Page 1

DELTA-trans

Operating instructions

Betriebsanleitung

Mode d'emploi

Manual de instrucciones

Dierential pressure transmitter,

model DPGT40

Dierenzdruck-Messumformer,

Typ DPGT40

Transmetteur de pression diérentielle,

type DPGT40

Transmisor de presión diferencial,

modelo DPGT40

GB

D

F

E

Dierential pressure transmitter with integrated dierential pressure and working

pressure indication, model DPGT40

Page 2

Operating instructions dierential pressure transmitter

GB

Model DPGT40 Page 3 - 20

Betriebsanleitung Dierenzdruck-Messumformer

D

Typ DPGT40 Seite 21 - 38

Mode d’emploi transmetteur de pression diérentielle

F

Type DPGT40 Page 39 - 56

Manual de instrucciones, transmisor de presión diferencial

E

Modelo DPGT40 Página 57 - 74

© 2014 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

®

WIKA

is a registered trademark in various countries.

®

WIKA

ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d‘emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta!

2

WIKA operating instructions dierential pressure transmitter, model DPGT40

14093267.01 03/2014 GB/D/F/E

Page 3

Contents

Contents

1. General information 4

2. Safety 5

3. Specications 8

4. Design and function 11

5. Transport, packaging and storage 12

6. Commissioning, operation 13

7. Options and accessories 17

8. Maintenance 18

9. Dismounting, return and disposal 19

Appendix 1: EC declaration of conformity 20

GB

14093267.01 03/2014 GB/D/F/E

WIKA operating instructions dierential pressure transmitter, model DPGT40 3

Page 4

1. General information

1. General information

■

GB

The dierential pressure transmitters described in the operating instructions

have been designed and manufactured using state-of-the-art technology.

All components are subject to stringent quality and environmental criteria

during production. Our management systems are certied to ISO 9001 and

ISO 14001.

■

These operating instructions contain important information on handling the

instrument. Working safely requires that all safety instructions and work

instructions are observed.

■

Observe the relevant local accident prevention regulations and general safety

regulations for the instrument's range of use.

■

The operating instructions are part of the product and must be kept in the

immediate vicinity of the instrument and readily accessible to skilled personnel

at any time.

■

Skilled personnel must have carefully read and understood the operating

instructions prior to beginning any work.

■

The manufacturer's liability is void in the case of any damage caused by

using the product contrary to its intended use, non-compliance with these

operating instructions, assignment of insuciently qualied skilled personnel

or unauthorised modications to the instrument.

■

The general terms and conditions contained in the sales documentation shall

apply.

■

Subject to technical modications.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: PV 17.19

Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can result in

serious injury or death, if not avoided.

Information

... points out useful tips, recommendations and information for

ecient and trouble-free operation.

WIKA operating instructions dierential pressure transmitter, model DPGT404

14093267.01 03/2014 GB/D/F/E

Page 5

1. General information / 2. Safety

2. Safety

WARNING!

Before installation, commissioning and operation, ensure that

the appropriate dierential pressure transmitter has been

selected in terms of design and specic measuring conditions.

Check the compatibility with the medium of the materials

subjected to pressure!

In order to guarantee the measuring accuracy and long-term

stability specied, the corresponding load limits must be

observed.

Only work on the gauge with the voltage disconnected.

Non-observance can result in serious injury and/or damage to

the equipment.

Further important safety instructions can be found in the

individual chapters of these operating instructions.

2.1 Intended use

The dierential pressure transmitters of the DELTA-line product family are

primarily used for the monitoring of low dierential pressures where there are high

requirements in terms of one-sided overpressure and static pressure.

Typical markets for these products are the shipbuilding industry, process heating

technology, the heating, ventilation and air-conditioning industries, the water/

wastewater industry, and machine building and plant construction. For these,

the main function of the measuring instruments is the monitoring of lters,

compressors and pumps.

GB

The instrument has been designed and built solely for the intended use described

here, and may only be used accordingly.

The manufacturer shall not be liable for claims of any type based on operation

contrary to the intended use.

14093267.01 03/2014 GB/D/F/E

WIKA operating instructions dierential pressure transmitter, model DPGT40 5

Page 6

2. Safety

2.2 Personnel qualication

GB

WARNING!

Risk of injury should qualication be insucient!

Improper handling can result in considerable injury and damage

to equipment.

■

The activities described in these operating instructions

may only be carried out by skilled personnel who have the

qualications described below.

Skilled personnel

Skilled personnel are understood to be personnel who, based on their technical

training, knowledge of measurement and control technology and on their

experience and knowledge of country-specic regulations, current standards

and directives, are capable of carrying out the work described and independently

recognising potential hazards.

2.3 Special hazards

WARNING!

For hazardous media such as oxygen, acetylene, ammable or

toxic gases or liquids, and refrigeration plants, compressors, etc.,

in addition to all standard regulations, the appropriate existing

codes or regulations must also be followed.

WARNING!

Residual media in dismounted measuring instruments can result

in a risk to persons, the environment and equipment.

Take sucient precautionary measures.

14093267.01 03/2014 GB/D/F/E

WIKA operating instructions dierential pressure transmitter, model DPGT406

Page 7

2. Safety

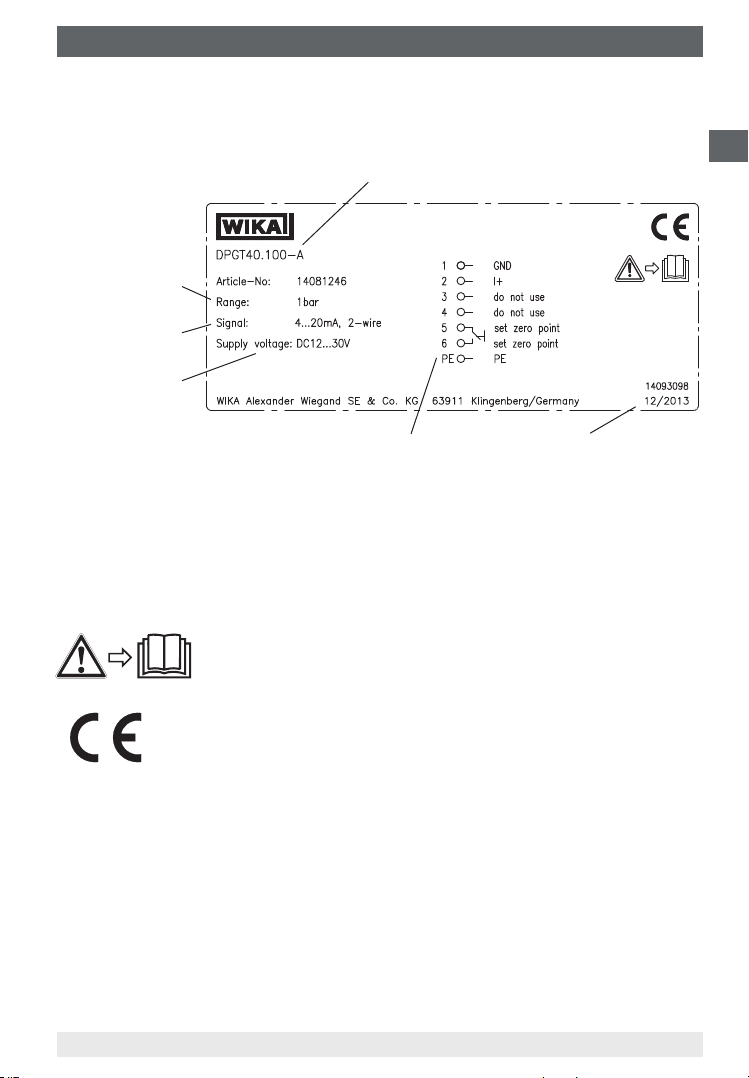

2.4 Labelling / safety marks

Product label

Measuring

range

Output signal

Power supply

1) A = output signal 4 ... 20 mA, 2-wire

E = output signal 4 ... 20 mA, 2-wire, ATEX Ex II 2G Ex ib IIC T4 / T5 / T6

B = output signal 0 ... 20 mA, 3-wire

F = output signal 0 ... 10 V, 3-wire

Explanation of symbols

Before mounting and commissioning the instrument, ensure

you read the operating instructions!

Output signal

Pin assignment

GB

1)

Date of

manufacture

CE, Communauté Européenne

Instruments bearing this mark comply with the relevant European

directives.

14093267.01 03/2014 GB/D/F/E

WIKA operating instructions dierential pressure transmitter, model DPGT40 7

Page 8

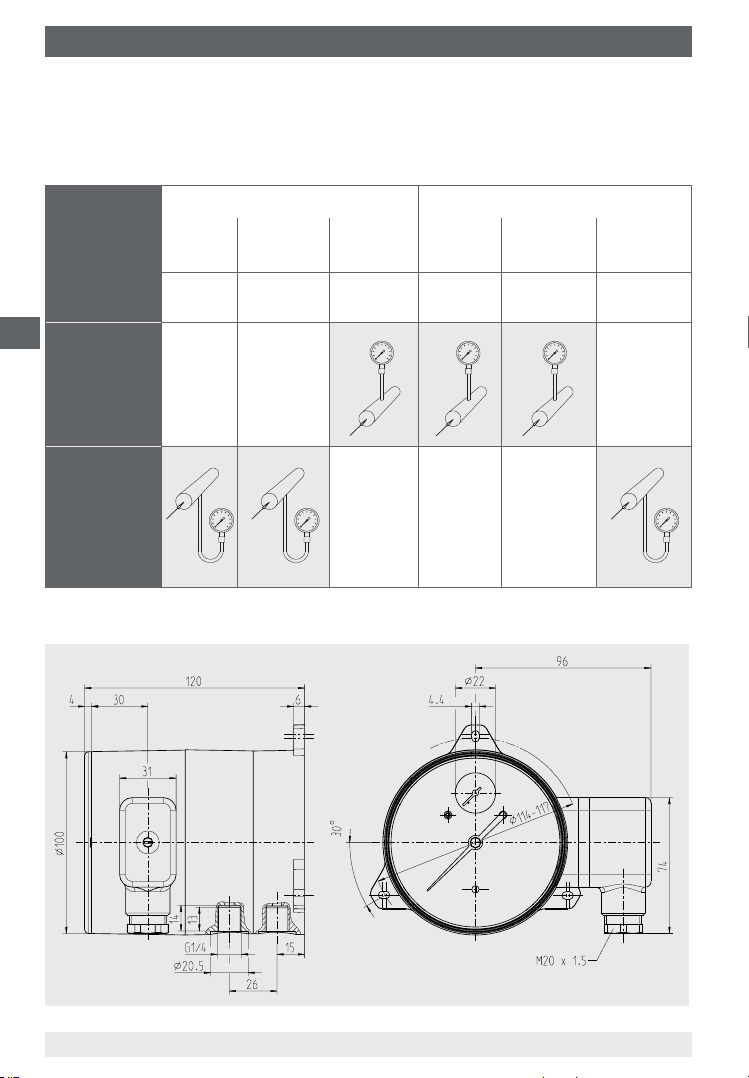

3. Specications

3. Specications

Specications DELTA-trans model DPGT40

GB

Mechanical data

Nominal size Dierential pressure indication: Ø 100 mm

Working pressure indication: Ø 22 mm

Accuracy class Dierential pressure indication: ≤ 2.5 % of span (option

≤ 1.6 %)

Working pressure indication: 4

Scale ranges (EN 837) Dierential pressure: 0 ... 0.25 to 0 ... 10 bar

Working pressure: 0 ... 25 bar

Max. working pressure (stat.) 25 bar

Overpressure safety Either side max. 25 bar

Permissible temperatures Ambient: -10 ... +70 °C, medium: -10 ... +90 °C

Storage: -40 ... +70 °C

Ingress protection IP 54 per EN 60529 / IEC 60529

Media chamber (wetted) Aluminium, EN AC–Al Si9Cu3(Fe), black lacquered

Process connections (wetted) 2 x G 1/4 female, lower mount (LM), in-line, centre

distance 26 mm

Pressure elements (wetted) Dierential pressure: Compression springs from stain-

less steel 1.4310 and separating diaphragm from FPM/

FKM (option: NBR)

Working pressure: Bourdon tube from Cu-alloy

Transmission parts (wetted) Stainless steel 1.4301, 1.4305, 1.4310, FPM/FKM (op-

tion: NBR)

Sealings (wetted) FPM/FKM (option: NBR)

Movement Copper alloy, wear parts argentan

Dial Dierential and working pressure indication: White dial,

black lettering

Pointer Dierential and working pressure indication: Blue pointer

Zero adjustment for dierential

pressure indication

Case Aluminium, EN AC–Al Si9Cu3(Fe), black lacquered

Window Plastic

Weight approx. 1.3 kg

Via screw in the dial

14093267.01 03/2014 GB/D/F/E

WIKA operating instructions dierential pressure transmitter, model DPGT408

Page 9

3. Specications

Electrical data

Power supply U

B

Inuence of power

supply

Permissible residual

ripple

Output signal

Permissible max. load R

for variant 1 - 3

Eect of load

(variant 1 - 3)

Electrical zero point

■

Long-term stability of

electronics

■

Electr. output signal ≤ 2.5 % of the measuring span (option ≤ 1.6 %)

Linearity

Electrical connection via angular connector, 180° rotatable, wire

Ingress protection Angular connector: IP 65 per EN 60529 / IEC 60529

EMC directive 2007/108/EC interference emission (limit class B)

DC V

% FS/10 V

% ss

Variant 1

Variant 3

Variant 4

A

% FS

% FS/a

% of span

12 < UB ≤ 30

≤ 0.1

≤ 10

4 … 20 mA, 2-wire, passive, per NAMUR NE 43

0 ... 20 mA, 3-wire

0 ... 10 V, 3-wire

RA ≤ (UB - 12 V)/0.02 A with RA in Ohm and UB in

Volt, however max. 600 Ω

≤ 0.1

through a jumper across terminals 5 and 6 (see

operating instructions)

< 0.3

≤ 2.5 % (option ≤ 1.6 %), terminal method

protection, cable gland M20 x 1.5, incl. strain relief,

connection cable: Outer diameter 7 ... 13 mm,

conductor cross-section 0.14 ... 1.5 mm

2

,

temperature resistance up to 70 °C

and immunity to EN 61 326-1

GB

As a power supply, an unstabilised DC power supply is sucient in the range of

the specied limits. It is important to ensure that the applied power supply is at

least greater than the maximum required voltage drop from the external display

and evaluation units; i.e. the voltage at the pressure transmitter must not fall

below 10 V.

14093267.01 03/2014 GB/D/F/E

WIKA operating instructions dierential pressure transmitter, model DPGT40 9

Page 10

3. Specications

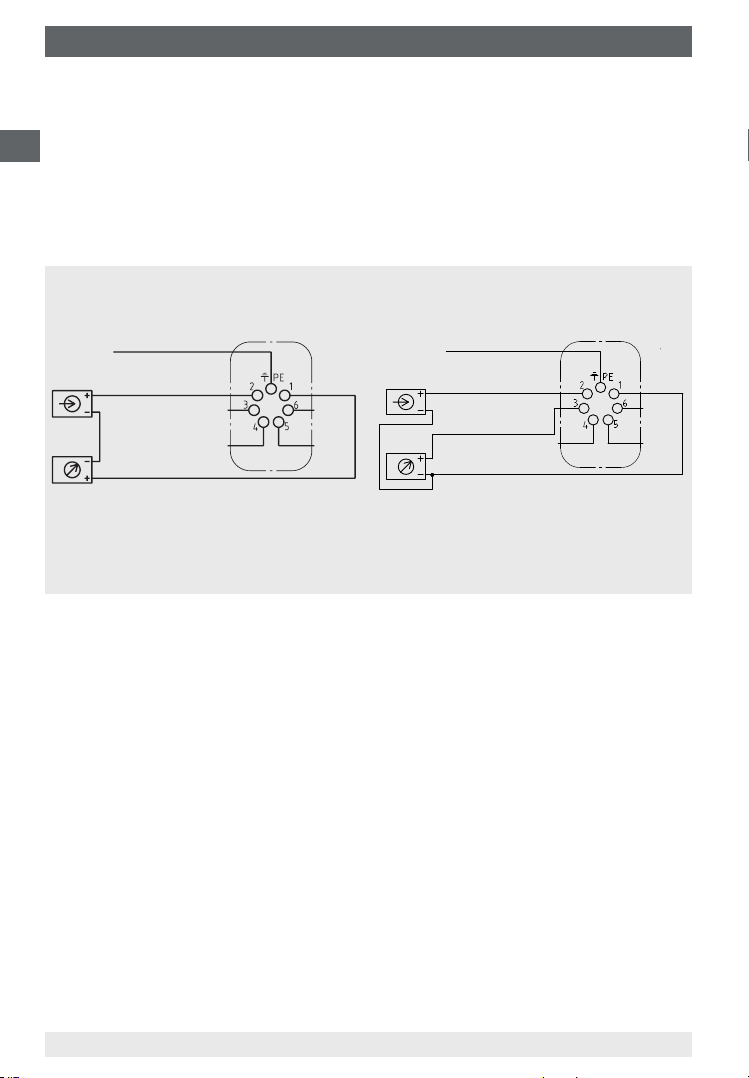

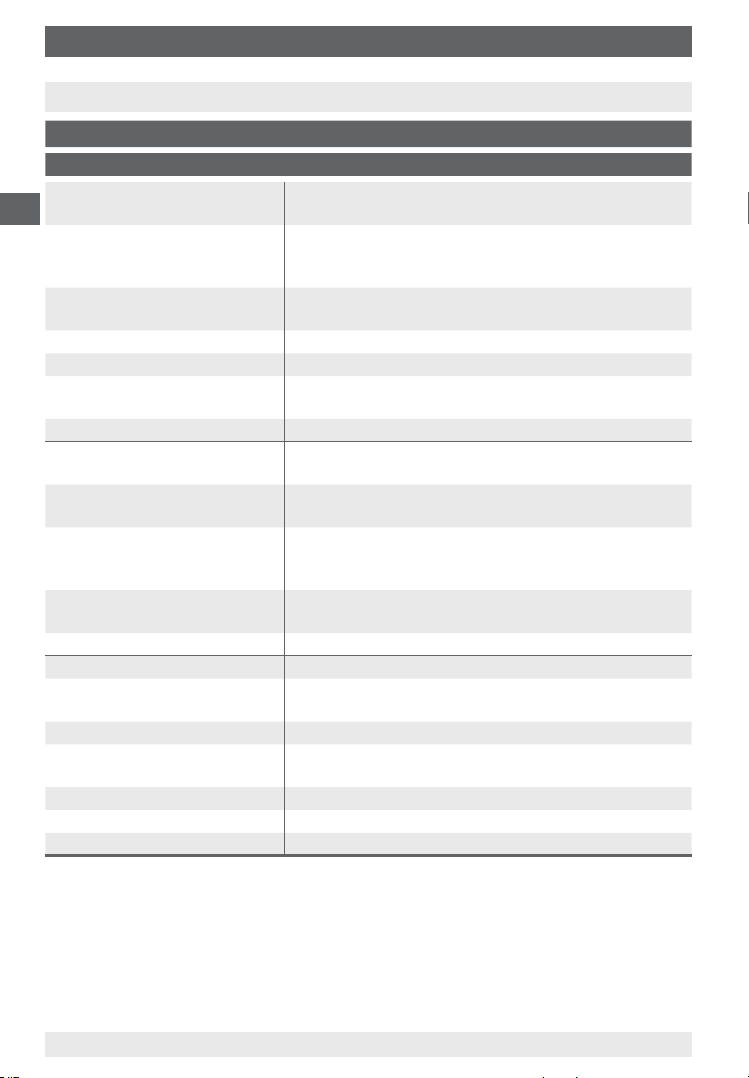

Designation of terminal connectors

The exact pin assignments can be found in the following drawings. In addition, the

pin assignment, output signal and the required power supply are stated on the

GB

product label.

The following diagram shows the standard terminal assignment. For customer-

specic designs, the terminal assignment on the product label must be followed.

2-wire system

4 … 20 mA

Earth, connected to

Power supply

Evaluation

(display)

case 1)

UB+/I+

0 V/GND

Terminals 3 and 4: for internal use only

Terminals 5 and 6: reset zero point

3-wire system

0 … 20 mA, 4 … 20 mA and 0 ... 10 V

Earth, connected to

Power supply

Evaluation

(display)

case 1)

U

+

B

Sig+

0 V/Sig-/GND

1) This connection must not be used

for equipotential bonding. The

instrument must be incorporated in the

equipotential bonding via the process

connection.

Explanation of the terminal assignments used:

UB+ Positive terminal of power supply

0 V/Sig-/GND Negative terminal of power supply and output signal

Sig+ Positive terminal of output signal

I+ Output signal

For further specications see the corresponding product label, WIKA data sheet

and the order documentation.

14093267.01 03/2014 GB/D/F/E

WIKA operating instructions dierential pressure transmitter, model DPGT4010

Page 11

4. Design and function

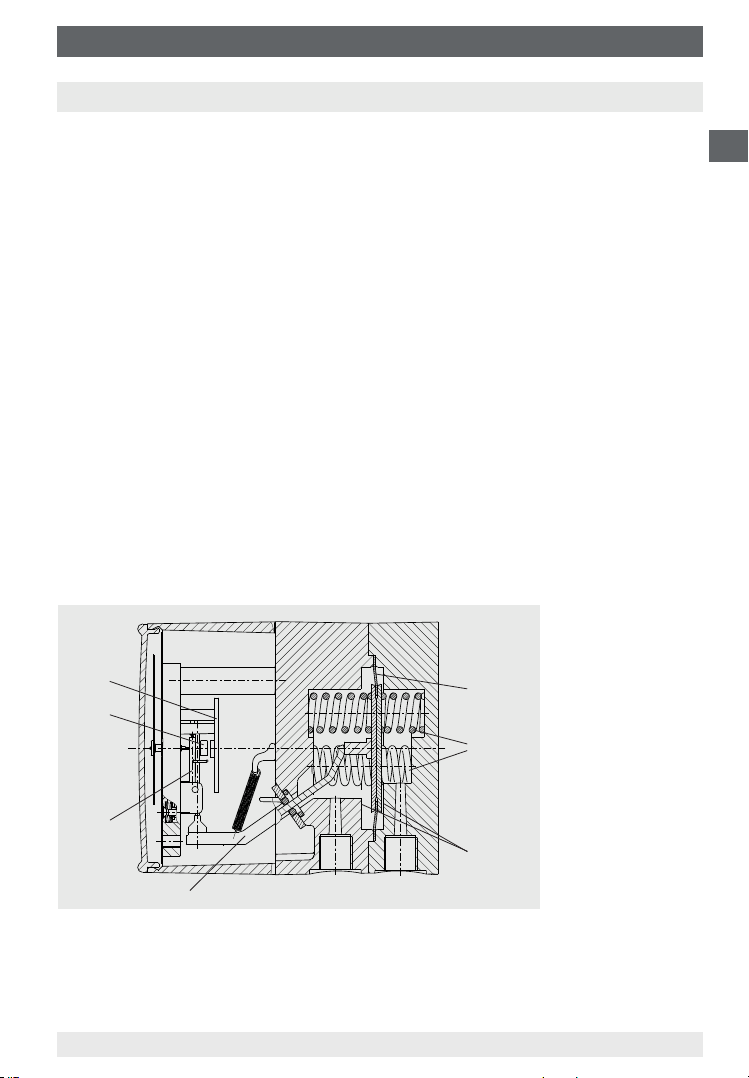

4. Design and function

4.1 Description

Pressures p1 and p2 act on the media chambers ⊕ and ⊖, which are separated by

an elastic diaphragm (1).

The dierential pressure (Δp = p

diaphragm against the measuring range springs (2).

The deection, which is proportional to the dierential pressure, is transmitted to

the movement (4) in the indicating case via a pressure-tight and low friction rocker

arm (3).

A magnet (5), xed to the rear of the movement, aects the electromagnetic eld

of the HALL sensor. The signal that results from this is converted to a standardised

current output signal by the signal conditioning board (6).

Overpressure safety is provided by metal bolsters (7) resting against the elastic

diaphragm.

- p2) leads to an axial deection of the

1

GB

14077606.01

4.2 Scope of delivery

Cross-check scope of delivery with delivery note.

14093267.01 03/2014 GB/D/F/E

WIKA operating instructions dierential pressure transmitter, model DPGT40 11

⊖ ⊕

Page 12

5. Transport, packaging and storage

5. Transport, packaging and storage

5.1 Transport

GB

Check the transmitter for any damage that may have been caused by transport.

Obvious damage must be reported immediately.

5.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g.

change in installation site, sending for repair).

5.3 Storage

Permissible conditions at the place of storage

Storage temperature: -40 ... +70 °C

In order to prevent damage, the following points should be noted for the

storage of the pressure transmitters:

■

Leave the measuring instruments in their original packaging

■

Following any possible removal of the measuring instruments, e.g. for testing,

the instrument should again be stored in its original packaging

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down hard)

■

Soot, vapour, dust, humidity and corrosive gases

■

Potentially explosive environments, ammable atmosphere

WARNING!

Before storing the instrument, any residual media must be

removed. This is of particular importance if the medium

is hazardous to health, e.g. caustic, toxic, carcinogenic,

radioactive, etc.

WIKA operating instructions dierential pressure transmitter, model DPGT4012

14093267.01 03/2014 GB/D/F/E

Page 13

6. Commissioning, operation

6. Commissioning, operation

6.1 Mechanical connection

■

In accordance with the general technical regulations for pressure gauges (e.g.

EN 837-2 “Selection and installation recommendations for pressure gauges”).

■

Mounting of the pressure connections according to axed symbols, ⊕ high

pressure, ⊖ low pressure

■

Mounting by means of:

- rigid measuring line or

- wall mounting with available mounting links

■

Process connections 2 x G 1/4 female, lower mount (LM), in-line, centre

distance 26 mm, operating position NL 90 (nominal position) per DIN 16257

(i.e. vertical dial), design the threads of the pressure connection in accordance

with EN 837-3 (section 7.3.2).

■

Prior to the installation of the pressure gauge, clean the measuring lines

thoroughly by tapping and blowing or rinsing

■

Protect measuring instruments from contamination and high temperature

changes!

■

The pressure gauge must be mounted free from vibration and should be

aligned so that it is easy to read. It is recommended that an isolation device is

interposed between the pressure tapping point and the pressure gauge, which

will enable the replacement of the pressure gauge and a zero point check while

the plant is running. The instruments should be protected against coarse dirt

and wide uctuations in ambient temperature.

GB

■

Correct sealing of the connections must be made using suitable at gaskets,

sealing rings or WIKA prole sealings. In order to orientate the gauge so that

the on-site display can be read as well as possible, a clamp socket or union nut

should be used. When screwing on and unscrewing the pressure gauges they

should not be gripped by the case, but rather only on the spanner ats of the

connection!

Wall mounting

Mounting using three integrally cast mounting lugs

14093267.01 03/2014 GB/D/F/E

WIKA operating instructions dierential pressure transmitter, model DPGT40 13

Page 14

6. Commissioning, operation

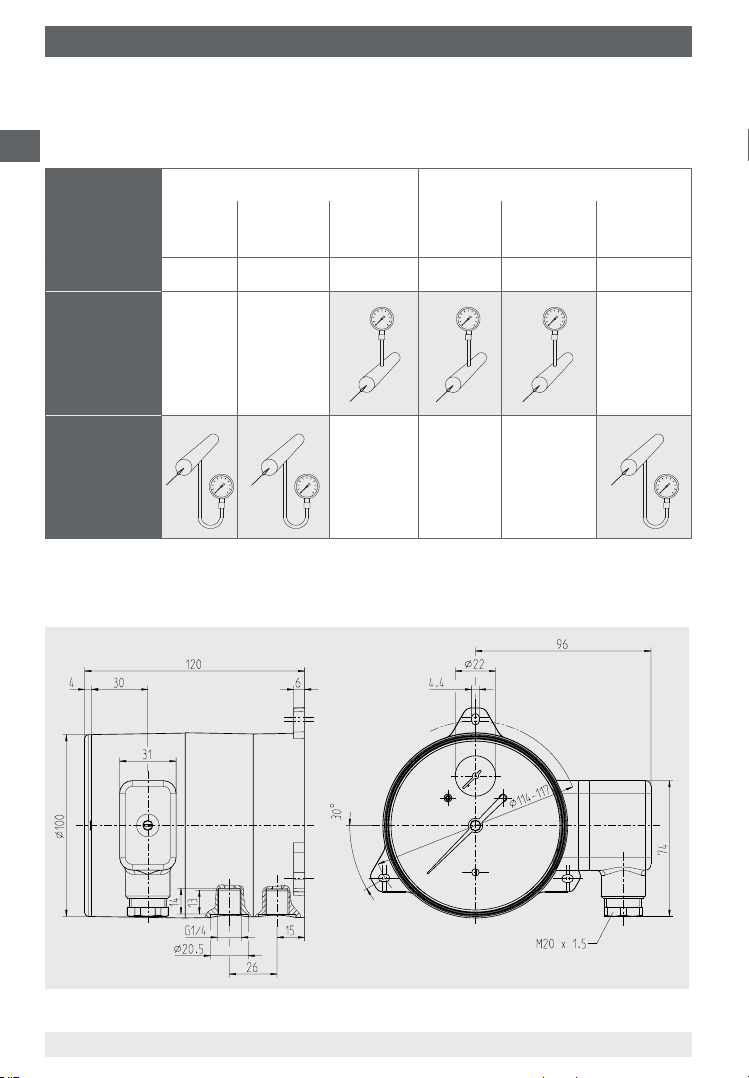

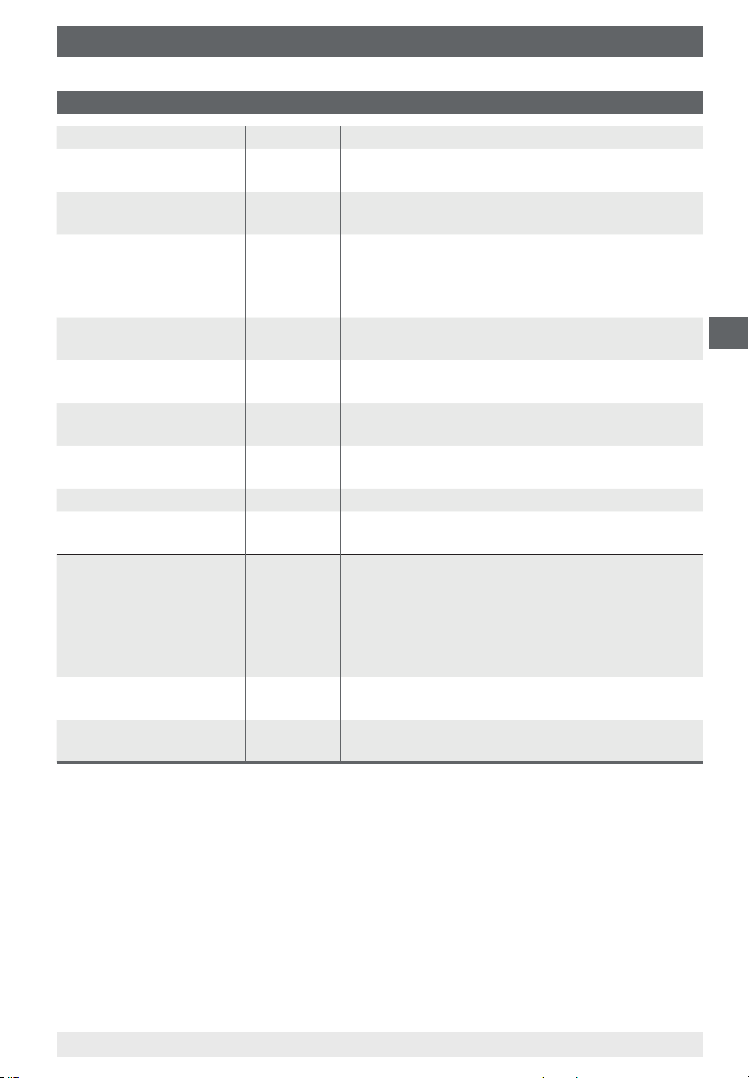

Measuring assemblies

Proven measuring assemblies for various types of media. The assemblies that are

particularly recommended for use are shown below.

GB

Filling of

the measu

-

liquid liquid with

ring line

Examples

condensate

Pressure

gauge

above the

tapping

point

Pressure

gauge

below the

tapping

point

Dimensions in mm

liquid media gaseous media

vapour

boiling liquid

vapour

only

“liqueed

gases”

gaseous partially

dry air

condensed

(damp)

moist air

ue gases

completely

condensed

Steam

14078303.01

14093267.01 03/2014 GB/D/F/E

WIKA operating instructions dierential pressure transmitter, model DPGT4014

Page 15

6. Commissioning, operation

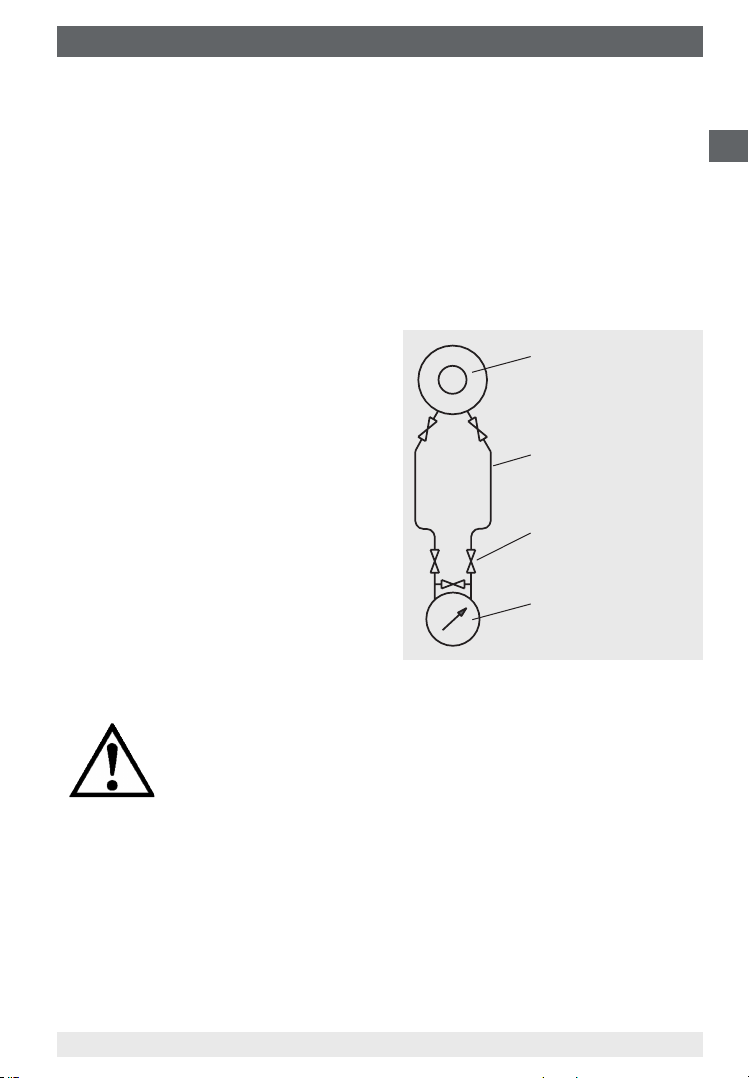

Measuring assemblies

The preferred measuring assemblies for various possible applications are

specied in DIN 19216.

The following schematic diagram shows a recommended assembly for liquid

media. As throttling devices, dierential pressure transducers should be provided

in accordance with DIN 1952 (issue 07.82), now replaced by EN 5167/1.

The dierential pressure lines must be made from metal, their bore must not

be less than 4 mm and the eective length between the valve manifold and the

dierential pressure transmitter must be at least 500 mm.

GB

In addition, the length and the bore of

the pressure lines should be such that,

with cold lines, the response time of

the pressure gauge is not more than

5 seconds.

The connections of the dierential

Dierential pressure

transducer

(throttling device in the

process line)

Dierential pressure

line

pressure lines must be welded, brazed or

screwed using metal sealing elements.

Shut-o valves

Shut-o valves in dierential pressure

(valve manifold)

lines must only be operated using tools.

Dierential pressure

instrument

(DELTA-trans)

Safety instructions for installation

■

Follow the installation and safety instructions within the

operating instructions.

■

Install instruments in accordance with the manufacturer's

instructions and the valid standards and regulations.

■

The instruments do not provide for incorporated overcurrent protectors!

Once the pressure connection and the electrical connections have been made,

the pressure transmitters are ready for immediate use.

Commissioning

During the commissioning process pressure surges must be avoided at all costs.

Open the shut-o valves slowly.

14093267.01 03/2014 GB/D/F/E

WIKA operating instructions dierential pressure transmitter, model DPGT40 15

Page 16

6. Commissioning, operation

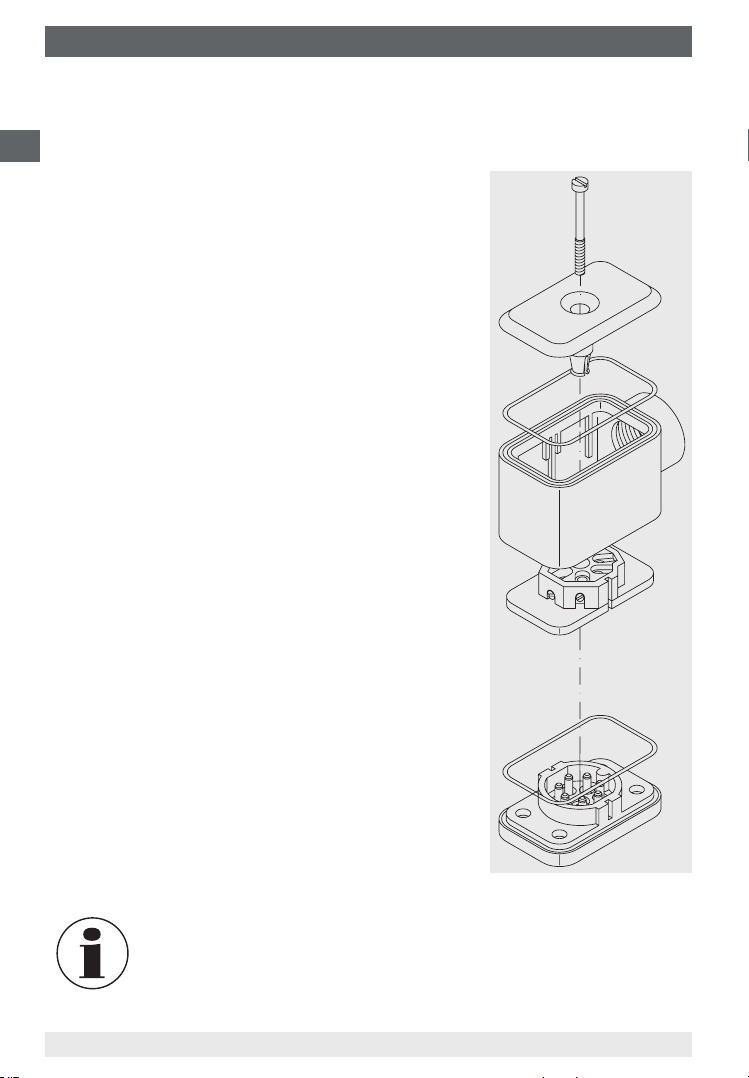

6.2 Electrical zero point (4 mA)

The zero point adjustment is made by an adjustment screw in the front, which,

depending on the instrument model, is accessible by loosening the window or the

GB

locking screw. By turning the adjustment screw using a screwdriver the desired zero

point is set.

If the mechanical zero point has been altered via the

adjustment screw, the electrical zero point must be

matched again to the mechanical one.

For this, the dierential pressure transmitter must rst be

depressurised.

Remove the entire cable cover on the right-hand side

of the transmitter. To do this, undo the screw on the

top of the cable cover cap completely with a slotted

screwdriver (0.6 x 3.5 mm). Remove the screw. Pull the

cable cover , along with the socket insert , out from the

cable socket baseplate .

This isolates the transmitter from the voltage supply.

Take the cable cover cap from the cable cap and

push the socket insert out, downwards, completely

through the cable cap .

Bridge contacts 5 and 6 on the socket insert with a

short length of wire, stripped at both ends (maximum

permissible resistance 30 Ω).

Reassemble the connector in the reverse order. Insert the

connector, with the piece of wire mounted, into the pin

insert . This remakes the voltage supply.

Within a max. of 30 seconds, the new zero point will be

saved within the electronics. During this time, the current in

the loop will rise to 9.5 mA.

The new zero point is maintained, even with a loss of

power, for an extended period.

Once more, disconnect the connector in the order

described above and remove the piece of wire. After again

assembling the connector, the electrical output signal will

once more match the display of the mechanical pointer.

In order that the ingress

protection is maintained, the

seals must be retted.

WIKA operating instructions dierential pressure transmitter, model DPGT4016

Screw

Cable cover cap

Cable cover

Socket insert

Cable socket baseplate

Sealings

14093267.01 03/2014 GB/D/F/E

Page 17

6. Commissioning, operation / 7. Options and accessories

6.3 Setting up a voltage supply

The voltage supply is made via a power supply unit or a control unit which

provides the energy limitation.

The power supply for the pressure transmitter must be made via an energy-

limited electrical circuit in accordance with section 9.3 of UL/EN/IEC 61010-1, or

an LPS to UL/EN/IEC 60950-1, or class 2 in accordance with UL1310/UL1585

(NEC or CEC). The power supply must be suitable for operation above 2,000 m

should the pressure transmitter be used at this altitude.

7. Options and accessories

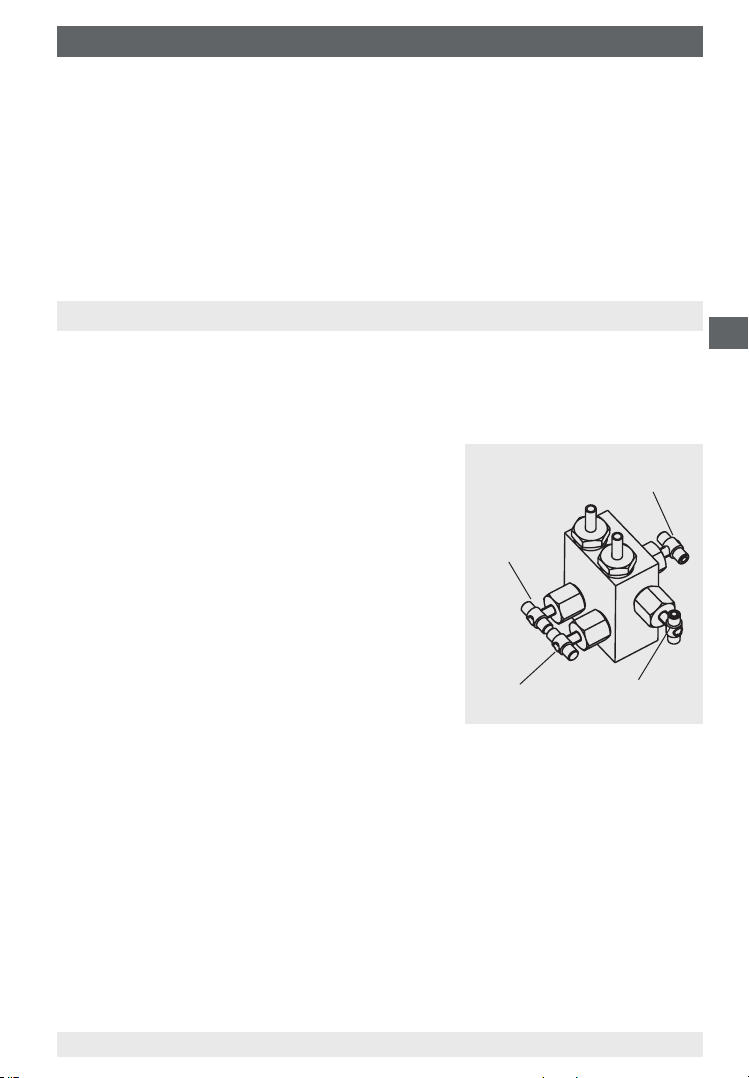

7.1 4-way valve manifold

■

Isolation of the ⊕ and ⊖ process lines for removing or testing the measuring

instrument without interrupting the running process operation.

Protection of the instrument against

excessive overpressure loading, such as

in pressure tests and undened operating

conditions (including intermittent shutdown).

Pressure

compensating valve

GB

■

Pressure compensation for zero point

checking with running processes, and

Shut-o valve

⊕ side

avoiding one-sided overpressure loading

during start-up and operation phases (with

opened pressure compensating valve).

■

Venting the measuring lines with liquid

media and ushing of the measuring lines,

in order to remove contamination.

Shut-o valve

⊖ side

Vent valve

Specications for handling

■

Sequence of operations to start measurement

1. Open the pressure compensating valve (middle valve spindle)

2. Open the shut-o valve for the negative media chamber (⊖, right-hand valve)

and the positive media chamber (⊕, left-hand valve)

3. Close the pressure compensating valve

■

Sequence of operations to ush/vent the measuring lines

1. Start: Open the shut-o valve for the ⊕ and ⊖ media chamber, open the

pressure compensating valve and vent valve

2. Finish: Close the pressure compensating valve and vent valve

14093267.01 03/2014 GB/D/F/E

WIKA operating instructions dierential pressure transmitter, model DPGT40 17

Page 18

7. Options and accessories / 8. Maintenance

■

Sequence of operations to nish measurement (also temporary shutdown)

GB

1. Open the pressure compensating valve

2. Close the shut-o valve for the ⊕ and ⊖ media chamber

■

Sequence of operations to dismount the measuring instrument with a running

process

1. Close the shut-o valve for the ⊕ and ⊖ media chamber

2. Open the vent valve

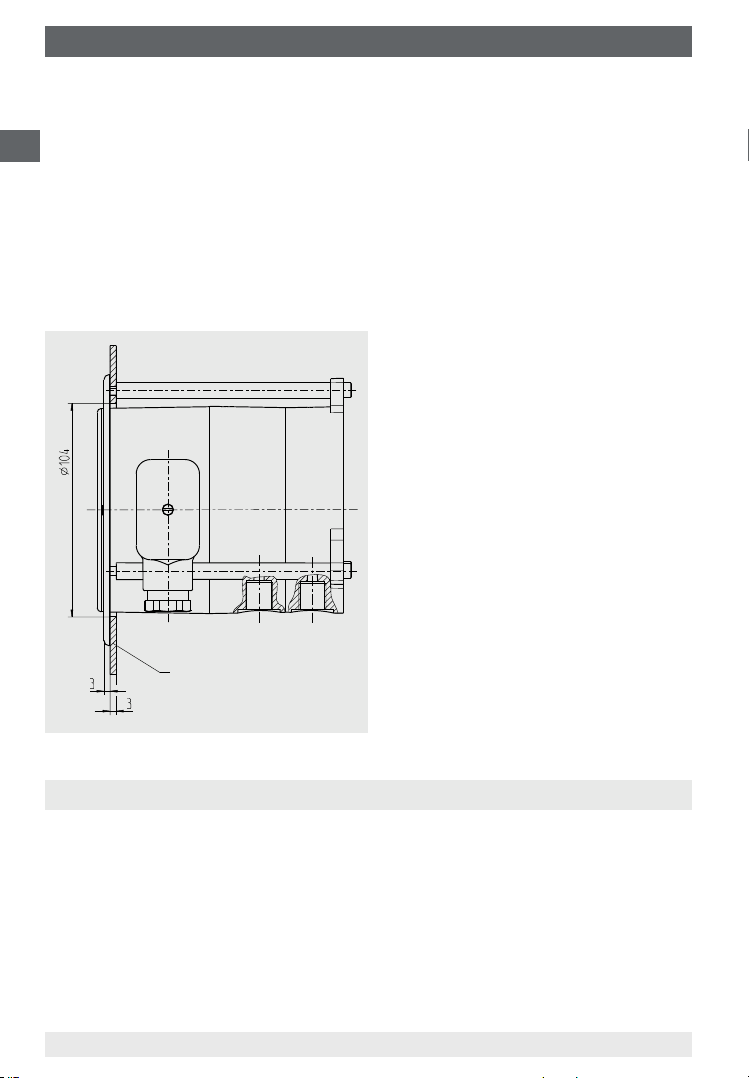

7.2 Panel mounting ange

Cutout

Panel

14078276.01

8. Maintenance

The instruments are maintenance-free.

The indicator and switching function should be checked once or twice every year.

For this the instrument must be disconnected from the process to check with a

pressure testing device.

Repairs must only be carried out by the manufacturer.

WIKA operating instructions dierential pressure transmitter, model DPGT4018

14093267.01 03/2014 GB/D/F/E

Page 19

9. Dismounting, return and disposal

9. Dismounting, return and disposal

WARNING!

Residual media in dismounted measuring instruments can result

in a risk to persons, the environment and equipment.

Take sucient precautionary measures.

9.1 Dismounting

Only disconnect the measuring instrument once the system has been depressurised and the power disconnected!

If necessary, the measuring line must have strain relief.

9.2 Return

Wash or clean the dismounted measuring instrument before returning it, in order

to protect personnel and the environment from exposure to residual media.

9.3 Disposal

Incorrect disposal can put the environment at risk. Dispose of instrument

components and packaging materials in an environmentally compatible way and

in accordance with the country-specic waste disposal regulations.

GB

14093267.01 03/2014 GB/D/F/E

WIKA operating instructions dierential pressure transmitter, model DPGT40 19

Page 20

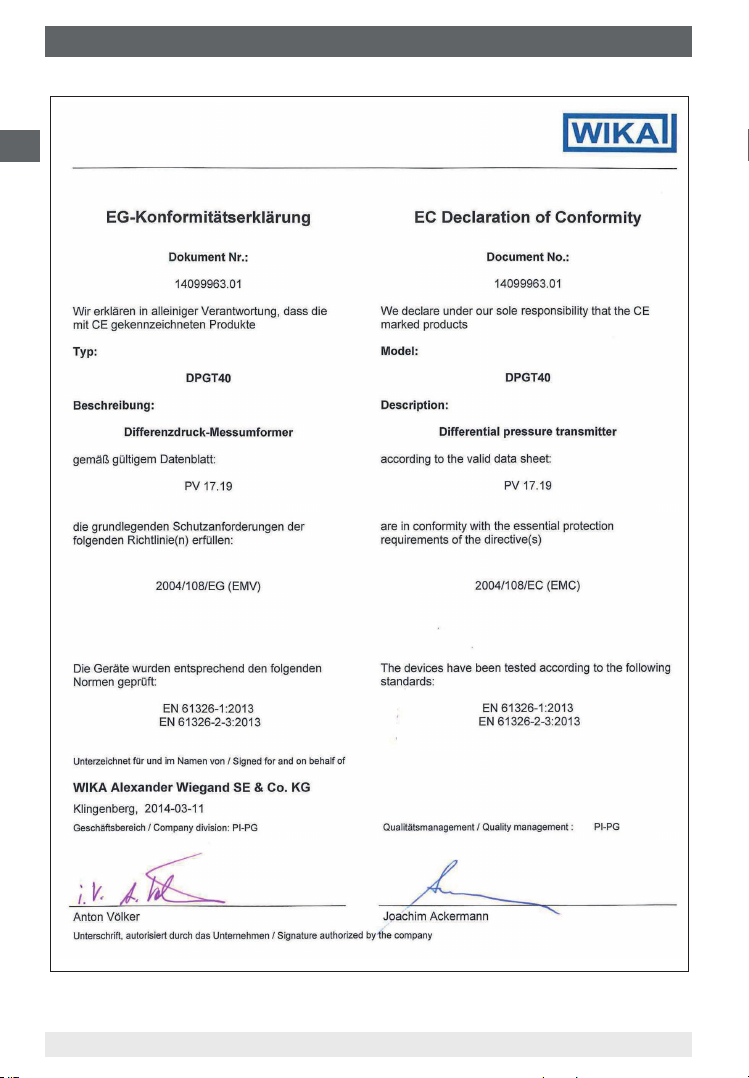

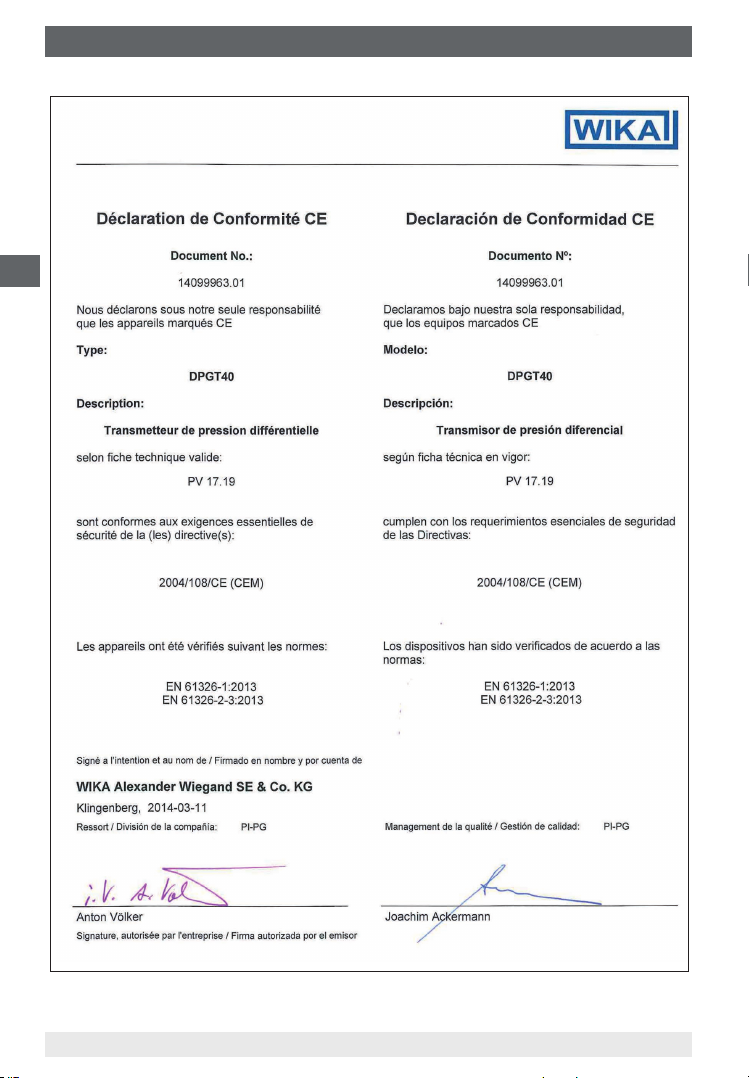

Appendix 1: EC declaration of conformity

GB

14093267.01 03/2014 GB/D/F/E

WIKA operating instructions dierential pressure transmitter, model DPGT4020

Page 21

Inhalt

Inhalt

1. Allgemeines 22

2. Sicherheit 23

3. Technische Daten 26

4. Aufbau und Funktion 29

5. Transport, Verpackung und Lagerung 30

6. Inbetriebnahme, Betrieb 31

7. Optionen und Zubehör 35

8. Wartung 36

9. Demontage, Rücksendung und Entsorgung 37

Anlage 1: EG-Konformitätserklärung 38

D

14093267.01 03/2014 GB/D/F/E

WIKA Betriebsanleitung Dierenzdruck-Messumformer, Typ DPGT40 21

Page 22

1. Allgemeines

1. Allgemeines

■

Die in der Betriebsanleitung beschriebenen Dierenzdruck-Messumformer

werden nach dem aktuellen Stand der Technik konstruiert und gefertigt.

Alle Komponenten unterliegen während der Fertigung strengen Qualitäts-

und Umweltkriterien. Unsere Managementsysteme sind nach ISO 9001 und

D

ISO 14001 zertiziert.

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem Gerät.

Voraussetzung für sicheres Arbeiten ist die Einhaltung aller angegebenen

Sicherheitshinweise und Handlungsanweisungen.

■

Die für den Einsatzbereich des Gerätes geltenden örtlichen Unfallverhütungsvorschriften und allgemeinen Sicherheitsbestimmungen einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe

des Gerätes für das Fachpersonal jederzeit zugänglich aufbewahrt werden.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig durchgelesen und verstanden haben.

■

Die Haftung des Herstellers erlischt bei Schäden durch bestimmungswidrige

Verwendung, Nichtbeachten dieser Betriebsanleitung, Einsatz ungenügend

qualizierten Fachpersonals sowie eigenmächtiger Veränderung am Gerät.

■

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- zugehöriges Datenblatt: PV 17.19

Symbolerklärung

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin, die

zum Tod oder zu schweren Verletzungen führen kann, wenn sie

nicht gemieden wird.

Information

… hebt nützliche Tipps und Empfehlungen sowie Informationen

für einen ezienten und störungsfreien Betrieb hervor.

WIKA Betriebsanleitung Dierenzdruck-Messumformer, Typ DPGT4022

14093267.01 03/2014 GB/D/F/E

Page 23

1. Allgemeines / 2. Sicherheit

2. Sicherheit

WARNUNG!

Vor Montage, Inbetriebnahme und Betrieb sicherstellen, dass

der richtige Dierenzdruck-Messumformer hinsichtlich Ausführung und spezischen Messbedingungen ausgewählt wurde.

Verträglichkeit der druckbelasteten Werkstoe mit dem Messsto prüfen!

Die Belastungsgrenzen sind einzuhalten, um die Messgenauig-

keit und die Lebensdauer zu gewährleisten.

Alle Arbeiten dürfen nur im spannungslosen Zustand erfolgen.

Bei Nichtbeachten können schwere Körperverletzungen und/

oder Sachschäden auftreten.

Weitere wichtige Sicherheitshinweise benden sich in den einzelnen Kapiteln dieser Betriebsanleitung.

2.1 Bestimmungsgemäße Verwendung

Die Dierenzdruck-Messumformer der Produktfamilie DELTA-line werden vorzugsweise zur Überwachung von niedrigen Dierenzdrücken mit hohen Anforderungen an einseitige Überlast und statischem Druck eingesetzt.

Typische Märkte dieser Produkte sind die Schisindustrie, Prozesswärmetechnik,

Heizungs-, Klima-, Lüftungstechnik, Wasser-/Abwasserindustrie und Maschinenund Anlagenbau. Hier ist die Hauptaufgabe der Messgeräte die Überwachung von

Filtern, Kompressoren und Pumpen.

D

Das Gerät ist ausschließlich für den hier beschriebenen bestimmungsgemäßen

Verwendungszweck konzipiert und konstruiert und darf nur dementsprechend

verwendet werden.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung

sind ausgeschlossen.

14093267.01 03/2014 GB/D/F/E

WIKA Betriebsanleitung Dierenzdruck-Messumformer, Typ DPGT40 23

Page 24

2. Sicherheit

2.2 Personalqualikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualikation!

Unsachgemäßer Umgang kann zu erheblichen Personen- und

D

Fachpersonal

Das Fachpersonal ist aufgrund seiner fachlichen Ausbildung, seiner Kenntnisse

der Mess- und Regelungstechnik und seiner Erfahrungen sowie Kenntnis der

landesspezischen Vorschriften, geltenden Normen und Richtlinien in der Lage,

die beschriebenen Arbeiten auszuführen und mögliche Gefahren selbstständig zu

erkennen.

2.3 Besondere Gefahren

Sachschäden führen.

■

Die in dieser Betriebsanleitung beschriebenen Tätigkeiten nur

durch Fachpersonal nachfolgend beschriebener Qualikation

durchführen lassen.

WARNUNG!

Bei gefährlichen Messstoen wie z. B. Sauersto, Acetylen,

brennbaren oder giftigen Stoen, sowie bei Kälteanlagen,

Kompressoren etc. müssen über die gesamten allgemeinen

Regeln hinaus die jeweils bestehenden einschlägigen Vorschriften

beachtet werden.

WARNUNG!

Messstoreste in ausgebauten Messgeräten können zur

Gefährdung von Personen, Umwelt und Einrichtung führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

WIKA Betriebsanleitung Dierenzdruck-Messumformer, Typ DPGT4024

14093267.01 03/2014 GB/D/F/E

Page 25

2. Sicherheit

2.4 Beschilderung / Sicherheitskennzeichnungen

Typenschild

Messbereich

Ausgangssignal

Hilfsenergie

Symbolerklärung

CE, Communauté Européenne

Geräte mit dieser Kennzeichnung stimmen überein mit den zu-

treenden europäischen Richtlinien.

Ausgangssignal

Anschlussbelegung

1) A = Ausgangssignal 4 ... 20 mA, 2-Leiter

E = Ausgangssignal 4 ... 20 mA, 2-Leiter, ATEX Ex II 2G Ex ib IIC T4 / T5 / T6

B = Ausgangssignal 0 ... 20 mA, 3-Leiter

F = Ausgangssignal 0 ... 10 V, 3-Leiter

1)

Herstellungsdatum

Vor Montage und Inbetriebnahme des Gerätes unbedingt die

Betriebsanleitung lesen!

D

14093267.01 03/2014 GB/D/F/E

WIKA Betriebsanleitung Dierenzdruck-Messumformer, Typ DPGT40 25

Page 26

3. Technische Daten

3. Technische Daten

Technische Daten DELTA-trans Typ DPGT40

Mechanische Daten

Nenngröße Dierenzdruckanzeige: Ø 100 mm

D

Genauigkeitsklasse Dierenzdruckanzeige: ≤ 2,5 % der Spanne

Anzeigebereiche (EN 837) Dierenzdruck: 0 ... 0,25 bis 0 ... 10 bar

Max. Betriebsdruck (stat.) 25 bar

Überlastbarkeit ein-, beid- und wechselseitig max. 25 bar

Zulässige Temperaturen Umgebung: -10 ... +70 °C, Messsto: -10 ... +90 °C

Schutzart IP 54 nach EN 60529 / IEC 60529

Messstokammer

(messstoberührt)

Prozessanschlüsse

(messstoberührt)

Messglieder (messstoberührt) Dierenzdruck: Druckfedern aus CrNi-Stahl 1.4310 und

Übertragungsteile

(messstoberührt)

Dichtungen (messstoberührt) FPM/FKM (Option: NBR)

Zeigerwerk Kupferlegierung, Laufteile Neusilber

Zierblatt Dierenz- und Betriebsdruckanzeige: Zierblatt weiß,

Zeiger Dierenz- und Betriebsdruckanzeige: Zeiger blau

Nullpunktkorrektur für Dierenz-

druckanzeige

Gehäuse Aluminium, EN AC–Al Si9Cu3(Fe), schwarz lackiert

Sichtscheibe Kunststo

Gewicht ca. 1,3 kg

Betriebsdruckanzeige: Ø 22 mm

(Option ≤ 1,6 %)

Betriebsdruckanzeige: 4

Betriebsdruck: 0 ... 25 bar

Lagerung: -40 ... +70 °C

Aluminium, EN AC–Al Si9Cu3(Fe), schwarz lackiert

2 x G 1/4 Innengewinde, Anschlusslage unten,

hintereinander, Achsabstand 26 mm

Trennmembrane aus FPM/FKM (Option: NBR)

Betriebsdruck: Rohrfeder aus Cu-Legierung

CrNi-Stahl 1.4301, 1.4305, 1.4310, FPM/FKM

(Option: NBR)

Skalierung schwarz

über Schraube im Zierblatt

14093267.01 03/2014 GB/D/F/E

WIKA Betriebsanleitung Dierenzdruck-Messumformer, Typ DPGT4026

Page 27

3. Technische Daten

Elektrische Daten

Hilfsenergie U

B

Einuss der Hilfsenergie

Zulässige Restwelligkeit

Ausgangssignal

Zulässige max. Bürde R

für Variante 1 - 3

Bürdeneinuss

(Variante 1 - 3)

Elektrischer Nullpunkt

■

Langzeitstabilität

Elektronik

■

Elektr. Ausgangssignal ≤ 2,5 % der Messspanne (Option ≤ 1,6 %)

Kennlinienabweichung

Elektrischer Anschluss über Winkelsteckverbinder, 180 ° verdrehbar,

Schutzart Winkelsteckverbinder: IP 65 nach EN 60529 /

EMV-Richtlinie 2007/108/EG Störaussendung (Grenzwertklasse

DC V

% v. EW/10 V

% ss

Variante 1

Variante 3

Variante 4

A

% vom EW

% vom EW/a

% d. Spanne

12 < UB ≤ 30

≤ 0,1

≤ 10

4 … 20 mA, 2-Leiter, passiv, nach NAMUR NE 43

0 ... 20 mA, 3-Leiter

0 ... 10 V, 3-Leiter

RA ≤ (UB - 12 V)/0,02 A mit RA in Ohm und UB in

Volt, jedoch max. 600 Ω

≤ 0,1

durch Überbrückung der Klemmen 5 und 6

(siehe Betriebsanleitung)

< 0,3

≤ 2,5 % (Option ≤ 1,6 %), Grenzpunkteinstellung

Drahtschutz, Kabelverschraubung M20 x 1,5,

inkl. Zugentlastung, Anschlusskabel:

Außendurchmesser 7 ... 13 mm, Leiterquerschnitt

0,14 ... 1,5 mm2, Temperaturbeständigkeit bis 70 °C

IEC 60529

B) und Störfestigkeit nach EN 61 326-1

D

Als Hilfsenergie genügt eine unstabilisierte Gleichspannung im Bereich der

angegebenen Grenzen. Es ist darauf zu achten, dass die angelegte Hilfsenergie

um den Betrag höher ist als die maximal erforderliche Spannung, die an den

externen Anzeige- und Auswertegeräten abfällt, d. h. dass die am Druckmessum-

former anliegende Spannung nicht unter 10 V abfällt.

14093267.01 03/2014 GB/D/F/E

WIKA Betriebsanleitung Dierenzdruck-Messumformer, Typ DPGT40 27

Page 28

3. Technische Daten

Belegung der Anschlussklemmen

Die genauen Anschlussbelegungen können den nachfolgenden Zeichnungen

entnommen werden. Zusätzlich sind Anschlussbelegung, Ausgangssignal und

erforderliche Hilfsenergie auf dem Typenschild vermerkt.

Die folgende Darstellung zeigt die Standard-Klemmenbelegung.

D

Bei kundenspezischen Ausführungen ist die Klemmenbelegung auf dem

Typenschild zu beachten.

Zweileitersystem

4 … 20 mA

Erde, verbunden

Hilfsenergie

Auswertung

(Anzeige)

mit Gehäuse

UB+/I+

0 V/GND

Klemmen 3 und 4: nur für internen Gebrauch

Klemmen 5 und 6: Nullpunkt zurücksetzen

1)

Dreileitersystem

0 … 20 mA, 4 … 20 mA und 0 ... 10 V

Hilfsenergie

Auswertung

(Anzeige)

Erde, verbunden

mit Gehäuse

U

B

Sig+

0 V/Sig-/GND

1) Dieser Anschluss darf nicht für

den Potentialausgleich verwendet

werden. Das Gerät muss über

den Prozessanschluss in den

Potentialausgleich einbezogen werden.

1)

+

Bedeutung der verwendeten Klemmenbezeichnungen:

UB+ Plusklemme der Hilfsenergie

0 V/Sig-/GND Minusklemme der Hilfsenergie und des Ausgangssignals

Sig+ Plusklemme des Ausgangssignals

I+ Ausgangssignal

Weitere technische Daten siehe jeweiliges Typenschild, WIKA-Datenblatt und

Bestellunterlagen.

14093267.01 03/2014 GB/D/F/E

WIKA Betriebsanleitung Dierenzdruck-Messumformer, Typ DPGT4028

Page 29

4. Aufbau und Funktion

4. Aufbau und Funktion

4.1 Beschreibung

In den Messstokammern ⊕ und ⊖, die durch eine elastische Membrane (1)

getrennt sind, herrschen die Drücke p

und p2.

1

D

Der Dierenzdruck (Δp = p

Membrane gegen die Messbereichsfedern (2).

Der dem Dierenzdruck proportionale Messweg wird über einen Kipphebel (3)

druckdicht und reibungsarm in das Anzeigegehäuse auf das Zeigerwerk (4)

übertragen.

Ein rückseitig am Zeigerwerk befestigter Magnet (5) beeinusst das

elektromagnetische Feld des HALL-Sensors. Das dabei entstehende Signal wird

durch die Signalverarbeitungsplatine (6) in ein normiertes Stromausgangssignal

gewandelt.

Die Überlastsicherheit wird durch Anlage der elastischen Membrane an

metallische Stützächen (7) erreicht.

- p2) bewirkt eine axiale Auslenkung (Messweg) der

1

14077606.01

⊖ ⊕

4.2 Lieferumfang

Lieferumfang mit dem Lieferschein abgleichen.

14093267.01 03/2014 GB/D/F/E

WIKA Betriebsanleitung Dierenzdruck-Messumformer, Typ DPGT40 29

Page 30

5. Transport, Verpackung und Lagerung

5. Transport, Verpackung und Lagerung

5.1 Transport

Dierenzdruck-Messumformer auf eventuell vorhandene Transportschäden

untersuchen. Oensichtliche Schäden unverzüglich mitteilen.

D

5.2 Verpackung

Verpackung erst unmittelbar vor der Montage entfernen.

Die Verpackung aufbewahren, denn diese bietet bei einem Transport einen

optimalen Schutz (z. B. wechselnder Einbauort, Reparatursendung).

5.3 Lagerung

Zulässige Bedingungen am Lagerort

Lagertemperatur: -40 ... +70 °C

Um Schäden zu vermeiden, sind für die Lagerung der DierenzdruckMessumformer folgende Punkte zu beachten:

■

Messgeräte in der Originalverpackung belassen

■

Nach einer eventuellen Entnahme der Messgeräte für z. B. Prüfungen, sollte

das Gerät wieder in der Originalverpackung eingelagert werden

Vermeiden Sie folgende Einüsse:

■

Direktes Sonnenlicht oder Nähe zu heißen Gegenständen

■

Mechanische Vibration, mechanischer Schock (hartes Aufstellen)

■

Ruß, Dampf, Staub, Feuchtigkeit und korrosive Gase

■

Explosionsgefährdete Umgebung, entzündliche Atmosphäre

WARNUNG!

Vor der Einlagerung des Gerätes müssen alle ggf. anhaftenden

Messstoreste entfernt werden. Dies ist besonders wichtig, wenn

das Medium gesundheitsgefährdend ist, wie z. B. ätzend, giftig,

krebserregend, radioaktiv, usw.

WIKA Betriebsanleitung Dierenzdruck-Messumformer, Typ DPGT4030

14093267.01 03/2014 GB/D/F/E

Page 31

6. Inbetriebnahme, Betrieb

6. Inbetriebnahme, Betrieb

6.1 Mechanischer Anschluss

■

Entsprechend den allgemeinen technischen Regeln für Druckmessgeräte

(z. B. EN 837-2 "Auswahl- und Einbauempfehlungen für Druckmessgeräte").

■

Montage der Druckanschlüsse nach angebrachten Symbolen,

⊕ hoher Druck, ⊖ niedriger Druck

■

Befestigung über:

- starre Messleitung oder

- Wandbefestigung über vorhandene Montagelaschen

■

Prozessanschlüsse 2 x G 1/4 lnnengewinde, Anschlusslage unten,

hintereinander, Achsabstand 26 mm, Gebrauchslage NL 90 nach DIN 16257

(d.h. Zierblatt senkrecht), Gewinde der Anschlusszapfen vorzugsweise nach

EN 837-3 (Abschnitt 7.3.2) ausführen.

■

Messleitungen vor der Gerätemontage gründlich durch Abklopfen und

Ausblasen oder Durchspülen reinigen

■

Messgeräte vor Verschmutzung und starken Temperaturschwankungen

schützen!

■

Das Druckmessgerät muss erschütterungsfrei befestigt werden und soll gut

ablesbar angeordnet sein. Es empehlt sich, zwischen Druckentnahmestelle

und Druckmessgerät eine Absperrvorrichtung zwischenzuschalten, die einen

Austausch des Messgerätes und eine Nullpunktkontrolle bei laufender Anlage

ermöglicht. Die Geräte sind vor grober Verschmutzung und starken Schwan-

kungen der Umgebungstemperatur zu schützen.

D

■

Zur Abdichtung der Anschlüsse sind Flachdichtungen, Dichtlinsen oder

WIKA-Proldichtungen einzusetzen. Um das Druckmessgerät in die Stellung

zu bringen, in der sich die örtliche Anzeige am besten ablesen lässt, ist ein

Anschluss mit Spannmue oder Überwurfmutter zu empfehlen. Beim Ein- und

Ausschrauben dürfen die Druckmessgeräte nicht am Gehäuse angezogen

werden, sondern nur an den Schlüsselächen des Anschlussstutzens!

Wandmontage

Befestigung über drei angegossene Befestigungslaschen

14093267.01 03/2014 GB/D/F/E

WIKA Betriebsanleitung Dierenzdruck-Messumformer, Typ DPGT40 31

Page 32

6. Inbetriebnahme, Betrieb

Messanordnungen

Bewährte Messanordnungen für verschiedene Messstoarten. Die zur Anwendung besonders empfohlenen Anordnungen sind nachfolgend dargestellt.

flüssige Messstoffe gasförmige Messstoffe

Füllung der

D

Messleitung

Beispiele

Druckmessgerät oberhalb des

Entnahmestutzens

flüssig zum Teil

ausgasend

Kondensat siedende

Flüssigkeiten

vollständig

verdampft

„Flüssiggase“

gasförmig zum Teil

trockene

Luft

kondensiert

(feucht)

feuchte Luft

Rauchgase

vollständig

kondensiert

Wasserdampf

Druckmessgerät unterhalb des

Entnahmestutzens

Abmessungen in mm

WIKA Betriebsanleitung Dierenzdruck-Messumformer, Typ DPGT4032

14078303.01

14093267.01 03/2014 GB/D/F/E

Page 33

6. Inbetriebnahme, Betrieb

Messanordnungen

Die zu bevorzugenden Messanordnungen für verschiedene Einsatzmöglichkeiten

sind in DIN 19216 beschrieben.

Die nachfolgende Prinzipdarstellung zeigt eine empfohlene Anordnung bei

üssigen Messstoen. Als Drosselgeräte sind Wirkdruckgeber nach DIN 1952

(Ausgabe 07.82) ersetzt durch EN 5167/1 vorzusehen.

Die Wirkdruckleitungen müssen aus Metall gefertigt sein, ihre lichte Weite darf

4 mm nicht unterschreiten und die gestreckte Länge zwischen Ventilblock und

Dierenzdruck-Messumformer muss mindestens 500 mm betragen.

D

Außerdem sind Länge und lichte Weite

der Wirkdruckleitungen so zu bemessen,

dass bei kalter Leitung die Ansprechzeit

des Druckmessgerätes nicht mehr als

Wirkdruckgeber

(Drosselgerät in der

Prozessleitung)

5 Sekunden beträgt.

Die Verbindungen der Wirkdruckleitungen

Wirkdruckleitung

müssen verschweißt, hartgelötet oder mit

metallischen Dichtelementen verschraubt

werden.

Absperrarmaturen

(Ventilblock)

Absperrarmaturen in Wirkdruckleitungen

dürfen nur mit Werkzeugen zu betätigen

sein.

Wirkdruckmessgerät

(DELTA-trans)

Sicherheitshinweise bei Installation

■

Installations- und Sicherheitshinweise der Betriebsanleitung

beachten.

■

Geräte gemäß Herstellerangaben und den gültigen Normen

und Regeln installieren.

■

In den Geräten sind keine Überstrom-Schutzeinrichtungen eingebaut!

Nach Herstellen der Druckverbindung und der elektrischen Anschlüsse sind die

Druckmessumformer sofort betriebsbereit.

Inbetriebnahme

Bei Inbetriebnahme Druckstöße unbedingt vermeiden, Absperrventile langsam

önen.

14093267.01 03/2014 GB/D/F/E

WIKA Betriebsanleitung Dierenzdruck-Messumformer, Typ DPGT40 33

Page 34

6. Inbetriebnahme, Betrieb

6.2 Elektrischer Nullpunkt (4 mA)

Die Nullpunkteinstellung erfolgt über eine frontseitige Einstellschraube, welche je nach

Gerätetyp durch Lösen der Sichtscheibe bzw. der Verschlussschraube zugänglich ist.

Durch Drehen der Einstellschraube mit einem Schraubendreher wird der gewünschte

Nullpunkt eingestellt.

Wird der mechanische Nullpunkt über die Einstellschrau-

D

be verändert, muss der elektrische Nullpunkt wieder dem

mechanischen angepasst werden.

Hierzu den Dierenzdruck-Messumformer zuerst in den

drucklosen Zustand bringen.

Die ganze Kabelhaube an der rechten Messumformerseite lösen. Dazu mit einem Schlitzschraubendreher

(0,6 x 3,5 mm) die Schraube an der Oberseite des

Kabelhaubendeckels vollständig lösen. Die Schraube

herausnehmen. Die Kabelhaube samt Buchseneinsatz

vom Kabeldosenunterteil abziehen.

Damit ist der Messumformer von der Spannungsversorgung getrennt.

Kabelhaubendeckel von der Kabelhaube entfernen

und den Buchseneinsatz ganz durch die Kabelhaube

nach unten herausdrücken.

Die Kontakte 5 und 6 an dem Buchseneinsatz mit einem

kurzen, an beiden Enden abisolierten Stück Litze (maximal

zulässiger Widerstand 30 Ω) überbrücken.

Den Stecker wieder in umgekehrter Reihenfolge montieren.

Den Stecker mit montiertem Stück Litzendraht auf den

Stifteinsatz stecken. Damit ist die Spannungsversorgung

wieder hergestellt.

Innerhalb von max. 30 Sekunden wird der neue Nullpunkt

in der Elektronik gespeichert. Während dieser Zeit steigt

der Strom in der Schleife auf 9,5 mA.

Der neue Nullpunkt bleibt auch bei Spannungsausfall auf

Dauer gespeichert.

Den Stecker in der oben beschriebenen Reihenfolge

wieder lösen und das Stück Litzendraht entfernen. Nach

erneutem Montieren des Steckers ist das elektrische Ausgangssignal wieder deckungsgleich mit der Anzeige des

mechanischen Zeigers.

Damit die Schutzart erhalten

bleibt, unbedingt die Dichtungen

wieder montieren.

WIKA Betriebsanleitung Dierenzdruck-Messumformer, Typ DPGT4034

Schraube

Kabelhaubendeckel

Kabelhaube

Buchseneinsatz

Kabeldosenunterteil

Dichtungen

14093267.01 03/2014 GB/D/F/E

Page 35

6. Inbetriebnahme, Betrieb / 7. Optionen und Zubehör

6.3 Spannungsversorgung einrichten

Die Spannungsversorgung erfolgt über Speise- oder Steuergeräte, die über eine

Energiebegrenzung verfügen.

Die Versorgung des Druckmessumformers muss durch einen energiebegrenzten Stromkreis gemäß 9.3 der UL/EN/IEC 61010-1 oder LPS gemäß UL/EN/IEC

60950-1 oder Class 2 gemäß UL1310/UL1585 (NEC oder CEC) erfolgen. Die

Stromversorgung muss für den Betrieb oberhalb 2.000 m geeignet sein, falls der

Druckmessumformer ab dieser Höhe verwendet wird.

7. Optionen und Zubehör

7.1 Vierfach-Ventilblock

■

Absperrung der ⊕- und ⊖-Prozessleitung zur Demontage oder Prüfung des

Messgerätes ohne Störung des laufenden Betriebsprozesses.

Schutz des Gerätes gegen unzulässige

Überdruckbelastung, wie z. B. bei

Druckprüfungen und undenierten

Betriebsverhältnissen (auch zeitweiliger

Stilllegung).

■

Druckausgleich zur Nullpunktkontrolle

bei laufendem Prozess sowie Vermeidung

einseitiger Überdruckbelastung während der

Anfahr- bzw. Betriebsphase (bei geönetem

Druckausgleichsventil).

Absperrventil

⊕-Seite

Druckaus-

gleichsventil

D

■

Entlüftung der Messleitungen bei üssigen

Messstoen und Spülung der Messlei-

tungen, um Verunreinigungen zu entfernen.

Absperrventil

⊖-Seite

Entlüftungsventil

Angaben zum Handling

■

Arbeitsgangfolge zum Messanfang

1. Druckausgleichsventil (mittlere Ventilspindel) önen

2. Absperrventil der Minus-Messstokammer (⊖, rechtes Ventil) und der PlusMessstokammer (⊕, linkes Ventil) önen

3. Druckausgleichsventil schließen

■

Arbeitsgangfolge zum Spülen/Entlüften der Messleitungen

1. Anfang: Absperrventil der ⊕- und ⊖-Messstokammer önen, Druckaus-

gleichsventil und Entlüftungsventil önen

2. Ende: Druckausgleichsventil und Entlüftungsventil schließen

14093267.01 03/2014 GB/D/F/E

WIKA Betriebsanleitung Dierenzdruck-Messumformer, Typ DPGT40 35

Page 36

7. Optionen und Zubehör / 8. Wartung

■

Arbeitsgangfolge zu Messende (auch zeitweise Stilllegung)

1. Druckausgleichsventil önen

2. Absperrventil der ⊕- und ⊖-Messstokammer schließen

■

Arbeitsgangfolge zur Demontage des Messgerätes bei laufenden Prozess

D

1. Absperrventil der ⊕- und ⊖-Messstokammer schließen

2. Entlüftungsventil önen

7.2 Befestigungsrand für Schalttafelmontage

Ausschnitt

Schalttafel

14078276.01

8. Wartung

Die Geräte sind wartungsfrei.

Eine Überprüfung der Anzeige und der Schaltfunktion sollte etwa 1 bis 2 mal pro

Jahr erfolgen. Dazu ist das Gerät vom Prozess zu trennen und mit einer Druckprüfvorrichtung zu kontrollieren.

Reparaturen sind ausschließlich vom Hersteller durchzuführen.

WIKA Betriebsanleitung Dierenzdruck-Messumformer, Typ DPGT4036

14093267.01 03/2014 GB/D/F/E

Page 37

9. Demontage, Rücksendung und Entsorgung

9. Demontage, Rücksendung und Entsorgung

WARNUNG!

Messstoreste in ausgebauten Messgeräten können zur

Gefährdung von Personen, Umwelt und Einrichtung führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

9.1 Demontage

Messgerät nur im drucklosen und spannungsfreiem Zustand demontieren!

Gegebenenfalls muss die Messleitung entspannt werden.

9.2 Rücksendung

Ausgebautes Messgerät vor der Rücksendung spülen bzw. säubern, um

Mitarbeiter und Umwelt vor Gefährdung durch anhaftende Messstoreste zu

schützen.

9.3 Entsorgung

Durch falsche Entsorgung können Gefahren für die Umwelt entstehen.

Gerätekomponenten und Verpackungsmaterialien entsprechend den

landesspezischen Abfallbehandlungs- und Entsorgungsvorschriften

umweltgerecht entsorgen.

D

14093267.01 03/2014 GB/D/F/E

WIKA Betriebsanleitung Dierenzdruck-Messumformer, Typ DPGT40 37

Page 38

Anlage 1: EG-Konformitätserklärung

D

14093267.01 03/2014 GB/D/F/E

WIKA Betriebsanleitung Dierenzdruck-Messumformer, Typ DPGT4038

Page 39

Sommaire

Sommaire

1. Généralités 40

2. Sécurité 41

3. Spécications 44

4. Conception et fonction 47

5. Transport, emballage et stockage 48

6. Mise en service, utilisation 49

7. Options et accessoires 53

8. Entretien 54

9. Démontage, retour et mise au rebut 55

Annexe 1 : Déclaration de conformité CE 56

F

14093267.01 03/2014 GB/D/F/E

39WIKA mode d‘emploi transmetteur de pression diérentielle, type DPGT40

Page 40

1. Généralités

1. Généralités

■

Les transmetteurs de pression diérentielle décrits dans le mode d'emploi

sont conçus et fabriqués selon les dernières technologies en vigueur. Tous les

composants sont soumis à des critères de qualité et d'environnement stricts

durant la fabrication. Nos systèmes de gestion sont certiés selon ISO 9001 et

ISO 14001.

■

Ce mode d'emploi donne des indications importantes concernant l'utilisation

F

de l'instrument. Il est possible de travailler en toute sécurité avec ce produit en

respectant toutes les consignes de sécurité et d'utilisation.

■

Respecter les prescriptions locales de prévention contre les accidents et les

prescriptions générales de sécurité en vigueur pour le domaine d'application

de l'instrument.

■

Le mode d'emploi fait partie de l'instrument et doit être conservé à proximité

immédiate de l'instrument et accessible à tout moment pour le personnel

qualié.

■

Le personnel qualié doit, avant de commencer toute opération, avoir lu

soigneusement et compris le mode d'emploi.

■

La responsabilité du fabricant n'est pas engagée en cas de dommages

provoqués par une utilisation non conforme à l'usage prévu, de non respect de

ce mode d'emploi, d'utilisation de personnel peu qualié de même qu'en cas

de modications de l'instrument eectuées par l'utilisateur.

■

Les conditions générales de vente mentionnées dans les documents de vente

s'appliquent.

■

Sous réserve de modications techniques.

■

Pour obtenir d'autres informations :

- Consulter notre site Internet : www.wika.fr

- Fiche technique correspondante : PV 17.19

Explication des symboles

AVERTISSEMENT !

… indique une situation présentant des risques susceptibles

de provoquer la mort ou des blessures graves si elle n'est pas

évitée.

Information

... met en exergue les conseils et recommandations utiles

de même que les informations permettant d'assurer un

fonctionnement ecace et normal.

WIKA mode d‘emploi transmetteur de pression diérentielle, type DPGT4040

14093267.01 03/2014 GB/D/F/E

Page 41

1. Généralités / 2. Sécurité

2. Sécurité

AVERTISSEMENT !

Avant le montage, la mise en service et le fonctionnement,

s'assurer que le transmetteur de pression diérentielle a été

choisie de façon adéquate, en ce qui concerne la plage de

mesure, la version et les conditions de mesure spéciques.

Vérier si les matériaux soumis à la pression sont compatibles

avec le uide de mesure !

Les limites de surpression admissible sont à respecter an

d'assurer la précision et la durée de vie.

Toutes les interventions doivent être eectuées hors tension.

Un non respect de cette consigne peut entraîner des blessures

corporelles graves et/ou des dégâts matériels.

Vous trouverez d'autres consignes de sécurité dans les sections

individuelles du présent mode d'emploi.

2.1 Utilisation conforme à l'usage prévu

Les transmetteurs de pression diérentielle de la ligne de produits DELTA-line

sont utilisés d'abord pour la surveillance de pressions diérentielles basses

comportant de hautes exigences en termes de pression sur un côté et de

pression statique.

Les débouchés typiques pour ces produits sont la construction navale, la

technologie de chauage de process, les industries du chauage, de la ventilation

et de la climatisation, de l'eau et des eaux usées, et de la construction de

machines et d'installations. Pour celles-ci, la fonction principale des instruments

de mesure et la surveillance de ltres, de compresseurs et de pompes.

L'instrument est conçu et construit exclusivement pour une utilisation conforme à

l'usage prévu décrit ici et ne doit être utilisé qu'en conséquence.

F

Aucune réclamation ne peut être recevable en cas d'utilisation non conforme à

l'usage prévu.

14093267.01 03/2014 GB/D/F/E

41WIKA mode d‘emploi transmetteur de pression diérentielle, type DPGT40

Page 42

2. Sécurité

2.2 Qualication du personnel

AVERTISSEMENT !

Danger de blessure en cas de qualication insusante !

Une utilisation non conforme peut entraîner d'importants

dommages corporels et matériels.

■

Les opérations décrites dans ce mode d'emploi ne doivent

être eectuées que par un personnel ayant la qualication

décrite ci-après.

F

Personnel qualié

Le personnel qualié est, en raison de sa formation spécialisée, de ses

connaissances dans le domaine de la technique de mesure et de régulation et de

ses expériences de même que de sa connaissance des prescriptions nationales,

des normes et directives en vigueur, en mesure d'eectuer les travaux décrits et

de reconnaître automatiquement les dangers potentiels.

2.3 Dangers particuliers

AVERTISSEMENT !

Dans le cas de uides de mesure dangereux comme notamment

l'oxygène, l'acétylène, les substances combustibles ou toxiques,

ainsi que dans le cas d'installations de réfrigération, de

compresseurs etc., les directives appropriées existantes doivent

être observées en plus de l'ensemble des règles générales.

AVERTISSEMENT !

Les restes de uides se trouvant dans des instruments de

mesure démontés peuvent mettre en danger les personnes,

l'environnement ainsi que l'installation.

Prendre des mesures de sécurité susantes.

WIKA mode d‘emploi transmetteur de pression diérentielle, type DPGT4042

14093267.01 03/2014 GB/D/F/E

Page 43

2. Sécurité

2.4 Etiquetage / marquages de sécurité

Plaque signalétique

Etendue de

mesure

Signal de sortie

Alimentation

1) A = signal de sortie 4 ... 20 mA, 2 ls

E = signal de sortie 4 ... 20 mA, 2 ls, ATEX Ex II 2G Ex ib IIC T4 / T5 / T6

B = signal de sortie 0 ... 20 mA, 3 ls

F = signal de sortie 0 ... 10 V, 3 ls

Explication des symboles

Lire impérativement le mode d'emploi avant le montage et la

mise en service de l'instrument !

CE, Communauté Européenne

Les instruments avec ce marquage sont conformes aux directives

européennes pertinentes.

Signal de sortie

Conguration du

raccordement

1)

F

Date de

fabrication

14093267.01 03/2014 GB/D/F/E

43WIKA mode d‘emploi transmetteur de pression diérentielle, type DPGT40

Page 44

3. Spécications

3. Spécications

Spécications DELTA-trans type DPGT40

Données mécaniques

Diamètre Indication de pression diérentielle: Ø 100 mm

Indication de la pression de service: Ø 22 mm

Classe de précision Indication de pression diérentielle: ≤ 2,5 % de

F

Etendues de mesure (EN 837) Pression diérentielle: 0 ... 0,25 à 0 ... 10 bar

Pression de service max. (stat.) 25 bar

Surpression admissible De chaque côté maxi. 25 bar

Températures admissibles Ambiante : -10 … +70 °C, uide : -10 ... +90 °C

Indice de protection IP 54 selon EN 60529 / CEI 60529

Chambre du uide

(en contact avec le uide)

Raccordement process

(contact avec uide)

Organe moteur

(en contact avec le uide)

Liaisons

(en contact avec le uide)

Joints d'étanchéité

(en contact avec le uide)

Mouvement Alliage de cuivre, pièces d'usure en argentan

Cadran Indication de la pression diérentielle et de la pression

Aiguille Indication de la pression diérentielle et de la pression

Réglage du zéro pour l'indication

de pression diérentielle

Boîtier Aluminium, EN AC–Al Si9Cu3(Fe), peint en noir

Voyant Plastique

Poids env. 1,3 kg

l'échelle (option ≤ 1,6 %)

Indication de la pression de service: 4

Pression de service: 0 ... 25 bar

Stockage: -40 ... +70 °C

Aluminium, EN AC–Al Si9Cu3(Fe), peint en noir

2 x G 1/4, femelle, raccord vertical (LM), en ligne,

distance au centre 26 mm

Pression diérentielle : ressorts de compression en

acier inox 1.4310 et membrane de séparation en

FPM/FKM (en option: NBR)

Pression de service : tube de Bourdon en alliage de

cuivre

Acier inox 1.4301, 1.4305, 1.4310, FPM/FKM

(option : NBR)

FPM/FKM (option: NBR)

de service: cadran blanc, inscriptions en caractères

noirs

de service: aiguille bleue

Au moyen de la vis située sur le cadran

14093267.01 03/2014 GB/D/F/E

WIKA mode d‘emploi transmetteur de pression diérentielle, type DPGT4044

Page 45

3. Spécications

Données électriques

Alimentation U

B

Inuence de

l'alimentation

Ondulation résiduelle

admissible

Signal de sortie

Charge maximale

autorisée R

pour

A

exécutions 1 - 3

Eet de charge

(exécution 1 - 3)

Point zéro électrique

■

Stabilité à long terme

de l'électronique

■

Signal de sortie

électrique

Linéarité

VDC

% FS/10 V

% ss

Exécution 1

Exécution 3

Exécution 4

% EM

% FS/a

% de

l'échelle

12 < UB ≤ 30

≤ 0,1

≤ 10

4 … 20 mA, 2 ls, passif, selon NAMUR NE 43

0 ... 20 mA, 3 ls

0 ... 10 V, 3 ls

RA ≤ (UB - 12 V)/0,02 A avec RA en ohms et UB en

volts, quoi qu'il en soit max. 600 Ω

≤ 0,1

par un cavalier à travers les bornes 5 et 6

(voir le mode d'emploi)

< 0,3

≤ 2,5 % d’intervalle de mesure (option ≤ 1,6 %)

≤ 2,5 % (option ≤ 1,6 %), méthode des bornes

Raccordement électrique par connecteur coudé, pivotant sur 180°, protection

de l, presse-étoupe M20 x 1,5, y compris la

compensation de contrainte, câble de connexion :

diamètre extérieur du câble 7 à 13 mm, diamètre

du conducteur 0,14 ... 1,5 mm

2

, résistance à la

température jusqu'à 70 °C

Indice de protection Connecteur coudé : IP 65 selon EN 60529 /

CEI 60529

Directive CEM 2007/108/EC émission d'interférences (classe de

valeur limite B) et immunité selon EN 61 326-1

F

Comme alimentation électrique, une alimentation non stabilisée DC est

susante dans l'étendue des limites spéciées. Il est important de s'assurer

que l'alimentation électrique appliquée est au moins supérieure à la baisse

de tension maximum requise provenant des unités d'achage externe et

d'évaluation; la tension au transmetteur de pression ne doit donc pas tomber

en-dessous de 10 V.

14093267.01 03/2014 GB/D/F/E

45WIKA mode d‘emploi transmetteur de pression diérentielle, type DPGT40

Page 46

3. Spécications

Désignation des bornes de raccordement

La distribution exacte des plots se trouve dans les dessins ci-dessous. En outre, la

distribution des plots, le signal de sortie et l'alimentation électrique sont marqués

sur la plaque signalétique du produit.

Le diagramme suivant indique la distribution standard des bornes. Pour des

versions spéciques au client, la distribution des bornes se trouvant sur l'étiquette

du produit doit être respectée.

F

Système à 2 ls

4 ... 20 mA

Système à 3 ls

0 … 20 mA, 4 … 20 mA et 0 ... 10 V

Alimentation

Evaluation

(achage)

Terre, reliée au

boîtier 1)

UB+/I+

0 V/GND

Bornes 3 et 4 : pour usage interne seulement

Bornes 5 et 6 : réinitialiser le point zéro

Alimentation

Evaluation

(achage)

Terre, reliée au

boîtier 1)

U

+

B

Sig+

0 V/Sig-/GND

1) Ce raccordement ne doit pas être

utilisé pour une liaison équipotentielle.

L'instrument doit être intégré dans la

liaison équipotentielle via le raccord

process.

Explication de la distribution des bornes utilisées :

UB+ Borne positive de l'alimentation électrique

0 V/Sig-/GND Borne négative de l'alimentation électrique et du signal de sortie

Sig+ Borne positive du signal de sortie

I+ Signal de sortie

Pour de plus amples spécications, voir la plaque signalétique correspondante,

la che technique WIKA et la documentation de commande.

14093267.01 03/2014 GB/D/F/E

WIKA mode d‘emploi transmetteur de pression diérentielle, type DPGT4046

Page 47

4. Conception et fonction

4. Conception et fonction

4.1 Description

Les pressions p1 et p2 s'exercent sur les chambres ⊕ et ⊖ qui sont séparées par

une membrane élastique (1).

La pression diérentielle (Δp = p

(course de mesure) contre les ressorts (2) liés à l'étendue de mesure.

La déformation, qui est proportionnelle à la pression diérentielle, est transmise

au mouvement (4) dans le boîtier d'indication par l'intermédiaire d'un arbre à

cames à faible frottement (3) et garantissant l'étanchéité du système.

Un aimant (5), xé à l'arrière du mouvement, aecte le champ électromagnétique

du capteur HALL. Le signal qui en résulte est converti en un signal de sortie de

courant standardisé par la platine de conditionnement des signaux (6).

La protection contre les surpressions est assurée par des renforts prolés (7) pour

la membrane élastique.

Lorsqu'on règle le point zéro sur l'achage mécanique, le signal de sortie doit être

mis à zéro.

- p2) provoque un déplacement de la membrane

1

14077606,01

⊖ ⊕

F

4.2 Détail de la livraison

Comparer le détail de la livraison avec le bordereau de livraison.

14093267.01 03/2014 GB/D/F/E

47WIKA mode d‘emploi transmetteur de pression diérentielle, type DPGT40

Page 48

5. Transport, emballage et stockage

5. Transport, emballage et stockage

5.1 Transport

Vérier s'il existe des dégâts sur le transmetteur liés au transport. Communiquer

immédiatement les dégâts constatés.

5.2 Emballage

N'enlever l'emballage qu'avant le montage.

Conserver l'emballage, celui-ci ore, lors d'un transport, une protection optimale

F

(par ex. changement de lieu d'utilisation, renvoi pour réparation).

5.3 Stockage

Conditions admissibles sur le lieu de stockage

Température de stockage : -40 ... +70 °C

An d'éviter des dommages, il faut respecter les points suivants concernant le stockage des transmetteurs :

■

Laisser les instruments de mesure dans leur emballage d'origine

■

Suite à tout déplacement éventuel des instruments de mesure, par exemple

pour des essais, l'instrument doit à nouveau être stocké dans son emballage

d'origine

Eviter les inuences suivantes :

■

Lumière solaire directe ou proximité d'objets chauds

■

Vibrations mécaniques, chocs mécaniques (mouvements brusques en le

posant)

■

Suie, vapeur, poussière, humidité et gaz corrosifs

■

Environnements présentant des risques d'explosion, atmosphères inammables

AVERTISSEMENT !

Enlever tous les restes de uides adhérents avant l'entreposage

de l'instrument. Ceci est particulièrement important lorsque le

uide représente un danger pour la santé, comme p. ex. des

substances corrosives, toxiques, cancérogènes, radioactives

etc.

WIKA mode d‘emploi transmetteur de pression diérentielle, type DPGT4048

14093267.01 03/2014 GB/D/F/E

Page 49

6. Mise en service, utilisation

6. Mise en service, utilisation

6.1 Raccordement mécanique

■

Conformément aux règles techniques générales pour les manomètres (par ex.

EN 837-2 “Recommandations sur le choix et l'installation des manomètres”).

■

Installation des connexions de pression suivant les symboles apposés, ⊕

pression haute, ⊖ pression basse

■

Montage au moyen de :

- conduit rigide de mesure ou

- montage sur paroi avec liens xx d'installation disponibles

■

Raccords process 2 x G 1/4 femelle, raccord vertical (LM), en ligne, distance

au centre 26 mm, position de fonctionnement NL 90 (position nominale) selon

DIN 16257 (c'est-à-dire cadran vertical), conception des letages du raccord

de pression en conformité avec la norme EN 837-3 (section 7.3.2).

■

Avant d'installer le manomètre, nettoyer les conduites de mesure en tapant et

en souant ou en rinçant

■

Protégez les instruments de mesure contre la contamination et les variations

de température élevées !

■

Le manomètre doit être monté sans entraîner de vibrations et doit être aligné

de façon qu'il puisse être bien lu. Il est recommandé qu'un dispositif d'isolation

soit interposé entre le point de mesure de la pression et le manomètre, ce

qui permet le remplacement du manomètre et un contrôle du point zéro lors

du fonctionnement de l'installation. Les instruments doivent être protégés

contre un encrassement important et contre les uctuations de la température

ambiante.

F

■

Pour assurer l'étanchéité des raccords, il faut utiliser des joints plats, des

bagues d'étanchéité ou les joints à écrasement WIKA. Pour orienter le

manomètre de sorte que l'achage local peut être lu aussi bien que possible,

un manchon de serrage ou un écrou à chapeau doit être utilisé. Lors du

vissage et dévissage, les manomètres ne doivent pas être saisis par le boîtier,

mais uniquement sur les pans à clé du raccordement !

Montage mural

Installation utilisant trois languettes de xation coulées d'un seul tenant

14093267.01 03/2014 GB/D/F/E

49WIKA mode d‘emploi transmetteur de pression diérentielle, type DPGT40

Page 50

6. Mise en service, utilisation

Installations de mesure

Installations de mesure éprouvées pour diérents types de uides. Les installations qui sont particulièrement recommandées sont indiquées ci-dessous.

Remplissage de la

conduite de

mesure

F

Exemples

Manomètre

au-dessus

du point de

mesure

Manomètre

en-dessous

du point de

mesure

Dimensions en mm

fluides liquides fluides gazeux

liquide liquide

condensat

avec

vapeur

liquide en

ébullition

vapeur

seulement

“gaz liq-

uéés”

gazeux partiellement

air sec

condensé

(humide)

air humide

gaz de combustion

complètement

condensé

Vapeur

14078303,01

14093267.01 03/2014 GB/D/F/E

WIKA mode d‘emploi transmetteur de pression diérentielle, type DPGT4050

Page 51

6. Mise en service, utilisation

Installations de mesure

Les installations de mesure préconisées pour diverses applications possibles sont

spéciées dans DIN 19216.

Le diagramme schématique suivant montre une installation recommandée pour

des uides liquides. En tant que dispositifs d'étranglement, les transducteurs de

pression diérentielle doivent être fournis en accord avec la norme DIN 1952

(édition 07.82), maintenant remplacée par EN 5167/1.

Les lignes de pression diérentielle doivent être en métal, leur orice ne doit pas

être inférieur à 4 mm et la longueur eective entre le collecteur de soupape et le

transmetteur de pression diérentielle doit être d'au moins 500 mm.

En outre, la longueur et l'orice des lignes

de pression doivent être tels que, avec

des lignes froides, le temps de réponse

du manomètre de pression ne dépasse

Transducteur de pression

diérentielle

(dispositif d'étranglement

dans la ligne de process)

pas 5 secondes.

Les connexions des lignes de pression

Ligne de pression

diérentielle

diérentielle doivent être soudées,

brasées ou vissées au moyen d'éléments

d'étanchéité en métal.

Robinets d'isolement

(manifold)

Les soupapes de fermeture des lignes

de pression diérentielle ne doivent être

manipulées qu'avec des outils.

Instrument de pression

diérentielle

(DELTA-trans)

Consignes de sécurité pour l'installation

■

Suivre les instructions d'installation et de sécurité

mentionnées dans les instructions d'utilisation.

■

Installer les instruments conformément aux instructions du

fabricant et aux normes et réglementations en vigueur.

■

Aucun dispositif de protection de surtension n‘est installé dans les instruments !

F

Une fois que la connexion de pression et les connexions électriques ont été

établies, les transmetteurs de pression sont prêts pour un usage immédiat.

Mise en service

Lors de la mise en service il faut absolument éviter les coups de bélier. Ouvrir

lentement les robinets d'isolement.

14093267.01 03/2014 GB/D/F/E

51WIKA mode d‘emploi transmetteur de pression diérentielle, type DPGT40

Page 52

6. Mise en service, utilisation

6.2 Point zéro électrique (4 mA)

Le réglage du point zéro se fait par une vis de réglage à l‘avant, auxquelle on accède

selon le type d‘instrument en démontant le voyant ou la vis de serrage.

En tournant la vis de réglage avec un tournevis, on règle le point zéro désiré.

Si le point zéro mécanique a été modié au moyen de la

vis de réglage, le point zéro électrique doit être adapté à

nouveau au point zéro mécanique.

Pour cela, le transmetteur de pression diérentielle doit

F

d‘abord être dépressurisé.

Retirer l‘ensemble du couvre-câble sur le côté droit du

transmetteur. Pour ce faire, desserrer complètement la vis

sur le haut du capot du couvre-câble à l‘aide d‘un

tournevis (0,6 x 3,5 mm). Enlever la vis. Retirer le couvre-

câble , avec l‘insert de prise , à partir de la base de

prise du câble .

Le transmetteur est ainsi isolé de la tension

d‘alimentation.

Retirer le capot du couvre-câble du couvre-câble et

pousser l‘insert de prise complètement vers l‘extérieur,

vers le bas, à travers le couvre-câble .

Ponter les contacts 5 et 6 sur l‘insert de prise avec une

faible longueur de câble, dénudé aux deux extrémités

(résistance maximale admissible 30 Ω).

Réassembler le connecteur dans l‘ordre inverse. Insérer

le connecteur, avec le morceau de câble installé, dans

l‘insert de plot . Ceci rétablit l‘alimentation électrique.

Dans l‘espace de 30 secondes maximum, le nouveau

point zéro sera sauvegardé dans l‘électronique. Pendant

ce temps, le courant dans la boucle va monter jusqu‘à

9,5 mA.

Le nouveau point zéro est maintenu, même avec une

perte de puissance, pendant une période prolongée.

Une fois de plus, débrancher le connecteur dans l‘ordre

décrit ci-dessus et retirer le morceau de câble. Après

avoir remonté le connecteur, le signal de sortie électrique

correspondra de nouveau avec l‘achage de l‘aiguille

mécanique.

Pour que l‘indice de protection

soit maintenu, les joints

d‘étanchéité doivent être

remontés.

WIKA mode d‘emploi transmetteur de pression diérentielle, type DPGT4052

Vis

Capot du couvre-câble

Couvre-câble

Insert de prise

Socle de prise du câble

Joints d’étanchéité

14093267.01 03/2014 GB/D/F/E

Page 53

6. Mise en service, fonctionnement / 7. Options et accessoires

6.3 Dénition d'une tension d'alimentation