

serial number in the process control system)

12. Maintenance and cleaning

12.1 Maintenance

Repairs must only be carried out by the manufacturer.

Clear the cooling element of soiling at regular intervals. The duration of maintenance

intervals is dependent on the application location. In dust-Ex areas, a soiled cooling

element can lead to an explosion, and thus cleaning is required at short intervals.

12.2 Cleaning

EN

CAUTION!

■

The exterior should only be cleaned when the instrument is closed and

sealed. This applies to the case head cover and all openings, e.g. the

cable glands.

■

Use a cloth moistened with soapy water or isopropanol.

■

Electrical connections must not come into contact with moisture.

■

Wash or clean the dismounted instrument before returning it, in order to

protect persons and the environment from exposure to residual media.

■

Residual media in the dismounted process transmitter can result in a risk

to personnel, the environment and equipment.

Take sucient precautionary measures.

For information on returning the instrument see chapter 14.2 “Return”.

12.3 Recalibration

DKD/DAkkS certicate - ocial certicates:

We recommend that the process transmitter is regularly recalibrated by the manufacturer, with time intervals of approx. 12 months.

14111166.02 04/2015 EN/DE

WIKA operating instructions process transmitter, model UPT-2x

51

Page 52

13. Faults

13. Faults

In the event of any faults, rst check whether the process transmitter is mounted

correctly, mechanically and electrically. For instruments with display and operating units,

the error code with error text will be displayed in the event of a failure.

EN

Faults Causes Measures

Display does not indicate

anything

Error code Error text Causes Measures

E001 Hardware fault Lack of communication Restart the instrument

E002 Sensor missing Communication to the

1)

E003

E004 Characteristic curve error Overow in calculation

E005 Temperature sensor Temperature sensor faulty Restart the instrument

1)

E006

E007 Sensor temperature Temperature exceeded

1) Error message can also appear when the pressure is greater than the nominal pressure range.

Sensor faulty Pressure status sensor

Overpressure sensor Overload pressure sensor Restart the instrument

Instrument is not mounted

correctly

sensor faulty

faulty

chain

at the pressure sensor,

limit monitoring in the

electronics

Install the electrical connection

and/or the display and operating unit correctly

Return the instrument

Restart the instrument

Return the instrument

Restart the instrument

Return the instrument

Restart the instrument

Switch to a linear

characteristic curve

Check the inputs

Return the instrument

Return the instrument

Depressurise the instrument (ambient pressure)

and restart

Return the instrument

Return the instrument

52

WIKA operating instructions process transmitter, model UPT-2x

14111166.02 04/2015 EN/DE

Page 53

13. Faults / 14. Dismounting, return and disposal

CAUTION!

If faults cannot be eliminated by means of the measures listed above, shut

down the process transmitter immediately, and ensure that pressure and/or

signal are no longer present, and secure the instrument from being put back

into operation inadvertently.

In this case, contact the manufacturer.

If a return is needed, please follow the instructions given in chapter 14.2

“Return”.

14. Dismounting, return and disposal

WARNING!

Residual media in the dismounted process transmitter can result in a risk to

personnel, the environment and equipment.

Take sucient precautionary measures.

14.1 Dismounting

Switch the pressure measuring instrument to a depressurised and unpowered state.

Observe the information given in the type examination certicate and the country-specic

regulations for installation and use in hazardous areas (e.g. IEC 60079-14, NEC, CEC)

this is not observed, serious injuries and damage could occur.

. If

EN

14.2 Return

WARNING!

Strictly observe the following when shipping the instrument:

All instruments delivered to WIKA must be free from any kind of hazardous

substances (acids, bases, solutions, etc.).

When returning the instrument, use the original packaging or a suitable transport

packaging.

14111166.02 04/2015 EN/DE

WIKA operating instructions process transmitter, model UPT-2x

53

Page 54

14. Dismounting, return and disposal

To avoid damage:

1. Place the protection cap onto the process connection.

2. Wrap the instrument in an antistatic plastic lm.

3. Place the instrument, along with the shock-absorbent material, in the packaging.

Place shock-absorbent material evenly on all sides of the transport packaging.

4. If possible, place a bag containing a desiccant inside the packaging.

EN

5. Label the shipment as carriage of a highly sensitive measuring instrument.

Information on returns can be found under the heading “Service” on our local

website.

14.3 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an environmentally

compatible way and in accordance with the country-specic waste disposal regulations.

54

WIKA operating instructions process transmitter, model UPT-2x

14111166.02 04/2015 EN/DE

Page 55

15. Specications

15. Specications

Measuring range

Measuring range See product label

Vacuum tightness Is provided, except for instruments for oxygen

Overpressure limit Measuring range ≤ 16 bar/300 psi: 3-fold

Accuracy specications

Accuracy see product label, model code

Mounting correction -20 ... +20 %

Non-repeatability ≤ 0.15 % of span

Behaviour with turndown

■

For measuring spans ≥ 1.6 bar

- TD ≤ 5:1 No inuence on the accuracy

- TD > 5:1 ... ≤ 100:1 Ges = GG + 0.03 % x (TD − 5)

■

For measuring spans < 1.6 bar

- TD = 1:1 No inuence on the accuracy

- TD > 1:1 ... ≤ 100:1 Ges = GG + 0.03 % x (TD − 1)

Long-term stability (referred to basic measuring

range)

Thermal change zero point/span (reference

temperature 20 °C)

applications

Measuring range > 16 bar/300 psi: 2-fold

UPT-2*-***-**-**-*****-****1*-** = 0.10 %

UPT-2*-***-**-**-*****-****2*-** = 0.15 %

UPT-2*-***-**-**-*****-****3*-** = 0.20 %

Including non-linearity, hysteresis, zero oset

and end value deviation (corresponds to

measured error per IEC 61298-2)

< 1 bar: 0.35 %/year

≥ 1 bar: 0.15 %/year

≥ 1.6 bar: 0.1 %/year

≥ 40 bar: 0.05 %/year

In compensated range 10 ... 70 °C:

no additional temperature error

EN

Thermal change of the current output (reference

temperature 20 °C)

Ges: Overall accuracy via turndown

GG: Accuracy (e.g. 0.15 %)

TD: Turndown factor (e.g. 4:1 corresponds to TD factor 4)

14111166.02 04/2015 EN/DE

WIKA operating instructions process transmitter, model UPT-2x

Outside compensated range:

Typical < 0.1 % / 10 K

< 18 °C and > 28 °C

0.1 % / 10 K (max. 0.15 %)

55

Page 56

15. Specications

Operating conditions

Range of applications Indoor and outdoor application

Humidity ≤ 93 % r. h.

EN

Ignition protection types See product label

Vibration resistance 4 g (5 ... 100 Hz) per GL characteristic curve 2

Shock resistance 150 g (3.2 ms) per IEC 60068-2-27

Ingress protection IP 66/67

Permissible temperature ranges

Temperature class / surface temperatures for all variants except for

UPT-2*-*I*-**-**-*****-*4****-** (model without cooling element):

Direct exposure to sunlight is permitted.

II 1/2G Ex ia IIC T4/T5/T6 Ga/Gb

II 2G Ex ia IIC T4/T5/T6 Gb

II 3G Ex ic IIC T4/T5/T6 Gc

II 1/2D Ex ia IIIC T135°C Da/Db

II 2D Ex ia IIIC T135°C Db

IP 65 for versions with circular connector,

angular connector or overvoltage protection

Ingress protection only applies with closed case

head and closed cable glands.

Temperature class / surface temperature Ambient and medium temperature (°C)

T5, T6 -40 ≤ Ta ≤ +60

T4 -40 ≤ Ta ≤ +80

T135 °C

-40 ≤ Ta ≤ +40 for Pi = 750 mW

-40 ≤ Ta ≤ +70 for Pi = 650 mW

-40 ≤ Ta ≤ +80 for Pi = 550 mW

Temperature classes / surface temperatures only for variant

UPT-2*-*I*-**-**-*****-*4****-** (model with cooling element):

Temperature class Max. medium temperature (°C)

T4 120 -40 ≤ Ta ≤ +50

T3 150 -40 ≤ Ta ≤ +40

56

WIKA operating instructions process transmitter, model UPT-2x

Ambient temperature (°C)

14111166.02 04/2015 EN/DE

Page 57

15. Specications

Restrictions to temperature ranges

Ambient temperature

■

Instrument with display -20 ... +60 °C

■

Instrument without display -40 ... +80 °C

■

Instrument without display and with angular

connector

■

Instrument without display and with circular

connector

Medium temperature

■

Oxygen application -20 ... +60 °C

■

Gas hazardous application Temperature class (maximum ambient

■

Dust hazardous application maximum output values of the current supply

■

Sealings NBR: -20 ... +105 °C

-30 ... +80 °C

-30 ... +80 °C

temperature)

(EN/IEC 60079-11, section 5.6.5).

FKM: -20 ... +105 °C, -20 ... +150 °C (for

process connection with cooling element)

EPDM: -40 ... +105 °C, -40 ... +150 °C (for

process connection with cooling element)

EPDM only with hygienic process connection

EN

Materials

Wetted parts Model UPT-20, measuring range ≤ 40 bar:

Stainless steel 1.4404

Model UPT-20, measuring range > 40 bar:

Stainless steel 1.4404 and stainless steel

2.4711

Model UPT-21: Stainless steel 1.4435

Sealings NBR, FKM, EPDM

Case head Plastic (PBT) with conductive surface per

EN 60079-0:2012

Colour: night blue RAL5022

Pressure transmission medium Model UPT-20

Measuring range ≤ 40 bar:

Synthetic oil, halocarbon oil

Measuring range > 40 bar:

Dry measuring cell

Model UPT-21

Synthetic oil, halocarbon oil

14111166.02 04/2015 EN/DE

WIKA operating instructions process transmitter, model UPT-2x

57

Page 58

EN

15. Specications

Display and operating unit (option)

Refresh rate 200 ms

Main display 4 ½-digit

Additional display Selectable, three-line scale range

Bar graph display 20 segments, radial, pressure gauge simulation

Colours Background: light grey, digits: black

Operating state Display via symbols

Output signal

Output signal See product label

4 ... 20 mA, 4 ... 20 mA with HART

- U

Load in Ω (U

) / 0.023 A

B

Bmin

UB = Applied power supply

U

= Minimum permissible power supply

Bmin

Damping 0 ... 99.9 s, adjustable

After the set damping time the instrument

outputs 63 % of the applied pressure as output

signal.

Settling time t

90

Refresh rate 20 ms without HART

60 ms without HART

80 ms with HART

50 ms with HART

®

®

®

®

®

signal

Voltage supply

Power supply U

B

DC 12 ... 30 V

Maximum voltage Ui DC 30 V

Maximum current li 100 mA

Maximum power Pi (gas) 1,000 mW

Maximum power Pi (dust, depending on the

750/650/550 mW

max. ambient temperature)

Eective internal capacitance 11 nF

Eective internal inductance 100 μH

58

WIKA operating instructions process transmitter, model UPT-2x

14111166.02 04/2015 EN/DE

Page 59

15. Specications

Electrical connections

Cable gland M20 x 1.5 and spring-loaded

terminals

Angular connector DIN 175301-803A with