Page 1

Current terms and conditions apply.

Details are available on ...

www.wika.us

Les modalités et conditions en vigueur s'appliquent.

Vous trouverez plus de renseignements à l'adresse

suivante :

www.wika.ca

WIKA Instrument, LP – U.S. Headquarters

1000 Wiegand Boulevard

Lawrenceville, GA 30043

Phone: (770) 513-8200

Fax: (770) 338-5118

info@wika.com

www.wika.us

Operating instructions

Mode d'emploi

E-10, E-11

Pressure transmitter

Transmetteur de pression

WIKA Instruments Ltd.

3103 Parsons Rd.

Edmonton, AB T6N 1C8

Phone : (780) 463-7035

Fax : (780) 462-0017

info@wika.ca

www.wika.ca

2451730.11 01/2015 US/FR

E-10

E-11

Page 2

US

Contents Page

1. Important details for your information 2

2. A quick overview for you 3

3. Signs, symbols and abbreviations 3

4. Function 5

5. For your safety 6

6. Packaging 7

7. Starting, operation 8

8. Maintenance, accessories 14

9. Trouble shooting 15

10. Storage, disposal 17

11. Control Drawing 18

Sommaire Page

1. Détails importants pour votre information 19

2. Une brève vue générale pour vous 20

3. Signes, symboles et abréviations 20

4. Fonction 21

5. Pour votre sécurité 22

6. Emballage 23

7. Mise en marche, fonctionnement 24

8. Entretien, accessoires 30

9. Dépannage 31

10. Stockage, mise au rebut 33

11. Dessin de contrôle 34

2

WIKA operating instructions, models E-10, E-11

2451730.11 01/2015 US/FR

Page 3

1. Important details for your information

US

1. Important details for your information

Read these operating instructions before installing and starting the pressure transmitter. Keep

the operating instructions in a place that is accessible to all users at any time.

The following installation and operating instructions have been compiled by us with great care

but it is not feasible to take all possible applications into consideration. These installation and

operation instructions should meet the needs of most pressure measurement applications.

If questions remain regarding a specific application, you can obtain further information:

■

Via our Internet address www.wika.de / www.wika.com

■

The product data sheet is designated as APE E-10

■

Contact WIKA for additional technical support (770) 513 8200

If the serial number on the case and/or the 2D code on the hexagon gets illegible (e.g. by

me-chanical damage or repainting), the retraceability of the instrument is not possible any more.

WIKA pressure transmitters are carefully designed and manufactured using state-of-the-art

technology. Every component undergoes strict quality and environmental inspection before

assembly and each instrument is fully tested prior to shipment.

Intended use

Use the explosion proof pressure transmitter to transform the pressure into an electrical signal in

hazardous areas.

FM and CSA certification

Pressure transmitter for operation in hazardous areas in compliance with the respective certificate (see Control drawing No. 2323872, section 12).

FM and CSA Approval ratings:

Explosion proof: Class I, Division 1, Groups A, B, C and D

Dust-ignitionproof: Class II, Division 1, Groups E, F, and G; Class III, Division 1

WIKA operating instructions, models E-10, E-11

2451730.11 01/2015 US/FR

3

Page 4

1. Important details ... 3. Signs, symbols and abbreviations

Knowledge required

Install and start the pressure transmitter only if you are familiar with the relevant regulations and

directives of your country and if you have the qualification required. You have to be acquainted

with the rules and regulations on hazardous areas, measurement and control technology and

electric circuits, since this pressure transmitter is „electrical equipment“. Depending on the

operating conditions of your application you have to have the corresponding knowledge, e.g. of

aggressive media.

US

2. A quick overview for you

If you want to get a quick overview, read Chapters 3, 5, 7 and 10. There you will get some short

safety instructions and important information on your product and its starting. Read these

chapters in any case.

3. Signs, symbols and abbreviations

WARNING!

Potential danger to life or of severe injuries.

WARNING!

Instructions for hazardous areas: "Potential danger of explosion, to life or of severe

injuries!

Notice

Important information, malfunction.

4

WIKA operating instructions, models E-10, E-11

2451730.11 01/2015 US/FR

Page 5

3. Signs, symbols and abbreviations / 4. Function

US

FM, Factory Mutual

The product was tested and certified by FM Approvals. It complies with the applicable

US-American standards on safety (including explosion protection).

CSA, Canadian Standard Association

The product was tested and certified by CSA International. It complies with the

applicable Canadian and US-American standards on safety (including explosion

protection).

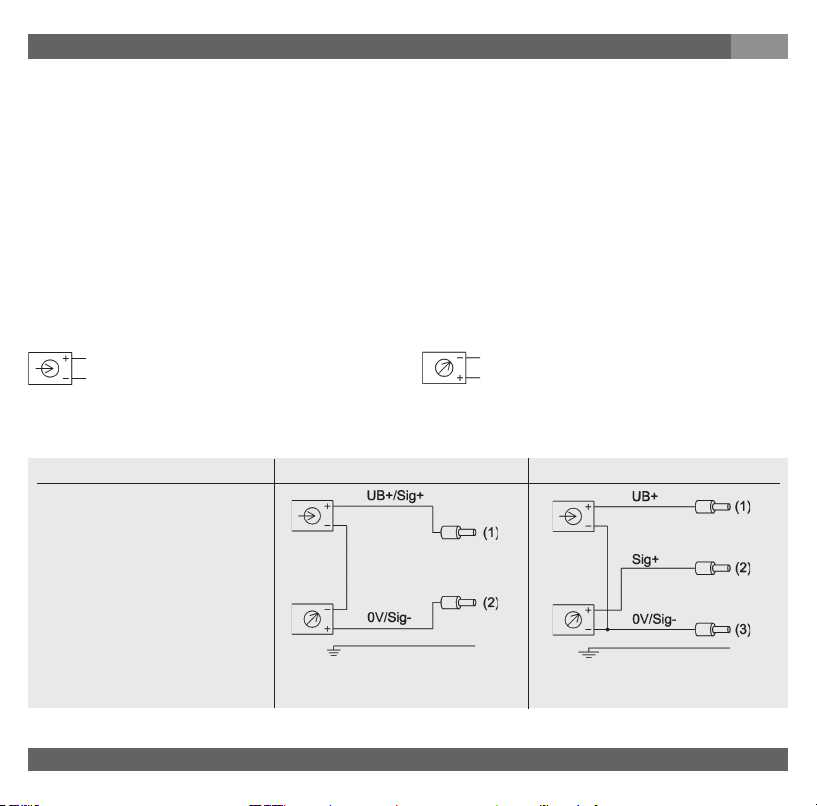

2-wire Two connection lines are intended for the voltage supply.

The supply current is the measurement signal.

3-wire Two connection lines are intended for the voltage supply.

One connection line is intended for the measurement signal.

4. Function

E-10: Pressure connection (explosion proof) with internal diaphragm (standard version).

E-11: Pressure connection with flush diaphragm (explosion proof) for highly viscous or solids

entrained media which might clog the pressure port.

Function

The pressure prevailing within the application is transformed into a standardised electrical signal

through the deflection of the diaphragm, which acts on the sensor element with the power supply

fed to the transmitter. This electric signal changes in proportion to the pressure and can be evaluated correspondingly

WIKA operating instructions, models E-10, E-11

2451730.11 01/2015 US/FR

5

Page 6

5. For your safety

5. For your safety

WARNING!

■

Select the appropriate pressure transmitter with regard to scale range, performance and specific measurement conditions prior to installing and starting the

instrument.

■

Observe the relevant national regulations (e.g.: NEC, CEC) and observe the applicable standards and directives for special applications (e.g. with dangerous media

such as acetylene, flammable gases or liquids and toxic gases or liquids and with

refrigeration plants or compressors). If you do not observe the appropriate regulations, serious injuries and/or damage can occur.

■

Open pressure connections only after the system is without pressure.

■

Please make sure that the pressure transmitter is only used within the overload

threshold limit all the time.

■

Observe the ambient and working conditions outlined in section 7 „Technical

data”.

■

Ensure that the pressure transmitter is only operated in accordance with the provisions i.e. as described in the following instructions.

■

Do not interfere with or change the pressure transmitter in any other way than

described in these operating instructions.

■

Remove the pressure transmitter from service and mark it to prevent it from being

used again accidentally, if it becomes damaged or unsafe for operation.

■

Take precautions with regard to remaining media in removed pressure transmitter.

Remaining media in the pressure port may be hazardous or toxic.

■

Have repairs performed by the manufacturer only.

US

6

WIKA operating instructions, models E-10, E-11

2451730.11 01/2015 US/FR

Page 7

5. For your safety / 6. Packaging

WARNING!

Consider the respective country specific regulations for installation and operation in

hazardous areas (e.g.: NEC, CEC). If you do not observe these stipulations, serious

injuries and/or damage can occur.

6. Packaging

Has everything been supplied?

Check the scope of supply:

■

Completely assembled pressure transmitters; with flush version E-11 including pre-assembled sealings and protection cap.

■

Inspect the pressure transmitter for possible damage during transportation. Should there be

any obvious damage, inform the transport company and WIKA without delay.

■

Keep the packaging, as it offers optimal protection during transportation (e.g. changing installation location, shipment for repair).

■

Ensure that the pressure connection thread and the connection contacts will not be damaged.

In order to protect the diaphragm, the pressure connection of the instrument E-11 is provided

with a special protection cap.

■

Remove this protection cap only just before installing the pressure transmitter in order to

prevent any damage to the diaphragm or the thread.

■

Keep the protection cap of the pressure connection thread and the diaphragm for later

storage or transport.

■

Mount the protection cap when removing and transporting the instrument.

US

WIKA operating instructions, models E-10, E-11

2451730.11 01/2015 US/FR

7

Page 8

Transmitter E-10

0 ... 10 bar

4 ... 20 mA

10 ... 30 V

P# 0639080

Code E-10-XXXXXXX

brown+ greenbrown S+ green GND

WIKA Alexander Wiegand SE & Co. KG 63911 Klingenberg Made in Germany

3D

Type 4

Explosionproof for

CLI, DIV.1, GRP A,B,C,D

CLII, DIV.1, GRP E, F, G; CL III

Ta < 60 °C, T6, Ta < 105 °C, T4

factory sealed,

conduit seal not required

CSA Single Seal ANSI/ISA12.27.01

-30 °C < Tprocess < 100 °C

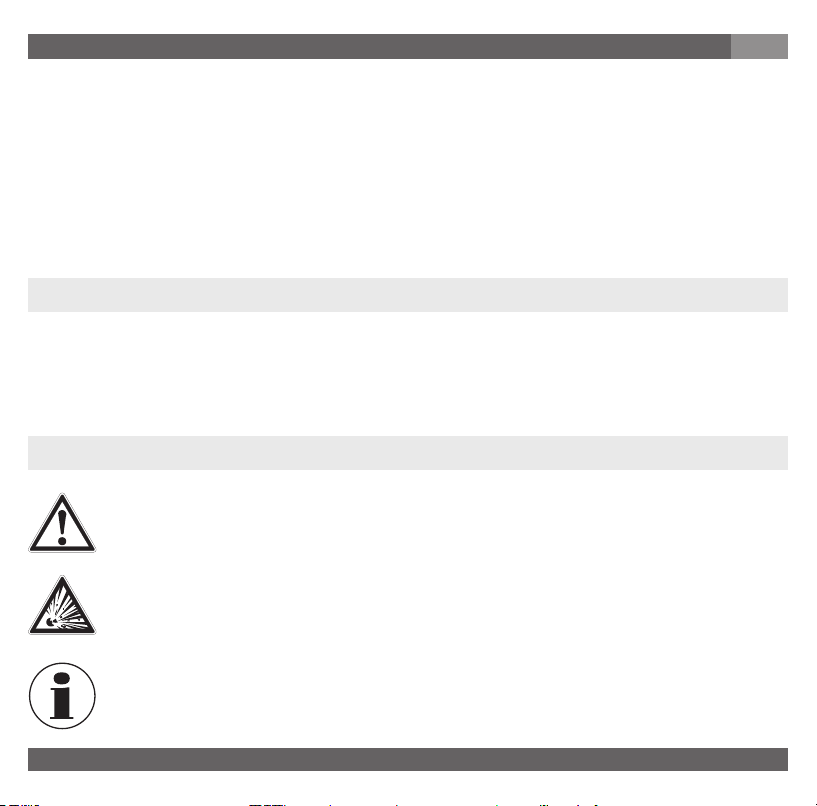

7. Starting, operation

US

7. Starting, operation

Required tools

Wrench (flats 27 or flats 41), screw driver

Diaphragm test for your safety

It is necessary that before starting the pressure transmitter you test the diaphragm visually, as

this is a safety-relevant component.

WARNING!

■

Pay attention to any liquid leaking out, for this points to a diaphragm damage.

■

Check the diaphragm visually for any damage (E-11).

■

Use the pressure transmitter only if the diaphragm is undamaged.

■

Use the pressure transmitter only if it is in a faultless condition as far as the

safety-relevant features are concerned.

Mechanical connection

Product label (example)

Make sure the ventilation

port remains open to

atmospharic pressure.

Use only to secure

transmitter while installing

electrical conduit

Use to install the transmitter process connection

Pressure range

Signal

Power Supply

P #: Product No.

If there is no serial number on the product label, the number on the hexagon will apply.

8

max. 50 Nm / 442 lbf

PIN assignment

WIKA operating instructions, models E-10, E-11

Coded

manufacture

date

2451730.11 01/2015 US/FR

Page 9

7. Starting, operation

WARNING!

■

Protect the diaphragm against any contact with abrasive substances and pressure

peaks and do not touch it with tools.

■

Observe the technical data for the use of the pressure transmitter in connection

with aggressive / corrosive media and for the avoidance of mechanical hazards.

■

Remove the protection cap only just before installation and absolutely avoid any damage to

the diaphragm during installation as well (E-11).

■

For Model E-10 you have to provide for a sealing element; exceptions are instruments with

self-sealing threads (e.g. NPT thread). For Model E-11 the sealing ring is included in delivery.

■

When mounting the instrument, ensure that the sealing faces of the instrument and the

measuring point are clean and undamaged.

■

Screw in or unscrew the instrument only via the flats using a suitable tool and the prescribed

torque. The appropriate torque depends on the dimension of the pressure connection and on

the sealing element used (form/material). Do not use the case as working surface for screwing

in or unscrewing the instrument.

■

When screwing the transmitter in, ensure that the threads are not jammed.

■

Do not torque the process connector with a force greater than 50 Nm / 442 lbf.

■

Be sure to install the system to meet NEC/CEC requirements.

US

WIKA operating instructions, models E-10, E-11

2451730.11 01/2015 US/FR

9

Page 10

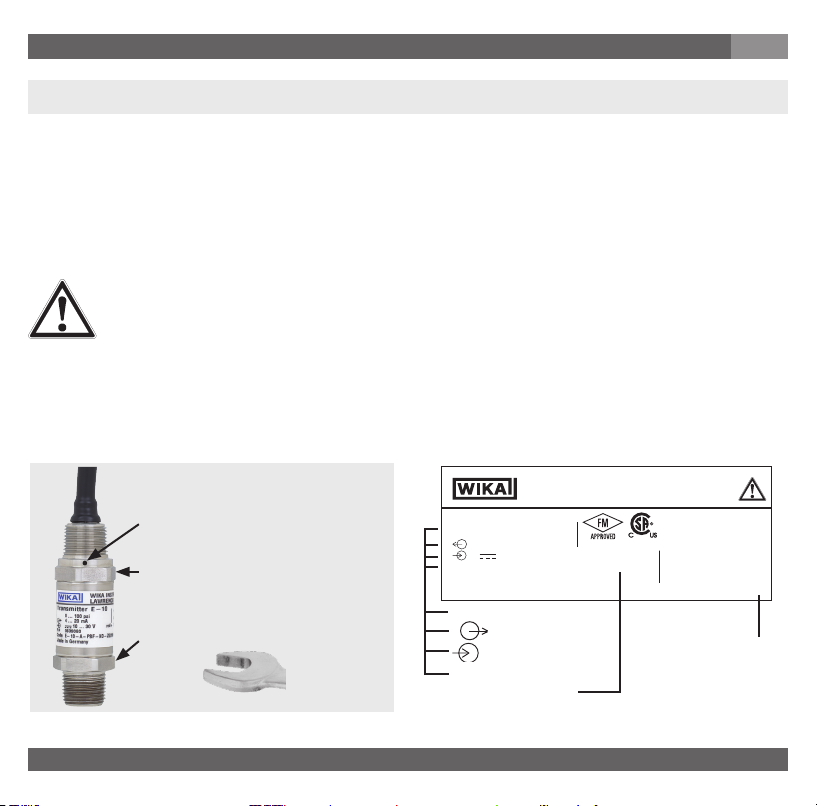

7. Starting, operation

Electrical Connection

WARNING!

■

Installation according control drawing 2323872.

■

Cable screen is connected to the case.

■

The simultaneous connection of case and shield wire to ground is only permitted

if ground loop problems between the shield wire connection (e.g. at the power

supply) and case can be excluded.

■

Switch on the operating voltage only after establishing the electrical connection in

order to avoid sparking.

■

Cover flying leads with fine wires by an end splice (cable preparation).

■

Attempting to remove the cable connection will damage the transmitter and void

the factory warranty and transmitter approvals.

■

The electrical connection to the transmitter must be used as originally supplied. It

must not be bypassed or modified (with the exception of the cable length). Improper assembly or alteration of the electrical connection will invalidate the explosion

protection class for which the transmitter is certified.

■

Installation with conduit: Use only threads NPT 1/2" according ANSI/ASME

B1.20.1.

■

Clamp the free cable end to a suitable certified clamp box or outside the hazardous area.

US

10

WIKA operating instructions, models E-10, E-11

2451730.11 01/2015 US/FR

Page 11

7. Starting, operation

■

Ground the housing through the process connection to protect the transmitter from electro-

US

magnetic fields and electrostatic discharge.

■

The transmitter is classified for overvoltage category II and the pollution degree 1: Use a NEC

or CEC Class 02 power supply (low voltage and low current max. 100 VA even under fault

conditions). Connect the cable shield or the green wire to ground.

■

Operate the pressure transmitter with a shielded cable and earth the shield at least on one

side of the cable, if the cable is longer than 30 m or if it is run outside of the building.

■

Please make sure that the ends of cables with flying leads do not allow any ingress of

moisture.

■

The pressure transmitters are supplied with a 1/2" NPT male conduit with 6 foot cable with

free ends, or 1/2" NPT male conduit with 6 foot flying leads.

Power supply

UB+/Sig+ Positive supply / measurement connection

OV/Sig- Negative supply / measurement connection

Cable with 6 foot (2 m) length,

IP 67 (NEMA 4x)

Order code: 2X

WIKA operating instructions, models E-10, E-11

2451730.11 01/2015 US/FR

shield wire / case

(green with open wires/

flying lead)

red

black

Load (e.g. display)

3-wire2-wire

red

brown

black

shield wire / case

(green with open wires/

flying lead)

11

Page 12

7. Starting, operation

US

Specifications Model E-10 / E-11

Pressure ranges psi 5 10 15 25 30 60 100

Over pressure safety psi 29 58 72 145 145 240 500

Burst pressure psi 35 69 87 170 170 290 600

Pressure ranges psi 200 300 500 600 1,000 1,500 2,000

Over pressure safety psi 1,160 1,160 1,160 1,160 1,740 2,900 4,600

Burst pressure psi 1390 1390 5800 5800 7970 11,600 14,500

Pressure ranges psi 3,000 5,000 8,000

10,000 1)15,000

Over pressure safety psi 7,200 11,600 17,400 17,400 21,750

Burst pressure psi 17,400 24,650 2)34,800 2)34,800 43,500

{Vacuum, gauge pressure, compound range, absolute pressure are available}

1) Only Model E-10.

2) For model E-11: the value specified in the table applies only when sealing is realised

with the sealing ring underneath the hex. Otherwise max. 21,000 bar applies.

Materials

■

Wetted parts (Other materials see WIKA diaphragm seal program)

Model E-10 Stainless steel (> 300 psi stainless steel and Elgiloy®)

Model E-11 Stainless steel

O-ring: NBR {FPM/FKM}

■

Case Stainless steel

Internal transmission fluid Synthetic oil (not for E-10 with pressure ranes > 300 psi)

Power supply U

B

UB in VDC 10 < UB ≤ 30 with signal output 4 ... 20 mA, 2-wire

Signal output and RA in Ohm 6 < UB < 30 with signal output 1 ... 5 V, 3-wire low power

maximum ohmic load R

A

4 ... 20 mA, 2-wire RA ≤ (UB - 10 V) / 0.02 A

1 ... 5 V, 3-wire, RA > 10,000

Response time (10 ... 90 %) ms ≤ 1 (≤ 10 ms at medium temperatures below < -22 °F / -30 °C for pressure

ranges up to 300 psi or with flush diaphragm)

Dielectric strength VDC 500

1)

12

WIKA operating instructions, models E-10, E-11

2451730.11 01/2015 US/FR

Page 13

7. Starting, operation

US

Specifications Model E-10 / E-11

Accuracy

Non-linearity % of span ≤ 0.2 (BFSL) according to IEC 61298-2

Non-repeatability % of span ≤ 0.1

1-year stability % of span ≤ 0.2 (at reference conditions)

Permissible temperature of

Compensated temp range +32 ... +176 °F

Temperature coefficients within

compensated temp range

Approval FM, CSA

RF immunity V/m 10

Burst KV 2

Shock resistance g 1,000 according to IEC 60068-2-27 (mechanical shock)

Vibration resistance g 20 according to IEC 60068-2-6 (vibration under resonance)

Wiring protection

Short-circuit proof Sig+ towards UBReverse polarity protection UB+ towards UB

Weight kg Approx. 0.2 (0.4 lbs)

{ } Items in curved brackets are optional extras for additional price.

2451730.11 01/2015 US/FR

3)

% of span ≤ 0.25 (BFSL)

≤ 0.5 3)

3) Including non-linearity, hysteresis, zero point and full scale error (corresponds to error

of measurement per IEC 61298-2). Adjusted in vertical mounting position with lower

pressure connection.

■

Medium T6: -40 ... +55 °C (-40 ... +131 °F)

T4: -40 ... +100 °C (-40 ... +212 °F)

■

Ambience T6: -40 ... +60 °C (-40 ... +140 °F)

T4: -40 ... +105 °C (-40 ... +221 °F)

■

Storage -40 ... +105 °C (-40 ... +221 °F)

■

Mean TC of zero % of span ≤ 0.2 / 10 K (< 0.4 for pressure range ≤ 250 mbar)

■

Mean TC of range % of span ≤ 0.2 / 10 K

■

Explosion proof: Class I, Division 1, Groups A, B, C and D

■

Dust ignition proof:

Class II, Division 1, Groups E, F and G; Class III, Division 1

WIKA operating instructions, models E-10, E-11

13

Page 14

7. Starting, operation / 8. Maintenance, accessories

US

Functional test

The output signal must be proportional to the pressure. If it is not, this might point to a damage of

the diaphragm. In that case refer to chapter 9 „Troubleshooting“.

WARNING!

■

Open pressure connections only after the system is without pressure!

■

Observe the ambient and working conditions outlined in section 7 „Technical

data.

■

Please make sure that the pressure transmitter is only used within the over load

threshold limit at all times!

■

When touching the pressure transmitter, keep in mind that the surfaces of the

instrument components might get hot during operation.

8. Maintenance, accessories

■

WIKA pressure transmitters require no maintenance.

■

Have repairs performed by the manufacturer only.

Accessories

For details about the accessories (e. g. connectors), please refer to WIKA‘s price list, WIKA‘s

product catalog on CD or or contact our sales department.

14

WIKA operating instructions, models E-10, E-11

2451730.11 01/2015 US/FR

Page 15

9. Trouble shooting

US

9. Trouble shooting

WARNING!

■

Open pressure connections only after the system is without pressure!

■

Take precautions with regard to remaining media in removed pressure transmitters. Remaining media in the pressure port may be hazardous or

toxic!

■

Remove the pressure transmitter from service and mark it to prevent it from being

used again accidentally, if it becomes damaged or unsafe for operation.

■

Have repairs performed by the manufacturer only.

Do not insert any pointed or hard objects into the pressure port for cleaning to prevent damage to

the diaphragm of the pressure connection.

Please verify in advance if pressure is being applied (valves/ ball valve etc. open) and if the right

voltage supply and the right type of wiring (2-wire/ 3-wire) has been chosen?

Failure Possible cause Procedure

No output signal

No/False output signal

Output signal unchanged after change

in pressure

Output signal unchanged after change

in pressure

No/incorrect voltage supply or current

spike

Cable break Check connections and cable

Incorrectly wired (e.g. Connected as

2-wire instead of 3-wire system)

Mechanical overload through overpressure

Wrong supply voltage or current spike Replace instrument

Mechanical overload through overpressure

Follow pin assignment (see Instrument

Label / Operating Instructions)

Replace instrument; if failure reoccurs,

consult the manufacturer *)

WIKA operating instructions, models E-10, E-11

2451730.11 01/2015 US/FR

15

Page 16

9. Trouble shooting

US

Failure Possible cause Procedure

Diaphragm is damaged, e.g. through

Signal span dropping off/too small

Signal span too small Power supply too high/too low

Signal span drops off Moisture present (e.g. at the cable tail) Install the cable correctly

Signal span erratic

In case of unjustified reclamation we charge the reclamation handling expenses.

*) Make sure that after the assembly the unit is working properly. In case the error continues to exist send in the instrument for repair (or replace

the unit).

impact, abrasive/agressive media;

corrosion of diaphragm/pressure

connector; transmission fluid missing.

Mechanical overload through overpressure

Electromagnetic interference source in

the vicinity, e.g. inverter drive

Contact the manufacturer and replace

the instrument

Correct the power supply in line with the

Operating Instructions

Replace instrument

Shield the device; shield the cables;

remove the interference source.

If the problem persists, contact our sales department.

USA, Canada

If the problem continues, contact WIKA or an authorized agent for assistance. If the pressure

transmitter must be returned obtain an RMA (return material authorization) number and

shipping instructions from the place of purchase. Be sure to include detailed information about

the problem. Pressure transmitters received by WIKA without a valid RMA number will not be

accepted.

16

WIKA operating instructions, models E-10, E-11

2451730.11 01/2015 US/FR

Page 17

9. Trouble shooting / 10. Storage, disposal

US

Process material certificate (Contamination declaration for returned goods)

Purge / clean dismounted instruments before returning them in order to protect our employees

and the environment from any hazard caused by adherent remaining media.

Service of instruments can only take place safely when a Product Return Form has been

submitted and fully filled-in. This Return Form contains information on all materials with which the

instrument has come into contact, either through installation, test purposes, or cleaning. You can

find the Product Return Form on our internet site (www.wika.de / www.wika.com).

10. Storage, disposal

WARNING!

When storing or disposing of the pressure transmitter, take precautions with regard

to remaining media in removed pressure transmitters. We recommend cleaning the

transmitter properly and carefully. Remaining media in the pressure port may be

hazardous or toxic!

Storage

Mount the protection cap when storing the pressure transmitter in order to prevent any damage

to the diaphragm (E-11).

Disposal

Dispose of instrument components and packaging materials in accordance with the respective

waste treatment and disposal regulations of the region or country to which the instrument is

supplied.

WIKA operating instructions, models E-10, E-11

2451730.11 01/2015 US/FR

17

Page 18

11. Control Drawing (FM, CSA)

11. Control Drawing (FM, CSA)

US

WIKA reserves the right to alter these technical specifications.

18

WIKA operating instructions, models E-10, E-11

Control Drawing S-No. 2323872.04

2451730.11 01/2015 US/FR

Page 19

1. Détails importants pour votre information

FR

1. Détails importants pour votre information

Lire ce mode d'emploi avant l'installation et la mise en marche du transmetteur de pression.

Conserver le mode d'emploi à un endroit accessible à tous les utilisateurs à tout moment.

Nous avons compilé les instructions d'installation et de fonctionnement suivantes avec le plus

grands soin, mais il n'est pas faisable de prendre en considération toutes les applications possibles. Ces instructions d'installation et de fonctionnement doivent répondre aux besoins de la

plupart des applications de mesure.

Si vous avez encore des questions concernant une application spécifique, vous pouvez obtenir

des informations supplémentaires :

■

via notre site Internet www.wika.ca / www.wika.com

■

La fiche technique du produit est désignée comme étant APE E-10

■

Contacter WIKA pour tout support technique supplémentaire à (780) 463.7035

Si le numéro de série sur le boîtier du produit et/ou le code 2D sur l'hexagone deviennent illisibles

(par exemple en raison d'un dommage mécanique ou en repeignant), la traçabilité de l'instrument

n'est plus possible.

Les transmetteurs de pression WIKA sont soigneusement conçus et fabriqués selon les

dernières technologies en vigueur. Chaque composant est soumis à une inspection sévère de

qualité et environnementale avant d'être installé et chaque instrument est entièrement testé

avant l'expédition.

Utilisation conforme à l'usage prévu

Utiliser le transmetteur de pression antidéflagrant pour transformer la pression en un signal

électrique dans les zones dangereuses.

Certification FM et CSA

Utilisation du transmetteur de pression dans les zones dangereuses conforme aux certificats

respectifs (voir le dessin de contrôle numéro 2323872, section 12).

Homologations FM et CSA :

Antidéflagrant : Classe I, division 1, groupes A, B, C et D

La preuve poussière allumage : Classe II, division 1, groupes E, F, et G; classe III, division 1

Mode d'emploi WIKA, modèle E-10, E-11

2451730.11 01/2015 US/FR

19

Page 20

1. Détails importants ... 3. Signes, symboles et abréviations

Connaissances requises

N'installez et ne démarrez le transmetteur de pression que si vous êtes familiarisés avec les

régulations s'y rapportant et avec les directives de votre pays, et si vous avez les qualifications

requises. Vous devez connaître les règles et les régulations sur les zones dangereuses, la

technologie de mesure et de contrôle et les circuits électriques, car ce transmetteur de pression

est un “dispositif électrique”. En fonction des conditions de fonctionnement de votre application,

vous devez posséder les connaissances pertinentes, par exemple celles portant sur les matières

corrosives.

FR

2. Une brève vue générale pour vous

Si vous voulez avoir une vue générale rapide, lisez les chapitres 3, 5, 7 et 10. Vous y trouverez

de brèves instructions de sécurité et des informations importantes concernant votre produit et sa

mise en service. Lisez dans tous les cas ces chapitres.

3. Signes, symboles et abréviations

AVERTISSEMENT !

Danger de mort potentiel ou de blessures graves.

AVERTISSEMENT !

Instructions pour des zones dangereuses : danger de mort potentiel ou de blessures

graves.

Note

Informations importantes, dysfonctionnement.

20

Mode d'emploi WIKA, modèle E-10, E-11

2451730.11 01/2015 US/FR

Page 21

3. Signes, symboles et abréviations / 4. Fonctionnement

FR

FM, Factory Mutual

Ce produit a été contrôlé et certifié par FM Approvals. Il est conforme aux normes

canadiennes et américaines de sécurité incluant la protection contre les explosions.

CSA, Canadian Standard Association

Ce produit a été contrôlé et certifié par CSA International. Il est conforme aux normes

canadiennes et américaines de sécurité incluant la protection contre les explosions.

2 fils Deux câbles de connexion sont destinés à l'alimentation en tension.

Le courant d'alimentation est le signal de mesure.

3 fils Deux câbles de connexion sont destinés à l'alimentation en tension.

Un câble de connexion est destiné au signal de mesure.

4. Fonction

E-10 : Connexion de pression (antidéflagrant) avec membrane interne (version standard).

E-11 : Raccordement de pression avec membrane affleurante (antidéflagrant) pour des fluides

visqueux ou contenant des solides qui pourraient obstruer l'orifice de refoulement.

Fonction

La pression régnant à l'intérieur de l'application est transformée en un signal électrique normalisé par la déformation de la membrane qui agit sur l'élément de capteur avec l'alimentation

électrique alimentant le transmetteur. Ce signal électrique varie en fonction de la pression et peut

être évalué en conséquence.

Mode d'emploi WIKA, modèle E-10, E-11

2451730.11 01/2015 US/FR

21

Page 22

5. Pour votre sécurité

5. Pour votre sécurité

AVERTISSEMENT !

■

Avant d'installer et mettre en marche l'instrument, sélectionner le transmetteur de

pression approprié concernant la gamme de mesure, la performance et les conditions de mesure spécifiques.

■

Respectez les réglementations nationales pertinentes (p. ex., NEC, CEC) et les

normes et directives en vigueur pour des applications spéciales (par exemple

avec des fluides dangereux tels que l'acétylène, des gaz ou liquides inflammables et des gaz ou liquides toxiques et avec des installations frigorifiques ou des

compresseurs). Si vous n'observez pas les régulations appropriées, vous risquez

des blessures sérieuses ou des dommages.

■

Ouvrir les connexions de pression uniquement lorsque le système n'est pas sous

pression.

■

Veuillez vous assurer que le transmetteur de pression est constamment et uniquement utilisé dans les limites de surpression.

■

Respecter les conditions ambiantes et de fonctionnement décrites dans la section

7 ”Données techniques“.

■

Vérifier que le transmetteur de pression est uniquement utilisé en conformité avec

les provisions décrites dans les instructions suivantes.

■

Ne pas manipuler ou modifier le transmetteur de pression d'une manière autre

que celle décrite dans le mode d'emploi.

■

Si le transmetteur de pression est endommagé ou devient trop dangereux pour

fonctionner correctement, arrêtez-le et marquez-le pour éviter qu'il soit utilisé à

nouveau par inadvertance.

■

Prendre des précautions en ce qui concerne les fluides restant dans les transmetteurs de pression enlevés. Des fluides restant dans l'orifice de pression peuvent

être dangereux ou toxiques.

■

Faire effectuer des réparations uniquement par le fabricant.

FR

22

Mode d'emploi WIKA, modèle E-10, E-11

2451730.11 01/2015 US/FR

Page 23

5. Pour votre sécurité / 6. Emballage

FR

AVERTISSEMENT !

Prenez en considération les détails contenus dans les régulations respectives de

chaque pays pour l'installation et le fonctionnement du dispositif en zone dangereuse

(p. ex., celles du NEC et du CEC). Si vous ne respectez pas ces stipulations, vous

risquez des blessures sérieuses ou des dommages.

6. Emballage

Est-ce que tout a bien été fourni?

Vérifiez le contenu de la livraison :

■

Transmetteurs de pression complètement assemblés (modèle E-11), y compris des joints

d'étanchéité pré-installés et un capuchon de protection.

■

Inspectez le transmetteur de pression pour vérifier s'il y a des dégâts liés au transport. En cas

d'un quelconque dommage apparent, veuillez informer sans délai la société de transport et

WIKA.

■

Conservez l'emballage, car il offre une protection optimale pendant le transport (par exemple

un changement de lieu d'installation, un envoi pour réparation).

■

Assurez-vous que le filetage de connexion de pression et les contacts de connexion ne sont

pas endommagés.

Pour protéger la membrane, le raccordement de pression de l'appareil E-11 est fourni avec un

capuchon de protection spécial.

■

Afin d'éviter d'endommager la membrane ou le filetage, ne retirez ce capuchon de protection

que juste avant d'installer le transmetteur de pression.

■

Conservez le capuchon de protection pour un transport ou un stockage ultérieur.

■

Placez le capuchon de protection lorsque vous retirez et transportez le transmetteur de

pression.

Mode d'emploi WIKA, modèle E-10, E-11

2451730.11 01/2015 US/FR

23

Page 24

Transmitter E-10

0 ... 10 bar

4 ... 20 mA

10 ... 30 V

P# 0639080

Code E-10-XXXXXXX

brown+ greenbrown S+ green GND

WIKA Alexander Wiegand SE & Co. KG 63911 Klingenberg Made in Germany

3D

Type 4

Explosionproof for

CLI, DIV.1, GRP A,B,C,D

CLII, DIV.1, GRP E, F, G; CL III

Ta < 60 °C, T6, Ta < 105 °C, T4

factory sealed,

conduit seal not required

CSA Single Seal ANSI/ISA12.27.01

-30 °C < Tprocess < 100 °C

7. Mise en marche, fonctionnement

7. Mise en marche, fonctionnement

Outils requis

Clés (clé plate 27 ou clé plate 41), tournevis

Test de membrane pour votre sécurité

Il est nécessaire, avant de démarrer le transmetteur de pression, de tester la membrane de

façon visuelle, car celle-ci est un composant essentiel pour la sécurité.

AVERTISSEMENT !

■

Faites attention à toute fuite de liquide, car ceci indiquerait un dommage sur la

membrane.

■

Vérifiez visuellement la membrane pour voir si elle est intacte (E-11).

■

N'utiliser le transmetteur de pression que si la membrane est intacte.

■

Le transmetteur de pression ne doit être utilisé qu'en parfait état de sécurité technique.

FR

Raccordement mécanique

Plaque signalétique (exemple)

Assurez-vous que le trou d'aération demeure ouvert à la pression

atmosphérique.

N'utiliser que pour sécuriser le

transmetteur pendant l'installation

d'un conduit électrique

Utiliser pour installer le raccord

process du transmetteur

S'il n'y a pas de numéro de série sur la plaque signalétique, on prendra le numéro situé sur l'hexagone.

24

max. 50 Nm / 442 lbf

Etendue de pression

Signal

Alimentation

P #: N° Produit

Conguration du

raccordement

Mode d'emploi WIKA, modèle E-10, E-11

Code de la

date de

fabrication

2451730.11 01/2015 US/FR

Page 25

7. Mise en marche, fonctionnement

AVERTISSEMENT !

■

Protéger la membrane contre tout contact avec des substances abrasives et des

pics de pression, et éviter de la toucher avec des outils.

■

Respectez les données techniques liées à l'utilisation du transmetteur de pression

relativement aux matières corrosives ou aggressives et évitez des dangers

mécaniques.

■

Retirez le capuchon de protection seulement juste avant l'installation et évitez d'endommager

la membrane lors de l'installation (E-11).

■

Pour le modèle E-10, vous devez fournir un joint d'étanchéité ; les exceptions sont les instruments avec des filetages auto-étanches (par exemple un filetage NPT). Pour le modèle E-11,

le joint d'étanchéité est inclus dans la livraison.

■

Lors du montage, assurez-vous que les surfaces d'étanchéité de l'instrument et le point de

mesure sont bien propres et intacts.

■

Ne vissez ou ne dévissez l'instrument qu'avec les raccords avec en utilisant un outil approprié. Le couple correct dépend des dimensions du raccord process et du joint utilisé (forme/

matériau). Lorsque vous vissez ou dévissez le transmetteur de pression, n'utilisez pas le

boîtier comme support de travail pour effectuer cette opération.

■

Lorsque vous vissez le transmetteur, assurez-vous que les filets ne sont pas endommagés.

■

N'exercez pas une force supérieure à 442 livres-force (50 Nm) sur le raccordement de process.

■

Assurez-vous d'installer le système conformément aux normes du NEC ou du CEC.

FR

Mode d'emploi WIKA, modèle E-10, E-11

2451730.11 01/2015 US/FR

25

Page 26

7. Mise en marche, fonctionnement

Raccordement électrique

AVERTISSEMENT !

■

Installation en fonction du dessin de contrôle n° 2323872.

■

La gaine est connectée au boîtier.

■

La connexion simultanée du boîtier et du câble blindé à la terre n'est permise

que si les problèmes de boucle de terre entre la connexion du câble blindé (par

exemple sur l'alimentation électrique) et le boîtier peuvent être exclus.

■

Afin d'éviter la formation d'étincelles, activez la tension de fonctionnement

seulement après avoir effectué le raccordement électrique.

■

Recouvrir les fils dénudés avec des fils fins au moyen d'une épissure d'extrémité

(préparation du câble).

■

Toute tentative de retirer la connexion par câble endommagerait le transmetteur et

invaliderait la garantie d'usine et les homologations du transmetteur.

■

Le raccordement électrique vers le transmetteur doit être utilisé dans son état

d'origine. Il ne faut pas le contourner ou le modifier (sauf pour la longueur du

câble). Une mauvaise installation ou une altération du raccordement électrique

invaliderait la classe de zone explosive pour laquelle le transmetteur est certifié.

■

Pour l'installation avec un conduit : utilisez seulement des filetages NPT de 1/2 po

conformes à ANSI/ASME B1.20.1.

■

Fixez l'extrémité libre du câble à une boîte de raccordement certifiée ou en dehors

de la zone dangereuse, en vous assurant de bien serrer cette extrémité.

FR

26

Mode d'emploi WIKA, modèle E-10, E-11

2451730.11 01/2015 US/FR

Page 27

7. Mise en marche, fonctionnement

■

Il faut mettre à la terre le boîtier par le raccord procédé pour protéger le transmetteur des

champs électromagnétiques et des décharges électrostatiques.

■

Le transmetteur est est classé Surtension catégorie II et Degré de pollution 1. Utilisez une

source d'alimentation électrique de classe 02 homologuée par le NEC ou ou le CEC (basse

tension et faible courant; maximum 100 VCA , même en cas de défaillance). Raccordez le blindage du câble ou le câble vert à la mise à la terre.

■

Utiliser le transmetteur de pression avec un câble blindé et mettre le blindage à la terre à au

moins un côté du câble, si le câble est long de plus de 30 m ou s'il court en-dehors du bâtiment.

■

Assurez-vous que les extrémités de câbles avec des fils dénudés ne permettent aucune intrusion d'humidité.

■

Les transmetteurs de pression sont alimentés à l'aide d'un conduit mâle NPT de 1,2 cm (1/2 po)

avec câble de 1,83 m (6 pi) avec les fils nus, ou par un conduit mâle de 1,2 cm (1/2 po) avec

des fils dénudés de 1,83 m (6 pi).

FR

Alimentation

UB+/Sig+ Alimentation positive/connexion de mesure

OV/Sig- Alimentation négative / connexion de mesure

Câble d'une longueur de 2 m (6 pi),

IP 67 (NEMA 4x)

Code de commande: 2X

Mode d'emploi WIKA, modèle E-10, E-11

2451730.11 01/2015 US/FR

câble blindé/gaine

(vert avec fils nus/

extrémité libre)

rouge

noir

Charge (par exemple affichage)

3 ls2 ls

rouge

marron

noir

câble blindé/gaine

(vert avec fils nus/

extrémité libre)

27

Page 28

7. Mise en marche, fonctionnement

Spécifications Type E-10 / E-11

Gammes de pression psi 5 10 15 25 30 60 100

Surpression admissible psi 29 58 72 145 145 240 500

Pression d'éclatement psi 35 69 87 170 170 290 600

Gammes de pression psi 200 300 500 600 1.000 1.500 2.000

Surpression admissible psi 1.160 1.160 1.160 1.160 1.740 2.900 4.600

Pression d'éclatement psi 1390 1390 5800 5800 7970 11.600 14.500

Gammes de pression psi 3.000 5.000 8.000

10.000 1)15.000

Surpression admissible psi 7.200 11.600 17.400 17.400 21.750

Pression d'éclatement psi 17.400 24.650 2)34.800 2)34.800 43.500

{Vide, pression relative, vide-pression et pression absolue offerts}

1) Seulement modèle E-10.

2) Pour le modèle E-11 : la valeur indiquée sur le tableau n'est valable que si l'étanchéité est

effectuée au moyen d'un joint d'étanchéité en dessous de l'hexagone. Dans les autres cas,

une pression maximale de 21.000 bar s'applique.

Matériaux

■

Parties en contact avec

(Pour d'autres matériaux, voir la gamme de séparateurs WIKA)

le fluide

Modèle E-10 Acier inoxydable (acier inoxydable et Elgiloy® > 300 psi)

Modèle E-11 Acier inoxydable

Joint torique : NBR {FPM / FKM}

■

Boîtier Acier inoxydable

Liquide de transmission

interne

Alimentation U

B

UB en VDC 10 < UB ≤ 30 avec signal de sortie 4... 20 mA, 2 fils

Huile synthétique (ne pas utiliser avec le modèle E-10 avec spécifications

de pression dépassant 300 psi)

Signal de sortie et RA en Ohms 6 < UB < 30 avec signal de sortie 1 ... 5 V, 3 fils basse puissance

charge ohmique maximale R

A

4 ... 20 mA, 2 fils RA ≤ (UB - 10 V) / 0,02 A

1 ... 5 V, 3 fils, RA > 10.000

Temps de réponse :

(10 ... 90 %)

ms ≤ 1 (≤ 10 ms à des températures moyennes sous -30 °C (-22 °F) pour des

plages de pression jusqu'à 300 psi ou avec membrane affleurante)

Rigidité diélectrique VDC 500

1)

FR

28

Mode d'emploi WIKA, modèle E-10, E-11

2451730.11 01/2015 US/FR

Page 29

7. Mise en marche, fonctionnement

FR

Spécifications Type E-10 / E-11

Précision

Non-linéarité % de l'échelle ≤ ± 0,2 (BFSL) selon CEI 61298-2

Non-répétabilité % de l'échelle ≤ 0,1

Stabilité sur 1 an % de l'échelle ≤ 0,2 (aux conditions de référence)

Température admissible de

Plage de température compensée +32 ... +176 °F

Coefficients de température sur plage

compensée

Agrément FM, CSA

Immunité aux fréquences radio V/m 10

Impulsion KV 2

Résistance aux chocs g 1.000 selon CEI 60068-2-27 (choc mécanique)

Résistance aux vibrations g 20 selon CEI 60068-2-6 (vibration sous résonance)

Protection du câblage

À l'épreuve des courts-circuits Sig+ vers UBProtection contre l'inversion de polarité UB+ vers UBPoids kg env. 0,2 (0,4 lbs)

{ } Les indications dans des accolades décrivent des particularités disponibles contre majoration de prix.

2451730.11 01/2015 US/FR

3)

% de l'échelle ≤ 0.25 (BFSL)

3)

≤ 0,5

3) Incluant la non-linéarité, l'hystérésis, l'erreur au point zéro et l'erreur à la pleine

échelle (correspond à l'erreur de mesure selon IEC 61298-2). Ajusté en position

verticale d'assemblage avec raccordement à basse pression.

■

Fluide T6: -40 ... +55 °C (-40 ... +131 °F)

T4: -40 ... +100 °C (-40 ... +212 °F)

■

Environnement T6: -40 ... +60 °C (-40 ... +140 °F)

T4: -40 ... +105 °C (-40 ... +221 °F)

■

Stockage -40 ... +105 °C (-40 ... +221 °F)

■

Coeff. de temp. moyen du point zéro % de l'échelle ≤ 0,2 / 10 K (< 0,4 pour gamme de pression ≤ 250 mbar)

■

Coeff. de temp. moyen de la plage % de l'échelle ≤ 0,2 / 10 K

■

Antidéflagrant : Classe I, division 1, groupes A, B, C et D

■

À l'épreuve des flambées de poussières :

Classe II, division 1, groupes E, F et G; Class III, division 1

Mode d'emploi WIKA, modèle E-10, E-11

29

Page 30

7. Mise en marche, fonctionnement / 8. Entretien, accessoires

FR

Test de fonctionnement

Le signal de sortie doit être proportionnel à la pression. Sinon, cela pourrait indiquer un endommagement de la membrane. Dans ce cas, reportez-vous au chapitre 9 “Dépannage”.

AVERTISSEMENT !

■

Ouvrir les connexions de pression uniquement lorsque le système n'est pas sous

pression !

■

Respecter les conditions ambiantes et de fonctionnement décrites dans la

section 7 ”Données techniques“.

■

Veuillez vous assurer que le transmetteur de pression est constamment et uniquement utilisé dans les limites de surpression !

■

Lors de tout contact avec le transmetteur de pression, notez que les surfaces de

l'instrument peuvent devenir chaudes lors du fonctionnement.

8. Entretien, accessoires

■

Les transmetteurs de pression WIKA ne requièrent aucun entretien.

■

Faire effectuer des réparations uniquement par le fabricant.

Accessoires

Pour plus de renseignements sur les accessoires (par exemple les raccords), prière de vous

référer à la liste de prix WIKA, au catalogue de produits WIKA sur CD ou de contacter notre

service à la clientèle.

30

Mode d'emploi WIKA, modèle E-10, E-11

2451730.11 01/2015 US/FR

Page 31

9. Dépannage

FR

9. Dépannage

AVERTISSEMENT !

■

Ouvrir les connexions de pression uniquement lorsque le système n'est pas sous

pression !

■

Prendre des précautions en ce qui concerne les fluides restant dans les transmetteurs de pression enlevés. Des fluides restant dans l'orifice de pression peuvent

être dangereux ou toxiques !

■

Si le transmetteur de pression est endommagé ou devient trop dangereux pour

fonctionner correctement, arrêtez-le et marquez-le pour éviter qu'il soit utilisé à

nouveau par inadvertance.

■

Faire effectuer des réparations uniquement par le fabricant.

Ne pas insérer d'objets pointus ou durs dans l'orifice de pression pour le nettoyage afin de ne

pas endommager la membrane du raccord procédé.

Prière de vérifier à l'avance si une pression est effectivement appliquée (soupapes/vanne à bille

etc. ouvertes) et si l'on a choisi la bonne tension d'alimentation et le bon type de raccordement

électrique (2 fils/3 fils).

Echec Cause possible Procédure

Pas de signal de sortie Pas de tension d'alimentation ou tension

Pas de/mauvais signal de sortie Mal connecté (par exemple connecté

Signal de sortie constant après une

variation de pression

incorrecte ou pointes de courant

Rupture de câble Vérifier les connexions et câbles

comme système à 2 fils au lieu de 3 fils)

Surcharge mécanique causée par une

surpression

Surcharge mécanique causée par une

surpression

Respecter la configuration du raccordement (voir l'étiquette de l'instrument ou

le mode d'emploi)

Remplacer l'instrument ; si le

dysfonctionnement se produit à

nouveau, consulter le fabricant *)

Mode d'emploi WIKA, modèle E-10, E-11

2451730.11 01/2015 US/FR

31

Page 32

9. Dépannage

FR

Echec Cause possible Procédure

Signal de sortie constant après une

variation de pression

Echelle de signaux qui tombe ou trop

petite

Echelle de signaux trop petite Alimentation trop élevée/trop basse Corriger l'alimentation en respectant le

La plage de signaux tombe Présence d'humidité (par exemple sur la

La plage de signaux est erratique Source d'interférences électromag-

En cas de réclamations qui ne sont pas justifiées, nous facturerons des frais de traitement.

*) Assurez-vous que l'appareil fonctionne correctement après l'avoir assemblé. Si le dysfonctionnement persiste, envoyez l'appareil en réparation

(ou le remplacer).

Mauvaise tension d'alimentation ou

pointes de courant

La membrane est endommagée, par

exemple par un impact, ou des fluides

abrasifs ou agressifs ; corrosion de la

membrane/du connecteur de pression;

absence de fluide de transmission.

Surcharge mécanique causée par une

surpression

queue du câble)

nétiques dans le voisinage, par exemple

convertisseur de fréquence

Remplacer l'instrument

Contacter le fabricant et remplacer

l'instrument

mode d'emploi

Remplacer l'instrument

Installer le câble correctement

Utiliser un blindage pour le dispositif et

les câbles ; se débarrasser de la source

d'interférences.

Si le problème persiste, contactez notre service à la clientèle.

USA, Canada

Si le problème continue, contacter WIKA ou un agent authorisé pour obtenir une assistance. Si

le transmetteur de pression doit être renvoyé, procurez-vous un numéro RMA (autorisation pour

retourner du matériel) et des instructions d'expédition à l'endroit où vous l'avez acheté. N'oubliez

pas d'inclure des informations détaillées concernant votre problème. Des transmetteurs de

pression reçus par WIKA sans numéro RMA valide ne seront pas acceptés.

32

Mode d'emploi WIKA, modèle E-10, E-11

2451730.11 01/2015 US/FR

Page 33

9. Dépannage / 10. Stockage, mise au rebut

FR

Certificat de matériau de process (déclaration de contamination pour les marchandises

renvoyées)

Purgez ou nettoyez les instruments démontés avant de les renvoyer pour protéger nos employés

ainsi que l'environnement de tout danger causé par des fluides qui seraient restés à l'intérieur.

La réparation d'instruments ne peut avoir lieu que si un formulaire de renvoi de marchandises

a été reçu et rempli entièrement. Ce formulaire de renvoi contient des informations sur tous les

matériaux avec lesquels l'instrument est entré en contact, soit lors de l'installation, soit lors de

tests, soit lors d'un nettoyage. Vous trouverez le formulaire de renvoi de marchandises sur notre

site internet (www.wika.ca/www.wika.com).

10. Stockage, mise au rebut

AVERTISSEMENT !

Lors du stockage ou de la mise au rebut du transmetteur de pression, prendre des

précautions relatives aux fluides restant dans les transmetteurs de pression enlevés.

Nous recommandons de nettoyer le transmetteur correctement et avec beaucoup

de soin. Des fluides restant dans l'orifice de pression peuvent être dangereux ou

toxiques !

Stockage

Afin d'éviter d'endommager la membrane (E-11), remettez le capuchon de protection en place

lorsque vous entreposez le transmetteur.

Mise au rebut

Eliminez les composants des appareils et les matériaux d'emballage conformément aux

prescriptions d'élimination et de traitement des déchets respectives de la région ou du pays

dans lequel l'instrument est livré.

Mode d'emploi WIKA, modèle E-10, E-11

2451730.11 01/2015 US/FR

33

Page 34

11. Dessin de contrôle (FM, CSA)

11. Dessin de contrôle (FM, CSA)

FR

WIKA se réserve le droit de modifier ces spécifications techniques.

34

Mode d'emploi WIKA, modèle E-10, E-11

Dessin de contrôle n° 2323872.04

2451730.11 01/2015 US/FR

Page 35

FR

Mode d'emploi WIKA, modèle E-10, E-11

2451730.11 01/2015 US/FR

35

Page 36

FR

36

Mode d'emploi WIKA, modèle E-10, E-11

2451730.11 01/2015 US/FR

Loading...

Loading...