Page 1

Multi-functional precision thermometer, model CTR3000

GB

Multi-functional precision thermometer, model CTR3000

Operating instructions

Page 2

14191761.01 03/2017 EN

GB

Multi-functional precision thermometer, model CTR3000

Page

1 - 67

Further languages can be found at www.wika.com.

© 2016 WIKA Alexander Wiegand SE & Co. KG

All rights reserved.

WIKA® is a registered trademark in various countries.

Prior to starting any work, read the operating instructions!

Keep for later use!

2 WIKA Operating Instruction, model CTR3000

Page 3

Contents

EN

14191761.01 03/2017 EN

1. General Information ............................................................................................................. 6

1.1 Software license agreement ............................................................................................. 6

2. Short overview ..................................................................................................................... 7

2.1 Overview ............................................................................................................................ 7

2.2 Description ........................................................................................................................ 7

2.3 Scope of delivery ............................................................................................................... 7

3. Safety .................................................................................................................................. 8

3.1 Explanation of symbols .................................................................................................... 8

3.2 Intended use ...................................................................................................................... 8

3.3 Improper use .................................................................................................................... 10

3.4 Responsibility of the operator ........................................................................................ 10

3.5 Personnel qualification ................................................................................................... 10

3.6 Personal protective equipment ...................................................................................... 11

3.7 Labelling, safety marks ................................................................................................... 11

4. Design and Function .......................................................................................................... 12

4.1 Overview .......................................................................................................................... 12

4.2 Principles of measurement ............................................................................................. 13

4.2.1 PRT measurement ............................................................................................................. 13

4.2.2 Thermocouple measurement ............................................................................................. 13

4.2.3 Thermocouple reference junction compensation ................................................................ 13

4.3 Front panel ....................................................................................................................... 14

4.3.1 Overview ........................................................................................................................... 14

4.3.2 Warm up time .................................................................................................................... 14

4.3.3 Main screen; Home ............................................................................................................ 15

4.3.4 Thermometer inputs ........................................................................................................... 16

4.3.4.1 Resistance thermometers ................................................................................. 16

4.3.4.2 Thermocouples ................................................................................................. 17

4.4 Application selection and parameter inputs ................................................................. 17

4.5 Rear panel ........................................................................................................................ 18

4.5.1 USB interface (standard).................................................................................................... 18

4.5.2 Ethernet interface .............................................................................................................. 18

4.5.3 RS232 Communication interface card ................................................................................ 18

4.5.4 Power input ........................................................................................................................ 18

4.5.5 Input channel expansion port (CTS Expansion, TC Expansion) .......................................... 19

4.5.6 Name plate ........................................................................................................................ 19

4.6 Applications and their functions .................................................................................... 20

WIKA Operating Instruction, model CTR3000 3

Page 4

Contents

EN

14191761.01 12/2016 EN

4.6.1 Application <<Home>> ...................................................................................................... 20

4.6.1.1 Status bar ......................................................................................................... 21

4.6.1.2 Channel selection ............................................................................................. 21

4.6.1.3 Freeze function ................................................................................................. 22

4.6.1.4 Unit selection .................................................................................................... 22

4.6.1.5 √2 current multiplier ........................................................................................... 23

4.6.1.6 Probe selection ................................................................................................. 23

4.6.1.7 Resolution “+/-“function ..................................................................................... 24

4.6.1.8 Peak “clear” function ......................................................................................... 24

4.6.1.9 Information bar .................................................................................................. 25

4.6.2 Application <<Settings>> ................................................................................................... 26

4.6.2.1 Language .......................................................................................................... 26

4.6.2.2 Backlight-Off ..................................................................................................... 26

4.6.2.3 Brightness ......................................................................................................... 27

4.6.2.4 Time and Date .................................................................................................. 27

4.6.2.5 Sound ............................................................................................................... 28

4.6.2.6 Data separator .................................................................................................. 28

4.6.2.7 Factory reset ..................................................................................................... 28

4.6.2.8 Display – Average value .................................................................................... 29

4.6.2.9 Probes – Standard probe settings ..................................................................... 29

4.6.2.10 Probes – Alarm for probes ................................................................................. 30

4.6.3 Application <<Probes>> .................................................................................................... 31

4.6.3.1 New probe <<Resistance thermometers>> ....................................................... 32

4.6.3.2 New probe <<thermocouples>> ........................................................................ 35

4.6.3.3 New probe <<thermistors>> .............................................................................. 38

4.6.3.4 Configure existing probes ................................................................................. 40

4.6.3.5 SMART probes ................................................................................................. 41

4.6.4 Application <<Scan>> ........................................................................................................ 42

4.6.4.1 Configuring a scan ............................................................................................ 42

4.6.4.2 View .................................................................................................................. 43

4.6.5 Application <<Logger>> ..................................................................................................... 46

4.6.5.1 General ............................................................................................................. 47

4.6.5.2 Log files ............................................................................................................ 48

4.6.6 Application <<Remote>> ................................................................................................... 50

4.6.7 Application <<Info>> .......................................................................................................... 51

4.6.8 Application <<Service>> .................................................................................................... 51

4.6.8.1 Firmware update ............................................................................................... 51

4.6.8.2 Program SMART probe ..................................................................................... 52

4.6.8.3 WIKA service level ............................................................................................ 52

4.7 Download function .......................................................................................................... 53

4.7.1 Log files ............................................................................................................................. 53

4 WIKA Operating Instruction, model CTR3000

Page 5

Contents

EN

14191761.01 03/2017 EN

4.7.2 Screenshot ........................................................................................................................ 54

4.7.3 Measured Probes .............................................................................................................. 54

4.7.4 SMART probes .................................................................................................................. 55

4.7.5 All probes .......................................................................................................................... 55

4.7.6 Instrument details .............................................................................................................. 56

4.8 Calibration services ........................................................................................................ 56

4.9 Remote operation ............................................................................................................ 56

5. Transport, packaging and storage ...................................................................................... 57

5.1 Transport ......................................................................................................................... 57

5.2 Packaging and storage ................................................................................................... 57

6. Commissioning, operation ................................................................................................. 58

7. Faults................................................................................................................................. 59

8. Maintenance, cleaning and servicing ................................................................................. 60

8.1 Maintenance .................................................................................................................... 60

8.2 Cleaning ........................................................................................................................... 60

8.3 Recalibration ................................................................................................................... 60

9. Dismounting, return and disposal ....................................................................................... 61

9.1 Dismounting .................................................................................................................... 61

9.2 Return ............................................................................................................................... 61

9.3 Disposal ........................................................................................................................... 62

10. Specifications .................................................................................................................... 63

11. Technical information ......................................................................................................... 64

11.1 Measurement uncertainty and traceability .................................................................... 64

11.2 International temperature scale ..................................................................................... 64

11.3 Measurement ................................................................................................................... 65

11.3.1 Thermocouple ................................................................................................................... 65

11.3.1.1 Introduction ....................................................................................................... 65

11.3.1.2 Connection ....................................................................................................... 66

11.3.2 Resistance thermometer .................................................................................................... 66

11.3.2.1 Linearization functions for resistance thermometers .......................................... 66

Declarations of conformity can be found online at www.wika.com.

WIKA Operating Instruction, model CTR3000 5

Page 6

1. General Information

EN

14191761.01 12/2016 EN

(S)PRT/RTD

Resistance thermometer

TC

Thermocouple

1. General Information

• The instrument described in the operating instructions has been designed and manufactured

using state-of-the-art technology. All components are subject to stringent quality and

environmental criteria during production. Our management systems are certified to ISO 9001

and ISO 14001.

• These operating instructions contain important information on handling the multi-functional

precision thermometer CTR3000. Working safely requires that all safety instructions and

work instructions are observed.

• Observe the relevant local accident prevention regulations and general safety regulations for

the range of use of the multi-functional precision thermometer CTR3000.

• The operating instructions are part of the instrument and must be kept in the immediate

vicinity of the multi-functional precision thermometer CTR3000 and readily accessible to

skilled personnel at any time.

• Skilled personnel must have carefully read and understood the operating instructions, prior

to beginning any work.

• The general terms and conditions, contained in the sales documentation, shall apply.

• Subject to technical modifications.

• Factory calibrations/DKD/DAkkS calibrations are carried out in accordance with international

standards.

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: CT 60.15

- Application consultant: Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.de

Abbreviations, definitions

1.1 Software license agreement

The software included in this product contains copyrighted software that is licensed under the

GPL/LGPL. A copy of the license texts can be found at the end of this document. You may obtain

the complete Corresponding Source code from us for a period of three years after our last shipment

of this product and/or spare parts therefor, which will be no earlier than 01/01/2030, for a fee of 10€.

Please write an e-mail to CTServiceteam@wika.com

and write „Corresponding Source for

CTR3000“ in the subject line. This offer is valid to anyone in receipt of this information.

WARNING! Installing modified versions of open source software components on the

product will result in the loss of warranty. Also support service and software updates will

be refused. Make sure to follow the safety precautions in the user manual. Improper access

to the instrument is likely to result in its damaging.

6 WIKA Operating Instruction, model CTR3000

Page 7

3. Safety

EN

14191761.01 03/2017 EN

2. Short overview

2.1 Overview

Input for resistance thermometers or thermistors (5-DIN plug)

Input for thermocouples (standard miniature plug)

User interface, touchscreen

Front end USB: Upload and download function

Power on/off

2.2 Description

The model CTR3000 precision thermometer provides a complete measurement and control

interface for users wishing to make high-accuracy temperature measurements or calibrate

thermometers. It supports a wide range of thermometer types including 25 Ω SPRTs, 100 Ω PRTs,

thermistors and thermocouples.

The CTR3000 is a high-accuracy instrument designed for laboratory and industrial temperature

measurement and calibration applications.

2.3 Scope of delivery

■ Model CTR3000 multi-functional precision thermometer incl. power cord

■ Choice of model CTP5000/CTP9000 temperature probes, when ordered

WIKA Operating Instruction, model CTR3000 7

Page 8

3. Safety

EN

14191761.01 12/2016 EN

3. Safety

3.1 Explanation of symbols

DANGER!

... indicates a directly dangerous situation resulting in serious injury or

death, if not avoided.

WARNING!

... indicates a potentially dangerous situation that can result in serious injury or death, if

not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result in light injuries or damage

to property or the environment, if not avoided.

DANGER!

... identifies hazards caused by electrical power. Should the safety instructions not be

observed, there is a risk of serious or fatal injury.

Information

... points out useful tips, recommendations and information for efficient and

trouble -free operation.

3.2 Intended use

Application

The model CTR3000 precision thermometer provides a complete measurement and control

interface for users wishing to make high-accuracy temperature measurements or calibrate

thermometers. It supports a wide range of thermometer types including 25 Ω SPRTs, 100 Ω PRTs,

thermistors and thermocouples.

The CTR3000 is a high-accuracy instrument designed for laboratory and industrial temperature

measurement and calibration applications intended to be used in a basic electromagnetic

environment.

Functionality

The instrument will operate with all 3- and 4-wire (S)PRTs (25 Ω, 100 Ω) platinum resistance

thermometers as well as most standard international thermocouple types and NTC thermistors. The

following temperature measurement units are selectable: °C, °F, K. Base measuring units mV and Ω

are also displayed. The temperature values will be calculated through common conversion of the

base measurement.

8 WIKA Operating Instruction, model CTR3000

Page 9

3. Safety

EN

14191761.01 03/2017 EN

Due to the wide range of this instrument it makes individual instruments needless and makes the

calibration cost-effective.

Features included:

■ Dual capability for both thermocouple and resistance thermometer measurements

■ Input channels can be expanded up to 44

■ Large graphic touchscreen for temperature measurement values as well as configuration settings

and statistical results

■ Logger and log-data transfer to USB stick or communication interface

■ Scan function with a live screen and graph

■ Communication interfaces available for automated monitoring and calibration applications

This instrument is not permitted to be used in hazardous areas!

The instrument has been designed and built solely for the intended use described here, and may

only be used accordingly.

The technical specifications contained in these operating instructions must be observed. Improper

handling or operation of the instrument outside of its technical specifications requires the instrument

to be taken out of service immediately and inspected by an authorised WIKA service engineer.

Handle electronic precision measuring instruments with the required care (protect from humidity,

impacts, strong magnetic fields, static electricity and extreme temperatures, do not insert any

objects into the instrument or its openings). Plugs and sockets must be protected from

contamination.

The manufacturer shall not be liable for claims of any type based on operation contrary to the

intended use.

For indoor use only

Use only the delivered power supply STONTRONICS 3A-182WP06

Input of external Power supply: 100/240 V~, 50-60 Hz, 0.6 A

Don't connect lines within a building which are longer than 30 m, or leave the building (including

lines of outdoor installations).

WIKA Operating Instruction, model CTR3000 9

Page 10

3. Safety

EN

14191761.01 12/2016 EN

3.3 Improper use

WARNING!

Injuries through improper use

Improper use of the instrument can lead to hazardous situations and injuries.

▶

Refrain from unauthorised modifications to the instrument.

▶

Do not use the instrument within hazardous areas.

▶

Do not use the instrument with abrasive or viscous media.

Any use beyond or different to the intended use is considered as improper use.

3.4 Responsibility of the operator

The CTR3000 multifunctional precision thermometer is a high accuracy instrument designed for

laboratory and industrial temperature measurement and calibration applications.

The operator is therefore responsible for legal obligations regarding safety at work.

The safety instructions within these operating instructions, as well as the safety, accident prevention

and environmental protection regulations for the application area must be maintained.

The operator is obliged to maintain the product label in a legible condition.

To ensure safe working on the instrument, the operating company must ensure

■

that the operating personnel are regularly instructed in all topics regarding work safety, first aid

and environmental protection and know the operating instructions and in particular, the safety

instructions contained therein.

■

that the instrument is suitable for the particular application in accordance with its intended

use.

■

that personal protective equipment is available.

3.5 Personnel qualification

WARNING!

Risk of injury should qualification be insufficient

Improper handling can result in considerable injury and damage to equipment.

▶

The activities described in these operating instructions may only be

carried out by skilled personnel who have the qualifications described below.

10 WIKA Operating Instruction, model CTR3000

Page 11

3. Safety

EN

14191761.01 03/2017 EN

Skilled personnel

Skilled personnel, authorised by the operator, are understood to be personnel who, based on

their technical training, knowledge of measurement and control technology and on their

experience and knowledge of country-specific regulations, current standards and directives,

are capable of carrying out the work described and independently recognising potential

hazards.

Special operating conditions require further appropriate knowledge, e.g. of aggressive media.

3.6 Personal protective equipment

The personal protective equipment is designed to protect the skilled personnel from hazards that

could impair their safety or health during work. When carrying out the various tasks on and with

the instrument, the skilled personnel must wear personal protective equipment.

Follow the instructions displayed in the work area regarding personal protective

equipment!

3.7 Labelling, safety marks

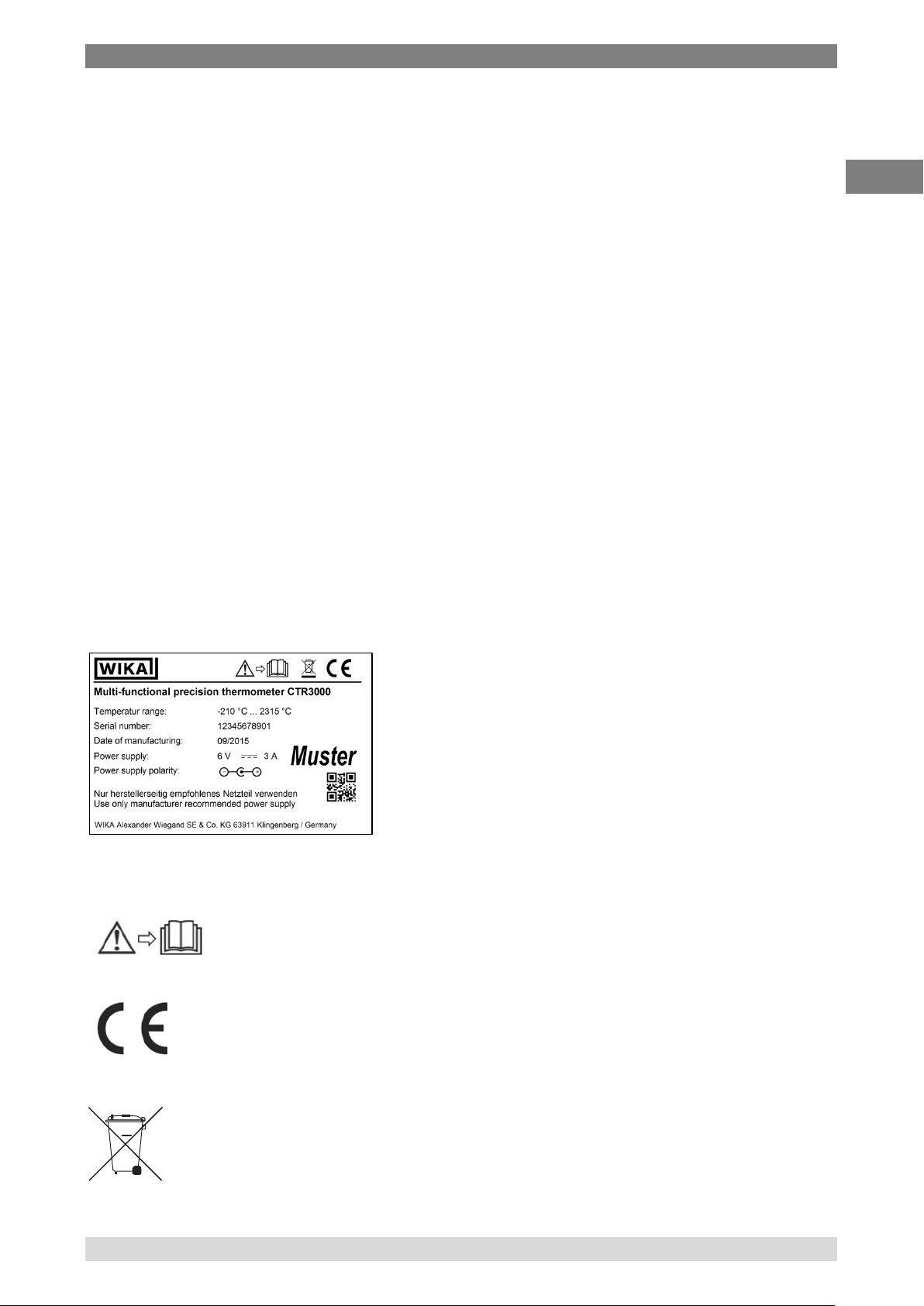

Product label

Symbols

Before mounting and commissioning the instrument, ensure you read the

operating instructions!

CE, Communauté Européenne

Instruments bearing this mark comply with the relevant European directives.

This marking on the instruments indicates that they must not be disposed of in

domestic waste. The disposal is carried out by return to the manufacturer or by the

corresponding municipal authorities (see EU directive 2012/19/EU).

WIKA Operating Instruction, model CTR3000 11

Page 12

4. Design and Function

EN

14191761.01 12/2016 EN

4. Design and Function

4.1 Overview

The CTR3000 is a high accuracy instrument designed for laboratory and industrial temperature

measurement and calibration applications.

Features include:

• unique dual capability for both thermocouple and resistance thermometer

measurements;

• number of input channel can be expanded from four to forty-four channels;

• large graphic touchscreen for temperature measurement values as well as

configuration settings and statistical results;

• advanced functions include differential measurement, programmable scanning

routines, programmable timer, data logging, statistical reporting;

• USB and Ethernet (RS232 as an option) communication interfaces available for

automated monitoring and calibration applications;

The CTR3000 will operate with all 3 and 4-wire Pt100 (100 Ohm) platinum resistance thermometers

as well as most standard international thermocouple types. Temperature measurement units are

selectable by front panel operation; °C, °F, K. Base measurement units mV,Ω are also displayed.

Resistance accuracy is better than ±2mΩ equivalent to temperature measurement precision of

±5mK for Pt100 thermometers.

Standard miniature sockets allow convenient connection for thermocouple inputs. Connection

sockets incorporate integral temperature compensation sensors making high accuracy

thermocouple measurement possible without the use of an external reference junction.

12 WIKA Operating Instruction, model CTR3000

Page 13

4. Design and Function

EN

14191761.01 03/2017 EN

4.2 Principles of measurement

4.2.1 PRT measurement

The CTR3000 measures the voltage (Vt) developed across the unknown sensor resistance (Rt) and

the voltage (Vs) across a stable internal reference resistance (Rs) connected in series and passing

the same current. The voltages are in proportion to the resistances so the thermometer resistance is

derived from: Rt = Rs x Vt / Vs This technique achieves immunity from slow moving time and

temperature drift in the electronics as it is not affected by voltage measurement gain variations or

current source fluctuations.

In the same way that AC resistance measurement eliminates thermal EMFs, switched DC achieves

a similar advantage. Switched DC works by reversing the current flow on alternate measurement

cycles and taking the average value, thereby cancelling any thermal EMF offsets from the

measurement.

For PRTs, the relationship between resistance and temperature varies slightly from one PRT to

another. Therefore, no matter how accurately the CTR3000 measures the PRT resistance, if the

relationship between resistance and temperature for a particular PRT is not known, accurate

temperature measurement is not possible.

The CTR3000 uses PRT calibration data to overcome this problem and calculates temperature from

temperature conversion functions stored in internal memory. This method enables the CTR3000

accurately to convert resistance to temperature, uniquely for each PRT used. It is very important

therefore that a PRT is used on the correct and properly configured input channel.

4.2.2 Thermocouple measurement

As well as the PRT resistance measurement facility the CTR3000 also functions as a precision

millivolt-meter. Designed for high accuracy measurement over the EMF voltage range of all

standard base and precious metal thermocouples, the CTR3000 achieves a basic voltage accuracy

of better than ±0,004 % + 2 μV over the full measurement range.

Thermocouple EMFs are converted to temperature using the EN60584 linearization functions.

The voltage input connection is specially designed to minimise the thermal gradient between the

terminals. This is particularly important when the internal reference junction compensation is used,

as any temperature difference at the connection junction will influence the measurement result.

4.2.3 Thermocouple reference junction compensation

The electrical connection between the thermocouple element and the CTR3000 input connector is

often referred to as the internal reference junction. All standard thermocouple reference functions

are defined relative to 0°C. To eliminate the physical need to reproduce this temperature inside the

CTR3000, the actual connection temperature is accurately measured with an internal PRT. This

temperature is converted to an equivalent EMF and added to the actual thermocouple voltage

measurement, thereby correcting for the connection temperature.

For high precision thermocouple measurement applications, i.e. calibration, an external reference

junction may be used. Using an external reference junction eliminates the uncertainties associated

with reference junction compensation.

WIKA Operating Instruction, model CTR3000 13

Page 14

4. Design and Function

EN

14191761.01 12/2016 EN

4.3 Front panel

4.3.1 Overview

Input for resistance thermometers or thermistors (5-DIN plug)

Input for thermocouples (standard miniature plug)

User interface, touchscreen

Front end USB: Upload and download function

Power on/off

4.3.2 Warm up time

It is recommended that the CTR3000 be warmed up before use to stabilize the environmentally

controlled components. This will ensure the best performance to the specifications. We recommend

1

a warm up time of 1 hour for full accuracy specifications.

1

The internal cold junction compensation needs up to 2 hours for performing best.

14 WIKA Operating Instruction, model CTR3000

Page 15

4. Design and Function

EN

14191761.01 03/2017 EN

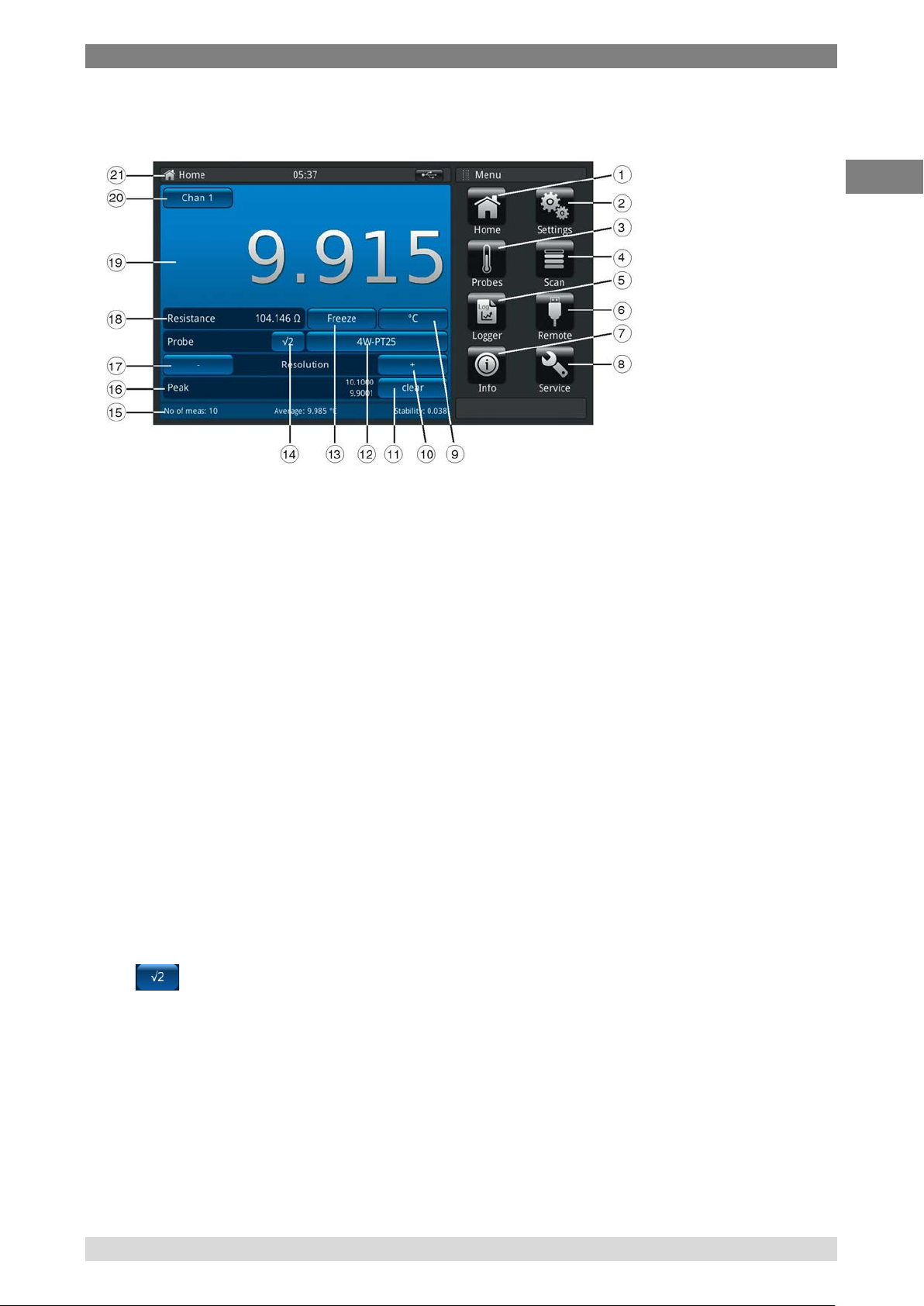

4.3.3 Main screen; Home

1 Home application

2 General settings

3 Probe settings

4 Scan settings

5 Logger settings

6 Remote settings

7 Info display

8 Service settings

9 Unit; shortcut

10 Plus decimal place

11 Clear the peak values (min, max

measured since starting the

instrument)

12 Selected probe (standard or custom);

shortcut

* Selecting √2 current multiplier

This option increases current through the probes by √2 (double-power), to determine any probe selfheating. The best method of using this option is first to let the sensor reach a steady temperature

and note the value. It may take some time to stabilise. Note the value down.

13 Freeze the display; function key

14 Root 2 for sensor current PRT;

function key*

15 Current displaying of average, stability

and number of measurements

16 Peak displaying

17 Minus decimal place

18 Measured value in the base unit

according to probe, e.g. Ω for Pt100

and mV for TC (displays °C, if the base

unit is selected using button 9)

19 Current measured value**

20 Selected channel; shortcut

21 Current application name

Press the probe will increase the heating effect on the probe, and the value displayed will

represent the temperature due to the increased current. When the reading has stabilised, note the

temperature and calculate the temperature change.

** The selected input channel is interrogated before each measurement cycle, and when enabled,

SMART probes are identified by ‘SMART´ appearing as (S) beside the field 14. Open circuit

thermometer input channels will display nothing, the symbol “OL” displays that the measurement

value is out of range.

WIKA Operating Instruction, model CTR3000 15

Page 16

4. Design and Function

EN

14191761.01 12/2016 EN

4.3.4 Thermometer inputs

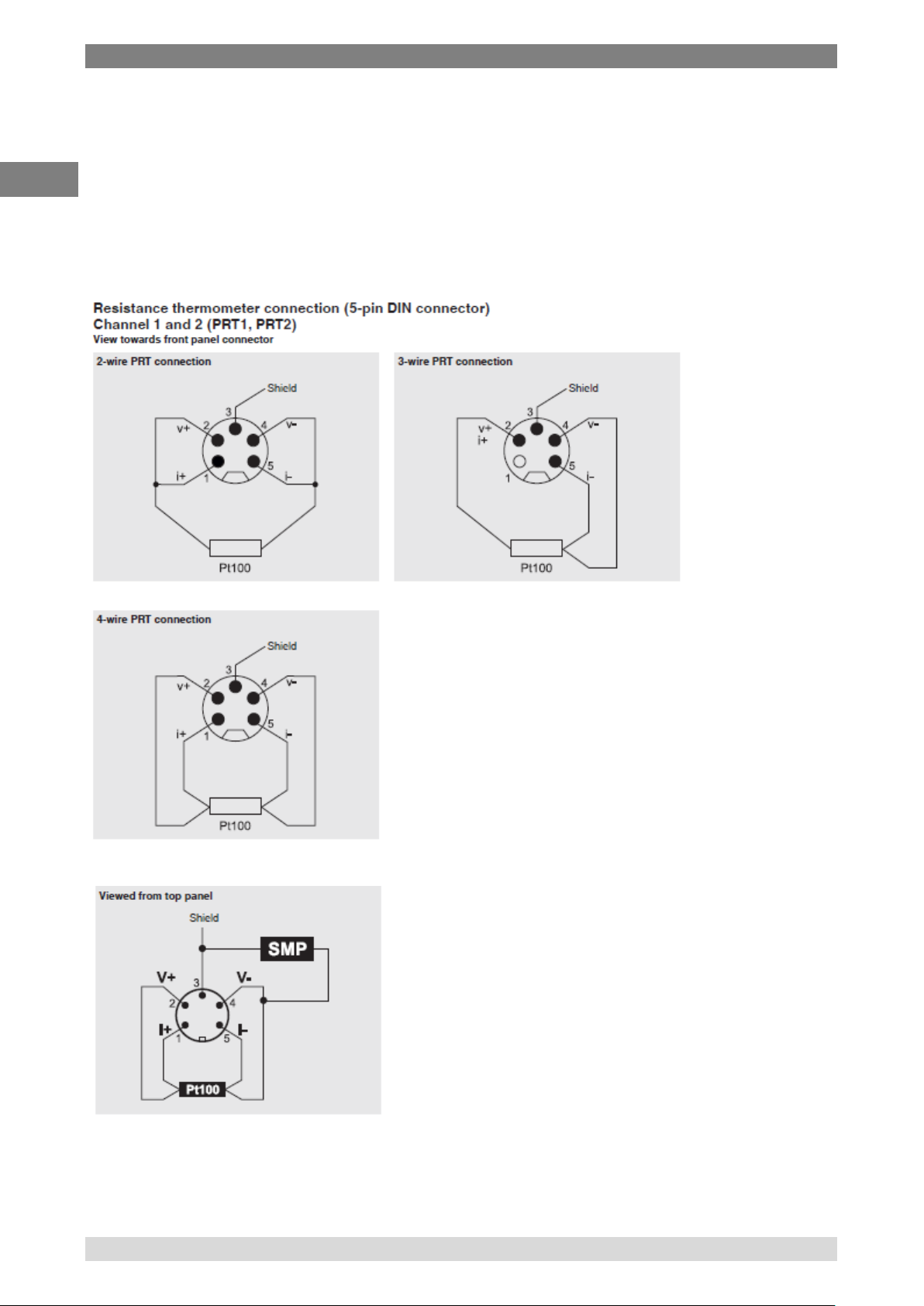

4.3.4.1 Resistance thermometers

The CTR3000 has two resistance thermometer and two thermocouple input channels, the input

sockets are located on the instruments front panel.

PRTs are connected via the 5 pin DIN sockets. You may connect 2, 3, or 4 wire PRTs as shown

below. Un-terminated platinum resistance thermometers may be connected through an optional

adapter box which is available as an accessory, (CTA5000-ADAP5-Z).

Options - with DIN plug or SMART plug

With the SMART connector on the probes, storing the

data is needed only once - in the connector! The

calibration data stays with the probe - permanently. It can

even be used on another instrument without any further

action.

The SMART connector saves time and reduces error. If there are existing calibrated or uncalibrated

probes, no problem, CTR3000 automatically registers if a probe is SMART or normal.

16 WIKA Operating Instruction, model CTR3000

Page 17

4. Design and Function

EN

14191761.01 03/2017 EN

Application title Input title

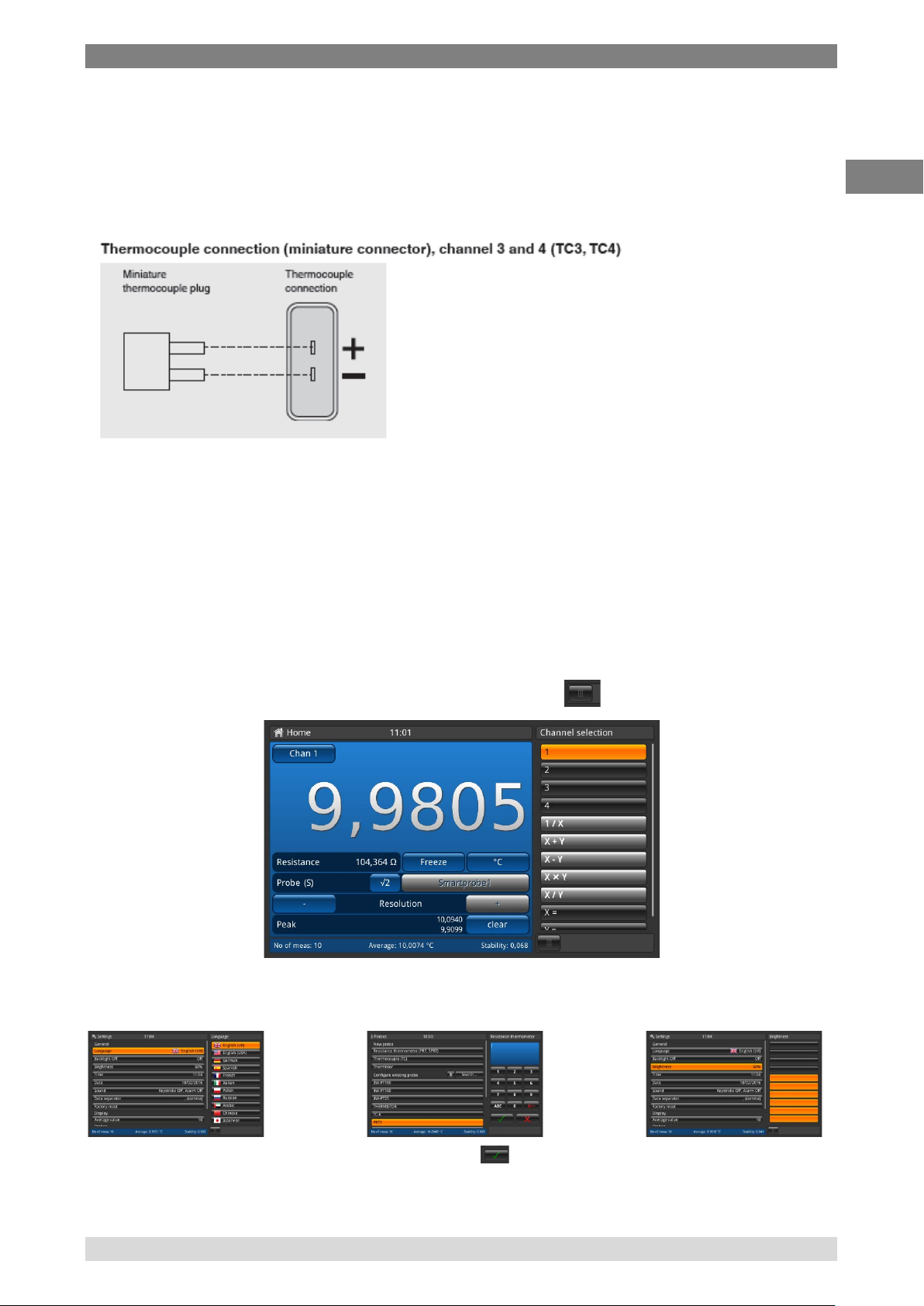

4.3.4.2 Thermocouples

Thermocouples may be directly connected to the CTR3000 at the standard miniature sockets.

These sockets are within a temperature compensated isothermal block which eliminates the need

for an external ice point reference junction. However, the CTR3000 may also be used with an

external ice point reference for high precision measurement and calibration work.

4.4 Application selection and parameter inputs

The application selection area on the right side of the screen is the area where settings, probes,

logger, service and other apps can be chosen. As each App is chosen, related application

parameters will appear on the left of the screen along with the name of the application, and a

reduced size icon in the top title section. When a parameter is chosen, related selections, sliding

scales or a data entry key pad will appear in the input area on the right where the application

selection buttons were previously displayed. An example of each type of input is shown below. To

return to the App selection menu, simply press the Menu button below the input area.

Parameter inputs:

Related selections Data entry key pad Sliding scales

The selection will be presented on the right Confirm the values with

side of the function key for the input. Min/max values will be indicated below the blue screen

also QWERTZ keyboard available

WIKA Operating Instruction, model CTR3000 17

Page 18

4. Design and Function

EN

14191761.01 12/2016 EN

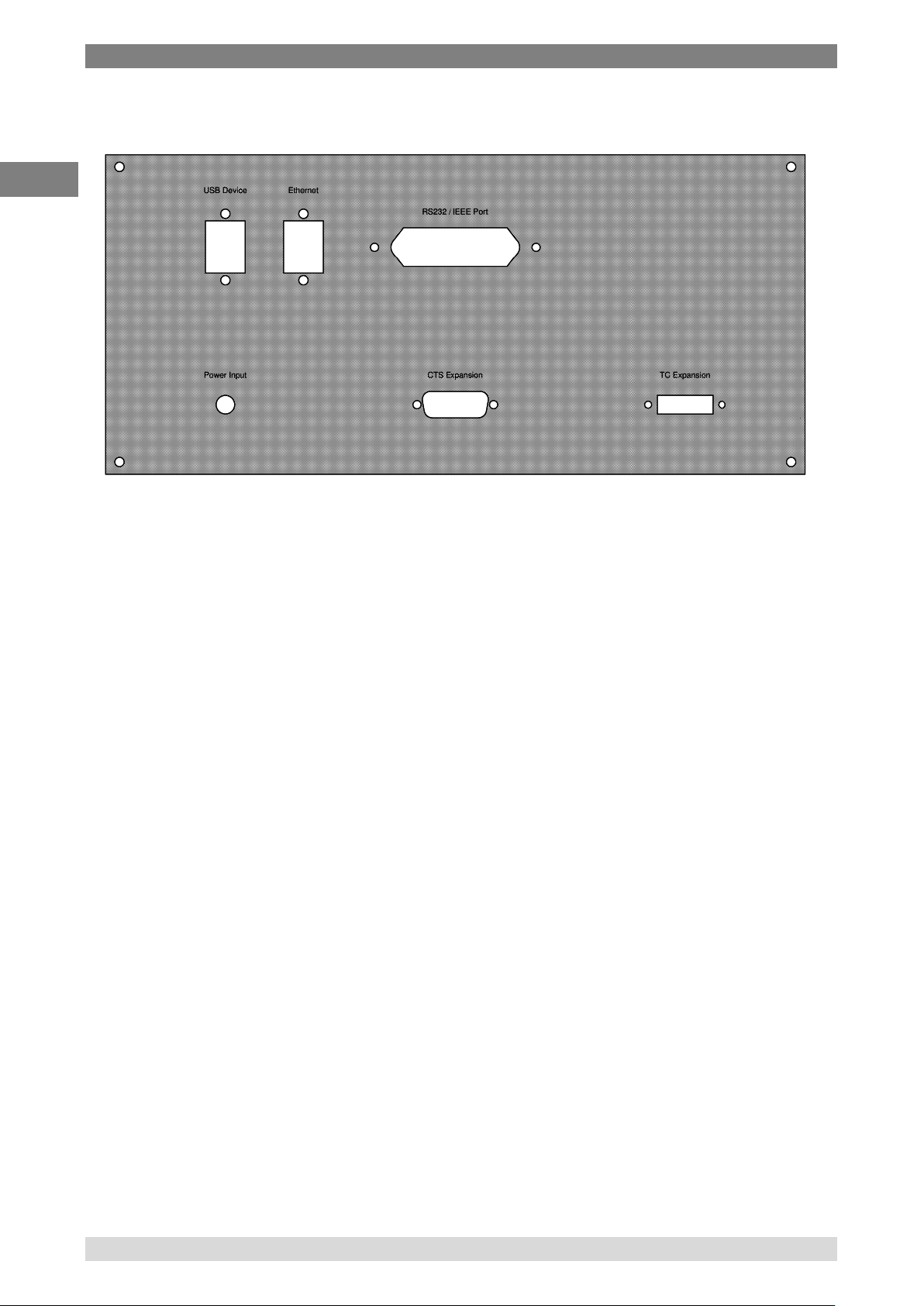

4.5 Rear panel

4.5.1 USB interface (standard)

The USB connector is fitted as standard. Communication requires the installation of the USB driver

on a PC.

The instrument can be controlled through simple SCIPI commands and can transmit SCIPI resultdata, which may be recorded using a simple terminal program.

Please refer to section 4.6.6 Application <<Remote>> for further details.

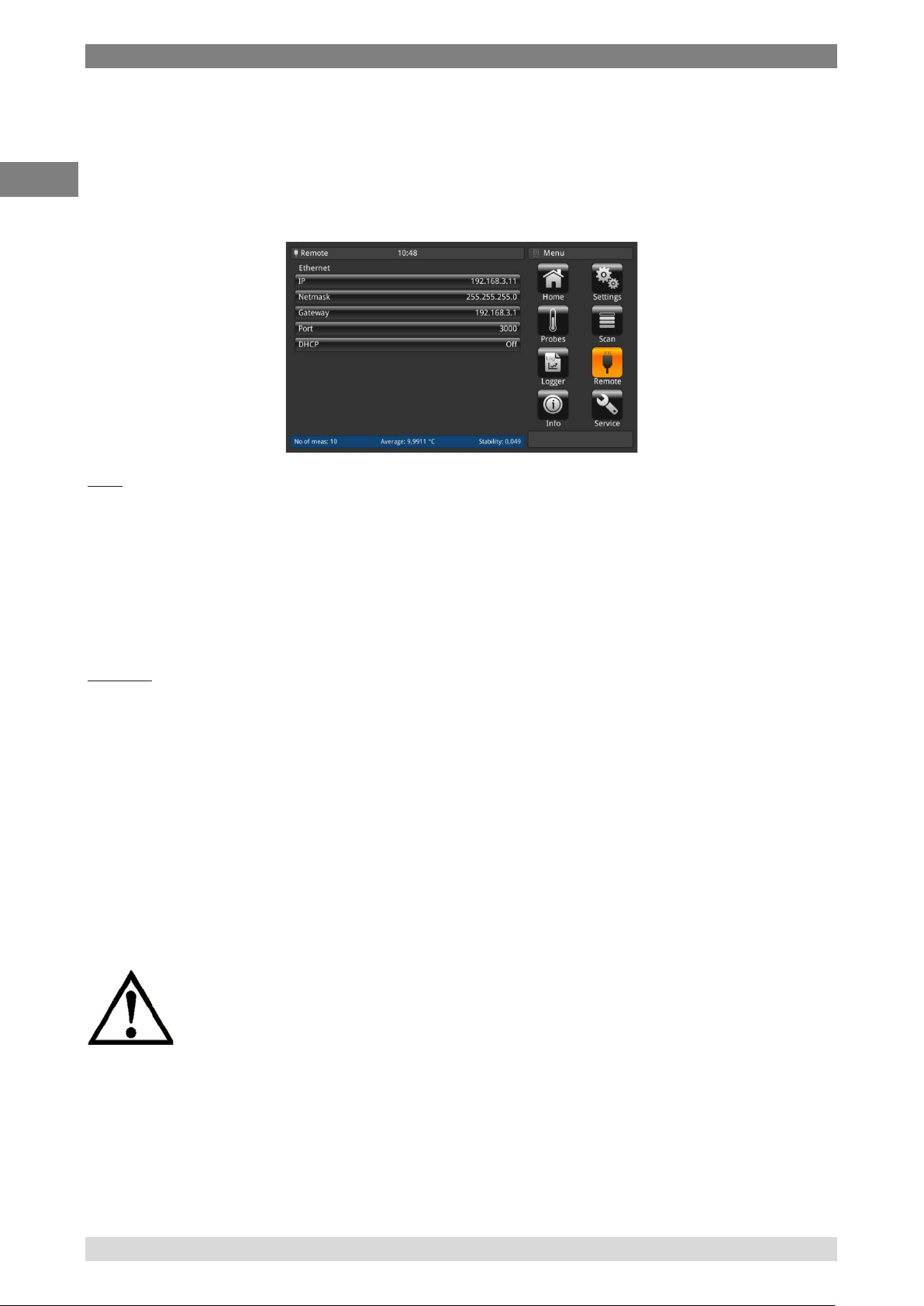

4.5.2 Ethernet interface

The Ethernet function allows the user to set the following by inputting a numeric value in each

separate field:

IP

Netmask

Gateway

Port

DHCP settings

Set the Ethernet communication parameters as described in Section 4.6.6 Application

<<Remote>>.

4.5.3 RS232 Communication interface card

Optional RS232 communication interface card slot. A blanking plate is fitted if there is no

communication interface card.

The CTR3000 may (optionally) be fitted with one of these interfaces. Operation is similar for all

communication interfaces. Please refer to section 4.6.6 Application <<Remote>> for further details.

4.5.4 Power input

Use only the delivered power cable!

18 WIKA Operating Instruction, model CTR3000

Page 19

4. Design and Function

EN

14191761.01 03/2017 EN

4.5.5 Input channel expansion port (CTS Expansion, TC Expansion)

Optional input channel expansion ports.

An expansion port connector is provided on the rear panel. The CTS expansion connector enables

up to four CTS5000 switchboxes to be used to expand the number of input connections to provide

up to 64 additional channels.

The universal switchbox CTS3000 will follow.

4.5.6 Name plate

Please see all details in chapter 3.7 Labelling, safety marks.

WIKA Operating Instruction, model CTR3000 19

Page 20

4. Design and Function

EN

14191761.01 12/2016 EN

4.6 Applications and their functions

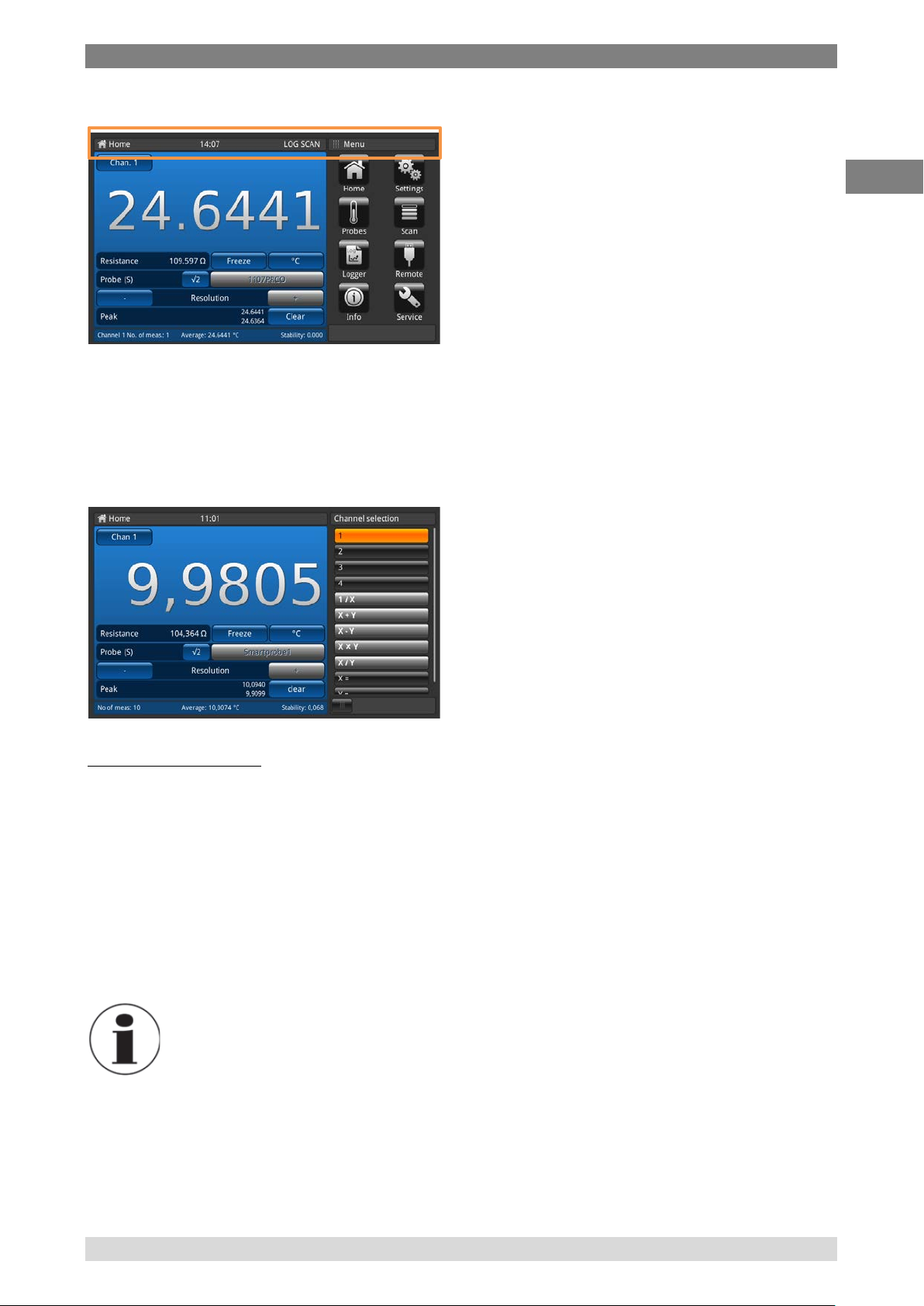

4.6.1 Application <<Home>>

The Home App is the normal operation screen. This application is different from the others in that it

is not use to setup the configuration but is used to monitor the temperature measurement values

applied to this device.

1 Home application

2 General settings

3 Probe settings

4 Scan settings

5 Logger settings

6 Remote settings

7 Info display

8 Service settings

9 Unit; shortcut

10 Plus decimal place

11 Clear the peak values (min, max

measured since starting the

instrument)

12 Selected probe (standard or custom);

shortcut

13 Freeze the display; function key

14 Root 2 for sensor current PRT;

function key*

15 Current displaying of average, stability

and number of measurements

16 Peak displaying

17 Minus decimal place

18 Measured value in the base unit

according to probe, e.g. Ω for Pt100

and mV for TC (displays °C, if the base

unit is selected using button 9)

19 Current measured value**

20 Selected channel; shortcut

22 Current application name

20 WIKA Operating Instruction, model CTR3000

Page 21

4. Design and Function

EN

14191761.01 03/2017 EN

4.6.1.1 Status bar

The status bar at the top end of the screen gives a

description of the actual operating mode of the

device.

Log = Logger is active

SCAN = Scan is running

REM = Interface is active

4.6.1.2 Channel selection

By pressing function key 20 (refer to section 4.3.3 Main screen; Home) the menu for the channel

selection opens on the right side. Back via the menu button on the bottom line.

1 = PRT 1

2 = PRT 2

3 = TC 3

4 = TC 4

The selected channel will be indicated in the

function key 20 like Chan “#selection#”.

Mathematical functions

The CTR3000 can display several mathematical functions between two different channels (X, Y).

The unit can be selected after the selection of the channel via function key 9 (refer to section 4.3.3

Main screen; Home). If the units for these two channels do not match (like PRT and TC), the value

will be displayed in a temperature unit like °C, °F, or K.

- Input necessary for X and Y

- If you click on “X=” or “Y=”then a list of available channels opens on the right side

o Only numbers for channels selectable, which are connected

o If an invalid number is selected, an information dialog appears.

SMART probes take time to read their stored information. The SMART probe ’read on

channel change’ is disabled once a difference mode is selected. To change probes,

select a single channel before reselecting a difference mode with SMART probes.

WIKA Operating Instruction, model CTR3000 21

Page 22

4. Design and Function

EN

14191761.01 12/2016 EN

4.6.1.3 Freeze function

While clicking on the button “Freeze” (function key 13 please refer to section 4.3.3 Main screen;

) the colour turns into orange and the display freezes/ holds.

Home

This function helps the user to read easier the values.

4.6.1.4 Unit selection

By pressing function key 9 (refer to section 4.3.3 Main screen; Home) the menu for the unit selection

opens on the right side. Back via the menu button on the bottom line.

Sequence as shown left for all PRT channels.

Sequence for all TC channels like °C, °F, K and

mV.

The selected unit will be indicated in the function

key 9 like “#selection#”.

Beside the “Freeze” Button on the left side the

corresponding value is displayed, e.g.:

- Pt100 and °C then show Ohm

- TC and mV then show °C

Calculation and units

1 °Celsius

x °C * 1,8 + 32 = y °Fahrenheit

x °C + 273,15 = y Kelvin

Temperature units

The temperature cannot be measured. The device measures Ohm or mV.

These electrical signals are calculated into temperature through the conversion of the probe.

22 WIKA Operating Instruction, model CTR3000

Page 23

4. Design and Function

EN

14191761.01 03/2017 EN

4.6.1.5 √2 current multiplier

This option increases current through the probes by √2 (double-power), to determine any probe selfheating. The best method of using this option is first to let the sensor reach a steady temperature

and note the value. It may take some time to stabilize.

Press the function key 14 (refer to section 4.3.3 Main screen; Home) and immediately the increased

current through the probe will increase the heating effect on the probe, and the value displayed will

represent the temperature change due to the increased current. When the reading has stabilized,

note the temperature change. The result is the actual temperature with the effect of probe selfheating eliminated.

4.6.1.6 Probe selection

By pressing function key 12 (refer to section 4.3.3 Main screen; Home) the menu for the probe

selection opens on the right side. Back via the menu button on the bottom line.

Standard probes see below.

Stored probes: List of all configured probes in the

menu “Probes”. Details see below.

The selected channel will be indicated in the function key 12 like “#selection#”.

Standard probes for all PRT channels:

- Default 3w PRT (Pt100): Pt100, 3w, DIN conversion, internal 100 Ohm 3W-PT100

- Default 4w PRT (Pt100): Pt100, 4w, DIN conversion, internal 100 Ohm

- Default SPRT (Pt25): Pt25, 4w, DIN conversion, internal 25 Ohm

- Default Thermistor: 500 kOhm, no temperature conversion

4W-PT100

4W-PT25

THERMISTOR

Standard probes for all TC channels:

- Default Thermocouple: TC K, internal reference cold junction

Stored probes:

- List of all configured probes in the menu “Probes”. Details see below.

- “+” allows the user to configure a new probe and the user is directly linked to the menu

“probes” (details in section 4.6.3 Application <<Probes).

- Sequence of the listed probes acc. ABC

A probe can only be assigned to one channel at a time, so it is not possible to e.g.

assign stored probe PRT1 to channel 1 and 2 at the same time. This means that if a

probe, which is currently assigned to a channel, is assigned to another channel. it is

no longer assigned to the first channel. If no probe is explicitly assigned to a channel,

the default probe for the channel type will be used. For PRT channels, this is 4WPT100, for TC channels TC(K).

WIKA Operating Instruction, model CTR3000 23

Page 24

4. Design and Function

EN

14191761.01 12/2016 EN

Easy access to probe settings:

Holding the button of the stored probes (in the home screen) >2s opens the probe menu for editing

the selected probe. Please find more details how to edit/change probes in section 4.6.3 Application

<<Probes>>.

If a SMART probe is connected to a channel this

function is invalid. Probe selection list will not show

up, button is disabled. The SMART probe’s

identifier is shown in the button; the label shows

“Probe (S)” to indicate the SMART probe.

4.6.1.7 Resolution “+/-“function

By pressing function key 17/10 (refer to section 4.3.3 Main screen; Home) the resolution will be

lower/higher. Means the numbers of decimal places are configured.

By pressing „+“ a digit after the point/comma will be

added, by pressing „-“ a digit after the point/comma

will be deleted.

The buttons will turn inactive if the maximum or

minimum setting is reached.

By changing the unit the numbers of the settable decimal places will change.

Minimum = 0 (no comma/point)

Maximum = 0.0001K/°C/°F / 0.00001Ω (PRT) / 0.00001mV (TC)

4.6.1.8 Peak “clear” function

The peak function (Min/Max) shows the maximum and minimum value for the actual recorded

measurement in the unit displayed in the function key 9.

The peak field 16 (refer to section 4.3.3 Main

screen; Home) shows in the first line Peak_Max

and in the second line Peak_Min.

By pressing the „Clear“ function key 11 (refer to

section 4.3.3 Main screen; Home) the values will

be deleted and the values are refreshed.

24 WIKA Operating Instruction, model CTR3000

Page 25

4. Design and Function

EN

14191761.01 03/2017 EN

Resolution fixed at 4 respectively 5 decimal places, only depending on unit selection.

Temperature selected 4 places

Base value selected 5 places

So only a change of the unit causes change of peak values.

4.6.1.9 Information bar

The information bar, field 15 (refer to section 4.3.3 Main screen; Home), displays relevant

measurements which help you to have an easier calibration documentation.

Values

- Number of measurements: Setting in Settings >> Display >> Average value

- Average : Average value over the last xy values; displayed in the

selected unit on the home screen

- Stability: shows the standard deviation

- Difference: displays the difference between the reference (first probe

marked as reference) and the device under test (all other

channels); displayed in the unit of the device under test

(only shown in scan mode when the selected view is

calibration, please refer to section 4.6.4 Application

<<Scan>>)

Information bar has the same colour as the corresponding channel selection on the

home screen (blue, green, red and orange). If channels are displayed in a list or no

channel relevant information is displayed the information bar will be displayed in grey.

WIKA Operating Instruction, model CTR3000 25

Page 26

4. Design and Function

EN

14191761.01 12/2016 EN

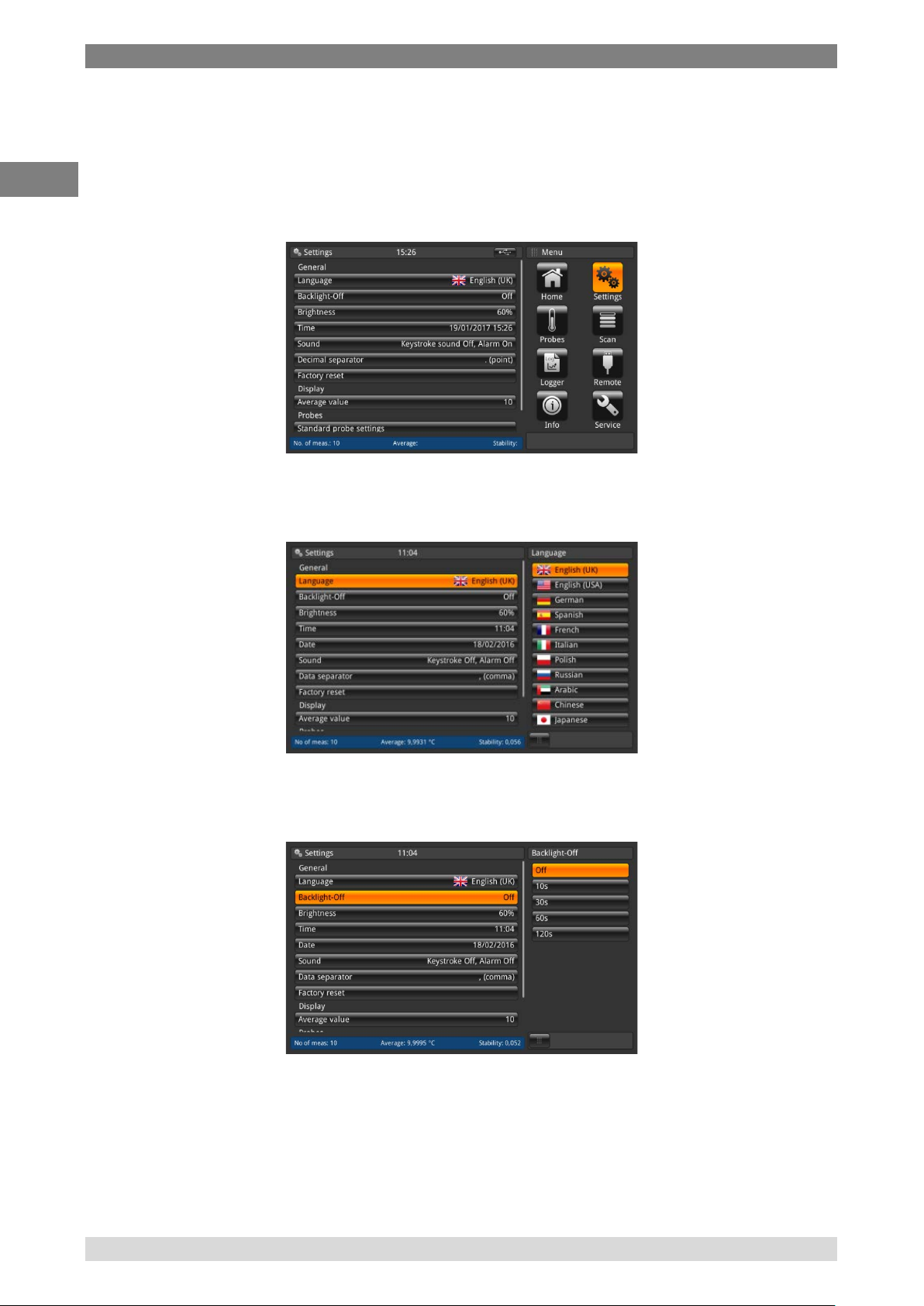

4.6.2 Application <<Settings>>

General settings can be done in this menu in the following categories: general, display and probes.

Pressing on the home screen the button “settings” guides the user into the sub-menu. This will open

on the left side. For every entry settings can be done by clicking on the button. The settings menu

opens on the right side.

4.6.2.1 Language

The language parameter provides a selection of different languages. Once a language is chosen all

words within all menus will appear in the chosen language. This will not affect the decimal separator.

4.6.2.2 Backlight-Off

This setting will mean that the backlight will switch off, if no button is pressed for the set time.

Options are displayed below.

26 WIKA Operating Instruction, model CTR3000

Page 27

4. Design and Function

EN

14191761.01 03/2017 EN

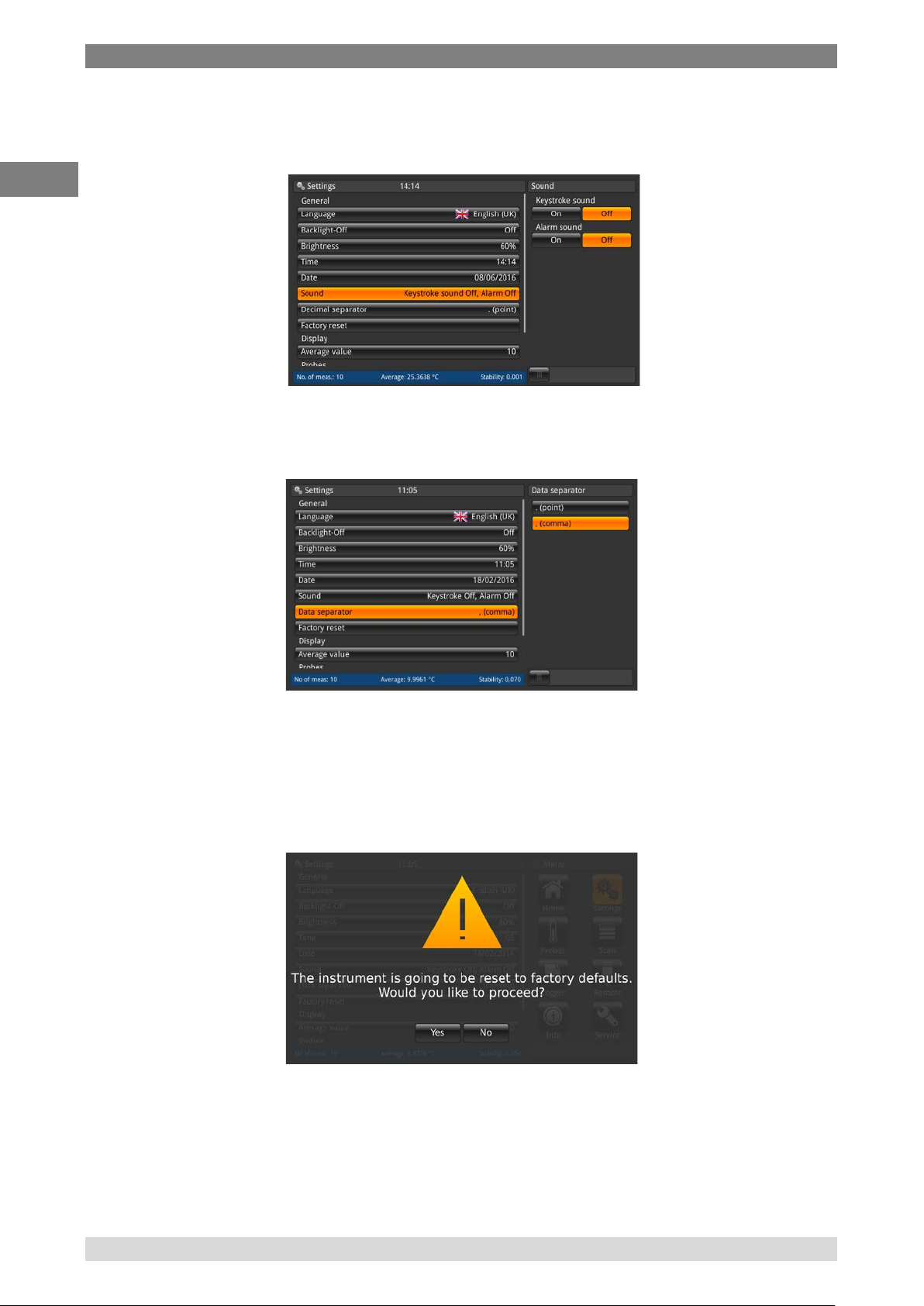

4.6.2.3 Brightness

The brightness setting provides a sliding scale to increment the screen brightness in all screens.

Sliding your finger along the bar graph or touching anywhere in the bar graph will change the

brightness of the screen. After the setting is made and your finger is removed from the screen the

menu will show the brightness percent selected and revert back to the main settings menu.

4.6.2.4 Time and Date

This setting ensured the correct time and date for your country. Different time and date formats are

available.

Time changes on the main screen e.g. home view according to this setting. Date changes affect the

stored calculation of the recalibration date.

Instrument has to restart after date or time change due to technical reasons. The

instrument has no internal battery for the clock. This means that when the instrument

remains powered off for several days, it loses the date and time setting.

WIKA Operating Instruction, model CTR3000 27

Page 28

4. Design and Function

EN

14191761.01 12/2016 EN

4.6.2.5 Sound

The setting enables/disables the keystroke sound and the alarm sound.

,

4.6.2.6 Data separator

The setting of the radix character (decimal mark) can be done from a dot (.) to a comma (,) or vice

versa.

4.6.2.7 Factory reset

This function resets all values to their standard. Defined user probes won’t be deleted. Factory reset

overwrites the user calibration data with the factory calibration data.

The following dialog will follow by pressing the button <<Factory reset>> in which the user must

obviously confirm that he resets the values to the standard ones.

28 WIKA Operating Instruction, model CTR3000

Page 29

4. Design and Function

EN

14191761.01 03/2017 EN

4.6.2.8 Display – Average value

The average value is stated in the information bar on the home screen or other measuring screens.

Definition: Average value = arithmetic average over the last measurements.

The setting defines the “n” value for the formula above. When clicking on the button below <<sample

count>> the numpad opens.

4.6.2.9 Probes – Standard probe settings

By clicking on the “Standard probe settings” button on the left side, the sub menu opens on the right.

This function helps because these standard settings are pre-configured, if the user wants to store a

new probe. Repeating types of thermometers can be easily pre-configured in this way.

For each section (standard conversion PRT, standard internal resistor, standard conversion TC and

standard reference junction) one selection is necessary! For more details refer to chapter 4.6.3

Application <<Probes>>.

Standard settings are marked in orange.

WIKA Operating Instruction, model CTR3000 29

Page 30

4. Design and Function

EN

14191761.01 12/2016 EN

4.6.2.10 Probes – Alarm for probes

By clicking on the “alarm for probes” button on the left side, the sub menu opens on the right.

The option is between having an alarm for probes or not.

If ON is clicked, then the measured temperature is compared with Tmax (set under probes). If Tmax

< measured temperature, then an error appears (exclamation mark left beside the function key 12).

30 WIKA Operating Instruction, model CTR3000

Page 31

4. Design and Function

EN

14191761.01 03/2017 EN

4.6.3 Application <<Probes>>

Higher accuracy measurements can be made using calibrated thermometers whose

characteristics have been determined. Before being used, the thermometer and its calibration

details must be entered into the CTR3000 in the application <<probes>> (press the button

<<probes>> while being in the <<Home>> application) under <<new probe>>. The

thermometer will then appear in the thermometer list below <<configure existing probes>> (refer

to the following chapters).

Existing thermometers can be deleted via the recycle bin. These can also be find quick by

searching the thermometers with the text search button (refer to section 4.6.3.4 Configure

existing probes

).

The maximum cable length of a temperature probe is 2 m.

WIKA Operating Instruction, model CTR3000 31

Page 32

4. Design and Function

EN

14191761.01 12/2016 EN

4.6.3.1 New probe <<Resistance thermometers>>

To configure a new resistance thermometer click on the button <<resistance thermometer (PRT,

SPRT)>> and the menu with all settings opens on the right. Once all settings are done the changes

must be confirmed with <<Store>>.

1. Probe name

Please enter a unique name (e.g. certificate number or serial number) for the new

thermometer. This name is also shown later under the existing probes and for this name a

search can be done. The input can be done via the qwertz keyboard.

2. Reference

Please mark the thermometer as reference or not. This is important for the scan mode - view

calibration because the difference between the first reference and the device under test will

be calculated and displayed in the information bar.

3. Probe type

Is the thermometer a Pt25 or Pt100?

4. Wiring

Will be the connection a 3-wire or 4-wire?

5. Keep warm current

The device has the facility to drive deselected resistors or PRTs from a constant DC current

source. This allows them to be kept at their normal working temperature, and so decrease

settling time for each channel.

The keep warm current is user selectable as ON/OFF. If set on, the CTR3000 automatically

adjusts the PRT current (from 1 mA for the 100 ohm reference) to 2 mA for the 25 ohm

reference.

6. Int. resistor

The CTR3000 allows the choice between two internal reference resistors (25Ω and 100Ω) or

the Auto-function. The 25 ohm resistor should only be used when a 25 ohm PRT (or lower) is

used. Use the 100Ω reference resistor for all probes with R0 values above 25 Ω

The menu allows the use of Auto selection. The auto selection looks at the R0 value of the

probe. If R0 is below 50 ohms, the 25 ohm reference is selected; any R0 value equal to or

above 50 ohms will use the 100 ohm reference.

The CTR3000 automatically adjusts the PRT current (from 1 mA for the 100 ohm reference)

to 2 mA for the 25 ohm reference.

32 WIKA Operating Instruction, model CTR3000

Page 33

4. Design and Function

EN

14191761.01 03/2017 EN

7. Tmin

Probes may have a minimum temperature set for them (positive or negative). When the

probe is assigned to a channel, the probe’s temperature is checked against the set minimum

and a range error (exclamation mark left beside the function key 12) issued if the minimum

temperature is exceed.

8. Tmax

Probes may have a maximum temperature set for them (positive or negative). When the

probe is measured and active on a channel, the probe’s temperature is checked against the

set maximum and a range error (exclamation mark left beside the function key 12) issued if

the maximum temperature is exceed.

9. Last cal.

Please enter the last calibration date of the thermometer.

If the system date = last cal date + 1 year then a pop up is coming up which reminds that the

probe is due to recalibration.

The recalibration cycle depends mainly on the thermal stress on the thermometer. The

calibration time can only be estimated and is decided on by the user. Therefore check

the calibration system at the triple point or freezing point of water on a regular basis

(independent of the recalibration cycle). Recommendation is a calibration once a year.

WIKA Operating Instruction, model CTR3000 33

Page 34

4. Design and Function

EN

14191761.01 12/2016 EN

10. Conversion

PRTs and SPRTs can be calibrated individually (resistance-temperature characteristics

determined) in order to achieve low uncertainties. There are two algorithms used to

represent the thermometer’s characteristic (the Callendar Van Dusen equation and the

ITS90 equations). The Callendar Van Dusen equation was developed first and was used as

the primary conversion algorithm for all PRTs up until 1990. It is still applicable for PRTs and

SPRT, although better uncertainty can be achieved by using the ITS90 equations

(particularly important when using higher accuracy SPRTs).

In 1990, the International Temperature Scale was revised and a new set of equations were

defined for converting the resistance of a PRT to temperature. These equations (commonly

referred to as ITS90) comprise a nominal conversion that represent the average conversion

characteristic and deviation functions that provide the adjustment for the characteristics of

the individual thermometer. They are intended for use with high purity platinum and provide a

better fit than can be achieved with the older Callendar Van Dusen equation. The ITS90

equations are sometimes also used with industrial PRTs made using the lower sensitivity

-1

0.00385K

wire and can provide a small improvement in uncertainty compared with the

Callendar Van Dusen equation.

a. EN60751 as defined in the standard

You can use the generic EN60751 conversion with PRTs that are made with a grade

of wire that meets the requirements of the standard. The measurement uncertainty

will depend on the class of thermometer and its temperature.

Standard coefficients:

= 100 Ohm

R

0

b. Callendar-van-Dusen like specified in the calibration certificate: R0, A, B and C

This follows the formula:

c. ITS 90 as specified in the calibration certificate: R0.01, an, bn, ap, bp, cp, dp

Make sure using the correct calibration parameters for the thermometer, since incorrect

calibration parameters lead to erroneous results. The coefficients can be found in the

calibration certificate while ordered a calculation.

If you order a CTR3000 with a resistance thermometer and a system calibration with

calculation of the coefficients, the probe will be stored under the serial number and will

be calibrated with the normal sensor current. No root 2.

A = 3.9083x10–3 °C–1

B = -5.775x10–7 °C–2

C = -4.183x10

Rt = R0[1 + At + Bt

(C = 0, if t> 0 °C )

–12

–4

°C

2

+ C(t - 100°C) t3]

34 WIKA Operating Instruction, model CTR3000

Page 35

4. Design and Function

EN

14191761.01 03/2017 EN

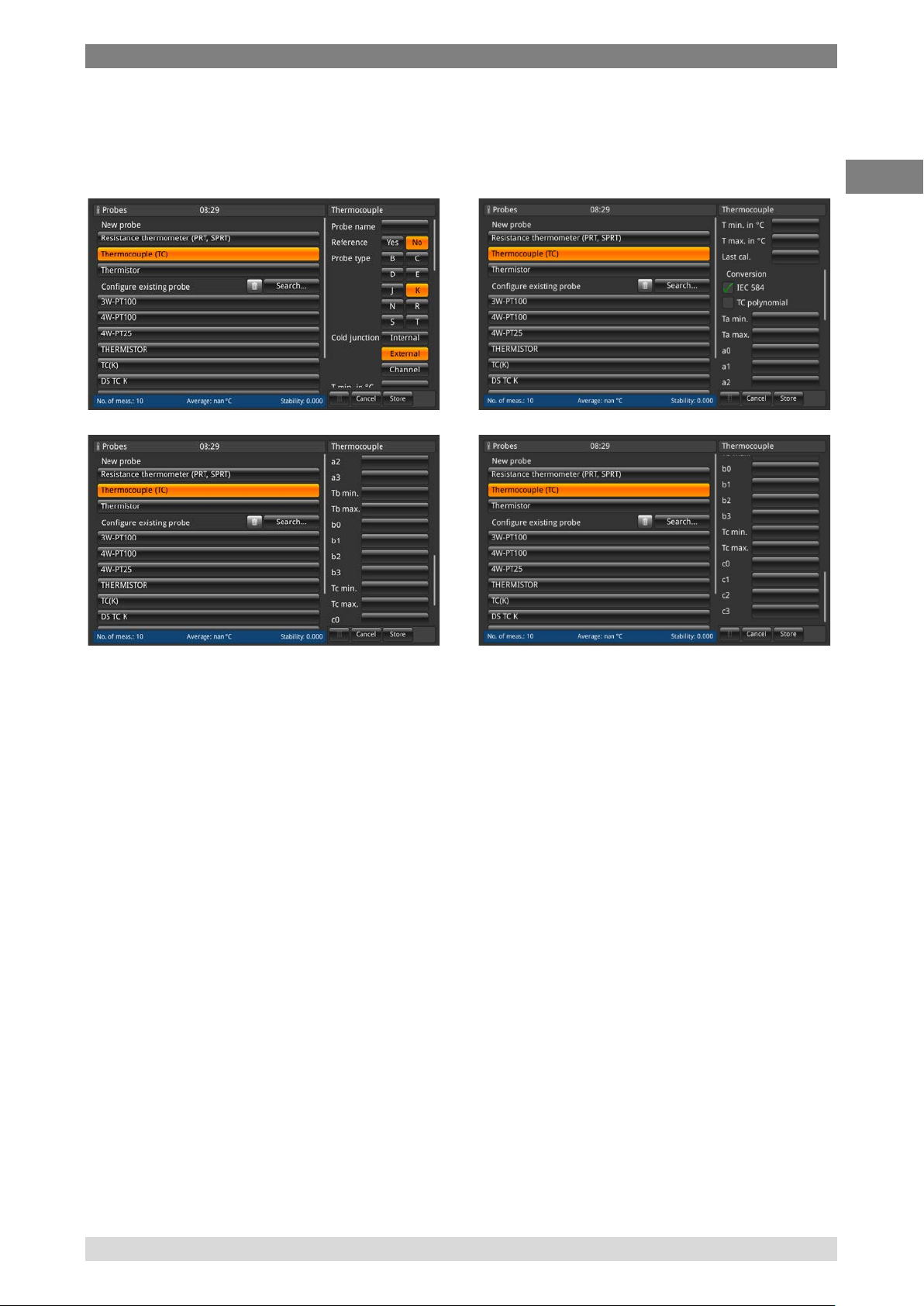

4.6.3.2 New probe <<thermocouples>>

To configure a new thermocouple click on the button <<thermocouple (TC)>> and the menu with all

settings opens on the right. Once all settings are done the changes must be confirmed with

<<Store>>.

The CTR3000 can be used with any thermocouple (calibrated or uncalibrated) fitted with a standard

miniature thermocouple connector. Connect your thermocouple to either of the miniature

thermocouple connectors on the front panel.

1. Probe name

Please enter a unique name (e.g. certificate number or serial number) for the new

thermometer. This name is also shown later under the existing probes and for this name a

search can be done.

2. Reference

Please mark the thermometer as reference or not. This is important for the scan mode - view

calibration because the difference between the first reference and the device under test will

be calculated and displayed in the information bar.

3. Probe type

Is this thermocouple type B, E, J, K, N, R, S or T?

WIKA Operating Instruction, model CTR3000 35

Page 36

4. Design and Function

EN

14191761.01 12/2016 EN

4. Cold junction

Three selections can be done: internal, external, channel

The selected issue turns into orange. If channel is selected then the num pad opens to

define the channel. The number of the channel is right-aligned showed left to the button

<<channel>>. Below the button <<channel>> the name of the probe is displayed.

a. Internal

Internal reference junction compensation using the internal temperature

compensated copper isothermal junction. This is the default mode.

For direct temperature connection with no external reference junction. High

accuracy measurement, requiring additional connection reference junctions.

b. External

No reference junction compensation applied to the measurement. All

measurements are made with respect to 0°C. Used with an external ice point

reference junction. Suitable for highest precision measurement.

c. Channel

External reference junction compensation using PRT measurement of reference

junction. No measurement channels are lost as the reference channel PRT uses

the corresponding input channel. For temperature controlled or ovenised

reference junctions.

5. Tmin

Probes may have a minimum temperature set for them (positive or negative). When the

probe is assigned to a channel, the probe’s temperature is checked against the set minimum

and a range error (exclamation mark left beside the function key 12) issued if the minimum

temperature is exceed.

6. Tmax

Probes may have a maximum temperature set for them (positive or negative). When the

probe is measured and active on a channel, the probe’s temperature is checked against the

set maximum and a range error (exclamation mark left beside the function key 12) issued if

the maximum temperature is exceed.

7. Last cal.

Please enter the last calibration date of the thermometer.

If the system date = last cal date + 1 year then a pop up is coming up which reminds that the

probe is due to recalibration.

The recalibration cycle depends mainly on the thermal stress on the thermometer. The

calibration time can only be estimated and is decided on by the user. Therefore check

the calibration system at the triple point or freezing point of water on a regular basis

(independent of the recalibration cycle). Recommendation is a calibration once a year.

36 WIKA Operating Instruction, model CTR3000

Page 37

4. Design and Function

EN

14191761.01 03/2017 EN

8. Conversion

The EMF-temperature characteristics of thermocouples are non-linear and the CTR3000

uses standard algorithms (from IEC584) to convert the measured EMF to a temperature.

Thermocouples can be calibrated individually to achieve better measurement uncertainty.

The calibration is presented as a deviation function polynomial.

a. IEC 584 as defined in the standard

b. TC polynomial like specified in the calibration certificate

ΔV = C

+C1t +C2 t 2 +C3 t3

0

where t is the temperature in °C and ΔV is the correction in millivolts.

Thermocouples are standardised, and the reference function for the most common

thermocouple types is defined in IEC 584. The characteristic of individual

thermocouples is usually close to the reference function. Therefore it is

recommended to determine the deviation function from the reference function for the

thermocouple under test in up to three temperature ranges, which must be indicated.

Make sure using the correct calibration parameters for the thermometer, since

incorrect calibration parameters lead to erroneous results. The coefficients can be

found in the calibration certificate while ordered a calculation.

WIKA Operating Instruction, model CTR3000 37

Page 38

4. Design and Function

EN

14191761.01 12/2016 EN

4.6.3.3 New probe <<thermistors>>

To configure a new thermistor click on the button <<thermistor>> and the menu with all settings

opens on the right. Once all settings are done the changes must be confirmed with <<Store>>.

The CTR3000 can be used with thermistors. These are typically NTCs (negative temperature

coefficient). Compared with PRTs/SPRTs, thermistors have a much higher resistance (typically

measured in tens of kΩ), operate over a more limited temperature range (typically < 150°C) are

highly non-linear (essentially logarithmic).

1. Probe name

Please enter an unique name (e.g. certificate number or serial number) for the new

thermometer. This name is also shown later under the existing probes and for this name a

search can be done.

2. Reference

Please mark the thermometer as reference or not. This is important for the scan mode - view

calibration because the difference between the first reference and the device under test will

be calculated and displayed in the information bar.

3. Tmin

Probes may have a minimum temperature set for them (positive or negative). When the

probe is assigned to a channel, the probe’s temperature is checked against the set minimum

and a range error (exclamation mark left beside the function key 12) issued if the minimum

temperature is exceed.

38 WIKA Operating Instruction, model CTR3000

Page 39

4. Design and Function

EN

14191761.01 03/2017 EN

4. Tmax

Probes may have a maximum temperature set for them (positive or negative). When the

probe is measured and active on a channel, the probe’s temperature is checked against the

set maximum and a range error (exclamation mark left beside the function key 12) issued if

the maximum temperature is exceed.

5. Last cal.

Please enter the last calibration date of the thermometer.

If the system date = last cal date + 1 year then a pop up is coming up which reminds that the

probe is due to recalibration.

The recalibration cycle depends mainly on the thermal stress on the thermometer. The

calibration time can only be estimated and is decided on by the user. Therefore check

the calibration system at the triple point or freezing point of water on a regular basis

(independent of the recalibration cycle). Recommendation is a calibration once a year.

6. Conversion

a. None, only the resistance is displayed

b. Steinhart-Hart like specified in the calibration certificate: a, b, and c

The Steinhart-Hart equation is commonly used to convert the measured resistance to

temperature.

c. Polynomial like specified in the calibration certificate; c0, c1, c2 and c3

1

= + ln() + ()

1

= + ln() + () + ()

Make sure using the correct calibration parameters for the thermometer, since incorrect

calibration parameters lead to erroneous results. The coefficients can be found in the

calibration certificate while ordered a calculation.

WIKA Operating Instruction, model CTR3000 39

Page 40

4. Design and Function

EN

14191761.01 12/2016 EN

4.6.3.4 Configure existing probes

Under the menu section <<configure existing probe>> existing standard or user-defined probes can

be changed or updated e.g. with new calibration data.

As soon as you click on a probe on the left side, all parameters (detailed description in the chapters

before) depending on the probe type (resistance thermometer, thermocouple or thermistor) will

open on the right side.

For the standard probes 3W-PT100, 4W-PT100, 4W-PT25, Thermistor and TC (K) only a few

changes can be done. All other user defined probes can be configured as needed.

Delete

The recycle bin has been placed on the left side of the search field. This function deletes existing

probes if they are selected in the list below. Every time the CTR3000 needs a confirmation for

deleting probes.

Search

By clicking on the “search” button on the left side, the text pad opens on the right. There you are

able to search after the probe name and the search button allows filtering the thermometer list,

which is helpful to find thermometers within a large list. The character * can be used as wildcard to

show all thermometers matching a name pattern. Found results are displayed then on the left side

under the menu section <<configure existing probe>>.

To get all existing probes again displayed please press the button <<clear>> beside the filter.

40 WIKA Operating Instruction, model CTR3000

Page 41

4. Design and Function

EN

14191761.01 03/2017 EN

Whenever you have changed the settings of your user-defined probe, you are able to restore the

last configuration over the <<restore>> button at the end of the setting dialog. The CTR3000 wants

to have a confirmation for restoring the last probe data. And then again the <<store>> button must

be pressed as a confirmation.

4.6.3.5 SMART probes

Under the menu section <<SMART probes>> you can disable SMART probes. When a SMART

probe is disabled for a channel, the instrument uses the probe settings assigned to the channel.

By clicking on the button << list connected SMART probes>> all connected SMART probes will be

listed on the right side with their probe name. Every probe highlighted in orange is enabled/active

and all others not. Clicking on the button of an active SMART probe means that this will be disabled.

This setting has to be confirmed.

When SMART probe disabled for a channel, the instrument uses the probe settings

assigned to the channel.

The scan of listed smart probes cannot be done while a scan is active.

WIKA Operating Instruction, model CTR3000 41

Page 42

4. Design and Function

EN

14191761.01 12/2016 EN

4.6.4 Application <<Scan>>

The application <<scan>> (via button <<scan>> in the right application menu) describes the

function of this device that sequentially measures each channel and either temporarily shows the

data on the display in the selected view. Scans are started manually by the user. To scan a channel,

the CTR3000 sequentially cycles through the channels that are selected and makes measurements.

Therefore this function allows the user to see more channels on the screen and to have a more or

less automatic measurement of several channels.

Modules are only available and selectable if these are connected.

4.6.4.1 Configuring a scan

Under the menu section <<channel configuration>> all or user-defined channels can be selected for

the scan routine. Same procedure as for all other inputs: click on the left side and the input options

will open on the right side.

Select the channels you want to measure and

then store the configuration by pressing the

button <<store>>.

Please ensure that for all configured resistance thermometers the keep warm current is

<<ON>>. This allows quicker and more accurate measurements.

Select the channels you want to measure and

then store the configuration by pressing the

button <<store>>. By pressing the buttons

<<select all>>/ <<deselect al>> the selection

is easier by choosing all or nothing with one

click.

42 WIKA Operating Instruction, model CTR3000

Page 43

4. Design and Function

EN

14191761.01 03/2017 EN

To set up a proper scan a hold time is needed. This value means how long the device stays at one

channel before it switches to the next channel. The input of the value is via the numpad on the right

side.

Valid values: 3 …600 s

Means the quickest changing between the channels is 3s.

After all settings are done start the scan via the button <<start>>. Also in this menu the scan routine

can be stopped, by pressing the button <<Stop>>. This button is active if the scan is already started.

Vice versa the start button is only active if the scan is stopped.

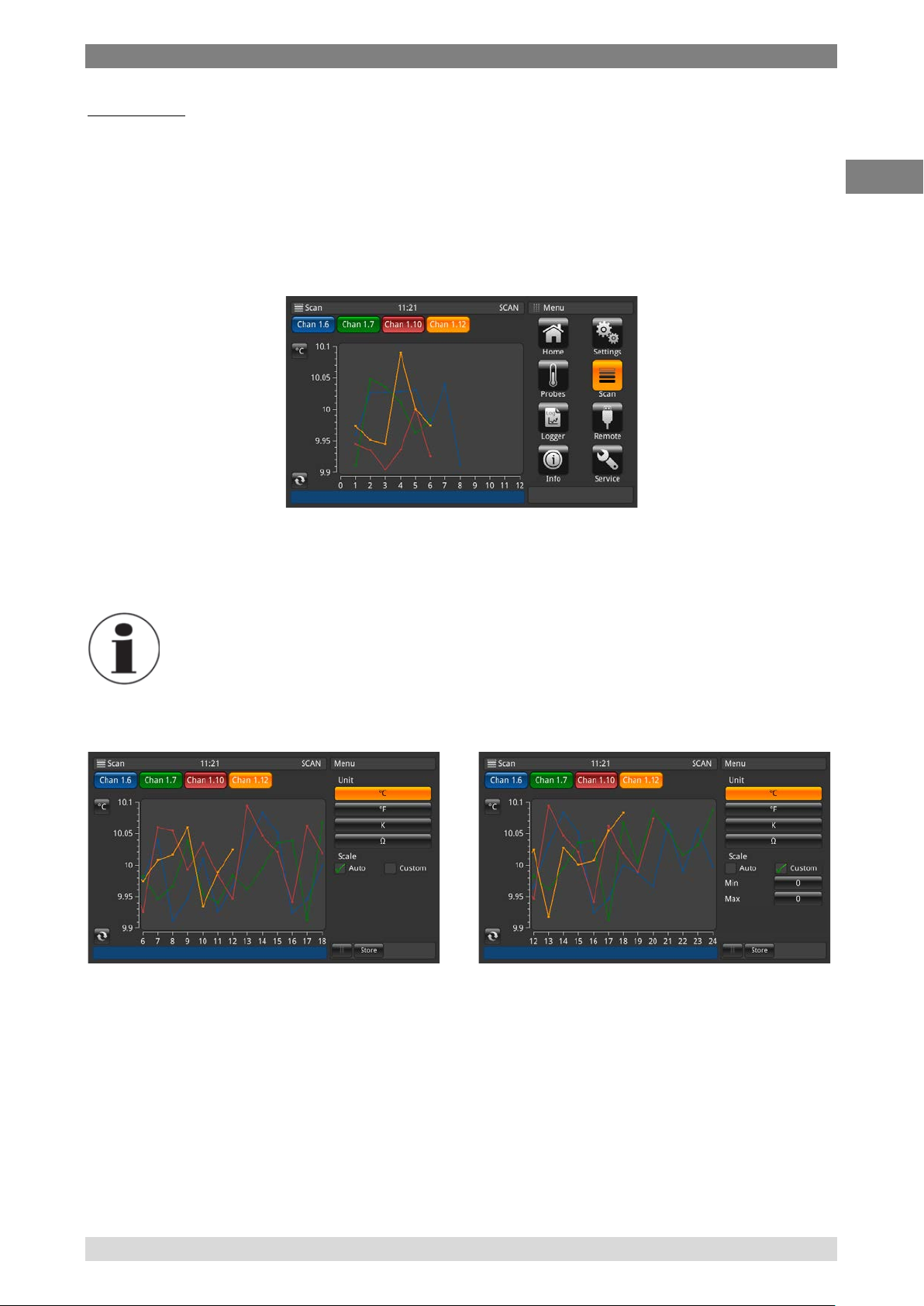

4.6.4.2 View

By pressing the button <<selected view>> the sub menu opens on the right side. Scan or calibration

view means that you see all channels you selected on the screens. According to the numbers of

selected channels the view changes a little bit. Please see below for details. The graph view shows

a graphic version with all selected channels.

To activate the selected view press the button <<Activate view>> (only active if the scan is started),

this action guides to the selected scan view.

While changing from the scan application to the home application, please note that the

scan is still active. This will be seen status and information bar.

WIKA Operating Instruction, model CTR3000 43

Page 44

4. Design and Function

EN

14191761.01 12/2016 EN

Scan/Calibration view:

The difference between these two views is the information bar at the bottom of the device. In this a

difference for the calibration view is displayed. The difference is the difference between the

reference (probe marked as reference and listed first) and the device under test (all other channels),

displayed in the unit of the device under test.

The function buttons and their behavior are known from the home application.

Scan/Calibration view: 2 channels selected Scan/Calibration view: 3 channels selected

Scan/Calibration view: 3 channels selected Scan/Calibration view: more than 4 channels

selected

Pressing again the application <<scan>>, during seeing the different views of the scan,

guides the user into the application <<scan>> menu, where all settings can be done and

the scan can be stopped. Please refer to section 4.6.4.1 Configuring a scan.

44 WIKA Operating Instruction, model CTR3000

Page 45

4. Design and Function

EN

14191761.01 03/2017 EN

Graph view:

With the graphic feature, channel measurement data for up to ten channels can be plotted and

viewed on the display.

A probe must be assigned to a channel before on the home screen or via the function button in the

graphic view itself. Also the unit must be chosen via the function button, which is indicated at the top

of the y-axis. Only the same units can be displayed. E.g. Chan PRT1=Ohm, Chan 8.1=mV

displaying the graph in °C/°F/K is possible, but not in Ohm/mV. If the unit changes the y-axis is

switched to auto scale.

The x-axis shows the numbers of measurement. This is scrollable from the left to the right and vice

versa. (Re-fresh button go to the actual measurement point in the graph) The y-axis shows the

measuring values.

Pressing again the application <<scan>>, during seeing the different views of the scan,

guides the user into the application <<scan>> menu, where all settings can be done and

the scan can be stopped. Please refer to section Configuring a scan.

Adjustment of the graph

Via clicking on the button <<unit>>, in this case <<°C>>, a sub menu opens where the unit and the

scale can be adjusted. Please take care that you set the right values for the customized scale in

<<min>> and <<max>>, so that all measured values are displayed in the graph. The division will be

choosen automatically. The closer min/max the better the resolution. Please confirm all inputs by

pressing the button <<store>>.

WIKA Operating Instruction, model CTR3000 45

Page 46

4. Design and Function

EN

14191761.01 12/2016 EN

4.6.5 Application <<Logger>>

The application <<logger>> (via button <<logger>> in the right application menu) describes the

function of this device that logs all data which is displayed on the <<Home>> or <<Scan>>

Application. If a scan is active the actual channel will be logged. The different possible settings are

explained in the following sections.

To start a logger with the preferred settings (described below) press the button <<Start>>. Then the

<<LOG>> appears in the status line, which shows that the logger is active. By pressing <<Stop>>

the logger is stopped and the <<LOG>> disappears in the status line.