Page 1

Operating instructions

Betriebsanleitung

Mode d'emploi

Manual de instrucciones

Connection head with integrated digital display

module model DIH10

Anschlusskopf mit integriertem digitalem

Anzeigemodul Typ DIH10

Tête de raccordement avec module d'achage

numérique intégré type DIH10

Cabezal con indicador digital integrado

modelo DIH10

Connection head with integrated digital display module

model DIH10

GB

D

F

E

Page 2

Operating instructions model DIH10

GB

Betriebsanleitung Typ DIH10

D

Page

Seite

3 - 24

25 - 46

Mode d'emploi type DIH10

F

Manual de instrucciones modelo DIH10

E

© 2014 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

®

WIKA

is a registered trademark in various countries.

®

WIKA

ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d'emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta!

WIKA operating instructions model DIH102

Page

Página

47 - 68

69 - 90

14089810.01 03/2014 GB/D/F/E

Page 3

Contents

Contents

1. General information 4

2. Safety 6

3. Specications 10

4. Design and function 12

5. Transport, packaging and storage 15

6. Commissioning, operation 16

7. Maintenance and cleaning 20

8. Faults 21

9. Dismounting, return and disposal 22

Appendix: EC declaration of conformity 24

Declarations of conformity can be found online at www.wika.com.

GB

14089810.01 03/2014 GB/D/F/E

WIKA operating instructions model DIH10 3

Page 4

1. General information

1. General information

■

The instrument described in these operating instructions has been

GB

designed and manufactured using state-of-the-art technology. All

components are subject to stringent quality and environmental

criteria during production. Our management systems are certied to

ISO 9001 and ISO 14001.

■

These operating instructions contain important information on

handling the instrument. Working safely requires that all safety

instructions and work instructions are observed.

■

Observe the relevant local accident prevention regulations and

general safety regulations for the instrument's range of use.

■

The operating instructions are part of the product and must be kept

in the immediate vicinity of the instrument and readily accessible to

skilled personnel at any time.

■

Skilled personnel must have carefully read and understood the

operating instructions prior to beginning any work.

■

The manufacturer's liability is void in the case of any damage

caused by using the product contrary to its intended use,

non-compliance with these operating instructions, assignment

of insuciently qualied skilled personnel or unauthorised

modications to the instrument.

■

The general terms and conditions contained in the sales

documentation shall apply.

■

Subject to technical modications.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: AC 80.11

- Application consultant:

Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.com

4 WIKA operating instructions model DIH10

14089810.01 03/2014 GB/D/F/E

Page 5

1. General information

Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can result

in serious injury or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can

result in light injuries or damage to equipment or the

environment, if not avoided.

Information

... points out useful tips, recommendations and information

for ecient and trouble-free operation.

DANGER!

... identies hazards caused by electrical power. Should

the safety instructions not be observed, there is a risk of

serious or fatal injury.

WARNING!

... indicates a potentially dangerous situation that can result

in burns, caused by hot surfaces or liquids, if not avoided.

GB

14089810.01 03/2014 GB/D/F/E

WIKA operating instructions model DIH10 5

Page 6

2. Safety

2. Safety

GB

2.1 Intended use

The model DIH10 digital indicator is an all-purpose, configurable

loop-powered indicator for single resistance thermometers (RTD),

thermocouples (TC) and resistance and sensor transmitters.

It is especially applicable where a standard signal of 4 ... 20 mA is

already available. The current-loop display is built into an appropriate

connection head or wall-mounted housing, and can thus be used as a

local display in all sectors of industry.

The instrument has been designed and built solely for the intended

use described here, and may only be used accordingly.

The technical specications contained in these operating instructions

must be observed. Improper handling or operation of the instrument

outside of its technical specications requires the instrument to be

taken out of service immediately and inspected by an authorised

WIKA service engineer.

If the instrument is transported from a cold into a warm environment,

the formation of condensation may result in instrument malfunction.

Before putting it back into operation, wait for the instrument

temperature and the room temperature to equalise.

WARNING!

Before mounting, commissioning and operation, make sure

that the display is suitable for the application.

Non-observance can result in serious injury and/or damage

to the equipment.

Further important safety instructions can be found in the

individual chapters of these operating instructions.

6 WIKA operating instructions model DIH10

14089810.01 03/2014 GB/D/F/E

Page 7

2. Safety

The manufacturer shall not be liable for claims of any type based on

operation contrary to the intended use.

2.2 Personnel qualication

WARNING!

Risk of injury should qualication be insucient!

Improper handling can result in considerable injury and

damage to equipment.

■

The activities described in these operating instructions

may only be carried out by skilled personnel who have

the qualications described below.

■

Keep unqualied personnel away from hazardous areas.

Skilled personnel

Skilled personnel are understood to be personnel who, based on

their technical training, knowledge of measurement and control

technology and on their experience and knowledge of country-specic

regulations, current standards and directives, are capable of carrying

out the work described and independently recognising potential

hazards.

Special operating conditions require further appropriate knowledge,

e.g. of aggressive media.

2.3 Special hazards

WARNING!

For hazardous media such as oxygen, acetylene,

ammable or toxic gases or liquids, and refrigeration

plants, compressors, etc., in addition to all standard

regulations, the appropriate existing codes or regulations

must also be followed.

GB

14089810.01 03/2014 GB/D/F/E

WIKA operating instructions model DIH10 7

Page 8

GB

2. Safety

WARNING!

Protection from electrostatic discharge (ESD) required!

The proper use of grounded work surfaces and personal

wrist straps is required when working with exposed circuitry

(printed circuit boards), in order to prevent static discharge

from damaging sensitive electronic components.

To ensure safe working on the instrument, the operating

company must ensure

DANGER!

Danger of death caused by electric current

Upon contact with live parts, there is a direct danger of

death.

WARNING!

Residual media in dismounted instruments can result in

a risk to persons, the environment and equipment. Take

sucient precautionary measures.

■

that suitable rst-aid equipment is available and aid is

provided whenever required.

■

that the operating personnel are regularly instructed

in all topics regarding work safety, rst aid and

environmental protection and know the operating

instructions and in particular, the safety instructions

contained therein.

■

Electrical instruments may only be installed and

connected by skilled electrical personnel.

■

Operation using a defective power supply unit (e.g. short

circuit from the mains voltage to the output voltage) can

result in life-threatening voltages at the instrument!

Do not use this instrument in safety or emergency stop

devices. Incorrect use of the instrument can result in injury.

8 WIKA operating instructions model DIH10

14089810.01 03/2014 GB/D/F/E

Page 9

2. Safety

Should a failure occur, aggressive media with extremely

high temperature and under high pressure or vacuum may

be present at the instrument.

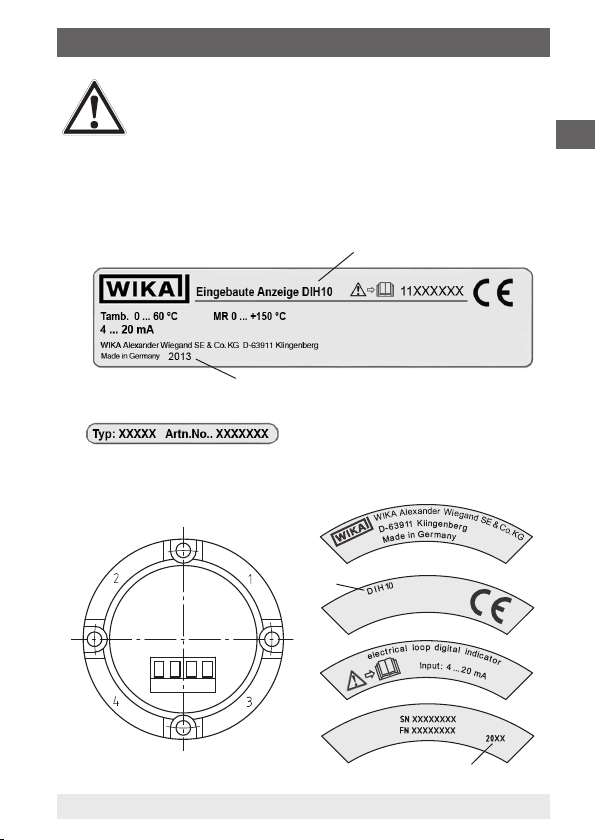

2.4 Labelling, safety marking

■

Product labels when tted into a connection head or housing

- Head/housing labelling

Year of manufacture

- Head/housing product label

■

Display module product label

Model

1

GB

Model

14089810.01 03/2014 GB/D/F/E

WIKA operating instructions model DIH10 9

2

3

4

Year of manufacture

Page 10

2. Safety / 3. Specications

Explanation of symbols

GB

Before mounting and commissioning the instrument,

ensure you read the operating instructions!

CE, Communauté Européenne

Instruments bearing this mark comply with the relevant

European directives.

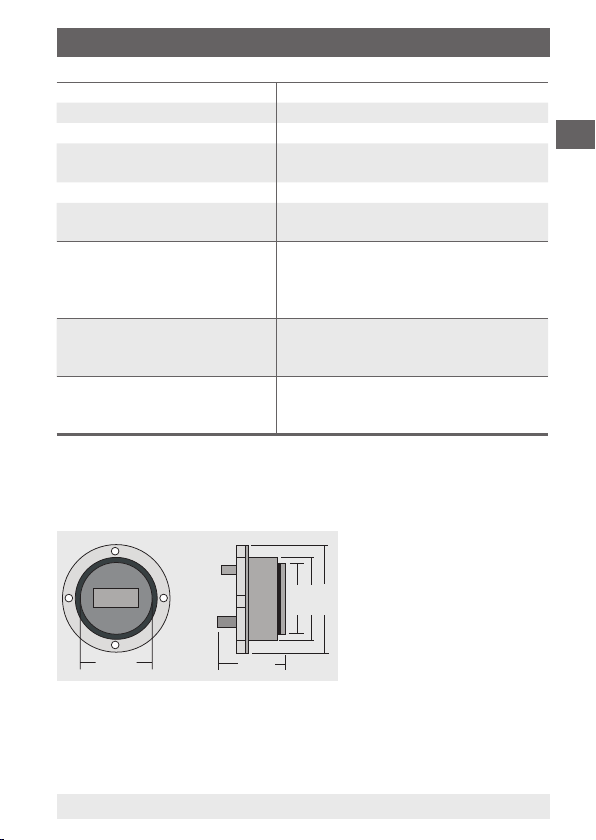

3. Specications

Specications Model DIH10 (display module)

Input

Current loop 4 ... 20 mA

Input impedance Ri at 20 mA < 160 Ω (U ≤ 3.2 V)

Accuracy

Resolution -999 ... 9999 digit

Measuring error ±0.2 % of measuring range, ±1 digit

Temperature drift 100 ppm/K

Display

Principle LED, rotatable in 90° steps

Measured value of display 7 segment, 8 mm high, red, 4-digit =

Overrange/underrange to HI / to LO

Display rate 0.1 s - 1 s - 10 s (adjustable)

Parameters

Maximum voltage U

Ambient conditions

Operating temperature 0 ... 80 °C

Storage temperature -20 ... +80 °C

i

Display 9999

DC 30 V

10 WIKA operating instructions model DIH10

14089810.01 03/2014 GB/D/F/E

Page 11

Ø 62,5

3. Specications

Module housing

Dimensions Ø 43.0 / 48.5 / 62.5 mm x 37 mm

Housing material Polycarbonate

Ingress protection Front: IP 67

Weight approx. 55 g

Electrical connection Plug-in terminal strip, up to 1.5 mm²

Programmable features Scale range, display time, decimal

Housing designs

(see chapter 4.2)

CE conformity

EMC directive

For further specications see WIKA data sheet AC 80.11 and order

documentation.

Dimensions in mm for the model DIH10 display module

Connection: IP 20 or IP 00

open cable ends

point, unit (°C/°F), zero point

stabilisation, programming lock,

reference points, TAG number

■

Connection head (standard)

■

Wall-mount housing

■

Housing with pipe support

2004/108/EC, EN 61326 emission

(group 1, class A) and interference

immunity (industrial application)

Ø 43

Ø 48,5

GB

43 mm

14089810.01 03/2014 GB/D/F/E

WIKA operating instructions model DIH10 11

40 mm

Page 12

4. Design and function

4. Design and function

4.1 Description

GB

The model DIH10 is a universal, microprocessor-controlled display,

monitoring and control instrument. It has an input, to which 4 … 20 mA

standard signals can be connected.

With its simple mounting and open programmability via the easily

accessible push-buttons, it can also be retrotted quickly to a pressure

transmitter which is already operating.

The display is loop-powered, and so no additional voltage supply is

needed. The 8 mm high LED display ensures good readability, even in

poor lighting conditions.

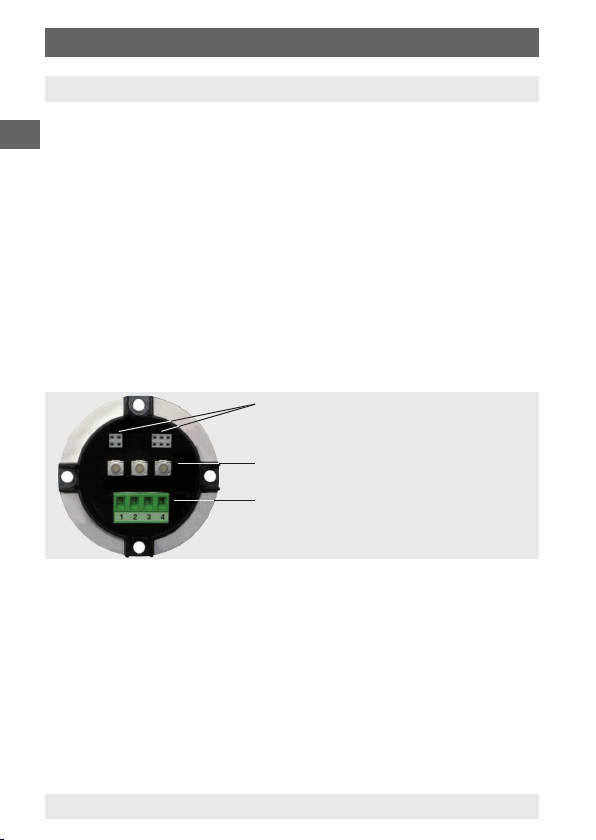

Model DIH10 display module, operating side

Connector pins for factory programming

▲

▼

P

12 WIKA operating instructions model DIH10

Buttons for programming

Coupler connector

14089810.01 03/2014 GB/D/F/E

Page 13

4. Design and function

4.2 Housing designs

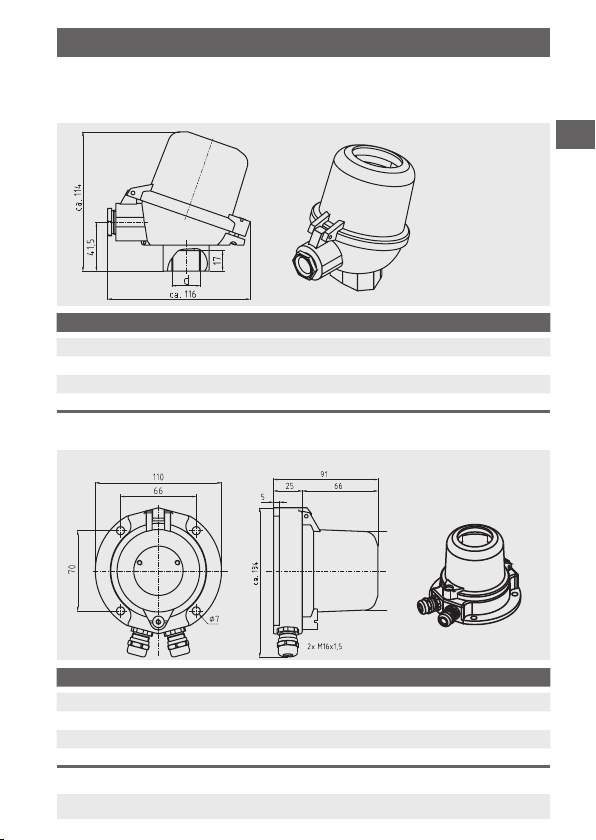

4.2.1 BSZ-H connection head (standard design), DIH10-Z-*A

Weight approx. 350 g

Specications Standard version

Connection to thermometer d M24 x 1.5 / ½ NPT

Material Aluminium black, lacquered

Cable gland 1 x M20 x 1.5 / 1 x ½ NPT

Ingress protection IP 65 (option: IP 67)

4.2.2 Wall-mount housing, DIH10-Z-*C

BSZ-H upper body special version

1)

GB

14053621.0114053621.01

Weight approx. 500 g

Specications Standard version

Material Aluminium black, lacquered

Lower body Aluminium black, lacquered

Cable gland 2 x M16 x 1.5

Ingress protection IP 65 (option: IP 67)

1) RAL 5022

14089810.01 03/2014 GB/D/F/E

WIKA operating instructions model DIH10 13

1)

1)

Page 14

95

20

25

136

91

20

2x M16x1,5

95

20

25

136

91

4. Design and function

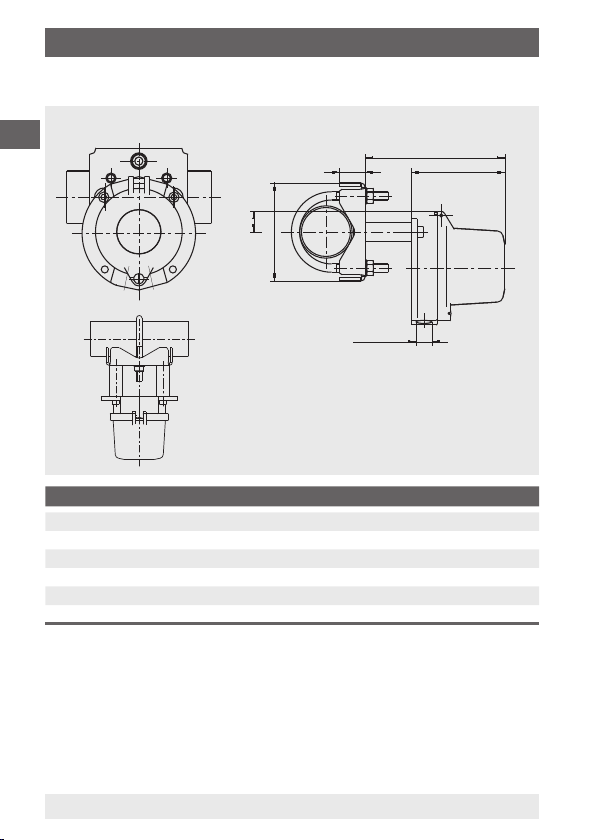

4.2.3 Housing with pipe support, DIH10-Z-*D

BSZ-H upper body special version

GB

95

Specications Standard version

Material Aluminium black, lacquered

Lower body Aluminium black, lacquered

Pipe support Stainless steel

Pipe diameter R 1" ... 2"

Cable gland 2 x M16 x 1.5

Ingress protection IP 65 (option: IP 67)

1) RAL 5022

4.3 Scope of delivery

Cross-check scope of delivery with delivery note.

25

2x M16x1,5

Weight approx. 950 g

136

91

1)

1)

14078928.01

14 WIKA operating instructions model DIH10

14089810.01 03/2014 GB/D/F/E

Page 15

5. Transport, packaging and storage

5. Transport, packaging and storage

5.1 Transport

Check the instrument for any damage that may have been caused by

transport. Obvious damage must be reported immediately.

5.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during

transport (e.g. change in installation site, sending for repair).

5.3 Storage

Permissible conditions at the place of storage:

■

Storage temperature: -20 ... +80 °C

■

Humidity: 35 ... 85 % relative humidity (no condensation)

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down hard)

■

Soot, vapour, dust and corrosive gases

■

Potentially explosive environments, ammable atmospheres

Store the instrument in its original packaging in a location that fulls

the conditions listed above. If the original packaging is not available,

pack and store the instrument as described below:

1. Wrap the instrument in an antistatic plastic lm.

2. Place the instrument along with shock-absorbent material in the

packaging.

3. If stored for a prolonged period of time (more than 30 days), place a

bag containing a desiccant inside the packaging.

WARNING!

Before storing the instrument (following operation), remove

any residual media. This is of particular importance if

the medium is hazardous to health, e.g. caustic, toxic,

carcinogenic, radioactive, etc.

14089810.01 03/2014 GB/D/F/E

WIKA operating instructions model DIH10 15

GB

Page 16

6. Commissioning, operation

6. Commissioning, operation

GB

WARNING!

■

Never connect directly to a voltage supply (e.g. 24 V) as

this will damage the display.

■

Only use a transmitter that will not exceed the

permissible electrical limit values.

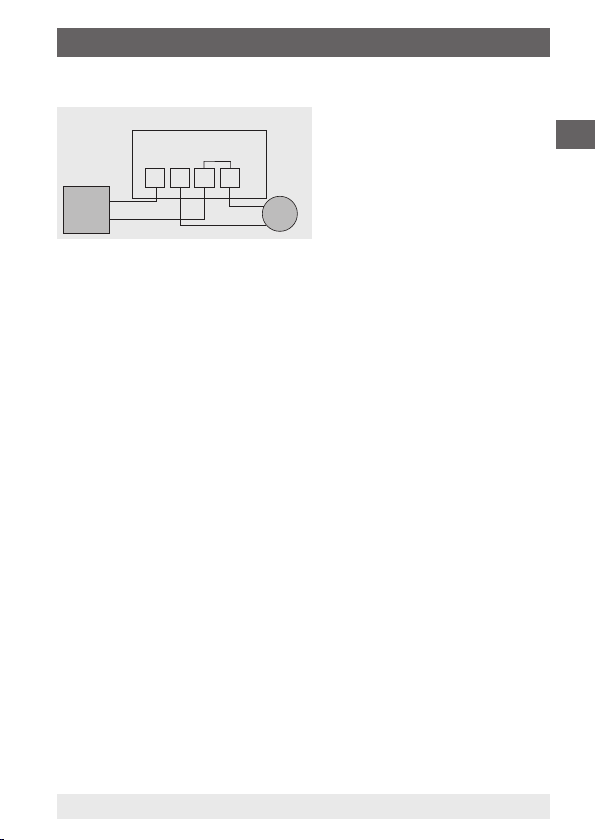

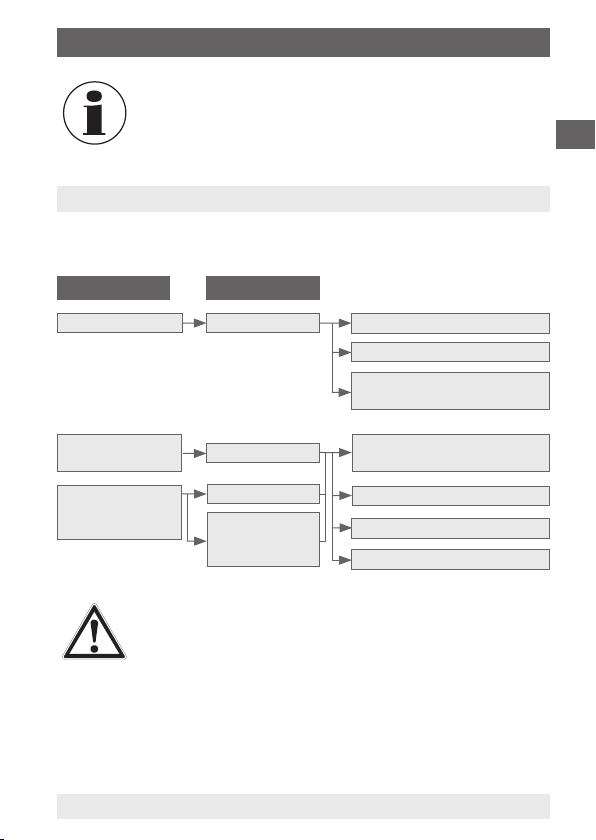

6.1 Operating a current loop

Power

supply

unit

DC 24 V

WARNING!

The display is only ever operated in a 4 ... 20 mA current

loop. A direct connection to a voltage supply (e.g. DC 24 V)

will lead to the display being damaged and will invalidate

the warranty.

For a functional check, the display must be powered from a

mA source (e.g. mA transmitter or calibrator).

In normal operation, the display is connected in series with

a 4 ... 20 mA transmitter or connected to the 4 ... 20 mA

analogue output of an instrument.

internal

bridge

DIH10

display

Housing

16 WIKA operating instructions model DIH10

14089810.01 03/2014 GB/D/F/E

Page 17

6. Commissioning, operation

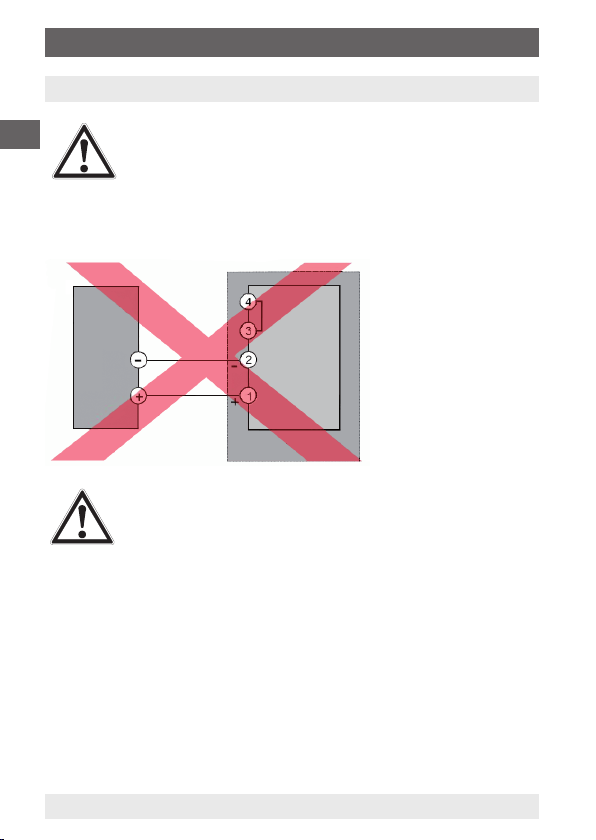

6.2 Model DIH10 connection

Coupler connector

Internal bridge

2341

+

-

+-

-

Transmitter

+

Power

supply

unit

The 4-pin plug-in terminal strip for the connection of the current-loop display is

located on the rear of the display and is accessible once the housing is open.

Terminal 1: Positive terminal of the current loop

Terminal 2: Negative terminal of the current loop

Terminals 3 and 4 are connected together on the PCB and enable the conven-

ient connection of a transmitter built into the connection head.

GB

14089810.01 03/2014 GB/D/F/E

WIKA operating instructions model DIH10 17

Page 18

6. Commissioning, operation

6.3 Programming the display

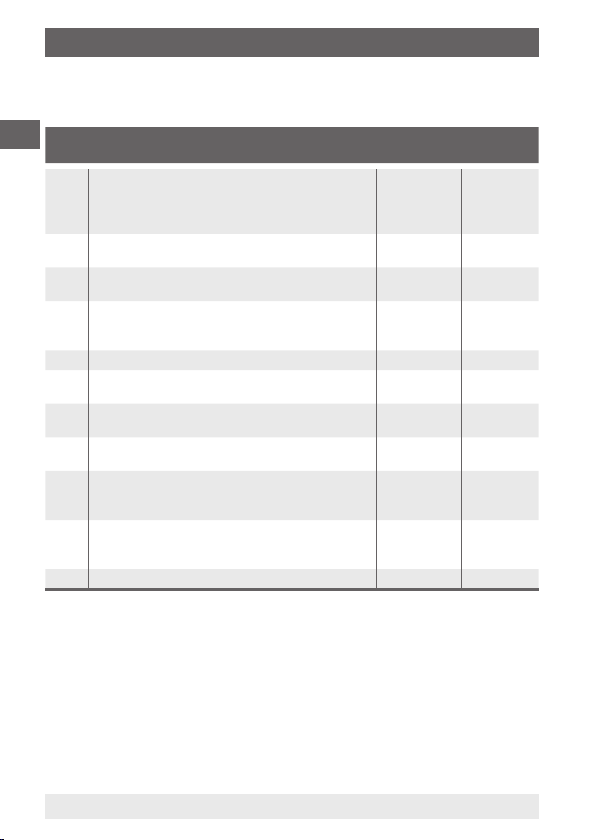

6.3.1 Programming table for programming the display

GB

PN Description Range Factory

0 Calibration mode

0 = Sensor calibration (signal must be

applied, only for factory setting)

1 = Rescaling (display value at 4 ... 20 mA)

1 Full scale value (programming the display

value at 20 mA, e.g. 600)

2 Initial value (programming the display value

at 4 mA, e.g. 100)

3 Decimal point or unit selection

(for programming a unit, the value shifts to

the left)

4

Display and averaging time in 1/10 of a second

5 ** Zero point stabilisation (the ± range in which

0000 will be displayed)

50 *** Denition of PIN code > 0000 (for

programming lock)

51 *** Authentication by PIN code (removal of

programming lock)

100 Number of reference points (reference points

for sensor calibration, reference points

reduce the measuring rate)

101 ...

Reference points (as programmed under

130

PN100)

200

TAG number

* For factory setting

** For programming a value >1 a hysteresis of 0.1 % will be activated. This prevents

the display jumping.

*** optional

(If no PIN code has been dened, PN50/PN51 are not available. A PIN code can

only be initially programmed via the serial interface for the factory programming. If a

PIN code has been dened (display after segment test: Pin), the programming lock

must be released, using the PIN code dened via PN50, through PN51 under input,

as otherwise, any changes made under the other PN's will not be able to be saved.

In order to reactivate the PIN code via PN50 on completion of any programming,

the programming mode must be left (by the input of 0000 under PN50 or by briey

interrupting the current loop).

18 WIKA operating instructions model DIH10

0/1 1

-999...9999 150

-999...9999 0

0 / 0.0 / 0.00

/ 0.000 /

°F / °C

5.0 ... 100.0 10

0 ... 100 2

0000...9999 0000

0000...9999 0000

0 ... 30 0

-999 ... 9999 0

0000 ... 9999 0

default *

°C

14089810.01 03/2014 GB/D/F/E

Page 19

6. Commissioning, operation

6.3.2 Programming the display

1. Connect instrument in accordance with connection diagram

2. Switch on the current loop supply (current between 4 ... 20 mA)

An initialisation and segment test is carried out. Then DIH10 and

subsequently the rmware version number (e.g. F1.24) is displayed.

Following this, the display switches into operating mode.

3. Press the program button P, the program number P 0 will be

displayed

4. By pressing P and the button or P and the button

simultaneously, change the program number

5. Under the selected program number, switch to the stored value with

the P button

6. By pressing P briey, the required digit can be selected;

the selected digit is changed using or

7. The entry is saved by pressing the P button for approx. 2 seconds;

the value has been saved once the display shows horizontal bars

8. If no button is pressed, after approx. 7 seconds the instrument

returns to operating mode

Additional functions in normal operation to retrieve the recorded

Min/Max values

■

Using the button, the recorded value of the Max memory is

shown in the display for some seconds

■

Using the button, the recorded value of the Min memory is

shown in the display for some seconds

■

By simultaneously pressing the and the buttons, the Min and

Max values are deleted

GB

CAUTION!

If the measuring range setting is changed, to maintain the

measuring accuracy, the display must be recalibrated.

14089810.01 03/2014 GB/D/F/E

WIKA operating instructions model DIH10 19

Page 20

6. Commissioning ... / 7. Maintenance, cleaning

6.3.3 Display information overrange/underrange

Range: 4 ... 20 mA

Displayed range: 3.9 ... 20.1 mA

GB

Usable range: 3.6 ... 21.5 mA

Advance warning of underrange: 3.6 ... < 3.9 mA

Advance warning of overrange: > 20.1 ... 21.5 mA

Underrange displayed: < 3.6 mA

Overrange displayed: > 21.5 mA

With the advance warning, the display blinks (normal display

alternates with horizontal bars).

For values under 3.6 mA, a horizontal bar alternates with the display

“undr”. For values over 21.5 mA, a horizontal bar alternates with the

display “over”.

7. Maintenance and cleaning

7.1 Maintenance

The instrument is maintenance-free.

Repairs must only be carried out by the manufacturer.

7.2 Cleaning

CAUTION!

■

Before cleaning, correctly disconnect the instrument

from the pressure supply, switch it o and disconnect it

from the mains.

■

Clean the instrument with a moist cloth.

■

Electrical connections must not come into contact with

moisture.

■

Wash or clean the dismounted instrument before

returning it, in order to protect persons and the

environment from exposure to residual media.

■

Residual media in dismounted instruments can result in

a risk to persons, the environment and equipment. Take

sucient precautionary measures.

20 WIKA operating instructions model DIH10

14089810.01 03/2014 GB/D/F/E

Page 21

7. Maintenance and cleaning / 8. Faults

For information on returning the instrument see chapter 9.2

“Return”.

8. Faults

Fault-tree

Display Measured value

GB

No display

Horizontal bar with

display “over.”

A horizontal bar

alternates with the

display “undr.”

I = 0 mA

I = > 20 mA

I = 4 mA

4 mA < I < 20 mA

wrong value

Current loop disconnected

Transmitter not connected

Power supply incorrectly

connected (reverse polarity)

Process temperature out of

range

Sensor break or short circuit

Sensor connected incorrectly

Wrong transmitter conguration

CAUTION!

If faults cannot be eliminated by means of the measures

listed above, shut down the instrument immediately, and

ensure that pressure and/or signal are no longer present,

and secure the instrument from being put back into

operation inadvertently.

In this case, contact the manufacturer.

If a return is needed, please follow the instructions given in

chapter 9.2 “Return”.

14089810.01 03/2014 GB/D/F/E

WIKA operating instructions model DIH10 21

Page 22

9. Dismounting, return and disposal

9. Dismounting, return and disposal

GB

9.1 Dismounting

Only disconnect the digital indicator once the system has been

depressurised!

9.2 Return

When returning the instrument, use the original packaging or a

suitable transport package.

To avoid damage:

1. Wrap the instrument in an antistatic plastic lm.

2. Place the instrument along with shock-absorbent material in the

packaging.

Place shock-absorbent material evenly on all sides of the transport

packaging.

3. If possible, place a bag containing a desiccant inside the packaging.

4. Label the shipment as carriage of a highly sensitive measuring

instrument.

WARNING!

Residual media in dismounted instruments can result in

a risk to persons, the environment and equipment. Take

sucient precautionary measures.

WARNING!

Strictly observe the following when shipping the

instrument:

All instruments delivered to WIKA must be free from any

kind of hazardous substances (acids, bases, solutions,

etc.).

Information on returns can be found under the heading

“Service” on our local website.

22 WIKA operating instructions model DIH10

14089810.01 03/2014 GB/D/F/E

Page 23

9. Dismounting, return and disposal

9.3 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an

environmentally compatible way and in accordance with the country-

specic waste disposal regulations.

GB

14089810.01 03/2014 GB/D/F/E

WIKA operating instructions model DIH10 23

Page 24

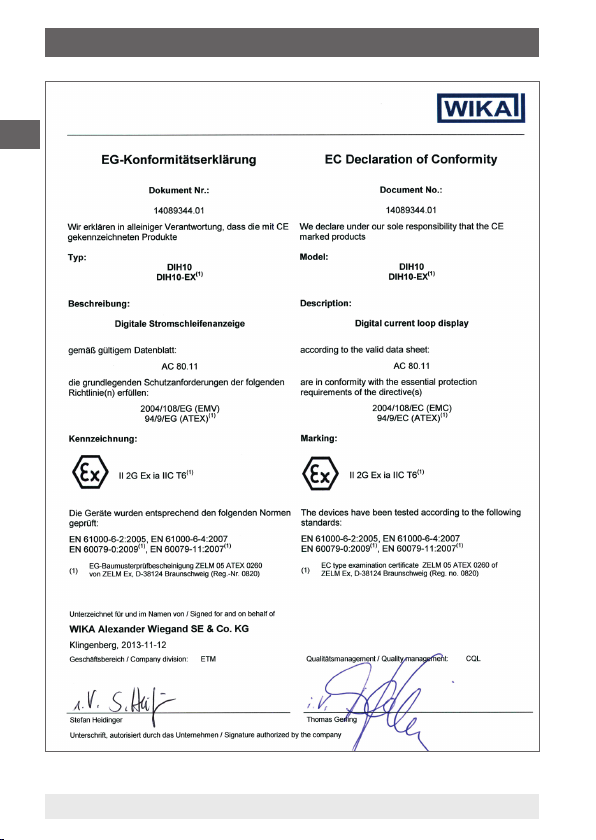

Appendix: EC declaration of conformity

GB

24 WIKA operating instructions model DIH10

14089810.01 03/2014 GB/D/F/E

Page 25

Inhalt

Inhalt

1. Allgemeines 26

2. Sicherheit 28

3. Technische Daten 32

4. Aufbau und Funktion 34

5. Transport, Verpackung und Lagerung 37

6. Inbetriebnahme, Betrieb 38

7. Wartung und Reinigung 42

8. Störungen 43

9. Demontage, Rücksendung und Entsorgung 44

Anlage: EG-Konformitätserklärung 46

Konformitätserklärungen nden Sie online unter www.wika.de.

D

14089810.01 03/2014 GB/D/F/E

WIKA Betriebsanleitung Typ DIH10

25

Page 26

1. Allgemeines

1. Allgemeines

■

Das in der Betriebsanleitung beschriebene Gerät wird nach dem

aktuellen Stand der Technik konstruiert und gefertigt.

Alle Komponenten unterliegen während der Fertigung strengen

Qualitäts- und Umweltkriterien. Unsere Managementsysteme sind

D

nach ISO 9001 und ISO 14001 zertiziert.

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit

dem Gerät. Voraussetzung für sicheres Arbeiten ist die Einhaltung

aller angegebenen Sicherheitshinweise und Handlungsanweisungen.

■

Die für den Einsatzbereich des Gerätes geltenden örtlichen Unfallverhütungsvorschriften und allgemeinen Sicherheitsbestimmungen

einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des Gerätes für das Fachpersonal jederzeit zugänglich

aufbewahrt werden.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller

Arbeiten sorgfältig durchgelesen und verstanden haben.

■

Die Haftung des Herstellers erlischt bei Schäden durch bestimmungswidrige Verwendung, Nichtbeachten dieser Betriebsan-

leitung, Einsatz ungenügend qualizierten Fachpersonals sowie

eigenmächtiger Veränderung am Gerät.

■

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- zugehöriges Datenblatt: AC 80.11

- Anwendungsberater:

26 WIKA Betriebsanleitung Typ DIH10

Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.de

14089810.01 03/2014 GB/D/F/E

Page 27

1. Allgemeines

Symbolerklärung

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin,

die zum Tod oder zu schweren Verletzungen führen kann,

wenn sie nicht gemieden wird.

VORSICHT!

… weist auf eine möglicherweise gefährliche Situation hin,

die zu geringfügigen oder leichten Verletzungen bzw. Sachund Umweltschäden führen kann, wenn sie nicht gemieden

wird.

Information

… hebt nützliche Tipps und Empfehlungen sowie Infor-

mationen für einen ezienten und störungsfreien Betrieb

hervor.

GEFAHR!

…kennzeichnet Gefährdungen durch elektrischen Strom.

Bei Nichtbeachtung der Sicherheitshinweise besteht die

Gefahr schwerer oder tödlicher Verletzungen.

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation

hin, die durch heiße Oberächen oder Flüssigkeiten zu

Verbrennungen führen kann, wenn sie nicht gemieden wird.

D

14089810.01 03/2014 GB/D/F/E

WIKA Betriebsanleitung Typ DIH10

27

Page 28

2. Sicherheit

2. Sicherheit

WARNUNG!

Vor Montage, Inbetriebnahme und Betrieb sicherstellen,

dass die Anzeige für den Anwendungsfall geeignet ist.

D

2.1 Bestimmungsgemäße Verwendung

Die Digitalanzeige Typ DIH10 ist eine universelle, konfigurierbare

Schleifenanzeige für Einzel-Widerstandsthermometer (RTD), Thermoelemente (TC) sowie Widerstands- und Sensorgeber.

Sie ist besonders dort einsetzbar, wo schon ein Standardsignal von

4 ... 20 mA vorhanden ist. Die Stromschleifen-Anzeige ist eingebaut

in geeignete Anschlussköpfe oder Wandgehäuse, und kann so als

Vor-Ort-Anzeige im gesamten industriellen Bereich eingesetzt werden.

Das Gerät ist ausschließlich für den hier beschriebenen bestimmungsgemäßen Verwendungszweck konzipiert und konstruiert und darf nur

dementsprechend verwendet werden.

Die technischen Spezikationen in dieser Betriebsanleitung sind

einzuhalten. Eine unsachgemäße Handhabung oder ein Betreiben

des Gerätes außerhalb der technischen Spezikationen macht die

sofortige Stilllegung und Überprüfung durch einen autorisierten WIKAServicemitarbeiter erforderlich.

Bei Nichtbeachten können schwere Körperverletzungen

und/oder Sachschäden auftreten.

Weitere wichtige Sicherheitshinweise benden sich in den

einzelnen Kapiteln dieser Betriebsanleitung.

Wird das Gerät von einer kalten in eine warme Umgebung transportiert, so kann durch Kondensatbildung eine Störung der Gerätefunktion eintreten. Vor einer erneuten Inbetriebnahme die Angleichung der

Gerätetemperatur an die Raumtemperatur abwarten.

28 WIKA Betriebsanleitung Typ DIH10

14089810.01 03/2014 GB/D/F/E

Page 29

2. Sicherheit

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer

Verwendung sind ausgeschlossen.

2.2 Personalqualikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualikation!

Unsachgemäßer Umgang kann zu erheblichen Personenund Sachschäden führen.

■

Die in dieser Betriebsanleitung beschriebenen Tätigkeiten nur durch Fachpersonal nachfolgend beschrie-

bener Qualikation durchführen lassen.

■

Unqualiziertes Personal von den Gefahrenbereichen

fernhalten.

Fachpersonal

Das Fachpersonal ist aufgrund seiner fachlichen Ausbildung, seiner

Kenntnisse der Mess- und Regelungstechnik und seiner Erfahrungen

sowie Kenntnis der landesspezischen Vorschriften, geltenden

Normen und Richtlinien in der Lage, die beschriebenen Arbeiten

auszuführen und mögliche Gefahren selbstständig zu erkennen.

Spezielle Einsatzbedingungen verlangen weiteres entsprechendes

Wissen, z. B. über aggressive Medien.

2.3 Besondere Gefahren

WARNUNG!

Bei gefährlichen Messstoen wie z. B. Sauersto, Acetylen, brennbaren oder giftigen Stoen, sowie bei Kältean-

lagen, Kompressoren etc. müssen über die gesamten

allgemeinen Regeln hinaus die einschlägigen Vorschriften

beachtet werden.

D

14089810.01 03/2014 GB/D/F/E

WIKA Betriebsanleitung Typ DIH10

29

Page 30

2. Sicherheit

D

WARNUNG!

Schutz vor elektrostatischer Entladung (ESD) erforderlich!

Die ordnungsgemäße Verwendung geerdeter Arbeits-

ächen und persönlicher Armbänder ist bei Arbeiten mit

oenen Schaltkreisen (Leiterplatten) erforderlich, um die

Beschädigung empndlicher elektronischer Bauteile durch

elektrostatische Entladung zu vermeiden.

Für ein sicheres Arbeiten am Gerät muss der Betreiber

sicherstellen,

■

dass eine entsprechende Erste-Hilfe-Ausrüstung vorhanden ist und bei Bedarf jederzeit Hilfe zur Stelle ist.

■

dass das Bedienpersonal regelmäßig in allen zutreffenden Fragen von Arbeitssicherheit, Erste-Hilfe und

Umweltschutz unterwiesen wird, sowie die Betriebsanleitung und insbesondere die darin enthaltenen

Sicherheitshinweise kennt.

GEFAHR!

Lebensgefahr durch elektrischen Strom

Bei Berührung mit spannungsführenden Teilen besteht

unmittelbare Lebensgefahr.

■

Einbau und Montage des elektrischen Gerätes dürfen

nur durch das Elektrofachpersonal erfolgen.

■

Bei Betrieb mit einem defekten Netzgerät (z. B.

Kurzschluss von Netzspannung zur Ausgangsspannung) können am Gerät lebensgefährliche Spannungen

auftreten!

WARNUNG!

Messstoreste in ausgebauten Geräten können zur

Gefährdung von Personen, Umwelt und Einrichtung führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

Dieses Gerät nicht in Sicherheits- oder in Not-Aus-Einrichtungen benutzen. Fehlerhafte Anwendungen des Gerätes

können zu Verletzungen führen.

30 WIKA Betriebsanleitung Typ DIH10

14089810.01 03/2014 GB/D/F/E

Page 31

2. Sicherheit

Am Gerät können im Fehlerfall aggressive Medien mit

extremer Temperatur und unter hohem Druck oder Vakuum

anliegen.

2.4 Beschilderung, Sicherheitskennzeichnungen

■

Typenschilder bei Einbau im Anschlusskopf oder Gehäuse

- Beschriftung Kopf/Gehäuse

Typ

Herstellungsjahr

- Typenschild Kopf/Gehäuse

■

Typenschild Anzeigenmodul

Typ

1

2

3

4

D

14089810.01 03/2014 GB/D/F/E

WIKA Betriebsanleitung Typ DIH10

Herstellungsjahr

31

Page 32

2. Sicherheit / 3. Technische Daten

Symbolerklärung

Vor Montage und Inbetriebnahme des Gerätes

unbedingt die Betriebsanleitung lesen!

D

CE, Communauté Européenne

Geräte mit dieser Kennzeichnung stimmen überein mit den

zutreenden europäischen Richtlinien.

3. Technische Daten

Technische Daten Typ DIH10 (Anzeigemodul)

Eingang

Stromschleife 4 ... 20 mA

Eingangswiderstand Ri

bei 20 mA

Genauigkeit

Auösung -999 ... 9999 Digit

Messfehler ±0,2 % vom Messbereich, ±1 Digit

Temperaturdrift 100 ppm/K

Anzeige

Prinzip LED, drehbar in 90°-Schritten

Anzeigemesswert 7-Segment, 8 mm hoch, rot, 4 Digit =

Überlauf/Unterlauf nach HI / nach LO

Anzeigezeit 0,1 s - 1 s - 10 s (einstellbar)

Kenngrößen

Maximale Spannung U

Umgebungsbedingungen

Betriebstemperatur 0 ... 80 °C

Lagertemperatur -20 ... +80 °C

< 160 Ω (U ≤ 3,2 V)

Anzeige 9999

DC 30 V

i

32 WIKA Betriebsanleitung Typ DIH10

14089810.01 03/2014 GB/D/F/E

Page 33

3. Technische Daten

Ø 62,5

Modulgehäuse

Abmessungen Ø 43,0 / 48,5 / 62,5 mm x 37 mm

Gehäusematerial Polycarbonat

Schutzart Front: IP 67

Gewicht ca. 55 g

Elektrischer Anschluss Klemmsteckleiste, bis 1,5 mm²

Programmierbare

Merkmale

Gehäuseausführungen

(siehe Kapitel 4.2)

CE-Konformität

EMV-Richtlinie

Weitere technische Daten siehe WIKA-Datenblatt AC 80.11 und

Bestellunterlagen.

Abmessungen in mm des Anzeigemoduls Typ DIH10

Anschluss: IP 20 bzw. IP 00

oene Kabelenden

Anzeigebereich, Anzeigezeit, Dezimalpunkt, Einheit (°C/°F), Nullpunktberuhigung, Programmiersperre,

Stützpunkte, TAG-Nummer

■

Anschlusskopf (Standard)

■

Wandaufbaugehäuse

■

Gehäuse mit Rohrhalterung

2004/108/EG, EN 61326 Emission

(Gruppe 1, Klasse A) und Störfestigkeit

(industrieller Bereich)

Ø 43

Ø 48,5

D

43 mm

14089810.01 03/2014 GB/D/F/E

WIKA Betriebsanleitung Typ DIH10

40 mm

33

Page 34

4. Aufbau und Funktion

4. Aufbau und Funktion

4.1 Beschreibung

Das Anzeigemodul Typ DIH10 ist ein universell einsetzbares, mikroprozessorgesteuertes Anzeige-, Überwachungs- und Regelgerät.

Es besitzt einen Eingang mit Anschlussmöglichkeit für Normsignale

D

4 … 20 mA.

Durch einfache Montage und freie Programmierbarkeit über die

vorhandenen Tasten können auch bereits im Einsatz bendliche

Messumformer in kurzer Zeit nachgerüstet werden.

Die Anzeige versorgt sich aus der Stromschleife, somit ist keine

weitere Spannungsversorgung notwendig. Die 8 mm hohe LED-Anzeige gewährleistet auch bei schlechten Lichtverhältnisse eine gute

Ablesbarkeit.

Anzeigemodul Typ DIH10 Bedienseite

Steckerkontakt für Werksprogrammierung

▲

▼

P

34 WIKA Betriebsanleitung Typ DIH10

Tasten für Programmierung

Anschlussstecker

14089810.01 03/2014 GB/D/F/E

Page 35

4. Aufbau und Funktion

4.2 Gehäuseausführungen

4.2.1 Anschlusskopf BSZ-H (Standardausführung), DIH10-Z-*A

Gewicht ca. 350 g

Technische Daten Standardausführung

Anschluss zum Thermometer d M24 x 1,5 / ½ NPT

Werksto Aluminium blau, lackiert

Kabelverschraubung 1 x M20 x 1,5 / 1 x ½ NPT

Schutzart IP 65 (Option: IP 67)

4.2.2 Wandaufbaugehäuse, DIH10-Z-*C

BSZ-H Oberteil Sonderausführung

1)

D

14053621.0114053621.01

Technische Daten Standardausführung

Werksto Aluminium blau, lackiert

Unterteil Aluminium blau, lackiert

Kabelverschraubung 2 x M16 x 1,5

Schutzart IP 65 (Option: IP 67)

1) RAL 5022

14089810.01 03/2014 GB/D/F/E

WIKA Betriebsanleitung Typ DIH10

Gewicht ca. 500 g

1)

1)

35

Page 36

95

20

25

136

91

20

2x M16x1,5

95

20

25

136

91

4. Aufbau und Funktion

4.2.3 Gehäuse mit Rohrhalterung, DIH10-Z-*D

BSZ-H Oberteil Sonderausführung

D

95

Technische Daten Standardausführung

Werksto Aluminium blau, lackiert

Unterteil Aluminium blau, lackiert

Rohrhalterung CrNi-Stahl

Rohrdurchmesser R 1" ... 2"

Kabelverschraubung 2 x M16 x 1,5

Schutzart IP 65 (Option: IP 67)

1) RAL 5022

4.3 Lieferumfang

Lieferumfang mit dem Lieferschein abgleichen.

25

2x M16x1,5

136

91

Gewicht ca. 950 g

1)

1)

14078928.01

36 WIKA Betriebsanleitung Typ DIH10

14089810.01 03/2014 GB/D/F/E

Page 37

5. Transport, Verpackung und Lagerung

5. Transport, Verpackung und Lagerung

5.1 Transport

Gerät auf eventuell vorhandene Transportschäden untersuchen.

Oensichtliche Schäden unverzüglich mitteilen.

5.2 Verpackung

Verpackung erst unmittelbar vor der Montage entfernen.

Die Verpackung aufbewahren, denn diese bietet bei einem Transport

einen optimalen Schutz (z. B. wechselnder Einbauort, Reparatursendung).

5.3 Lagerung

Zulässige Bedingungen am Lagerort:

■

Lagertemperatur: -20 ... +80 °C

■

Feuchtigkeit: 35 ... 85 % relative Feuchte (keine Betauung)

Folgende Einüsse vermeiden:

■

Direktes Sonnenlicht oder Nähe zu heißen Gegenständen

■

Mechanische Vibration, mechanischer Schock (hartes Aufstellen)

■

Ruß, Dampf, Staub und korrosive Gase

■

Explosionsgefährdete Umgebung, entzündliche Atmosphären

Das Gerät in der Originalverpackung an einem Ort, der die oben

gelisteten Bedingungen erfüllt, lagern. Wenn die Originalverpackung

nicht vorhanden ist, dann das Gerät wie folgt verpacken und lagern:

1. Das Gerät in eine antistatische Plastikfolie einhüllen.

2. Das Gerät mit dem Dämmmaterial in der Verpackung platzieren.

3. Bei längerer Einlagerung (mehr als 30 Tage) einen Beutel mit Trocknungsmittel der Verpackung beilegen.

D

WARNUNG!

Vor der Einlagerung des Gerätes (nach Betrieb) alle

anhaftenden Messstoreste entfernen. Dies ist besonders

wichtig, wenn der Messsto gesundheitsgefährdend ist, wie

z. B. ätzend, giftig, krebserregend, radioaktiv, usw.

14089810.01 03/2014 GB/D/F/E

WIKA Betriebsanleitung Typ DIH10

37

Page 38

6. Inbetriebnahme, Betrieb

6. Inbetriebnahme, Betrieb

WARNUNG!

■

Niemals direkt an eine Spannungsversorgung (z. B.

24 V) anschließen, die Anzeige wird dadurch zerstört.

■

D

6.1 Betrieb einer Stromschleife

Nur Geber verwenden, die die zulässigen elektrischen

Grenzwerte nicht überschreiten.

Netzteil

DC 24 V

interne

Brücke

DIH10-

Anzeige

Gehäuse

WARNUNG!

Die Anzeige wird grundsätzlich nur in einer Stromschleife

von 4 ... 20 mA betrieben. Ein direkter Anschluss an eine

Spannungsversorgung (z. B. DC 24 V) führt zur Zerstörung

der Anzeige und zum Verlust der Garantie.

Für eine Funktionsprüfung muss die Anzeige aus einer

mA-Quelle gespeist werden (z. B. mA-Geber oder -Kalibrator).

Im Normalbetrieb ist die Anzeige mit einem Messumformer

4 ... 20 mA in Reihe geschaltet oder wird am Analogausgang 4 ... 20 mA eines Gerätes angeschlossen.

38 WIKA Betriebsanleitung Typ DIH10

14089810.01 03/2014 GB/D/F/E

Page 39

6. Inbetriebnahme, Betrieb

6.2 Anschluss Typ DIH10

Anschlussstecker

Interne Brücke

2341

+-

+

Netzteil

-

Die 4-polige Klemmsteckleiste zum Anschluss der Stromschleifenanzeige

bendet sich auf der Rückseite des Displays und ist nach Önen des Gehäuses

zugänglich.

Klemme 1: Pluspol der Stromschleife

Klemme 2: Minuspol der Stromschleife

Klemme 3 und Klemme 4 sind auf der Platine gebrückt und dienen zum komfor-

tablen Anschluss eines im Anschlusskopf eingebauten Transmitters.

-

Transmitter

+

D

14089810.01 03/2014 GB/D/F/E

WIKA Betriebsanleitung Typ DIH10

39

Page 40

6. Inbetriebnahme, Betrieb

6.3 Anzeigenprogrammierung

6.3.1 Programmtabelle für die Anzeigenprogrammierung

PN Beschreibung Bereich Liefer-

0 Kalibrationsmodus

D

0 = Sensorkalibration (Signal muss anliegen,

nur für Werkseinstellung)

1 = Umskalieren (Anzeigewert bei 4 ... 20 mA)

1 Endwert (Programmierung Anzeigewert bei

20 mA, z. B. 600)

2 Anfangswert (Programmierung Anzeigewert

bei 4 mA, z. B. 100)

3 Kommaeinstellung oder Dimensionswahl

(bei Programmierung einer Einheit verschiebt

sich die Anzeige nach links)

4

Anzeige- und Mittelungszeit in 1/10 Sekunden

5 ** Nullpunktberuhigung (der ± Bereich, in dem

0000 angezeigt wird)

50 ***

Denition PIN-Code > 0000 (für

Programmiersperre)

51 *** Authentizierung durch PIN-Code (Aufhebung

Programmiersperre)

100 Anzahl der Stützpunkte (Stützpunkte für die

Sensorkalibration, Stützpunkte reduzieren die

Messrate)

101 ...

Stützpunkte (wie unter PN100 programmiert)

130

200

TAG-Nummer

* Bei Werkseinstellung

** Bei Programmierung eines Wertes >1 wird eine Hysterese von 0,1 % aktiviert.

Dies verhindert ein Springen der Anzeige.

*** optional

(Wenn kein PIN-Code deniert ist, sind PN50/PN51 nicht vorhanden. Ein PIN-Code

kann nur über die Schnittstelle der Werksprogrammierung erstmals programmiert

werden. Wenn ein PIN-Code deniert ist (Anzeige nach Segmenttest: Pin), muss

die Programmiersperre unter PN51 unter Eingabe des unter PN50 denierten

PIN-Codes aufgehoben werden, da sonst vorgenommene Änderungen unter den

anderen PN nicht gespeichert werden können. Um nach einer Programmierung den

PIN-Code unter PN50 wieder zu aktivieren, muss der Programmiermodus durch

Eingabe von 0000 unter PN50 verlassen werden oder die Stromschleife kurzzeitig

unterbrochen werden.

40 WIKA Betriebsanleitung Typ DIH10

0/1 1

-999...9999 150

-999...9999 0

0 / 0.0 / 0.00

/ 0.000 /

°F / °C

5.0 ... 100.0 10

0 ... 100 2

0000 ... 9999 0000

0000 ... 9999 0000

0 ... 30 0

-999 ... 9999 0

0000 ... 9999 0

zustand *

°C

14089810.01 03/2014 GB/D/F/E

Page 41

6. Inbetriebnahme, Betrieb

6.3.2 Programmierung der Anzeige

1. Gerät gemäß Anschlussplan anschließen

2. Stromschleifenversorgung einschalten (Strom zwischen 4 ... 20 mA)

Es erfolgt eine Initialisierung und ein Segmenttest. Dann wird

DIH10 und anschließend die Firmware-Versionsnummer angezeigt

(z. B. F1.24). Danach schaltet die Anzeige in den Betriebsmodus.

3. Programmtaste P drücken, die Programmnummer P 0 wird

angezeigt

4. Durch gleichzeitiges Drücken von P und -Taste oder P und

-Taste die Programmnummer wechseln

5. Unter gewählter Programmnummer zum hinterlegten Wert mit

P-Taste wechseln

6. Durch kurzes Drücken von P erfolgt ein Stellenwechsel;

die angewählte Stelle wird mit oder verändert

7. Das Speichern erfolgt durch Betätigung der P-Taste für

ca. 2 Sekunden; die Speicherung ist erfolgt, wenn die Anzeige

Querbalken anzeigt

8. Ohne Betätigung einer Taste wechselt das Gerät nach

ca. 7 Sekunden in den Betriebsmodus

Zusatzfunktionen im Normalbetrieb für Speicherabfrage der

Min/Max-Werte

■

Mit der Taste wird der Wert des Max-Speichers für einige

Sekunden im Display angezeigt

■

Mit der Taste wird der Wert des Min-Speichers für einige

Sekunden im Display angezeigt

■

Gleichzeitiges Drücken der und Tasten löscht den Min- und

den Max-Wert

D

VORSICHT!

Bei Änderung der Messbereichseinstellung ist zur Erhaltung der Messgenauigkeit die Anzeige grundsätzlich neu

zu kalibrieren.

14089810.01 03/2014 GB/D/F/E

WIKA Betriebsanleitung Typ DIH10

41

Page 42

6. Inbetriebnahme, Betrieb / 7. Wartung ...

6.3.3 Anzeigeinfo Unterlauf/Überlauf

Bereich: 4 ... 20 mA

angezeigter Bereich: 3,9 ... 20,1 mA

nutzbarer Bereich: 3,6 ... 21,5 mA

Vorwarnung Unterlauf: 3,6 ... < 3,9 mA

Vorwarnung Überlauf: > 20,1 ... 21,5 mA

D

Anzeige Unterlauf: < 3,6 mA

Anzeige Überlauf: > 21,5 mA

Bei Vorwarnung blinkt die Anzeige (normale Anzeige wechselt mit

Querbalken).

Bei Werten unter 3,6 mA wechselt ein Querbalken mit der Anzeige "undr".

Bei Werten über 21,5 mA wechselt ein Querbalken mit Anzeige "over".

7. Wartung und Reinigung

7.1 Wartung

Das Gerät ist wartungsfrei.

Reparaturen sind ausschließlich vom Hersteller durchzuführen.

7.2 Reinigung

VORSICHT!

■

Vor der Reinigung das Gerät ordnungsgemäß von der

Druckversorgung trennen, ausschalten und vom Netz

trennen.

■

Das Gerät mit einem feuchten Tuch reinigen.

■

Elektrische Anschlüsse nicht mit Feuchtigkeit in

Berührung bringen.

■

Ausgebautes Gerät vor der Rücksendung spülen bzw.

säubern, um Personen und Umwelt vor Gefährdung

durch anhaftende Messstoreste zu schützen.

■

Messstoreste in ausgebauten Geräten können zur

Gefährdung von Personen, Umwelt und Einrichtung

führen. Ausreichende Vorsichtsmaßnahmen ergreifen.

42 WIKA Betriebsanleitung Typ DIH10

14089810.01 03/2014 GB/D/F/E

Page 43

7. Wartung und Reinigung / 8. Störungen

Hinweise zur Rücksendung des Gerätes siehe Kapitel

9.2 „Rücksendung“.

8. Störungen

Fehlerbaum

Anzeige Messwert

Keine Anzeige

Querbalken mit

Anzeige „over.“

Wechselt ein

Querbalken mit

der Anzeige

„undr.“

VORSICHT!

Können Störungen mit Hilfe der oben aufgeführten

Maßnahmen nicht beseitigt werden, ist das Gerät unverzüglich außer Betrieb zu setzen, sicherzustellen, dass kein

Druck bzw. Signal mehr anliegt und gegen versehentliche

Inbetriebnahme zu schützen.

In diesem Falle Kontakt mit dem Hersteller aufnehmen.

Bei notwendiger Rücksendung die Hinweise unter Kapitel

9.2 „Rücksendung“ beachten.

14089810.01 03/2014 GB/D/F/E

WIKA Betriebsanleitung Typ DIH10

I = 0 mA

I = > 20 mA

I = 4 mA

4 mA < I < 20 mA

jedoch falscher

Wert

D

Stromschleife nicht geschlossen

Transmitter nicht angeschlossen

Hilfsenergie falsch angeschlossen (verpolt)

Prozesstemperatur außerhalb

des Messbereiches

Sensorbruch oder Sensorkurzschluss

Sensor falsch angeschlossen

Falsche Transmitterkonguration

43

Page 44

9. Demontage, Rücksendung und Entsorgung

9. Demontage, Rücksendung und Entsorgung

WARNUNG!

Messstoreste in ausgebauten Geräten können zur

D

9.1 Demontage

Digitalanzeige nur im drucklosen Zustand demontieren!

9.2 Rücksendung

Zur Rücksendung des Gerätes die Originalverpackung oder eine

geeignete Transportverpackung verwenden.

Um Schäden zu vermeiden:

1. Das Gerät in eine antistatische Plastikfolie einhüllen.

2. Das Gerät mit dem Dämmmaterial in der Verpackung platzieren.

Zu allen Seiten der Transportverpackung gleichmäßig dämmen.

3. Wenn möglich einen Beutel mit Trocknungsmittel der Verpackung

beifügen.

4. Sendung als Transport eines hochempndlichen Messgerätes

kennzeichnen.

Gefährdung von Personen, Umwelt und Einrichtung führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

WARNUNG!

Beim Versand des Gerätes unbedingt beachten:

Alle an WIKA gelieferten Geräte müssen frei von Gefahr-

stoen (Säuren, Laugen, Lösungen, etc.) sein.

Hinweise zur Rücksendung benden sich in der Rubrik

„Service“ auf unserer lokalen Internetseite.

44 WIKA Betriebsanleitung Typ DIH10

14089810.01 03/2014 GB/D/F/E

Page 45

9. Demontage, Rücksendung und Entsorgung

9.3 Entsorgung

Durch falsche Entsorgung können Gefahren für die Umwelt entstehen.

Gerätekomponenten und Verpackungsmaterialien entsprechend den

landesspezischen Abfallbehandlungs- und Entsorgungsvorschriften

umweltgerecht entsorgen.

D

14089810.01 03/2014 GB/D/F/E

WIKA Betriebsanleitung Typ DIH10

45

Page 46

Anlage: EG-Konformitätserklärung

D

46 WIKA Betriebsanleitung Typ DIH10

14089810.01 03/2014 GB/D/F/E

Page 47

Sommaire

Sommaire

1. Généralités 48

2. Sécurité 50

3. Spécications 54

4. Conception et fonction 56

5. Transport, emballage et stockage 59

6. Mise en service, utilisation 60

7. Entretien et nettoyage 64

8. Dysfonctionnements 65

9. Démontage, retour et mise au rebut 66

Annexe : Déclaration de conformité CE 68

Déclarations de conformité disponibles sur www.wika.fr.

F

14089810.01 03/2014 GB/D/F/E

WIKA mode d'emploi type DIH10 47

Page 48

1. Généralités

1. Généralités

■

L'instrument décrit dans ces modes d'emploi est conçu et fabriqué

selon les dernières technologies en vigueur. Tous les composants

sont soumis à des critères de qualité et d'environnement stricts

durant la fabrication. Nos systèmes de gestion sont certiés selon

ISO 9001 et ISO 14001.

■

Ce mode d'emploi donne des indications importantes concernant

F

l'utilisation de l'instrument. Il est possible de travailler en toute

sécurité avec ce produit en respectant toutes les consignes de

sécurité et d'utilisation.

■

Respecter les prescriptions locales de prévention contre les

accidents et les prescriptions générales de sécurité en vigueur pour

le domaine d'application de l'instrument.

■

Le mode d'emploi fait partie de l'instrument et doit être conservé à

proximité immédiate de l'instrument et accessible à tout moment

pour le personnel qualié.

■

Le personnel qualié doit, avant de commencer toute opération,

avoir lu soigneusement et compris le mode d'emploi.

■

La responsabilité du fabricant n'est pas engagée en cas de

dommages provoqués par une utilisation non conforme à l'usage

prévu, de non respect de ce mode d'emploi, d'utilisation de

personnel peu qualié de même qu'en cas de modications de

l'instrument eectuées par l'utilisateur.

■

Les conditions générales de vente mentionnées dans les

documents de vente s'appliquent.

■

Sous réserve de modications techniques.

■

Pour obtenir d'autres informations :

- Consulter notre site Internet : www.wika.fr

- Fiche technique correspondante : AC 80.11

- Conseiller applications :

Tel. : +33 1 343084-84

Fax : +33 1 343084-94

info@wika.fr

WIKA mode d'emploi type DIH1048

14089810.01 03/2014 GB/D/F/E

Page 49

1. Généralités

Explication des symboles

AVERTISSEMENT !

… indique une situation présentant des risques

susceptibles de provoquer la mort ou des blessures graves

si elle n'est pas évitée.

ATTENTION !

… indique une situation potentiellement dangereuse et

susceptible de provoquer de légères blessures ou des

dommages matériels et pour l'environnement si elle n'est

pas évitée.

Information

... met en exergue les conseils et recommandations utiles

de même que les informations permettant d'assurer un

fonctionnement ecace et normal.

DANGER !

… indique les dangers liés au courant électrique. Danger

de blessures graves ou mortelles en cas de non respect

des consignes de sécurité.

AVERTISSEMENT !

… indique une situation présentant des risques

susceptibles de provoquer des brûlures dues à des

surfaces ou liquides chauds si elle n'est pas évitée.

F

14089810.01 03/2014 GB/D/F/E

WIKA mode d'emploi type DIH10 49

Page 50

2. Sécurité

2. Sécurité

AVERTISSEMENT !

Avant le montage, la mise en service et l'exploitation,

s'assurer que l'achage convient à l'application.

Un non respect de cette consigne peut entraîner des

blessures corporelles graves et/ou des dégâts matériels.

F

2.1 Utilisation conforme à l'usage prévu

L'affichage numérique type DIH10 est un indicateur à tout faire

configurable alimenté par boucle de courant pour sondes à résistance

simples (RTD), thermocouples (TC) et transmetteurs de résistance et

de capteur.

Il est particulièrement applicable lorsqu'un signal standard de

4 ... 20 mA est déjà disponible. L'affichage en boucle de courant est

intégré dans une tête de connexion appropriée ou dans un boîtier

monté sur paroi et peut ainsi être utilisé comme affichage local dans

tous les secteurs de l'industrie.

L'instrument est conçu et construit exclusivement pour une utilisation

conforme à l'usage prévu décrit ici et ne doit être utilisé qu'en

conséquence.

Les spécications techniques mentionnées dans ce mode

d'emploi doivent être respectées. En cas d'utilisation inadéquate

ou de fonctionnement de l'instrument en dehors des spécications

techniques, un arrêt et contrôle doivent être immédiatement eectués

par un collaborateur autorisé du service de WIKA.

Si l'instrument est transporté d'un environnement froid dans un

environnement chaud, la formation de condensation peut provoquer

un dysfonctionnement fonctionnel de l'instrument. Il est nécessaire

Vous trouverez d'autres consignes de sécurité dans les

sections individuelles du présent mode d'emploi.

WIKA mode d'emploi type DIH1050

14089810.01 03/2014 GB/D/F/E

Page 51

2. Sécurité

d'attendre que la température de l'instrument se soit adaptée à la

température ambiante avant une nouvelle mise en service.

Aucune réclamation ne peut être recevable en cas d'utilisation non

conforme à l'usage prévu.

2.2 Qualication du personnel

AVERTISSEMENT !

Danger de blessure en cas de qualication insusante !

Une utilisation non conforme peut entraîner d'importants

dommages corporels et matériels.

■

Les opérations décrites dans ce mode d'emploi ne

doivent être eectuées que par un personnel ayant la

qualication décrite ci-après.

■

Tenir le personnel non qualié à l'écart des zones

dangereuses.

Personnel qualié

Le personnel qualié est, en raison de sa formation spécialisée, de

ses connaissances dans le domaine de la technique de mesure et de

régulation et de ses expériences de même que de sa connaissance des

prescriptions nationales, des normes et directives en vigueur, en mesure

d'eectuer les travaux décrits et de reconnaître automatiquement les

dangers potentiels.

Les conditions d'utilisation spéciales exigent également une

connaissance adéquate par exemple des liquides agressifs.

F

2.3 Dangers particuliers

AVERTISSEMENT !

Dans le cas de uides de mesure dangereux comme

notamment l'oxygène, l'acétylène, les substances

combustibles ou toxiques, ainsi que dans le cas

d'installations de réfrigération, de compresseurs etc., les

directives appropriées existantes doivent être observées

en plus de l'ensemble des règles générales.

14089810.01 03/2014 GB/D/F/E

WIKA mode d'emploi type DIH10 51

Page 52

2. Sécurité

F

AVERTISSEMENT !

Protection nécessaire contre les décharges électrostatiques !

L'utilisation conforme de surfaces de travail et de bracelets

personnels mis à la terre est nécessaire lors des opérations

eectuées avec des circuits ouverts (circuits imprimés) an

d'éviter une détérioration des composants électroniques

sensibles due à une décharge électrostatique.

An de travailler en toute sécurité sur l'instrument, la

société exploitante doit s'assurer

■

qu'un équipement de premier secours adapté est

disponible et que les premiers soins peuvent être

dispensés sur place à tout moment en cas de besoin.

■

que le personnel de service reçoit à intervalles réguliers

des instructions relatives à toutes les questions

pertinentes concernant la sécurité du travail, les

premiers secours et la protection de l'environnement et

qu'il connaît le mode d'emploi et particulièrement les

consignes de sécurité contenues dans celui-ci.

DANGER !

Danger de mort lié au courant électrique

Danger de mort en cas de contact avec les pièces sous

tension.

■

Le montage et le raccordement de l'instrument électrique

ne doit être eectué que par un électricien qualié.

■

En cas d'utilisation avec un instrument d'alimentation

défectueux (par exemple court-circuit entre la tension du

secteur et la tension de sortie), des tensions présentant

un danger de mort peuvent apparaître sur l'instrument !

AVERTISSEMENT !

Les restes de uides se trouvant dans les instruments

démontés peuvent mettre en danger les personnes,

l'environnement ainsi que l'installation. Prendre des

mesures de sécurité susantes.

Ne pas utiliser cet instrument dans des dispositifs de

sécurité ou d'arrêt d'urgence. Une utilisation incorrecte de

l'instrument peut occasionner des blessures.

WIKA mode d'emploi type DIH1052

14089810.01 03/2014 GB/D/F/E

Page 53

2. Sécurité

En cas d'erreur, des uides agressifs peuvent être présents

à une température extrême et sous une pression élevée ou

sous vide au niveau de l'instrument.

2.4 Etiquetage, marquages de sécurité

■

Plaques signalétiques lorsqu'elles sont montées dans une tête de

raccordement ou un boîtier

- Etiquetage tête/boîtier

Année de fabrication

- Plaque signalétique tête/boîtier

■

Plaque signalétique de module d'achage

Type

1

F

Type

14089810.01 03/2014 GB/D/F/E

WIKA mode d'emploi type DIH10 53

2

3

4

Année de fabrication

Page 54

2. Sécurité / 3. Spécications

Explication des symboles

Lire impérativement le mode d'emploi avant le

montage et la mise en service de l'instrument !

CE, Communauté Européenne

Les instruments avec ce marquage sont conformes aux

directives européennes pertinentes.

F

3. Spécications

Spécications

Entrée

Boucle de courant 4 ... 20 mA

Impédance d'entrée Ri à 20

mA

Incertitude

Résolution -999 ... 9999 chires

Erreur de mesure

Écart de température 100 ppm/K

Achage

Principe LED, rotatif par étapes de 90°

Valeur mesurée de l'achage 7 segments, 8 mm de hauteur,

Dépassement inférieur/

supérieur

Vitesse d'achage 0,1 s - 1 s - 10 s (réglable)

Paramètres

Tension maximale U

Conditions ambiantes

Température admissible 0 ... 80 °C

Température de stockage -20 ... +80 °C

i

Type DIH10 (module d'achage)

< 160 Ω (U ≤ 3,2 V)

±0,2 % de l'étendue de mesure,

±1 chire

rouge, 4 chires = Achage 9999

vers HI / vers LO

30 VDC

WIKA mode d'emploi type DIH1054

14089810.01 03/2014 GB/D/F/E

Page 55

Ø 62,5

3. Spécications

Boîtier du module

Dimensions Ø 43,0 / 48,5 / 62,5 mm x 37 mm

Matériau du boîtier Polycarbonate

Indice de protection Face avant : IP 67

Poids env. 55 g

Raccordement électrique Bornier enchable, jusqu'à 1,5 mm²

Particularités

programmables

Exécutions de boîtier

(voir chapitre 4.2)

Conformité CE

Directive CEM

Pour de plus amples spécications, voir la che technique WIKA

AC 80.11 et la documentation de commande.

Dimensions en mm pour le module d'achage type DIH10

Raccord : IP 20 ou IP 00

extrémités ouvertes du câble

Echelle de mesure, heure d'achage,

point décimal, unité (°C/°F),

stabilisation du point zéro, blocage de

programmation, points de référence,

numéro TAG

■

Tête de raccordement (standard)

■

Boîtier pour montage sur paroi

■

Boîtier avec support de tuyauterie

2004/108/CE, EN 61326 émission

(groupe 1, classe A) et immunité

d'interférence (application industrielle)

Ø 43

Ø 48,5

F

43 mm

14089810.01 03/2014 GB/D/F/E

WIKA mode d'emploi type DIH10 55

40 mm

Page 56

4. Conception et fonction

4. Conception et fonction

4.1 Description

Le type DIH10 est un achage universel contrôlé par un

microprocesseur et un instrument de surveillance et de contrôle. Il a

une entrée à laquelle des signaux standard 4 ... 20 mA peuvent être

connectés.

Avec son montage simple et sa programmabilité ouverte eectuée par

F

les boutons poussoirs facilement accessibles, il peut aussi être installé

rapidement ultérieurement sur un transmetteur de pression qui est

déjà en activité.

L'achage est alimenté par boucle et ainsi aucune alimentation

électrique supplémentaire n'est nécessaire. L'achage LED d'une

hauteur de 8 mm garantit une bonne lisibilité, même dans de

mauvaises conditions d'éclairage.

Module d'achage type DIH10, côté de service

Bornes de connecteur pour la

programmation en usine

▲

▼

P

Touches pour la programmation

Prise

14089810.01 03/2014 GB/D/F/E

WIKA mode d'emploi type DIH1056

Page 57

4. Conception et fonction

4.2 Exécutions de boîtier

4.2.1 Tête de raccordement BSZ-H (exécution standard), DIH10-Z-*A

Poids environ 350 g

Spécications Version standard

Raccord vers le thermomètre d M24 x 1,5 / ½ NPT

Matériau Aluminium peint en noir

Presse-étoupe 1 x M20 x 1,5 / 1 x ½ NPT

Indice de protection IP 65 (option: IP 67)

4.2.2 Boîtier pour montage sur paroi, DIH10-Z-*C

BSZ-H version spéciale de la partie supérieure

1)

14053621.0114053621.01

F

Poids environ 500 g

Spécications Version standard

Matériau Aluminium peint en noir

Partie inférieure Aluminium peint en noir

1)

1)

Presse-étoupe 2 x M16 x 1,5

Indice de protection IP 65 (option: IP 67)

1) RAL 5022

14089810.01 03/2014 GB/D/F/E

WIKA mode d'emploi type DIH10 57

Page 58

95

20

25

136

91

20

2x M16x1,5

95

20

25

136

91

4. Conception et fonction

4.2.3 Boîtier avec support de tuyauterie, DIH10-Z-*D

BSZ-H version spéciale de la partie supérieure

25

95

F

2x M16x1,5

Poids environ 950 g

Spécications Version standard

Matériau Aluminium peint en noir

Partie inférieure Aluminium peint en noir

Support de tuyauterie Acier inox

Diamètre de tuyauterie R 1" ... 2"

Presse-étoupe 2 x M16 x 1,5

Indice de protection IP 65 (option: IP 67)

1) RAL 5022

4.3 Détail de la livraison

Comparer le détail de la livraison avec le bordereau de livraison.

1)

1)

136

91

14078928.01

WIKA mode d'emploi type DIH1058

14089810.01 03/2014 GB/D/F/E

Page 59

5. Transport, emballage et stockage

5. Transport, emballage et stockage

5.1 Transport

Vérier s'il existe des dégâts sur l'instrument liés au transport.

Communiquer immédiatement les dégâts constatés.

5.2 Emballage

N'enlever l'emballage qu'avant le montage.

Conserver l'emballage, celui-ci ore, lors d'un transport, une protection

optimale (par ex. changement de lieu d'utilisation, renvoi pour réparation).

5.3 Stockage

Conditions admissibles sur le lieu de stockage :

■

Température de stockage : -20 ... +80 °C

■

Humidité : 35 ... 85 % d'humidité relative (sans condensation)

Eviter les inuences suivantes :

■

Lumière solaire directe ou proximité d'objets chauds

■

Vibrations mécaniques, chocs mécaniques (mouvements brusques

en le posant)

■

Suie, vapeur, poussière et gaz corrosifs

■

Environnement présentant des risques d'explosion, atmosphères

inammables

Conserver l'instrument dans l'emballage original dans un endroit qui

satisfait aux conditions susmentionnées. Si l'emballage d'origine n'est

pas disponible, emballer et stocker l'instrument comme suit :

1. Emballer l'instrument dans une feuille de plastique antistatique.

2. Placer l'instrument avec le matériau isolant dans l'emballage.

3. En cas d'entreposage long (plus de 30 jours), mettre également un

sachet absorbeur d'humidité dans l'emballage.

AVERTISSEMENT !

Enlever tous les restes de uides adhérents avant

l'entreposage de l'instrument (après le fonctionnement). Ceci

est particulièrement important lorsque le uide représente

un danger pour la santé, comme p. ex. des substances

14089810.01 03/2014 GB/D/F/E

WIKA mode d'emploi type DIH10 59

corrosives, toxiques, cancérogènes, radioactives etc.

F

Page 60

6. Mise en service, utilisation

6. Mise en service, utilisation

AVERTISSEMENT !

■

Ne jamais se connecter directement à une source

de tension (par exemple 24 V) car cela pourrait

endommager l'achage.

■

Utiliser uniquement un transmetteur qui ne dépassera

pas les valeurs limites électriques admissibles.

F

6.1 Fonctionnement d'une boucle de courant

Unité

d'alimentation

24 VDC

pont

interne

Achage

DIH10

Boîtier

AVERTISSEMENT !

L'achage ne fonctionne que dans une boucle de

courant de 4 ... 20 mA. Une connexion directe vers une

alimentation électrique (par exemple 24 VDC) provoquerait

des dommages à l'acheur et rendrait la garantie invalide.

Pour une vérication de fonctionnement, l'achage doit

être alimenté depuis une source en mA (par exemple un

transmetteur ou un calibrateur mA).

En fonctionnement normal, l'achage est relié en série

avec un transmetteur de 4 ... 20 mA ou à une sortie

analogique de 4 ... 20 mA provenant d'un instrument.

WIKA mode d'emploi type DIH1060

14089810.01 03/2014 GB/D/F/E

Page 61

6. Mise en service, utilisation

6.2 Raccord type DIH10

Prise

Pont interne

2341

+

-

+-

-

Transmitter

+

Unité

d'alimentation

Le bornier enchable à 4 broches pour la connexion de l'achage de boucle de

courant est situé à l'arrière de l'achage et est accessible lorsque le boîtier est

ouvert.

Borne 1 : borne positive de la boucle de courant

Borne 2 : borne négative de la boucle de courant

Les bornes 3 et 4 sont raccordées ensemble sur le PCB et permettent une

connexion facile d'un transmetteur placé dans la tête de raccordement.

F

14089810.01 03/2014 GB/D/F/E

WIKA mode d'emploi type DIH10 61

Page 62

6. Mise en service, utilisation

6.3 Programmation de l'achage

6.3.1 Table de programmation pour la programmation de l'achage

PN Description Gamme Réglage

0 Mode d'étalonnage

0 = Etalonnage du capteur (le signal doit être

appliqué, uniquement pour réglage en usine)

1 = Changement d'échelle (valeur d'achage

F

à 4 ... 20 mA)

1 Valeur pleine échelle (programmation de la

valeur d'achage à 20 mA, par exemple 600)

2 Valeur initiale (programmation de la valeur

d'achage à 4 mA, par exemple 100)

3 Sélection de point décimal ou de l'unité

(pour programmer une unité, la valeur se

déplace vers la gauche)

4

Achage et durée d'établissement de la

moyenne en dixièmes de seconde

5 ** Stabilisation du point zéro (l'étendue ± dans

laquelle 0000 sera aché)

50 *** Dénition du code PIN > 0000 (pour le

blocage de la programmation)

51 *** Authentication par code PIN (retrait du

blocage de programmation)

100 Nombre de points de référence (points de

référence pour l'étalonnage de capteur, les

points de référence réduisent le taux de

mesure)

101 ...

Points de référence (tels que programmés

130

sous PN100)

200

Numéro TAG

* Réglage d'usine

** Pour la programmation d'une valeur >1, une hystérésis de 0,1 % sera activée. Ceci

empêche que l'achage ne saute.

*** optional

(Si aucun code PIN n'a été déni, PN50/PN51 ne sont pas disponibles. Un code PIN

ne peut être programmé initialement que par l'interface sérielle pour la programmation

en usine. Si un code PIN a été déni (achage après test de segment : Pin), le

blocage de programmation doit être déverrouillé en utilisant le code PIN déni par

PN50, par PN51 sous entrée, car sinon toute modication eectuée sous les autres

PN ne pourra pas être sauvegardée. Pour réactiver le code PIN via PN50 en achevant

toute programmation, le mode de programmation doit être quitté (en entrant 0000

sous PN50 ou en interrompant brièvement la boucle de courant).

0/1 1

-999...9999 150

-999...9999 0

0 / 0,0 / 0,00

/ 0,00 / °F /

°C

5.0 ... 100.0 10

0 ... 100 2

0000...9999 0000

0000...9999 0000

0 ... 30 0

-999 ... 9999 0

0000 ... 9999 0

WIKA mode d'emploi type DIH1062

d'usine *

°C

14089810.01 03/2014 GB/D/F/E

Page 63

6. Mise en service, utilisation

6.3.2 Programmation de l'achage

1. Connecter l'instrument en respectant le diagramme de connexion

2. Allumer l'alimentation de boucle de courant (courant entre 4 ... 20 mA)

Un test d'initialisation et de segment est eectué. Alors DIH10

et ensuite le numéro de version du micrologiciel (par exemple

F1.24) s'ache. À la suite de ceci, l'achage passe en mode de

fonctionnement.

3. Presser la touche de programme P, le numéro de programme P 0

va être aché

4. En pressant P et la touche ou P et la touche simultanément,

changer le numéro de programme

5. Sous le numéro de programme sélectionné, commuter vers la

valeur enregistrée avec la touche P

6. En pressant brièvement P, on peut sélectionner le chire requis ;

le chire requis est modié en utilisant ou

7. On sauvegarde l'entrée en pressant la touche P pendant

environ 2 secondes ; la valeur a été sauvegardée dès que

l'achage montre des barres horizontales

8. Si on ne presse aucune touche, après environ 7 secondes,

l'instrument revient au mode de fonctionnement

Fonctions supplémentaires en fonctionnement normal pour aller

chercher les valeurs min/max enregistrées

■

Au moyen de la touche , la valeur enregistrée de la mémoire

max s'ache pendant quelques secondes

■

Au moyen de la touche , la valeur enregistrée de la mémoire min

s'ache pendant quelques secondes

■

En pressant simultanément les touches et on eace les

valeurs min/max

F

ATTENTION !

Si on modie le réglage de l'étendue de mesure,il faut

ré-étalonner l'achage pour conserver la précision de

mesure.

14089810.01 03/2014 GB/D/F/E

WIKA mode d'emploi type DIH10 63

Page 64

6. Mise en service ... / 7. Entretien et nettoyage

6.3.3 Achage d'informations, dépassement supérieur/inférieur

Etendue : 4 ... 20 mA

Etendue achée : 3,9 ... 20,1 mA

Etendue utilisable : 3,6 ... 21,5 mA

Avertissement à l'avance de dépassement inférieur :

Avertissement à l'avance de dépassement supérieur :

Dépassement inférieur aché : < 3,6 mA

Dépassement supérieur aché : > 21,5 mA

Avec l'avertissement à l'avance, l'achage clignote (l'achage normal

F

alterne avec les barres horizontales).

Pour des valeurs inférieures à 3,6 mA, une barre horizontale alterne

avec l'achage “undr”. Pour des valeurs supérieures à 21,5 mA, une

barre horizontale alterne avec l'achage “over”.

7. Entretien et nettoyage

7.1 Entretien

L'instrument ne requiert aucun entretien.

Les réparations ne doivent être eectuées que par le fabricant.

7.2 Nettoyage

ATTENTION !

■

Avant le nettoyage, débrancher correctement l'instrument

de l'alimentation, l'éteindre et le déconnecter du secteur.

■

Nettoyer l'instrument avec un chion humide.

■

Eviter tout contact des raccords électriques avec l'humidité.

■

Laver ou nettoyer l'instrument démonté avant de

le renvoyer, an de protéger les personnes et

l‘environnement contre le danger lié aux restes de

uides adhérents.

■

Les restes de uides se trouvant dans les instruments

démontés peuvent mettre en danger les personnes,

l'environnement ainsi que l'installation. Prendre des

mesures de sécurité susantes.

WIKA mode d'emploi type DIH1064

3,6 ... < 3,9 mA

> 20,1 ... 21,5 mA

14089810.01 03/2014 GB/D/F/E

Page 65

8. Dysfonctionnements