Page 1

Operating instructions

Betriebsanleitung

Intrinsically safe hand-held thermometer, models CTH63I0

and CTH65I0

Eigensicheres Hand-Held Thermometer, Typen CTH63I0

und CTH65I0

EN

DE

Intrinsically hand-held thermometer, models CTH63I0 and

CTH65I0

Page 2

Operating instructions, models CTH63I0 and CTH65I0 Page 3 - 38

EN

Betriebsanleitung, Typen CTH63I0 und CTH65I0 Seite 39 - 75

DE

© 2015 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

®

WIKA

is a registered trademark in various countries.

®

WIKA

ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

2

WIKA operating instructions, models CTH63I0 and CTH65I0

14120692.01 04/2015 EN/DE

Page 3

Contents

Contents

1. General information 5

2. Safety 6

2.1 Explanation of symbols . . . . . . . . . . . . . . . . . . .6

2.2 Intended use. . . . . . . . . . . . . . . . . . . . . . .6

2.3 Improper use . . . . . . . . . . . . . . . . . . . . . .7

2.4 Personnel qualification . . . . . . . . . . . . . . . . . . .7

2.5 Personal protective equipment. . . . . . . . . . . . . . . . .8

2.6 Labelling, safety marks . . . . . . . . . . . . . . . . . . .9

2.7 Ex marking . . . . . . . . . . . . . . . . . . . . . . 10

3. Design and function 12

3.1 Description . . . . . . . . . . . . . . . . . . . . . . 12

3.2 Scope of delivery . . . . . . . . . . . . . . . . . . . . 12

3.3 Hand-held thermometer . . . . . . . . . . . . . . . . . . 13

3.4 Keypad . . . . . . . . . . . . . . . . . . . . . . . 14

3.5 Voltage supply . . . . . . . . . . . . . . . . . . . . . 14

3.6 USB interface . . . . . . . . . . . . . . . . . . . . . 15

3.7 Temperature probe . . . . . . . . . . . . . . . . . . . 15

3.7.1 Connecting/replacing the temperature probe . . . . . . . . . 16

4. Transport, packaging and storage 16

4.1 Transport . . . . . . . . . . . . . . . . . . . . . . . 16

4.2 Packaging and storage . . . . . . . . . . . . . . . . . . 17

5. Commissioning, operation 18

5.1 Commissioning . . . . . . . . . . . . . . . . . . . . . 18

5.2 Switching on/Switching off . . . . . . . . . . . . . . . . . 19

5.3 Menu structure and settings . . . . . . . . . . . . . . . . 20

5.4 Menu tree. . . . . . . . . . . . . . . . . . . . . . . 20

5.4.1 Unit switching °C and °F [Unit] . . . . . . . . . . . . . . 20

5.4.2 Activating/deactivating display option differential temperature [Lin2]

(only for 2-channel instruments) . . . . . . . . . . . . . . 21

5.4.3 Calibration mode CAL . . . . . . . . . . . . . . . . . 21

5.4.4 Activating/deactivating measuring channels (only for 2-channel

instruments) [Chnl] . . . . . . . . . . . . . . . . . . 25

14120692.01 04/2015 EN/DE

5.4.5 Storage management [Lo6] (not possible for CTH63I0) . . . . . . 26

EN

3

3WIKA operating instructions, models CTH63I0 and CTH65I0

Page 4

Contents

5.5 Storage query [HOLD-MAX-MIN-AVE] . . . . . . . . . . . . . 27

5.6 Change measurement cycle (FAST mode) . . . . . . . . . . . 27

5.7 AUTO-OFF function . . . . . . . . . . . . . . . . . . . 27

EN

5.8 Special functions . . . . . . . . . . . . . . . . . . . . 28

5.8.1 Zero adjustment (zero) . . . . . . . . . . . . . . . . . 28

5.8.2 Deactivation of channel 2 (toggle) . . . . . . . . . . . . . 28

6. Faults 28

7. Maintenance, cleaning and recalibration 31

7.1 Maintenance. . . . . . . . . . . . . . . . . . . . . . 31

7.1.1 Battery replacement . . . . . . . . . . . . . . . . . . 31

7.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . 32

7.3 Recalibration. . . . . . . . . . . . . . . . . . . . . . 32

8. Return and disposal 33

8.1 Return . . . . . . . . . . . . . . . . . . . . . . . . 33

9. Specifications 34

9.1 Disposal . . . . . . . . . . . . . . . . . . . . . . . 34

10. Accessories 38

Anlage: Konformitätserklärung 75

Declarations of conformity can be found online at www.wika.com.

4 WIKA operating instructions, models CTH63I0 and CTH65I0

14120692.01 04/2015 EN/DE

Page 5

1. General information

1. General information

■

The model CTH63I0 and CTH65I0 intrinsically safe, hand-held thermometers

described in the operating instructions have been designed and manufactured

using state-of-the-art technology. All components are subject to stringent quality and

environmental criteria during production. Our management systems are certified to

ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the

instrument. Working safely requires that all safety instructions and work instructions

are observed.

■

Observe the relevant local accident prevention regulations and general safety

regulations for the instrument's range of use.

■

The operating instructions are part of the product and must be kept in the immediate

vicinity of the instrument and readily accessible to skilled personnel at any time.

Pass the operating instructions onto the next operator or owner of the instrument.

■

Skilled personnel must have carefully read and understood the operating

instructions prior to beginning any work.

EN

■

The general terms and conditions contained in the sales documentation shall apply.

■

Subject to technical modifications.

■

Factory calibrations / DKD/DAkkS calibrations are carried out in accordance with

international standards.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: CT 51.05 and CT 55.10

- Application consultant:

Tel.: +49 9372 132-5049

Fax: +49 9372 132-8005049

CTServiceteam@wika.com

14120692.01 04/2015 EN/DE

5

5WIKA operating instructions, models CTH63I0 and CTH65I0

Page 6

2. Safety

2. Safety

2.1 Explanation of symbols

EN

WARNING!

... indicates a potentially dangerous situation that can result in serious

injury or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result in light injuries

or damage to equipment or the environment, if not avoided.

DANGER!

... identifies hazards caused by electrical power. Should the safety

instructions not be observed, there is a risk of serious or fatal injury.

DANGER!

... indicates a potentially dangerous situation in the hazardous area that

can result in serious injury or death, if not avoided.

WARNING!

... indicates a potentially dangerous situation that can result in burns,

caused by hot surfaces or liquids, if not avoided.

Information

... points out useful tips, recommendations and information for efficient and

trouble-free operation.

2.2 Intended use

The intrinsically safe hand-held thermometers are used for a mobile temperature

measurement which processes the signals of resistance thermometers. Thus

temperatures from -200 ... +600 °C can be measured.

6 WIKA operating instructions, models CTH63I0 and CTH65I0

14120692.01 04/2015 EN/DE

Page 7

2. Safety

The instruments have been designed and built solely for the intended use described

here, and may only be used accordingly.

The technical specifications contained in these operating instructions must be

observed. Improper handling or operation of the instruments outside of its technical specifications requires the instrument to be taken out of service immediately and

inspected by an authorised WIKA service engineer.

Handle the hand-held instruments with the required care (protect from humidity,

impacts, strong magnetic fields, static electricity and extreme temperatures, do not

insert any objects into the instrument or its openings). Protect the plugs and sockets

from contamination.

The manufacturer shall not be liable for claims of any type based on operation contrary

to the intended use.

2.3 Improper use

WARNING!

Injuries through improper use

Improper use of the instrument can lead to hazardous situations and

injuries.

▶

Refrain from unauthorised modifications to the instrument.

▶

Do not use any third-party manufacturer's temperature probes.

▶

The instrument should not be used for abrasive media.

▶

Avoid any external forces such as impacts or pressure

EN

Any use beyond or different to the intended use is considered as improper use.

2.4 Personnel qualification

WARNING!

Risk of injury should qualification be insufficient

Improper handling can result in considerable injury and damage to

equipment.

▶

The activities described in these operating instructions may only be

carried out by skilled personnel who have the qualifications described

below.

14120692.01 04/2015 EN/DE

7

7WIKA operating instructions, models CTH63I0 and CTH65I0

Page 8

2. Safety

Skilled personnel

Skilled personnel, authorised by the operator, are understood to be personnel

who, based on their technical training, knowledge of measurement and control

technology and on their experience and knowledge of country-specific regulations,

EN

current standards and directives, are capable of carrying out the work described and

independently recognising potential hazards.

Special knowledge for working with instruments for hazardous areas:

The skilled personnel must have knowledge of ignition protection types, regulations

and provisions for equipment in hazardous areas.

Special operating conditions require further appropriate knowledge, e.g. of aggressive

media.

2.5 Personal protective equipment

The personal protective equipment is designed to protect the skilled personnel from

hazards that could impair their safety or health during work. When carrying out the

various tasks on and with the instrument, the skilled personnel must wear personal

protective equipment.

Follow the instructions displayed in the work area regarding personal

protective equipment!

The requisite personal protective equipment must be provided by the operating

company.

Wear safety goggles!

Protect eyes from flying particles and liquid splashes.

Wear protective gloves!

Protect hands from friction, abrasion, cuts or deep injuries and also from

contact with hot surfaces and aggressive media.

8 WIKA operating instructions, models CTH63I0 and CTH65I0

14120692.01 04/2015 EN/DE

Page 9

2. Safety

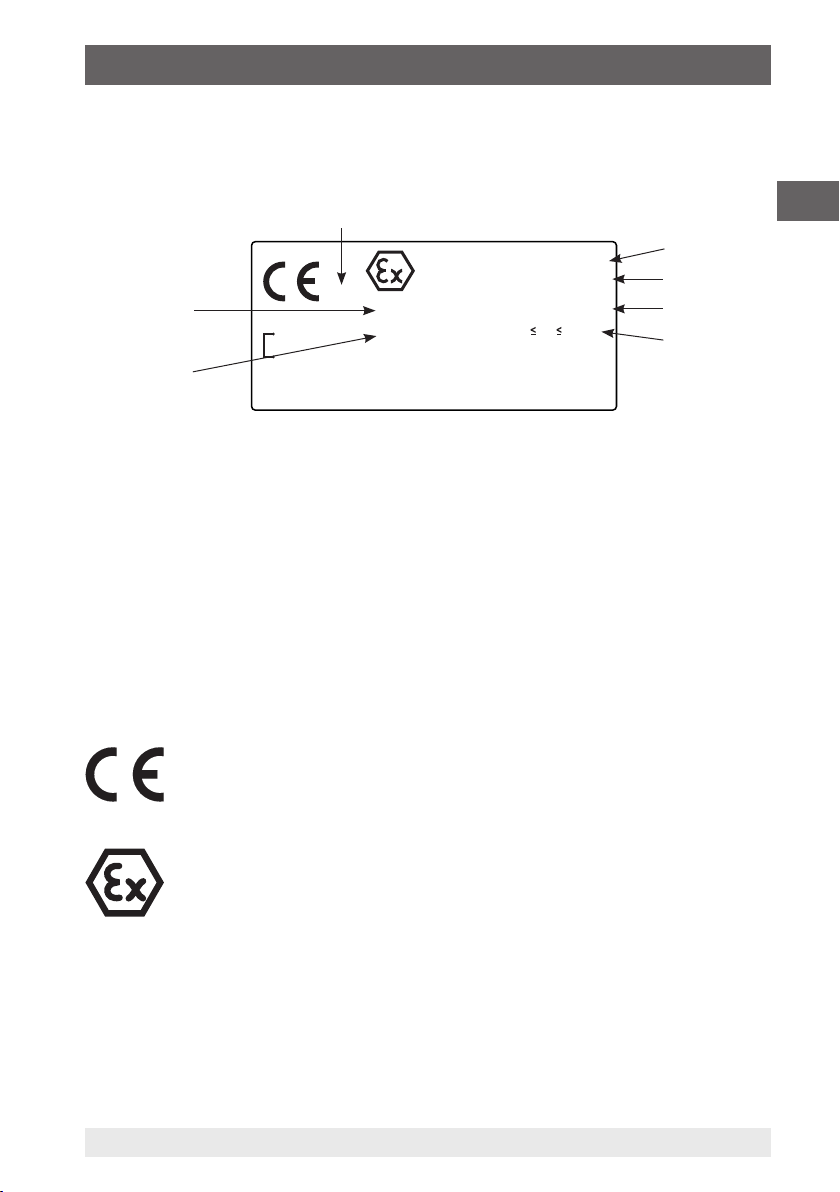

2.6 Labelling, safety marks

Product label

WARNUNG:

Batterie nur außerhalb des Ex-Bereiches wechseln !

Certificate no.

Ignition protection type

Instrument model

Permissible ambient temperature

Serial no.

Year of manufacture

Test centre

Symbols

Instruments bearing this mark comply with the relevant European

directives.

Alexander Wiegand SE & C0. KG · D-63911 Klingenberg

0158

TÜV 14 ATEX 143825 X

II 2 G Ex ib IIB T4 Gb

HD 2015

SNR. WX15001

CTH6XI0

0°C Ta 40°C

EN

ATEX European explosion protection directive

(Atmosphère = AT, explosible = EX)

Instruments bearing this mark comply with the requirements of the European directive 94/9/EC (ATEX) on explosion protection.

14120692.01 04/2015 EN/DE

9

9WIKA operating instructions, models CTH63I0 and CTH65I0

Page 10

2. Safety

2.7 Ex marking

DANGER!

EN

Check whether the classification is suitable for the application. Observe the relevant

national regulations.

ATEX directive: 94/9/EC

Certificate no. TÜV 14 ATEX 143825 X

Ignition protection type: II 2 G Ex ib IIB T4 Gb

CE marking: 0158

Applied standards: EN 60079-0:2012

EMC directive: 2004/108/EC

Applied standards: EN 61326 (group 1, class B)

Danger to life due to loss of explosion protection

Non-observance of these instructions and their contents may result in the

loss of explosion protection.

▶

Observe the safety instructions in this chapter and further explosion

instructions in these operating instructions.

▶

Observe the information given in the applicable type examination certificate and the relevant country-specific regulations for installation and

use in hazardous areas (e.g. IEC 60079-14, NEC, CEC).

EN 60079-11:2012

II 2 G, Ex ib IIB T4 Gb

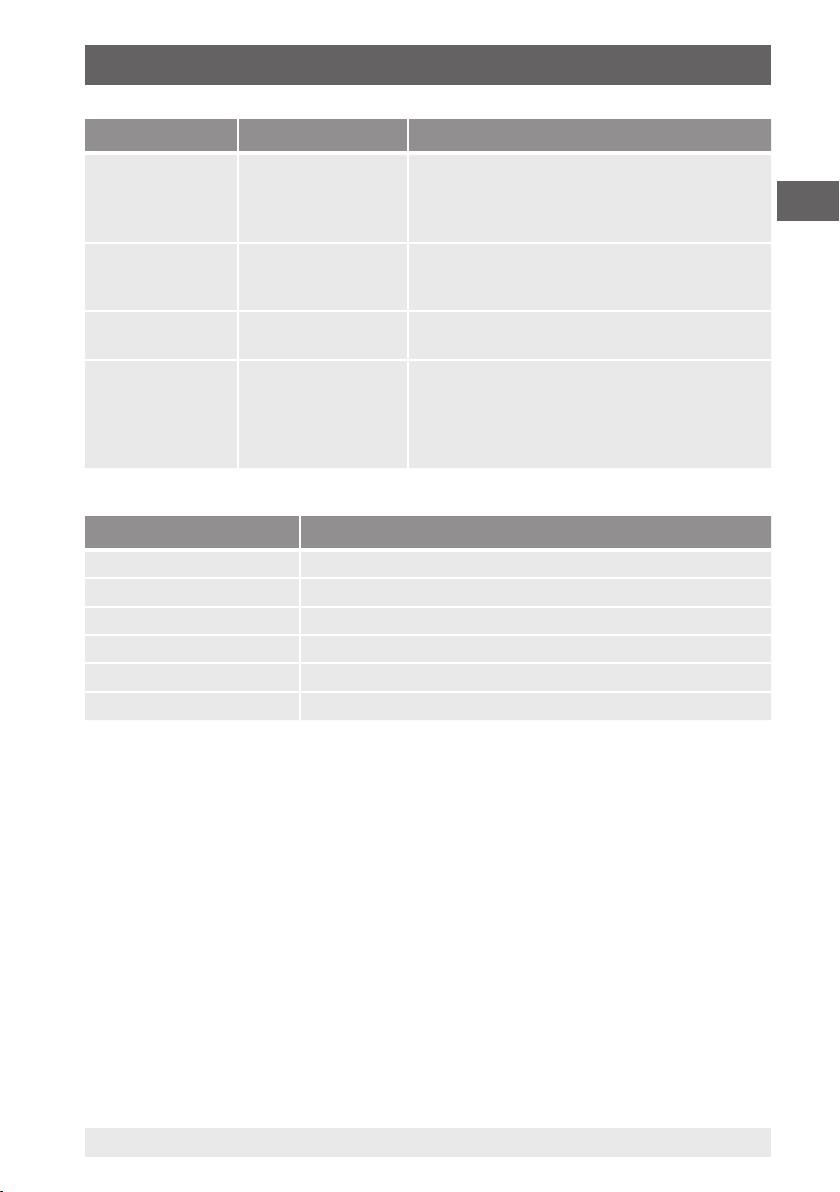

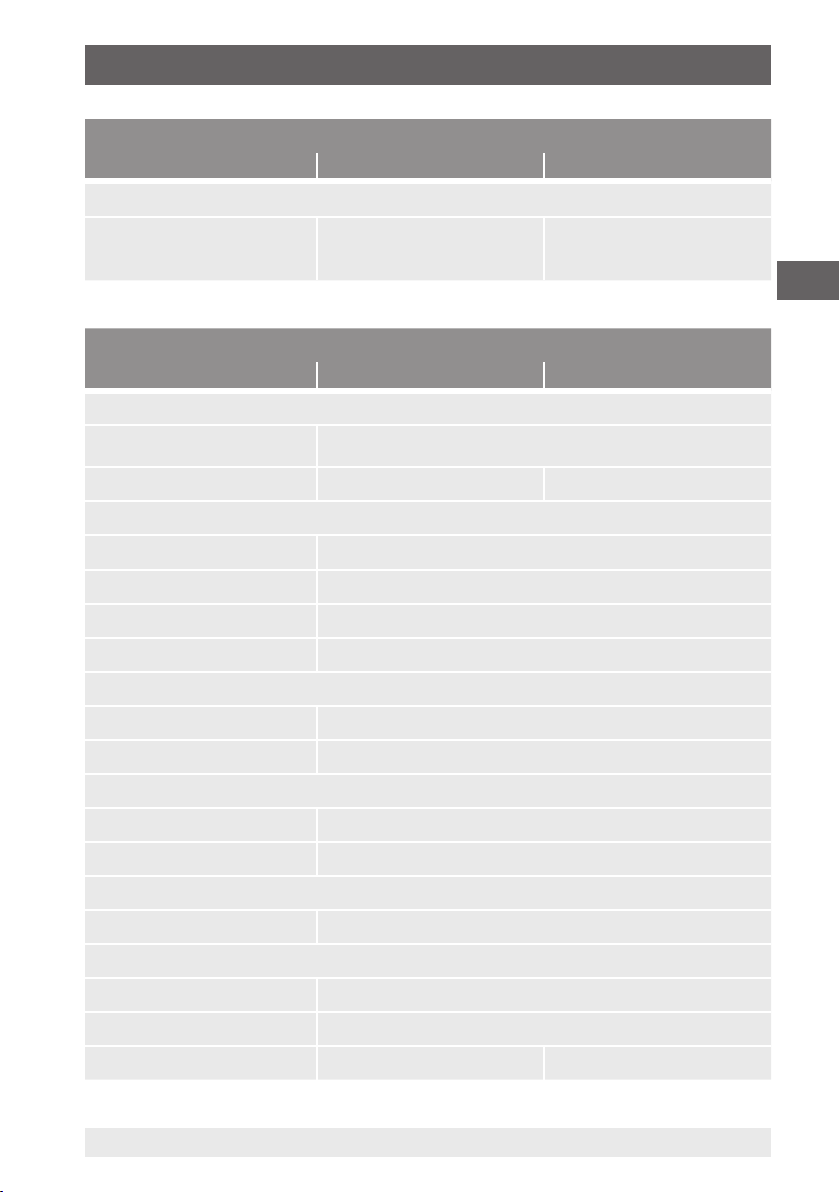

Marking Designation Meaning

CE marking Conformity markings in accordance with appendix

X of the 94/9/EC directive. The manufacturer shall

apply it before placing on the market.

II Instrument group The instrument may be used in hazardous areas,

except within the mining industry.

2G Instrument category With instrument category 2G, an potentially

explosive atmosphere involving gases (G) may

occur occasionally. The instrument can be used in

zone 1 and zone 2.

10 WIKA operating instructions, models CTH63I0 and CTH65I0

14120692.01 04/2015 EN/DE

Page 11

2. Safety

Marking Designation Meaning

ib Intrinsic safety The instrument contains an intrinsically safe

current loop. A current loop is intrinsically safe if

neither sparks nor thermal effects can cause the

ignition of a specified explosive atmosphere.

IIB Instrument group Electrical instrument group designated for

gas hazardous areas in accordance with

DIN EN 60079-0.

T4 Temperature class Maximum occurring surface temperature of

135 °C.

Gb Equipment Protection

Level (EPL)

Temperature class Maximum surface temperature

T1 450 °C

T2 300 °C

T3 200 °C

T4 135 °C

T5 100 °C

T6 85 °C

With equipment protection level Gb, in accordance with DIN EN 60079-0 (2007), a potentially

explosive atmosphere involving gases (G) may

occur occasionally. The instrument can be used in

zone 1 and zone 2.

EN

14120692.01 04/2015 EN/DE

11

11WIKA operating instructions, models CTH63I0 and CTH65I0

Page 12

3. Design and function

3. Design and function

3.1 Description

The general-purpose, intrinsically safe hand-held thermometers for demanding mobile

EN

temperature measurement, distinguished by flexibility and easy handling. Temperatures

from -200 ... +600 °C can be measured.

Low-drift measuring amplifiers ensure small measurement errors, while easy-to-use

adjustment features considerably simplify adjustments and calibrations:

■

Calibration by code for fast setting of standard probes via key data

■

Physical calibration of probe and display at one, two or three different temperatures

In this way it is possible to reduce measuring errors to a minimum and ensure a high

indication accuracy.

Intrinsically safe hand-held thermometer model CTH63I0, industrial version

Its design makes CTH63I0 especially suitable for the commissioning, maintenance and

service/calibration of temperature instruments and equipment.

Intrinsically safe hand-held thermometer model CTH65I0, precision version

Due to its high accuracy of 0.03 K in ranges from -50 ... +199.99 °C, the CTH65I0 can

also be used as a reference measuring instrument in biotechnology, pharmaceutical

and food industries. The CTH65I0 is thus ideal for all service and maintenance tasks.

3.2 Scope of delivery

CTH63I0 or CTH65I0

■

Intrinsically safe hand-held thermometer model CTH63I0 or CTH65I0, incl. 9 V

battery

■

3.1 calibration certificate per DIN EN 10204

■

Choice of temperature probes

Cross-check scope of delivery with delivery note.

12 WIKA operating instructions, models CTH63I0 and CTH65I0

14120692.01 04/2015 EN/DE

Page 13

3. Design and function

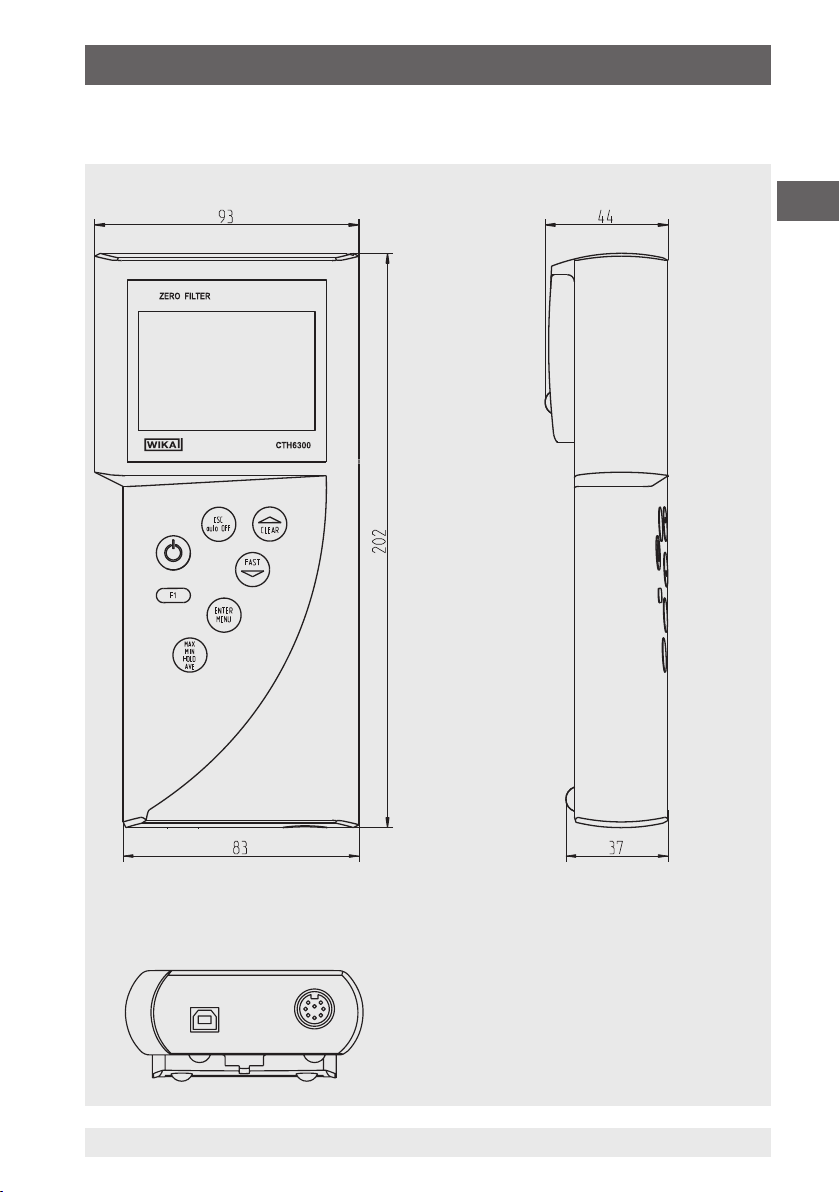

3.3 Hand-held thermometer

EN

6

5

3

4

1

Probe holder

2

First connection port for temperature probe

3

Second connection port for temperature probe

4

USB connection port for PC

5

Keypad

1

2

6

Large LC display

14120692.01 04/2015 EN/DE

13

13WIKA operating instructions, models CTH63I0 and CTH65I0

Page 14

3. Design and function

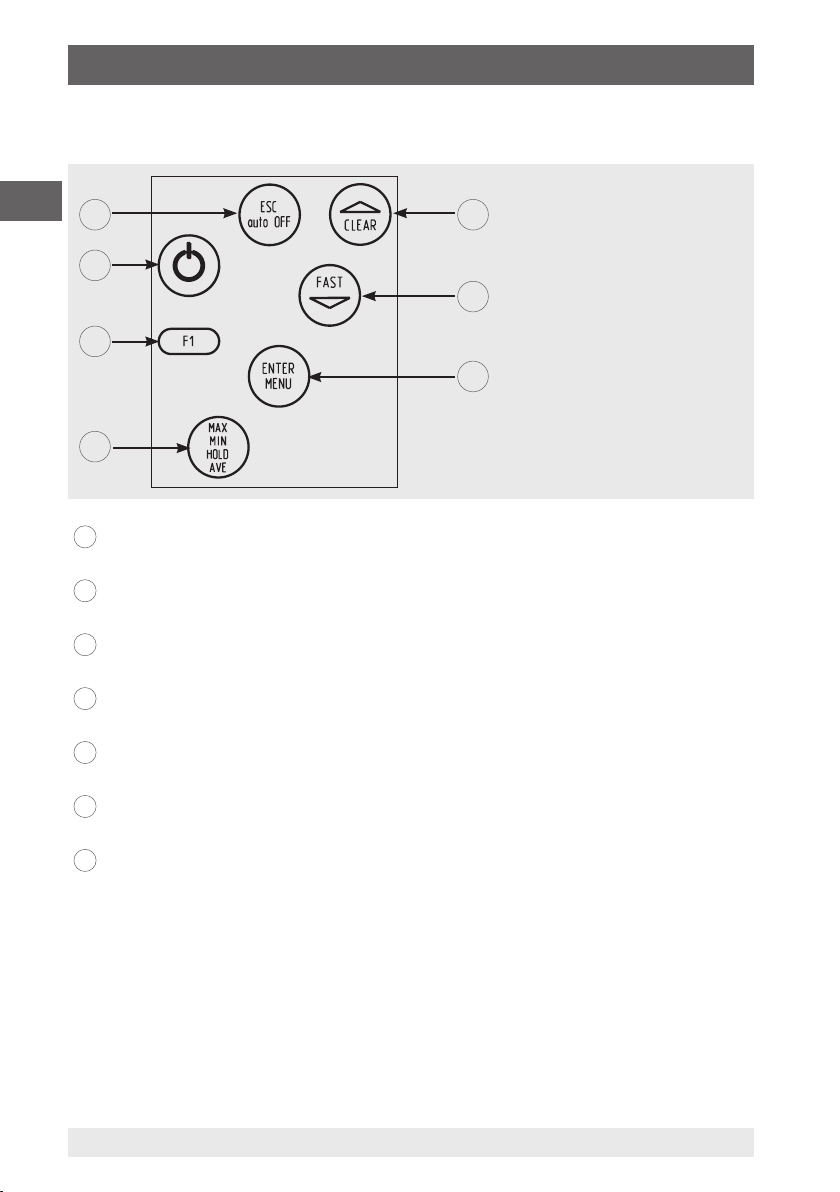

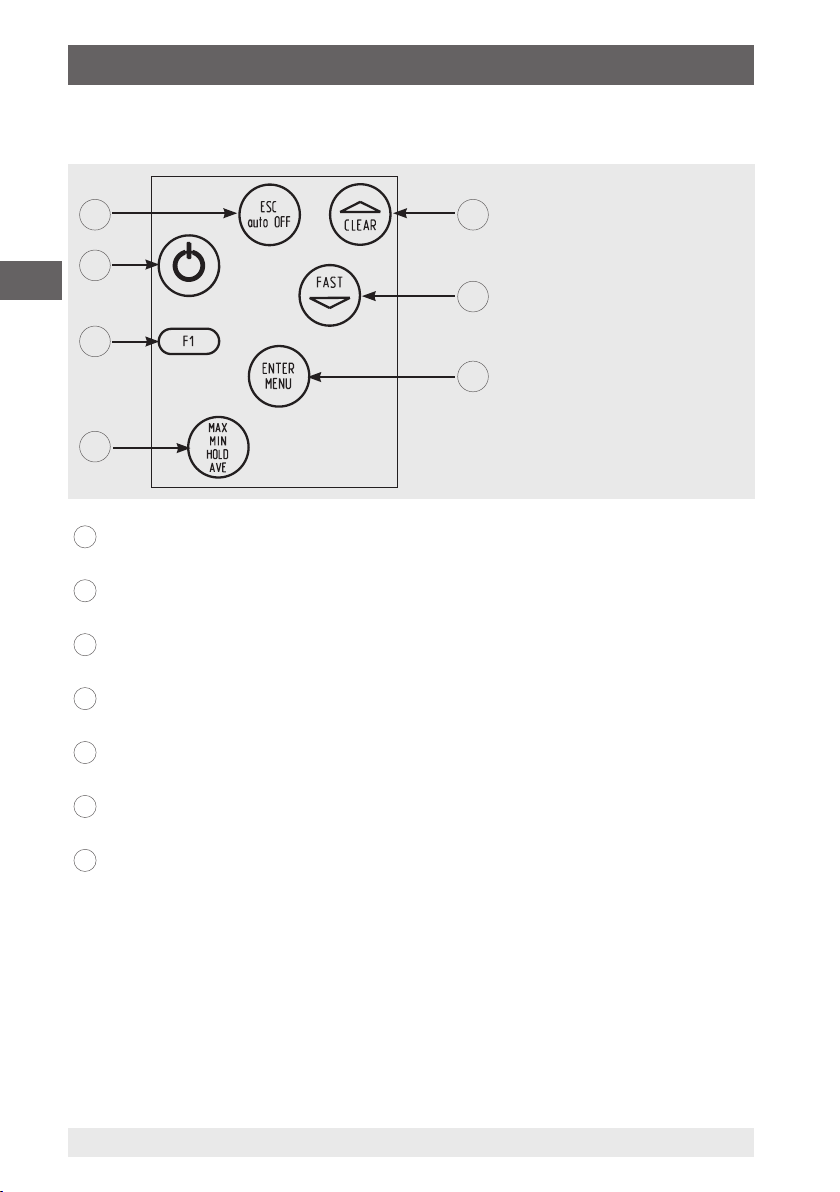

3.4 Keypad

EN

7

6

5

4

Arrow key CLEAR

1

Selection of menu items

Arrow key FAST

2

Selection of menu items

ENTER/MENU key

3

Access to the main menu, confirming the function

MIN/MAX/HOLD/AVE key

4

Setting MIN and MAX, HOLD and AVE

Function keys

5

Configuring the instrument

ON/OFF key

6

Turning the instrument on and off

ESC key

7

Back to measuring mode

1

2

3

3.5 Voltage supply

The battery life is approx. 20 hours for continuous operation.

The BAT segment indicates that the battery must be replaced soon. At this point

correct measurements can be performed for approx. 2 hours.

A 9 V battery is used as voltage supply of the instrument.

14 WIKA operating instructions, models CTH63I0 and CTH65I0

14120692.01 04/2015 EN/DE

Page 15

3. Design and function

To avoid false readings, replace the battery as soon as the battery indicator appears.

For information on the battery see chapter 7.1.1 “Battery replacement”.

3.6 USB interface

DANGER!

Danger to life from explosion!

Through working in flammable atmospheres, there is a risk of explosion

which can cause death.

▶

Using the USB interface is not allowed in hazardous areas!

The model CTH63I0 or CTH65I0 has a USB interface as standard. The serial data

transmission can be used for configuration, calibration and for the transmission of

measured values from the hand-held thermometer.

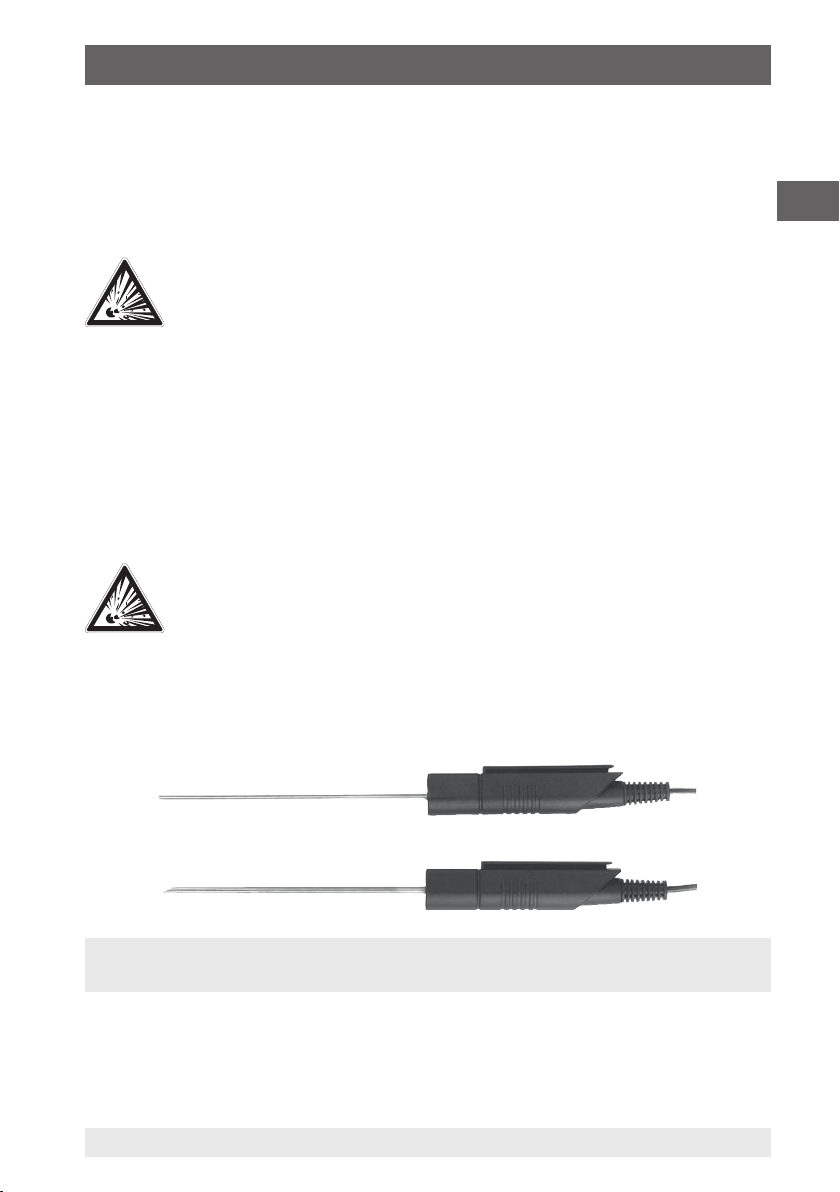

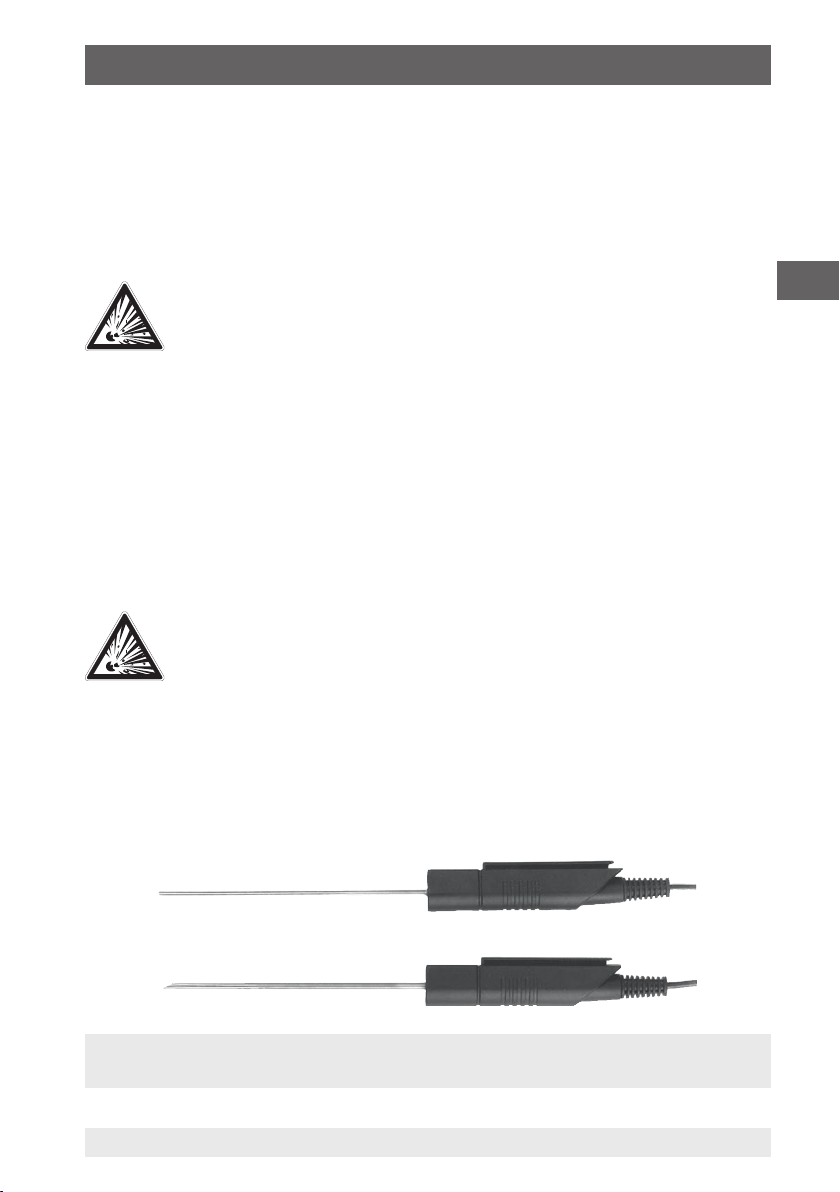

3.7 Temperature probe

DANGER!

Danger to life from explosion!

The use of incorrect temperature probes can lead to a loss of the explosion

protection.

▶

Only use the Pt100 temperature probes supplied for hazardous areas!

Different temperature probes guarantee flexibility (see chpater 9 “Specifications”).

EN

Fig. top: immersion probe

Fig. bottom: penetration probe

At the measuring point (measuring probe), the temperatures (dependent on the

temperature class) are permitted (see chapter 2.7 “Ex marking”).

14120692.01 04/2015 EN/DE

15

15WIKA operating instructions, models CTH63I0 and CTH65I0

Page 16

3. Design and function / 4. Transport, packaging and storage

For operation in non-hazardous areas, the temperature ranges specified in the specifications are valid (see chapter 9 “Specifications”). The highest permissible ambient

temperature for the measuring instrument is 40 °C.

EN

3.7.1 Connecting/replacing the temperature probe

1. Switch off the instrument for probe replacement.

2. Before switching the instrument on, connect the probe, otherwise it may not be

correctly identified by the instrument.

3. Do not apply force to plug the connector into the socket.

The digital instrument and the temperature probe are connected to each other electrically by means of a separate connection cable.

For probe replacement please pay attention to the following:

■

Do not apply force to plug the connector into the sockets.

■

To connect the temperature probe to the hand-held plug the 8-pin plug connection

according to the guiding into the connection port for temperature probes.

■

Connect the connector without crossing the threads. If the connector is positioned

correctly, it can be plugged in without any significant effort.

■

To disconnect the probe, do not pull on the cable, but rather only on the connector

sleeve.

4. Transport, packaging and storage

4.1 Transport

Check intrinsically safe hand-held thermometer for any damage that may have been

caused by transport.

Obvious damage must be reported immediately.

CAUTION!

Damage through improper transport

With improper transport, a high level of damage to property can occur.

▶

When unloading packed goods upon delivery as well as during internal

transport, proceed carefully and observe the symbols on the packaging.

▶

With internal transport, observe the instructions in chapter

4.2 “Packaging and storage”.

16 WIKA operating instructions, models CTH63I0 and CTH65I0

14120692.01 04/2015 EN/DE

Page 17

4. Transport, packaging and storage

If the instrument is transported from a cold into a warm environment, the formation

of condensation may result in instrument malfunction. Before putting it back into

operation, wait for the instrument temperature and the room temperature to equalise.

4.2 Packaging and storage

Keep the packaging as it will provide optimum protection during transport (e.g. change

in installation site, sending for repair).

Permissible conditions at the place of storage:

■

Humidity: 35 ... 85 % relative humidity (no condensation)

■

Storage temperature: -10 ... +50 °C

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down hard)

■

Soot, vapour, dust and corrosive gases

Store the instrument in its original packaging in a location that fulfils the conditions

listed above. If the original packaging is not available, pack and store the instrument as

described below:

1. Place the instrument, along with shock-absorbent material, in the packaging.

2. If stored for a prolonged period of time (more than 30 days), place a bag containing

a desiccant inside the packaging.

EN

14120692.01 04/2015 EN/DE

17

17WIKA operating instructions, models CTH63I0 and CTH65I0

Page 18

5. Commissioning, operation

5. Commissioning, operation

Personnel: Skilled personnel

EN

Only use original parts (see chapter 10 “Accessories”).

DANGER!

Danger to life from explosion!

Through working in flammable atmospheres, there is a risk of explosion

which can cause death.

▶

Only carry out probe replacement in non-hazardous environments!

▶

In case of any defects, the measuring instruments must not be operated

in hazardous areas!

▶

Do not use the intrinsically safe hand-held thermometer in damaged

condition. Before using the instrument, check that there are no cracks

or missing plastic parts on the case. Pay particular attention to the

insulation of the connectors.

▶

Do not use the instrument if it is not working properly. The instrument

protection might be compromised. If in doubt, have the instrument

checked.

▶

The battery compartment must not be opened in hazardous areas!

WARNING!

Physical injuries and damage to property and the environment

caused by hazardous media

Upon contact with hazardous media (e.g. oxygen, acetylene, flammable

or toxic substances), harmful media (e.g. corrosive, toxic, carcinogenic,

radioactive), and also with refrigeration plants and compressors, there is a

danger of physical injuries and damage to property and the environment.

Should a failure occur, aggressive media with extreme temperature may be

present at the temperature probe.

▶

For these media, in addition to all standard regulations, the appropriate

existing codes or regulations must also be followed.

▶

Wear the requisite protective equipment (see chapter 2.5 “Personal

protective equipment”).

5.1 Commissioning

Before switching on connect the temperature probe(s) to the intended female

connector of the hand-held and make sure that a fully charged 9 V battery is inserted.

The probe connection sockets are marked on the instrument case with 1 or 2

correspondingly. The USB interface is marked next to them.

18 WIKA operating instructions, models CTH63I0 and CTH65I0

14120692.01 04/2015 EN/DE

Page 19

5. Commissioning, operation

5.2 Switching on/Switching off

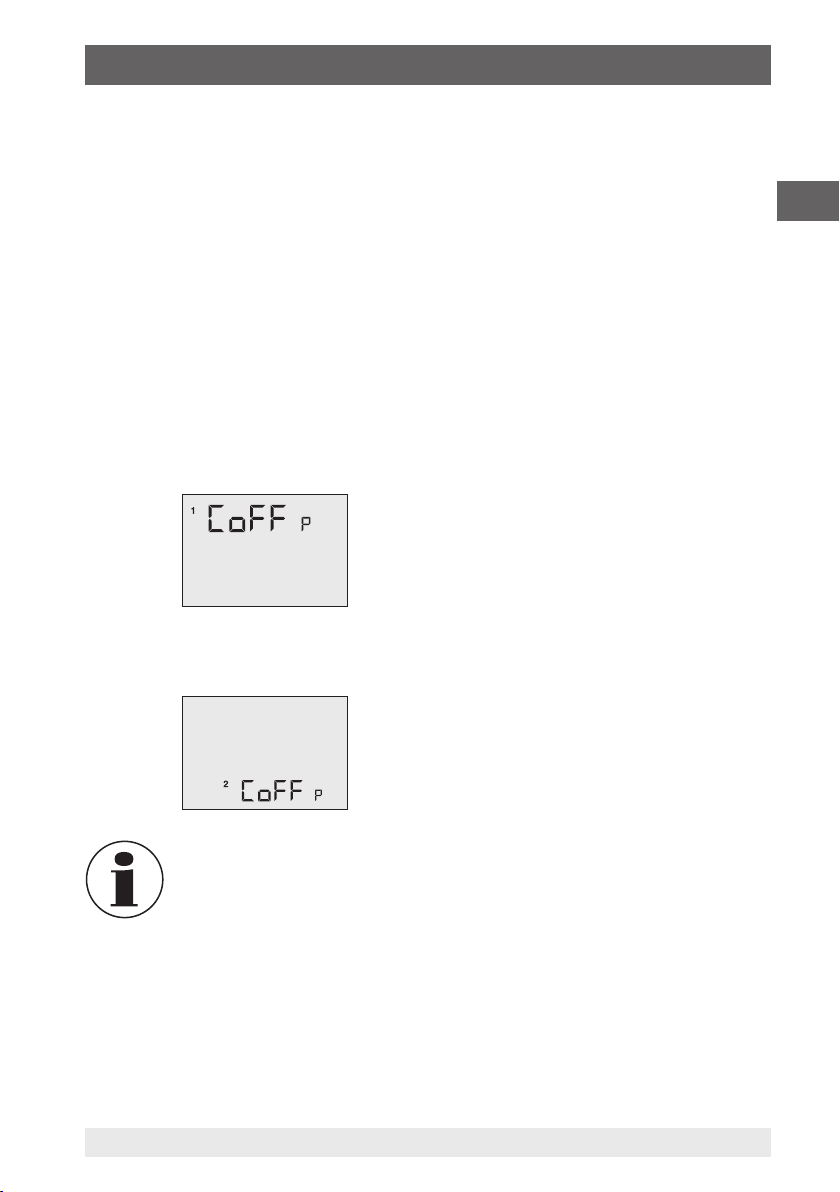

To switch the measuring instrument on and off, press the ON/OFF key. After switching

the instrument on all segments are indicated on the display for approx. 1.5 seconds (full

segment indication). For the next approx. 1.5 seconds the instrument indicates the set

probe calibration code as well as the set measurement parameter for channel 1 (e.g.

CoFF for DIN characteristic curve and P for Pt100). After that the calibration data for

the 2nd channel are displayed.

Finally, the instrument switches automatically to the measuring mode and displays the

current measurement parameter. In the upper display line (large display) the measured

value is displayed, a bar graph is located beneath it for graphical measured value

representation. In all 2-channel instruments the 2nd channel is displayed in the lower

display line (small display).

Channel 1

Line 1: CoFF P = calibration on channel 1 per DIN, probe selection set to Pt100.

Channel 2

Line 2: CoFF P = calibration on channel 2 per DIN, probe selection set to Pt100.

EN

For all measuring instruments the measuring channels can be selected

according to the model-specific measurement parameters. For the version

with only one probe the correct measurement parameter is already set.

When using the measuring instruments with several channels and/or

different probes make sure that the correct measurement parameter is set

(see chapter 9 “Specifications”).

If no probe is connected to the measuring instrument during switching on,

“open” is indicated on the display (see chapter 8 “Faults”).

14120692.01 04/2015 EN/DE

19

19WIKA operating instructions, models CTH63I0 and CTH65I0

Page 20

5. Commissioning, operation

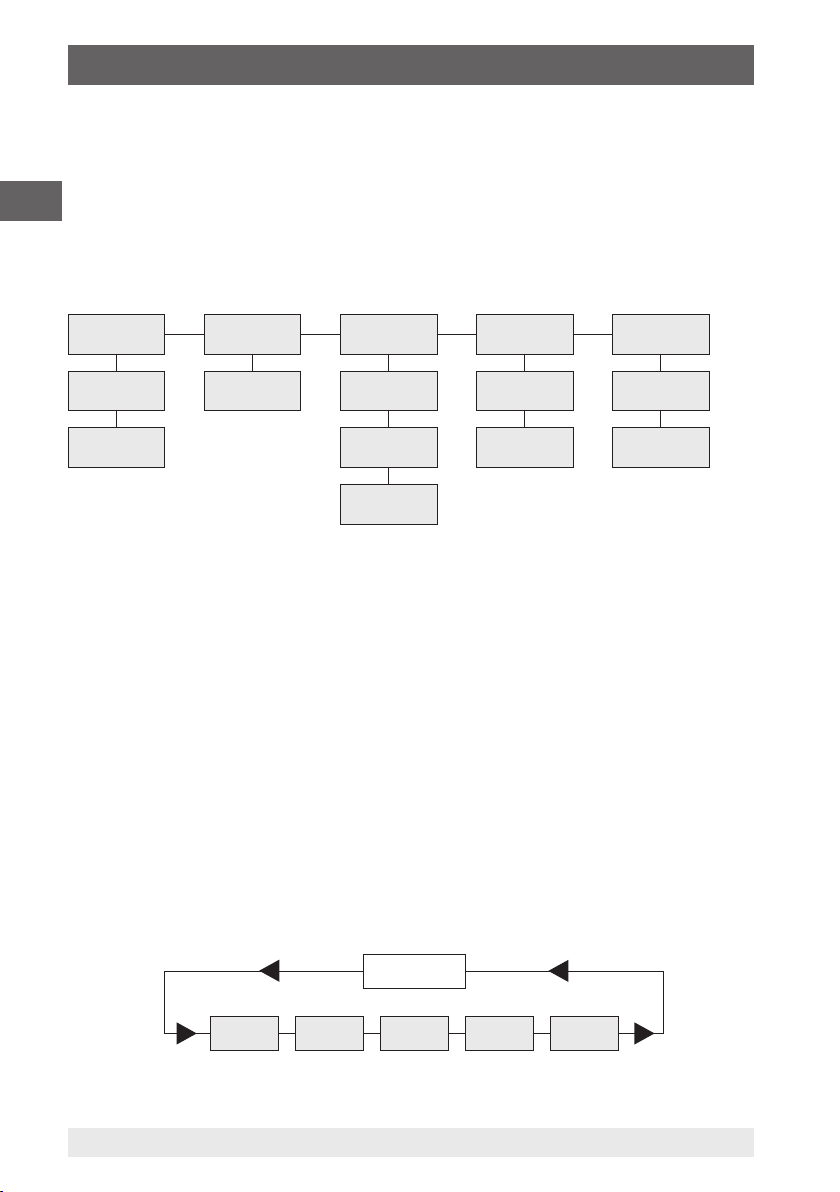

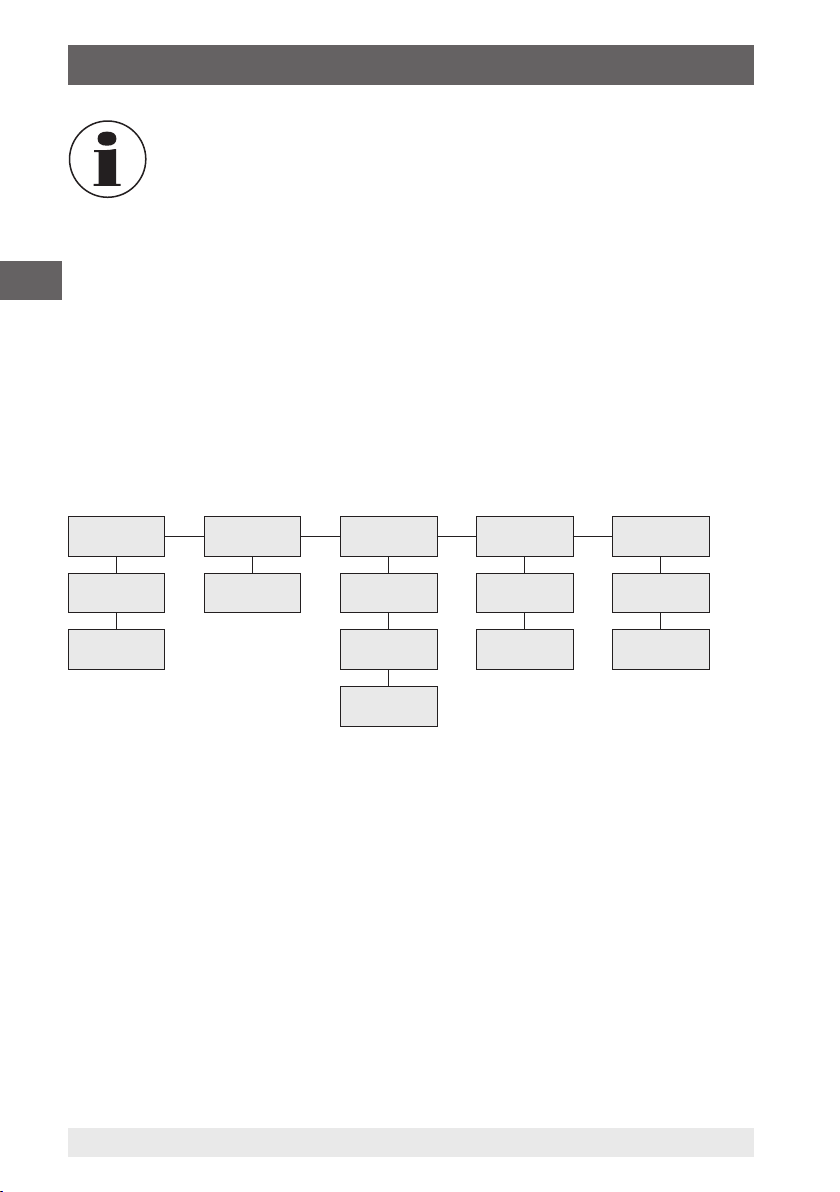

5.3 Menu structure and settings

Instrument settings such as measurement parameters, probe calibration, channel

deactivation, arrow keys, etc. are adjusted using a menu tree. To open the main menu,

press the ENTER/MENU key. Use the arrow keys ▲▼ to select the desired menu items.

EN

Press ESC to return to the measuring mode.

5.4 Menu tree

Unit Lin2 CAL Chnl Lo6

°C T1-T2 CoFF OFF OFF

°F oP1 ON ON

oP2

5.4.1 Unit switching °C and °F [Unit]

Unit

Measuring unit temperature (°C = Celsius, °F = Fahrenheit)

Press the ENTER/MENU key and select Unit using the arrow keys ▲▼. Then press

ENTER/MENU again. A small 1 appears on the left side of the display, it indicates the

channel.

Use the ▲▼ arrow keys to select the channel for which the displayed unit needs to be

changed. Confirm with ENTER/MENU (channel selection only possible with 2-channel

instruments).

Select the desired unit (°C or °F) using the arrow keys ▲▼ and confirm it by pressing

ENTER/MENU.

Use ESC to return to the measuring mode.

MENU

Unit Lin2 CAL Chnl Lo6

20 WIKA operating instructions, models CTH63I0 and CTH65I0

14120692.01 04/2015 EN/DE

Page 21

5. Commissioning, operation

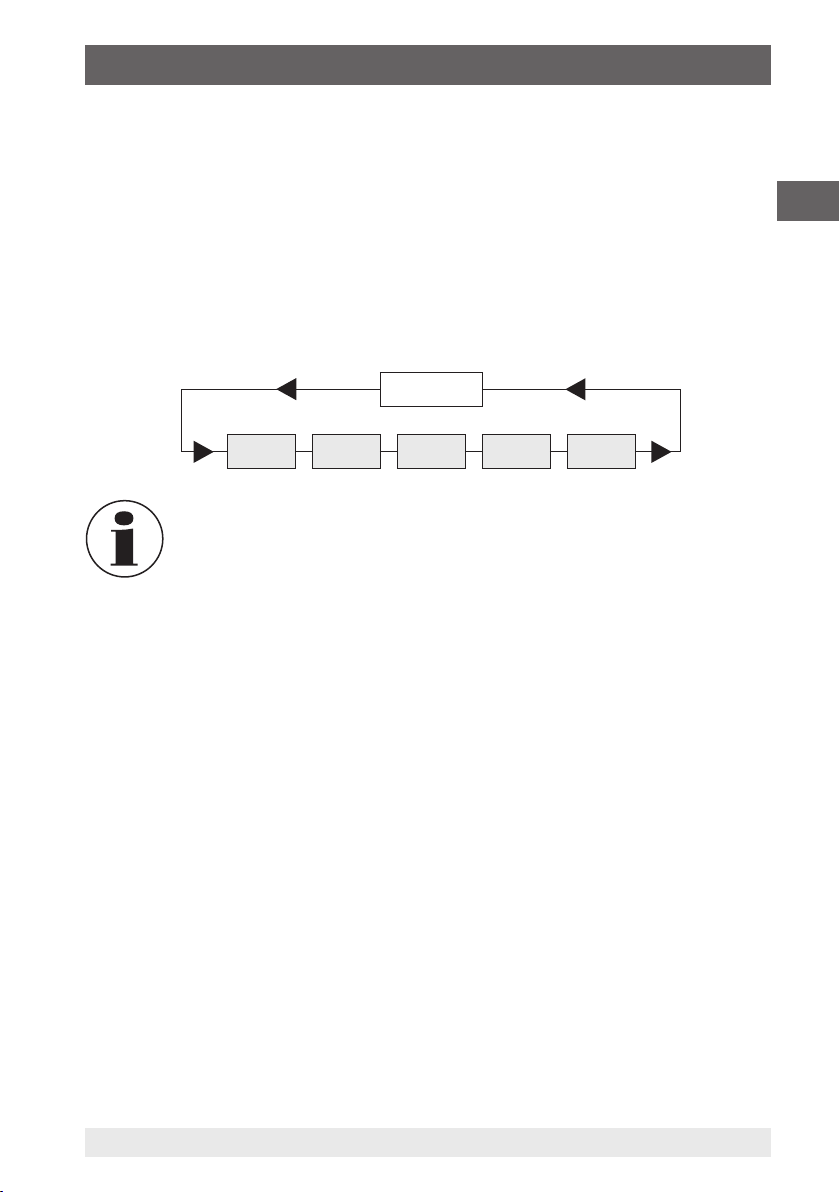

5.4.2 Activating/deactivating display option differential temperature [Lin2]

(only for 2-channel instruments)

Press the ENTER/MENU key and select Lin2 using the arrow keys ▲▼. Then press

ENTER/MENU again. Now activate or deactivate the display “Differential temperature”

T1-T2 using the arrow keys ▲▼.

If T1-T2 is visible on the LC display, the differential temperature is active. Press ENTER/

MENU to confirm the desired setting.

Use ESC to return to the measuring mode.

MENU

Unit Lin2 CAL Chnl Lo6

To display differential temperature, both channels must be activated.

5.4.3 Calibration mode CAL

This measuring instrument allows to perform a simple calibration when replacing the

probes in order to compensate the manufacturer-specific tolerances of the probes and

guarantee a consistently high accuracy of the measuring chain.

The instrument has 3 different calibration modes:

CoFF: Standard characteristic curve

for example, for Pt100 resistance measurements DIN IEC 60751

oP1: Calibration by code

The 2 x 4-digit code is displayed on the handles of the probes, corresponds

to a 2-point calibration

oP2: Physical calibration

Calibration with reference standards: 1-point, 2-point or 3-point calibration

possible

EN

The calibration coefficients are given in the calibration certificate.

CAL = calibrate

Press the ENTER/MENU key and select CAL using the ▲▼ arrow keys, then press

ENTER/MENU again. A small 1 appears on the left side of the display which indicates

14120692.01 04/2015 EN/DE

21

21WIKA operating instructions, models CTH63I0 and CTH65I0

Page 22

5. Commissioning, operation

the channel. Use the ▲▼ arrow keys to select the channel (1 or 2) to be calibrated

(channel selection only possible with 2-channel instruments).

Confirm selection by pressing ENTER/MENU.

EN

MENU

Unit Lin2 CAL Chnl Lo6

Now use the arrow keys ▲▼ to select the desired calibration function.

CAL

CoFF oP1 oP2

Standard linearisation in accordance with DIN IEC 60751 “CoFF”

Use the arrow keys ▲▼ to select CoFF. Press ENTER/MENU to confirm the desired

setting.

Use ESC to return to the measuring mode.

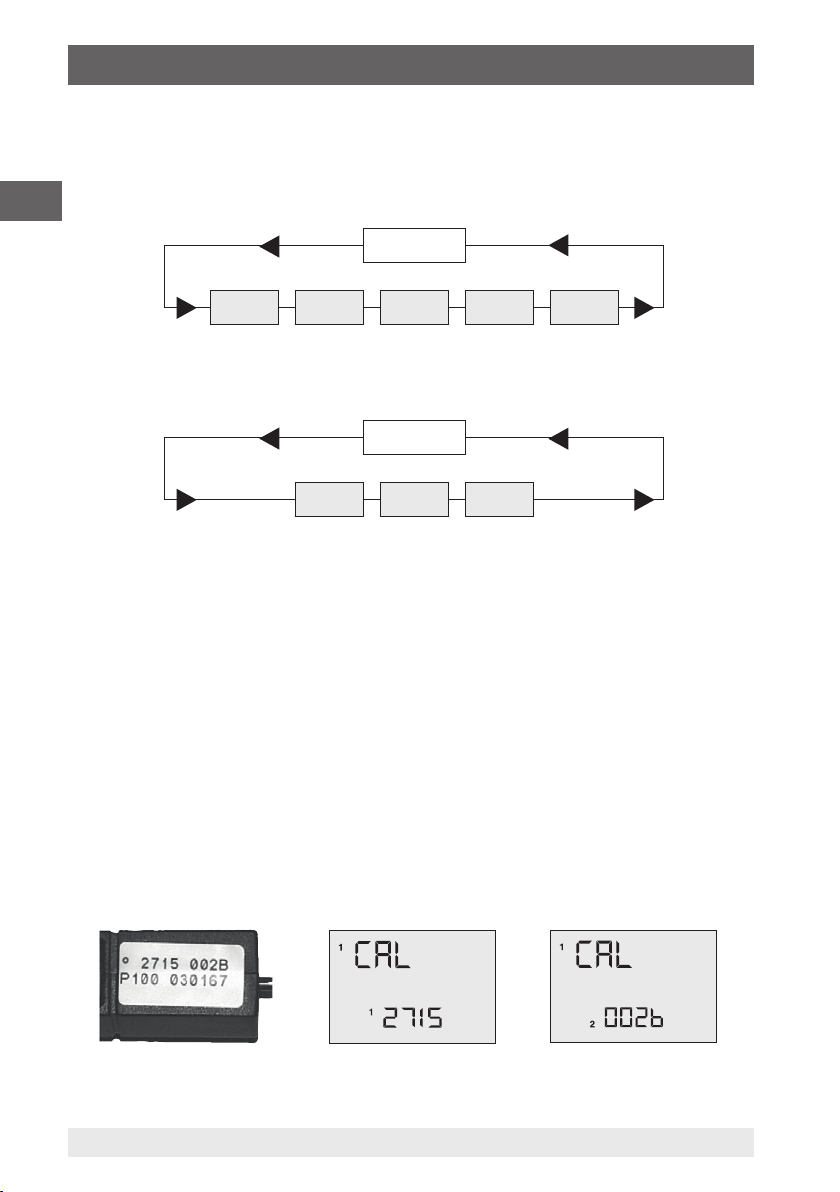

Calibration by code oP1

Use the ▲▼ arrow keys to select oP1. Press ENTER/MENU to confirm the desired

setting. A small 1 appears in the lower part of the display. 4 characters follow it (hex

code / 0 ... F). The 4 characters can be changed upwards by means of the ▲ arrow key.

Press the ▼ arrow key to go to the next position.

If all 4 characters are entered as required, confirm by pressing ENTER/MENU. A small

2 appears and the following 4 characters can be changed as well.

Use ESC to return to the measuring mode.

22 WIKA operating instructions, models CTH63I0 and CTH65I0

14120692.01 04/2015 EN/DE

Page 23

5. Commissioning, operation

When calling the oP1 by means of ENTER/MENU the oP1 function

(calibration by code) is activated even if the menu has been exited by

pressing ESC.

Example of the measured value display after entering a probe calibration code:

The small 1 in the left corner in connection with the display segment CAL in the centre

of the display indicates that the calibration by code oP1 has been activated.

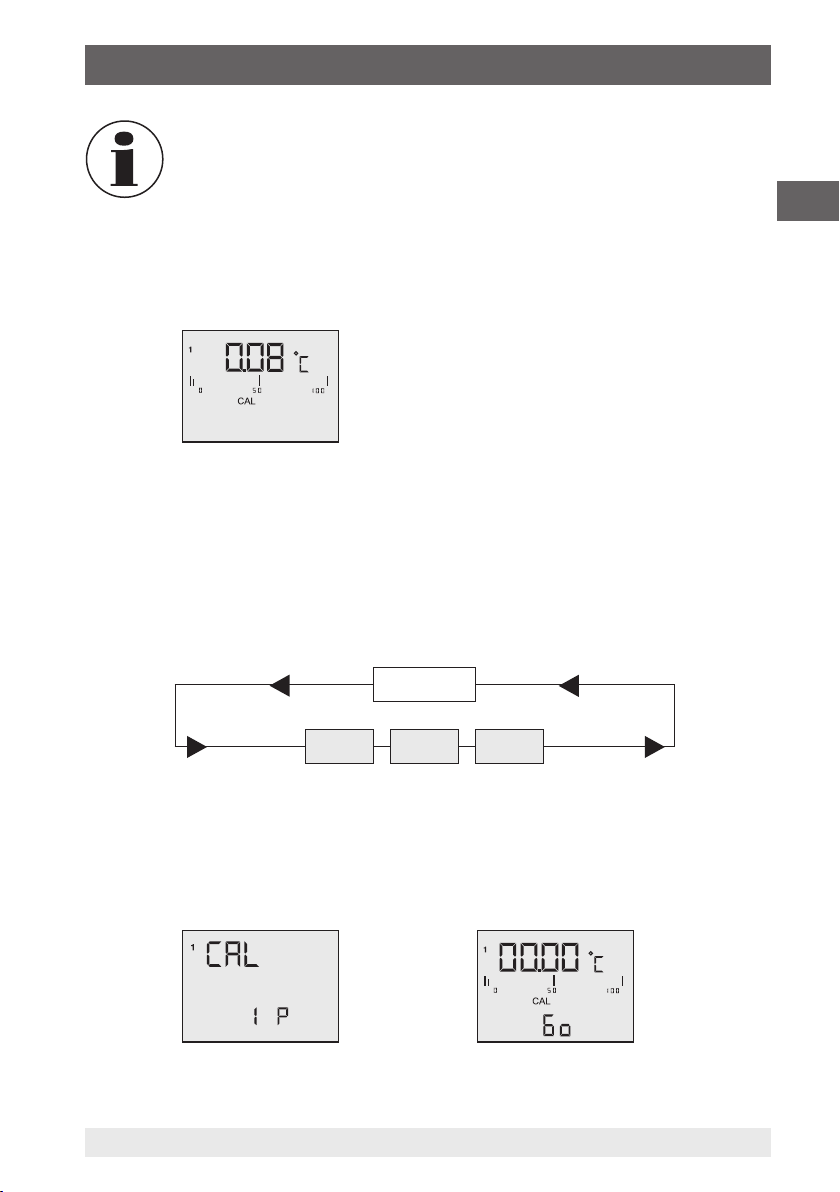

Physical calibration oP2

Use the arrow keys ▲▼ to select oP2. Press ENTER/MENU to confirm the desired

setting. 1 P is displayed in the lower display part.

Use the arrow keys ▲▼ to choose from 1-point 1 P-, 2-point 2 P- and 3-point 3 P-

calibration.

EN

oP2

1P 2P 3P

Example of 1-point calibration:

Confirm 1-point calibration 1 P by pressing ENTER/MENU. Go appears on the display.

Once the measured value is stable, confirm by pressing ENTER/MENU.

14120692.01 04/2015 EN/DE

23

23WIKA operating instructions, models CTH63I0 and CTH65I0

Page 24

5. Commissioning, operation

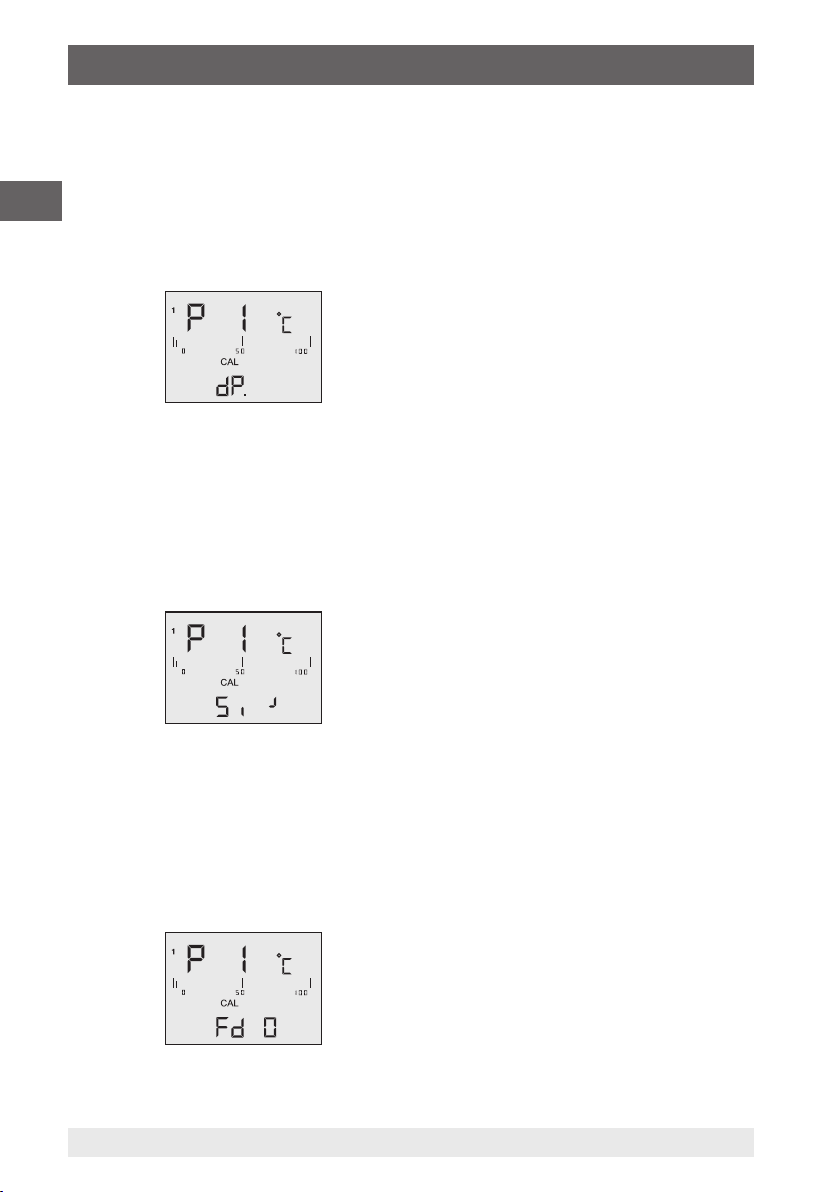

After approx. 2 seconds P1 appears in the first display line for the measured value 1,

dP appears in the 2nd line for the decimal point.

Use the arrow keys ▲▼ to select the desired number of decimal places:

EN

d P. = two decimal places

dP . = one decimal place (decimal point moves one position to the right)

Press ENTER/MENU to confirm the desired setting. Si_ appears on the display. Use

the arrow keys ▲▼ to select the sign:

Si_ = the number to be entered is in the negative range (below 0.00 °C)

Si┘= the number to be entered is in the positive range

Press ENTER/MENU to confirm the desired setting. Fd 0 appears on the display.

Select the range using the arrow keys ▲▼:

Fd 0 = below 1,000 °C

Fd 1 = above 1,000 °C

24 WIKA operating instructions, models CTH63I0 and CTH65I0

14120692.01 04/2015 EN/DE

Page 25

5. Commissioning, operation

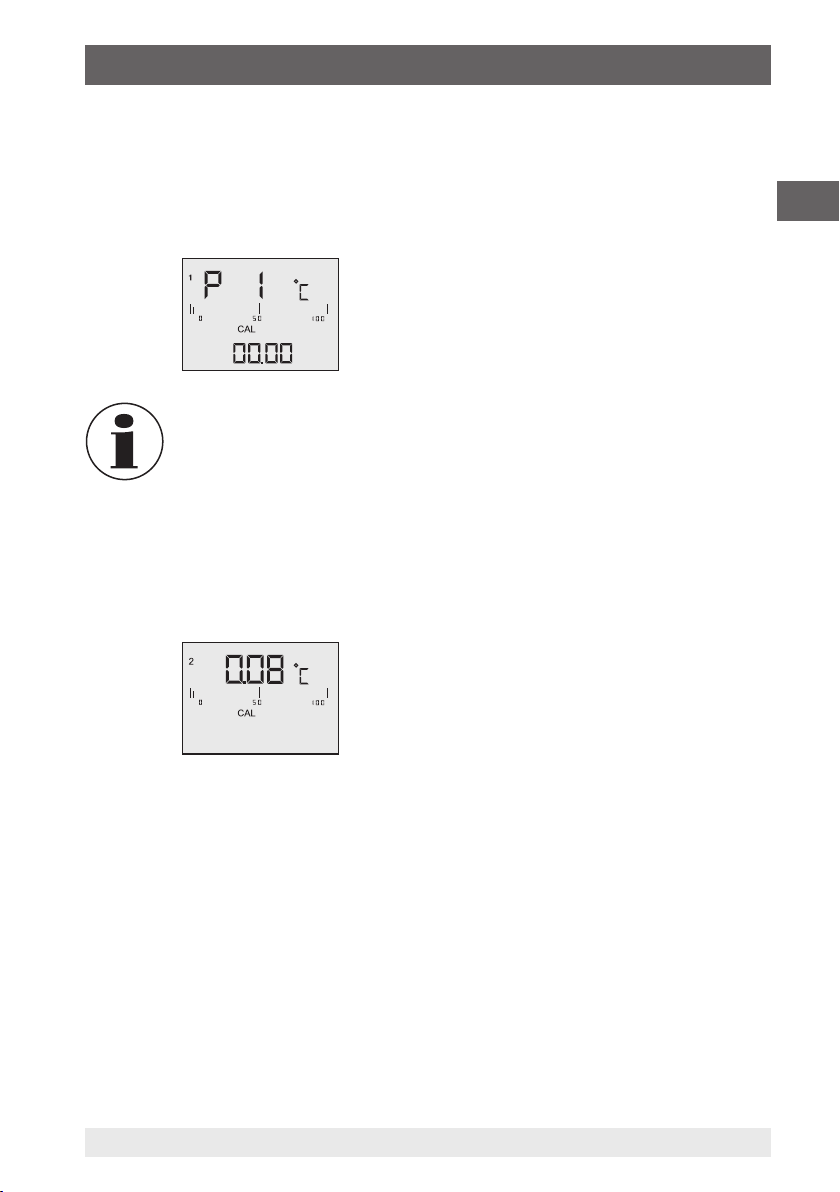

Press ENTER/MENU to confirm the desired setting. 00.00 appears on the display (or

similar). Enter the temperature of your reference now. Change the digits using the arrow

key ▲. Use the arrow key ▼ to switch to the next digit. After completing the input of the

temperature confirm by pressing ENTER/MENU.

Press [ESC] to return to the measuring mode.

The physical calibration oP2 cannot be cancelled by means of the ESC

key. If required, the calibration can be cancelled by switching off the

measuring instrument.

Example of the measured value display after physical calibration against a

reference standard:

The small 2 in the left corner in connection with the display segment CAL in the centre

of the display indicates that the physical probe calibration oP2 has been activated.

EN

5.4.4 Activating/deactivating measuring channels (only for 2-channel

instruments) [Chnl]

Chnl = Channel = select

Press the ENTER/MENU key and select Chnl using the arrow keys ▲▼. Then press

ENTER/MENU again. A small 1 appears on the left side of the display, it indicates the

channel. Use the arrow keys ▲▼ to select the channel to be activated or deactivated.

Confirm selection by pressing ENTER/MENU. Use the arrow keys ▲▼ now to activate

(on) or deactivate (off) the set channel. Press ENTER/MENU to confirm the desired

setting.

Use ESC to return to the measuring mode.

14120692.01 04/2015 EN/DE

25

25WIKA operating instructions, models CTH63I0 and CTH65I0

Page 26

5. Commissioning, operation

Alternative: keep the HOLD/MAX/MIN/AVE key pressed for 2 seconds; this deactivates

or activates channel 2.

EN

Unit Lin2 CAL Chnl Lo6

At least one channel is always active!

5.4.5 Storage management [Lo6] (not possible for CTH63I0)

Press the ENTER/MENU key and select Lo6 using the ▲▼ arrow keys (only when the

data logger version has been ordered). Then press ENTER/MENU again. OFF appears

in the lower display line. Now use the ▲▼ arrow keys to start the logger mode with ON.

Confirm selection by pressing ENTER/MENU.

Unit Lin2 CAL Chnl Lo6

Use the arrow keys ▲▼ to choose between the automatic Auto or manual SPot saving

and confirm by pressing ENTER/MENU. Decide whether to add or create a new log file

by selecting Add and nLo6. When selecting the automatic saving at the end you are

asked to select the measuring interval:

MENU

MENU

1S = 1 second 1M = 1 minute

5S = 5 seconds 2M = 2 minutes

10S = 10 seconds 5M = 5 minutes

20S = 20 seconds 10M = 10 minutes

30S = 30 seconds 20M = 20 minutes

Confirm the input by pressing ENTER/MENU. Use ESC to return to the measuring

mode. Manual saving by means of SPot. Press ESC to save individual measured

values manually.

26 WIKA operating instructions, models CTH63I0 and CTH65I0

14120692.01 04/2015 EN/DE

Page 27

5. Commissioning, operation

5.5 Storage query [HOLD-MAX-MIN-AVE]

After pressing the HOLD-MAX-MIN-AVE key for the first time, the current measured

values at the moment of actuation are “frozen” and indicated on the display as hold

values. Press this key repeatedly to request saved maximum, minimum and average

values in the lower line (small display).

Note for 2-channel instruments:

After displaying the hold values for both channels (large and small display),

the MAX-MIN-AVE values of the first channel are displayed in the lower line

(small display), after that the values of the second channel are displayed.

If only one probe is connected to a 2-channel measuring instrument, the

2nd channel should be deactivated (see chapter 5.4.4 “Activate/deactivate

measuring channels (only for 2-channel instruments) [Chnl]”).

During storage query the extremes MAX-MIN and the average value AVE

are not updated or calculated.

Clear storage (MAX-MIN-AVE)

Press CLEAR once. Clr appears on the display. All extremes (MAX-MIN and AVE)

measured up to that moment are deleted. After deletion of the storage the measuring

instrument switches back to the measuring mode automatically.

EN

5.6 Change measurement cycle (FAST mode)

Press FAST/▼ once to enter the Fast mode now. The measuring instrument measures

4 times per second now. Press FAST/▼ again and you will return to the normal mode

with 1 measured value per second again.

Note that the battery consumption in the Fast mode is approximately three

times higher than it is in the normal mode.

This setting is deactivated by switching off.

5.7 AUTO-OFF function

Press ESC-AUTO-OFF. dAoF is indicated on the display. The Auto-Off function is

deactivated now.

Press the ESC-AUTO-OFF key again. EAoF is indicated on the display. The measuring

instrument is shut down automatically after 30 minutes.

14120692.01 04/2015 EN/DE

27

27WIKA operating instructions, models CTH63I0 and CTH65I0

Page 28

5. Commissioning, operation / 6. Faults

dAoF = Disable Auto-off

EAoF = Enable Auto-off

EN

This setting is deactivated by switching off (default setting is EAoF).

5.8 Special functions

5.8.1 Zero adjustment (zero)

Keep the Clear key pressed (for approx. 3 seconds) to set the displayed value to 0.

Before pressing the key make sure that the actual value is also 0 (no flows/pressure

available at the probe).

5.8.2 Deactivation of channel 2 (toggle)

Keep the Hold key pressed (for approx. 3 seconds) to deactivate or activate the 2nd

measuring channel.

6. Faults

Personnel: Skilled personnel

DANGER!

Danger to life from explosion

Through working in flammable atmospheres, there is a risk of explosion

which can cause death.

▶

Only rectify faults in non-flammable atmospheres!

CAUTION!

Physical injuries and damage to property and the environment

If faults cannot be eliminated by means of the measures listed, the

intrinsically safe hand-held thermometer must be taken out of operation

immediately.

▶

Contact the manufacturer.

▶

If a return is needed, please follow the instructions given in chapter

8.1 “Return”.

28 WIKA operating instructions, models CTH63I0 and CTH65I0

14120692.01 04/2015 EN/DE

Page 29

6. Faults

WARNING!

Physical injuries and damage to property and the environment

caused by hazardous media

Upon contact with hazardous media (e.g. oxygen, acetylene, flammable

or toxic substances), harmful media (e.g. corrosive, toxic, carcinogenic,

radioactive), and also with refrigeration plants and compressors, there is a

danger of physical injuries and damage to property and the environment.

▶

For these media, in addition to all standard regulations, the appropriate

existing codes or regulations must also be followed.

▶

Wear the requisite protective equipment (see chapter 2.5 “Personal

protective equipment”).

For contact details, please see chapter 1 “General information” or the back

page of the operating instructions.

In case of maloperation or faults the instrument helps the operator by means of the

following error messages.

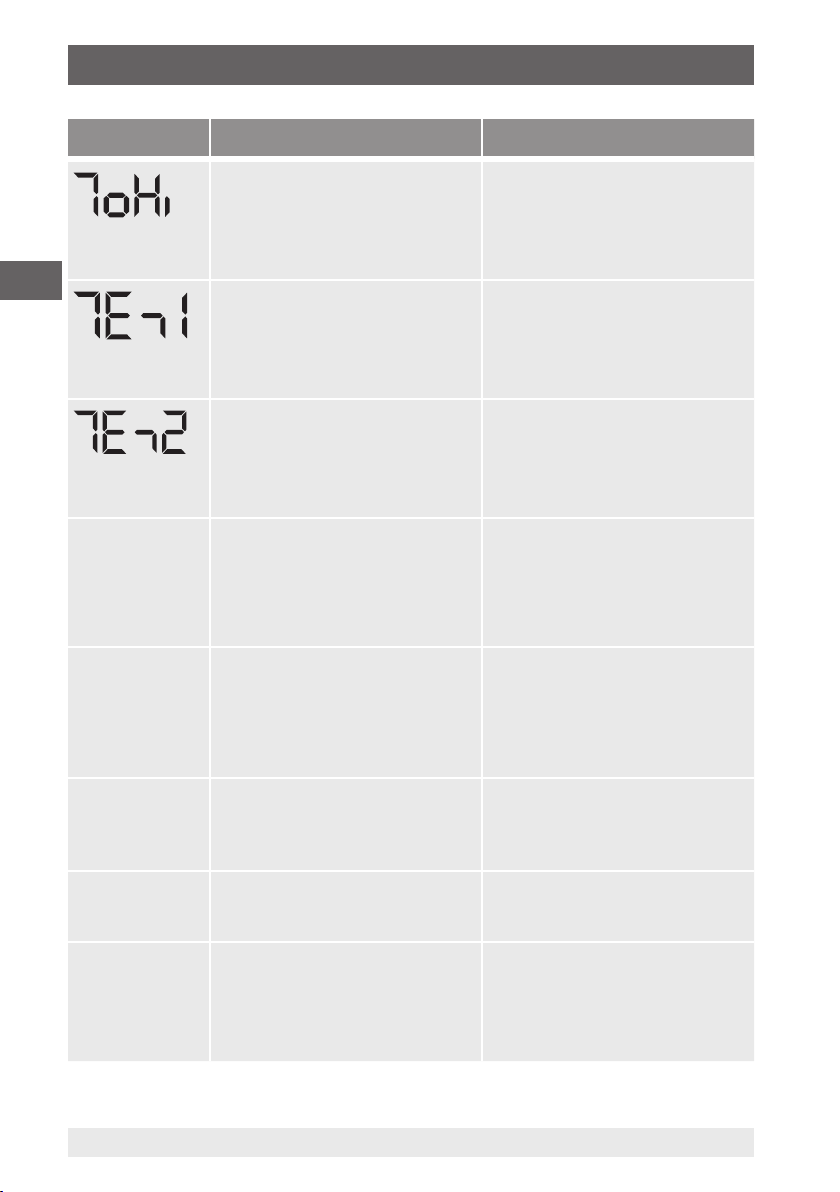

Display Cause Measures

EN

14120692.01 04/2015 EN/DE

Wrong probe or no probe

connected

“too low” underrange of the

measuring range

“too high” overrange of the

measuring range

Temperature of the reference

measuring point exceeds the

upper limit of the measuring

range

Connect probe or connect

correct probe.

Use the temperature probe

according to the technical

specifications. See chapter

9 “Specifications”.

Use the temperature probe

according to the technical

specifications. See chapter

9 “Specifications”.

Use the temperature probe

according to the technical

specifications. See chapter

9 “Specifications”.

29

29WIKA operating instructions, models CTH63I0 and CTH65I0

Page 30

6. Faults

Display Cause Measures

EN

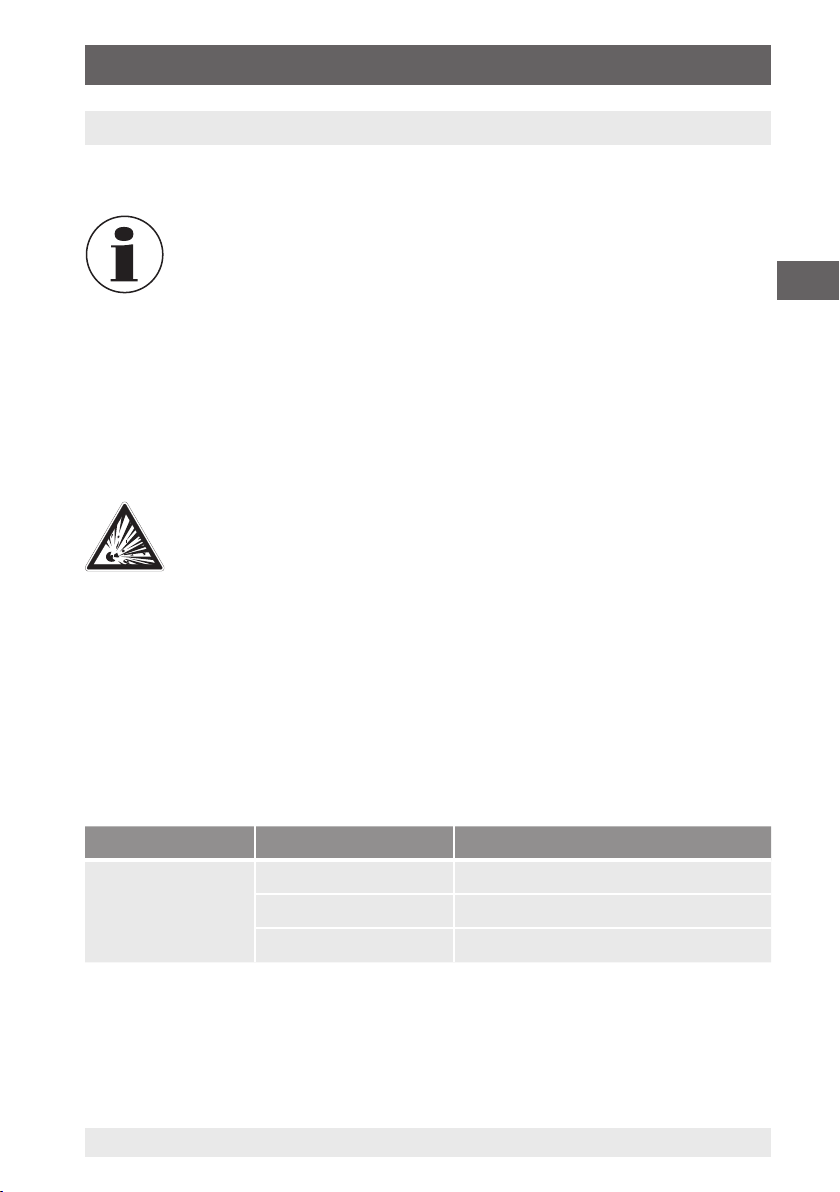

E15 /

E19 /

E1dh

E16 /

E1oh /

E1eh

E23 /

E25

E12

E31

Temperature of the reference

measuring point is below the

lower limit of the measuring

range

Battery is completely discharged Insert new batteries. See chapter

Interruption of the Auto-off

function

EE-prom content destroyed Send in for repair

Overflow Remove the battery and then

Temperature of the reference

measuring point is outside of the

measuring range

Use the temperature probe

according to the technical

specifications. See chapter

9 “Specifications”.

7.1.1 “Battery replacement”

Switch on the Auto-off function

again, see chapter 5.7 “AUTOOFF function”.

re-insert it.

Use the temperature probe

according to the technical

specifications. See chapter

9 “Specifications”.

30 WIKA operating instructions, models CTH63I0 and CTH65I0

14120692.01 04/2015 EN/DE

Page 31

7. Maintenance, cleaning and recalibration

7. Maintenance, cleaning and recalibration

Personnel: Skilled personnell

For contact details, please see chapter 1 “General information” or the back

page of the operating instructions.

7.1 Maintenance

These intrinsically safe hand-held thermometers are maintenance-free. Repairs must

only be carried out by the manufacturer.

This does not apply to the battery replacement.

Only use original parts (see chapter 10 “Accessories”).

7.1.1 Battery replacement

DANGER!

Danger to life from explosion!

Through working in flammable atmospheres, there is a risk of explosion

which can cause death.

▶

Only use batteries specified by the manufacturer!

▶

Never use rechargeable batteries in hazardous areas!

▶

The instruments must not be opened in hazardous areas!

▶

Do not change the battery while in a hazardous area!

▶

The battery cover must be closed and locked in place!

▶

Secure the battery cover with a screw!

EN

Permitted 9 V batteries are:

Battery type Manufacturer Battery name

6LR61

1. To change the battery, switch off the instrument and open the battery compartment

at the rear. To do this, unscrew the battery compartment screw, remove it and then

remove the battery cover.

2. Remove the battery and disconnect the connection cable.

14120692.01 04/2015 EN/DE

Varta Varta High Energy 4922

Varta Varta Industrial 4022

Duracell Duracell Plus Power

31

31WIKA operating instructions, models CTH63I0 and CTH65I0

Page 32

7. Maintenance, cleaning and recalibration

3. Connect the new battery to the connection cable and insert it into the battery

compartment.

4. Put the battery cover back on, re-insert the screw into the cover and screw it tightly

EN

down.

If the instrument is not used for a long time, remove the battery.

When closing the battery compartment make sure that the battery

connection wires are not jammed or damaged.

7.2 Cleaning

CAUTION!

Physical injuries and damage to property and the environment

Improper cleaning may lead to physical injuries and damage to property

and the environment. Residual media at the instrument and/or temperature

probe can result in a risk to persons, the environment and equipment.

▶

Do not use aggressive cleaning agents or solvents.

▶

Do not use any pointed and hard objects for cleaning.

▶

Carry out the cleaning process as described below.

1. Prior to cleaning, switch off the instrument.

2. Use the requisite protective equipment.

3. Clean the instrument with a moist cloth and then wipe it with a dry cloth.

Electrical connections must not come into contact with moisture.

4. Clean the temperature probe in order to protect personnel and the environment from

exposure to residual media.

7.3 Recalibration

DKD/DAkkS certificate - official certificates:

We recommend that the instrument is regularly recalibrated by the manufacturer, with

time intervals of approx. 12 months. The basic settings will be corrected if necessary.

32 WIKA operating instructions, models CTH63I0 and CTH65I0

14120692.01 04/2015 EN/DE

Page 33

8. Return and disposal

8. Return and disposal

Personnel: Skilled personnel

WARNING!

Physical injuries and damage to property and the environment

through residual media

Upon contact with hazardous media (e.g. oxygen, acetylene, flammable

or toxic substances), harmful media (e.g. corrosive, toxic, carcinogenic,

radioactive), and also with refrigeration plants and compressors, there is a

danger of physical injuries and damage to property and the environment.

▶

Clean the intrinsically safe hand-held thermometer and/or temperature

probe in order to protect persons and the environment from exposure to

residual media.

▶

Wear the requisite protective equipment (see chapter 2.5 “Personal

protective equipment”).

▶

Observe the information in the material safety data sheet for the

corresponding medium.

WARNING!

Risk of burns

On switching off, there is a risk of dangerously hot media.

▶

After using the temperature probe, let it cool down sufficiently!

EN

8.1 Return

Strictly observe the following when shipping the instrument:

All instruments delivered to WIKA must be free from any kind of hazardous substances

(acids, bases, solutions, etc.) and must therefore be cleaned before being returned.

WARNING!

Physical injuries and damage to property and the environment

through residual media

Residual media at the instrument and/or temperature probe can result in a

risk to persons, the environment and equipment.

▶

With hazardous substances, include the material safety data sheet for

the corresponding medium.

▶

Clean the instrument and/or temperature probe, see chapter

7.2 “Cleaning”.

14120692.01 04/2015 EN/DE

33

33WIKA operating instructions, models CTH63I0 and CTH65I0

Page 34

8. Return and disposal / 9. Specifications

When returning the instrument, use the original packaging or a suitable transport

packaging.

To avoid damage:

EN

1. Place the instrument, along with shock-absorbent material, in the packaging. Place

shock-absorbent material evenly on all sides of the transport packaging.

2. If possible, place a bag containing a desiccant inside the packaging.

3. Label the shipment as carriage of a highly sensitive measuring instrument.

Information on returns can be found under the heading “Service” on our

local website.

8.2 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an environmentally

compatible way and in accordance with the country-specific waste disposal regulations.

This marking on the instruments indicates that they must not be

disposed of in domestic waste. The disposal is carried out by return to

the manufacturer or by the corresponding municipal authorities (see EU

directive 2002/96/EC).

9. Specifications

DANGER!

Danger to life due to loss of explosion protection

The non-observance of the instructions for use in hazardous areas can

lead to the loss of the explosion protection.

▶

Adhere to the following limit values and instructions.

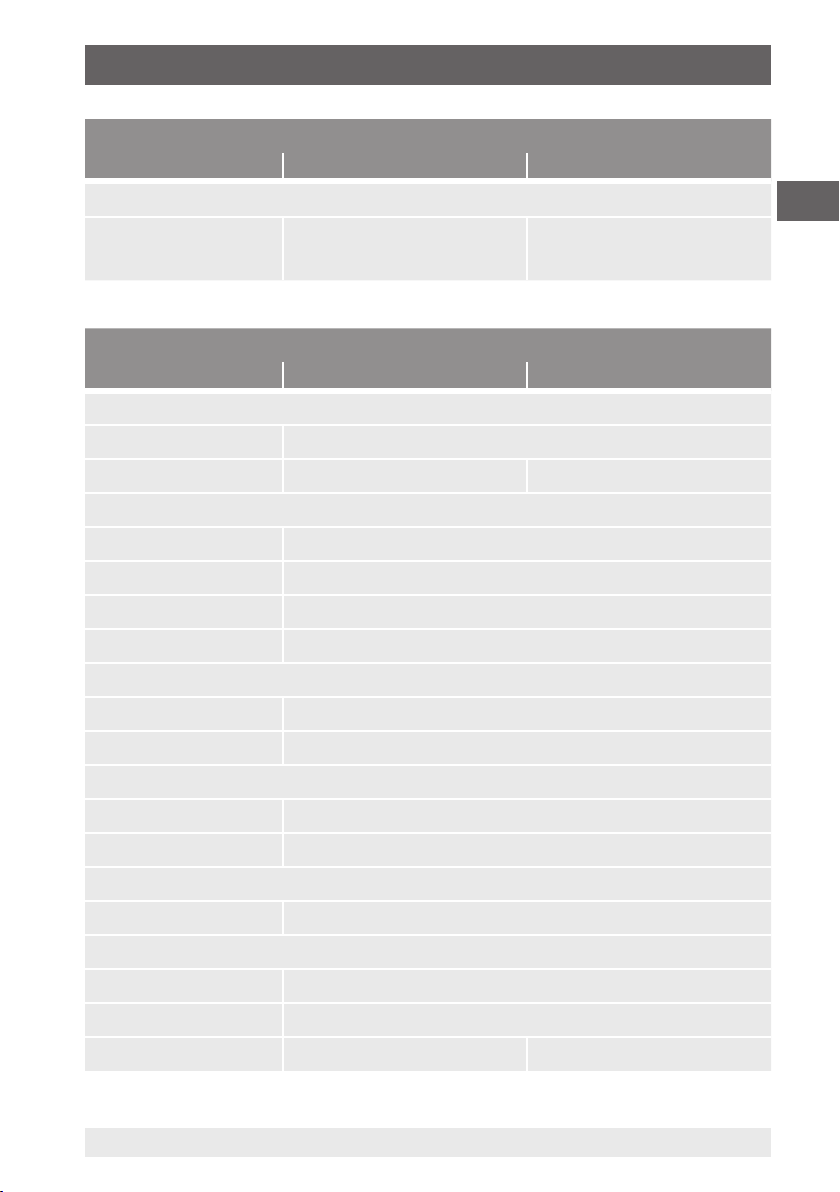

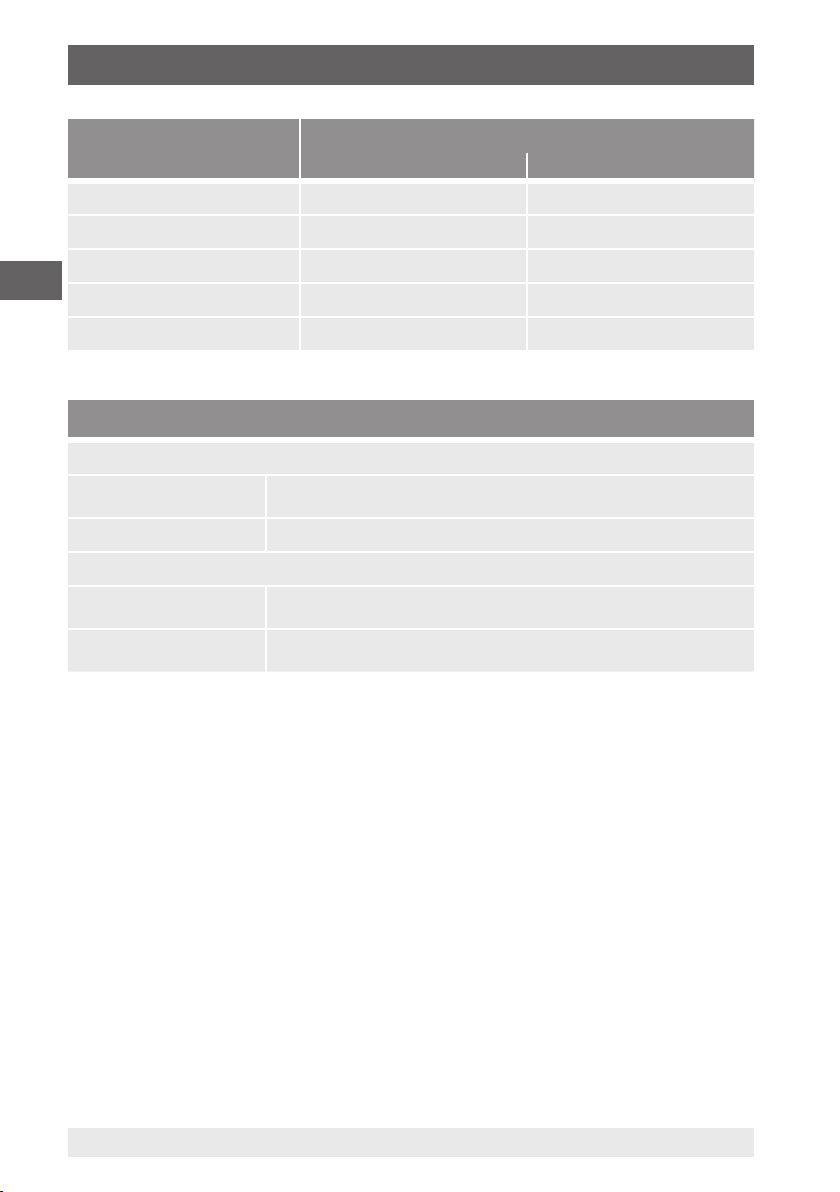

Intrinsically safe hand-held thermometer

Instrument model CTH63I0 CTH65I0

Probe types Pt100 Pt100

Measuring inputs 1 or 2 1 or 2

Measuring range

Pt100 -200 ... +600 °C (-392 ... +1,112 °F)

34 WIKA operating instructions, models CTH63I0 and CTH65I0

14120692.01 04/2015 EN/DE

Page 35

9. Specifications

Intrinsically safe hand-held thermometer

Instrument model CTH63I0 CTH65I0

Accuracy

Resistance thermometer

model Pt100

0.1 K for -100 ... +200 °C

otherwise 0.1 % of reading

0.03 K for -50 ... +199.99 °C

0.05 K for -200 ... -50.01 °C

otherwise 0.05 % of reading

Digital indicator

Instrument model CTH63I0 CTH65I0

Display

Screen 4 1/2-digit, large two-line LC display with backlighting

Resolution 0.1 K 0.01 K up to 200 °C, then 0.1 K

Functions

Measuring rate 4/s (“fast”); 1/s (“slow”)

Memory Min/Max

Functions via key press Min/Max memory, hold, zero adjustment

Real-time clock integrated clock with date

Voltage supply

Power supply DC 9 V, battery or rechargeable battery

Battery life approx. 20 hours of operation with battery

EN

Permissible ambient conditions

Operating temperature 0 ... 40 °C

Storage temperature -10 ... +50 °C

Communication

Interface USB via interface cable

Case

Material impact-resistant ABS plastic, transparent screen

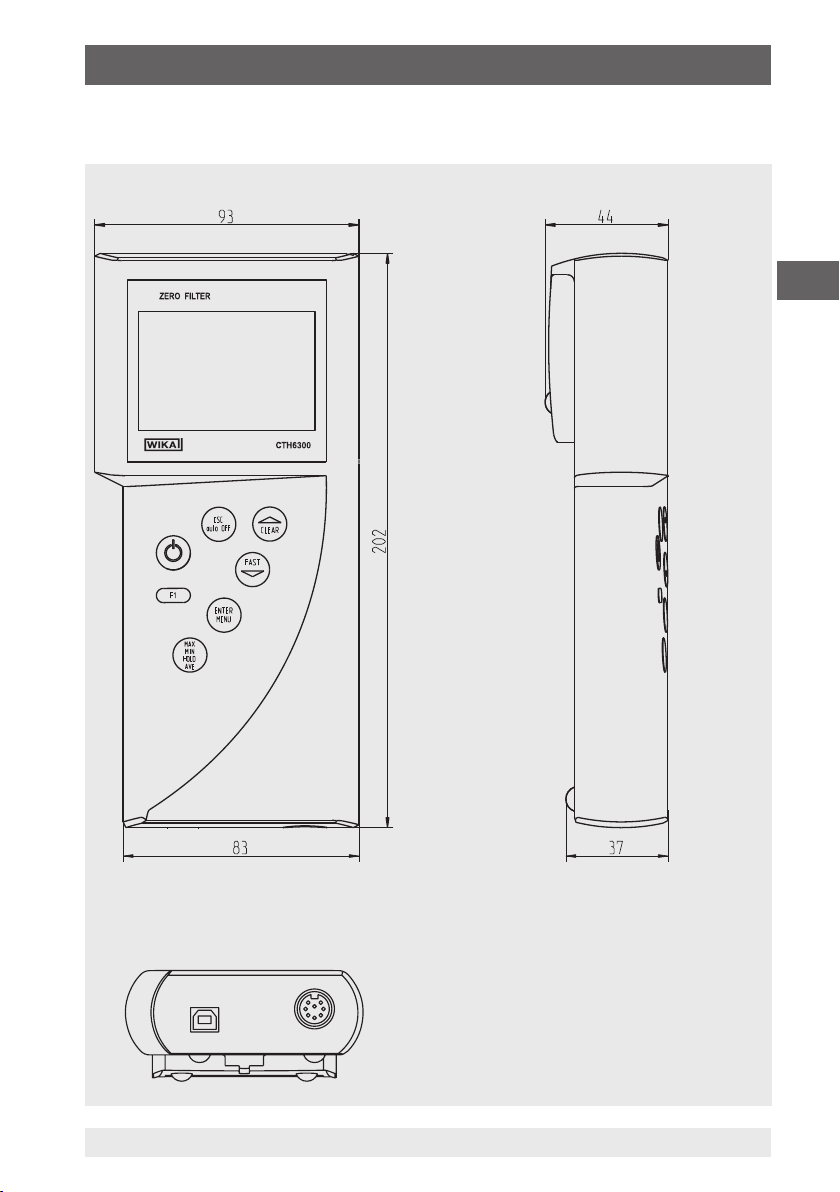

Dimensions 200 x 93 x 44 mm (L x W x H)

Weight 300 g 350 g

14120692.01 04/2015 EN/DE

35

35WIKA operating instructions, models CTH63I0 and CTH65I0

Page 36

9. Specifications

Standard probe

(immersion probe)

Pt100, d = 3 mm, l = 150 mm -200 ... +450 -328 ... +842

EN

Pt100, d = 3 mm, l = 300 mm -200 ... +450 -328 ... +842

Pt100, d = 6 mm, l = 300 mm -200 ... +450 -328 ... +842

Pt100, d = 3 mm, l = 1,000 mm -200 ... +450 -328 ... +842

Pt100, d = 4 mm, l = 300 mm -40 ... +500 -40 .... +932

Temperature range

°C °F

EC conformity, approvals and certificates for CTH63I0 and CTH65I0

CE conformity

EMC directive 2004/108/EC, EN 61326 emission (group 1, class B) and

interference immunity (portable test and measuring equipment)

ATEX directive 94/9/EC, category II 2 G, ignition protection type Ex ib IIB T4 Gb

Certificates

Calibration Standard: 3.1 calibration certificate per DIN EN 10204

Option: DKD/DAkkS calibration certificate

Recommended recalibration interval

Approvals and certificates, see website

1 year (dependent on conditions of use)

For further specifications, see WIKA data sheet CT 51.05 and CT 55.10 and the order

documentation.

36 WIKA operating instructions, models CTH63I0 and CTH65I0

14120692.01 04/2015 EN/DE

Page 37

9. Specifications

Dimensions in mm

Front view Side view (left)

EN

Bottom view (1-channel instrument)

14120692.01 04/2015 EN/DE

37

37WIKA operating instructions, models CTH63I0 and CTH65I0

Page 38

10. Accessories

10. Accessories

Temperature probe

■

EN

Immersion probe

■

Penetration probe

■

Customer-specific probes are available on request

Voltage supply

■

9 V battery

Test case

■

Transport case, robust

■

Case set with interface cable and software

Software

■

DE-Graph software

■

PC adapter cable USB

Other

■

DKD/DAkkS calibration certificate

38 WIKA operating instructions, models CTH63I0 and CTH65I0

14120692.01 04/2015 EN/DE

Page 39

Inhalt

Inhalt

1. Allgemeines 41

2. Sicherheit 42

2.1 Symbolerklärung . . . . . . . . . . . . . . . . . . . . 42

2.2 Bestimmungsgemäße Verwendung . . . . . . . . . . . . . . 42

2.3 Fehlgebrauch . . . . . . . . . . . . . . . . . . . . . 43

2.4 Personalqualifikation . . . . . . . . . . . . . . . . . . . 43

2.5 Persönliche Schutzausrüstung . . . . . . . . . . . . . . . 44

2.6 Beschilderung, Sicherheitskennzeichnungen. . . . . . . . . . . 45

2.7 Ex-Kennzeichnung. . . . . . . . . . . . . . . . . . . . 46

3. Aufbau und Funktion 48

3.1 Beschreibung . . . . . . . . . . . . . . . . . . . . . 48

3.2 Lieferumfang. . . . . . . . . . . . . . . . . . . . . . 48

3.3 Hand-Held Thermometer . . . . . . . . . . . . . . . . . 49

3.4 Tastenfeld. . . . . . . . . . . . . . . . . . . . . . . 50

3.5 Spannungsversorgung . . . . . . . . . . . . . . . . . . 50

3.6 USB-Schnittstelle . . . . . . . . . . . . . . . . . . . . 51

3.7 Temperaturfühler . . . . . . . . . . . . . . . . . . . . 51

3.7.1 Temperaturfühler anstecken/wechseln. . . . . . . . . . . . 52

4. Transport, Verpackung und Lagerung 52

4.1 Transport . . . . . . . . . . . . . . . . . . . . . . . 52

4.2 Verpackung und Lagerung . . . . . . . . . . . . . . . . . 53

5. Inbetriebnahme, Betrieb 54

5.1 Inbetriebnahme . . . . . . . . . . . . . . . . . . . . . 54

5.2 Ein-/Ausschalten . . . . . . . . . . . . . . . . . . . . 55

5.3 Menüstruktur und Einstellungen . . . . . . . . . . . . . . . 56

5.4 Menübaum . . . . . . . . . . . . . . . . . . . . . . 56

5.4.1 Einheitenumschaltung °C und °F [Unit] . . . . . . . . . . . 56

5.4.2 Anzeigeoption Differenztemperatur aktivieren/deaktivieren [Lin2]

(Nur für 2-Kanalgeräte) . . . . . . . . . . . . . . . . . 57

5.4.3 Kalibriermodus CAL . . . . . . . . . . . . . . . . . . 57

5.4.4 Messkanäle aktivieren/deaktivieren (nur für 2-Kanalgeräte) [Chnl] . . 62

5.4.5 Speicherverwaltung [Lo6] (nicht möglich bei CTH63I0) . . . . . . 62

5.5 Speicherabfrage [HOLD-MAX-MIN-AVE] . . . . . . . . . . . . 63

14120692.01 04/2015 EN/DE

DE

39WIKA Betriebsanleitung, Typen CTH63I0 und CTH65I0

Page 40

Inhalt

5.6 Messzyklus ändern (FAST-Modus) . . . . . . . . . . . . . . 63

5.7 AUTO-OFF-Funktion . . . . . . . . . . . . . . . . . . . 64

5.8 Sonderfunktionen . . . . . . . . . . . . . . . . . . . . 64

5.8.1 Nullpunktabgleich (Zero) . . . . . . . . . . . . . . . . 64

5.8.2 Kanal 2 Deaktivierung (Toggle) . . . . . . . . . . . . . . 64

6. Störungen 64

DE

7. Wartung, Reinigung und Rekalibrierung 67

7.1 Wartung . . . . . . . . . . . . . . . . . . . . . . . 67

7.1.1 Batteriewechsel . . . . . . . . . . . . . . . . . . . 67

7.2 Reinigung. . . . . . . . . . . . . . . . . . . . . . . 68

7.3 Rekalibrierung . . . . . . . . . . . . . . . . . . . . . 68

8. Rücksendung und Entsorgung 69

8.1 Rücksendung . . . . . . . . . . . . . . . . . . . . . 69

9. Technische Daten 70

9.1 Entsorgung . . . . . . . . . . . . . . . . . . . . . . 70

10. Zubehör 74

Anlage: Konformitätserklärung 75

Konformitätserklärungen finden Sie online unter www.wika.de.

40 WIKA Betriebsanleitung, Typen CTH63I0 und CTH65I0

14120692.01 04/2015 EN/DE

Page 41

1. Allgemeines

1. Allgemeines

■

Die in der Betriebsanleitung beschriebenen eigensicheren Hand-Held Thermometer

Typ CTH63I0 und Typ CTH65I0 werden nach dem aktuellen Stand der Technik

konstruiert und gefertigt. Alle Komponenten unterliegen während der Fertigung

strengen Qualitäts- und Umweltkriterien. Unsere Managementsysteme sind nach

ISO 9001 und ISO 14001 zertifiziert.

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem Gerät.

Voraussetzung für sicheres Arbeiten ist die Einhaltung aller angegebenen Sicherheitshinweise und Handlungsanweisungen.

■

Die für den Einsatzbereich des Gerätes geltenden örtlichen Unfallverhütungsvorschriften und allgemeinen Sicherheitsbestimmungen einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des

Gerätes für das Fachpersonal jederzeit zugänglich aufbewahrt werden. Betriebsanleitung an nachfolgende Benutzer oder Besitzer des Gerätes weitergeben.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig

durchgelesen und verstanden haben.

DE

■

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Werkskalibrierungen / DKD/DAkkS-Kalibrierungen erfolgen nach internationalen

Normen.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- zugehöriges Datenblatt: CT 51.05 und CT 55.10

- Anwendungsberater:

Tel.: +49 9372 132-5049

Fax: +49 9372 132-8005049

CTServiceteam@wika.com

14120692.01 04/2015 EN/DE

41WIKA Betriebsanleitung, Typen CTH63I0 und CTH65I0

Page 42

2. Sicherheit

2. Sicherheit

2.1 Symbolerklärung

DE

WARNUNG!

... weist auf eine möglicherweise gefährliche Situation hin, die zum Tod

oder zu schweren Verletzungen führen kann, wenn sie nicht gemieden

wird.

VORSICHT!

... weist auf eine möglicherweise gefährliche Situation hin, die zu geringfügigen oder leichten Verletzungen bzw. Sach- und Umweltschäden führen

kann, wenn sie nicht gemieden wird.

GEFAHR!

... kennzeichnet Gefährdungen durch elektrischen Strom. Bei Nichtbeachtung der Sicherheitshinweise besteht die Gefahr schwerer oder tödlicher

Verletzungen.

GEFAHR!

... weist auf eine möglicherweise gefährliche Situation im explosionsgefährdeten Bereich hin, die zum Tod oder zu schweren Verletzungen führen

kann, wenn sie nicht gemieden wird.

WARNUNG!

... weist auf eine möglicherweise gefährliche Situation hin, die durch heiße

Oberflächen oder Flüssigkeiten zu Verbrennungen führen kann, wenn sie

nicht gemieden wird.

Information

... hebt nützliche Tipps und Empfehlungen sowie Informationen für einen

effizienten und störungsfreien Betrieb hervor.

2.2 Bestimmungsgemäße Verwendung

Die eigensicheren Hand-Held Thermometer werden für eine mobile Temperaturmessung verwendet, bei der die Signale von Widerstandsthermometern verarbeitet werden.

So können Temperaturen von -200 ... +600 °C gemessen werden.

42 WIKA Betriebsanleitung, Typen CTH63I0 und CTH65I0

14120692.01 04/2015 EN/DE

Page 43

2. Sicherheit

Die Geräte sind ausschließlich für den hier beschriebenen bestimmungsgemäßen

Verwendungszweck konzipiert und konstruiert und dürfen nur dementsprechend

verwendet werden.

Die technischen Spezifikationen in dieser Betriebsanleitung sind einzuhalten. Eine

unsachgemäße Handhabung oder ein Betreiben der Geräte außerhalb der technischen

Spezifikationen machen die sofortige Stilllegung und Überprüfung durch einen autorisierten WIKA-Servicemitarbeiter erforderlich.

Die Hand-Helds mit erforderlicher Sorgfalt behandeln (vor Nässe, Stößen, starken

Magnetfeldern, statischer Elektrizität und extremen Temperaturen schützen, keine

Gegenstände in das Gerät bzw. Öffnungen einführen). Stecker und Buchsen vor

Verschmutzung schützen.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung sind

ausgeschlossen.

2.3 Fehlgebrauch

WARNUNG!

Verletzungen durch Fehlgebrauch

Fehlgebrauch des Gerätes kann zu gefährlichen Situationen und Verletzungen führen.

▶

Eigenmächtige Umbauten am Gerät unterlassen.

▶

Keine herstellerfremde Temperaturfühler verwenden.

▶

Gerät nicht für abrassive Messstoffe verwenden.

▶

Gewalteinwirkung wie Stöße oder Druck vermeiden

DE

Jede über die bestimmungsgemäße Verwendung hinausgehende oder andersartige

Benutzung gilt als Fehlgebrauch.

2.4 Personalqualifikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualifikation

Unsachgemäßer Umgang kann zu erheblichen Personen- und Sachschäden führen.

▶

Die in dieser Betriebsanleitung beschriebenen Tätigkeiten nur durch

Fachpersonal nachfolgend beschriebener Qualifikation durchführen

14120692.01 04/2015 EN/DE

lassen.

43WIKA Betriebsanleitung, Typen CTH63I0 und CTH65I0

Page 44

2. Sicherheit

Fachpersonal

Das vom Betreiber autorisierte Fachpersonal ist aufgrund seiner fachlichen Ausbildung,

seiner Kenntnisse der Mess- und Regelungstechnik und seiner Erfahrungen sowie

Kenntnis der landesspezifischen Vorschriften, geltenden Normen und Richtlinien in der

Lage, die beschriebenen Arbeiten auszuführen und mögliche Gefahren selbstständig

zu erkennen.

DE

Besondere Kenntnisse bei Arbeiten mit Geräten für explosionsgefährdete

Bereiche:

Das Fachpersonal muss Kenntnisse haben über Zündschutzarten, Vorschriften und

Verordnungen für Betriebsmittel in explosionsgefährdeten Bereichen.

Spezielle Einsatzbedingungen verlangen weiteres entsprechendes Wissen, z. B. über

aggressive Medien.

2.5 Persönliche Schutzausrüstung

Die persönliche Schutzausrüstung dient dazu, das Fachpersonal gegen Gefahren

zu schützen, die dessen Sicherheit oder Gesundheit bei der Arbeit beeinträchtigen

könnten. Beim Ausführen der verschiedenen Arbeiten an und mit dem Gerät muss das

Fachpersonal persönliche Schutzausrüstung tragen.

Im Arbeitsbereich angebrachte Hinweise zur persönlichen Schutzausrüstung

befolgen!

Die erforderliche persönliche Schutzausrüstung muss vom Betreiber zur Verfügung

gestellt werden.

Schutzbrille tragen!

Schutz der Augen vor umherfliegenden Teilen und Flüssigkeitsspritzern.

Schutzhandschuhe tragen!

Schutz der Hände vor Reibung, Abschürfung, Einstichen oder tieferen

Verletzungen sowie vor Berührung mit heißen Oberflächen und aggressiven Medien.

44 WIKA Betriebsanleitung, Typen CTH63I0 und CTH65I0

14120692.01 04/2015 EN/DE

Page 45

2. Sicherheit

2.6 Beschilderung, Sicherheitskennzeichnungen

Typenschild

TÜV 14 ATEX 143825 X

II 2 G Ex ib IIB T4 Gb

HD 2015

SNR. WX15001

WARNUNG:

Batterie nur außerhalb des Ex-Bereiches wechseln !

Bescheinigungs-Nr.

Zündschutzart

Gerätetyp

Zulässige Umgebungstemperatur

Serien-Nr.

Herstellungsjahr

Prüfstelle

Alexander Wiegand SE & C0. KG · D-63911 Klingenberg

0158

CTH6XI0

0°C Ta 40°C

DE

Symbole

Geräte mit dieser Kennzeichnung stimmen überein mit den zutreffenden

europäischen Richtlinien.

ATEX Europäische Explosionsschutz-Richtlinie

(Atmosphère = AT, explosible = EX)

Geräte mit dieser Kennzeichnung stimmen überein mit den Anforderungen

der europäischen Richtlinie 94/9/EG (ATEX) zum Explosionsschutz.

14120692.01 04/2015 EN/DE

45WIKA Betriebsanleitung, Typen CTH63I0 und CTH65I0

Page 46

2. Sicherheit

2.7 Ex-Kennzeichnung

GEFAHR!

Lebensgefahr durch Verlust des Explosionsschutzes

Die Nichtbeachtung dieser Inhalte und Anweisungen kann zum Verlust des

Explosionsschutzes führen.

▶

Sicherheitshinweise in diesem Kapitel sowie weitere

DE

Überprüfen, ob die Klassifizierung für den Einsatzfall geeignet ist. Die jeweiligen nationalen Vorschriften und Bestimmungen beachten.

ATEX-Richtlinie: 94/9/EG

Bescheinigungs-Nr.: TÜV 14 ATEX 143825 X

Zündschutzart: II 2 G Ex ib IIB T4 Gb

CE-Kennzeichnung: 0158

Angewandte Normen: EN 60079-0:2012

EMV-Richtlinie: 2004/108/EG

Angewandte Normen: EN 61326 (Gruppe 1, Klasse B)

Explosionshinweise in dieser Betriebsanleitung beachten.

▶

Die Angaben der geltenden Baumusterprüfbescheinigung sowie die

jeweiligen landesspezifischen Vorschriften zur Installation und Einsatz

in explosionsgefährdeten Bereichen (z. B. IEC 60079-14, NEC, CEC)

einhalten.

EN 60079-11:2012

II 2G, Ex ib IIB T4 Gb

Kennzeichnung Benennung Bedeutung

CE-Zeichen Konformitätskennzeichen nach Anhang X der

Richtlinie 94/9/EG. Der Hersteller bringt es vor

dem In-Verkehr-Bringen an.

II Gerätegruppe Das Gerät darf in explosionsgefährdeten

Bereichen, außer im Bergbau, eingesetzt werden.

2G Gerätekategorie Bei Gerätekategorie 2G darf eine

explosionsfähige Atmosphäre unter Beteiligung

von Gasen (G) gelegentlich auftreten. Das Gerät

ist in Zone 1 und Zone 2 einsetzbar.

46 WIKA Betriebsanleitung, Typen CTH63I0 und CTH65I0

14120692.01 04/2015 EN/DE

Page 47

2. Sicherheit

Kennzeichnung Benennung Bedeutung

ib Eigensicherheit Das Gerät enthält einen eigensicheren Stromkreis.

Ein Stromkreis ist eigensicher, wenn kein Funke

und kein thermischer Effekt die Zündung einer

bestimmten explosionsfähigen Atmosphäre

verursachen kann.

IIB Gerätegruppe Elektrische Gerätegruppe ausgewiesen für

gasexplosionsgefährdete Bereiche nach DIN EN

60079-0.

T4 Temperaturklasse Maximal auftretende Oberflächentemperatur von

135 °C.

Gb Geräteschutzniveau

(EPL)

Temperaturklasse Maximale Oberflächentemperatur

T1 450 °C

T2 300 °C

T3 200 °C

T4 135 °C

T5 100 °C

T6 85 °C

Bei Geräteschutzniveau Gb nach DIN EN 60079-0

(2007) darf eine explosionsfähige Atmosphäre

unter Beteiligung von Gasen (G) gelegentlich

auftreten. Das Gerät ist in Zone 1 und Zone 2

einsetzbar.

DE

14120692.01 04/2015 EN/DE

47WIKA Betriebsanleitung, Typen CTH63I0 und CTH65I0

Page 48

3. Aufbau und Funktion

3. Aufbau und Funktion

3.1 Beschreibung

Die universell einsetzbaren eigensicheren Hand-Held Thermometer für die mobile,

anspruchsvolle Temperaturmessung bestechen durch Flexibilität und leichte

Handhabung. Es können Temperaturen von -200 ... +600 °C gemessen werden.

DE

Driftarme Messverstärker gewährleisten kleine Messabweichungen und leicht anwendbare Justierfunktionen vereinfachen die Justage und die Kalibrierung deutlich:

■

Nummernkalibrierung zur schnellen Anpassung von Standardfühlern über

Kennzahlen

■

Physikalische Kalibrierung von Fühler und Anzeige an einer, zwei oder drei

beliebigen Temperaturen

Auf diese Weise ist es möglich, Messfehler auf ein Minimum zu reduzieren und eine

hohe Anzeigegenauigkeit zu sichern.

Eigensicheres Hand-Held Thermometer Typ CTH63I0, industrielle Ausführung

Aufgrund seiner Ausführung ist der CTH63I0 besonders geeignet für Inbetriebnahme,

Wartung und den Service/Kalibrierung von Temperaturinstrumenten und Anlagen.

Eigensicheres Hand-Held Thermometer Typ CTH65I0, präzise Ausführung

Durch seine hohe Genauigkeit von 0,03 K im Bereich von -50 ... +199,99 °C kann das

CTH65I0 als Referenzmessgerät im Bio-, Pharma- und Lebensmittelbereich eingesetzt

werden. Das CTH65I0 ist damit auch bestens für alle Wartungs- und Serviceaufgaben

geeignet.

3.2 Lieferumfang

CTH63I0 oder CTH65I0

■

Eigensicheres Hand-Held Thermometer Typ CTH63I0 oder CTH65I0, inkl. 9-V-Block-

batterie

■

Kalibrierzertifikat 3.1 nach DIN EN 10204

■

Temperaturfühler nach Wahl

Lieferumfang mit dem Lieferschein abgleichen.

48 WIKA Betriebsanleitung, Typen CTH63I0 und CTH65I0

14120692.01 04/2015 EN/DE

Page 49

3. Aufbau und Funktion

3.3 Hand-Held Thermometer

DE

6

5

34

Fühlerhalterung

1

Erster Anschlussport für Temperaturfühler

2

Zweiter Anschlussport für Temperaturfühler

3

USB-Anschlussport für PC

4

Tastatur

5

1

2

Große LC-Anzeige

6

14120692.01 04/2015 EN/DE

49WIKA Betriebsanleitung, Typen CTH63I0 und CTH65I0

Page 50

3. Aufbau und Funktion

3.4 Tastenfeld

DE

7

6

5

4

Pfeiltaste CLEAR

1

Auswahl der Menüpunkte

Pfeiltaste FAST

2

Auswahl der Menüpunkte

ENTER/MENU-Taste

3

Zugang zum Hauptmenü, Bestätigen der Funktion

MIN/MAX/HOLD/AVE-Taste

4

Einstellen von MIN und MAX, HOLD und AVE

Funktionstasten

5

Konfigurieren des Gerätes

EIN-/AUS-Taste

6

Ein- und Ausschalten des Gerätes

ESC-Taste

7

Zurück zum Messmodus

1

2

3

3.5 Spannungsversorgung

Die Batterielebensdauer beträgt ca. 20 Stunden bei Dauerbetrieb.

Das Segment BAT zeigt an, dass die Batterie in Kürze ausgewechselt werden müssen.

Es können jetzt noch ca. 2 Std. korrekte Messungen durchgeführt werden.

Als Spannungsversorgung des Gerätes dient eine 9-V-Blockbatterie.

50 WIKA Betriebsanleitung, Typen CTH63I0 und CTH65I0

14120692.01 04/2015 EN/DE

Page 51

3. Aufbau und Funktion

Zur Vermeidung einer falschen Anzeige, die Batterie ersetzen, sobald die Batterieanzeige erscheint.

Hinweise zur Batterie siehe Kapitel 7.1.1 „Batteriewechsel“.

3.6 USB-Schnittstelle

GEFAHR!

Lebensgefahr durch Explosion!

Durch Arbeiten in entzündlichen Atmosphären besteht Explosionsgefahr,

die zum Tod führen kann.

▶

Ein Benutzen der USB-Schnittstelle ist in explosionsgefährdeten Bereichen nicht zulässig!

Der Typ CTH63I0 oder CTH65I0 besitzt standardmäßig eine USB-Schnittstelle. Die

serielle Datenübertragung kann zur Konfiguration, Kalibrierung und zur Übertragung

von Messwerten des Hand-Held Themometers verwendet werden.

3.7 Temperaturfühler

GEFAHR!

Lebensgefahr durch Explosion!

Bei Verwendung falscher Temperaturfühler kann es zum Verlust des Explosionsschutzes führen

▶

Nur die für den Ex-Bereich gelieferte Pt100-Temperaturfühler verwenden!

Verschiedene Temperaturfühler gewährleisten Flexibilität (siehe Kapitel 9 „Technische

Daten“).

DE

Abb. oben: Eintauchfühler

Abb. unten: Einstechfühler

14120692.01 04/2015 EN/DE

51WIKA Betriebsanleitung, Typen CTH63I0 und CTH65I0

Page 52

3. Aufbau und Funktion / 4. Transport, Verpackung und ...

An der Messstelle (Messfühler) sind die Temperaturen in Abhängigkeit von der Temperaturklasse zulässig (siehe Kapitel 2.7 „Ex-Kennzeichnung“).

Beim Betrieb in nicht explosionsgefährdeten Bereichen gelten die Temperaturbereiche

die in den Technischen Daten angegeben sind (siehe 9 „Technische Daten“).

Die höchstzulässige Umgebungstemperatur für das Messgerät beträgt 40 °C.

3.7.1 Temperaturfühler anstecken/wechseln

DE

1. Zum Fühlerwechsel Gerät ausschalten.

2. Fühler vor dem Einschalten des Gerätes anstecken, sonst wird er vom Gerät evtl.

nicht richtig erkannt.

3. Stecker nicht mit Gewalt in die Buchse einstecken.

Digitalgerät und Temperaturfühler werden mittels eines separaten Verbindungskabels

elektrisch miteinander verbunden.

Beim Fühlerwechsel ist folgendes zu beachten:

■

Stecker nicht mit Gewalt in die Buchsen einstecken.

■

Zum Anschluss des Temperaturfühlers an das Hand-Held die 8-polige

Steckverbindung gemäß der Orientierungsführung in den Anschlussport für

Temperaturfühler stecken.

■

Stecker nicht verkantet anstecken. Bei richtig angesetztem Stecker kann dieser

ohne größeren Kraftaufwand eingesteckt werden.

■

Beim Abstecken des Fühlers nicht am Kabel ziehen, sondern nur an der

Steckerhülse.

4. Transport, Verpackung und Lagerung

4.1 Transport

Eigensicheres Hand-Held Thermometer auf eventuell vorhandene Transportschäden

untersuchen.

Offensichtliche Schäden unverzüglich mitteilen.

VORSICHT!

Beschädigungen durch unsachgemäßen Transport

Bei unsachgemäßem Transport können Sachschäden in erheblicher Höhe

entstehen.

▶

Beim Abladen der Packstücke bei Anlieferung sowie innerbetrieblichem

Transport vorsichtig vorgehen und die Symbole auf der Verpackung

beachten.

▶

Bei innerbetrieblichem Transport die Hinweise unter Kapitel

4.2 „Verpackung und Lagerung“ beachten.

52 WIKA Betriebsanleitung, Typen CTH63I0 und CTH65I0

14120692.01 04/2015 EN/DE

Page 53

4. Transport, Verpackung und Lagerung

Wird das Gerät von einer kalten in eine warme Umgebung transportiert, so kann durch

Kondensatbildung eine Störung der Gerätefunktion eintreten. Vor einer erneuten

Inbetriebnahme die Angleichung der Gerätetemperatur an die Raumtemperatur

abwarten.

4.2 Verpackung und Lagerung

Die Verpackung aufbewahren, denn diese bietet bei einem Transport einen optimalen

Schutz (z. B. wechselnder Einbauort, Reparatursendung).

Zulässige Bedingungen am Lagerort:

■

Feuchtigkeit: 35 ... 85 % relative Feuchte (keine Betauung)

■

Lagertemperatur: -10 ... +50 °C

Folgende Einflüsse vermeiden:

■

Direktes Sonnenlicht oder Nähe zu heißen Gegenständen

■

Mechanische Vibration, mechanischer Schock (hartes Aufstellen)

■

Ruß, Dampf, Staub und korrosive Gase

Das Gerät in der Originalverpackung an einem Ort lagern, der die oben gelisteten

Bedingungen erfüllt. Wenn die Originalverpackung nicht vorhanden ist, dann das Gerät

wie folgt verpacken und lagern:

1. Das Gerät mit dem Dämmmaterial in der Verpackung platzieren.

2. Bei längerer Einlagerung (mehr als 30 Tage) einen Beutel mit Trocknungsmittel der

Verpackung beilegen.

DE

14120692.01 04/2015 EN/DE

53WIKA Betriebsanleitung, Typen CTH63I0 und CTH65I0

Page 54

5. Inbetriebnahme, Betrieb

5. Inbetriebnahme, Betrieb

Personal: Fachpersonal

Nur Originalteile verwenden (siehe Kapitel 10 „Zubehör“).

GEFAHR!

DE

Lebensgefahr durch Explosion!

Durch Arbeiten in entzündlichen Atmosphären besteht Explosionsgefahr,

die zum Tod führen kann.

▶

Fühlerwechsel nur in nicht-explosionsgefährdeter Umgebung durchführen!

▶

Im Falle von Mängeln dürfen die Messgeräte nicht in explosionsgefährdeten Bereichen betrieben werden!

▶

Das eigensichere Hand-Held Thermometer nicht im beschädigtem

Zustand verwenden. Vor dem Verwenden das Gerät prüfen, ob das

Gehäuse Risse oder fehlende Kunststoffteile aufweist. Besonders auf

die Isolierung der Stecker achten.

▶

Das Gerät nicht verwenden, wenn es nicht richtig funktioniert. Der

Geräteschutz kann beeinträchtigt sein. Im Zweifelsfall das Gerät

überprüfen lassen.

▶

Das Batteriefach nicht in explosionsgefährdeten Bereichen öffnen!

WARNUNG!

Körperverletzungen, Sach- und Umweltschäden durch gefährliche

Messstoffe

Bei Kontakt mit gefährlichen Messstoffen (z. B. Sauerstoff, Acetylen,

brennbaren oder giftigen Stoffen), gesundheitsgefährdenden Messstoffen

(z. B. ätzend, giftig, krebserregend, radioaktiv) sowie bei Kälteanlagen,

Kompressoren besteht die Gefahr von Körperverletzungen, Sach- und

Umweltschäden.

Am Temperaturfühler können im Fehlerfall aggressive Medien mit extremer

Temperatur anliegen.

▶

Bei diesen Messstoffen müssen über die gesamten allgemeinen Regeln

hinaus die einschlägigen Vorschriften beachtet werden.

▶

Notwendige Schutzausrüstung tragen (siehe Kapitel 2.5 „Persönliche

Schutzausrüstung“).

5.1 Inbetriebnahme

Vor dem Einschalten den oder die Temperaturfühler in die dafür vorgesehene Buchse

des Hand-Helds anstecken und sicherstellen dass eine volle 9-V-Blockbatterie einge-

54 WIKA Betriebsanleitung, Typen CTH63I0 und CTH65I0

14120692.01 04/2015 EN/DE

Page 55

5. Inbetriebnahme, Betrieb

legt ist. Die Fühleranschlussbuchsen sind entsprechend am Gerätegehäuse mit 1 oder

2 gekennzeichnet. Daneben ist die USB-Schnittstelle gekennzeichnet.

5.2 Ein-/Ausschalten

Durch Betätigen der ON/OFF-Taste wird das Messgerät ein- und ausgeschaltet.

Nach dem Einschalten werden auf dem Display für ca. 1,5 Sekunden alle Segmente

angezeigt (Vollsegmentanzeige). Anschließend zeigt das Gerät für ca. weitere

1,5 Sekunden den eingestellten Fühler-Kalibriercode sowie die eingestellte Messgröße

für Kanal 1 an (z. B. CoFF für DIN-Kennlinie und P für Pt100). Danach werden die