WIKA 232.53, 233.53 Specifications

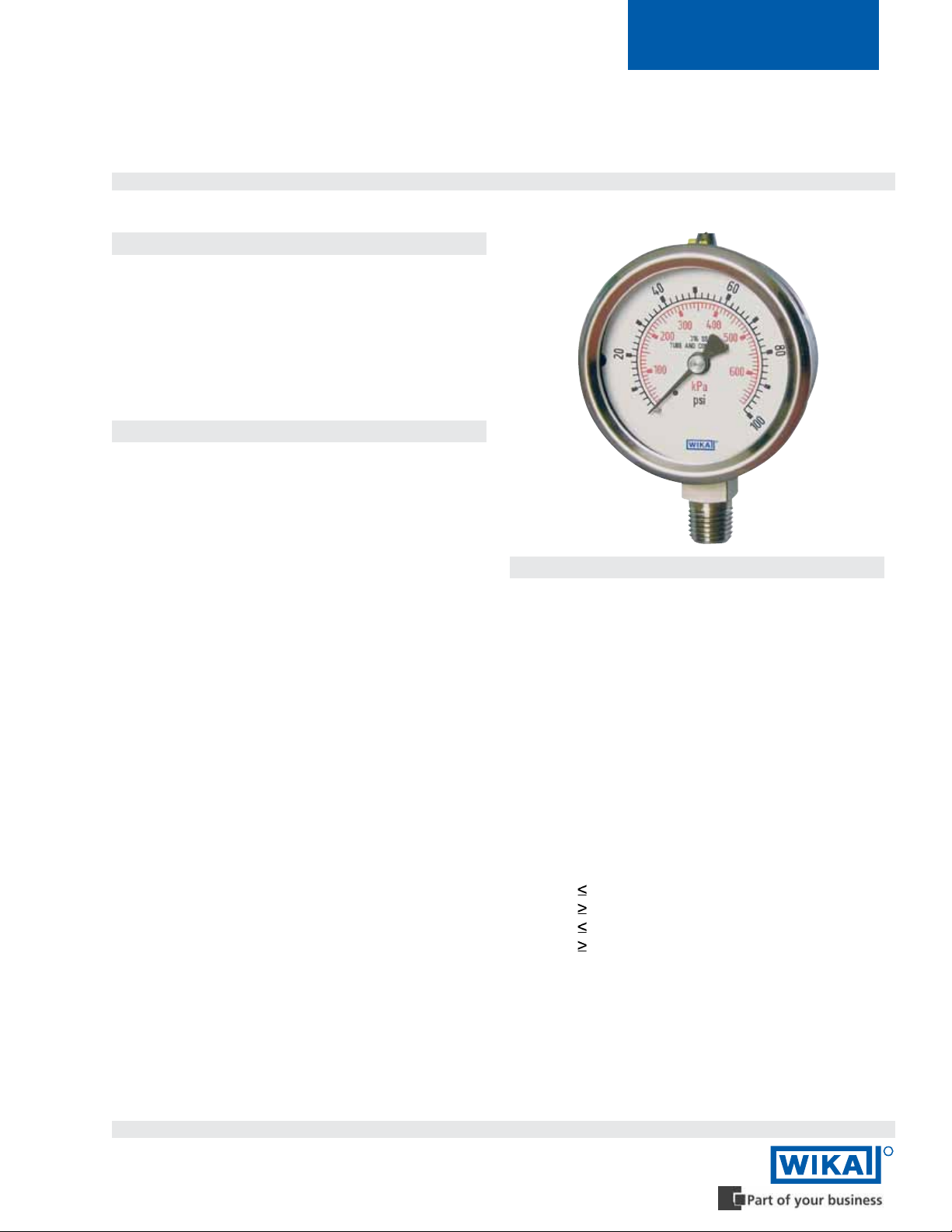

Bourdon Tube Pressure Gauges

Stainless Steel Series

Type 232.53 - Dry Case

Type 233.53 - Liquid-filled Case

Applications

With liquid filled case for applications with high dynamic

pressure pulsations or vibration

Suitable for corrosive environments and gaseous or

liquid media that will not obstruct the pressure system

Process industry: chemical/petrochemical, power

stations, mining, on and offshore, environmental technology, mechanical engineering and plant construction

Special features

Excellent load-cycle stability and shock resistance

All stainless steel construction

Positive pressure ranges to 15,000 psi

Mechanical

Pressure Measurement

WIKA Datasheet 23X.53

Standard Features

Design

ASME B40.100 & EN 837-1

Sizes

2”, 2½” & 4” (50, 63 and 100 mm)

Accuracy class

2” & 2½”: ± 2/1/2% of span (ASME B40.100 Grade A)

4”: ± 1.0% of span (ASME B40.100 Grade 1A)

Ranges

Vacuum / compound to 200 psi

Pressure from 15 psi to 15,000 psi

or other equivalent units of pressure or vacuum

Working pressure

2” & 2½”: Steady: 3/4 scale value

Fluctuating: 2/3 full scale value

Short time: full scale value

4 ”: Steady: full scale value

Fluctuating: 0.9 x full scale value

Short time: 1.3 x full scale value

Bourdon Tube Pressure Gauge Model 232.53

Temperature error

Additional error when temperature changes from reference

temperature of 68°F (20°C) ±0.4% for every 18°F (10°C) rising

or falling. Percentage of span.

Weather protection

Weather tight (NEMA 4X / IP65)

Pressure connection

Material: 316L stainless steel

Lower mount (LM) or center back mount (CBM)

Lower back mount (LBM) for 4” size

1/8” NPT, 1/4” NPT or 1/2” NPT limited to wrench flat area

Bourdon tube

Material: 316L stainless steel

2” & 2½”:

4”:

Movement

Stainless steel

1,000 PSI: C-type,

1,500 PSI: helical type

1,500 PSI: C-type,

2,000 PSI: helical type

Operating temperature

Ambient: -40°F to +140°F (-40°C to +60°C) - dry

-4°F to +140°F (-20°C to +60°C) - glycerine filled

-40°F to +140°F (-40°C to +60°C) - silicone filled

Medium: +212°F (+100°C) maximum

WIKA Datasheet 23X.53 · 05/2009

Dial

White aluminum with black lettering, 2” and 2½” with stop pin

Page 1 of 2

R

Pointer

Black aluminum

Case

304 stainless steel with vent plug and SS crimp ring

Welded case / socket connection

Window

Polycarbonate

Liquid filling

Glycerine 99.7% - Type 233.53

Dimensions

Optional extras

SS restrictor

SS front flange

SS rear flange (2½” and 4” only)

Zinc-plated steel or SS u-clamp bracket

(field installable - see note)

Cleaned for oxygen service

Red drag pointer or mark pointer (2½” and 4” only)

External zero adjustment (4” size only)

Other pressure connections

Silicone or Fluorolube case filling

Other pressure scales available:

bar, kPa, MPa, kg/cm² and dual scales

Note: U-clamp bracket for 2” must be ordered with gauge

Size

A B C D E G H J M N S T W Weight

2” mm 55 48 30 50 12 53 - 3.6 71 60 5.5 14 0.27 lb. dry

in 2.17 1.89 1.18 1.97 0.47 2.09 - 0.14 2.80 2.36 0.22 1/4” 0.55 0.33 lb. filled

2.5” mm 69 54 32 62 13 54 - 3.6 88.1 75 6.5 14 0.36 lb. dry

in 2.69 2.13 1.26 2.45 0.51 2.13 - 0.14 3.47 2.95 0.26 1/4” 0.55 0.44 lb. filled

4” mm 107 87 48 100 15.5 79.5 30 4.8 132 116 8 22 1.10 lb. dry

in 4.21 3.43 1.89 3.91 0.61 3.13 1.18 0.19 5.20 4.57 0.31 1/2” 0.87 1.76 lb. filled

Recommended panel cutout is dimension D + 1 mm

WIKA Datasheet 23X.53 · 05/2009Page 2 of 2

Ordering information

Pressure gauge model / Nominal size / Scale range / Size of connection / Optional extras required

Specifications and dimensions given in this leaflet represent the state of engineering at the time of printing.

Modifications may take place and materials specified may be replaced by others without prior notice.

WIKA Instrument Corporation

1000 Wiegand Boulevard

Lawrenceville, GA 30043

Tel (770) 513-8200 Toll-free 1-888-WIKA-USA

Fax (770) 338-5118

E-Mail info@wika.com

www.wika.com

R

Loading...

Loading...