Page 1

F-20 / F-21

Operating instructions

Betriebsanleitung

Pressure Transmitter with Field Case

Druckmessumformer in Feldgehäuseausführung

F-20

WIKA Alexander Wiegand GmbH & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/ Germany

Tel. (+49) 93 72/132-295

Fax (+49) 93 72/132-706

E-Mail support-tronic@wika.de

www.wika.de

2103870.03 GB/D 01/2006

F-21

GB

GB

D

Page 2

Operating instructions

Betriebsanleitung

F-20, F-21

Pressure transmitter /

Druckmessumformer

WIKA Alexander Wiegand GmbH & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg

Phone (+49) 93 72/132-295

Fax (+49) 93 72/132-706

E-Mail support-tronic@wika.de

www.wika.de

2103870.03 GB/D 01/2006

/Germany

F-20

F-21

Page 3

Contents / Inhalt

Contents Page 3-15

GB

1. Important details for your information

2. A quick overview for you

3. Abbreviations, signs and symbols

4. Function and accessories

5. For your safety

6. Packaging

7. Starting, operation

8. Maintenance, spare parts

9. Trouble shooting

10. Storage, disposal

WIKA Global (Page 32)

Current terms and conditions apply.

Details are available on www.wika.de

2 WIKA Operating instructions / Betriebsanleitung F-20, F-21

Inhalt Seite 16-30

1. Wichtiges zu Ihrer Information

2. Der schnelle Überblick für Sie

3. Zeichenerklärungen, Abkürzungen

4. Funktion und Zubehör

5. Zu Ihrer Sicherheit

6. Verpackung

7. Inbetriebnahme, Betrieb

8. Wartung, Ersatzteile

9. Störbeseitigung

10. Lagerung, Entsorgung

WIKA Global (Seite 32)

Es gelten unsere aktuellen Verkaufs- und

Lieferbedingungen siehe unter www.wika.de

GB D

1. Important details for your information / 2. A quick overview for you

D

1. Important details for your information

GB

Read these operating instructions before installing and starting the pressure transmitter.

Keep the operating instructions in a place that is accessible to all users at any time.

The following installation and operating instructions have been compiled by us with great care

but it is not feasible to take all possible applications into consideration. These installation and

operation instructions should meet the needs of most pressure measurement applications. If

questions remain regarding a specific application, you can obtain further information (data

sheets, instructions, etc.) via our Internet address (www.wika.de / www.wika.com ) or contact

WIKA for additional technical support (see section7 Starting, Operation/Further information).

With special model number, e.g. F-20000 or F-21000, please note specifications in the

delivery note.

The product data sheet is designated as PE 81.19

WIKA pressure transmitters are carefully designed and manufactured using state-of-the-art

technology. Every component undergoes strict quality inspection before assembly and each

instrument is fully tested prior to shipment.

S

Use of the product in accordance with the intended use F-2

Use the pressure transmitter for pressure measurement.

Knowledge required

Install and start the pressure transmitter only if you are familiar with the relevant regulations

and directives of your country and if you have the qualification required. You have to be

acquainted with the rules and regulations on measurement and control technology and

electric circuits, since this pressure transmitter is electrical equipment as defined by EN

50178. Depending on the operating conditions of your application you have to have the

corresponding knowledge, e.g. of aggressive media.

2. A quick overview for you

If you want to get a quick overview, read Chapters 5, 7 and 10. There you will get some short

safety instructions and important information on your product and its starting.

Read these chapters in any case. Get some more detailed information on this product in

Chapters 4 Function and accessories and 6 Packaging. Read Chapter 8 for

Maintenance. In the case of failures please refer to Chapter 9.

2103870.03 GB/D 01/2006

2103870.03 GB/D 01/2006

3WIKA Operating instructions / Betriebsanleitung F-20, F-21

Page 4

3. Abbreviations, signs and symbols / 4. Function and accessories

GB

3. Abbreviations, signs and symbols

Power supply

Load (e.g. display)

intended for the voltage supply.

The supply current is the

measurement signal.

intended for the voltage supply.

One connection line is intended

for the measurement signal.

measurement connection

measurement connection

!

Warning

Warning

Caution

Potential danger of life or of

severe injuries.

Potential danger of life or of

severe injuries due to catapulting

parts.

Potential danger of burns due to

hot surfaces.

Notice, important information,

malfunction.

The product complies with the

applicable European directives.

FDA Food and Drug Administration

2-wire Two connection lines are

3-wire Two connection lines are

UB+/Sig+ Positive supply /

OV/Sig- Negative supply /

4. Function and accessories

F-20: Standard pressure connection

F-21: Pressure connection with flush diaphragm for highly viscous or solids entrained

media which might clog the pressure port.

Function: With the pressure transmitter you measure the pressure of your application, which

is trans-formed into an electric signal. This electric signal changes in proportion to the

pressure and can be evaluated correspondingly.

Accessories: For details about the accessories, please refer to WIKAs price list, WIKAs

product catalog on CD or WIKAs web site www.wika.de. Please refer to our data sheet

Pressure gauge sealing washers AC 09.08 in WIKAs product catalog Pressure and

Temperature Measurement or our web site www.wika.de for details about sealing washers.

4 WIKA Operating instructions / Betriebsanleitung F-20, F-21

5. For your safety

5. For your safety

n Select the appropriate pressure transmitter with regard to scale range,

!

Warning

n Open pressure connections only after the system is without pressure!

n Please make sure that the pressure transmitter is only used within the overload

n Observe the ambient and working conditions outlined in section 7 Technical data.

n Ensure that the pressure transmitter is only operated in accordance with the provisions

n Do not interfere with or change the pressure transmitter in any other way than

n Remove the pressure transmitter from service and mark it to prevent it from being

n Take precautions with regard to remaining media in removed pressure

n Have repairs performed by the manufacturer only.

Information about material consistency against corrosion and diffusion can be found in our

WIKA-Handbook, 'Pressure and Temperature Measurement'.

2103870.03 GB/D 01/2006

2103870.03 GB/D 01/2006

performance and specific measurement conditions prior to installing and

starting the instrument.

n Observe the relevant national safety regulations (e.g.: EN 50178)

and observe the applicable standards and directives for special applications

(e.g. with dangerous media such as oxygen, acetylene, flammable gases or

liquids and toxic gases or liquids and with refrigeration plants or compressors).

If you do not observe the appropriate regulations, serious injuries and/or

damage can occur!

threshold limit all the time!

i.e. as described in the following instructions.

described in these operating instructions

used again accidentally, if it becomes damaged or unsafe for operation.

transmitter. Remaining media in the pressure port may be hazardous or toxic!

.

GB

5WIKA Operating instructions / Betriebsanleitung F-20, F-21

Page 5

6. Packaging / 7. Starting, operation

GB

6. Packaging

n Inspect the pressure transmitter for possible damage during transportation.

Should there be any obvious damage, inform the transport company and WIKA

without delay.

n Keep the packaging, as it offers optimal protection during transportation

(e.g. changing installation location, shipment for repair).

n Keep the protection cap of the pressure connection thread and the diaphragm

for later storage or transport.

In order to protect the diaphragm, the pressure connection of the instrument F-21 is provided

with a special protection cap.

n Remove this protection cap only just before installing the pressure

transmitter in order to prevent any damage to the diaphragm.

n Ensure that the pressure connection thread and the connection contacts

will not be damaged.

n Mount the protection cap when removing and transporting the instrument.

7. Starting, operation

Has everything been supplied?

Check the scope of supply:

n Completely assembled pressure transmitters; with flush version F-21

including pre-assembled sealings and protection cap.

Required tools: wrench (flats 27), screw driver

Diaphragm test for your safety

It is necessary that before starting the pressure transmitter you test the diaphragm, as this is

a safety-relevant component.

n Pay attention to any liquid leaking out, for this points to a diaphragm damage.

n Check the diaphragm visually for any damage.

!

Warning

n Use the pressure transmitter only if the diaphragm is undamaged.

n Use the pressure transmitter only if it is in a faultless condition as far as the

safety-relevant features are concerned.

6 WIKA Operating instructions / Betriebsanleitung F-20, F-21

7. Starting, operation

Installation

Product label

Test

P #

S #

2103870.03 GB/D 01/2006

2103870.03 GB/D 01/2006

n Remove the protection cap only just before installation and absolutely avoid

any damage to the diaphragm during installation as well.

n Ensure that the cable diameter you select fits to the cable gland of the

connector. Ensure that the cable gland of the mounted connector is positioned

correctly and that the sealings are available and undamaged. Tighten the

threaded connection and check the correct position of the sealings in order to

ensure the ingress protection.

n Connect the instrument to earth via the pressure connection and/or

connection terminal 5.

n Hold the instrument on the flat of the nut with an appropriate tool and tighten

the screws to the required torque or unscrew it as the case may be.

Do not hold onto the housing with pliers to screw or unscrew.

For Model F-20

the sealing ring

is available as

an optional

Coded manufacture date

Signal

Test circuit connection

Power Supply

Product No.

Serial No.

PIN assignment

max. 50 Nm

Sealing

extra.

For Model F-21

the sealing ring

is included in

delivery.

For tapped holes and welding sockets

please see Technical Information IN 00.14

for download at www.wika.de -Service

GB

7WIKA Operating instructions / Betriebsanleitung F-20, F-21

Page 6

7. Starting, operation

GB

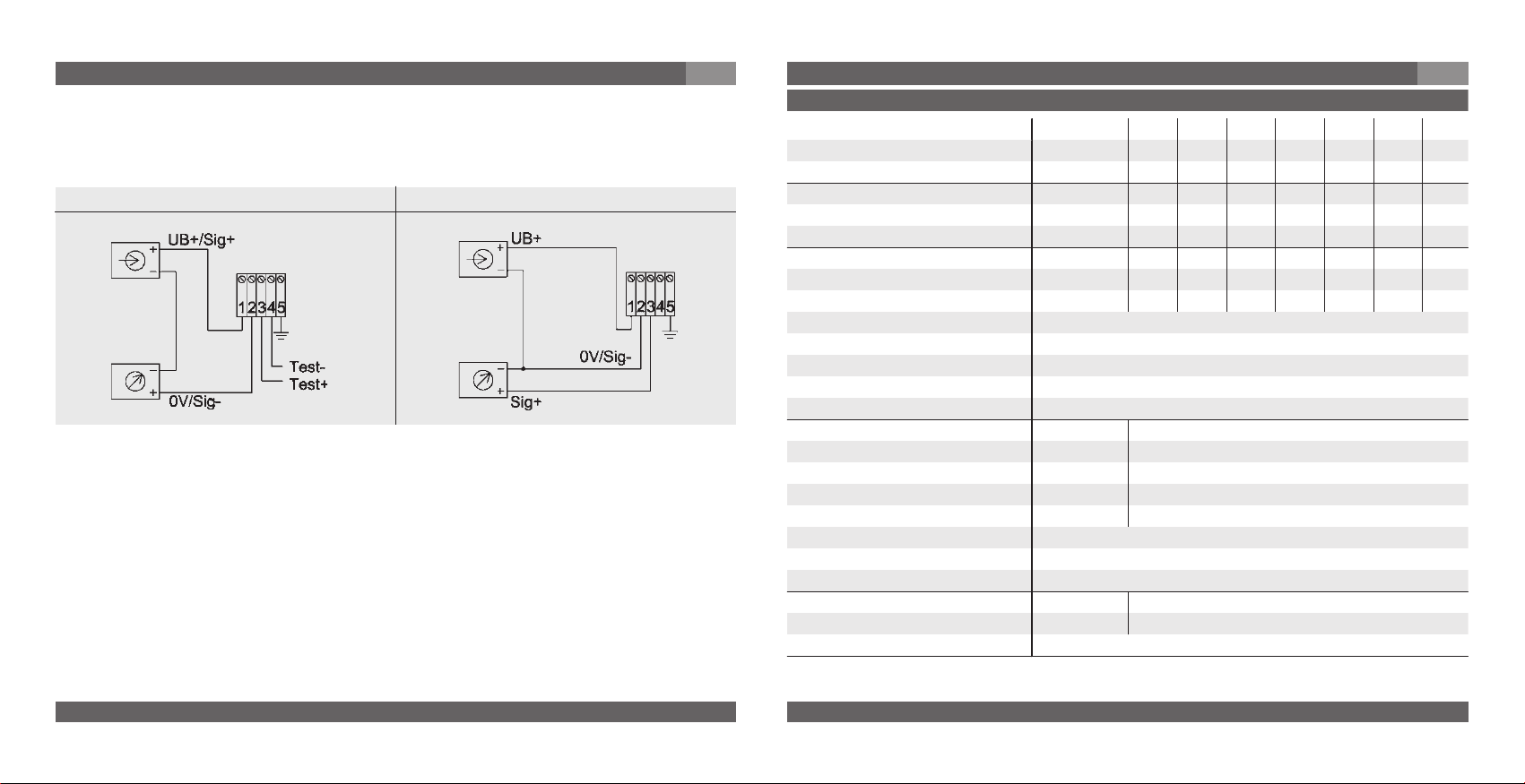

Wiring

Ingress protection IP 68 per IEC 60529

(Please make sure that the ends of cables do not allow any ingress of moisture.

)

conductor outer diameter 7 - 13 mm

2-wire

3-wire

Cable connection in the spring clip terminal

n Cover the stripped wire ends with end splices.

n Unscrew the case cover.

n Loosen the cable gland using an open-end wrench, wrench size 24.

n Lead the cable through the cable gland into the opened case head.

n Press the corresponding plastic lever at the spring clip terminal down using a screw driver,

so that the clamped contact will be released.

n Lead the prepared flying lead into the opening and let go of the plastic lever, so that the

flying lead will be squeezed inside the spring clip terminal.

n After connecting the individual wires, tighten the cable gland and screw down the case over.

7. Starting, operation

Specifications

Pressure ranges *

Over pressure safety bar 1 1.5 2 2 4 5 10

Burst pressure bar 2 2 2.4 2.4 4.8 6 12

Pressure ranges *

Over pressure safety bar 10 17 35 35 80 50 80

Burst pressure bar 12 20.5 42 42 96 96 400

Pressure ranges *

Over pressure safety bar 120 200 320 500 800 1200 1500

Burst pressure bar 550 800 1000 1200 1700 2)2400 2)3000

Materials

Wetted parts

n

Model F-20 *

Ø

Model F-21

Ø

Case

n

Electrical connection

n

Internal transmission fluid

)

)

)

)

3)

bar 0.1 0.16 0.25 0.4 0.6 1 1.6

bar 2.5 4 6 10 16 25 40

bar 60 100 160 250 400 600 1000

{Vacuum, gauge pressure, compound range, absolute pressure are

available}

1)

Only Model F-20

2)

For Model F-21: the value specified in the table applies only when sealing is realised

with the sealing ring underneath the hex. Otherwise max. 1500 bar applies.

with internal spring clip terminal; cross section max. 2.5 mm2,

Ground terminals internal for brass nickel-plated and

{stainless steel} and {stainless steel conduit} threaded connection

3)

Not for F-20 with pressure ranges > 25 bar

Model F-20, F-21

(Other materials see WIKA diaphragm seal program)

Stainless steel

Stainless steel {Hastelloy C4}; O-ring: NBR {FPM/FKM}

Stainless steel

Synthetic oil {Halocarbon oil for oxygen applications}

{Listed by FDA for Food & Beverage}

GB

1)

8 WIKA Operating instructions / Betriebsanleitung F-20, F-21

2103870.03 GB/D 01/2006

2103870.03 GB/D 01/2006

9WIKA Operating instructions / Betriebsanleitung F-20, F-21

Page 7

7. Starting, operation

Specifications

Power supply U

B

Signal output and RA in Ohm

maximum load R

A

Test circuit signal / max. load R

Adjustability zero/span % ± 10 using potentiometers inside the instrument

Response time (10 ... 90 %) ms

Dielectric strength DC V 500

Accuracy % of span

Non-linearity % of span

1-year stability % of span

Permissible temperature of

n

Ambience

n

Storage

n

6)

6)

6) *)

Medium

10 WIKA Operating instructions / Betriebsanleitung F-20, F-21

UB in DC V

A

% of span

4)

Accuracy { } for pressure ranges ≥ 0.25 bar

5)

Including non-linearity, hysteresis, non-repeatability, zero point and full scale error

(corresponds to error of measurement per IEC 61298-2).

Adjusted in vertical mounting position with lower pressure connection.

6)

Also complies with EN 50178, Tab. 7, Operation (C) 4K4H, Storage (D) 1K4, Transport (E) 2K3

7)

Response time F-20: ≤ 10 ms

ranges up to 25 bar

Response time F-21: ≤ 10 ms at medium temperatures below -30 °C (-22 °F)

Model F-20, F-21

10 < U

30 (11 ... 30 with signal output 4 ... 20 mA,

≤

B

14 ... 30 with signal output 0 ... 10 V)

4 ... 20 mA, 2-wire R

0 ... 20 mA, 3-wire RA ≤ (UB - 3 V) / 0,02 A

{0 ... 5 V, 3-wire} RA > 5 000 {0 ... 10 V, 3-wire} RA > 10 000

Only for instruments with 4 ... 20 mA signal output;

RA < 15 Ohm with 20mA

1

≤

0.25 {0.125}

≤

0.5 {0.25}

≤

0.2 (BFSL) according to IEC 1298-2

≤

0.2 (at reference conditions)

≤

4) 5)

-30 ... +100 °C {-40 ... +125 °C 7)} -22 ... +212°F {-40 ...+ 257°F 7)}

-20 ... + 80 °C {-30 ... +105 °C} -4 ... +176 °F {-22 ... +221°F}

-40 ... +100 °C -40 ... +212 °F

at medium temperatures below -30 °C for pressure

≤ (UB - 11 V) / 0,02 A

A

4)

(BFSL)

GB

7. Starting, operation

Specifications

Compensated temperature range 0 ... + 80 °C +32 ... +176 °F

Temperature coefficients within

compensated temp range

Mean TC of zero

n

Mean TC of range % of span / 10 K

n

a

- conformity

% of span / 10 K

Shock resistance g 600 according to IEC 60068-2-27 (mechanical shock)

Vibration resistance g 10 according to IEC 60068-2-6 (vibration under resonance)

Wiring protection Protected against reverse polarity and and short circuiting on the

Mass kg Approx. 0.35

*) In an oxygen version model F-21 is not available. In an oxygen version model F-20 is only available in gauge pressure ranges

0.25 bar with media temperatures between -20 … +60 °C / -4 … +140 °F and using stainless steel or Elgiloy

≥

{ } Items in curved brackets are optional extras for additional price.

When designing your plant, take into account that the stated values (e.g. burst pressure, over

pressure safety) apply depending on the material, thread and sealing element used.

Functional test

n Open pressure connections only after the system is without pressure!

n Observe the ambient and working conditions outlined in section 7

Warning

Technical data.

n Please make sure that the pressure transmitter is only used within the overload

threshold limit at all times!

When touching the pressure transmitter, keep in mind that the surfaces of the

instrument components might get hot during operation.

Caution

The output signal must be proportional to the pressure. If not, this might point to

2103870.03 GB/D 01/2006

2103870.03 GB/D 01/2006

a damage of the diaphragm. In that case refer to chapter 9 Trouble shooting.

Model F-20, F-21

0.2 (< 0.4 for pressure range 0 ... 0.1 and 0 ... 0.16 bar)

≤

0.2

≤

89/336/EEC interference emission and immunity see

EN 61 326, interference emission limit class A and B

97/23/EG Pressure equipment directive (Module H)

instrument side

®

wetted parts.

GB

11WIKA Operating instructions / Betriebsanleitung F-20, F-21

Page 8

7. Starting, operation

GB

8. Maintenance, spare parts

GB

Adjustment of zero point / span

n Make sure using a pressure standard with

adequate accuracy.

Pressure standard with adequate accuracy

means with an accuracy that is at least 3x

more accurate than the accuracy indicated

for the instrument.

n Open the pressure transmitter by

twisting off the field case over.

n Adjust the zero point (Z) by generating the

lower limit of the pressure range.

n Adjust the span (S) by generating the

higher limit of the pressure range.

n Check the zero point.

n If the zero point is incorrect, repeat

procedure as required.

n Close the pressure transmitter carefully.

Make sure that the sealings are not

damaged and check their correct

position in order to ensure the ingress

protection.

And make sure that no braids get pinched.

Recommended recalibration cycle: 1 year

Function of the test circuit for 2-wire

By means of the test circuit the current can be metered during normal operation without having to disconnect the instrument. For that purpose you have to connect an ammeter (internal

resistance < 15 Ohm) to the test +/- terminals.

12 WIKA Operating instructions / Betriebsanleitung F-20, F-21

Z = Zero

For further information

(+49) 9372/132-295

S = Span

8. Maintenance, spare parts

WIKA pressure transmitters require no maintenance!

n Open pressure connections only after the system is without pressure!

Warning

n Take precautions with regard to remaining media in removed pressure

!

Warning

Spare parts

For spare part details refer to our current stock price list, the CD catalog or contact our sales

department.

2103870.03 GB/D 01/2006

2103870.03 GB/D 01/2006

transmitters. Remaining media in the pressure port may be hazardous or toxic!

n Remove the pressure transmitter from service and mark it to prevent it from

being used again accidentally, if it becomes damaged or unsafe for operation.

n Have repairs performed by the manufacturer only.

Do not insert any pointed or hard objects into the pressure port for cleaning to

prevent damage to the diaphragm of the pressure connection.

13WIKA Operating instructions / Betriebsanleitung F-20, F-21

Page 9

9. Trouble shooting

GB

9. Trouble shooting

Problem Possible cause Remedy

No output

Output steady as pressure

changes

Full span output low

Zero signal too low

Zero signal too high

Non-linear output

*) Test the system for proper operation after adjustments are made. An excessive change in the output signal that

cannot be corrected by calibration indicates possible transmitter damage. This may cause the output to be non-linear,

requiring transmitter replacement.

If the problem persists, contact our sales department.

Power supply failure

Open wiring

Wiring reversed

No pressure or port blocked

Transmitter failure due to wrong

Supply voltage or power surge

Pressure port blocked

Transmitter over-pressurized

Transmitter failure due to wrong

Supply voltage or power surge

Supply voltage too low

Load impedance too high or too low

Transmitter over-pressurized

Transmitter over-pressurized

Transmitter over-pressurized

Transmitter over-pressurized

Check power supply

Check continuity

Correct polarity

Check pressure port

Replace transmitter

Check pressure port

Replace transmitter

Replace Transmitter

Check supply voltage

Adjust load or supply voltage

Recalibrate Transmitter

Replace Transmitter *)

Recalibrate Transmitter

Replace Transmitter *)

Recalibrate Transmitter

Replace Transmitter *)

Replace Transmitter

9. Trouble shooting / 10. Storage, disposal

GB

USA, Canada

If the problem continues, contact WIKA or an authorized agent for assistance. If the pressure

transmitter must be returned obtain an RMA (return material authorization) number and

shipping instructions from the place of purchase. Be sure to include detailed information

about the problem. Pressure

transmitters received by WIKA without a valid RMA number will

not be accepted.

Process material certificate (Contamination declaration for returned goods)

Purge / clean dismounted instruments before returning them.

Service of instruments can only take place safely when a contamination declaration has been

submitted and fully filled-in. This declaration contains information on all materials with which

the instrument has come into contact, either through installation, test purposes, or cleaning.

You can find a contamination declaration on our internet site (www.wika.de / www.wika.com).

10. Storage, disposal

When storing or disposing of the pressure transmitter, take precautions with

!

Warning

Storage

Disposal

regard to remaining media in removed pressure

the pressure port may be hazardous or toxic!

Mount the protection cap when storing the pressure transmitter in order to

prevent any damage to the diaphragm.

Dispose of instrument components and packaging materials in accordance

with the respective waste treatment and disposal regulations of the region or

country to which the instrument is supplied.

transmitters. Remaining media in

14 WIKA Operating instructions / Betriebsanleitung F-20, F-21

WIKA reserves the right to alter these technical specifications.

2103870.03 GB/D 01/2006

2103870.03 GB/D 01/2006

15WIKA Operating instructions / Betriebsanleitung F-20, F-21

Page 10

1. Wichtiges zu Ihrer Information

D

2. Der schnelle Überblick für Sie / 3. Zeichenerklärungen, Abkürzungen

D

1. Wichtiges zu Ihrer Information

Lesen Sie diese Betriebsanleitung vor Montage und Inbetriebnahme des Druckmessgerätes.

Bewahren Sie die Betriebsanleitung an einem für alle Benutzer jederzeit zugänglichen Ort auf.

Die nachfolgenden Einbau- und Bedienungshinweise haben wir mit Sorgfalt zusammengestellt. Es ist jedoch nicht möglich, alle erdenklichen Anwendungsfälle zu berücksichtigen.

Sollten Sie Hinweise für Ihre spezielle Aufgabenstellung vermissen, können Sie über unsere

Internet-Adresse (www.wika.de / www.wika.com) weitere Informationen (Datenblätter,

Hinweise, etc.) erhalten oder sich mit einem unserer Anwendungsberater in Verbindung

setzen (siehe Punkt 7, Inbetriebnahme, Betrieb/ Rückfragen).

Bei Sondertypennummer, z.B. F-20000 oder F-21000, bitte Spezifikation gemäß Lieferschein

beachten.

Das zugehörige Produkt-Datenblatt hat die Bezeichnung PE 81.19

Die in der Betriebsanleitung beschriebenen WIKA-Druckmessgeräte werden nach den neuesten Erkenntnissen konstruiert und gefertigt. Alle Komponenten unterliegen während der

Fertigung strengen Qualitätskriterien.

S

Bestimmungsgemäße Produktverwendung F-2

Verwenden Sie den Druckmessumformer zum Messen von Druck.

Ihre erforderlichen Kenntnisse

Montieren und nehmen Sie das Druckmessgerät nur in Betrieb, wenn Sie mit den zutreffenden

landesspezifischen Richtlinien vertraut sind und die entsprechende Qualifikation besitzen. Sie

müssen mit den Kenntnissen von Mess- und Regeltechnik sowie elektrischen Stromkreisen

vertraut sein, da das Druckmessgerät ein elektrisches Betriebsmittel nach EN 50178 ist. Je

nach Einsatzbedingung müssen Sie über entsprechendes Wissen verfügen, z. B. über

agressive Medien.

2. Der schnelle Überblick für Sie

Wollen Sie sich einen schnellen Überblick verschaffen, lesen Sie Kapitel 5, 7 und 10. Dort

erhalten Sie kurz Hinweise zu Ihrer Sicherheit und wichtige Informationen über Ihr Produkt

und zur Inbetriebnahme. Lesen Sie diese unbedingt.

Informieren Sie sich detaillierter über dieses Produkt in Kapitel 4 Funktion und Zubehör und

6 Verpackung. Lesen Sie Kapitel 8 zum Thema Wartung. Bei Auftreten von Störungen

lesen Sie bitte im Kapitel 9 weiter.

3. Zeichenerklärungen, Abkürzungen

Mögliche Gefahr für Ihr Leben

oder schwerer Verletzungen.

!

Warnung

Mögliche Gefahr für Ihr Leben

oder schwerer Verletzungen

Warnung

Vorsic ht

FDA Food and Drug Administration

2-Leiter Zwei Anschlussleitungen dienen zur Spannungsversorgung.

3-Leiter Zwei Anschlussleitungen dienen zur Spannungsversorgung.

UB+/Sig+ Positiver Versorgungs- / Messanschluss

OV/Sig- Negativer Versorgungs- / Messanschluss

durch wegschleudernde Teile.

Mögliche Gefahr von

Verbrennungen durch heisse

Oberflächen.

Der Speisestrom ist das Mess-Signal.

Eine Anschlussleitung dient für das Mess-Signal.

Hinweis, wichtige Information,

Funktionsstörung.

Das Produkt stimmt mit den

zutreffenden europäischen

Richtlinien überein.

Spannungsversorgung

Verbraucher

16 WIKA Operating instructions / Betriebsanleitung F-20, F-21

2103870.03 GB/D 01/2006

2103870.03 GB/D 01/2006

17WIKA Operating instructions / Betriebsanleitung F-20, F-21

Page 11

4. Funktion und Zubehör

D

5. Zu Ihrer Sicherheit

D

4. Funktion und Zubehör

F-20: Standardausführung

F-21: Mit frontbündiger Membran für hochviskose oder kristallisierende Medien, die

die Bohrung des Druckanschlusses zusetzen können.

Funktion

Mit dem Druckmessgerät messen Sie den in Ihrer Anwendung anstehenden Druck, der in ein

elektrisches Signal umgewandelt wird. Dieses elektrische Signal verändert sich proportional

zum Druck und kann entsprechend ausgewertet werden.

Zubehör

Hinweise zu Zubehör entnehmen Sie bitte der WIKA-Preisliste, dem WIKA Product Catalog

auf CD-Rom oder unserer Internet-Seite unter www.wika.de.

Hinweise zu Dichtungen entnehmen Sie bitte unserer Information Zubehör Dichtungen

AC 09.08 im Gesamtkatalog Druck- und Temperaturmesstechnik oder unserer Internet-Seite

unter www.wika.de

5. Zu Ihrer Sicherheit

n Wählen Sie das richtige Druckmessgerät hinsichtlich Messbereich, Ausführung

!

Warnung

n Öffnen Sie Anschlüsse nur im drucklosen Zustand!

n Betreiben Sie das Druckmessgeräte immer innerhalb des Überlastgrenzbereiches!

n Beachten Sie die Betriebsparameter gemäß Punkt 7 Technische Daten.

n Stellen Sie sicher, dass das Druckmessgerät bestimmungsgemäß -also wie in

n Unterlassen Sie unzulässige Eingriffe und Änderungen am Druckmessgerät, welche

n Setzen Sie das Druckmessgerät außer Betrieb und schützen Sie es gegen versehent-

n Ergreifen Sie Vorsichtsmaßnahmen für Messstoffreste in ausgebauten Druck-

n Lassen Sie Reparaturen nur vom Hersteller durchführen.

Angaben zu Korrosions- bzw. Diffusionsbeständigkeit der Gerätewerkstoffe entnehmen Sie

bitte unserem WIKA-Handbuch zur Druck- und Temperaturmesstechnik.

und spezifischen Messbedingungen vor Montage oder Inbetriebnahme.

n Halten Sie die entsprechenden landesspezifischen Sicherheitsvorschriften ein

(z. B.: EN 50178) und beachten Sie bei speziellen Anwendungen

die geltenden Normen und Richtlinien (z. B. bei gefährlichen Messstoffen wie

Sauerstoff, Acetylen, brennbaren oder giftigen Stoffen sowie bei Kälteanlagen

und Kompressoren, hohen Drücken).

Wenn Sie die entsprechenden Vorschriften nicht beachten, können

schwere Körperverletzungen und Sachschäden entstehen!

der folgenden Anleitung beschrieben- betrieben wird.

nicht in dieser Betriebsanleitung beschrieben sind.

liche Inbetriebnahme, wenn Sie Störungen nicht beseitigen können.

messgeräten. Messstoffreste können zur Gefährdung von Menschen, Umwelt

und Einrichtung führen!

18 WIKA Operating instructions / Betriebsanleitung F-20, F-21

2103870.03 GB/D 01/2006

2103870.03 GB/D 01/2006

19WIKA Operating instructions / Betriebsanleitung F-20, F-21

Page 12

6. Verpackung / 7. Inbetriebnahme, Betrieb

D

7. Inbetriebnahme, Betrieb

D

6. Verpackung

n Untersuchen Sie das Druckmessgerät auf eventuell entstandene Transport-

schäden.

Sind offensichtlich Schäden vorhanden, teilen Sie dies dem Transportunternehmen und WIKA unverzüglich mit.

n Bewahren Sie die Verpackung auf, denn diese bietet bei einem Transport einen

optimalen Schutz (z. B. wechselnder Einbauort, Reparatursendung).

n Bewahren Sie die Schutzkappe des Druckanschluss-Gewindes und der Mem-

bran zur späteren Lagerung oder Transport auf.

Zum Schutz der Membran ist der Druckanschluss des Gerätes F-21 mit einer speziellen

Schutzkappe versehen.

n Entfernen Sie diese Schutzkappe erst kurz vor dem Einbau, damit die

Membran nicht beschädigt wird.

n Achten sie darauf, dass das Druckanschluss-Gewinde und die Anschlusskon-

takte nicht beschädigt werden.

n Montieren Sie die Schutzkappe bei Ausbau und Transport des Gerätes.

7. Inbetriebnahme, Betrieb

Wurde alles geliefert?

Überprüfen Sie den Lieferumfang:

Komplett montierte Druckmessgeräte; bei frontbündiger Ausführung F-21 mit

vormontierten Dichtungen und Schutzkappe.

Benötigtes Werkzeug: Maulschlüssel SW 27, Schraubendreher

Membran-Prüfung zu Ihrer Sicherheit

Es ist erforderlich, daß Sie vor Inbetriebnahme des Druckmessgerätes die Membran prüfen,

denn sie ist ein sicherheitsrelevantes Teil.

n Achten Sie auf auslaufende Flüssigkeit, denn sie ist ein Hinweis auf eine

!

Warnung

Montage

Membranbeschädigung.

n Prüfen Sie die Membran optisch auf Beschädigung.

n Setzen Sie das Druckmessgerät nicht ein, wenn die Membran beschädigt ist.

n Setzen Sie das Druckmessgerät nur in sicherheitstechnisch einwandfreiem

Zustand ein.

n Entfernen Sie die Schutzkappe erst kurz vor dem Einbau und achten Sie unbe-

dingt darauf, dass die Membran auch während des Einbaus nicht beschädigt

wird.

n Erden Sie das Gerät über den Druckanschluss und/oder die

Anschlussklemme 5.

n Fassen Sie das Gerät mit dem geeigneten Werkzeug an der Schlüsselfläche

und schrauben Sie es mit dem vorgeschriebenen Drehmoment ein bzw. aus.

Fassen Sie es zum Ein- bzw. Ausschrauben nicht mit der Zange am Gehäuse

an.

20 WIKA Operating instructions / Betriebsanleitung F-20, F-21

2103870.03 GB/D 01/2006

2103870.03 GB/D 01/2006

21WIKA Operating instructions / Betriebsanleitung F-20, F-21

Page 13

7. Inbetriebnahme, Betrieb

Typenschild

D

Bei Typ F-20

ist der Dichtring optional

erhältlich.

7. Inbetriebnahme, Betrieb

Elektrischer Anschluss

Schutzart IP 68 nach IEC 60 529

(Stellen Sie sicher, dass am Ende des Kabels keine Feuchtigkeit eintritt.)

Leitungsaußendurchmesser 7 bis 13 mm

3-Leiter 2-Leiter

D

Codiertes Herstelldatum

Signal

Test Testkreisanschluss

Spannungsversorgung

Erzeugnis-Nr.

P #

Fabrik-Nr.

S #

Anschlussbelegung

max. 50 Nm

Dichtung

Bei Typ F-21

ist der Dichtring im Lieferumfang enthalten.

Angaben zu Einschraublöchern und Einschweißstutzen entnehmen Sie bitte unserer

Technischen Information IN 00.14 unter www.wika.de -Service

22 WIKA Operating instructions / Betriebsanleitung F-20, F-21

Kabelanschluss im Federklemmblock

n Konfektionieren Sie die abgemantelten Aderenden mit Aderendhülsen.

n Schrauben Sie den Gehäusedeckel auf.

n Lösen Sie mit einem Maulschlüssel SW24 die Kabelverschraubung.

n Führen Sie das Kabel durch die Kabelverschraubung in den geöffneten Gehäusekopf.

n Drücken Sie den entsprechenden Kunststoffhebel am Federklemmblock mit einem Schrau-

bendreher herunter, damit sich der Klemmkontakt öffnet.

n Führen Sie das konfektionierte Kabelende in die Öffnung ein und lassen den Kunststoff-

hebel los, so dass das Kabelende im Federklemmblock eingeklemmt wird.

n Nach Anschließen der einzelnen Adern ziehen Sie die Kabelverschraubung fest und ver-

schrauben den Gehäusedeckel.

2103870.03 GB/D 01/2006

2103870.03 GB/D 01/2006

23WIKA Operating instructions / Betriebsanleitung F-20, F-21

Page 14

7. Inbetriebnahme, Betrieb

D

7. Inbetriebnahme, Betrieb

D

Technische Daten Typ F-20 / F-21

Messbereich *

Überlastgrenze bar 1 1,5 2 2 4 5 10

Berstdruck bar 2 2 2,4 2,4 4,8 6 12

Messbereich *

Überlastgrenze bar 10 17 35 35 80 50 80

Berstdruck bar 12 20,5 42 42 96 96 400

Messbereich *

Überlastgrenze bar 120 200 320 500 800 1200 1500

Berstdruck bar 550 800 1000 1200 1700 2)2400 2)3000

Werkstoff

Messstoffberührte Teile (Andere Werkstoffe siehe WIKA Druckmittler-Programm)

n

Ø

Ø

Gehäuse

n

Elektrischer Anschluss mit innenliegenden Federklemmen; Anschlussquerschnitt

n

Interne Übertragungsflüssigkeit

Hilfsenergie U

24 WIKA Operating instructions / Betriebsanleitung F-20, F-21

)

)

)

bar 0,1 0,16 0,25 0,4 0,6 1 1,6

bar 2,5 4 6 10 16 25 40

bar 60 100 160 250 400 600 1000

{Unterdruck, Überdruck, +/-, sowie Absolutdruck erhältlich}

1)

Nur für Typ F-20 gültig.

2)

Bei Typ F-21: Der Tabellenwert gilt ausschließlich bei Abdichtung mittels Dichtring

unterhalb vom Sechskant. Andernfalls gilt max. 1500 bar.

Typ F-20 *

)

CrNi-Stahl

Typ F-21 CrNi-Stahl {Hastelloy C4}; O-Ring: NBR {FPM/FKM}

CrNi-Stahl

max. 2,5 mm2; Erdungsklemme innen bei Verschraubung

3)

Synthetisches Öl {Halocarbonöl für Sauerstoff-

Messing vernickelt und {CrNi} und {CrNi conduit

}

Ausführungen} {FDA-gelistet für Nahrungsmittelindustrie}

3)

Nicht vorhanden bei Typ F-20 bei Messbereichen > 25 bar

B

UB in DC V

10 < U

30 (11 ... 30 bei Ausgang 4 ... 20 mA,

≤

B

14 ... 30 bei Ausgang 0 ... 10 V)

Technische Daten Typ F-20 / F-21

Ausgangssignal und

zulässige max. Bürde R

A

RA in Ohm

4 ... 20 mA, 2-Leiter R

0 ... 20 mA, 3-Leiter RA ≤ (UB - 3 V) / 0,02 A

{0 ... 5 V, 3-Leiter} RA > 5 000

{0 ... 10 V, 3-Leiter} RA >10 000

Testkreissignal und zul. Bürde Nur bei Geräten mit 4 ... 20 mA Ausgangssignal;

RA < 15 Ohm bei 20mA

1)

Einstellbarkeit Nullpunkt/Spanne % ± 10 durch Potentiometer im Gerät

Einstellzeit (10 ... 90 %) ms < 1

Spannungsfestigkeit DC V 500

Genauigkeit % d. Spanne

% d. Spanne

4)

Genauigkeit

5)

Einschließlich Nichtlinearität, Hysterese, Nichtwiederholbarkeit, Nullpunkt- und End-

wertabweichung (entspricht Messabweichung nach IEC 61298-2).

Kalibriert bei senkrechter Einbaulage Druckanschluss nach unten.

Nichtlinearität % d. Spanne

Stabilität pro Jahr % d. Spanne

0,25 {0,125}

≤

0,5 {0,25}

≤

ür Messbereiche ≥ 0,25 bar.

{ } f

0,2 (Toleranzbandeinstellung, BFSL) nach IEC 61298-2

≤

0,2 (bei Referenzbedingungen)

≤

4)

4) 5)

Zulässige Temperaturbereiche

Messstoff

n

Umgebung

n

Lagerung

n

6) *)

6)

6)

°C -20 ... +80 {-30 ... +105}

°C -40 ... +100

6)

Erfüllt auch EN 50178, Tab. 7, Betrieb (C) 4K4H, Lagerung (D) 1K4, Transport (E) 2K3

7)

Einstellzeit (10 … 90 %) bei F-20: < 10 ms bei Messstofftemperatur < -30 °C

für Messbereiche bis 25 bar.

Einstellzeit (10 … 90 %) bei F-21: < 10 ms bei Messstofftemperatur < -30 °C

°C -30 ... +100 {-40 ... +125

Kompensierter Temperaturbereich °C 0 ... +80

2103870.03 GB/D 01/2006

2103870.03 GB/D 01/2006

≤ (UB - 11 V) / 0,02 A

A

(Toleranzbandeinstellung, BFSL)

7)

}

25WIKA Operating instructions / Betriebsanleitung F-20, F-21

Page 15

7. Inbetriebnahme, Betrieb

{ }Ang

D

Technische Daten Typ F-20 / F-21

Temperaturkoeffizienten im

kompensierten Temperaturbereich

Mittlerer TK des Nullpunktes % d. Spanne

n

Mittlerer TK der Spanne

n

a

- Kennzeichen 89/336/EWG Störemission und Störfestigkeit nach

Schockbelastbarkeit g 600 nach IEC 60068-2-27 (Schock mechanisch)

Vibrationsbelastbarkeit g 10 nach IEC 60068-2-6 (Vibration bei Resonanz)

Elektrische Schutzarten Verpolungs- und Kurzschlussschutz geräteseitig

Masse kg Ca. 0,35

In Sauerstoff-Ausführung ist Typ F-21 nicht erhältlich. In Sauerstoff-Ausführung ist Typ F-20 nur möglich mit Überdruck-Messbereich

*)

> 0,25 bar, Messstofftemperatur -20 … +60 °C und messstoffberührte Teile in CrNi-Stahl oder Elgiloy

aben in geschweiften Klammern beschreiben gegen Mehrpreis lieferbare Sonderheiten.

% d. Spanne

0,2 / 10 K (< 0,4 für Messbereiche 0...0,1 und 0...0,16 bar)

≤

0,2 / 10 K

≤

EN 61 326, Störemission Grenzwertklasse A und B

97/23/EG Druckgeräterichtlinie (Modul H)

®

.

Beachten Sie bei der Auslegung Ihrer Anlage, dass die angegebenen Werte (z. B. Berstdruck,

Überlastgrenze) in Abhängigkeit vom verwendeten Material, Gewinde und Dichtung gelten.

Funktionsprüfung / Betrieb

n Öffnen Sie Anschlüsse nur im drucklosen Zustand!

n Beachten Sie die Betriebsparameter gemäß Punkt 7 Technische Daten.

Warnung

n Betreiben Sie das Druckmessgeräte immer innerhalb des

Überlastgrenzbereiches!

Beachten Sie beim Berühren des Druckmessgerätes, dass die Oberflächen der

Gerätekomponenten während des Betriebes heiß werden können.

Vorsic ht

Das Ausgangssignal muss sich dem anstehenden Druck proportional verhalten.

Wenn dies nicht so ist, kann das ein Hinweis auf eine Beschädigung der

Membran sein. Lesen Sie in diesem Fall in Kapitel 9 Störbeseitigung nach.

26 WIKA Operating instructions / Betriebsanleitung F-20, F-21

7. Inbetriebnahme, Betrieb

Einstellung Nullpunkt / Spanne

n Stellen Sie ausreichend genaue Druck-

referenz ein. Ausreichend genaue Druck

referenz bedeutet mindestens 3x genauer

als die angegebene Genauigkeit.

n Öffnen Sie das Gerät indem Sie den Deckel

des Feldgehäuse aufschrauben.

n Stellen Sie den Nullpunkt (Z) ein, indem Sie

den Druckanfangswert anfahren.

n Stellen Sie die Spanne (S) mit, indem Sie

den Druckendwert anfahren.

n Überprüfen Sie den Nullpunkt.

n Wenn der Nullpunkt nicht stimmt ggf.

Prozedur wiederholen.

n Schließen Sie das Gerät wieder sorgfältig.

Achten Sie darauf, dass die Dichtungen

unbeschädigt und sauber sind und auf die

korrekte Lage der Dichtungen, um die

Z = Nullpunkt

Schutzart zu gewährleisten.

Und achten Sie darauf, dass keine Litzen

eingequetscht werden.

Empfohlener Nachkalibrier-Zyklus: 1 Jahr

Bei Rückfragen (+49) 9372/132-295

Funktion des Testkreises für 2-Leiter

Anhand des Testkreises ist es möglich, während des normalen Betriebes eine Strommessung

durchzuführen ohne das Gerät abzuklemmen. Sie müssen hierzu ein Amperemeter (Innenwiderstand < 15 Ohm) an die Klemmen Test +/- anschließen.

2103870.03 GB/D 01/2006

2103870.03 GB/D 01/2006

S = Spanne

D

27WIKA Operating instructions / Betriebsanleitung F-20, F-21

Page 16

8. Wartung, Ersatzteile

D

9. Störbeseitung

D

8. Wartung, Ersatzteile

WIKA Druckmessgeräte sind wartungsfrei!

n Öffnen Sie Anschlüsse nur im drucklosen Zustand!

Warnung

n Ergreifen Sie Vorsichtsmaßnahmen für Messstoffreste in ausgebauten Druck-

!

Warnung

Ersatzteile

Entnehmen Sie bitte Ersatzteilangaben unserer aktuellen Lagerpreisliste, dem CD-Katalog

oder setzen Sie sich mit unserem Vertriebsmitarbeiter in Verbindung.

messgeräten. Messstoffreste können zur Gefährdung von Menschen, Umwelt

und Einrichtung führen!

n Setzen Sie das Druckmessgerät außer Betrieb und schützen Sie es gegen

versehentliche Inbetriebnahme, wenn Sie Störungen nicht beseitigen können.

n Lassen Sie Reparaturen nur vom Hersteller durchführen.

Verwenden Sie keine spitzen bzw. harten Gegenstände zur Reinigung, denn die

Membran des Druckanschlusses darf nicht beschädigt werden.

9. Störbeseitigung

Störung Mögliche Ursache Maßnahme

Kein Ausgangssignal Keine Versorgungsspannung Spannungsversorgung überprüfen

Leitungsbruch Durchgang überprüfen

Leitungsverpolung Polung korrigieren

Kein Druck oder Druckkanal blockiert Druckkanal überprüfen

Messumformer defekt wegen falscher

Versorgungsspannung oder Stromstoß Messumformer austauschen

Gleichbleibendes Ausgangssignal Druckkanal blockiert Druckkanal überprüfen

bei Druckänderung Mechanische Überbelastung Messumformer austauschen

Messumformer defekt wegen falscher

Versorgungsspannung oder Stromstoß Messumformer austauschen

Signalspannung zu klein Versorgungsspannung zu niedrig Versorgungsspannung überprüfen

Bürde zu hoch oder zu niedrig Bürde bzw. Versorgungsspannung

korrigieren

Mechanische Überbelastung Messumformer neu kalibrieren

Messumformer austauschen *)

Nullpunktsignal zu niedrig Mechanische Überbelastung Messumformer neu kalibrieren

Messumformer austauschen *)

Nullpunktsignal zu hoch Mechanische Überbelastung Messumformer neu kalibrieren

Messumformer austauschen *)

Signalkennlinie unlinear Mechanische Überbelastung Messumformer austauschen

*) Überprüfen Sie nach dem Justieren die korrekte Arbeitsweise des Systems. Eine extreme Änderung des

Ausgangssignals, die durch eine Kalibrierung nicht korrigiert werden kann, deutet auf eine mögliche Beschädigung des

Messumformers hin. Diese könnte die Ursache für ein unlineares Ausgangssignal sein und den Austausch des

Messumformers erforderlich machen.

28 WIKA Operating instructions / Betriebsanleitung F-20, F-21

Wenn das Problem bestehen bleibt, setzen Sie sich mit unserem Vertriebsmitarbeiter in

Verbindung.

2103870.03 GB/D 01/2006

2103870.03 GB/D 01/2006

29WIKA Operating instructions / Betriebsanleitung F-20, F-21

Page 17

9. Störbeseitigung / 10. Lagerung, Entsorgung

Prozess Material Zertifikat (Kontaminationserklärung im Servicefall)

Spülen bzw. säubern Sie ausgebaute Geräte vor der Rücksendung.

Eine Überprüfung ausgefallener Geräte kann nur sicher erfolgen, wenn die vollständig ausgefüllte Kontaminationserklärung vorliegt. Eine solche Erklärung beinhaltet alle Materialien,

welche mit dem Gerät in Berührung kamen, auch solche, die zu Testzwecken, zum Betrieb

oder zur Reinigung eingesetzt wurden. Die Kontaminationserklärung ist über unsere InternetAdresse (www.wika.de / www.wika.com) verfügbar.

D

10. Lagerung, Entsorgung

Ergreifen Sie bei Lagerung Entsorgung Vorsichtsmaßnahmen für Messstoffreste

!

Warnung

Lagerung

Entsorgung

in ausgebauten Druckmessgeräten. Messstoffreste können zur Gefährdung von

Menschen, Umwelt und Einrichtung führen!

Montieren Sie die Schutzkappe bei Lagerung des Druckmessgerätes, damit die

Membran nicht beschädigt wird.

Entsorgen Sie Gerätekomponenten und Verpackungsmaterialien entsprechend

den einschlägigen landesspezifischen Abfallbehandlungs- und Entsorgungsvorschriften des Anliefergebietes.

Memo / Notiz / Notice

GB

D

Technische Änderungen vorbehalten.

30 WIKA Operating instructions / Betriebsanleitung F-20, F-21

2103870.03 GB/D 01/2006

2103870.03 GB/D 01/2006

31WIKA Operating instructions / Betriebsanleitung F-20, F-21

Page 18

WIKA Global

Argentina WIKA Argentina S.A.

Australia WIKA Australia Pty. Ltd.

Austria WIKA Messgerätevertrieb

Benelux WIKA Benelux

Netherlands Phone: (+31) 4 75/53 55 00

Brazil WIKA do Brasil Ind. e Com. Ltda.

Canada WIKA Instruments Ltd.

China WIKA Alexander Wiegand GmbH Co. KG

Finland WIKA Finland Oy

France WIKA Instruments s.a.r.l.

Germany WIKA Alexander Wiegand GmbH Co. KG

India WIKA Instruments India Pvt. Ltd.

Italy WIKA Italiana S.r.l.

Japan WIKA JAPAN K. K.

Kazakhstan TOO WIKA Kazakhstan

Phone: (+54) 11/47 30 18 00

E-Mail: info@wika.com.ar

Phone: (+61) 2-88 45 52 22

E-Mail: sales@wika.com.au

Ursula Wiegand Ges.m.b.H & Co. KG

Phone: (+43) 1/8 69 16 31

E-Mail: info@wika.at

E-Mail: info@wika.nl

Phone: (+55) 15-32 66 16 55

E-Mail: vendas@wika.com.br

Phone: (+1) 780/463-7035

E-Mail: info@wika.ca

Shanghai Representative Office

Phone: (+86) 21 53 85 25 72

E-Mail: wikash@online.sh.cn

Phone: (+358) 9/6 82 49 20

E-Mail: wika@wika.fi

Phone: (+33) 1/34 30 84 84

E-Mail: info@wika.fr

Phone: (+49) 93 72/13 20

E-Mail: info@wika.de

Phone: (+91) 20/ 27 05 29 01

E-Mail: sales@wika.co.in

Phone: (+39) 02/9 39 70 01

E-Mail: info@wika.it

Phone: (+81) 3/54 39-66 73

E-Mail: t-shimane@wika.co.jp

Phone: (+7) 32 72/33 08 48

E-Mail: wika-kazakhstan@nursat.kz

Korea WIKA Korea Ltd.

Malaysia WIKA Instrumentation (M) Sdn. Bhd.

Poland Kujawska Fabryka Manometrow KFM S.A.

Russia ZAO WIKA MERA

Serbia and WIKA Merna Tehnika d.o.o.

Montenegro Phone: (+381) 11 2763 722

Singapore WIKA Instrumentation Pte. Ltd.

South Africa WIKA Instruments (Pty.) Ltd.

Spain Instrumentos WIKA S.A.

Switzerland MANOMETER AG

Ta iw an WIKA Instrumentation Taiwan Ltd.

Ukraine WIKA Pribor GmbH

United Arab WIKA Middle East FZE

Emirates Phone: (+971) 4/883 90 90

United Kingdom WIKA Instruments Limited

U.S.A. WIKA Instrument Corporation

Phone: (+82) 2/8 69 05 05

E-Mail: info@wika.co.kr

Phone: (+60) 3 56 36/88 58

E-Mail: info@wika.com.my

Phone: (+48) 54 23 13 84 1

E-Mail: gawel@manometry.com.pl

Phone: (+7) 095 - 786 21 25

E-Mail: info@wika.ru

E-Mail: info@wika.co.yu

Phone: (+65) 68 44 55 06

info@wika.com.sg

Phone: (+27) 11/6 21 00 00

E-Mail: sales@wika.co.za

Phone: (+34) 902 902 577

E-Mail: info@wika.es

Phone: (+41) 41/9 19 72 72

E-Mail: info@manometer.ch

Phone: (+886) 34 20 60 52

E-Mail: info@wika.com.tw

Phone: (+38) 062 382 67 92

E-mail: info@wika.donetsk.ua

E-Mail: wikame@emirates.net.ae

Phone: (+44) 1737 644 008

E-Mail: info@wika.co.uk

Phone: (+1) 770 / 5 13 82 00

E-Mail: info@wika.com

www.wika.dewww.wika.de

Loading...

Loading...