Page 1

Operating Instructions

Betriebsanleitung

Mode d'emploi

Pressure gauges Model 7 per directive 94/9/EC (ATEX)

with inductive contacts Model 831

Druckmessgeräte Typ 7 nach Richtlinie 94/9/EG (ATEX)

mit Induktivkontakten Typ 831

Manomètres Type 7 selon directive 94/9/EG (ATEX)

avec contacts inductifs Type 831

II 2 GD c TÜV 03 ATEX 2304 X

GB

D

F

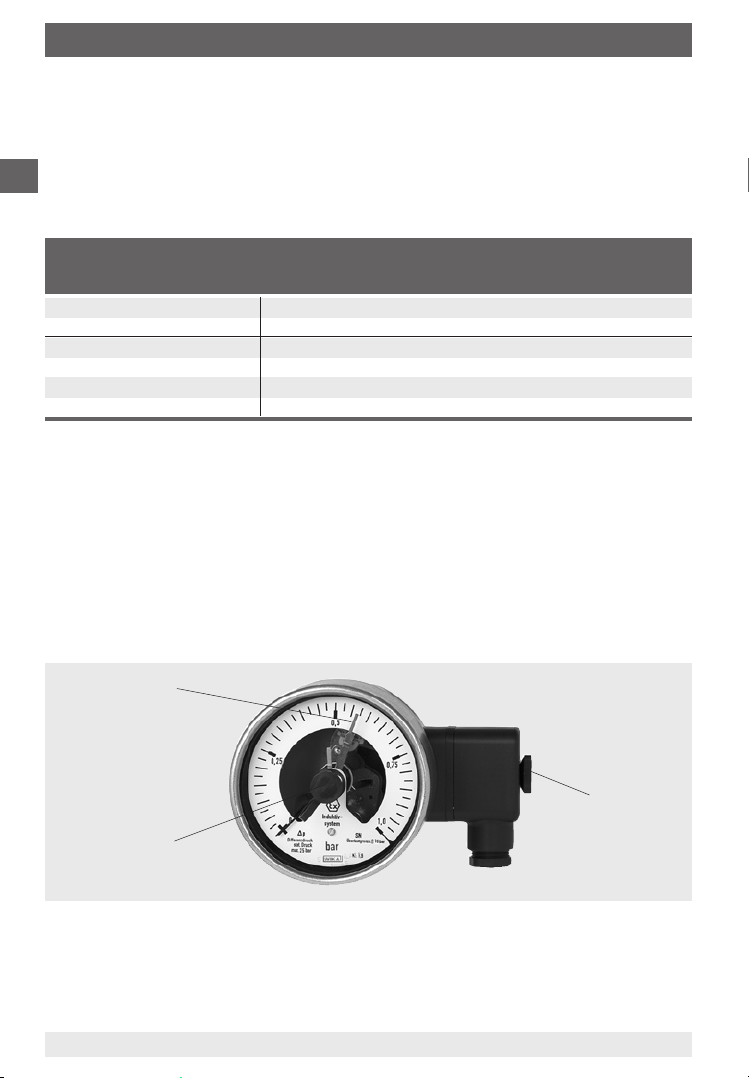

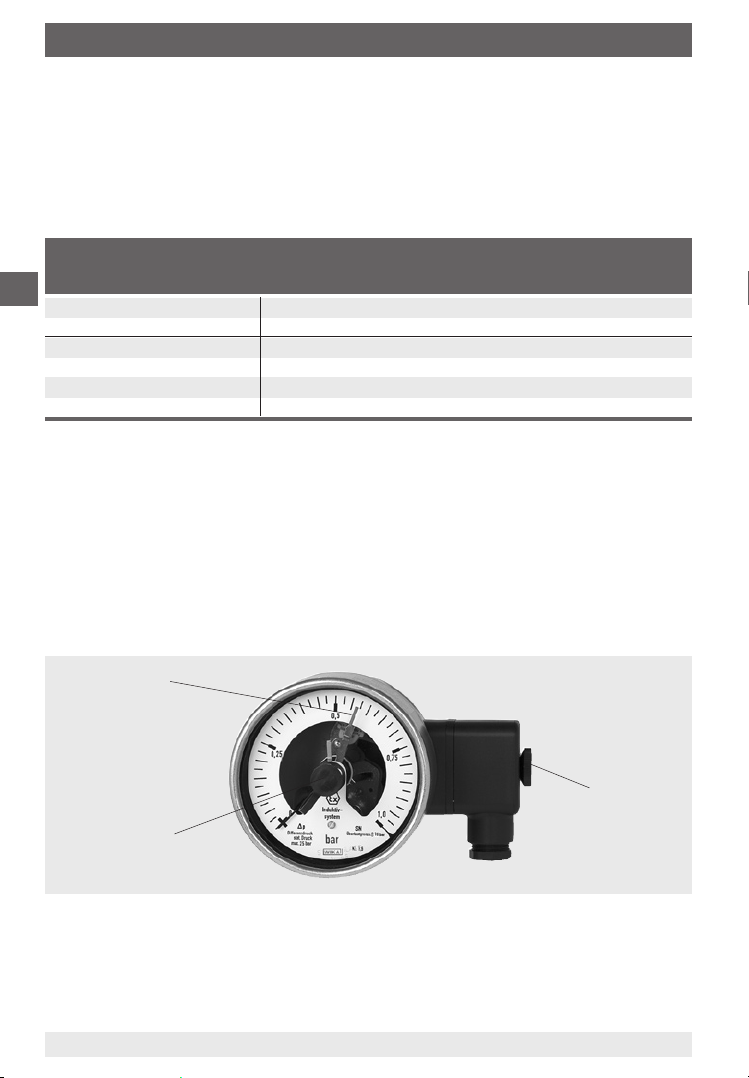

Model 732.51.100 per ATEX with

inductive contact Model 831.1

Model 732.14.100 per ATEX with

inductive contact Model 831.12

Page 2

Operating instructions Model 7 per ATEX

GB

with Model 831 Page 3-23

Betriebsanleitung Typ 7 nach ATEX

D

mit Typ 831 Seite 25-45

Mode d’emploi Type 7 selon ATEX

F

avec Type 831 Page 47-53

2

2080250 07/2009 GB/D/F

Page 3

Contents

Contents

1. Safety instructions 4

2. Description 4

3. Technical data and intended use 5

4. Switch contacts 7

5. Commissioning 9

6. Maintenance and servicing / cleaning 9

7. Repairs 9

8. Disposal 9

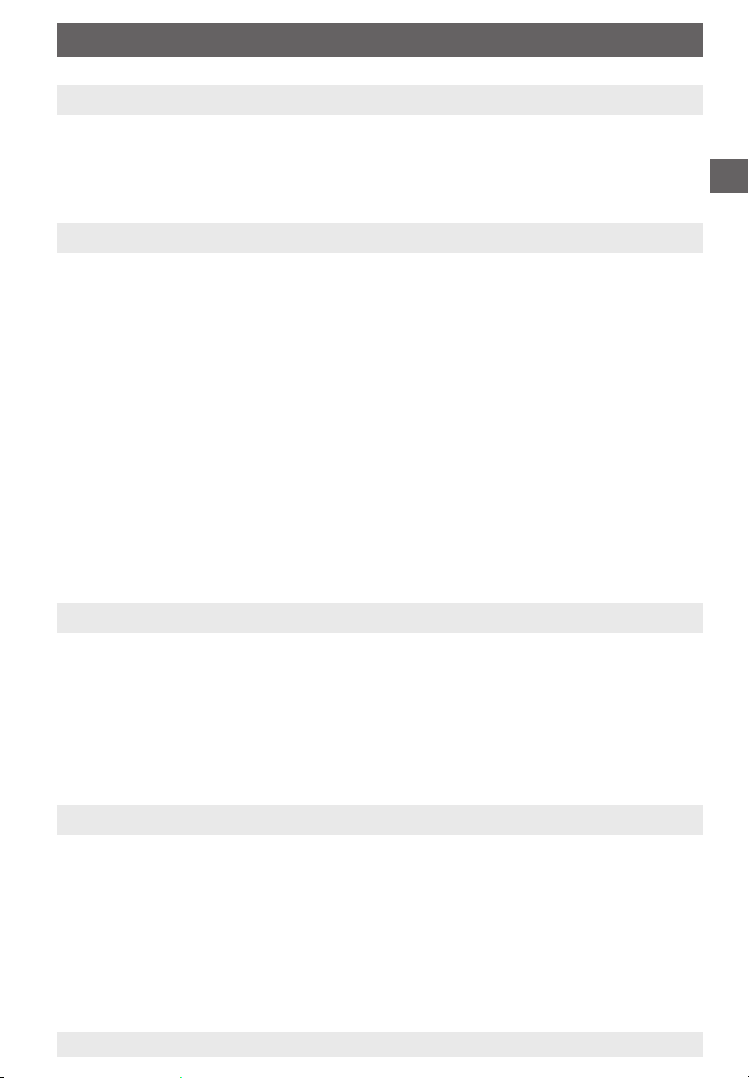

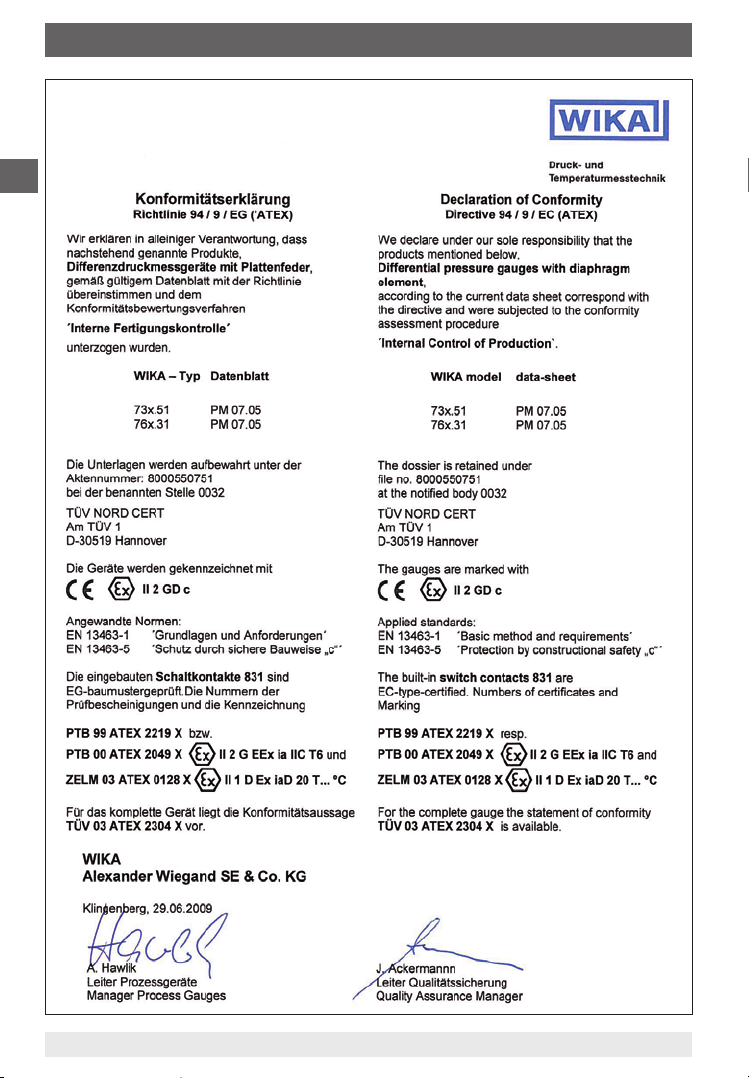

Appendix 1: Declaration of conformity for Models 73X.51 and

73X.31

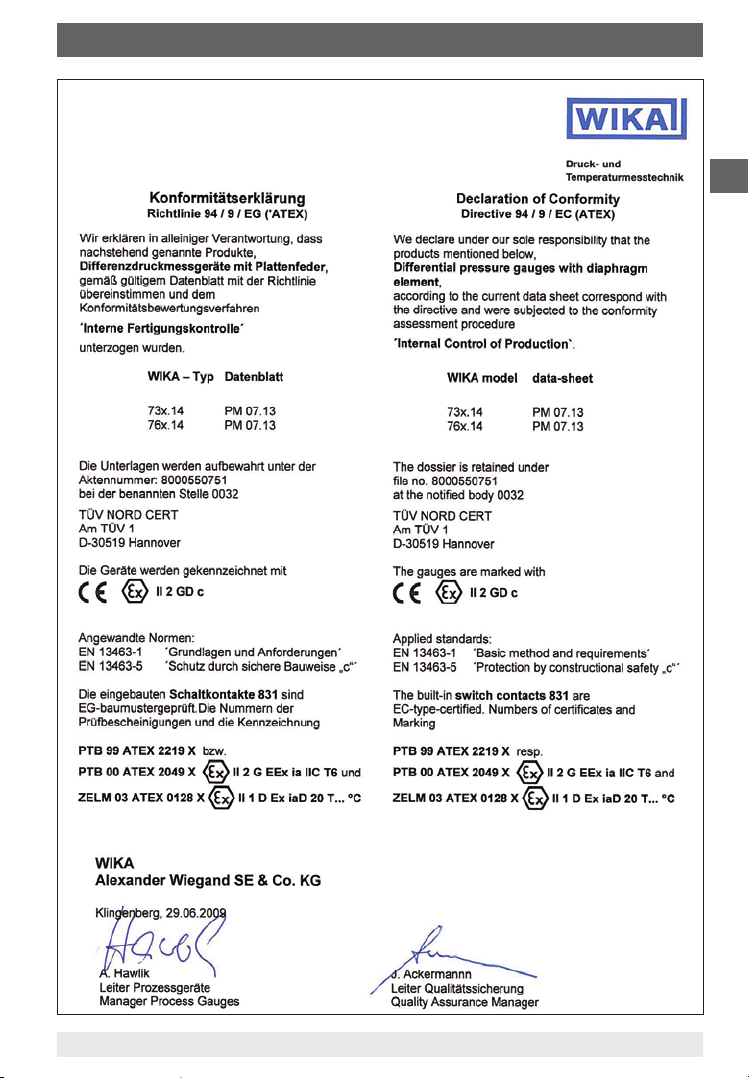

Appendix 2: Declaration of conformity for Models 73X.14 and

76X.14

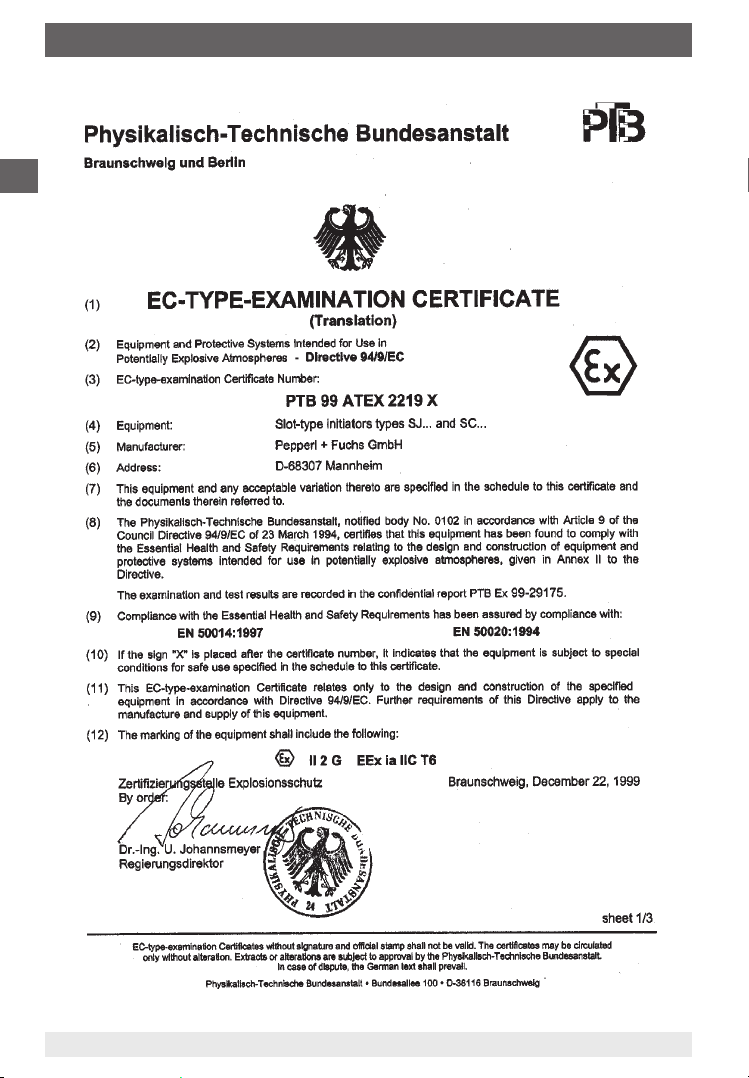

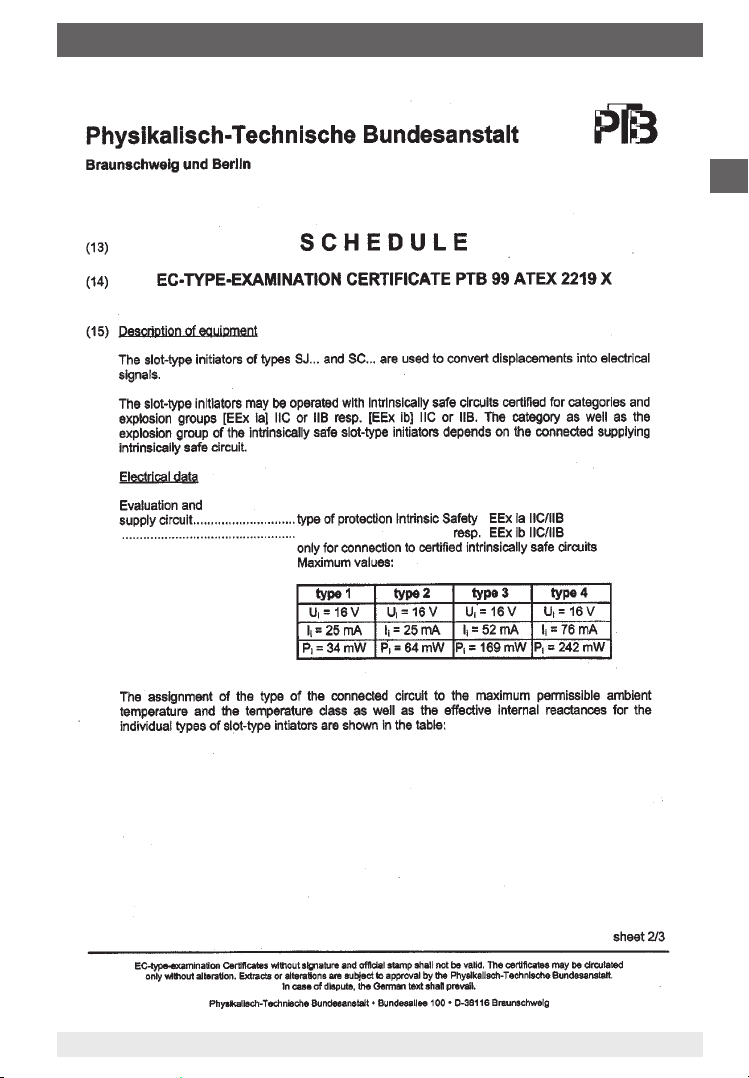

Appendix 3: EC-type examination certificate (Ex approval

for gases) for slot-type initiators types SJ

(WIKA-Model 831)

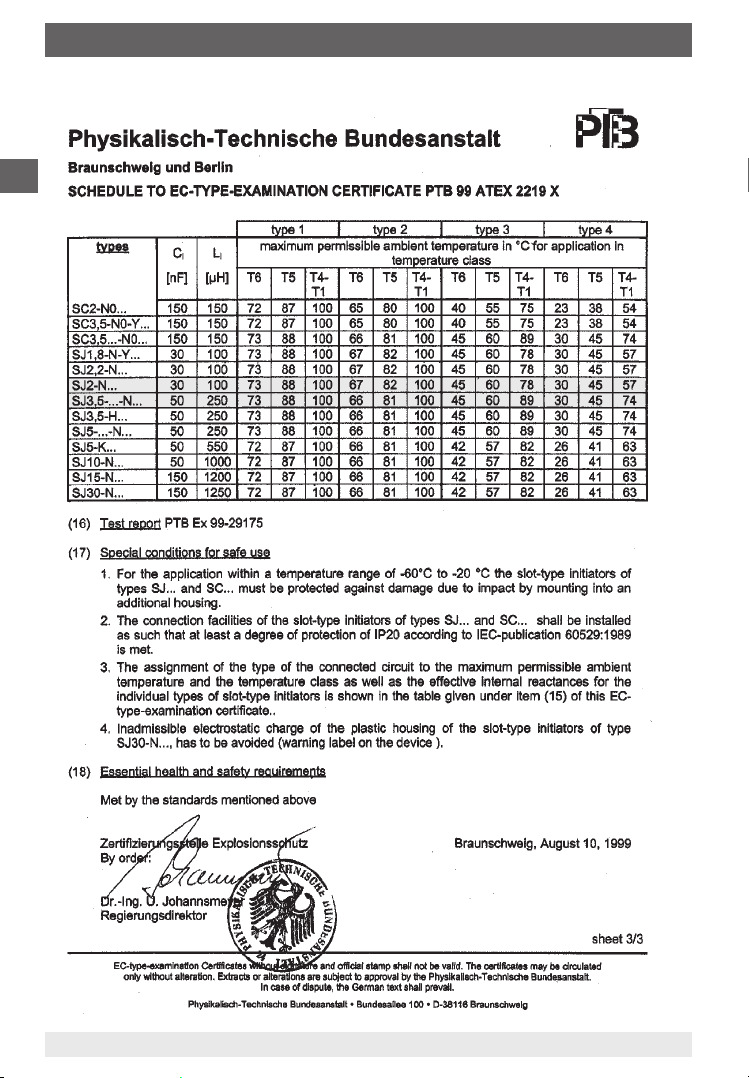

Appendix 4: EC-type examination certificate (Ex approval

for gases) for SN-sensors types SJ

(WIKA-Model 831-SN / S1N)

Appendix 5: EC-type examination certificate (Ex approval

for dust) for SN-proximity sensors types SJ

(WIKA-Model 831 and 831-SN / S1N)

10

11

12-14

15-18

19-23

GB

2080250 07/2009 GB/D/F

WIKA Operating instructions pressure gauges Model 7 with 831 per ATEX

3

Page 4

1. Safety instructions / 2. Description

1. Safety instructions

The appropriate national safety regulations (i.e. VDE 0100 /

GB

!

Caution

Only work on the gauge with the voltage disconnected

Serious injuries and/or damage can occur should the appropriate regulations

not be observed

Only appropriately qualified personnel should work on these instruments

EN 60 079-14 / EN 837-2) must be observed when installing,

commissioning and operating these instruments.

2. Description

The pressure gauges measure the pressure by means of elastic diaphragm

measuring elements

The measuring characteristics are in accordance with the EN 837-3 and

DIN 16 085 standards

In addition the Model 73X.31 also meet the requirements, relating to safety

pattern pressure gauges, outlined in the EN 837-3 (user protection) standard

The built-in electrical switch contacts are non-contact slot-type inductive

proximity sensors, which are powered from switching amplifiers with certified

intrinsically safe circuits. When any of the adjustable set points is reached, the

associated output circuits will either open or close.

As standard Model 831 slot sensors, to EC-type examination certificate

PTB 99 ATEX 2219 X (see Appendix 3) and ZELM 03 ATEX 0128 X (see

Appendix 5), are used

Model 831-SN and -S1N SN sensors, to PTB 00 ATEX 2049 X (see Appen-

dix 4) and ZELM 03 ATEX 0128 X (see Appendix 5), are special designs with

safety features (that are not relevant to explosion protection) for special

applications

The connected loads for the switches are in accordance with EN 60 947-5-6

("NAMUR").

4

WIKA Operating instructions pressure gauges Model 7 with 831 per ATEX

2080250 07/2009 GB/D/F

Page 5

3. Technical data and intended use

3. Technical data and intended use

Pressure limitation

Model 73X.51/31: Steady: full scale value

Fluctuating: 0.9 x full scale value

Table 1: Max. working pressure / Overpressure safety maximum in bar

Pressure ranges Working pressure max.

(static pressure)

Standard Option

0 ... 16 to 0 ... 40 mbar 2.5 6 2.5 0 ... 60 to 0 ...

0 ... 400 mbar 25 40 4 40

0 ... 0.6 bar 25 40 6 40

0 ... 1 bar 25 40 10 40

0 ... 1.6 bar 25 40 16 40

0 ... 2.5 to 0 ... 25 bar 25

250 mbar

6 10 2.5 6

40 25 40

Model 73X.14: Steady: full scale value

Fluctuating: 0.9 x full scale value

Overpressure safety: 40, 100; 250 or 400 bar

Process connection

Overpressure safety, single,

dual or alternating sides

Standard Option

GB

In accordance with the general technical regulations for pressure gauges

(i.e. EN 837-2 „Selection and installation recommendations for pressure

gauges“).

When screwing gauges in, the force required for this must not be applied

through the case, but rather through the spanner flats (using a suitable tool)

provided for this purpose on the square shaft of standard connections.

Temperature effect

When the temperature of the measuring system deviates from the reference

temperature (+20 °C): max. ±0.5 %/10 K of full scale value

IP Ingress protection

IP 54 per EN 60 529 / IEC 60 529

(with liquid filling IP 65)

2080250 07/2009 GB/D/F

WIKA Operating instructions pressure gauges Model 7 with 831 per ATEX

5

Page 6

3. Technical data and intended use

Operating Temperature

Ambient: -20 ... +60 °C

GB

Medium: The permissible medium temperature does not only depend on the

instrument design, but also on the ignition temperature of the

surrounding explosive atmosphere. Both aspects must be taken

into account.

For maximum permissible medium temperatures see Table 2.

Attention! In the case of gaseous substances, the temperature may increase

due to compression warming. In these cases it may be necessary to throttle

the rate of change of pressure or reduce the permissible temperature of the

pressure medium.

Table 2: Permissible medium temperature

Temperature Class of the

ambient atmosphere

Maximum permissible medium temperature

(in the pressure system)

(ignition temperature)

T 6 (85 °C < T ≤ 100 °C) +70 °C

T 5 (100 °C < T ≤ 135 °C) +85 °C

T 4 (135 °C < T ≤ 200 °C) +100 or +120 °C

T 3 (200 °C < T ≤ 300 °C) +100 or +185 °C

T 2 (300 °C < T ≤ 450 °C) +100 or +200 °C

T 1 (T > 450 °C) +100 or +200 °C

1) The higher values only apply to special versions with higher permissible media temperatures.

1)

1)

1)

1)

Installation

Nominal position per EN 837-3 / 9.6.6 Figure 7: 90° ( ⊥ )

Process connection: lower mount (LM)

In order to ensure that with Model 73X.31 pressure can be safely and reliably

vented through the case back, a distance of at least 25 mm must be left free

behind the case!

In order to avoid any additional heating, the instruments must not be

exposed to direct solar irradiation while in operation!

With filled versions the vent valve on the top of the casing must be opened

prior to commissioning!

6

WIKA Operating instructions pressure gauges Model 7 with 831 per ATEX

2080250 07/2009 GB/D/F

Page 7

3. Technical data and intended use / 4. Switch contacts

Permissible vibration load at the mounting point

The instruments should always be installed in locations free from vibration.

If necessary, it is possible to isolate the instrument from the mounting point

by installing a flexible connection line between the measuring point and the

pressure gauge and mounting the instrument on a suitable bracket.

If this is not possible, the following limit values must not be exceeded:

GB

Dry gauges: Frequency range < 150 Hz

(Model 732) Acceleration < 0.7 g (7 m/s

2

)

Liquid-filled gauges: Frequency range < 150 Hz

(Model 733) Acceleration < 4 g (40 m/s

2

)

The liquid filling must be checked on a regular basis.

The liquid level must not drop below 75 % of the gauge diameter.

4. Switch contacts

EC-type examination certificates

Standard version Model 831.XX

PTB 99 ATEX 2219 X (Appendix 3) and ZELM 03 ATEX 0128 X (Appendix 5)

Depending on the number of switches and on the case diameter either

Model SJ2-N... or Model SJ3.5-...-N... is used.

Safety pattern version Models 831.XX - SN or - S1N

PTB 00 ATEX 2049 X (Appendix 4) and ZELM 03 ATEX 0128 X (Appendix 5

Depending on the number of switches and on the case diameter either

Models SJ 2-SN..., SJ 2-S1N..., SJ 3.5-SN.. or SJ 3.5-S1N... are used.

The built-in sensor type is stated on the product label of the pressure gauge.

Wiring details

The electrical connections must only be made by qualified personnel

Connection of the switches via screw terminals in the terminal box

Conductor cross section max. 1.5 mm

The terminal assignment is stated on the connection plate of the

2

pressure gauge

The instruments must be connected to the equipotential bonding of the plant

2080250 07/2009 GB/D/F

WIKA Operating instructions pressure gauges Model 7 with 831 per ATEX

7

Page 8

4. Switch contacts

The permissible limits of Ui, Ii and Pi for the intrinsically safe supply circuits

depend on the sensor type. They can be taken from the corresponding EC-type

examination certificates. (The sensor type is stated on the connection plate of

the pressure gauge.)

GB

Suitable switch amplifiers are e.g.:

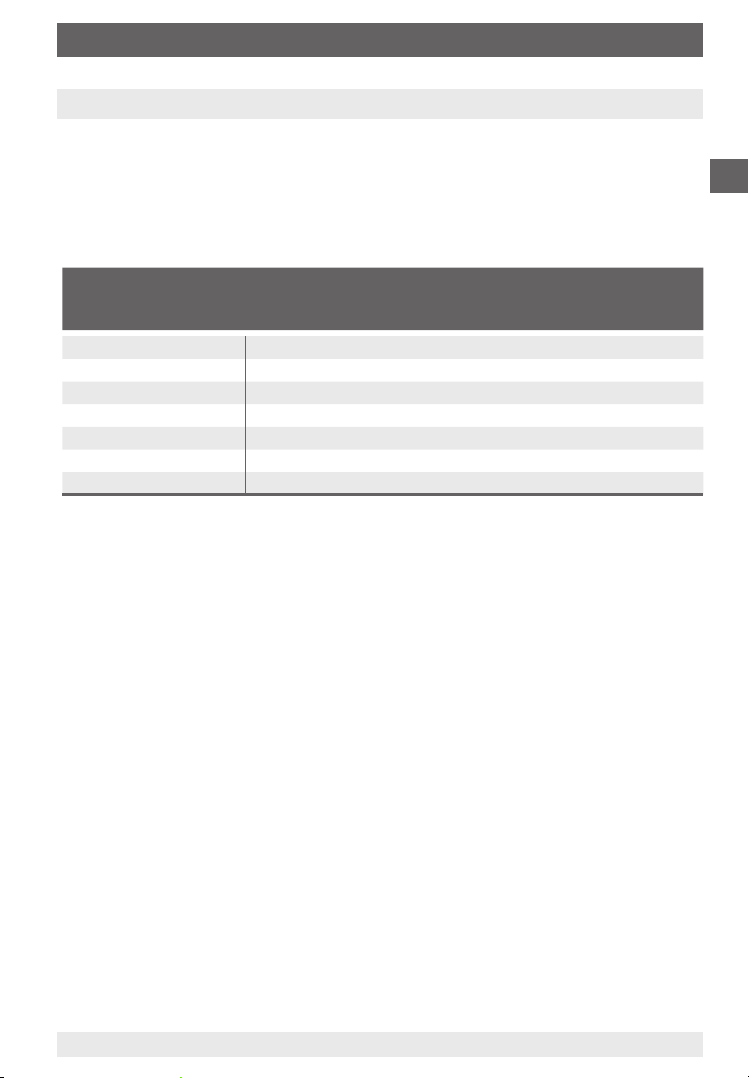

Circuit Sensor type Model designation EC-type exami- WIKA-

(s. Ex-certific.) Fa. Pepperl & Fuchs nation certificate Model

Model 1 standard KFD2-SR2-Ex1 PTB 00 ATEX 2080 904.31

standard KFD2-SR2 Ex2 PTB 00 ATEX 2080 904.32

Model 2 standard KFA6-SR2-Ex1 PTB 00 ATEX 2081 904.28

standard KFA6-SR2-Ex2 PTB 00 ATEX 2081 904.29

SN-sensors KFD2-SH-Ex1 PTB 00 ATEX 2042 904.33

SN-sensors KHA6-SH-Ex1 PTB 00 ATEX 2043 904.30

Electromagnetic compatibility

EMC to EN 60 947-5-2.

The instruments must be protected against strong electromagnetic fields.

Adjusting red set pointers

The setting of the set point is achieved using the adjustment lock in the window

with the aid of the adjustment key (part of the scope of supply; found in

standard instruments on the side of the terminal box).

Red set pointer

Removable

Adjustment

lock

adjustment key

The set point indicators for the switch contacts are freely adjustable over the

full scale range. For reasons of switching accuracy and long life of the mechanical measuring system, the switching points should be between 10 % and 90 %

of the measuring range.

8

WIKA Operating instructions pressure gauges Model 7 with 831 per ATEX

2080250 07/2009 GB/D/F

Page 9

5. Commissioning ... 8. Disposal

5. Commissioning

During the commissioning process pressure peaks must be avoided at all

costs. Open the shut-off valves slowly.

6. Maintenance and servicing / cleaning

The instruments require no maintenance or servicing.

The indicator and switching function should be checked once or twice every

12 months. The instrument must be disconnected from the process to check

with a pressure testing device.

The instruments should be cleaned with a damp cloth moistened with soap

solution. For cleaning, the instruments should be disconnected from the mains

power supply. It must be ensured that all the parts are dry before the power is

switched on again.

Any residual pressure medium contained in the pressure element may be

hazardous or toxic. This should be taken into account when handling and

storing pressure gauges which have been removed.

7. Repairs

GB

Repairs are only to be carried out by the manufacturer or appropriately trained

personnel.

For further details see WIKA Data Sheet AC 08.01 or the data sheet for the

respective basic gauge.

8. Disposal

Dispose of instrument components and packaging materials in accordance

with the respective waste treatment and disposal regulations of the region or

country to which the instrument is supplied.

2080250 07/2009 GB/D/F

WIKA Operating instructions pressure gauges Model 7 with 831 per ATEX

9

Page 10

GB

Appendix 1

10

WIKA Operating instructions pressure gauges Model 7 with 831 per ATEX

2080250 07/2009 GB/D/F

Page 11

Appendix 2

GB

2080250 07/2009 GB/D/F

WIKA Operating instructions pressure gauges Model 7 with 831 per ATEX

11

Page 12

GB

Appendix 3

12

WIKA Operating instructions pressure gauges Model 7 with 831 per ATEX

2080250 07/2009 GB/D/F

Page 13

Appendix 3

GB

2080250 07/2009 GB/D/F

WIKA Operating instructions pressure gauges Model 7 with 831 per ATEX

13

Page 14

GB

Appendix 3

14

WIKA Operating instructions pressure gauges Model 7 with 831 per ATEX

2080250 07/2009 GB/D/F

Page 15

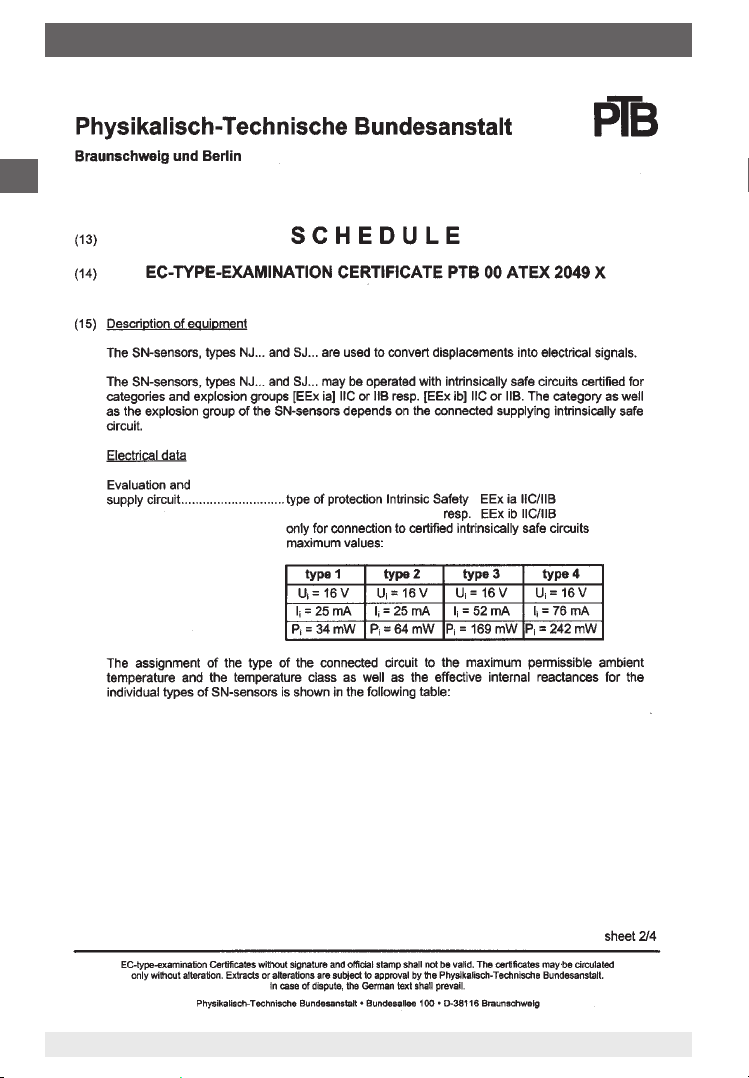

Appendix 4

GB

2080250 07/2009 GB/D/F

WIKA Operating instructions pressure gauges Model 7 with 831 per ATEX

15

Page 16

GB

Appendix 4

16

WIKA Operating instructions pressure gauges Model 7 with 831 per ATEX

2080250 07/2009 GB/D/F

Page 17

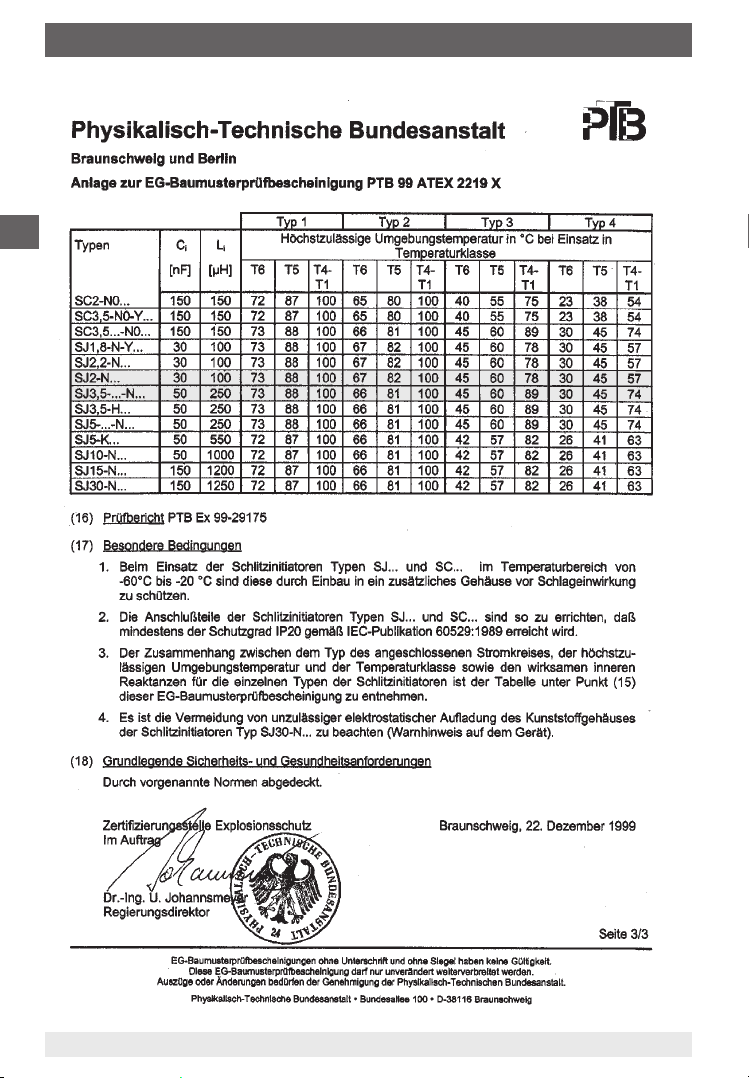

Appendix 4

GB

2080250 07/2009 GB/D/F

WIKA Operating instructions pressure gauges Model 7 with 831 per ATEX

17

Page 18

GB

Appendix 4

18

WIKA Operating instructions pressure gauges Model 7 with 831 per ATEX

2080250 07/2009 GB/D/F

Page 19

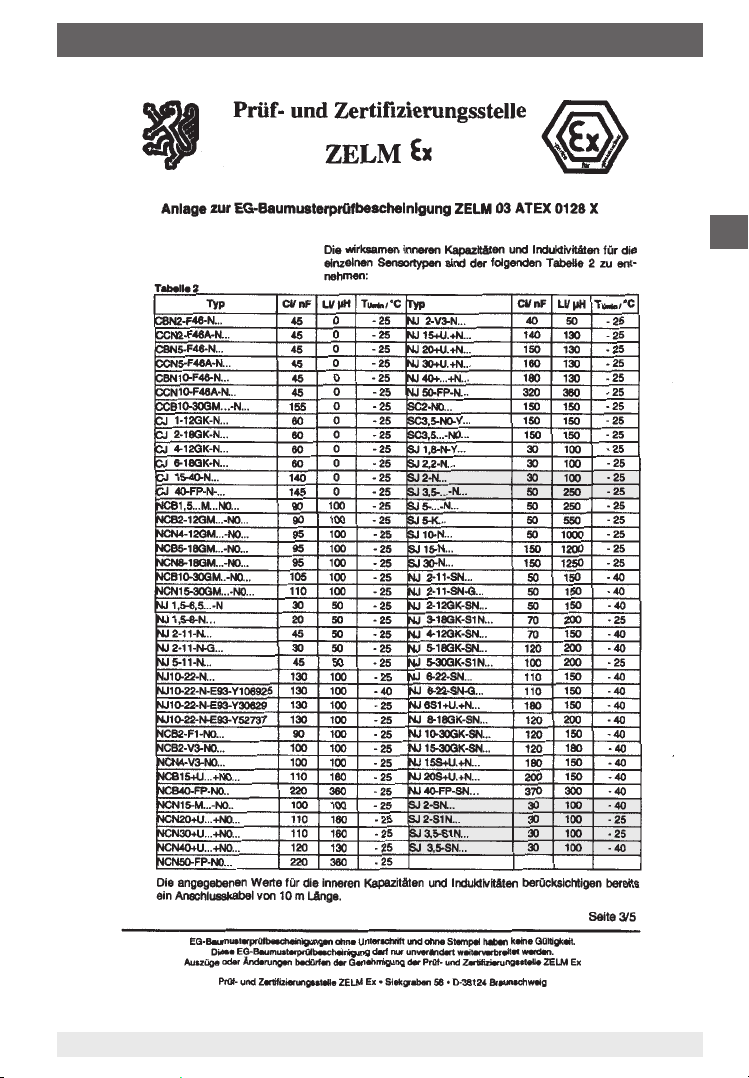

Appendix 5

GB

2080250 07/2009 GB/D/F

WIKA Operating instructions pressure gauges Model 7 with 831 per ATEX

19

Page 20

GB

Appendix 5

20

WIKA Operating instructions pressure gauges Model 7 with 831 per ATEX

2080250 07/2009 GB/D/F

Page 21

Appendix 5

GB

2080250 07/2009 GB/D/F

WIKA Operating instructions pressure gauges Model 7 with 831 per ATEX

21

Page 22

GB

Appendix 5

22

WIKA Operating instructions pressure gauges Model 7 with 831 per ATEX

2080250 07/2009 GB/D/F

Page 23

Appendix 5

D

2080250 07/2009 GB/D/F

WIKA Betriebsanleitung Druckmessgeräte Typ 7 mit 831 nach ATEX

23

Page 24

D

24

WIKA Betriebsanleitung Druckmessgeräte Typ 7 mit 831 nach ATEX

2080250 07/2009 GB/D/F

Page 25

Inhalt

Inhalt

1. Sicherheitshinweise 26

2. Beschreibung 26

3. Technische Daten und bestimmungsgemäße Verwendung 27

4. Elektrische Schaltkontakte 29

5. Inbetriebnahme 31

6. Wartung / Reinigung 31

7. Reparaturen 31

8. Entsorgung 31

Anlage 1: Konformitätserklärung für Typen 73X.51 und

73X.31

Anlage 2: Konformitätserklärung für Typen 73X.14 und

76X.14

Enclosure 3: EG-Baumusterprüfbescheinigung (Ex-Zulassung

für Gase) für Schlitzinitiatoren Typen SJ

(WIKA-Typ 831)

Enclosure 4: EG-Baumusterprüfbescheinigung (Ex-Zulassung

für Gase) für SN-Sensoren Typen SJ

(WIKA-Typ 831-SN / S1N)

Anlage 5: EG-Baumusterprüfbescheinigung (Ex-Zulassung

für Stäube) für Näherungssensoren Typen SJ

(WIKA-Typ 831 und 831-SN / S1N)

32

33

34-36

37-40

41-45

D

2080250 07/2009 GB/D/F

WIKA Betriebsanleitung Druckmessgeräte Typ 7 mit 831 nach ATEX

25

Page 26

1. Sicherheitshinweise / 2. Beschreibung

1. Sicherheitshinweise

Beachten Sie unbedingt bei Montage, Inbetriebnahme

und Betrieb dieser Geräte die entsprechenden nationalen

!

Vorsicht

D

Alle Arbeiten dürfen nur im spannungslosen Zustand erfolgen

Bei Nichtbeachten der entsprechenden Vorschriften können schwere Körper-

verletzungen und / oder Sachschäden auftreten

Nur entsprechend qualifiziertes Personal darf an diesen Geräten arbeiten

Sicherheitsvorschriften (z. B. VDE 0100 / EN 60 079-14 / EN 837-2).

2. Beschreibung

Die Geräte erfassen den zu messenden Druck mit elastischen Plattenfeder-

Messgliedern

Die messtechnischen Eigenschaften entsprechen den Normen EN 837-3

und DIN 16 085

Der Typ 73X.31 erfüllet außerdem die Anforderungen der EN 837-3 an

Sicherheitsdruckmessgeräte (Anwenderschutz)

Die eingebauten elektrischen Grenzwertschalter sind berührungslos arbeitende,

induktive Näherungsschalter in Schlitzbauform, die aus Trennschaltverstärkern

mit bescheinigten eigensicheren Stromkreisen versorgt werden. Bei Überschreiten der einstellbaren Grenzwerte werden deren Ausgangsstromkreise geöffnet

bzw. geschlossen.

Standard sind die Schlitzinitiatoren Typ 831 entsprechend der

EG-Baumusterprüfbescheinigung PTB 99 ATEX 2219 X (siehe Anlage 3)

und ZELM 03 ATEX 0128 X (siehe Anlage 5)

Die SN-Sensoren Typ 831-SN bzw. -S1N nach PTB 00 ATEX 2049 X (siehe

Anlage 4) und ZELM 03 ATEX 0128 X (siehe Anlage 5) sind eine Sonderausführung mit (nicht den Explosionsschutz betreffenden) Sicherheitsmerkmalen

für spezielle Anwendungen

Die Anschlusswerte der Schalter entsprechen der EN 60 947-5-6 ("NAMUR").

26

WIKA Betriebsanleitung Druckmessgeräte Typ 7 mit 831 nach ATEX

2080250 07/2009 GB/D/F

Page 27

3. Technische Daten und bestimmungsgemäße Verwendung

3. Technische Daten und bestimmungsgemäße Verwendung

Druckbelastbarkeit

Typ 73X.51/31: Ruhebelastung: Skalenendwert

Wechselbelastung: 0,9 x Skalenendwert

Tabelle 1: Max. Betriebsdruck / Überlastbarkeit in bar

Anzeigebereiche max. Betriebsdruck

(statischer Druck)

Standard Option

0 ... 16 bis 0 ... 40 mbar 2,5 6 2,5 0 ... 60 bis 0 ... 250 mbar

0 ... 400 mbar 25 40 4 40

0 ... 0,6 bar 25 40 6 40

0 ... 1 bar 25 40 10 40

0 ... 1,6 bar 25 40 16 40

0 ... 2,5 bis 0 ... 25 bar 25

6 10 2,5 6

40 25 40

Typ 73X.14: Ruhebelastung: Skalenendwert

Wechselbelastung: 0,9 × Skalenendwert

Überlastbarkeit: 40, 100, 250 oder 400 bar

Prozessanschluss

Überlastbarkeit

ein-, beid- u. wechselseitig

Standard Option

D

Entsprechend den allgemeinen technischen Regeln für Druckmessgeräte

(z. B. EN 837-2 "Auswahl- und Einbauempfehlungen für Druckmessgeräte").

Beim Einschrauben der Geräte darf die zum Abdichten erforderliche Kraft nicht

über das Gehäuse oder die Kabelanschlussdose aufgebracht werden, sondern

mit geeignetem Werkzeug nur über die dafür vorgesehenen Schlüsselflächen.

Temperatureinfluss

Bei Abweichung von der Referenztemperatur am Messsystem (+20 °C):

max. ±0,5 %/10 K vom jeweiligen Skalenendwert

IP Schutzart

IP 54 nach EN 60 529 / IEC 60 529

(mit Flüssigkeitsfüllung IP 65)

2080250 07/2009 GB/D/F

WIKA Betriebsanleitung Druckmessgeräte Typ 7 mit 831 nach ATEX

27

Page 28

3. Technische Daten und bestimmungsgemäße Verwendung

Zulässige Temperaturen

Umgebung: -20 ... +60 °C

Messstoff: Die zulässige Messstofftemperatur hängt außer von der Geräte-

bauart auch von der Zündtemperatur der umgebenden Gase,

Dämpfe bzw. Stäube ab. Beide Aspekte sind zu berücksichtigen.

D

Maximal zulässige Grenzwerte siehe Tabelle 2.

Achtung! Bei gasförmigen Stoffen kann sich die Temperatur durch Kompres-

sionswärme erhöhen. In solchen Fällen muss ggf. die Druckänderungsge-

schwindigkeit gedrosselt bzw. die zulässige Messstofftemperatur reduziert

werden.

Tabelle 2: Zulässige Messstofftemperatur

Temperaturklasse der

umgebenden zündfähigen

Zulässige maximale Messstofftemperatur

(im Messsystem)

Atmosphäre (Zündtemperatur)

T 6 (85 °C < T ≤ 100 °C) +70 °C

T 5 (100 °C < T ≤ 135 °C) +85 °C

T 4 (135 °C < T ≤ 200 °C) +100 bzw. +120 °C

T 3 (200 °C < T ≤ 300 °C) +100 bzw. +185 °C

T 2 (300 °C < T ≤ 450 °C) +100 bzw. +200 °C

T 1 (T > 450 °C) +100 bzw. +200 °C

1) Die höheren Werte gelten nur für Sonderausführungen mit höheren zulässigen Messstofftemperaturen

1)

1)

1)

1)

Installation

Nennlage nach EN 837-3 / 9.6.6 Bild 7: 90° ( ⊥ )

Prozessanschluss unten

Damit bei Typ 73X.31 im Fehlerfall die sichere Druckentlastung durch die

Rückwand erfolgen kann, müssen hinter dem Gehäuse mindestens 25 mm

frei bleiben!

Um zusätzliche Aufheizung zu vermeiden, dürfen die Geräte im Betrieb

keiner direkten Sonneneinstrahlung ausgesetzt werden!

Bei gefüllten Ausführungen muss vor Inbetriebnahme das Entlüftungsventil

an der Oberseite des Gehäuses geöffnet werden!

28

WIKA Betriebsanleitung Druckmessgeräte Typ 7 mit 831 nach ATEX

2080250 07/2009 GB/D/F

Page 29

3. Technische Daten ... / 4. Elektrische Schaltkontakte

Zulässige Schwingungsbelastung am Einbauort

Die Geräte sollten grundsätzlich nur an Stellen ohne Schwingungsbelastung

eingebaut werden

Gegebenenfalls kann z. B. durch eine flexible Verbindungsleitung von der

Messstelle zum Druckmessgerät und die Befestigung über eine Messgerätehalterung eine Entkopplung vom Einbauort erreicht werden.

Falls dies nicht möglich ist, dürfen folgende Grenzwerte nicht überschritten

werden:

Ungefüllte Geräte: Frequenzbereich < 150 Hz

(Typ 732) Beschleunigung < 0,7 g (7 m/s

2

)

D

Flüssigkeitsgefüllte Geräte: Frequenzbereich < 150 Hz

(Typ 733) Beschleunigung < 4 g (40 m/s

2

)

Die Flüssigkeitsfüllung ist regelmäßig zu überprüfen.

Der Flüssigkeitsspiegel darf nicht unter 75 % des Gerätedurchmessers fallen.

4. Elektrische Schaltkontakte

EG-Baumusterprüfbescheinigungen

Standardausführung Typen 831.XX

PTB 99 ATEX 2219 X (Anlage 3) und ZELM 03 ATEX 0128 X (Anlage 5)

Abhängig von der Anzahl der Schalter und vom Gehäusedurchmesser wird

entweder der Typ SJ2-N ... oder der Typ SJ3,5- ... -N ... eingesetzt.

Sicherheitsausführung Typen 831.XX - SN oder - S1N

PTB 00 ATEX 2049 X (Anlage 4) und ZELM 03 ATEX 0128 X (Anlage 5)

Abhängig von der Schalterzahl und vom Gehäusedurchmesser werden ent-

weder die Typen SJ 2-SN..., SJ 2-S1N..., SJ 3,5-SN ... oder SJ 3,5-S1N ...

eingesetzt.

Der eingebaute Sensortyp ist auf dem Typenschild des Druckmessgerätes

angegeben.

Elektrischer Anschluss

Der elektrische Anschluss darf nur durch qualifiziertes Personal erfolgen

Anschluss der Schalter über Schraubklemmen in der Kabeldose

Leitungsquerschnitt max. 1,5 mm

Klemmenbelegung auf Anschlussschild am Druckmessgerät

Die Geräte sind in den Potenzialausgleich der Anlage mit einzubeziehen

2080250 07/2009 GB/D/F

WIKA Betriebsanleitung Druckmessgeräte Typ 7 mit 831 nach ATEX

2

29

Page 30

4. Elektrische Schaltkontakte

Die zulässigen Grenzwerte für Ui, Ii und Pi der eigensicheren Versorgungsstrom-

kreise hängen vom Initiatortyp ab. Sie sind aus den jeweiligen EG-Baumusterprüfbescheinigungen zu entnehmen. (Der Initiatortyp ist auf dem Anschluss-

schild des Druckmessgerätes angegeben.)

Geeignete Trennschaltverstärker sind z. B.:

D

Stromkreis Sensortyp Typenbezeichnung EG-Baumuster- WIKA-

(s. Ex-Schein) Fa. Pepperl & Fuchs prüfbescheinigung Typ

Typ 1 Standard KFD2-SR2-Ex1 PTB 00 ATEX 2080 904.31

Standard KFD2-SR2 Ex2 PTB 00 ATEX 2080 904.32

Typ 2 Standard KFA6-SR2-Ex1 PTB 00 ATEX 2081 904.28

Standard KFA6-SR2-Ex2 PTB 00 ATEX 2081 904.29

SN-Sensoren KFD2-SH-Ex1 PTB 00 ATEX 2042 904.33

SN-Sensoren KHA6-SH-Ex1 PTB 00 ATEX 2043 904.30

Elektromagnetische Verträglichkeit

EMV gemäß EN 60 947-5-2.

Die Geräte sind vor starken elektromagnetischen Feldern zu schützen.

Einstellen der Sollwertzeiger

Das Einstellen der Sollwerte erfolgt über das Verstellschloss in der Sichtscheibe mit Hilfe des Verstellschlüssels (gehört zum Lieferumfang; befindet sich bei

Standardgeräten seitlich an der Kabeldose).

Sollwertzeiger

abnehmbarer

Verstellschlüssel

Verstellschloss

Die Sollwertzeiger der Grenzwertschalter sind im gesamten Skalenbereich

frei einstellbar. Aus Gründen der Schaltgenauigkeit und der Lebensdauer der

mechanischen Messsysteme sollen die Schaltpunkte zwischen 10 % und 90 %

der Messspanne liegen.

30

WIKA Betriebsanleitung Druckmessgeräte Typ 7 mit 831 nach ATEX

2080250 07/2009 GB/D/F

Page 31

5. Inbetriebnahme ... 8. Entsorgung

5. Inbetriebnahme

Bei Inbetriebnahme Druckstöße unbedingt vermeiden, Absperrventile langsam

öffnen.

6. Wartung / Reinigung

Die Geräte sind wartungsfrei.

Eine Überprüfung der Anzeige und der Schaltfunktion sollte etwa 1 bis 2 mal

pro Jahr erfolgen. Dazu ist das Gerät vom Prozess zu trennen und mit einer

Druckprüfvorrichtung zu kontrollieren.

Reinigen der Geräte mit einem (in Seifenlauge) angefeuchteten Tuch.

Zur Reinigung sind die Geräte vom Netz zu trennen. Vor Wiedereinschalten des

Stromes ist sicherzustellen, dass alle Teile abgetrocknet sind.

Messstoffreste in ausgebauten Druckmessgeräten können zur Gefährdung von

Menschen, Umwelt und Einrichtung führen. Ausreichende Vorsichtsmaßnahmen

sind zu ergreifen.

7. Reparaturen

Reparaturen sind ausschließlich vom Hersteller oder entsprechend geschultem

Personal durchzuführen.

Weitere technische Daten bitte dem WIKA Datenblatt AC 08.01 bzw.

dem Datenblatt des jeweiligen Grundgerätes entnehmen.

8. Entsorgung

D

Entsorgen Sie Gerätekomponenten und Verpackungsmaterialien entsprechend

den einschlägigen landesspezifischen Abfallbehandlungs- und Entsorgungsvor-

schriften des Anliefergebietes.

2080250 07/2009 GB/D/F

WIKA Betriebsanleitung Druckmessgeräte Typ 7 mit 831 nach ATEX

31

Page 32

D

Anlage 1

32

WIKA Betriebsanleitung Druckmessgeräte Typ 7 mit 831 nach ATEX

2080250 07/2009 GB/D/F

Page 33

Anlage 2

D

2080250 07/2009 GB/D/F

WIKA Betriebsanleitung Druckmessgeräte Typ 7 mit 831 nach ATEX

33

Page 34

D

Anlage 3

34

WIKA Betriebsanleitung Druckmessgeräte Typ 7 mit 831 nach ATEX

2080250 07/2009 GB/D/F

Page 35

Anlage 3

D

2080250 07/2009 GB/D/F

WIKA Betriebsanleitung Druckmessgeräte Typ 7 mit 831 nach ATEX

35

Page 36

D

Anlage 3

36

WIKA Betriebsanleitung Druckmessgeräte Typ 7 mit 831 nach ATEX

2080250 07/2009 GB/D/F

Page 37

Anlage 4

D

2080250 07/2009 GB/D/F

WIKA Betriebsanleitung Druckmessgeräte Typ 7 mit 831 nach ATEX

37

Page 38

D

Anlage 4

38

WIKA Betriebsanleitung Druckmessgeräte Typ 7 mit 831 nach ATEX

2080250 07/2009 GB/D/F

Page 39

Anlage 4

D

2080250 07/2009 GB/D/F

WIKA Betriebsanleitung Druckmessgeräte Typ 7 mit 831 nach ATEX

39

Page 40

D

Anlage 4

40

WIKA Betriebsanleitung Druckmessgeräte Typ 7 mit 831 nach ATEX

2080250 07/2009 GB/D/F

Page 41

Anlage 5

D

2080250 07/2009 GB/D/F

WIKA Betriebsanleitung Druckmessgeräte Typ 7 mit 831 nach ATEX

41

Page 42

D

Anlage 5

42

WIKA Betriebsanleitung Druckmessgeräte Typ 7 mit 831 nach ATEX

2080250 07/2009 GB/D/F

Page 43

Anlage 5

D

2080250 07/2009 GB/D/F

WIKA Betriebsanleitung Druckmessgeräte Typ 7 mit 831 nach ATEX

43

Page 44

D

Anlage 5

44

WIKA Betriebsanleitung Druckmessgeräte Typ 7 mit 831 nach ATEX

2080250 07/2009 GB/D/F

Page 45

Anlage 5

D

2080250 07/2009 GB/D/F

WIKA Betriebsanleitung Druckmessgeräte Typ 7 mit 831 nach ATEX

45

Page 46

D

46

WIKA Betriebsanleitung Druckmessgeräte Typ 7 mit 831 nach ATEX

2080250 07/2009 GB/D/F

Page 47

Sommaire

Sommaire

1. Consignes de sécurité 48

2. Description 48

3. Caractéristiques techniques et utilisation correspondante 49

4. Commutateurs 51

5. Mise en service 53

6. Entretien / Nettoyage 53

7. Réparations 53

8. Mise au rebus 53

Déclaration de Conformité des types 7XX

avec contact inductifs type 831 (allemand/anglais)

Attestation d’examen CE (homologation Ex pour gaz) pour

détecteurs de proximité à fente des types SJ anglais

(WIKA-type 831) allemand

Attestation d’examen CE (homologation Ex pour gaz)

pour détecteurs SN des types SJ anglais

(WIKA-type 831-SN/S1N) allemand

Attestation d’examen CE (homologation Ex pour poussières)

pour détecteurs de proximité à fente des types SJ anglais

(WIKA-type 831 et 831-SN/S1N) allemand

32-33

12-14

34-36

15-18

37-40

19-23

41-45

F

2080250 07/2009 GB/D/F

WIKA Mode d'emploi manomètres Type 7 avec selon ATEX

47

Page 48

1. Consignes de sécurité / 2. Description

1. Consignes de sécurité

Les prescriptions de sécurité nationales en vigueur (par exemple

!

Avertissement

Toutes les interventions doivent être effectuées hors tension

F

Le non-respect des instructions correspondantes est susceptible d‘entraîner

des risques de blessure et/ou des dégâts matériels

Seul le personnel habilité et qualifié est autorisé à manipuler les instruments

VDE 0100 / EN 60 079-14 / EN 837-2) doivent absolument

être respectées lors du montage, de la mise en service et de

l‘utilisation des instruments ici présentés.

2. Description

Les appareils mesurent la pression par le biais d’une membrane à

déformation élastique

Les caractéristiques techniques de mesure correspondent aux normes

EN 837-3 et DIN 16 085

Le type 73X.31 remplit les exigences de la EN 837-3 sur les manomètres

de sécurité (protection de l‘utilisateur)

Les contacts électriques intégrés sont des détecteurs de proximité travaillant sans contact mécanique en forme d‘entrefer. Ils sont alimentés par des

relais amplificateurs homologués pour circuits en sécurité intrinsèque. Lors

du dépassement des seuils réglables, les circuits de sortie s‘ouvrent ou se

ferment.

Les détecteurs inductifs standard du type 831 correspondent aux

procédures d‘attestation de la conformité PTB 99 ATEX 2219 X (voir annexe

3) et ZELM 03 ATEX 0128 X (voir annexe 5)

Les détecteurs SN type 831-SN ou -S1N selon PTB 00 ATEX 2049 X (voir

annexe 4) et ZELM 03 ATEX 0128 X (voir annexe 5) sont une exécution

spéciale (ne concernant pas la protection anti-explosion) avec des attributs

de sécurité pour des utilisations spéciales.

Les valeurs de branchement des contacts correspondent à la EN 60 9475-6

("NAMUR").

48

WIKA Mode d'emploi manomètres Type 7 avec 831 selon ATEX

2080250 07/2009 GB/D/F

Page 49

3. Caractéristiques techniques et utilisation correspondante

3. Caractéristiques techniques et utilisation correspondante

Limitations en pression

Type 73X.51/31: Charge statique: fin d'échelle

Charge dynamique: 90 % de fin d'échelle

Tableau 1: Pression de service maxi / surpression admissible en bar

Etendues de mesure Pression maxi

(pression statique)

Standard Option

0 ... 16 à 0 ... 40 mbar 2,5 6 2,5 -

0 ... 60 à 0 ... 250 mbar 6 10 2,5 6

0 ... 400 mbar 25 40 4 40

0 ... 0,6 bar 25 40 6 40

0 ... 1 bar 25 40 10 40

0 ... 1,6 bar 25 40 16 40

0 ... 2,5 à 0 ... 25 bar 25 40 25 40

Type 73X.14: Charge statique: fin d'échelle de mesure

Charge dynamique: 90 % fin d'échelle de mesure

Surpression admissible: 40, 100, 250 ou 400 bar

Raccord process

Surcharge

bi-latérale

Standard Option

F

Conformément aux règles techniques générales pour les manomètres (par

exemple EN 837-2 „Recommandations sur le choix et l'installation des

manomètres“).

Lors du vissage des appareils, la force nécessaire ne doit pas être appliquée

sur le boîtier ou sur le boîtier de raccordement mais seulement sur les surfaces

prévues par un outil approprié sur le carré du raccord.

Influence de la température

En cas de divergence de la température de référence (+20 °C)

sur l’organe moteur: max. ±0,5 %/10 K de la valeur d’échelle finale respective

IP Indice de protection

IP 54 selon EN 60 529 / IEC 60 529

(avec bain amortisseur IP 65)

2080250 07/2009 GB/D/F

WIKA Mode d'emploi manomètres Type 7 avec selon ATEX

49

Page 50

3. Caractéristiques techniques et utilisation correspondante

Températures autorisées

Ambiante: -20 ... +60 °C

Fluide: La température de fluide autorisée dépend, en plus de la

de l'appareil, également de la température d'inflammation du gaz, des

vapeurs ou des poussières de l'environnement. Ces deux paramètres

sont à prendre en considération. Voir le tableau 2 pour les limites de

température autorisées.

F

Attention! Pour les fluides gazeux la température peut s'élever par le biais

d'une température de compression. Dans ces cas il faut, soit limiter la vitesse

d'élévation de la pression, soit réduire la température de fluide admissible.

Tableau 2: Température de fluide admissible

conception

Classe de température de

l'atmosphère environnante

Température maximale autorisée du fluide

(dans le système de mesure)

(température d'inflammation)

T 6 ( 85 °C < T ≤ 100 °C) +70 °C

T 5 (100 °C < T ≤ 135 °C) +85 °C

T 4 (135 °C < T ≤ 200 °C) +100 ou +120 °C

T 3 (200 °C < T ≤ 300 °C) +100 ou +185 °C

T 2 (300 °C < T ≤ 450 °C) +100 ou +200 °C

T 1 (T > 450 °C) +100 ou +200 °C

1)

1)

1)

1)

Installation

Position de base selon EN 837-3 / 9.6.6 image 7: 90° ( ⊥ )

Raccordement process : raccords verticaux

Pour qu’une surpression puisse s’évacuer en toute sécurité par l’arrière

du boîtier en cas d’incident sur un manomètre type 73X.31, une distance

minimum de 25 mm doit rester libre à l’arrière du boîtier de l’appareil.

Afin d‘éviter un échauffement additionnel en fonctionnement, les appareils

ne doivent pas être exposés aux rayons solaires!

Pour les appareils remplis de liquide il faut, avant la mise en service, ouvrir le

dispositif de mise à l’atmosphère se trouvant au sommet du boîtier!

50

WIKA Mode d'emploi manomètres Type 7 avec 831 selon ATEX

2080250 07/2009 GB/D/F

Page 51

3. Caractéristiques techniques ... / 4. Commutateurs

Contrainte de vibration admissible sur le point de montage

Les appareils ne devraient en principe être installés que sur des applications

exemptes de vibrations

Le cas échéant, on peut obtenir un isolement du point de mesure en utilisant

une liaison flexible entre le manomètre et le point de mesure et en le fixant à

l’aide d’un support d’appareil mural.

Dans le cas où cela n'est pas possible, les valeurs suivantes ne doivent pas

être dépassées:

Appareils sans remplissage : Plage de fréquence < 150 Hz

2

(Type 732) Accélération < 0,7 g (7 m/s

)

Appareils avec remplissage : Plage de fréquence < 150 Hz

2

(Type 733) Accélération < 4 g (40 m/s

)

Le liquide de remplissage est a contrôler régulièrement. Le niveau de remplissage de liquide ne doit pas descendre en-dessous de 75 % du diamètre du boîtier.

4. Commutateurs

Attestation d‘examen CE

Exécution standard types 831.XX

PTB 99 ATEX 2219 X (annexe 3) et ZELM 03 ATEX 0128 X (annexe 5)

En fonction du nombre de contacts et du diamètre du boîtier on

utilise soit le type SJ2-N…, soit le type SJ3,5- … -N

Exécution de sécurité types 831.XX - SN ou - S1N

PTB 00 ATEX 2049 X (annexe 4) et ZELM 03 ATEX 0128 X (annexe 5)

En fonction du nombre de contacts et du diamètre du boîtier on

utilise soit les types SJ 2-SN..., SJ 2-S1N..., SJ 3,5-SN ..., soit SJ 3,5-S1N ...

Le type de détecteur intégré est indiqué sur la plaquette d‘identification

du manomètre.

Raccords électriques

Les travaux de raccordement électrique ne doivent être effectués que par

des ouvriers qualifiés pour ce faire

L

e branchement des contacts se fait par des bornes dans la boîte de jonction

La section des conducteurs est de maxi 1,5 mm

La codification des borniers se trouve sur la plaquette de branchement de

2

l‘appareil

Les appareils sont à inclure dans la compensation de potentiel de l’installation

2080250 07/2009 GB/D/F

WIKA Mode d'emploi manomètres Type 7 avec selon ATEX

F

51

Page 52

4. Commutateurs

Les valeurs limites autorisées pour Ui, Ii et Pi de l‘alimentation intrinsèque

des circuits dépendent du type de détecteur. Ces valeurs sont indiquées

dans les procédures d‘attestation de la conformité CE. (Le type de détecteur

est indiqué sur le schéma de branchement du manomètre).

Exemple pour relais d‘amplification appropriés:

Circuit Type de Code de désignation Attestation Type

(voir fiche Ex) détecteur Etbs. Pepperl & Fuchs d‘examen CE WIKA

F

Type 1 Standard KFD2-SR2-Ex1 PTB 00 ATEX 2080 904.31

Standard KFD2-SR2 Ex2 PTB 00 ATEX 2080 904.32

Type 2 Standard KFA6-SR2-Ex1 PTB 00 ATEX 2081 904.28

Standard KFA6-SR2-Ex2 PTB 00 ATEX 2081 904.29

SN-Sensoren KFD2-SH-Ex1 PTB 00 ATEX 2042 904.33

SN-Sensoren KHA6-SH-Ex1 PTB 00 ATEX 2043 904.30

Compatibilité électromagnétique

CEM selon EN 60 947-5-2.

Les appareils sont à protéger contre de forts champs électromagnétiques.

Réglage de la valeur de consigne

Le réglage des valeurs de consigne s‘effectue via le trou de réglage dans le

cadran à l‘aide de la clef de réglage (fournie avec l‘appareil, elle se trouve,

dans les modèles standard, sur le côté du boîtier de raccordement).

Indicateur de

la valeur

de consigne

Clef de réglage

amovible

Trou de réglage

Les indicateurs de valeur de consigne des seuils peuvent être réglés librement

sur toute l‘échelle de mesure. Pour des raisons de précision et de sécurité de

commutation, et afin de ne pas porter préjudice à la durée de vie des appareils,

il est recommander de fixer les points de commutation entre 10 % et 90 % de

l‘échelle.

52

WIKA Mode d'emploi manomètres Type 7 avec 831 selon ATEX

2080250 07/2009 GB/D/F

Page 53

5. Mise en service ... 8. Mise au rebus

5. Mise en service

Lors de la mise en service il faut absolument éviter les coups de bélier. Ouvrir

lentement les vannes de fermeture.

6. Entretien / Nettoyage

Les instruments ne requièrent aucun entretien.

Un contrôle de l’affichage et des fonctions de commande est recommandé 1

à 2 fois/an. Pour le contrôle de l’affichage et des fonctions de commande, il

faut isoler l’appareil du process et le contrôler avec un dispositif de contrôle de

pression.

Nettoyer les instruments avec un légèrement humidifié avec une lessive (de

savon). Avant de procéder au nettoyage, débrancher l'instrument du réseau.

Avant de rebrancher l'instrument, s'assurer que toutes les pièces sont entièrement sèches.

Des restes de fluide se trouvant dans les manomètres démontés peuvent provoquer

une mise en danger de personnes, de l’environnement et de l’équipement. Des

précautions adéquates sont à prendre.

7. Réparations

Toute réparation doit être exclusivement confiée au fabricant ou au personnel

qualifié correspondant.

F

Pour autres données, se reporter à la fiche type WIKA AC 08.01 ou à la fiche

technique de l’instrument correspondant.

8. Mise au rebus

Mettez les composants des appareils et les emballages au rebus en respectant

les prescriptions nationales pour le traitement et la mise au rebus des régions

de livraison.

2080250 07/2009 GB/D/F

WIKA Mode d'emploi manomètres Type 7 avec selon ATEX

53

Page 54

WIKA Global

Europe

Austria

WIKA Messgerätevertrieb

Ursula Wiegand

GmbH & Co. KG

1230 Vienna

Tel. (+43) 1 86916-31

Fax: (+43) 1 86916-34

E-mail: info@wika.at

www.wika.at

Benelux

WIKA Benelux

6101 WX Echt

Tel. (+31) 475 535-500

Fax: (+31) 475 535-446

E-mail: info@wika.nl

www.wika.nl

Bulgaria

WIKA Bulgaria EOOD

Bul. „Al. Stamboliiski“ 205

1309 Sofia

Tel. (+359) 2 82138-10

Fax: (+359) 2 82138-13

E-Mail: t.antonov@wika.bg

Croatia

WIKA Croatia d.o.o.

Hrastovicka 19

10250 Zagreb-Lucko

Tel. (+385) 1 6531-034

Fax: (+385) 1 6531-357

E-Mail: info@wika.hr

Finland

WIKA Finland Oy

00210 Helsinki

Tel. (+358) 9 68249-20

Fax: (+358) 9 68249-270

E-mail: info@wika.fi

www.wika.fi

France

WIKA Instruments s.a.r.l.

95610 Eragny-sur-Oise

Tel. (+33) 1 343084-84

Fax: (+33) 1 343084-94

E-mail: info@wika.fr

www.wika.fr

Germany

WIKA

Alexander Wiegand SE & Co. KG

63911 Klingenberg

Tel. (+49) 9372 132-0

Fax: (+49) 9372 132-406

E-mail: info@wika.de

www.wika.de

Italy

WIKA Italiana SRL

20020 Arese (Milano)

Tel. (+39) 02 9386-11

Fax: (+39) 02 9386-174

E-mail: info@wika.it

www.wika.it

Poland

WIKA Polska S.A.

87-800 Wloclawek

Tel. (+48) 542 3011-00

Fax: (+48) 542 3011-01

E-mail: info@wikapolska.pl

www.wikapolska.pl

Romania

WIKA Instruments Romania S.R.L.

Bucuresti, Sector 5

Calea Rahovei Nr. 266-268

Corp 61, Etaj 1

Tel. (+40) 21 4048327

Fax: (+40) 21 4563137

E-mail: m.anghel@wika.ro

Russia

ZAO WIKA MERA

127015 Moscow

Tel. (+7) 495 64801-80

Fax: (+7) 495 64801-81

E-mail: info@wika.ru

www.wika.ru

Serbia

WIKA Merna Tehnika d.o.o.

Sime Solaje 15

11060 Belgrade

Tel. (+381) 11 2763-722

Fax: (+381) 11 7536-74

E-mail: info@wika.co.yu

www.wika.co.yu

Spain

Instrumentos WIKA, S.A.

C/Josep Carner, 11-17

08205 Sabadell (Barcelona)

Tel. (+34) 902902577

Fax: (+34) 933938666

E-Mail: info@wika.es

www.wika.es

Switzerland

Manometer AG

6285 Hitzkirch

Tel. (+41) 41 91972-72

Fax: (+41) 41 91972-73

E-mail: info@manometer.ch

www.manometer.ch

Turkey

WIKA Instruments Istanbul

Basinc ve Sicaklik Ölcme Cihazlari

Ith. Ihr. ve Tic. Ltd. Sti.

Bayraktar Bulvari No. 21

34775 Yukari Dudullu - Istanbul

Tel. (+90) 216/415 90 66

Fax: (+90) 216/415 90 97

E-mail: info@wika.com.tr

www.wika.com.tr

Ukraine

WIKA Pribor GmbH

83016 Donetsk

Tel. (+38) 062 34534-16

Fax: (+38) 062 34534-17

E-mail: info@wika.ua

www.wika.ua

United Kingdom

WIKA Instruments Ltd

Merstham, Redhill RH13LG

Tel. (+44) (0) 1737644-008

Fax: (+44) (0) 1737644-403

E-mail: info@wika.co.uk

www.wika.co.uk

North America

Canada

WIKA Instruments Ltd.

Head Office

Edmonton, Alberta, T6N 1C8

Tel. (+1) 780 4637035

Fax: (+1) 780 4620017

E-mail: info@wika.ca

www.wika.ca

Mexico

Instrumentos WIKA Mexico S.A.

de C.V.

01210 Mexico D.F.

Tel. (+52) 555 02053-00

Fax: (+52) 555 02053-01

E-Mail: ventas@wika.com

www.wika.com.mx

USA

WIKA Instrument Corporation

Lawrenceville, GA 30043

Tel. (+1) 770 5138200

Fax: (+1) 770 3385118

E-mail: info@wika.com

www.wika.com

54

WIKA Betriebsanleitung Druckmessgeräte Typ 7 mit 831 nach ATEX

2080250 07/2009 GB/D/F

Page 55

WIKA Global

WIKA Instrument Corporation

Electrical Temperature Division

950 Hall Court

Deer Park, TX 77536

Tel. (+1) 713 47500-22

Fax (+1) 713 47500-11

E-mail: info@wikaetemp.com

www.wika.com

Mensor Corporation

201 Barnes Drive

San Marcos, TX 78666

Tel. (+1) 512 396420015

Fax (+1) 512 3961820

E-mail: sales@mensor.com

www.mensor.com

South America

Argentina

WIKA Argentina S.A.

Buenos Aires

Tel. (+54) 11-4730 18 00

Fax: (+54) 11-4761 00 50

E-mail: info@wika.com.ar

www.wika.com.ar

Brazil

WIKA do Brasil Ind. e Com. Ltda.

CEP 18560-000 Iperó - SP

Tel. (+55) 15-3459 97 00

Fax: (+55) 15-3266 16 50

E-mail: marketing@wika.com.br

www.wika.com.br

Asia

China

WIKA International Trading

(Shanghai) Co., Ltd.

200001 Shanghai

Tel. (+86) 21 538525-72

Fax: (+86) 21 538525-75

E-mail: info@wika.com.cn

India

WIKA Instruments India Pvt. Ltd.

Village Kesnand, Wagholi

Pune - 412 207

Tel. (+91) 20 66293-200

Fax: (+91) 20 66293-325

E-mail: sales@wika.co.in

www.wika.co.in

Japan

WIKA Japan K. K.

Tokyo 105-0023

Tel. (+81) 3 543966-73

Fax: (+81) 3 543966-74

E-mail: t-shimane@wika.co.jp

Kazakhstan

TOO WIKA Kazakhstan

050050 Almaty

Tel. (+7) 32 72330848

Fax: (+7) 32 72789905

E-mail: info@wika.kz

Korea

WIKA Korea Ltd.

Seoul 153-023

Tel. (+82) 2 86905-05

Fax: (+82) 2 86905-25

E-mail: info@wika.co.kr

Malaysia

WIKA Instrumentation (M) Sdn.

Bhd.

47100 Puchong, Selangor

Tel. (+60) 3 806310-80

Fax: (+60) 3 806310-70

E-mail: info@wika.com.my

www.wika.com.my

Singapore

WIKA Instrumentation Pte. Ltd.

569625 Singapore

Tel. (+65) 68 4455-06

Fax: (+65) 68 4455-07

E-mail: info@wika.com.sg

www.wika.com.sg

Taiwan

WIKA Instrumentation Taiwan Ltd.

Pinjen, Taoyuan

Tel. (+886) 3 4206052

Fax: (+886) 3 4900080

E-mail: info@wika.com.tw

www.wika.com.tw

Africa / Middle East

Egypt

WIKA Near East Ltd.

El-Serag City Towers

-Tower#2 - Office#67Nasr City Cairo

Tel. (+20) 2 227 33 140

Fax: (+20) 2 227 03 815

E-mail: wika.repcairo@wika.de

www.wika.com.eg

South Africa

WIKA Instruments (Pty.) Ltd.

Gardenview, Johannesburg 2047

Tel. (+27) 11-621 00 00

Fax: (+27) 11-621 00 59

E-mail: sales@wika.co.za

www.wika.co.za

United Arab Emirates

WIKA Middle East FZE

Jebel Ali, Dubai

Tel. (+971) 4 8839-090

Fax: (+971) 4 8839-198

E-mail:

wikame@emirates.net.ae

Australia

Australia

WIKA Australia Pty. Ltd.

Rydalmere, NSW 2116

Tel. (+61) 2 88455222

Fax: (+61) 2 96844767

E-mail: sales@wika.com.au

www.wika.com.au

New Zealand

Process Instruments Limited

Unit 7 / 49 Sainsbury Road

St Lukes - Auckland 1025

Tel. (+64) 9 8479020

Fax: (+64) 9 8465964

E-mail: info@wika.co.nz

www.wika.co.nz

2080250 07/2009 GB/D/F

WIKA Betriebsanleitung Druckmessgeräte Typ 7 mit 831 nach ATEX

55

Page 56

Technical alteration rights reserved.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg • Germany

Tel. (+49) 9372/132-0

Fax (+49) 9372/132-406

E-Mail info@wika.de

www.wika.de

56

WIKA Betriebsanleitung Druckmessgeräte Typ 7 mit 831 nach ATEX

2080250.02 07/2009 GB/D/F

Loading...

Loading...