WIKA PGT23.063, PGT43.100, APGT43.100, PGT63HP.100, PGT23.100 Operating Instructions Manual

...Page 1

Operating instructions

Betriebsanleitung

Pressure gauges with output signal,

optional for hazardous areas

Manometer mit Ausgangssignal,

optional für explosionsgefährdete Bereiche

Examples for pressure gauges with output signal

Model PGT23.063

Model PGT23.100 Model PGT43.100

EN

DE

Model PGT63HP.100

Model APGT43.100

Model DPGT43HP.100

Model DPGT43.100

Page 2

Operating instructions for pressure gauges with

EN

output signal, optional for hazardous areas

Page 3 - 32

Betriebsanleitung für Manometer mit Ausgangssi-

DE

gnal, optional für explosionsgefährdete Bereiche

© 07/2019 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

®

WIKA

is a registered trademark in various countries.

®

WIKA

ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Seite 33 - 63

2

Pressure gauges with output signal, optional for hazardous areas

11297264.05 07/2019 EN/DE

Page 3

Contents

Contents

1. General information 4

2. Design and function 5

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Description. . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Scope of delivery . . . . . . . . . . . . . . . . . . . . 5

3. Safety 6

3.1 Explanation of symbols . . . . . . . . . . . . . . . . . . 6

3.2 Intended use . . . . . . . . . . . . . . . . . . . . . . 6

3.3 Improper use . . . . . . . . . . . . . . . . . . . . . . 7

3.4 Responsibility of the operator . . . . . . . . . . . . . . . . 7

3.5 Personnel qualification. . . . . . . . . . . . . . . . . . . 8

3.6 Skilled personnel . . . . . . . . . . . . . . . . . . . . 8

3.7 Labelling, safety marks . . . . . . . . . . . . . . . . . . 8

3.8 Ex marking (option) . . . . . . . . . . . . . . . . . . . .10

3.9 Specifications and temperature limits. . . . . . . . . . . . . .10

3.10 Special conditions for safe use (X conditions) . . . . . . . . . . .12

4. Transport, packaging and storage 13

4.1 Transport . . . . . . . . . . . . . . . . . . . . . . .13

4.2 Packaging and storage . . . . . . . . . . . . . . . . . .13

5. Commissioning, operation 14

5.1 Mechanical connection . . . . . . . . . . . . . . . . . .14

5.2 Electrical connection . . . . . . . . . . . . . . . . . . .17

5.3 Zero point setting (not for PGT23.063) . . . . . . . . . . . . .19

5.4 Commissioning . . . . . . . . . . . . . . . . . . . . .20

6. Faults 21

7. Maintenance and cleaning 22

7.1 Maintenance . . . . . . . . . . . . . . . . . . . . . .22

7.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . .23

8. Dismounting, return and disposal 24

8.1 Dismounting . . . . . . . . . . . . . . . . . . . . . .24

8.2 Return . . . . . . . . . . . . . . . . . . . . . . . .24

8.3 Disposal . . . . . . . . . . . . . . . . . . . . . . .25

9. Specications 26

9.1 Electrical connection . . . . . . . . . . . . . . . . . . .26

9.2 Transmitter electronics for non-hazardous areas . . . . . . . . . .27

9.3 Transmitter electronics for hazardous areas . . . . . . . . . . .27

9.4 Pressure gauges with output signal . . . . . . . . . . . . . .28

Annex: EU declaration of conformity 63

EN

Declarations of conformity can be found online at www.wika.com.

11297264.05 07/2019 EN/DE

3Pressure gauges with output signal, optionally for hazardous areas

Page 4

1. General information

1. General information

The contact pressure gauge described in the operating instructions has been designed

and manufactured using state-of-the-art technology. All components are subject to stringent quality and environmental criteria during production. Our management systems are

EN

certied to ISO 9001 and ISO 14001.

These operating instructions contain important information on handling the instrument.

Working safely requires that all safety instructions and work instructions are observed.

Observe the relevant local accident prevention regulations and general safety regulations

for the instrument's range of use.

The operating instructions are part of the product and must be kept in the immediate

vicinity of the instrument and readily accessible to skilled personnel at any time.

Skilled personnel must have carefully read and understood the operating instructions

prior to beginning any work.

The manufacturer's liability is void in the case of any damage caused by using the

product contrary to its intended use, non-compliance with these operating instructions,

assignment of insuciently qualied skilled personnel or unauthorised modications to

the instrument.

The general terms and conditions contained in the sales documentation shall apply.

Subject to technical modications.

Further information:

- Internet address: www.wika.de / www.wika.com

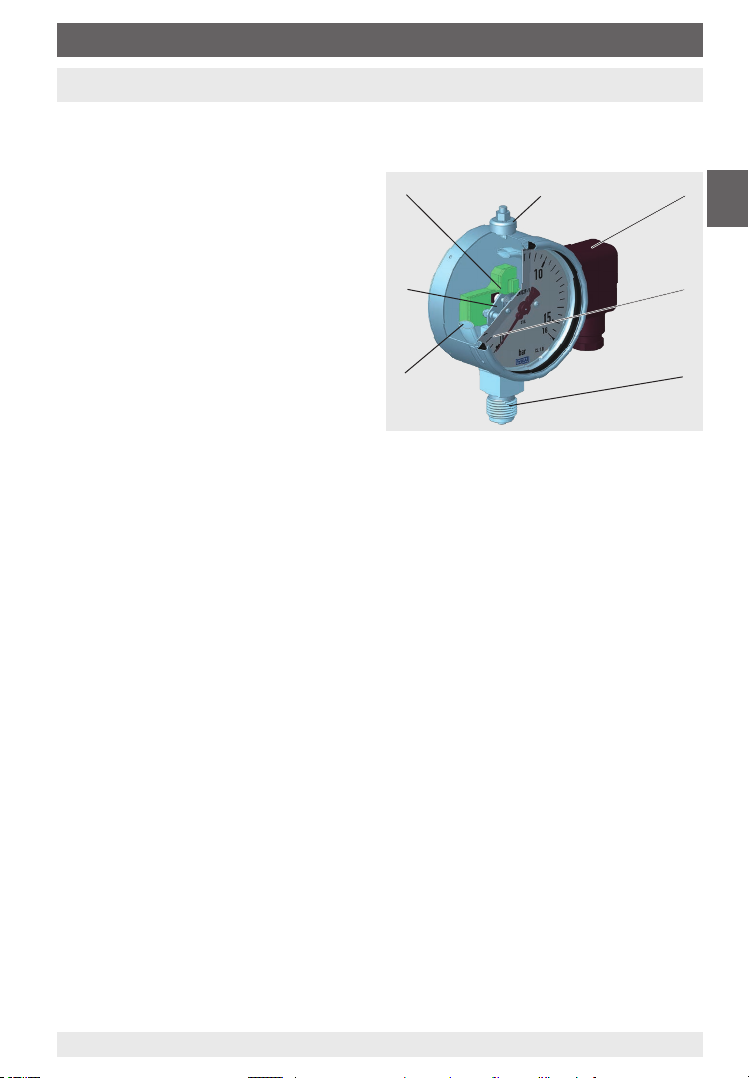

Model Transmitter electronics

for non-hazardous areas

Model Variant

PGT23.063 891.44 1, 3, 4 - - PV 12.03

PGT23.1x0, PGT26.1x0 891.44 1, 3, 4 892.44 2 PV 12.04

PGT43 891.44 1, 3, 4 892.44 2 PV 14.03

PGT43HP 891.44 1, 3, 4 892.44 2 PV 14.07

PGT63HP 891.44 1, 3, 4 892.44 2 PV 16.06

APGT43 891.44 1, 3, 4 892.44 2 PV 15.02

DPGT43 891.44 1, 3, 4 892.44 2 PV 17.05

DPGT43HP 891.44 1, 3, 4 892.44 2 PV 17.13

1) Variant of the output signal

1: 4 … 20 mA, 2-wire, passive, per NAMUR NE 43

2: 4 ... 20 mA, 2-wire, for hazardous areas

3: 0 ... 20 mA, 3-wire

4: 0 ... 10 V, 3-wire

Transmitter electronics

for hazardous areas

1)

Model Variant

For instruments which are additionally tted with switch contact(s), the following operating instructions also apply:

- “Pressure gauges with inductive contact model 831, for hazardous areas”,

article number 14320154

- “Pressure gauges with switch contact model 821, 851 or 830 E”,

article number 14057651

Pressure gauges with output signal, optionally for hazardous areas4

Data

sheet

1)

11297264.05 07/2019 EN/DE

Page 5

2. Design and function

2. Design and function

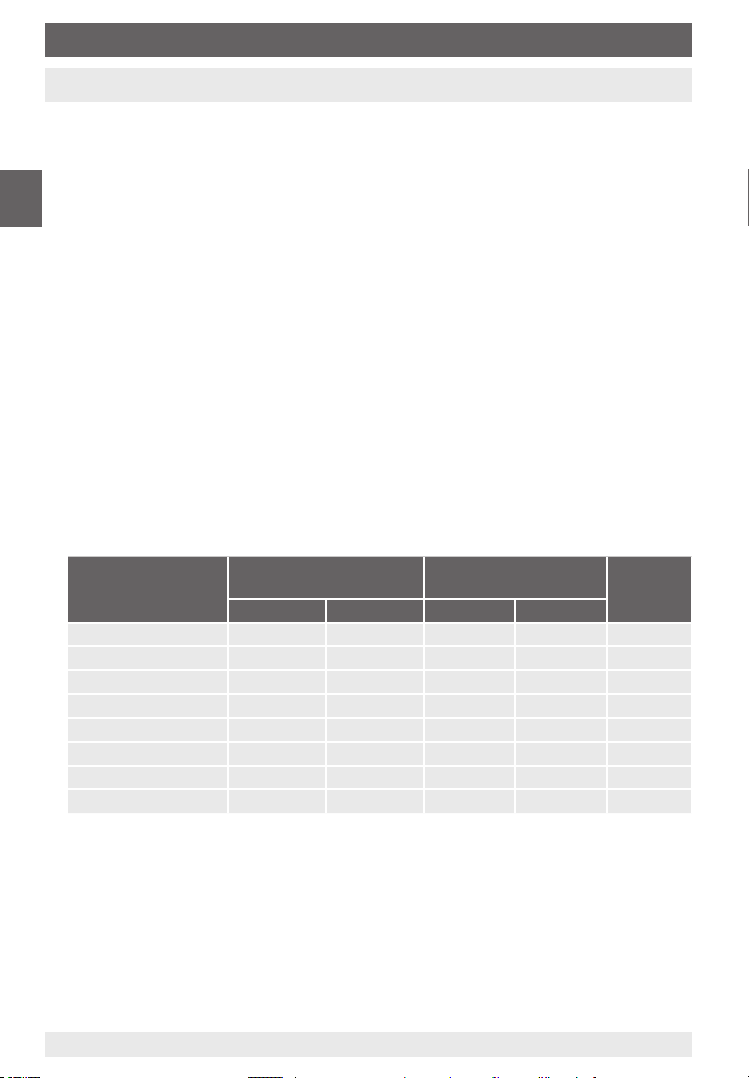

2.1 Overview

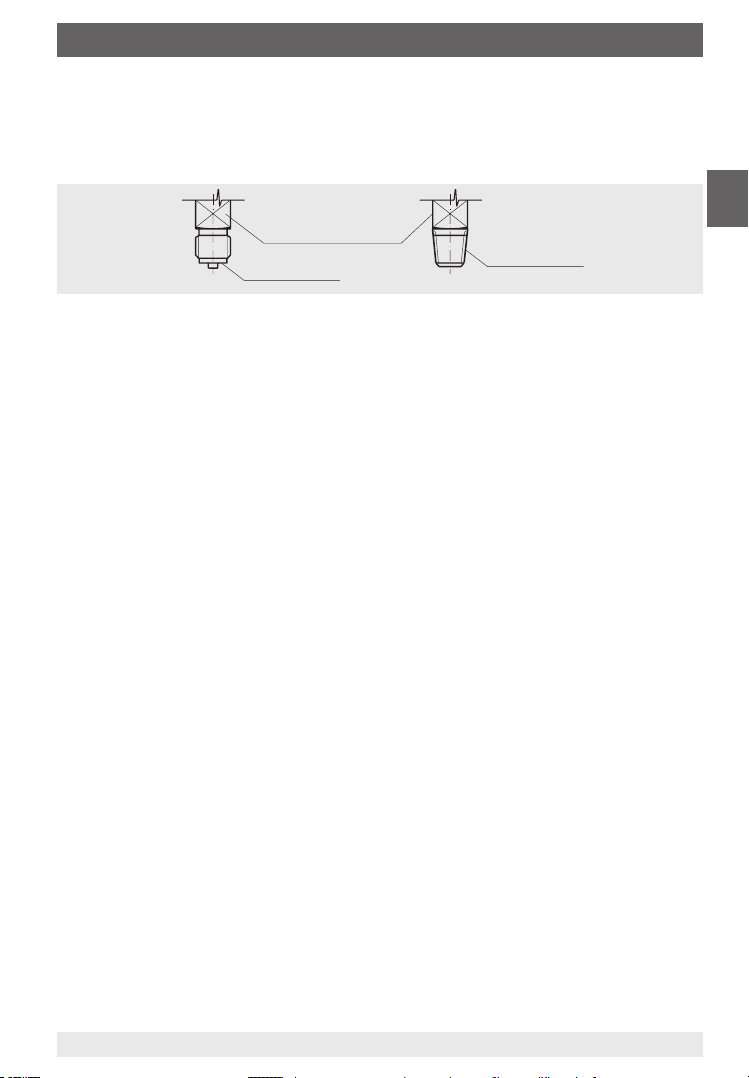

Example model PGT23.100, version “S3” per EN 837

Pressure element

Movement

Transmitter electronics

Pressure compensating valve

Electrical connection with cable box

Laminated safety glass

Process connection

EN

2.2 Description

For the instruments described, because of their robustness and ease of use, Bourdon tube,

diaphragm, capsule and corrugated steel measuring elements are widely used. Under the

inuence of pressure, the pressure elements deform within their elastic limits. A mechanical

movement transfers this deformation into a rotational motion. A magnet on the pointer shaft

rotates proportionally to the instrument pointer as a direct linear function of the process

pressure. The angle sensor contained in the transmitter electronics measures the rotational

motion of the magnet in the range 0 ... 270°. The angle change is registered without any

contact and, thus, wear-free and is converted to an analogue output signal via an amplier.

The span of the output signal corresponds to the measuring span on the dial.

Safety version “S3” per EN 837

This version is made up of laminated safety glass, a solid bae wall between measuring

system and dial and a blow-out back. In the event of a failure, the operator is protected at the

front side, as media or components can only be ejected via the back of the case.

Ex version

All instruments, except for the model PGT23.063, are also optionally available in a design for

hazardous areas.

2.3 Scope of delivery

Cross-check scope of delivery with delivery note.

11297264.05 07/2019 EN/DE

5Pressure gauges with output signal, optionally for hazardous areas

Page 6

2. Design and function / 3. Safety

3. Safety

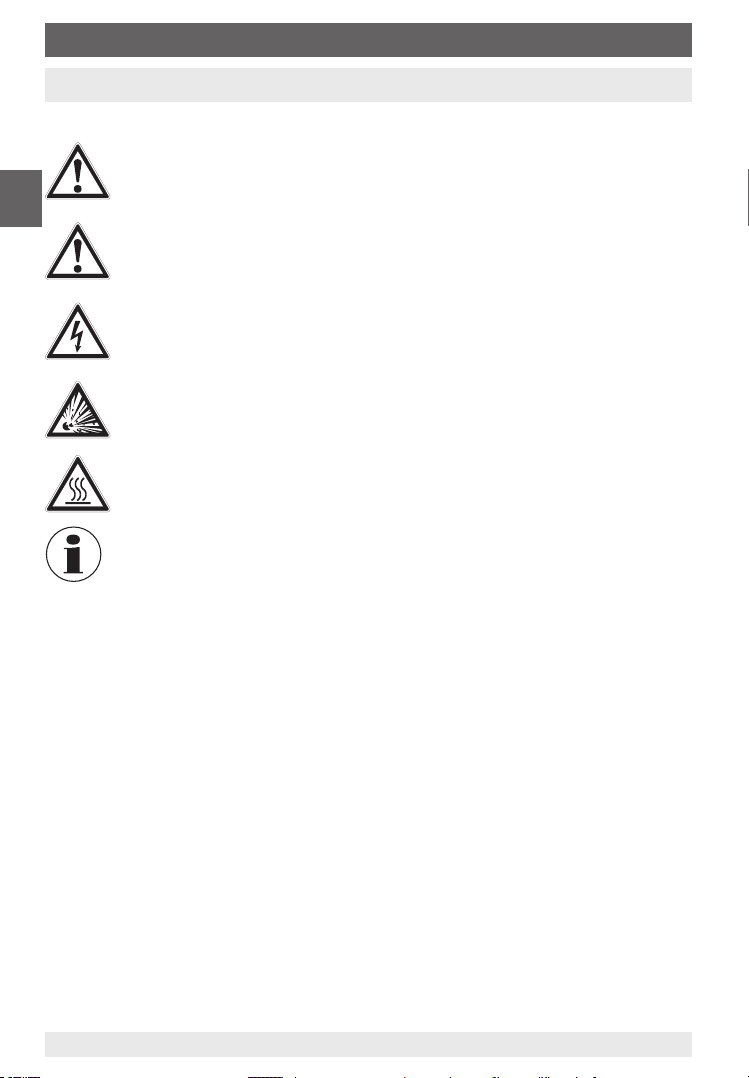

3.1 Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can result in serious injury or

EN

3.2 Intended use

Pressure gauges with output signal combine a mechanical measuring system with electronic

signal processing and are used to control process values as well as for plant monitoring in

industrial applications. The instrument oers many application possibilities for gaseous and

liquid aggressive media that are not highly viscous or crystallising.

Only use the instrument in applications that lie within its technical performance limits (e.g.

temperature limits, material compatibility, ...).

→ For performance limits see chapter 9 “Specications”.

The instrument has been designed and built solely for the intended use described here, and

may only be used accordingly.

The manufacturer shall not be liable for claims of any type based on operation contrary to

the intended use.

death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result in light injuries or

damage to property or the environment, if not avoided.

DANGER!

... identies hazards caused by electrical power. Should the safety instructions

not be observed, there is a risk of serious or fatal injury.

WARNING!

... indicates a potentially dangerous situation in the hazardous area that results

in serious injury or death, if not avoided.

WARNING!

... indicates a potentially dangerous situation that can result in burns, caused by

hot surfaces or liquids, if not avoided.

Information

... points out useful tips, recommendations and information for ecient and

trouble-free operation.

Pressure gauges with output signal, optionally for hazardous areas6

11297264.05 07/2019 EN/DE

Page 7

3. Safety

3.3 Improper use

WARNING!

Injuries through improper use

Improper use of the instrument can lead to hazardous situations and injuries.

▶

Refrain from unauthorised modications to the instrument.

▶

Do not use the instrument with abrasive or viscous media.

Exceptions are diaphragm pressure gauges (models PGT43 and PGT43HP)

with specially coated diaphragms (abrasive) or versions with open connect-

ing anges (viscous).

Any use beyond or dierent to the intended use is considered as improper use.

3.4 Responsibility of the operator

The instrument is used in the industrial sector. The operator is therefore responsible for legal

obligations regarding safety at work.

The safety instructions within these operating instructions, as well as the safety, accident

prevention and environmental protection regulations for the application area must be

maintained.

The operator is obliged to maintain the product label in a legible condition.

To ensure safe working on the instrument, the operating company must ensure

that suitable rst-aid equipment is available and aid is provided whenever required.

that the operating personnel are regularly instructed in all topics regarding work safety,

rst aid and environmental protection and know the operating instructions and in particular, the safety instructions contained therein.

that the instrument is suitable for the particular application in accordance with its intended

use.

that personal protective equipment is available.

EN

On the wetted parts of the instrument, small residual amounts of the adjustment

medium (e.g. compressed air, water, oil) can adhere from production. With

increased requirements for technical cleanliness, suitability for the application

must be checked by the operator before commissioning.

11297264.05 07/2019 EN/DE

7Pressure gauges with output signal, optionally for hazardous areas

Page 8

3. Safety

3.5 Personnel qualification

WARNING!

Riskofinjuryshouldqualicationbeinsucient!

Improper handling can result in considerable injury and damage to equipment.

The activities described in these operating instructions may only be carried out

EN

3.6 Skilled personnel

Skilled personnel are understood to be personnel who, based on their technical training,

knowledge of measurement and control technology and on their experience and knowledge

of country-specic regulations, current standards and directives, are capable of carrying out

the work described and independently recognising potential hazards.

3.7 Labelling, safety marks

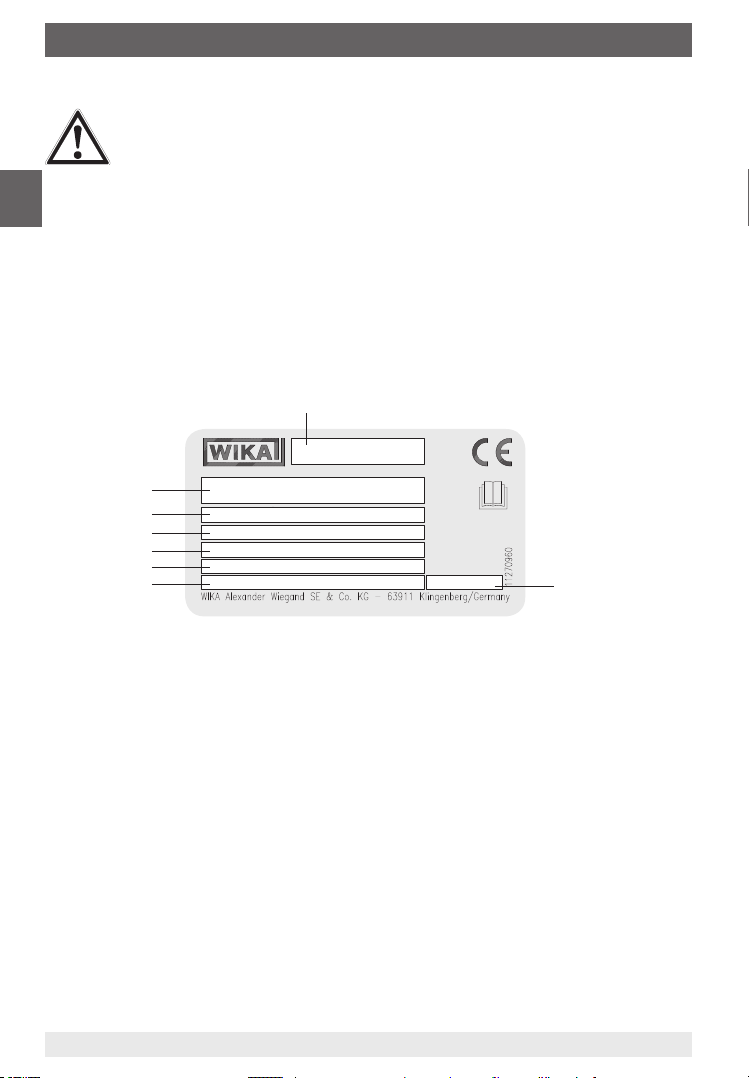

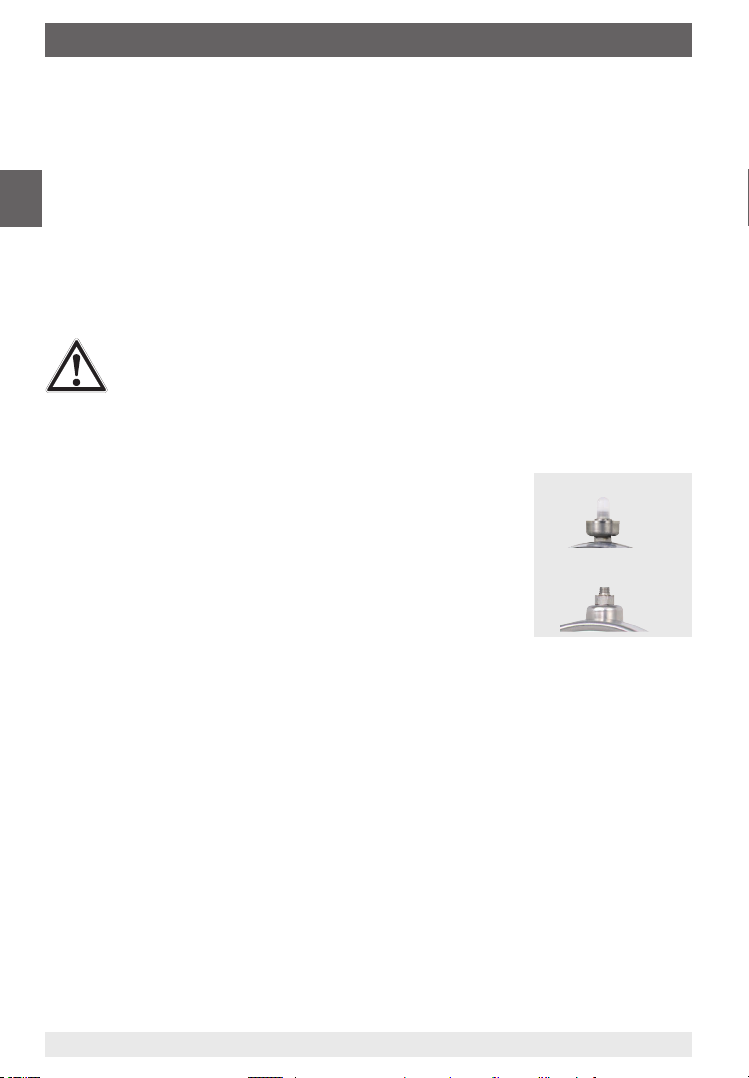

Product label Non-Ex version (example PGT23.063)

by skilled personnel who have the qualications described below.

Instrument type

Model + transmitter electronics

Scale range

Output signal

Supply voltage

Case lling

Article number

Date of manufacture (month/year)

Pressure gauges with output signal, optionally for hazardous areas8

11297264.05 07/2019 EN/DE

Page 9

3. Safety

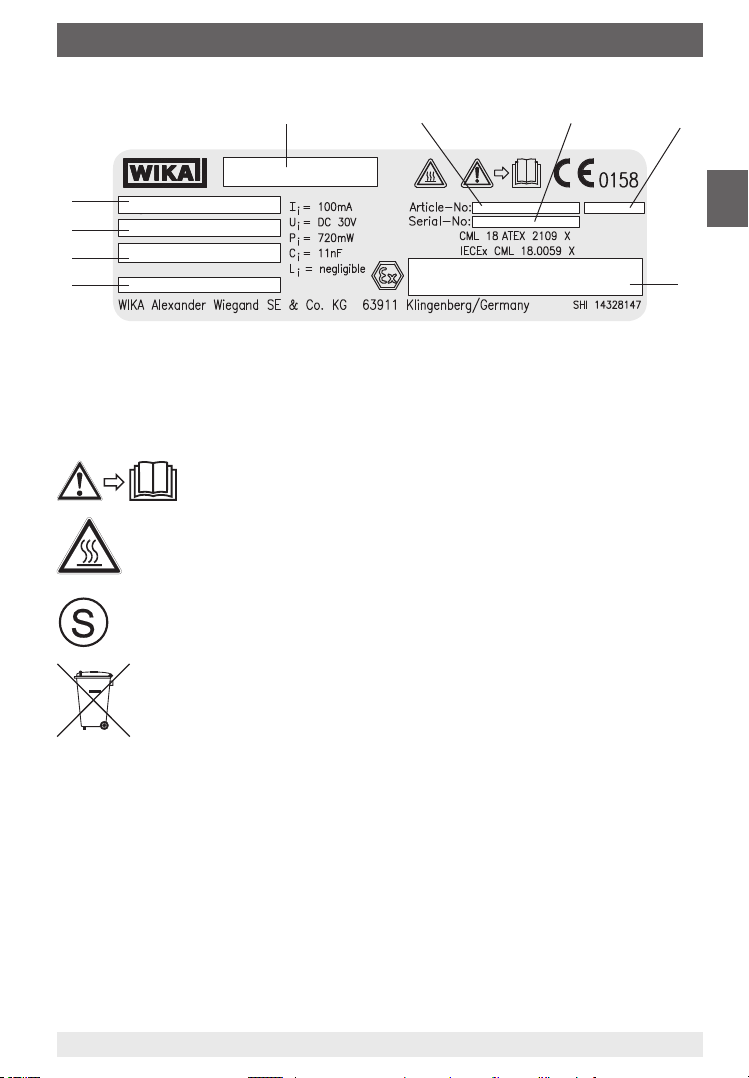

Product label Ex version (example)

Model + transmitter electronics

Article number

Serial number

Date of manufacture (month/year)

Ex marking

Risk of burns!

Potentially dangerous situation caused by hot surfaces.

The instrument bearing this mark is a safety pressure gauge with a solid bae

wall in accordance with EN 837, safety version “S3”.

Do not dispose of with household waste. Ensure a proper disposal in accordance with national regulations.

Case lling

Supply voltage

Output signal

Scale range

Before mounting and commissioning the instrument, ensure you read the

operating instructions!

EN

11297264.05 07/2019 EN/DE

9Pressure gauges with output signal, optionally for hazardous areas

Page 10

3. Safety

3.8 Ex marking (option)

DANGER!

Danger to life due to loss of explosion protection

Non-observance of these instructions and their contents may result in the loss of

explosion protection.

EN

Check whether the classication is suitable for the application. Observe the relevant national

regulations.

Instruments without PTFE lining

ATEX

II 2G Ex ia IIC T6/T5/T4 Gb

II 2D Ex ia IIIB T85°C /T100°C/T135°C Db

Instruments with PTFE lining

Option with models: PGT43, PGT43HP

ATEX

II 2G Ex ia IIB T6/T5/T4 Gb

▶

Observe the safety instructions in this chapter and further explosion protection instructions in these operating instructions.

▶

Observe the information given in the applicable type examination certicate and the relevant country-specic regulations for installation and use in

hazardous areas (e.g. IEC 60079-14, NEC, CEC).

IECEx

IECEx

3.9 Specifications and temperature limits

Ingress protection per IEC/EN 60529

For information on the ingress protection of the respective instrument, see chapter 9 “Speci-

cations”. For the IECEx assessment, IP20 ingress protection was assumed.

Permissible temperature range

For determining the maximum temperature at the instrument, besides the medium

temperature also other inuences such as the ambient temperature and, if applicable, the

solar irradiation must be taken into account.

Gas hazardous areas

Required temperature class

(ignition temperature)

T6 -20 ... +45 °C

T5 -20 ... +60 °C

T4 ... T1 -20 ... +60 °C, (+70 °C optional)

Permissible temperature range at the instrument

Pressure gauges with output signal, optionally for hazardous areas10

11297264.05 07/2019 EN/DE

Page 11

3. Safety

T-Ref

T-Ref

Dust hazardous areas

Maximum surface temperature Permissible temperature range at the instru-

ment

T85°C -20 ... +45 °C

T100°C -20 ... +60 °C

T135°C -20 ... +60 °C, (+70 °C optional)

The installation should be made in such a way that the temperature range of the instrument,

also considering the eects of convection and thermal radiation, neither exceeds nor falls

below the permissible limits.

The permissible temperature ranges must not be exceeded at the instrument either. If necessary, measures for cooling (e.g. syphon, instrumentation valve) have to be taken.

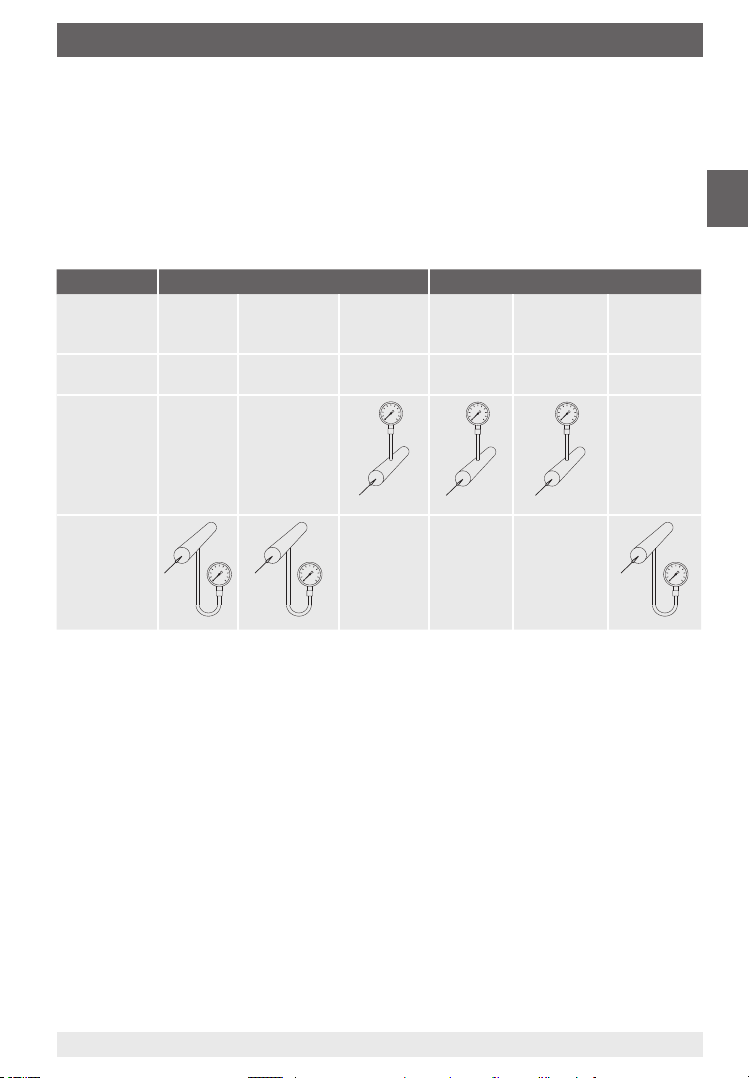

Pressure gauge Dierential pressure gauge

EN

Compliance with the permissible temperature range during operation must be ensured by

the operator by means of temperature measurement(s) at “T-Ref” within the shown hatched

area(s).

11297264.05 07/2019 EN/DE

11Pressure gauges with output signal, optionally for hazardous areas

Page 12

3. Safety

3.10 Special conditions for safe use (X conditions)

i. The temperature class and permitted maximum ambient temperature, are dependent

upon the options tted within the equipment and may not be marked on the equipment

label. The user shall refer to this certicate and to the equipment instructions for details of

the applicable temperature class and ambient temperature range.

ii. The user shall consider that heat may be transferred along the measurement probe and

EN

the equipment shall not exceed the maximum permitted ambient temperature. For further

information, refer to the user instructions.

iii. Models which incorporate a PTFE lining may be marked for use in Group IIB only. The

user shall ensure that such models marked as such are not used in Group IIC Gas nor

Group III dust hazardous areas.

iv. Models which incorporate a PTFE lining may be marked for use in Group IIC gas and

Group IIIB dust hazardous area. Such models also incorporate a warning label advising

the user of a potential electro-static hazard within the process connection area. The user

shall take all necessary precautions to mitigate the risk of electro-static discharge within

the process connection.

v. The equipment may incorporate an integral cable. The user shall ensure that, when

installed, the cable is xed in place and is protected from mechanical damage.

vi. For Group III applications, under certain extreme circumstances, the non-metallic coating

of the enclosure of this equipment may generate an ignition-capable level of electrostatic

charge. Therefore, the equipment shall not be installed in a location where the external

conditions are conducive to the build-up of electrostatic charge on such surfaces. The

user/installer shall implement precautions to prevent the build-up of electrostatic charge,

e.g. locate the equipment where a charge-generating mechanism (such as wind-blown

dust) is unlikely to be present and clean with a damp cloth.

Pressure gauges with output signal, optionally for hazardous areas12

11297264.05 07/2019 EN/DE

Page 13

4. Transport, packaging

4. Transport, packaging and storage

4.1 Transport

Check the instrument for any damage that may have been caused by transport.

Obvious damage must be reported immediately.

CAUTION!

Damage through improper transport

With improper transport, a high level of damage to property can occur.

▶

When unloading packed goods upon delivery as well as during internal transport, proceed carefully and observe the symbols on the packaging.

▶

With internal transport, observe the instructions in chapter 4.2 “Packaging

and storage”.

4.2 Packaging and storage

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change in

installation site, sending for repair).

Permissible conditions at the place of storage:

Storage temperature: -20 ... +70 °C

Avoid exposure to the following factors:

Direct sunlight or proximity to hot objects

Mechanical vibration, mechanical shock (putting it down hard)

Soot, vapour, dust and corrosive gases

Hazardous environments, ammable atmospheres

EN

Store the instrument in its original packaging in a location that fulls the conditions listed

above.

11297264.05 07/2019 EN/DE

13Pressure gauges with output signal, optionally for hazardous areas

Page 14

5. Commissioning, operation

5. Commissioning, operation

Personnel: Skilled personnel

Before installation, commissioning and operation, ensure that the appropriate instrument has

been selected in terms of scale range, design and specic measuring conditions.

EN

WARNING!

Physical injuries and damage to property and the environment caused by

hazardous media

Upon contact with hazardous media (e.g. with ammable or toxic substances),

harmful media (e.g. corrosive, toxic, carcinogenic, radioactive), there is a danger of

physical injuries and damage to property and the environment.

Should a failure occur, aggressive media with extremely high temperature and

under high pressure may be present at the instrument.

▶

For these media, in addition to all standard regulations, the appropriate existing codes or regulations must also be followed.

▶

Wear the requisite protective equipment.

WARNING!

Physical injuries and damage to property and the environment caused by

media escaping under high pressure

With the pressurisation of the instrument, as a result of poor sealing of the

process connection, media under high pressure can escape.

Due to the high energy of the media that can escape in the event of a failure, the

possibility of physical injuries and damage to property exists.

▶

The sealing of the process connection must be carried out expertly and

checked for leak tightness.

5.1 Mechanical connection

In accordance with the general technical regulations for pressure gauges (e.g. EN 837-2

“Selection and installation recommendations for pressure gauges”).

When screwing the instruments in, the force required for sealing must not be applied through

the case, but only through the spanner ats provided for this purpose, and using a suitable

tool.

Installation with open-ended

spanner

For parallel threads, use at gaskets, lens-type sealing rings or WIKA prole sealings at the

sealing face . With tapered threads (e.g. NPT threads), sealing is made in the threads ,

Pressure gauges with output signal, optionally for hazardous areas14

11297264.05 07/2019 EN/DE

Page 15

5. Commissioning, operation

using a suitable sealing material (EN 837-2).

The tightening torque depends on the sealing used. In order to orientate the measuring

instrument so that it can be read as well as possible, a connection with LH-RH union or

union nut should be used. When a blow-out device is tted to an instrument, it must be

protected against being blocked by debris and dirt.

Spanner ats

Sealing face

Installation

Nominal position per EN 837-3 / 9.6.6 gure 7: 90° ( ⊥ )

Process connection lower mount

With lled versions the vent valve at the top of the case must be opened before commis-

sioning!

For outdoor applications, the selected installation location has to be suitable for the

specied ingress protection, so that the instrument is not exposed to impermissible

weather conditions.

In order to avoid any additional heating, the instruments must not be exposed to direct

solar irradiation while in operation!

To ensure that the pressure can be safely vented in the case of failure, due to the

blow-out back, a minimum distance of 20 mm from any object must be maintained.

Sealing in the thread

EN

Requirements for the installation point

If the line to the measuring instrument is not adequately stable, an instrument mounting

bracket should be used for fastening. If vibrations cannot be avoided by means of suitable

installation, lled instruments should be used. The instruments should be protected against

coarse dirt and wide uctuations in ambient temperature.

Permissible vibration load at the installation site

The instruments should always be installed in locations free from vibration. If necessary,

it is possible to isolate the instrument from the mounting point, e.g. by installing a exible

connection line between the measuring point and the instrument and mounting the instrument on a suitable bracket.

If this is not possible, the following limit values must not be exceeded:

Frequency range < 150 Hz

Acceleration < 0.5 g (5 m/s

11297264.05 07/2019 EN/DE

2

)

15Pressure gauges with output signal, optionally for hazardous areas

Page 16

5. Commissioning, operation

Test connection

In specic applications (e.g. steam boilers) the shut-o devices must have a test connection,

so that the instrument can be tested without being dismounted.

Temperature load

The installation of the instrument should be made in such a way that the permissible operat-

EN

ing temperature, also considering the eects of convection and thermal radiation, neither

exceeds nor falls below the permissible limits. Thus the instrument and the shut-o device

must be protected by suciently long measuring lines or syphons.

The inuence of temperature on the indication and measurement accuracy must be

observed.

WARNING!

The actual maximum surface temperature depends not on the equipment itself,

but mainly on the operating conditions. With gaseous substances, the temperature may increase as a result of compression warming. In these cases it may be

necessary to throttle the rate of change of pressure or reduce the permissible

medium temperature.

Commissioning of pressure compensating valve

Instruments which are tted with a pressure compensating valve

must, following installation, be vented for internal pressure compensation.

Tool: Open-ended spanner SW 9

1. Remove plastic cap

2. Loosen the threaded connection above the valve body

3. Screw the valve body tight, turned through 180°, with ≤ 4.5 Nm

Before commissioning

After commissioning

For information on the ingress protection, see Technical information IN 00.18

Protection of the pressure elements from overload

If the medium is subject to rapid changes in pressure, or pressure surges are expected, then

these must not act directly on the pressure element. The action of the pressure surges must

be dampened, for example with the tting of a throttle section (reduction in cross-section in

the pressure port) or through the addition of an adjustable snubber.

Pressure tapping point

The pressure tapping point should be arranged with as large a bore as possible (≥ 6 mm)

via a shut-o device, so that the pressure tap is not distorted by a ow in the medium. The

measuring line between the pressure tapping points and the instrument should have a large

enough internal diameter to prevent blockage and lag in the pressure transmission.

Measuring line

The measuring lines must be as short as possible and should be arranged without sharp

radii in order to avoid any disruptive time lags. When routing these lines, a steady inclination

of approx. 1:15 is recommended.

Pressure gauges with output signal, optionally for hazardous areas16

11297264.05 07/2019 EN/DE

Page 17

5. Commissioning, operation

The measuring line should be designed and installed so that the loads occurring due to

expansion, vibration and thermal eects can be absorbed. With gaseous media, a drain

should be provided at the lowest point; with liquid media, a vent should be provided at the

highest point.

The measuring instruments must be mounted in the common mounting position per EN

837-1, with a max. permissible incline of 5° on all sides.

Measuring assemblies

Proven measuring assemblies for various types of media.

Liquid media Gaseous media

Filling of the

measuring

line

Examples conden-

Pressure

gauge above

the tapping

point

Pressure

gauge below

the tapping

point

liquid liquid with

vapour

boiling liquids “liquid

sate

completely

vapourised

gases”

gaseous partially

condensed

(damp)

dry air moist air

ue gases

completely

condensed

steam

EN

5.2 Electrical connection

The electrical connection must only be made by qualied skilled personnel. The instrument

must be connected to the equipotential bonding of the plant.

→ For performance data see chapter 9 „Specications“

Supply voltage non-Ex version

Suitable supply voltage

Model KFA6-STR-1.24.500, AC 115/230 V, for DIN rail, order number: 7305636

Supply voltage Ex version

The instrument must only be used in conjunction with a corresponding Ex repeater power

supply.

Suitable Ex repeater power supply

Model KFD2-STC4-Ex1, DC 20 ... 35 V, for DIN rail, order number: 2341268

11297264.05 07/2019 EN/DE

17Pressure gauges with output signal, optionally for hazardous areas

Page 18

5. Commissioning, operation

Safety instructions for installation

Install instruments in accordance with the manufacturer's instructions and the valid stand-

ards and regulations.

Only connect circuits with the same voltage and type of protection to the connecting

EN

cables of the instrument.

Size the connecting cables for the largest current strength in the circuits and ensure

sucient UV resistance and mechanical stability.

With exible connecting cables, use isolated end splices. Max. permissible conductor

cross-section 1.5 mm².

Connecting cables must be suited to the ambient temperature range of the application.

The connecting cables must also be suitable for the supplied cable gland (for diameter

range, see below).

Seal the cable entry with the appropriate approved cable glands.

Install the connection cables securely.

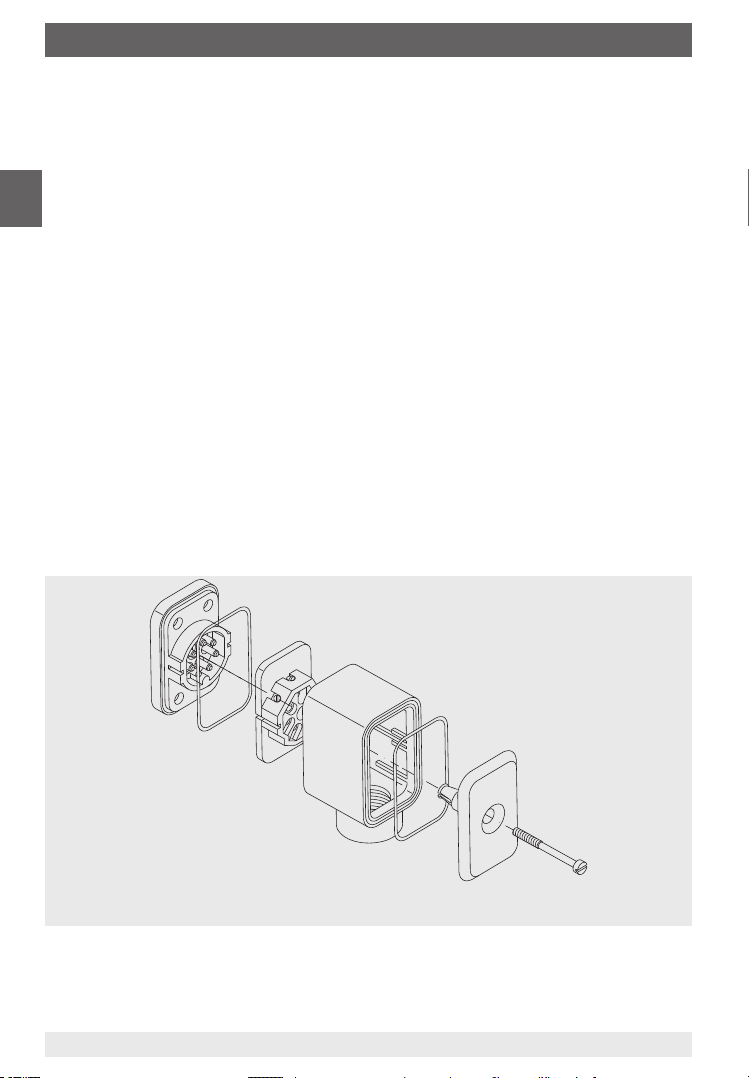

Dismounting cable socket

The cable socket is pretted and must be dismantled as described below.

Only use cable with a diameter of

7 ... 13 mm

Screw

Cable cover cap

Cable cover

Socket insert

Cable socket baseplate

Sealings

Pressure gauges with output signal, optionally for hazardous areas18

11297264.05 07/2019 EN/DE

Page 19

5. Commissioning, operation

Fully loosen the screws on the cable cover cap with a slotted screwdriver (0.6 x 3.5 mm)

and remove them.

Pull the cable cover, along with the socket insert, out from the cable socket baseplate

(joined permanently with the instrument).

Take the cable cover cap and push the socket insert out, downwards, completely through

the cable cap.

Pin assignment cable socket

EN

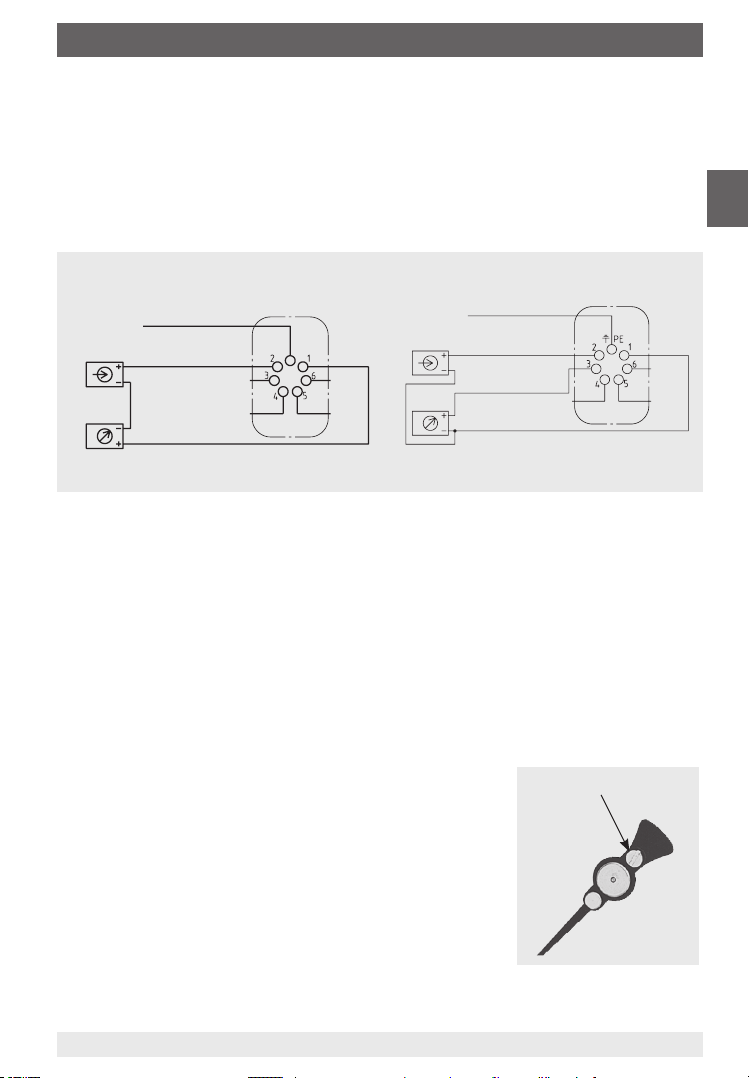

2-wire system

e.g. 4 ... 20 mA

Do not use this

terminal

Supply

voltage

Evaluation

(display)

Terminals 3 and 4: For internal use only

Terminals 5 and 6: Reset zero point

U

+/I+

B

+0V/GND

3-wire system:

e.g. 0 ... 20 mA / 0 ... 10 V

Ground, connect-

Supply

voltage

Evaluation

(display)

ed to case

U

+/I+

B

I

out/Uout

+0V/I-

Terminals 4, 5 and 6:

for internal use only

Pin assignment model PGT23.063

Cable Connector Assignment

red Pin 1 U

black Pin 4 0 V/I-

B

+/I+

brown Pin 2 n.c.

- - - Pin 3 n.c

5.3 Zero point setting (not for PGT23.063)

In most cases, the zero point should only be checked and adjusted after the system has

been depressurised. Instruments whose scale does not start at atmospheric pressure the

pressure gauge must be pressurised with the pressure value of the scale start. With dierential pressure gauges, the setting of the zero point should be made by opening the pressure

equalisation valve under static load.

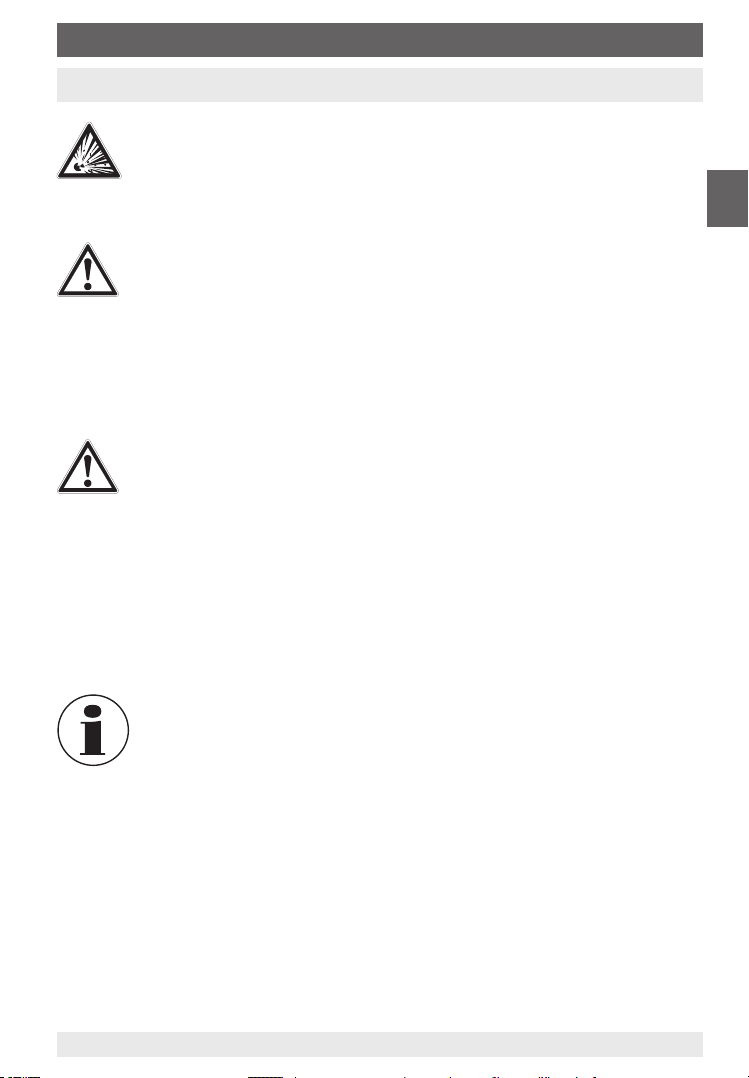

Slotted screw

Mechanical zero point

If there is a deviation from the zero point (in depressurised

condition), the zero point setting can be carried out via the builtin adjustable pointer. For this, remove the bayonet ring including

the window and the seal from the case.

By turning the slotted screw of the adjustable pointer, a mechanical zero point setting can be carried out.

11297264.05 07/2019 EN/DE

19Pressure gauges with output signal, optionally for hazardous areas

Page 20

5. Commissioning, operation

Electrical zero point

If the mechanical zero point has been altered via the adjustable pointer, the electrical zero

point must be matched to the mechanical one. To do this, apply the pressure value of the

scale start. The scale start corresponds to the smallest electrical signal (depending on the

variant either 0 mA, 4 mA or 0 V).

EN

With a small piece of stranded wire (maximum permissible resistance 30 Ω), stripped at both

ends, bridge terminals 5 and 6 on the socket insert.

Installation cable socket

Connect the socket insert to the cable cover and assemble the cable cover cap with the

sealing and screw (see cable socket drawing).

Insert the assembly, which has just been assembled, onto the cable socket baseplate

with sealing.

Screw the screws on the cable cover cap in fully with a slotted screwdriver (0.6 x 3.5 mm).

In order that the ingress protection is maintained, the seals must be retted.

Store zero point in transmitter electronics

After switching on the supply voltage, within a max. 30 seconds, the new zero point will

be saved in the transmitter electronics. As a check, during this time, a current increase to

9.5 mA can be measured in the current loop on a display unit (e.g. ammeter).

Removing the terminal bridge

Switch o supply voltage and display unit.

Carry out the “Dismounting cable socket” described above.

Remove the stranded wire for bridging terminals 5 and 6 from the socket insert.

Carry out the “Installation cable socket” described above.

The electrical output signal will once more match the display of the mechanical pointer.

Close all valves opened for the zero point setting again.

5.4 Commissioning

Pressure surges must be avoided at all costs, open the shut-o valves slowly.

Pressure gauges with output signal, optionally for hazardous areas20

11297264.05 07/2019 EN/DE

Page 21

6. Faults

6. Faults

DANGER!

Danger to life from explosion

Through working in ammable atmospheres, there is a risk of explosion which

can cause death.

▶

Only rectify faults in non-ammable atmospheres!

CAUTION!

Physical injuries and damage to property and the environment

If faults cannot be eliminated by means of the listed measures, the instrument

must be taken out of operation immediately.

▶

Ensure that pressure or signal is no longer present and protect against

accidental commissioning.

▶

Contact the manufacturer.

▶

If a return is needed, please follow the instructions given in chapter 8.2

“Return”.

WARNING!

Physical injuries and damage to property and the environment caused by

hazardous media

Upon contact with hazardous media (e.g. oxygen, acetylene, ammable or toxic

substances), harmful media (e.g. corrosive, toxic, carcinogenic, radioactive),

and also with refrigeration plants and compressors, there is a danger of physical

injuries and damage to property and the environment.

Should a failure occur, aggressive media with extremely high temperature and

under high pressure or vacuum may be present at the instrument.

▶

For these media, in addition to all standard regulations, the appropriate existing codes or regulations must also be followed.

▶

Wear the requisite protective equipment.

EN

For contact details see chapter 1 “General information” or the back page of the

operating instructions.

11297264.05 07/2019 EN/DE

21Pressure gauges with output signal, optionally for hazardous areas

Page 22

6. Faults / 7. Maintenance and cleaning

Faults Causes Measures

No output signal. Insucient supply voltage or cable

EN

Constant output signal

upon change in pressure.

Too high, constant output

signal upon change in

pressure.

Signal span too small. Insucient supply voltage. Check voltage supply and

Zero point signal too low or

too high.

break.

Wrong pin assignment. Check pin assignment.

Defective transmitter electronics due

to overvoltage.

Pressure port blocked at process

connection.

Supply voltage connected the wrong

way. (I = ca. 4.5 mA).

Defective transmitter electronics Replace instrument.

Bridge on terminals 5 and 6 not

removed (I = approx. 9.5 mA).

Defective transmitter electronics due

to overvoltage.

Load too high. Maintain permissible load.

Zero point maladjusted. See chapter 5.3. “Zero point

Zero point maladjusted. See chapter 5.3. “Zero point

For the exchange of the instrument chapters 8 “Dismounting, return and disposal” and 5

“Commissioning, operation” must be observed.

Check voltage supply and

cables.

Clean pressure port at process connection

Check pin assignment.

Remove the terminal bridge.

See chapter 5.3. “Zero point

setting”.

Replace instrument.

cables.

setting”.

setting”.

7. Maintenance and cleaning

7.1 Maintenance

The instruments are maintenance-free.

The indicator and switching function should be checked once or twice every year. For this

the instrument must be disconnected from the process to check with a pressure testing

device.

Testingoflledinstruments

For lled instruments, the level must be checked once or twice every year.

The liquid level must not drop below 75 % of the instrument diameter.

Pressure gauges with output signal, optionally for hazardous areas22

11297264.05 07/2019 EN/DE

Page 23

7. Maintenance and cleaning / 8. Dismounting

WARNING!

Dangertolifeduetoimpermissiblelling/rellingoftheinstrumentwith

loss of explosion protection

The lling/relling of instruments by non-authorised personnel leads to a loss of

the explosion protection and can lead to damage to the instrument.

▶

Repair of the instruments may only be carried out by authorised bodies.

▶

If a return is needed, please follow the instructions given in chapter 8.2

“Return”.

Repairs must only be carried out by the manufacturer.

7.2 Cleaning

CAUTION!

Physical injuries and damage to property and the environment

Improper cleaning may lead to physical injuries and damage to property and the

environment. Residual media in the dismounted instrument can result in a risk to

persons, the environment and equipment.

▶

Carry out the cleaning process as described below.

1. Before cleaning, correctly disconnect the instrument from the pressure supply, switch it

o and disconnect it from the mains.

2. Use the requisite protective equipment.

3. Clean the instrument with a moist cloth.

Electrical connections must not come into contact with moisture!

CAUTION!

Damage to the instrument

Improper cleaning may lead to damage to the instrument!

▶

Do not use any aggressive cleaning agents.

▶

Do not use any hard or pointed objects for cleaning.

EN

4. Wash or clean the dismounted instrument, in order to protect persons and the environment from exposure to residual media.

11297264.05 07/2019 EN/DE

23Pressure gauges with output signal, optionally for hazardous areas

Page 24

8. Dismounting, return and disposal

WARNING!

Physical injuries and damage to property and the environment through

residual media

EN

8.1 Dismounting

Residual media in the dismounted instrument can result in a risk to persons, the

environment and equipment.

▶

Wear the requisite protective equipment.

▶

Observe the information in the material safety data sheet for the

corresponding medium.

▶

Wash or clean the dismounted instrument, in order to protect persons and

the environment from exposure to residual media.

WARNING!

Risk of burns

During dismounting there is a risk of dangerously hot media escaping.

▶

Let the instrument cool down suciently before dismounting it!

DANGER!

Danger to life caused by electric current

Upon contact with live parts, there is a direct danger to life.

▶

The dismounting of the instrument may only be carried out by skilled personnel.

▶

Remove the instrument once the system has been isolated from power sources.

WARNING!

Physical injury

When dismounting, there is a danger from aggressive media and high

pressures.

▶

Observe the information in the material safety data sheet for the corresponding medium.

▶

Dismount the instrument when there is no pressure.

If necessary, the measuring line must have strain relief. For diaphragm pressure gauges, the

clamping bolts of the upper and lower ange must not be loosened.

8.2 Return

Strictly observe the following when shipping the instrument:

All instruments delivered to WIKA must be free from any kind of hazardous substances

(acids, bases, solutions, etc.) and must therefore be cleaned before being returned.

Pressure gauges with output signal, optionally for hazardous areas24

11297264.05 07/2019 EN/DE

Page 25

WARNING!

Physical injuries and damage to property and the environment through

residual media

Residual media in the dismounted instrument can result in a risk to

persons, the environment and equipment.

▶

With hazardous substances, include the material safety data sheet for the

corresponding medium.

▶

Clean the instrument, see chapter 7.2 “Cleaning”.

When returning the instrument, use the original packaging or a suitable transport packaging.

Information on returns can be found under the heading “Service” on our local

website.

8.3 Disposal

Incorrect disposal can put the environment at risk. Dispose of instrument components and

packaging materials in an environmentally compatible way and in accordance with the

country-specic waste disposal regulations.

Do not dispose of with household waste. Ensure a proper disposal in accordance with national regulations.

EN

11297264.05 07/2019 EN/DE

25Pressure gauges with output signal, optionally for hazardous areas

Page 26

9. Specifications

9. Specifications

DANGER!

Danger to life due to loss of explosion protection

The non-observance of the instructions for use in hazardous areas can lead to

EN

9.1 Electrical connection

Standard cable socket

Cable socket, tted on the right-hand side of the case.

Material: PA 6, black

Per VDE 0110 insulation group C/250 V

Cable gland M20 x 1.5 (facing downwards) with strain relief

6 screw terminals + PE for conductor cross-section 1.5 mm²

Cable outlet

Cable length 2 m or 5 m, facing downwards and to the right

Material: PVC

the loss of the explosion protection.

▶

Adhere to the following limit values and instructions.

▶

The case contains parts made of non-metallic material, which could be

adversely aected by environmental conditions. It must be ensured that the

non-metallic parts are not damaged as a result of the environmental conditions.

Non-metallic parts of the case

PUR, TPU, PA 6, EPDM, NBR (option), FMQ (option)

Miniature connector

Miniature connector M8 x 1, 4-pin

Pressure gauges with output signal, optionally for hazardous areas26

11297264.05 07/2019 EN/DE

Page 27

9. Specifications

9.2 Transmitter electronics for non-hazardous areas

Model 891.44

Output signal Variant 1: 4 … 20 mA, 2-wire, passive, per NAMUR NE 43

Supply voltage U

Inuenceofsupplyvoltage ≤ 0.1 % of full scale/10 V

Permissible residual ripple of U

Permissible max. load R

Eectofload(variant1+3) ≤ 0.1 % of full scale

Impedance at voltage output 0.5 Ω

Long-term stability of electronics < 0.3 % of full scale per year

Electr. output signal ≤ 1 % of measuring span

Linear error ≤ 1 % of measuring span (terminal method)

Resolution 0.13 % of full scale (10 bit resolution at 360°)

Refresh rate (measuring rate) 600 ms

B

A

9.3 Transmitter electronics for hazardous areas

Model 892.44

Output signal Variant 2: 4 ... 20 mA, 2-wire, for hazardous areas

Supply voltage U

Inuenceofsupplyvoltage ≤ 0.1 % of full scale/10 V

Permissible residual ripple of U

Permissible max. load R

Eectofload ≤ 0.1 % of full scale

Impedance at voltage output 0.5 Ω

Long-term stability of electronics < 0.3 % of full scale per year

Electr. output signal ≤ 1 % of measuring span

Linear error ≤ 1 % of measuring span (terminal method)

Resolution 0.13 % of full scale (10 bit resolution at 360°)

Refresh rate (measuring rate) 600 ms

B

A

Variant 3: 0 ... 20 mA, 3-wire

Variant 4: 0 ... 10 V, 3-wire

Variant 1+3: DC 12 ... 30 V

Variant 4: DC 15 ... 30 V

≤ 10 % ss

B

Variant 1, 3: RA ≤ (UB - 12 V)/0.02 A with RA in Ohm and UB in

Volt, however max. 600 Ω

Variant 4: R

DC 14 ... 30 V

≤ 10 % ss

B

RA ≤ (UB - 12 V)/0.02 A with RA in Ω and UB in V, however max.

600 Ω

= 100 kΩ

A

EN

Safety-related maximum values

Ui Ii Pi Ci Li

DC 30 V 100 mA 720 mW 11 nF negligible

For further information see Annex “EU declaration of conformity”

11297264.05 07/2019 EN/DE

27Pressure gauges with output signal, optionally for hazardous areas

Page 28

9. Specifications

9.4 Pressure gauges with output signal

Model PGT23.063

Pressure limitation

Steady 3/4 x full scale value

Fluctuating 2/3 x full scale value

EN

Short time Full scale value

Temperatureeect When the temperature of the measuring system deviates from

Wetted materials

Process connection, pressure

element

Non-wetted materials

Case, bayonet ring Stainless steel

Movement Brass

Dial Aluminium, white, black lettering

Pointer Aluminium, black

Window Polycarbonate or laminated safety glass

Ingress protection per IEC/EN 60529 IP54; option: IP65

For further specications see data sheet PV 12.03

the reference temperature (+20 °C): max. ±0.8 %/10 K of full

scale value

Stainless steel 316L

Models PGT23.100, PGT23.160, PGT26.100, PGT26.160

Pressure limitation

Steady Full scale value

Fluctuating 0.9 x full scale value

Short time 1.3 x full scale value

Temperatureeect When the temperature of the measuring system deviates from

Wetted materials

Process connection, pressure

element

Non-wetted materials

Case, bayonet ring Stainless steel

Movement Brass

Dial Aluminium, white, black lettering

Instrument pointer Aluminium, black

Pointer Aluminium, red

Window Laminated safety glass

Ingress protection per IEC/EN 60529 IP65

1) Ingress protection IP54 with lower back mount.

For further specications see data sheet PV 12.04

the reference temperature (+20 °C): max. ±0.4 %/10 K of full

scale value

PGT23.100, PGT23.160: Stainless steel 316L

PGT26.100, PGT26.160: Monel

1)

; option: IP66

Pressure gauges with output signal, optionally for hazardous areas28

11297264.05 07/2019 EN/DE

Page 29

9. Specifications

Models PGT43.100, PGT43.160

Pressure limitation

Steady Full scale value

Fluctuating 0.9 x full scale value

Overload safety 5 x full scale value, however max. 40 bar

Temperatureeect When the temperature of the measuring system deviates from

Wetted materials

Process connection with lower

measuring ange

Pressure element ≤ 0.25 bar: Stainless steel 316L

Sealing FPM/FKM

Non-wetted materials

Case, bayonet ring Stainless steel

Movement Brass

Dial Aluminium, white, black lettering

Pointer Aluminium, black

Window Laminated safety glass

Ingress protection per IEC/EN 60529 IP54; option: IP65

For further specications see data sheet PV 14.03

Model PGT43HP

Pressure limitation

Steady Full scale value

Fluctuating 0.9 x full scale value

Overload safety 40, 100 or 400 bar

Temperatureeect When the temperature of the measuring system deviates from

Wetted materials

Process connection with lower

measuring ange

Pressure element ≤ 0.25 bar: Stainless steel 316L

Sealing FPM/FKM

Non-wetted materials

Case, bayonet ring Stainless steel

Movement Brass

Dial Aluminium, white, black lettering

Pointer Aluminium, black

Window Laminated safety glass

Ingress protection per IEC/EN 60529 IP54; option: IP65

For further specications see data sheet PV 14.07

11297264.05 07/2019 EN/DE

the reference temperature (+20 °C): max. ±0.8 %/10 K of full

scale value

Stainless steel 316L

> 0.25 bar: NiCr alloy (Inconel)

the reference temperature (+20 °C): max. ±0.8 %/10 K of full

scale value

Stainless steel 316L

> 0.25 bar: NiCr alloy (Inconel)

EN

29Pressure gauges with output signal, optionally for hazardous areas

Page 30

9. Specifications

Model PGT63HP

Pressure limitation

Steady Full scale value

Fluctuating 0.9 x full scale value

Overload safety 50 x full scale value

Temperatureeect When the temperature of the measuring system deviates from

EN

Wetted materials

Process connection, pressure

element

Sealing PTFE

Non-wetted materials

Case, bayonet ring Stainless steel

Movement Brass

Dial Aluminium, white, black lettering

Pointer Aluminium, black

Window Laminated safety glass

Ingress protection per IEC/EN 60529 IP54

For further specications see data sheet PV 16.06

Model APGT43

Pressure limitation

Steady Full scale value

Fluctuating 0.9 x full scale value

Overload safety at least 1 bar absolute pressure (atmospheric pressure), in

Temperatureeect When the temperature of the measuring system deviates from

Wetted materials

Process connection Stainless steel 316L

Pressure element ≤ 0.25 bar: Stainless steel 316Ti (1.4571)

Non-wetted materials

Case, bayonet ring Stainless steel

Movement Brass

Dial Aluminium, white, black lettering

Pointer Aluminium, black

Window Laminated safety glass

Ingress protection per IEC/EN 60529 IP54; option: IP65

For further specications see data sheet PV 15.02

the reference temperature (+20 °C): max. ±0.6 %/10 K of full

scale value

Stainless steel 316Ti (1.4571)

addition 10 x full scale value, max. 25 bar absolute pressure

the reference temperature (+20 °C): max. ±0.8 %/10 K of full

scale value

> 0.25 bar: NiCr alloy (Inconel)

Pressure gauges with output signal, optionally for hazardous areas30

11297264.05 07/2019 EN/DE

Page 31

9. Specifications

Models DPGT43.100, DPGT43.160

Pressure limitation

Steady Full scale value

Fluctuating 0.9 x full scale value

Overload safety and

max. working pressure

Temperatureeect When the temperature of the measuring system deviates from

Wetted materials

Media chamber with process

connection, venting of the media

chambers, bellows

Pressure element ≤ 0.25 bar: Stainless steel 316L

Non-wetted materials

Case, bayonet ring Stainless steel

Movement Brass

Dial Aluminium, white, black lettering

Pointer Aluminium, black

Window Laminated safety glass

Ingress protection per IEC/EN 60529 IP54; option: IP65

Overload safety and max. working pressure

Scale ranges Overload safety in bar

Either side max.

Standard Option Standard Option

0 ... 16 to 0 ... 40 mbar 2.5 - 2.5 6

0 ... 60 to 0 ... 250 mbar 2.5 6 6 10

0 ... 400 mbar 4 40 25 40

0 ... 0.6 bar 6 40 25 40

0 ... 1 bar 10 40 25 40

0 ... 1.6 bar 16 40 25 40

0 ... 2.5 to 0 ... 25 bar 25 40 25 40

see the following table

the reference temperature (+20 °C): max. ±0.5 %/10 K of full

scale value

Stainless steel 316Ti (1.4571)

> 0.25 bar: NiCr alloy (Inconel)

max. working pressure in bar

(static pressure)

EN

For further specications see data sheet PV 17.05

11297264.05 07/2019 EN/DE

31Pressure gauges with output signal, optionally for hazardous areas

Page 32

9. Specifications

Models DPGT43HP.100, DPGT43HP.160

Pressure limitation

Steady Full scale value

Fluctuating 0.9 x full scale value

Overload safety and

max. working pressure

EN

Temperatureeect When the temperature of the measuring system deviates from

Wetted materials

Media chamber with process

connection, venting of the media

chambers, bellows

Pressure element ≤ 0.25 bar: Stainless steel 316L

Non-wetted materials

System ll uid measuring cell Silicone oil

Case, movement, bayonet ring Stainless steel

Dial Aluminium, white, black lettering

Pointer Aluminium, black

Window Laminated safety glass

Ingress protection per IEC/EN 60529 IP54; option: IP65

For further specications see data sheet PV 17.13

Either side max. 40, 100, 250 or 400 bar

the reference temperature (+20 °C): max. ±0.5 %/10 K of full

scale value

Stainless steel 316Ti (1.4571)

> 0.25 bar: Stainless steel 316L/Inconel

Pressure gauges with output signal, optionally for hazardous areas32

11297264.05 07/2019 EN/DE

Page 33

Inhalt

Inhalt

1. Allgemeines 35

2. Aufbau und Funktion 36

2.1 Überblick . . . . . . . . . . . . . . . . . . . . . . .36

2.2 Beschreibung . . . . . . . . . . . . . . . . . . . . . .36

2.3 Lieferumfang . . . . . . . . . . . . . . . . . . . . . .36

3. Sicherheit 37

3.1 Symbolerklärung. . . . . . . . . . . . . . . . . . . . .37

3.2 Bestimmungsgemäße Verwendung . . . . . . . . . . . . . .37

3.3 Fehlgebrauch . . . . . . . . . . . . . . . . . . . . . .38

3.4 Verantwortung des Betreibers . . . . . . . . . . . . . . . .38

3.5 Personalqualifikation . . . . . . . . . . . . . . . . . . .39

3.6 Fachpersonal . . . . . . . . . . . . . . . . . . . . . .39

3.7 Beschilderung, Sicherheitskennzeichnungen . . . . . . . . . . .39

3.8 Ex-Kennzeichnung (Option) . . . . . . . . . . . . . . . . .41

3.9 Spezifikation und Temperaturgrenzen. . . . . . . . . . . . . .41

3.10 Besondere Bedingungen für die sichere Verwendung (X-Conditions) . . .43

4. Transport, Verpackung und Lagerung 44

4.1 Transport . . . . . . . . . . . . . . . . . . . . . . .44

4.2 Verpackung und Lagerung . . . . . . . . . . . . . . . . .44

5. Inbetriebnahme, Betrieb 45

5.1 Mechanischer Anschluss . . . . . . . . . . . . . . . . . .45

5.2 Elektrischer Anschluss. . . . . . . . . . . . . . . . . . .48

5.3 Nullpunkteinstellung (nicht für PGT23.063) . . . . . . . . . . . .50

5.4 Inbetriebnahme . . . . . . . . . . . . . . . . . . . . .51

6. Störungen 52

7. Wartung und Reinigung 53

7.1 Wartung. . . . . . . . . . . . . . . . . . . . . . . .53

7.2 Reinigung . . . . . . . . . . . . . . . . . . . . . . .54

8. Demontage, Rücksendung und Entsorgung 55

8.1 Demontage . . . . . . . . . . . . . . . . . . . . . .55

8.2 Rücksendung . . . . . . . . . . . . . . . . . . . . . .55

8.3 Entsorgung . . . . . . . . . . . . . . . . . . . . . .56

9. Technische Daten 57

9.1 Elektrischer Anschluss. . . . . . . . . . . . . . . . . . .57

9.2 Transmitterelektronik für Nicht-Ex-Bereiche. . . . . . . . . . . .58

9.3 Transmitterelektronik für Ex-Bereiche . . . . . . . . . . . . . .58

9.4 Manometer mit Ausgangssignal . . . . . . . . . . . . . . .59

Anlage: EU-Konformitätserklärung 63

DE

Konformitätserklärungen nden Sie online unter www.wika.de.

11297264.05 07/2019 EN/DE

33Manometer mit Ausgangssignal, optional für explosionsgefährdete Bereiche

Page 34

1. Allgemeines

1. Allgemeines

Das in der Betriebsanleitung beschriebene Kontaktmanometer wird nach den neuesten

Erkenntnissen konstruiert und gefertigt. Alle Komponenten unterliegen während der Fertigung strengen Qualitäts- und Umweltkriterien. Unsere Managementsysteme sind nach

DE

ISO 9001 und ISO 14001 zertiziert.

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem Gerät. Vorausset-

zung für sicheres Arbeiten ist die Einhaltung aller angegebenen Sicherheitshinweise und

Handlungsanweisungen.

Die für den Einsatzbereich des Gerätes geltenden örtlichen Unfallverhütungsvorschriften

und allgemeinen Sicherheitsbestimmungen einhalten.

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des

Gerätes für das Fachpersonal jederzeit zugänglich aufbewahrt werden.

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig durch-

gelesen und verstanden haben.

Die Haftung des Herstellers erlischt bei Schäden durch bestimmungswidrige Verwen-

dung, Nichtbeachten dieser Betriebsanleitung, Einsatz ungenügend qualizierten

Fachpersonals sowie eigenmächtiger Veränderung am Gerät.

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

Technische Änderungen vorbehalten.

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

Typ Transmitterelektronik für

Nicht-Ex-Bereiche

Typ Variante

PGT23.063 891.44 1, 3, 4 - - PV 12.03

PGT23.1x0, PGT26.1x0 891.44 1, 3, 4 892.44 2 PV 12.04

PGT43 891.44 1, 3, 4 892.44 2 PV 14.03

PGT43HP 891.44 1, 3, 4 892.44 2 PV 14.07

PGT63HP 891.44 1, 3, 4 892.44 2 PV 16.06

APGT43 891.44 1, 3, 4 892.44 2 PV 15.02

DPGT43 891.44 1, 3, 4 892.44 2 PV 17.05

DPGT43HP 891.44 1, 3, 4 892.44 2 PV 17.13

1) Variante des Ausgangssignals

1: 4 … 20 mA, 2-Leiter, passiv, nach NAMUR NE 43

2: 4 ... 20 mA, 2-Leiter, für explosionsgefährdete Bereiche

3: 0 ... 20 mA, 3-Leiter

4: 0 ... 10 V, 3-Leiter

Transmitterelektronik

für Ex-Bereiche

1)

Typ Variante

Für Geräte die zusätzlich mit Schaltkontakte(n) ausgestattet sind, gelten außerdem

folgende Betriebsanleitungen:

- „Manometer mit Induktivkontakt Typ 831, für explosionsgefährdete Bereiche“,

Artikelnummer 14320154

- „Manometer mit Schaltkontakt Typ 821, 851 oder 830 E“, Artikelnummer 14057651

Datenblatt

1)

Manometer mit Ausgangssignal, optional für explosionsgefährdete Bereiche34

11297264.05 07/2019 EN/DE

Page 35

2. Aufbau und Funktion

2. Aufbau und Funktion

2.1 Überblick

Beispiel Typ PGT23.100, Ausführung „S3“ nach EN 837

Messglied

Zeigerwerk

Transmitterelektronik

Druckausgleichsventil

Elektrischer Anschluss mit Kabelbox

Mehrschichten-Sicherheitsglas

Prozessanschluss

DE

2.2 Beschreibung

Für die beschriebenen Geräte werden wegen ihrer Robustheit und einfachen Handhabung

weit verbreitete Rohr-, Platten-, Kapselfeder- und Wellrohrfedermessglieder verwendet. Die

Messglieder verformen sich unter Druckeinuss im elastischen Bereich. Ein mechanisches

Zeigerwerk übeträgt diese Verformung in eine Drehbewegung. Ein auf der Zeigerwelle

aufgesetzter Magnet dreht sich proportional mit dem Instrumentenzeiger in direkter linearer

Abhängigkeit zum Prozessdruck. Der auf der Transmitterelektronik enthaltene Winkelsensor

erfasst die Drehbewegung des Magneten im Bereich von 0 ... 270°. Die Winkeländerung wird

berührungslos und daher verschleißfrei registriert und über einen Verstärker in ein analoges

Ausgangssignal umgesetzt. Die Spanne des Ausgangssignals entspricht der Messspanne

auf dem Zierblatt.

Sicherheitsausführung „S3“ nach EN 837

Diese Ausführung besteht aus Mehrschichten-Sicherheitsglas, einer bruchsicheren

Trennwand zwischen Messsystem und Zierblatt sowie einer ausblasbaren Rückwand. Im

Fehlerfall ist der Bediener an der Frontseite geschützt, da Messstoe und Bauteile nur über

die Rückseite des Gehäuses austreten können.

Ex-Ausführung

Alle Geräte außer Typ PGT23.063 sind optional auch in einer Ausführung für explosionsgefährdete Bereiche lieferbar.

2.3 Lieferumfang

Lieferumfang mit dem Lieferschein abgleichen.

11297264.05 07/2019 EN/DE

35Manometer mit Ausgangssignal, optional für explosionsgefährdete Bereiche

Page 36

2. Aufbau und Funktion / 3. Sicherheit

3. Sicherheit

3.1 Symbolerklärung

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin, die zum Tod oder zu

DE

schweren Verletzungen führen kann, wenn sie nicht gemieden wird.

VORSICHT!

... weist auf eine möglicherweise gefährliche Situation hin, die zu geringfügigen

oder leichten Verletzungen bzw. Sach- und Umweltschäden führen kann, wenn

sie nicht gemieden wird.

GEFAHR!

... kennzeichnet Gefährdungen durch elektrischen Strom. Bei Nichtbeachtung

der Sicherheitshinweise besteht die Gefahr schwerer oder tödlicher

Verletzungen.

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation im explosionsgefährdeten Bereich hin, die zum Tod oder zu schweren Verletzungen führt, wenn sie

nicht gemieden wird.

WARNUNG!

... weist auf eine möglicherweise gefährliche Situation hin, die durch heiße

Oberächen oder Flüssigkeiten zu Verbrennungen führen kann, wenn sie nicht

gemieden wird.

Information

… hebt nützliche Tipps und Empfehlungen sowie Informationen für einen ezienten und störungsfreien Betrieb hervor.

3.2 Bestimmungsgemäße Verwendung

Manometer mit Ausgangssignal vereinen mechanisches Messsystem mit elektronischer

Signalverarbeitung und dienen zum Steuern und Regeln von Prozesswerten sowie zur

Anlagenüberwachung in industriellen Anwendungen. Das Gerät bietet viele Anwendungs-

möglichkeiten für gasförmige und üssige, aggressive, nicht hochviskose und nicht kristallisierende Messstoe.

Das Gerät nur in Anwendungen verwenden, die innerhalb seiner technischen Leistungsgrenzen liegen (z. B. Temperaturgrenzen, Materialverträglichkeit, ...).

→ Leistungsgrenzen siehe Kapitel 9 „Technische Daten“.

Das Gerät ist ausschließlich für den hier beschriebenen bestimmungsgemäßen Verwendungszweck konzipiert und konstruiert und darf nur dementsprechend verwendet werden.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung sind ausgeschlossen.

Manometer mit Ausgangssignal, optional für explosionsgefährdete Bereiche36

11297264.05 07/2019 EN/DE

Page 37

3. Sicherheit

3.3 Fehlgebrauch

WARNUNG!

Verletzungen durch Fehlgebrauch

Fehlgebrauch des Gerätes kann zu gefährlichen Situationen und Verletzungen

führen.

▶

Eigenmächtige Umbauten am Gerät unterlassen.

▶

Gerät nicht für abrasive und viskose Messstoe verwenden.

Ausnahmen hierbei sind Plattenfedermanometer (Typen PGT43, PGT43HP)

mit speziell beschichteten Membranen (abrasiv) oder Ausführungen mit

oenem Anschlussansch (viskos).

Jede über die bestimmungsgemäße Verwendung hinausgehende oder andersartige Benutzung gilt als Fehlgebrauch.

3.4 Verantwortung des Betreibers

Das Gerät wird im gewerblichen Bereich eingesetzt. Der Betreiber unterliegt daher den

gesetzlichen Pichten zur Arbeitssicherheit.

Die Sicherheitshinweise dieser Betriebsanleitung, sowie die für den Einsatzbereich des

Gerätes gültigen Sicherheits-, Unfallverhütungs- und Umweltschutzvorschriften einhalten.

Der Betreiber ist verpichtet das Typenschild lesbar zu halten.

Für ein sicheres Arbeiten am Gerät muss der Betreiber sicherstellen,

dass eine entsprechende Erste-Hilfe-Ausrüstung vorhanden ist und bei Bedarf jederzeit

Hilfe zur Stelle ist.

dass das Bedienpersonal regelmäßig in allen zutreenden Fragen von Arbeitssicherheit,

Erste Hilfe und Umweltschutz unterwiesen wird, sowie die Betriebsanleitung und insbesondere die darin enthaltenen Sicherheitshinweise kennt.

dass das Gerät gemäß der bestimmungsgemäßen Verwendung für den Anwendungsfall

geeignet ist.

dass die persönliche Schutzausrüstung verfügbar ist.

DE

An den messstoberührten Teilen des Gerätes können herstellungsbedingt

geringe Restmengen des Justagemediums (z. B. Druckluft, Wasser, Öl)

anhaften. Bei erhöhten Anforderungen an die technische Sauberkeit muss die

Eignung für den Anwendungsfall vor Inbetriebnahme vom Betreiber geprüft sein.

11297264.05 07/2019 EN/DE

37Manometer mit Ausgangssignal, optional für explosionsgefährdete Bereiche

Page 38

3. Sicherheit

3.5 Personalqualifikation

WARNUNG!

VerletzungsgefahrbeiunzureichenderQualikation!

Unsachgemäßer Umgang kann zu erheblichen Personen- und Sachschäden

führen.

DE

3.6 Fachpersonal

Das Fachpersonal ist aufgrund seiner fachlichen Ausbildung, seiner Kenntnisse der Mess-

und Regelungstechnik und seiner Erfahrungen sowie Kenntnis der landesspezischen

Vorschriften, geltenden Normen und Richtlinien in der Lage, die beschriebenen Arbeiten

auszuführen und mögliche Gefahren selbstständig zu erkennen.

3.7 Beschilderung, Sicherheitskennzeichnungen

Typenschild Nicht-Ex-Ausführung (Beispiel PGT23.063)

Die in dieser Betriebsanleitung beschriebenen Tätigkeiten nur durch Fachperso-

nal nachfolgend beschriebener Qualikation durchführen lassen.

Geräteart

Typ + Transmitterelektronik

Anzeigebereich

Ausgangssignal

Hilfsenergie

Gehäusefüllung

Artikelnummer

Herstellungsdatum (Monat/Jahr)

Manometer mit Ausgangssignal, optional für explosionsgefährdete Bereiche38

11297264.05 07/2019 EN/DE

Page 39

3. Sicherheit

Typenschild Ex-Ausführung (Beispiel)

Typ + Transmitterelektronik

Artikelnummer

Seriennummer

Herstellungsdatum (Monat/Jahr)

Ex-Kennzeichnung

Verbrennungsgefahr!

Möglicherweise gefährliche Situation durch heiße Oberächen.

Das Gerät mit dieser Kennzeichnung ist ein Sicherheitsdruckmessgerät mit

bruchsicherer Trennwand nach EN 837, Sicherheitsausführung „S3“.

Nicht mit dem Hausmüll entsorgen. Für eine geordnete Entsorgung gemäß

nationaler Vorgaben sorgen.

Gehäusefüllung

Hilfsenergie

Ausgangssignal

Anzeigebereich

Vor Montage und Inbetriebnahme des Gerätes unbedingt die Betriebsanleitung lesen!

DE

11297264.05 07/2019 EN/DE

39Manometer mit Ausgangssignal, optional für explosionsgefährdete Bereiche

Page 40

3. Sicherheit

3.8 Ex-Kennzeichnung (Option)

GEFAHR!

Lebensgefahr durch Verlust des Explosionsschutzes

Die Nichtbeachtung dieser Inhalte und Anweisungen kann zum Verlust des

Explosionsschutzes führen.

DE

Überprüfen, ob die Klassizierung für den Einsatzfall geeignet ist. Die jeweiligen nationalen

Vorschriften und Bestimmungen beachten.

Geräte ohne PTFE-Auskleidung

ATEX

II 2G Ex ia IIC T6/T5/T4 Gb

II 2D Ex ia IIIB T85°C /T100°C/T135°C Db

Geräte mit PTFE-Auskleidung

Option bei Typen: PGT43, PGT43HP

ATEX

II 2G Ex ia IIB T6/T5/T4 Gb

▶

Sicherheitshinweise in diesem Kapitel sowie weitere Explosionsschutzhinweise in dieser Betriebsanleitung beachten.

▶

Die Angaben der geltenden Baumusterprüfbescheinigung sowie die jeweiligen landesspezischen Vorschriften zur Installation und Einsatz in explosionsgefährdeten Bereichen (z. B. IEC 60079-14, NEC, CEC) einhalten.

IECEx

IECEx

3.9 Spezifikation und Temperaturgrenzen

Schutzart nach IEC/EN 60529

Informationen zur Schutzart des jeweiligen Gerätes siehe Kapitel 9 „Technische Daten“. Für

die IECEx-Bewertung wurde die Schutzart IP20 angenommen.

Zulässiger Temperaturbereich

Für die Ermittlung der maximalen Temperatur am Gerät sind außer der Messstotemperatur

noch andere Einüsse wie z. B. die Umgebungstemperatur und gegebenenfalls die

Sonneneinstrahlung zu berücksichtigen.

Gasexplosionsgefährdeter Bereich

Geforderte Temperaturklasse

(Zündtemperatur)

T6 -20 ... +45 °C

T5 -20 ... +60 °C

T4 ... T1 -20 ... +60 °C, (+70 °C optional)

Zulässiger Temperaturbereich am Gerät

Manometer mit Ausgangssignal, optional für explosionsgefährdete Bereiche40

11297264.05 07/2019 EN/DE

Page 41

3. Sicherheit

T-Ref

T-Ref

Staubexplosionsgefährdeter Bereich

MaximaleOberächentemperatur Zulässiger Temperaturbereich am Gerät

T85°C -20 ... +45 °C

T100°C -20 ... +60 °C

T135°C -20 ... +60 °C, (+70 °C optional)

Die Montage ist so auszuführen, dass der zulässige Temperaturbereich des Gerätes, auch

unter Berücksichtigung des Einusses von Konvektion und Wärmestrahlung, weder unter-

noch überschritten wird.

Die zulässigen Temperaturbereiche dürfen auch am Gerät nicht überschritten werden.

Gegebenenfalls sind Maßnahmen zur Kühlung (wie z. B. Wassersackrohr, Instrumentierungsventil) zu ergreifen.

Manometer Dierenzdruckmanometer

DE

Die Einhaltung des zulässigen Temperaturbereiches ist vom Betreiber während des Betrie-

bes mit Hilfe von Temperaturmessung(en) bei „T-Ref“ innerhalb der schraerten Fläche(n)

sicherzustellen.

11297264.05 07/2019 EN/DE

41Manometer mit Ausgangssignal, optional für explosionsgefährdete Bereiche

Page 42

3. Sicherheit

3.10 Besondere Bedingungen für die sichere Verwendung (X-Conditions)

i. Die Temperaturklasse und die zulässige maximale Umgebungstemperatur richten

sich nach den im Gerät installierten Optionen und dürfen auf dem Geräte-Schild

nicht angegeben sein. Einzelheiten zur anwendbaren Temperaturklasse und zum

Umgebungstemperaturbereich sind aus dem vorliegenden Zertikat und der Betriebsan-

DE

leitung ersichtlich.

ii. Der Benutzer muss beachten, dass Wärme entlang der Messsonde übertragen werden

kann und darauf achten, dass das Gerät die maximal zulässige Umgebungstemperatur

nicht überschreitet. Näheres ist der Betriebsanleitung zu entnehmen.

iii. Typen mit einer PTFE-Auskleidung dürfen nur für den Einsatz in Gruppe IIB gekennzeich-

net sein. Der Benutzer muss dafür sorgen, dass Typen, die so gekennzeichnet sind, nicht

in gasexplosionsgefährdeten Bereichen der Gruppe IIC oder in staubexplosionsgefährdeten Bereichen der Gruppe III verwendet werden.

iv. Typen mit PTFE-Auskleidung dürfen nur für den Einsatz in gasexplosionsgefährdeten

Bereichen der Gruppe IIC und in staubexplosionsgefährdeten Bereichen der Gruppe IIIB

gekennzeichnet sein. Derartige Typen sind auch mit einem Warnetikett versehen, das

den Benutzer auf eine mögliche elektrostatische Gefährdung innerhalb des Prozessanschlussbereichs hinweist. Der Benutzer muss alle notwendigen Sicherheitsvorkehrungen

ergreifen, damit die Gefahr einer elektrostatischen Entladung innerhalb des Prozessanschlusses minimiert wird.

v. Im Gerät kann ein Kabel integriert sein. Ist dies der Fall, muss der Benutzer dafür sorgen,

dass dieses gut befestigt und gegen mechanische Beschädigung geschützt ist.

vi. Bei Anwendungen der Gruppe III kann die nichtmetallische Beschichtung des Geräte-

gehäuses unter bestimmten extremen Bedingungen eine zündfähige elektrostatische

Ladung erzeugen. Aus diesem Grunde darf das Gerät nicht an einem Ort installiert

werden, an dem durch die äußeren Bedingungen der Aufbau elektrostatischer Ladung

an solchen Oberächen begünstigt wird. Der Benutzer/Installateur muss Vorsichtsmaßnahmen ergreifen, um einen Aufbau elektrostatischer Ladung zu verhindern, indem er

das Gerät z. B. an einem Ort aufstellt, an dem ein ladungserzeugender Mechanismus

(wie z. B. vom Wind verwehter Staub) wenig wahrscheinlich ist, und das Gerät mit einem

feuchten Tuch abwischt.

Manometer mit Ausgangssignal, optional für explosionsgefährdete Bereiche42

11297264.05 07/2019 EN/DE

Page 43

4. Transport, Verpackung

4. Transport, Verpackung und Lagerung

4.1 Transport

Gerät auf eventuell vorhandene Transportschäden untersuchen.

Oensichtliche Schäden unverzüglich mitteilen.

VORSICHT!

Beschädigungen durch unsachgemäßen Transport

Bei unsachgemäßem Transport können Sachschäden in erheblicher Höhe

entstehen.

▶

Beim Abladen der Packstücke bei Anlieferung sowie innerbetrieblichem

Transport vorsichtig vorgehen und die Symbole auf der Verpackung

beachten.

▶

Bei innerbetrieblichem Transport die Hinweise unter Kapitel 4.2 „Verpackung

und Lagerung“ beachten.

4.2 Verpackung und Lagerung

Verpackung erst unmittelbar vor der Montage entfernen.

Die Verpackung aufbewahren, denn diese bietet bei einem Transport einen optimalen Schutz

(z. B. wechselnder Einbauort, Reparatursendung).

Zulässige Bedingungen am Lagerort:

Lagertemperatur: -20 ... +70 °C

FolgendeEinüssevermeiden:

Direktes Sonnenlicht oder Nähe zu heißen Gegenständen

Mechanische Vibration, mechanischer Schock (hartes Aufstellen)

Ruß, Dampf, Staub und korrosive Gase

Explosionsgefährdete Umgebung, entzündliche Atmosphären

DE

Das Gerät in der Originalverpackung an einem Ort lagern, der die oben gelisteten Bedingungen erfüllt.

11297264.05 07/2019 EN/DE

43Manometer mit Ausgangssignal, optional für explosionsgefährdete Bereiche

Page 44

5. Inbetriebnahme, Betrieb

5. Inbetriebnahme, Betrieb

Personal: Fachpersonal

Vor Montage, Inbetriebnahme und Betrieb sicherstellen, dass das richtige Gerät hinsichtlich

Anzeigebereich, Ausführung und spezischen Messbedingungen ausgewählt wurde.

DE

WARNUNG!

Körperverletzungen, Sach- und Umweltschäden durch gefährliche

Messstoe

Bei Kontakt mit gefährlichen Messstoen (z. B. bei brennbaren oder giftigen

Stoen), gesundheitsgefährdenden Messstoen (z. B. ätzend, giftig, krebserregend,

radioaktiv) besteht die Gefahr von Körperverletzungen, Sach- und Umweltschäden.

Am Gerät können im Fehlerfall aggressive Messstoe mit extremer Temperatur

und unter hohem Druck anliegen.

▶

Bei diesen Messstoen müssen über die gesamten allgemeinen Regeln

hinaus die einschlägigen Vorschriften beachtet werden.

▶

Notwendige Schutzausrüstung tragen.

WARNUNG!

Körperverletzungen, Sach- und Umweltschäden durch unter hohem

DruckaustretendeMessstoe

Bei der Druckbeaufschlagung des Gerätes kann aufgrund schlechter Abdich-

tung des Prozessanschlusses Messsto unter hohem Druck entweichen.

Durch die hohe Energie des im Fehlerfall austretenden Messstoes besteht die

Gefahr von Körperverletzungen und Sachschäden.

▶

Die Abdichtung des Prozessanschlusses muss fachgerecht ausgeführt und

auf Dichtheit überprüft werden.

5.1 Mechanischer Anschluss

Entsprechend den allgemeinen technischen Regeln für Manometer (z. B. EN 837-2

„Auswahl- und Einbauempfehlungen für Druckmessgeräte“).

Beim Einschrauben der Geräte darf die zum Abdichten erforderliche Kraft nicht über das

Gehäuse aufgebracht werden, sondern mit geeignetem Werkzeug nur über die dafür

vorgesehenen Schlüsselächen.

Montage mit Gabelschlüssel

Für zylindrische Gewinde sind an der Dichtäche Flachdichtungen, Dichtlinsen oder

WIKA-Proldichtungen einzusetzen. Bei kegeligen Gewinden (z. B. NPT-Gewinde) erfolgt die

Manometer mit Ausgangssignal, optional für explosionsgefährdete Bereiche44

11297264.05 07/2019 EN/DE

Page 45

5. Inbetriebnahme, Betrieb