Page 1

Operating Instructions

Betriebsanleitung

Mode d'emploi

Manual de Instrucciones

Differential Pressure Transmitter, Model DP-10

Differenzdruck-Messumformer, Typ DP-10

Transmetteur de pression différentielle, Type DP-10

Transmisor de presión diferencial, Modelo DP-10

GB

D

F

E

Differential Pressure Transmitter, Model DP-10

Page 2

Operating Instructions Model DP-10 Page 3 - 11

GB

Betriebsanleitung Typ DP-10 Seite 12 - 21

D

F

Mode d'emploi Type DP-10 Page 22 - 31

E

Manual de Instrucciones Modelo DP-10 Página 32 - 41

Information

This symbol provides you with information, notes and tips.

Warning!

This Symbol warns you against actions that can cause injury to

people or damage to the instrument.

2333401 07/2009 GB/D/F/E

2

Page 3

Contents

Contents

1. Safety instructions 4

Measuring principle 4

2.

3. Mounting 5

3.1

Mounting instructions

3.2

Process connections

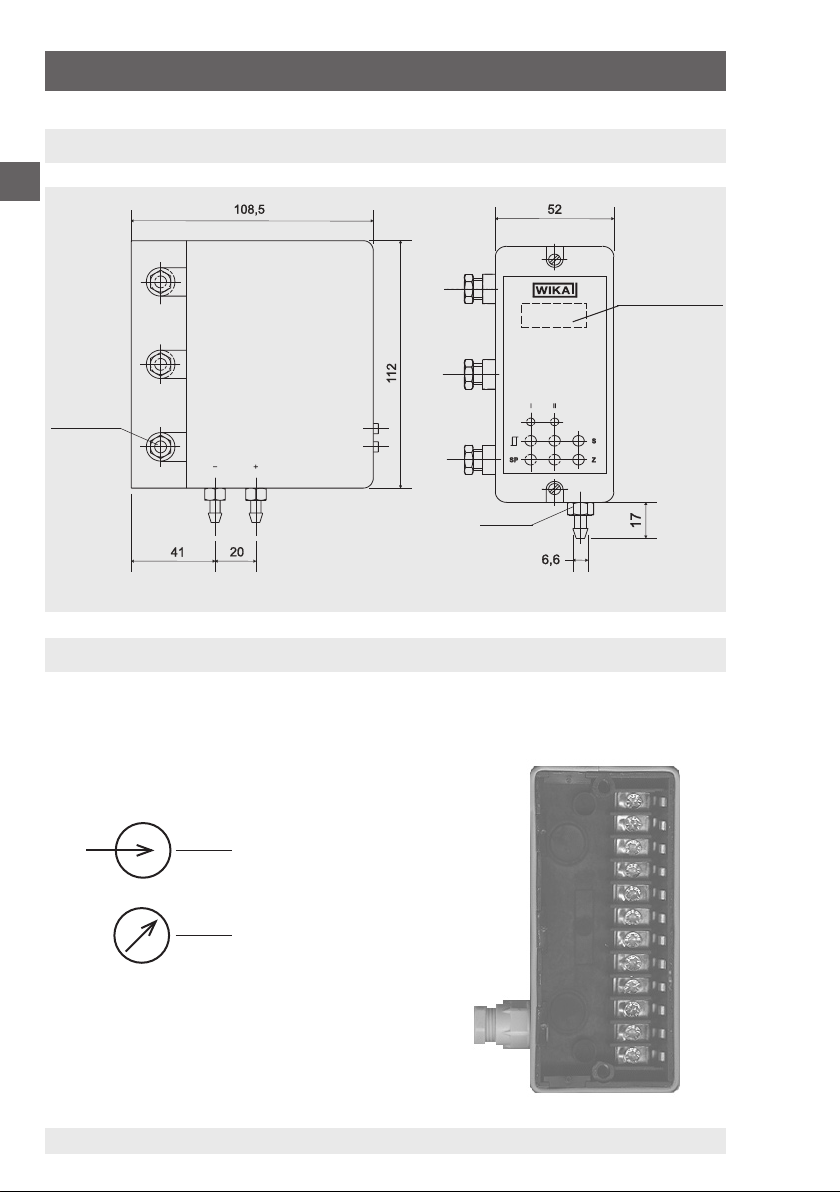

4. Dimensions in mm 6

5. Electrical connection 6

6. Calibration instructions 8

6.1

Zero point adjustment (Z)

6.2

Span adjustment (S)

6.3

Adjustment of the alarm contacts

7. Specifications 10

GB

5

5

8

8

8

8. EC-Declaration of Conformity 42

2333401 07/2009 GB/D/F/E

WIKA Operating Instructions Differential Pressure Transmitter 3

Page 4

1. Safety instructions / 2. Measuring principle

1. Safety instructions

GB

Please observe the following operating parameters

The relevant national safety provisions (e.g. VDE 0100) must be

observed when mounting, putting into commission and operating this pressure transmitter. Severe injuries and/or damage

might occur as a result of non-compliance with the corresponding provisions. Only qualified personnel is authorised to work on

these instruments.

The pressure transmitter is exclusively suitable for dry, clean,

non-aggressive gases.

Do not blow into the process connections!

The measuring cell might be damaged by the respiratory

pressure.

Max. medium/ambient temperature: 10 ... 50 °C

It has to be made sure that during transportation both

process connections are open. Instruments with absolute

pressure measuring ranges must be transported in pressure

compensation cabins.

2. Measuring principle

The pressure mesurement is realised via a sensitive diaphragm or, in the case of

absolute pressure measuring ranges, a capsule which is adapted to the measuring

range. An inductive system generates a linear signal which changes in proportion to

the prevailing pressure.

4

WIKA Operating Instructions Differential Pressure Transmitter

2333401 07/2009 GB/D/F/E

Page 5

3. Mounting

3. Mounting

The differential pressure transmitter is designed for wall-mounting. After unscrewing

the two screws at the case the black connection socket can be pulled off the case.

The socket has rated break points for the fastening screws.

3.1 Mounting instructions

The wall-mounting should be carried out in a vertical position, i.e. the process

connections facing down, because the instrument was adjusted in this position.

Thus a possible condensate penetration into the pressure line is avoided.

The mounting location should be free of shocks, vibrations and heat irradiation.

The instrument should not be mounted in the close environment of sources of

interference (e.g. transformers, motors, senders).

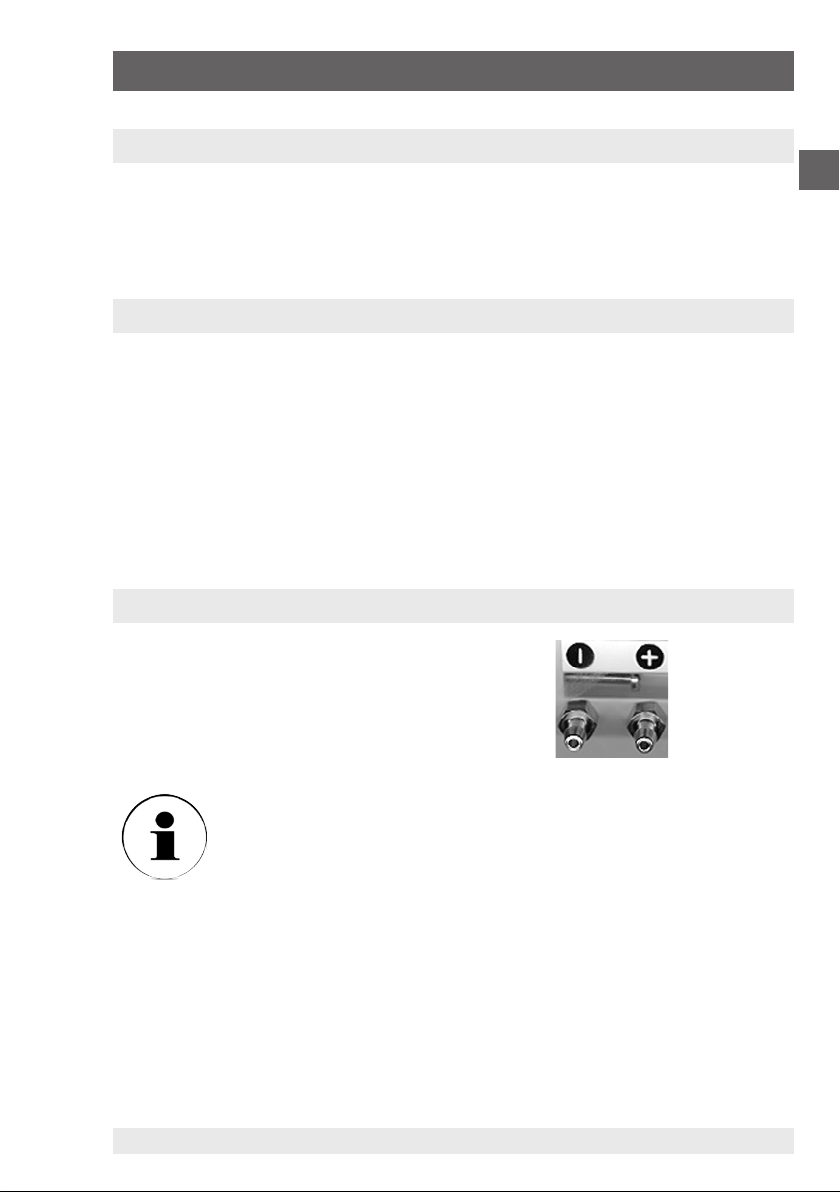

3.2 Process connections

GB

2 x hose connection 6.6 x 11 mm

for hoses with an inside diameter of 5 ... 6 mm.

Pressure is to be connected to the „+“ connection.

Vacuum is to be connected to the „-“ connection.

Instruments with absolute pressure measuring ranges have only

one process connection.

2333401 07/2009 GB/D/F/E

WIKA Operating Instructions Differential Pressure Transmitter 5

Page 6

4. Dimensions in mm / 5. Electrical connection

4. Dimensions in mm

GB

M12 x 1.5

Digital display

SW 10

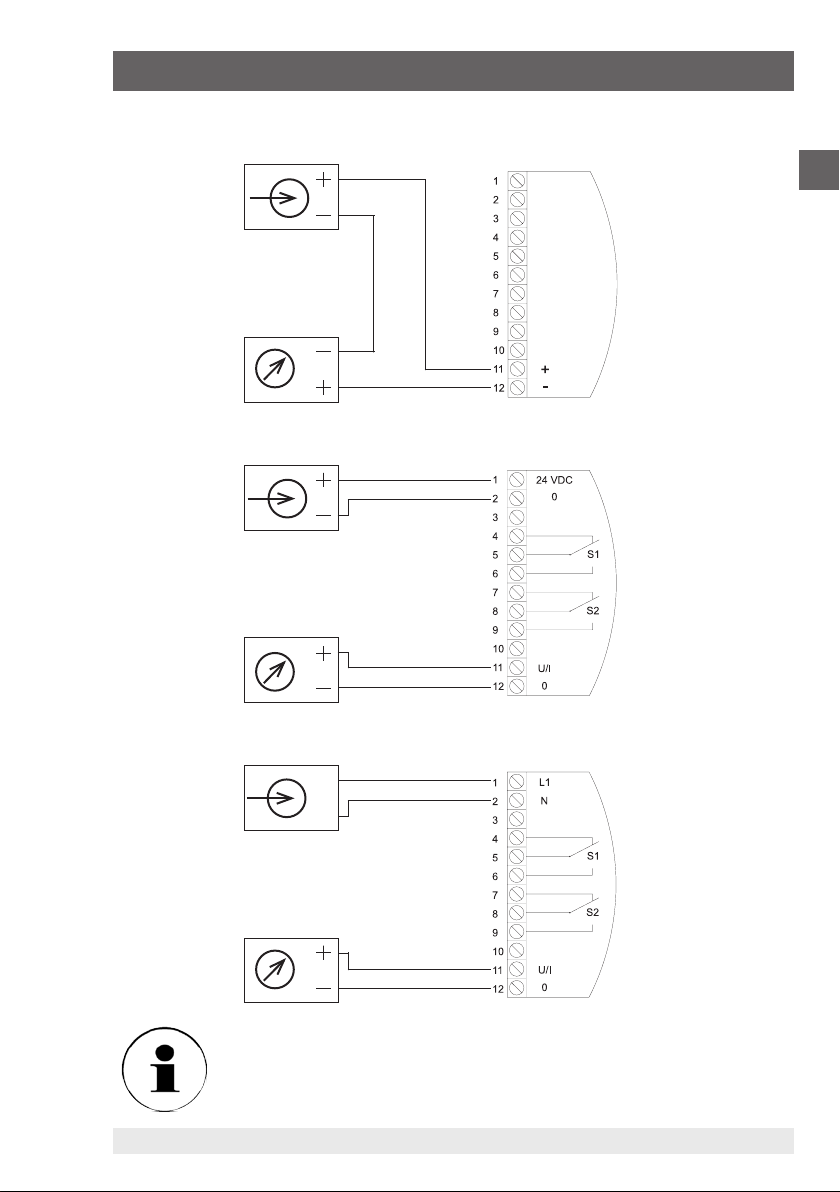

5. Electrical connection

The cable is led through the M12 x 1.5 gland into the connection socket. In the

socket are screw terminals for the wiring (terminal area up to 1.5 mm²).

Power supply

Sink e.g. display

6

WIKA Operating Instructions Differential Pressure Transmitter

2333401 07/2009 GB/D/F/E

Page 7

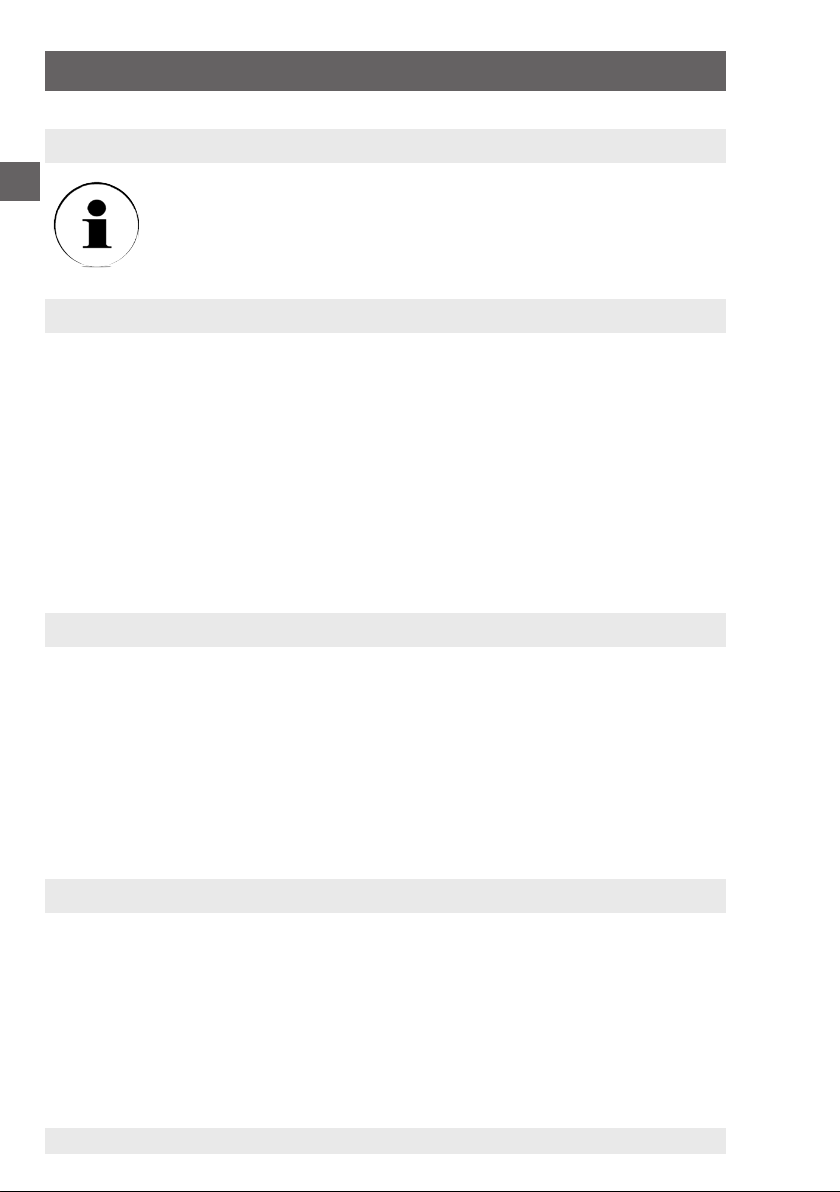

5. Electrical connection

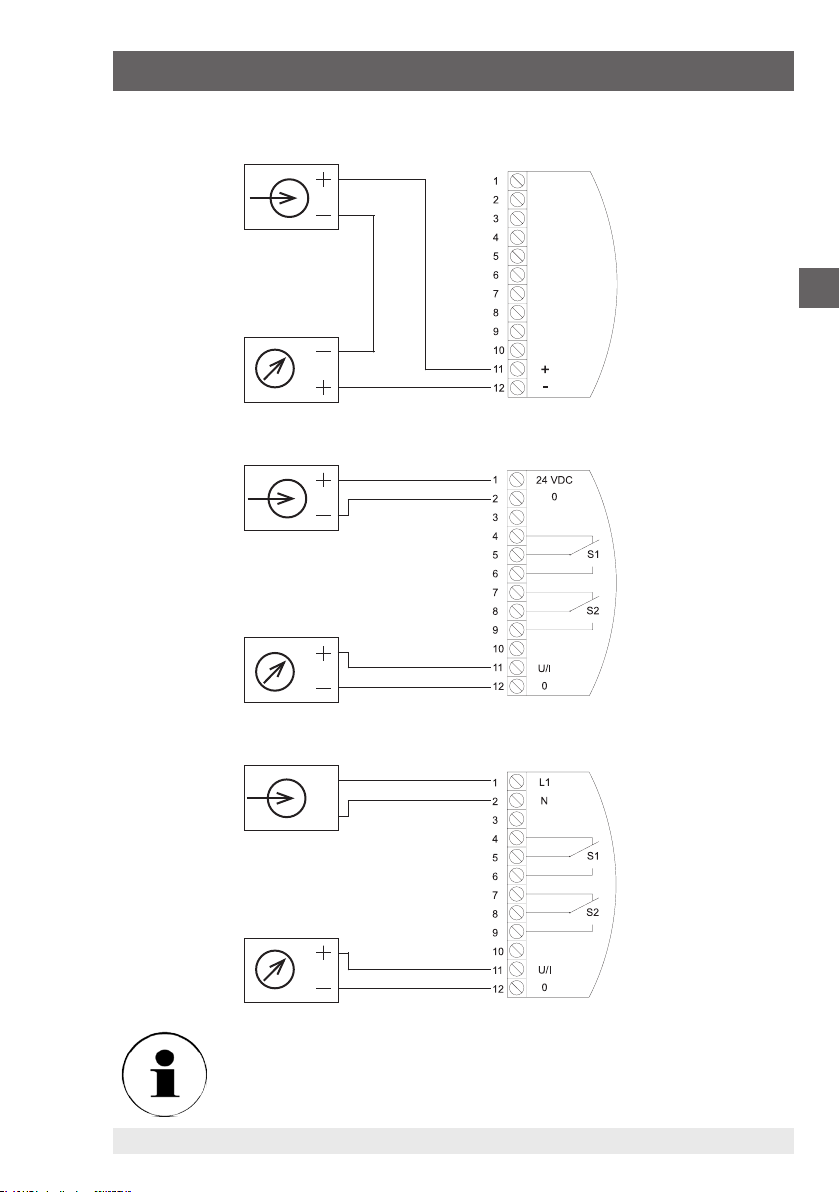

2-wire

3-wire

GB

4-wire (AC-Supply)

L1

N

Be cautious when connecting supply voltages.

Do not connect supply voltage to the output terminals

2333401 07/2009 GB/D/F/E

WIKA Operating Instructions Differential Pressure Transmitter 7

Page 8

6. Calibration instructions

6. Calibration instructions

GB

Please start the calibration only after a running-in period of approx.

30 - 60 minutes.

6.1 Zero point adjustment (Z)

For the zero point adjustment both process connections must be open. After pulling

off the rubber plugs at the instrument‘s front the output signal can be adjusted with

the zero potentiometer (Z).

For the adjustment of pressure transmitters with absolute pressure measuring range

the process connection is to be connected to a pressure generator and an absolute

pressure reference via a T-piece. Subsequently an absolute pressure is generated for

which the output signal shall be: 0 V / 0 mA or 4 mA. Now the output signal can be

adjusted with the zero potentiometer (Z).

6.2 Span adjustment (S)

For the span adjustment the nominal pressure must be connected via a T-piece from

the pressure generation to the pressure reference and the pressure channel.

The WIKA precision calibrator model CPC2000, which has a pressure generation

and a pressure reference, is excellently suitable for this task.

Pressure is to be connected to the “+” connection and vacuum to the “-” connection. Now the output signal may be adjusted with the span potentiometer (S).

6.3 Adjustment of the alarm contacts

For the adjustment of the alarm contacts the reference pressure must be applied

at which the contact is supposed to close. This is accomplished with a pressure

generator which is connected to the pressure reference and the pressure channel via

a T-piece. Pressure is to be connected to the “+” connection and vacuum to the “-”

connection. The potentiometer of the switch point SP I or II must be adjusted until

the red LED above the respective potentiometer lights up, i.e. the switch value has

been reached and the contact closes.

8

WIKA Operating Instructions Differential Pressure Transmitter

2333401 07/2009 GB/D/F/E

Page 9

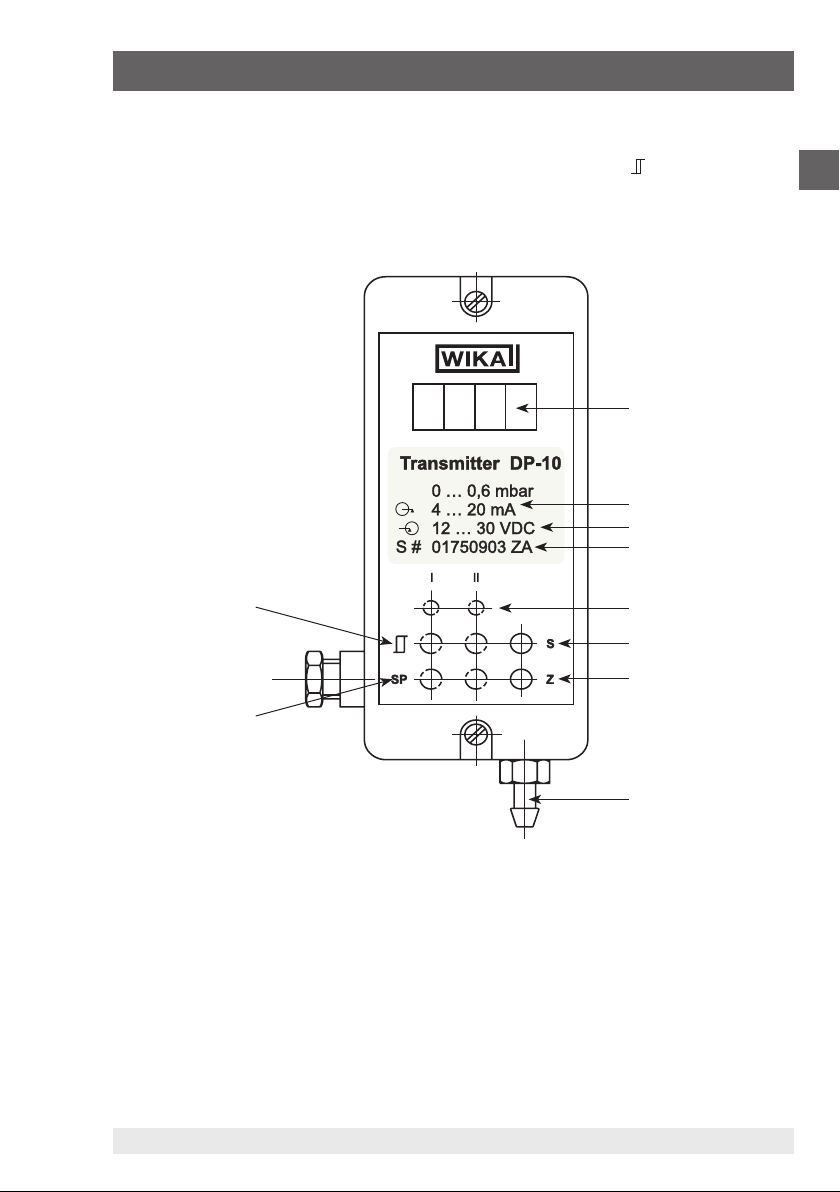

6. Calibration instructions

Then the pressure at which the contact is desired to break again must be applied.

Now the respective hysteresis potentiometer must be adjusted ( ) until the LED

goes out again. The switching hysteresis is adjustable within a range of 0 ... 15 %.

3. LCD (optional)

CE

4. Signal

5. Power Supply

6. Product No.

GB

1. Potentiometer for

switching hysteresis

2. Potentiometer for

switching points

2333401 07/2009 GB/D/F/E

7. Alarm contacts

(optional)

8. Span potentiometer

9. Zero potentiometer

10. Process connection

WIKA Operating Instructions Differential Pressure Transmitter 9

Page 10

7. Specifications

7. Specifications

GB

Specifications Model DP-10

Pressure ranges

Over pressure safety mbar 3 5 8 12.5 20 30 50 80 125

Pressure ranges

Over pressure safety mbar 200 300 500 800 1000 1000 1200 2000

Maximum static pressure mbar 1000 {2000}

Pressure reference

Pressure connection mm two hose connections Ø 6.6 x 11 for hoses with

Materials

Wetted parts Ms, CuBe, PU, Ni

Case bottom part: ABS, glass fibre reinforced, top part: ABS

Power supply U

Signal output and Maximum load R

Power consumption mA

Response time (10 ... 90 %) ms approx. 20 {attenuation on request}

Adjustability zero point / span ± 5 % of span

Accuracy ≤ 1.0 % of span (limit point calibration) {0.5 or 0.2 for pressure

Hysteresis ≤ 0.1 % d. Spanne

Repeatability ≤ 0.05 % of span

1-year stability ≤ 0.5 % of span (at reference conditions)

Permissible temperature of

Medium -10 ... +50 °C 14 ... 122 °F

Ambient -10 ... +50 °C {-10 ... +60 °C} 14 ... 122 °F (14 ... 140 °F)

Storage -10 ... +70 °C 14 ... 158 °F

Compensated temperature range +10 ... +50 °C 14 ... 122 °F

Temperature coefficients in compensated temp range:

Mean TC of zero ≤ 0.3 % of span/10K

Mean TC of range ≤ 0.3 % of span/10K

{ } Items in curved brackets are optional extras for additional price.

1) The measuring ranges 0 ... 0.1 mbar; 0 ... 0.25 mbar; 0 ... 0.4 mbar are available on request.

For these measuring ranges a larger measuring cell and consequently also a case with larger dimensions is required.

2) Only with 4 ... 20 mA 2-wire, other output signals on request.

1)

1)

mbar 0.6 1 1.6 2.5 4 6 10 16 25

mbar 40 60 100 160 250 400 600 1000

relative pressure, differential pressure, {absolute pressure2) from

500 mbar abs; special pressure range 800 ... 1200 mbar abs}

inside Ø 5 ... 6 {2 x clamping ring connection G ⅛, Ms}

DC V

B

19 ... 31 {12 ... 30 with signal output 4 ... 20 mA, 2-wire system}

AC V {24, 115 or 230 (respectively ± 10 %, 50 ... 60 Hz)}

A

0 ... 10 V, 3-wire system RA > 2,0 kOhm

{0 ... 5 V, 3-wire system} R

{0 (4)... 20 mA, 3-wire system} R

{4 ... 20 mA, 2-wire system} R

{other on request}

≤ 2,0 kOhm

A

≤ 500 Ohm

A

≤ (U

[V] – 12 V) / 0,02 mA

A

B

≤ 10; (3-/4-wire); (AC-/DC-supply)

range from 2.5 mbar}

2333401 07/2009 GB/D/F/E

10

WIKA Operating Instructions Differential Pressure Transmitter

Page 11

7. Specifications

Specifications Model DP-10

Shock resistance g 10

Suitable media clean, non-aggressive, dry gases

Sensor volume ml approx. 5 (approx. 7 for measuring ranges < 2.5 mbar)

Increase in volume ml approx. 1 at nominal pressure

CE-conformity Interference emission and immunity see EN 61 326 / A1;

{integrated indicator}

Digital LC display, 3 ½-digits; height of digits 10 mm, pick-up rate

Analogue analogue indicator 0 ... 100 %

{Alarm contacts} only with 3-wire systems

Number 1 or 2

Switching function standard setting 2 x max.

Adjustability 1 ... 100 % of span

Switching accuracy ≤ 1 % of span

Switching repeatability 0,2 % of span, typical

Switching hysteresis 0 ... 10 % of span, adjustable

Contacts 1 potential-free relay change-over contact per alarm contact

Contact rating AC 6 A, 230 V with ohmic load

{Root-evolved output signal}

Accuracy 1,0 % of span

Calculation the root is evolved according to the following equations:

Electrical connection via cable gland PG 7 and internal screw terminals in the

Ingress of protection IP54, per EN 60 529 / IEC 529

Weight kg approx. 0.6 {approx. 0.7 with power supply}

Dimensions mm see drawings

Mounting case for wall mounting

{ } Items in curved brackets are optional extras for additional price.

1) The measuring ranges 0 ... 0.1 mbar; 0 ... 0.25 mbar; 0 ... 0.4 mbar are available on request.

For these measuring ranges a larger measuring cell and consequently also a case with larger dimensions is required.

2) Only with 4 ... 20 mA 2-wire, other output signals on request.

declaration of conformity on request european guideline for

low voltages EN 610 10

3/sec.

UR = √ 10 x UL) UL = linear output 0 ... 10 V

IR = √ 20 x IL) IL = linear output 0 ... 20 mA

bottom part of the case, terminal champing diameter 1.5 mm²

GB

2333401 07/2009 GB/D/F/E

WIKA Operating Instructions Differential Pressure Transmitter 11

Page 12

D

Information

Dieses Zeichen gibt Ihnen Informationen, Hinweise oder Tipps.

Warnung!

Dieses Symbol warnt Sie vor Handlungen, die Schäden an

Personen oder am Gerät verursachen können.

WIKA Betriebsanleitung Differenzdruckmessumformer12

2333401 07/2009 GB/D/F/E

Page 13

Inhalt

Inhalt

1. Sicherheitshinweise 14

Messprinzip 14

2.

3. Montage 15

D

3.1

Montagehinweise

3.2

Prozessanschlüsse

4. Abmessungen in mm 16

5. Elektrischer Anschluss 16

6. Kalibrieranleitung 18

6.1

Einstellung des Nullpunktes (Z)

6.2

Einstellung der Spanne (S)

6.3

Einstellung der Grenzkontakte

7. Technische Daten 20

8. EG-Konformitätserklärung 42

15

15

18

18

18

2333401 07/2009 GB/D/F/E

WIKA Betriebsanleitung Differenzdruckmessumformer 13

Page 14

1. Sicherheitshinweise / 2. Messprinzip

1. Sicherheitshinweise

Beachten Sie unbedingt bei Montage, Inbetriebnahme und

D

Bitte beachten Sie folgende Betriebsparameter

Betrieb dieses Druckmessumformers die entsprechenden nationalen Sicherheitsvorschriften

(z. B.: VDE 0100). Bei Nichtbeachten entsprechender

Vorschriften können schwere Körperverletzungen und/oder

Sachschäden auftreten.

Nur entsprechend qualifiziertes Personal darf an diesen Geräten

arbeiten.

Der Druckmessumformer ist ausschließlich für trockene,

saubere, nicht aggressive Gase geeignet.

Nicht in die Prozessanschlüsse blasen!

Die Messzelle kann durch den Lungendruck beschädigt

werden.

Max. Messstoff-/Umgebungstemperatur: 10 ... 50 °C

Beim Transport ist darauf zu achten, dass beide Prozessan-

schlüsse offen sind. Geräte mit Absolutdruck-Messbereichen

müssen bei Luftfracht in Kabinen mit Druckausgleich befördert werden.

2. Messprinzip

Die Druckmessung erfolgt über eine dem Messbereich angepasste, empfindliche

Plattenfeder, bzw. einer Kapselfeder bei Absolutdruck-Messbereichen. Ein induktives System erzeugt ein lineares Signal, das sich proportional zum anstehenden

Druck verändert.

WIKA Betriebsanleitung Differenzdruckmessumformer14

2333401 07/2009 GB/D/F/E

Page 15

3. Montage

3. Montage

Der Differenzdruck-Messumformer ist für Wandmontage vorgesehen. Nach dem

Lösen der beiden Schrauben am Gehäuse kann der schwarze Anschluss-Sockel

vom Gehäuse abgezogen werden. Im Sockel sind Sollbruchstellen für die Befestigungsschrauben vorhanden.

3.1 Montagehinweise

Der Wandanbau sollte in vertikaler Lage erfolgen, d. H. die Prozessanschlüsse

zeigen nach unten, da das Gerät in dieser Lage eingestellt wurde. Das eventuelle

Eindringen von Kondensat in die Druckleitungen wird so vermieden.

Der Montageort sollte frei von Erschütterungen, Vibrationen, sowie von Wärme-

einstrahlung sein.

Die Montage sollte nicht in unmittelbarer Nähe von Störquellen (z. B. Trafos,

Motoren, Sender) erfolgen.

3.2 Prozessanschlüsse

D

2 x Schlauchanschluss 6,6 x 11 mm

für Schläuche mit Innendurchmesser 5 ... 6 mm.

Ein positiver Überdruck wird an den „+” Eingang angeschlossen.

Ein negativer Überdruck wird an den „-“ Eingang angeschlossen.

Geräte mit Absolutdruck-Messbereichen verfügen nur über einen

Prozessanschluss.

2333401 07/2009 GB/D/F/E

WIKA Betriebsanleitung Differenzdruckmessumformer 15

Page 16

4. Abmessungen in mm / 5. Elektrischer Anschluss

4. Abmessungen in mm

D

M12 x 1,5

SW 10

Anzeigefeld

Digitalanzeige

5. Elektrischer Anschluss

Das Kabel wird durch die M12 x 1,5 Verschraubung in den Anschlusssockel geführt.

Im Sockel befinden sich Schraubklemmen für die Verdrahtung (Klemmbereich bis

1,5 mm²).

Hilfsenergie

Verbraucher

z. B. Anzeige

WIKA Betriebsanleitung Differenzdruckmessumformer16

2333401 07/2009 GB/D/F/E

Page 17

5. Elektrischer Anschluss

2-Leiter

3-Leiter

D

4-Leiter (AC-Versorgung)

L1

N

Vorsicht beim Anschließen von Versorgungsspannungen.

Versorgungsspannung nicht an die Ausgangsklemmen anschlie-

2333401 07/2009 GB/D/F/E

ßen.

WIKA Betriebsanleitung Differenzdruckmessumformer 17

Page 18

6. Kalibrieranleitung

6. Kalibrieranleitung

Bitte beginnen Sie mit der Kalibrierung erst nach einer Einlaufzeit

D

6.1 Einstellung des Nullpunktes (Z)

Zum Abgleich des Nullpunktes müssen beide Druckeingänge offen sein. Nach dem

Abziehen der Gummistopfen auf der Gerätevorderseite kann das Ausgangssignal mit

dem Nullpunktpotentiometer (Z) eingestellt werden.

Beim Abgleich von Druckmessumformern mit Absolutdruck-Messbereich wird der

Druckeingang über ein T-Stück mit einer Druckerzeugung und mit einer Absolutdruckreferenz verbunden. Danach wird der Absolutdruck erzeugt, bei dem das

Ausgangssignal: 0 V bzw. 0 mA oder 4 mA betragen soll. Jetzt kann das Ausgangssignal mit dem Nullpunktpotentiometer (Z) eingestellt werden.

6.2 Einstellung der Spanne (S)

von ca. 30 ... 60 Minuten.

Zum Abgleich der Spanne wird der Nenndruck über ein T-Stück von der Druckerzeugung an die Druckreferenz und den Druckkanal angeschlossen.

Der WIKA Präzisionskalibrator Typ CPC2000, der über eine Druckerzeugung, sowie

über die Druckreferenz verfügt, ist hierfür hervorragend geeignet.

Positiver Überdruck wird an den „+“ Eingang und negativer Überdruck an den „–“

Eingang angeschlossen. Nun kann das Ausgangssignal mit dem Spanne-Potentiometer (S) eingestellt werden.

6.3 Einstellung der Grenzkontakte

Zur Einstellung der Grenzkontakte wird der Druck angelegt, bei dem der Kontakt

schließen soll. Dies erfolgt mit einer Druckerzeugung, die über ein T-Stück mit der

Druckreferenz und dem Druckkanal verbunden ist. Positiver Überdruck wird an

den „+“ Eingang und negativer Überdruck an den „–“ Eingang angeschlossen. Das

Potentiometer des Schaltpunktes SP I bzw. II wird solange verstellt, bis die rote LED

oberhalb des jeweiligen Potentiometers aufleuchtet. Damit ist der Einschaltwert

erreicht, das Relais ist geschlossen.

WIKA Betriebsanleitung Differenzdruckmessumformer18

2333401 07/2009 GB/D/F/E

Page 19

6. Kalibrieranleitung

Danach wird der Druck angelegt, bei dem sich der Kontakt wieder öffnen soll. Jetzt

wird das entsprechende Hysterese- Potentiomer ( ) solange verstellt, bis die LED

wieder erlischt. Die Schalthysterese ist im Bereich von 0 ... 15 % einstellbar.

3. LCD-Anzeige (Option)

CE

4. Signal

5. Hilfsenergie

6. Fabrik-Nr.

7.

1. Potentiometer für

Schalthysterese

Grenzkontakte (Option)

8. Spanne-Potentiometer

D

9. Nullpunkt-Potentio-

2. Potentiometer für

Schaltpunkte

2333401 07/2009 GB/D/F/E

meter

10. Prozessanschluss

WIKA Betriebsanleitung Differenzdruckmessumformer 19

Page 20

7. Technische Daten

7. Technische Daten

Technische Daten Typ DP-10

D

Messbereich

Überlastgrenze mbar 3 5 8 12,5 20 30 50 80 125

Messbereich

Überlastgrenze mbar 200 300 500 800 1000 1000 1200 2000

Maximaler statischer Druck mbar 1000 {2000}

Druckart Relativdruck, Differenzdruck {Absolutdruck2) ab 500 mbar

Druckanschluss mm zwei Schlauchanschlüsse Ø 6,6 x 11 für Schläuche mit Innen-

Werkstoff

Hilfsenergie U

Ausgangssignal und zulässige max.

Bürde R

Stromaufnahme mA ≤ 10; (3-/4-Leiter); (AC-/DC-Versorgung)

Einstellzeit (10 ... 90 %) ms ca. 20 {Dämpfung auf Anfrage}

Einstellbarkeit: Nullpunkt/Spanne ± 5 % d. Spanne

Kennlinienabweichung √ 1,0 % d. Spanne (Grenzpunkteinstellung) {0,5 oder 0,2 ab

Hysterese ≤ 0,1 % d. Spanne

Reproduzierbarkeit ≤ 0,05 % d. Spanne

Stabilität pro Jahr ≤ 0,5 % d. Spanne (bei Referenzbedingungen)

Zulässige Temperaturen

Kompensierter Temperaturbereich +10 ... +50 °C 14 ... 122 °F

Temperaturkoeffizienten im Kompensierten Temperaturbereich:

{ } Angaben in geschweiften Klammern beschreiben gegen Mehrpreis lieferbare Sonderheiten

1) Die Messbereiche 0 ... 0,1 mbar; 0 ... 0,25 mbar; 0 ... 0,4 mbar sind auf Anfrage lieferbar.

Bei diesen Messbereichen wird eine größere Messzelle und deshalb ein Gehäuse mit größeren Abmessungen benötigt.

2) Nur bei 4 ... 20 mA Zweileiter, andere Ausgangssignale auf Anfrage.

1)

1)

mbar 0,6 1 1,6 2,5 4 6 10 16 25

mbar 40 60 100 160 250 400 600 1000

abs; Sondermessbereich 800 ... 1200 mbar abs}

Ø 5 ... 6 {2 x Klemmringverschraubung G ⅛, Ms}

Messstoffberührte Teile Ms, CuBe, PU, Ni

Gehäuse Unterteil: ABS, glasfaserverstärkt, Oberteil: ABS

B

DC V 19 ... 31 {12 ... 30 bei Ausgang 4 ... 20 mA, Zweileiter}

AC V {24, 115 oder 230 (jeweils ± 10 %, 50 ... 60 Hz)}

0 ... 10 V, Dreileiter RA > 2,0 kOhm

A

{0 ... 5 V, Dreileiter} R

{0 (4)... 20 mA, Dreileiter} R

{4 ... 20 mA, Zweileiter} R

{andere auf Anfrage}

≤ 2,0 kOhm

A

≤ 500 Ohm

A

≤ (U

[V] – 12 V) / 0,02 mA

A

B

Messbereich 2,5 mbar}

Messstoff -10 ... +50 °C 14 ... 122 °F

Umgebung -10 ... +50 °C {-10 ... +60 °C} 14 ... 122 °F (14 ... 140 °F)

Lagerung -10 ... +70 °C 14 ... 158 °F

Mittlerer TK des Nullpunktes ≤ 0,3 % d. Spanne/10K

Mittlerer TK der Spanne ≤ 0,3 % d. Spanne/10K

2333401 07/2009 GB/D/F/E

WIKA Betriebsanleitung Differenzdruckmessumformer20

Page 21

7. Technische Daten

Technische Daten Typ DP-10

Schockbelastbarkeit g 10

Geeignete Messstoffe saubere, nicht aggressive, trockene Gase

Sensorvolumen ml ca. 5 (ca. 7 bei Messbereichen < 2,5 mbar)

Volumenzuwachs ml ca. 1 bei Nenndruck

CE-Kennzeichen Störemission und Störfestigkeit nach EN 61 326/A1,

{integrierte Anzeige}

Digital LCD-Anzeige, 3 ½-stellig; Ziffernhöhe 10 mm, Wandlungsrate

Analog Analoganzeige 0 ... 100 %

{Grenzkontakte} nur bei Dreileitersystemen

Anzahl 1 oder 2

Schaltfunktion Standardeinstellung 2 x max.

Einstellbarkeit 1 ... 100 % d. Spanne

Schaltgenauigkeit ≤ 1 % d. Spanne

Schaltreproduzierbarkeit 0,2 % d. Spanne , typisch

Schalthysterese 0 ... 10 % d. Spanne, einstellbar

Kontakte je 1 potentialfreier Relaisumschaltkontakt pro Grenzkontakt

Kontaktbelastung AC 6 A, 230 V bei ohmscher Last

{radiziertes Ausgangssignal}

Genauigkeit 1,0 % d. Spanne

Berechnung Die Radizierung wird nach folgenden Gleichungen vorgenommen:

Elektrischer Anschluss über Kabelverschraubung PG 7 und innenliegende Schraub-

Schutzart IP54, nach EN 60 529 / IEC 529

Masse kg ca. 0,6 {ca. 0,7 mit Netzteil}

Maße mm siehe Abmessungen

Montage Gehäuse für Wandmontage

{ } Angaben in geschweiften Klammern beschreiben gegen Mehrpreis lieferbare Sonderheiten

1) Die Messbereiche 0 ... 0,1 mbar; 0 ... 0,25 mbar; 0 ... 0,4 mbar sind auf Anfrage lieferbar.

Bei diesen Messbereichen wird eine größere Messzelle und deshalb ein Gehäuse mit größeren Abmessungen benötigt.

2) Nur bei 4 ... 20 mA Zweileiter, andere Ausgangssignale auf Anfrage.

Konformitätserklärung auf Anfrage,

Niederspannungsrichtlinie EN 610 10

3/sek.

UR = √ 10 x UL) UL = linearer Ausgang 0 ... 10 V

IR = √ 20 x IL) IL = linearer Ausgang 0 ... 20 mA

klemmen im Gehäuseunterteil

Klemmbereich 1,5 mm²

D

2333401 07/2009 GB/D/F/E

WIKA Betriebsanleitung Differenzdruckmessumformer 21

Page 22

F

Information

Ce signe indique des informations, des remarques ou des

conseils.

Avertissement !

Ce symbole vous avertit d‘actions qui sont susceptibles

d‘entraîner des dommages physiques ou matériels.

WIKA Mode d'emploi Transmetteur de pression différentielle22

2333401 07/2009 GB/D/F/E

Page 23

Sommaire

Sommaire

1. Remarques de sécurité 24

Principe de mesure 24

2.

3. Montage 25

3.1

Remarques pour le montage

3.2

Raccords de pression

4. Dimensions en mm 26

5. Raccords électriques 26

6. Instructions de calibration 28

6.1

Réglage du zéro (Z)

6.2

Réglage du gain (S)

6.3

Réglage des seuils d’alarme

7. Caractéristiques techniques 30

8. Déclaration de Conformité CE 43

25

25

28

28

28

F

2333401 07/2009 GB/D/F/E

WIKA Mode d'emploi Transmetteur de pression différentielle 23

Page 24

1. Remarques de sécurité / 2. Principe de mesure

1. Remarques de sécurité

Observez strictement lors du montage, de la mise en service

et de l‘utilisation de ce transmetteur de pression, les prescriptions de sécurité nationales (par exemple VDE 0100). La nonobservance des prescriptions peut provoquer de graves lésions

F

Veuillez respecter les conditions suivantes:

corporelles et/ ou des dégâts matériels. Seul du personnel

qualifié doit travailler sur ces appareils.

Le transmetteur de pression est uniquement adapté pour la

mesure de gaz secs, propres et non aggressifs.

Ne pas souffler dans les raccords pression!

La cellule de mesure peut être détériorée par la pression

pulmonaire.

Température de fluide / ambiante: 10 ... 50 °C

Lors du transport s‘assurer que les deux raccords de

pression sont ouverts. Quant au transport aérien, les

appareils avec plages de mesure en pression absolue doivent

être transportés dans des cabines à compensation de

pression.

2. Principe de mesure

La mesure de pression se fait par une membrane sensible, adaptée à la plage de

mesure, ou par capsule pour les plages de mesure absolues. Un système inductif

génère un signal linéaire changeant proportionnellement par rapport à la pression

appliquée.

WIKA Mode d'emploi Transmetteur de pression différentielle24

2333401 07/2009 GB/D/F/E

Page 25

3. Montage

3. Montage

Le transmetteur de pression différentielle est prévu pour un montage sur paroi.

Après avoir dévissé les deux vis sur le boîtier, le socle de montage peut être retiré du

boîtier. Dans le socle se trouvent des orifices prédécoupés pour le passage des vis

de fixation.

3.1 Remarques pour le montage

Le montage sur paroi doit se faire verticalement, c‘est à dire raccords de pression

dirigés vers le bas, étant donné que l‘appareil a été réglé dans cette position. La

pénétration de condensat dans les conducteurs de pression est ainsi évitée.

Le lieu de montage doit être exempt de chocs, de secousses, de vibrations ainsi

que de radiations thermiques.

Le transmetteur ne doit pas être installé à proximité d’une source d’interférences

magnétiques (Transformateurs, moteurs, )

F

3.2 Raccords de pression

2 raccords pour tuyaux flexibles Ø 6,6 x 11 mm

pour tuyaux d‘un diamètre interne de 5 ... 6 mm.

Une pression positive est raccordée à l‘entrée marquée „+“.

Une pression négative est raccordée à l‘entrée marquée „-“.

Les instruments avec étendues de mesure à pression absolue ne

possèdent qu‘un raccord process.

2333401 07/2009 GB/D/F/E

WIKA Mode d'emploi Transmetteur de pression différentielle 25

Page 26

4. Dimensions en mm / 5. Raccords électriques

4. Dimensions en mm

F

M12 x 1,5

SW 10

fenêtre pour

indicateur

digital

5. Raccords électriques

Le câble est introduit dans le socle de branchement à travers du presse-étoupe M12 x 1,5.

Dans le socle se trouvent des bornes pour le cablâge (section jusqu‘à 1,5 mm²).

Alimentation

WIKA Mode d'emploi Transmetteur de pression différentielle26

Indicateur

2333401 07/2009 GB/D/F/E

Page 27

5. Raccords électriques

2 fils

3 fils

F

4 fils (AC - Alimentation de courant alternatif)

L1

N

Attention lors du branchement de la tension d‘alimentation.

Ne pas brancher la tension d‘alimentation sur les bornes de

2333401 07/2009 GB/D/F/E

sortie.

WIKA Mode d'emploi Transmetteur de pression différentielle 27

Page 28

6. Instructions de calibration

6. Instructions de calibration

Veuillez commencer la calibration après un temps de stabilisation de

30 - 60 minutes.

F

6.1 Réglage du zéro (Z)

Pour le réglage du zéro, il est nécessaire que les deux entrées pression soient

ouvertes. Après avoir retiré les bouchons de caoutchouc sur le devant de l‘appareil,

le signal de sortie peut être réglé à l‘aide du potentiomètre de zéro (Z).

Lors du réglage du transmetteur de pression avec une plage de mesure de pression

absolue, l‘entrée de pression est reliée par un raccord en T à un générateur de

pression et à une référence de pression absolue. Par la suite la pression absolue est

appliquée pour laquelle le signal de sortie doit être de:

0 V, 0 mA ou 4 mA. Maintenant le signal de sortie peut être réglé à l‘aide du potentiomètre (Z).

6.2 Réglage du gain (S)

Pour le réglage du gain, la pression nominale est appliquée, par l‘intermédiaire d‘un

raccord en T, à une référence de pression et au canal de pression. Le calibrateur

de précision WIKA type CPC2000 qui est équipé d‘un générateur ainsi que d‘une

référence de pression est particulièrement approprié pour cette opération.

La pression positive est raccordée à l‘entrée ”+“ et la pression négative à l‘entrée

”-“. Maintenant le signal de sortie peut être réglé par le potentiomètre de gain (S).

6.3 Réglage des seuils d’alarme

Pour le réglage des seuils d’alarme, on applique la pression sous laquelle le contact

doit être fermé. Ceci se fait à l’aide d’un générateur de pression relié par un raccord

en T à une référence de pression et au canal de pression. La pression positive est

raccordée à l’entrée ”+“ et la pression négative à l’entrée ”-“. Le potentiomètre du

seuil d’alarme SP I ou SP II est déplacé jusqu’à ce que la DEL rouge se trouvant audessus du potentiomètre respectif s’allume. La valeur de commutation est atteinte,

le relais est fermé.

WIKA Mode d'emploi Transmetteur de pression différentielle28

2333401 07/2009 GB/D/F/E

Page 29

6. Instructions de calibration

Ensuite on applique la pression à laquelle le contact doit s’ouvrir à nouveau. Maintenant on déplace le potentiomètre d’hystéréris correspondant ( ) jusqu’à ce que la

DEL s’éteigne. La plage d’hystérésis est réglable dans une zone de 0 ... 15 %.

3. LCD (option)

CE

4. Signal de sortie

5. Alimentation

6. No. Serie

F

1. Potentiomètre de

reg-lage pour l‘hystérésis

2. Potentiomètre des

points de communtation

2333401 07/2009 GB/D/F/E

7. Contacts de limite

8. Marge-potentiomètre

9. Zéro-potentiomètre

10. Raccordement

process

WIKA Mode d'emploi Transmetteur de pression différentielle 29

Page 30

7. Caractéristiques techniques

7. Caractéristiques techniques

Specifications Model DP-10

Pressure ranges

Over pressure safety mbar 3 5 8 12.5 20 30 50 80 125

F

Pressure ranges

Over pressure safety mbar 200 300 500 800 1000 1000 1200 2000

Maximum static pressure mbar 1000 {2000}

Pressure reference

Pressure connection mm two hose connections Ø 6.6 x 11 for hoses with

Materials

Wetted parts Ms, CuBe, PU, Ni

Case bottom part: ABS, glass fibre reinforced, top part: ABS

Power supply U

Signal output and Maximum load R

Power consumption mA

Response time (10 ... 90 %) ms approx. 20 {attenuation on request}

Adjustability zero point / span ± 5 % of span

Accuracy ≤ 1.0 % of span (limit point calibration) {0.5 or 0.2 for pressure

Hysteresis ≤ 0.1 % d. Spanne

Repeatability ≤ 0.05 % of span

1-year stability ≤ 0.5 % of span (at reference conditions)

Permissible temperature of

Medium -10 ... +50 °C 14 ... 122 °F

Ambient -10 ... +50 °C {-10 ... +60 °C} 14 ... 122 °F (14 ... 140 °F)

Storage -10 ... +70 °C 14 ... 158 °F

Compensated temperature range +10 ... +50 °C 14 ... 122 °F

Temperature coefficients in compensated temp range:

Mean TC of zero ≤ 0.3 % of span/10K

Mean TC of range ≤ 0.3 % of span/10K

{ } Items in curved brackets are optional extras for additional price.

1) The measuring ranges 0 ... 0.1 mbar; 0 ... 0.25 mbar; 0 ... 0.4 mbar are available on request.

For these measuring ranges a larger measuring cell and consequently also a case with larger dimensions is required.

2) Only with 4 ... 20 mA 2-wire, other output signals on request.

1)

1)

mbar 0.6 1 1.6 2.5 4 6 10 16 25

mbar 40 60 100 160 250 400 600 1000

relative pressure, differential pressure, {absolute pressure2) from

500 mbar abs; special pressure range 800 ... 1200 mbar abs}

inside Ø 5 ... 6 {2 x clamping ring connection G ⅛, Ms}

DC V

B

19 ... 31 {12 ... 30 with signal output 4 ... 20 mA, 2-wire system}

AC V {24, 115 or 230 (respectively ± 10 %, 50 ... 60 Hz)}

A

0 ... 10 V, 3-wire system RA > 2,0 kOhm

{0 ... 5 V, 3-wire system} R

{0 (4)... 20 mA, 3-wire system} R

{4 ... 20 mA, 2-wire system} R

{other on request}

≤ 2,0 kOhm

A

≤ 500 Ohm

A

≤ (U

[V] – 12 V) / 0,02 mA

A

B

≤ 10; (3-/4-wire); (AC-/DC-supply)

range from 2.5 mbar}

2333401 07/2009 GB/D/F/E

WIKA Mode d'emploi Transmetteur de pression différentielle30

Page 31

7. Caractéristiques techniques

Specifications Model DP-10

Shock resistance g 10

Suitable media clean, non-aggressive, dry gases

Sensor volume ml approx. 5 (approx. 7 for measuring ranges < 2.5 mbar)

Increase in volume ml approx. 1 at nominal pressure

CE-conformity Interference emission and immunity see EN 61 326 / A1;

{integrated indicator}

Digital LC display, 3 ½-digits; height of digits 10 mm, pick-up rate

Analogue analogue indicator 0 ... 100 %

{Alarm contacts} only with 3-wire systems

Number 1 or 2

Switching function standard setting 2 x max.

Adjustability 1 ... 100 % of span

Switching accuracy ≤ 1 % of span

Switching repeatability 0,2 % of span, typical

Switching hysteresis 0 ... 10 % of span, adjustable

Contacts 1 potential-free relay change-over contact per alarm contact

Contact rating AC 6 A, 230 V with ohmic load

{Root-evolved output signal}

Accuracy 1,0 % of span

Calculation the root is evolved according to the following equations:

Electrical connection via cable gland PG 7 and internal screw terminals in the

Ingress of protection IP54, per EN 60 529 / IEC 529

Weight kg approx. 0.6 {approx. 0.7 with power supply}

Dimensions mm see drawings

Mounting case for wall mounting

{ } Items in curved brackets are optional extras for additional price.

1) The measuring ranges 0 ... 0.1 mbar; 0 ... 0.25 mbar; 0 ... 0.4 mbar are available on request.

For these measuring ranges a larger measuring cell and consequently also a case with larger dimensions is required.

2) Only with 4 ... 20 mA 2-wire, other output signals on request.

declaration of conformity on request european guideline for

low voltages EN 610 10

3/sec.

UR = √ 10 x UL) UL = linear output 0 ... 10 V

IR = √ 20 x IL) IL = linear output 0 ... 20 mA

bottom part of the case, terminal champing diameter 1.5 mm²

F

2333401 07/2009 GB/D/F/E

WIKA Mode d'emploi Transmetteur de pression différentielle 31

Page 32

E

Información

Este signo indica informaciones, indicaciones o consejos.

¡Advertencia!

Este símbolo advierte sobre acciones que pueden provocar

daños personales o al equipo.

WIKA Manual de Instrucciones Transmisor de presión diferencial32

2333401 07/2009 GB/D/F/E

Page 33

Contenido

Contenido

1. Instrucciones de seguridad 34

Principio de medida 34

2.

3. Montaje 35

3.1

Instrucciones para el montaje

3.2

Conexiones de procesamiento

4. Dimensiones en mm 36

5. Conexión eléctrica 36

6. Instrucciones para el calibrado 38

6.1

Ajuste de punto cero (Z)

6.2

Ajuste de span (S)

6.3

Ajuste de los contactos

7. Datos técnicos 40

8. Declaración de Conformidad CE 43

35

35

38

38

38

E

2333401 07/2009 GB/D/F/E

WIKA Manual de Instrucciones Transmisor de presión diferencial 33

Page 34

1. Instrucciones de seguridad / 2. Principio de medida

1. Instrucciones de seguridad

Durante el montaje, la puesta en servicio y el funcionamiento

de este transmisor de presión es obligatorio tener en cuenta

las correspondientes prescripciones nacionales de seguridad

(p. ej.: VDE 0100 (Asociación de Electrotécnicos Alemanes)).

En caso de incumplimiento de las respectivas prescripciones

pueden producirse daños físicos y/o daños materiales conside-

E

Tenga en cuenta los siguientes parámetros de funcionamiento

rables.

Dichos aparatos deben ser utilizados únicamente por personal

cualificado.

El transmisor de presión está concebido exclusivamente

para gases secos, limpios y no agresivos.

No sople en las conexiones de procesamiento.

La célula de medida puede deteriorarse por la presión.

Temperatura ambiente / de la sustancia de medición máxima:

10 ... 50 °C

Durante el transporte es debe prestar atención a que ambas

conexiones de procesamiento estén abiertas. En caso de

transporte aéreo, los aparatos con gamas de medición de

presión absoluta deben ser transportados en cabinas con

compensación de presión.

2. Principio de medida

La medición de presión se realiza con una gama de medición adecuada, con una

membrana elástica y con un muelle de membrana elástica para gamas de medición

de presión absoluta. Un sistema inductivo produce una señal lineal, que se va

modificando proporcionalmente a la presión existente.

34

WIKA Manual de Instrucciones Transmisor de presión diferencial

2333401 07/2009 GB/D/F/E

Page 35

3. Montaje

3. Montaje

El transmisor de presión diferencial está previsto para el montaje en pared. Tras

aflojar los dos tornillos de la carcasa se podrá extraer el casquillo de conexión negro

de la carcasa. En el casquillo hay puntos de rotura controlada para los tornillos de

fijación.

3.1 Instrucciones para el montaje

El montaje en pared debe realizarse en posición vertical, es decir, las conexiones

de procesamiento señalan hacia abajo, debido a que el aparato se ha ajustado en

esta posición. De este modo, se evita la posible penetración de condensado en

las tuberías a presión.

El lugar de montaje debe estar libre de golpes, vibraciones y de radiaciones

térmicas.

El montaje no debe realizarse en las cercanías a fuentes de interferencias (p. ej.

transformadores, motores, emisores).

3.2 Conexiones de procesamiento

2 x racores de empalme de Ø 6,6 x 11 mm para

tubos flexibles de un diámetro interior de 5 ... 6 mm.

En la entrada „+“ se conecta una sobrepresión positiva.

En la entrada „-“ se conecta una sobrepresión negativa.

Los aparatos con gamas de medición de presión absoluta dispo-

nen solo de una conexión de procesamiento.

E

2333401 07/2009 GB/D/F/E

WIKA Manual de Instrucciones Transmisor de presión diferencial 35

Page 36

4. Dimensiones en mm / 5. Conexión eléctrica

4. Dimensiones en mm

E

M12 x 1,5

SW 10

Campo de indicación para

digital

5. Conexión eléctrica

El cable se introduce en el casquillo de conexión a través de la unión roscada M12

x 1,5. En el casquillo se encuentran bornes roscados para el cableado (margen de

sujeción de hasta 1,5 mm²).

Energía auxiliar

Consumidor de

energía, p. ej, indicación

WIKA Manual de Instrucciones Transmisor de presión diferencial36

2333401 07/2009 GB/D/F/E

Page 37

5. Conexión eléctrica

Conductor bifilar

3-hilos

E

4-hilos (AC - Alimentación eléctrica)

L1

N

Proceda con cuidado durante las conexiones de tensiones de

alimentación.

No conecta la tensión de alimentación a los bornes de salida.

2333401 07/2009 GB/D/F/E

WIKA Manual de Instrucciones Transmisor de presión diferencial 37

Page 38

6. Instrucciones para el calibrado

6. Instrucciones para el calibrado

Comience con el calibrado después de un tiempo de rodaje de

aprox. 30 - 60 minutos.

6.1 Ajuste de punto cero (Z)

E

Para el ajuste del punto cero, ambas entradas de presión deberán estar abiertas.

Tras retirar los tapones de goma situados en la parte delantera del aparato, se podrá

ajustar la señal de salida con el potenciómetro de punto cero (Z).

En el ajuste de convertidores de medición de presión con gama de medición de

presión absoluta, la entrada de presión se conecta con la fuente de generación de

presión y con la referencia de presión absoluta mediante una pieza en T. A continuación se genera la presión absoluta y la señal de salida deberá ser de 0 V y 0 mA o 4

mA. Ahora se podrá ajustar la señal de salida con el potenciómetro de punto cero (Z).

6.2 Ajuste de span (S)

Para ajustar el intervalo de medida, la presión nominal se conecta mediante una

pieza en T desde la fuente de generación de presión a la referencia de presión y al

canal de presión.

Para este procedimiento resulta especialmente adecuado el calibrador de precisión

WIKA tipo CPC2000, que dispone una fuente de generación de presión y de una

referencia de presión.

La sobrepresión positiva se conecta en la entrada „+“ y la sobrepresión negativa

en la entrada „-“. Ahora se podrá ajustar la señal de salida con el potenciómetro de

intervalo de medida (S).

6.3 Ajuste de los contactos

Para el ajuste de los contactos se aplica la presión con la que se debe bloquear el

contacto. Esto se realiza con una fuente de generación de presión que se encuentra conectada con la referencia de presión y con el canal de presión mediante una

pieza en T. La sobrepresión positiva se conecta en la entrada „+“ y la sobrepresión

negativa en la entrada „-“.

WIKA Manual de Instrucciones Transmisor de presión diferencial38

2333401 07/2009 GB/D/F/E

Page 39

6. Instrucciones para el calibrado

El potenciómetro del punto de conexión SP I y II se ajusta hasta que se encienda

el LED rojo situado encima del potenciómetro correspondiente. De este modo, se

alcanza el valor de conexión y el relé está cerrado.

Posteriormente, la presión se aplica la presión con la que se deberá desbloquear

nuevamente el contacto. A continuación, se deberá ajustar el potenciómetro de

histéresis ( ) hasta que se vuelva a apagar el LED. La histéresis de conexión se

puede ajustar en un margen de 0 … 15 %.

E

1. Potenciómetro

para la histéresis

de conexión

2. Potenciómetro

para los punots de

conexión

CE

3. Indicación LED (op

cional)

4. Señal

5. Energía auxiliar

6. N° de fábrica

7. Contactos (opcional)

8. Potenciómetro de span

9. Potenciómetro de

punto cero

10. Conexión de proce-

samiento

-

2333401 07/2009 GB/D/F/E

WIKA Manual de Instrucciones Transmisor de presión diferencial 39

Page 40

7. Datos técnicos

7. Datos técnicos

Specifications Model DP-10

Pressure ranges

Over pressure safety mbar 3 5 8 12.5 20 30 50 80 125

Pressure ranges

Over pressure safety mbar 200 300 500 800 1000 1000 1200 2000

Maximum static pressure mbar 1000 {2000}

E

Pressure reference

Pressure connection mm two hose connections Ø 6.6 x 11 for hoses with

Materials

Wetted parts Ms, CuBe, PU, Ni

Case bottom part: ABS, glass fibre reinforced, top part: ABS

Power supply U

Signal output and Maximum load R

Power consumption mA

Response time (10 ... 90 %) ms approx. 20 {attenuation on request}

Adjustability zero point / span ± 5 % of span

Accuracy ≤ 1.0 % of span (limit point calibration) {0.5 or 0.2 for pressure

Hysteresis ≤ 0.1 % d. Spanne

Repeatability ≤ 0.05 % of span

1-year stability ≤ 0.5 % of span (at reference conditions)

Permissible temperature of

Medium -10 ... +50 °C 14 ... 122 °F

Ambient -10 ... +50 °C {-10 ... +60 °C} 14 ... 122 °F (14 ... 140 °F)

Storage -10 ... +70 °C 14 ... 158 °F

Compensated temperature range +10 ... +50 °C 14 ... 122 °F

Temperature coefficients in compensated temp range:

Mean TC of zero ≤ 0.3 % of span/10K

Mean TC of range ≤ 0.3 % of span/10K

{ } Items in curved brackets are optional extras for additional price.

1) The measuring ranges 0 ... 0.1 mbar; 0 ... 0.25 mbar; 0 ... 0.4 mbar are available on request.

For these measuring ranges a larger measuring cell and consequently also a case with larger dimensions is required.

2) Only with 4 ... 20 mA 2-wire, other output signals on request.

1)

1)

mbar 0.6 1 1.6 2.5 4 6 10 16 25

mbar 40 60 100 160 250 400 600 1000

relative pressure, differential pressure, {absolute pressure2) from

500 mbar abs; special pressure range 800 ... 1200 mbar abs}

inside Ø 5 ... 6 {2 x clamping ring connection G ⅛, Ms}

DC V

B

19 ... 31 {12 ... 30 with signal output 4 ... 20 mA, 2-wire system}

AC V {24, 115 or 230 (respectively ± 10 %, 50 ... 60 Hz)}

A

0 ... 10 V, 3-wire system RA > 2,0 kOhm

{0 ... 5 V, 3-wire system} R

{0 (4)... 20 mA, 3-wire system} R

{4 ... 20 mA, 2-wire system} R

{other on request}

≤ 2,0 kOhm

A

≤ 500 Ohm

A

≤ (U

[V] – 12 V) / 0,02 mA

A

B

≤ 10; (3-/4-wire); (AC-/DC-supply)

range from 2.5 mbar}

2333401 07/2009 GB/D/F/E

WIKA Manual de Instrucciones Transmisor de presión diferencial40

Page 41

7. Datos técnicos

Specifications Model DP-10

Shock resistance g 10

Suitable media clean, non-aggressive, dry gases

Sensor volume ml approx. 5 (approx. 7 for measuring ranges < 2.5 mbar)

Increase in volume ml approx. 1 at nominal pressure

CE-conformity Interference emission and immunity see EN 61 326 / A1;

{integrated indicator}

Digital LC display, 3 ½-digits; height of digits 10 mm, pick-up rate

Analogue analogue indicator 0 ... 100 %

{Alarm contacts} only with 3-wire systems

Number 1 or 2

Switching function standard setting 2 x max.

Adjustability 1 ... 100 % of span

Switching accuracy ≤ 1 % of span

Switching repeatability 0,2 % of span, typical

Switching hysteresis 0 ... 10 % of span, adjustable

Contacts 1 potential-free relay change-over contact per alarm contact

Contact rating AC 6 A, 230 V with ohmic load

{Root-evolved output signal}

Accuracy 1,0 % of span

Calculation the root is evolved according to the following equations:

Electrical connection via cable gland PG 7 and internal screw terminals in the

Ingress of protection IP54, per EN 60 529 / IEC 529

Weight kg approx. 0.6 {approx. 0.7 with power supply}

Dimensions mm see drawings

Mounting case for wall mounting

{ } Items in curved brackets are optional extras for additional price.

1) The measuring ranges 0 ... 0.1 mbar; 0 ... 0.25 mbar; 0 ... 0.4 mbar are available on request.

For these measuring ranges a larger measuring cell and consequently also a case with larger dimensions is required.

2) Only with 4 ... 20 mA 2-wire, other output signals on request.

declaration of conformity on request european guideline for

low voltages EN 610 10

3/sec.

UR = √ 10 x UL) UL = linear output 0 ... 10 V

IR = √ 20 x IL) IL = linear output 0 ... 20 mA

bottom part of the case, terminal champing diameter 1.5 mm²

E

2333401 07/2009 GB/D/F/E

WIKA Manual de Instrucciones Transmisor de presión diferencial 41

Page 42

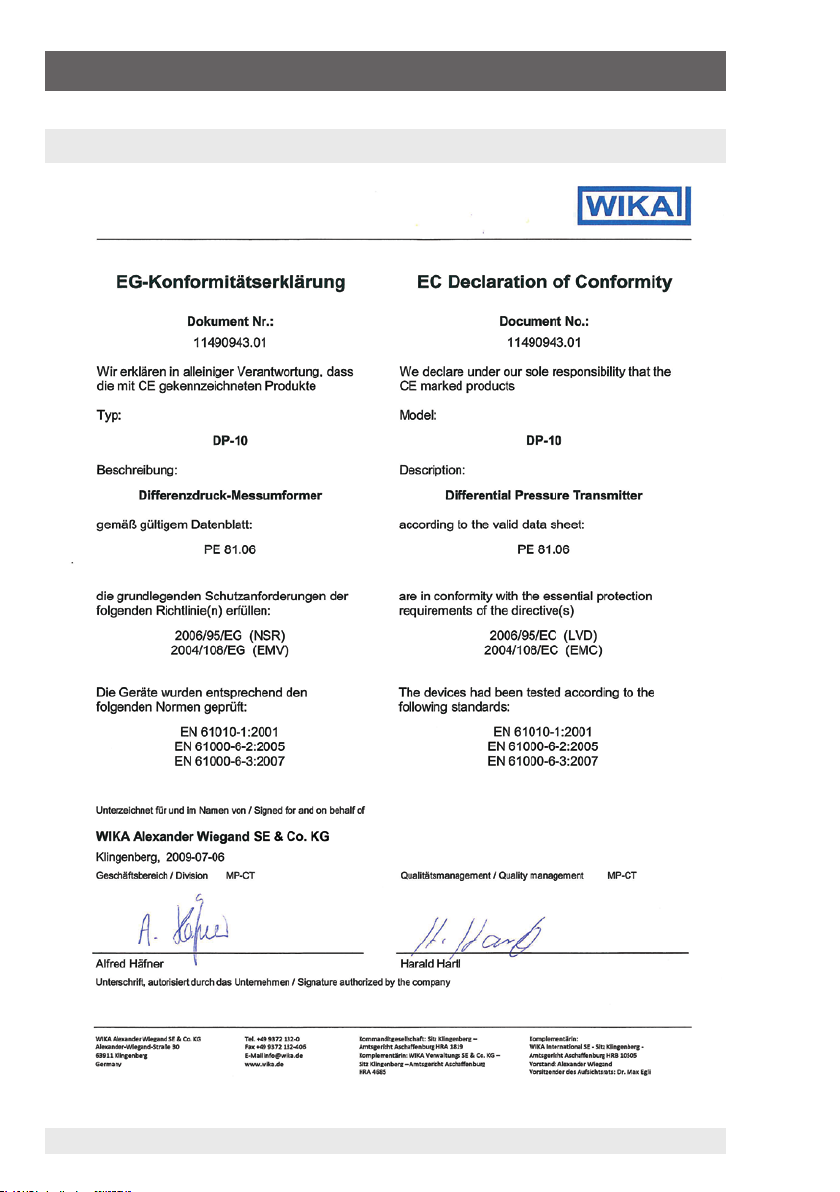

8. EG-Konformitätserklärung / EC Declaration of Conformity

8. EG-Konformitätserklärung / EC Declaration of Conformity

42

2333401 07/2009 GB/D/F/E

Page 43

8. Déclaration de Conformité CE / Declaración de Conformidad CE

8. Déclaration de Conformité CE / Declaración de Conformidad CE

2333401 07/2009 GB/D/F/E

43

Page 44

WIKA Global

All WIKA subsidiaries worldwide can be found online at www.wika.de.

Technical alteration rights reserved.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

Se reserva el derecho de modificaciones técnicas.

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg • Germany

Tel. (+49) 9372/132-0

Fax (+49) 9372/132-406

E-Mail

www.wika.de

44

info@wika.de

2333401.03 07/2009 GB/D/F/E

Loading...

Loading...