Page 1

IX.ReplacementParts 4½” 6”

Threaded ring 2086000 4006755

Acrylic window 4000021 2246104

Instrument glass window 0561134 1111710

Laminated safety glass window 0561150 0154075

Restrictor (SS) (0.6 mm I.D.) standard 0029122 0029122

Restrictor (SS) (0.3 mm I.D.) "super" 0165514 0165514

Restrictor (Monel

Restrictor (brass) (0.6 mm I.D.) 4324 4324

Window o-ring 0564354 2016818

Adjustable pointer 2087431 1656244

Case (blow-out back separate) 2085993 4006747

Fill plug 0589705 0589705

Vent plug 0659835 0659835

Socket o-ring 1063707 1063707

Blow-out back (LM) 2086018 2247283

Back o-ring (for dry gauges) 2208741 2208741

Membrane LM (for glycerine or silicone) 1053019 1053019

Membrane LM (for fluorocarbon) 1095390 1095390

Membrane LBM (for glycerine or silicone) 1654250 1654250

Filling kit LM (for glycerine & silicone) 1126768 1126768

Filling kit LM (for fluorocarbon) 1126776 1126776

Filling kit LBM (for glycerine & silicone) 2044480 2044480

Movement for vacuum ranges 4001842 2054761

Movement for 15 psi to 60 psi 4001851 2019868

Movement for 100 psi and up 4001869 2091941

X.Warning

Pressure gauges must be selected and installed so that the possibility of failure resulting in injury or damage

caused by misuse or misapplication is minimized. For correct selection and use of gauges, refer to ASME B40.1,

which can be obtained from The American Society of Mechanical Engineers, Three Park Avenue, New York, NY

10016 - 5990. Important factors for proper gauge selection are:

Process: Wetted parts must be compatible with the measured media.

Pressure: The range of the gauge should generally be twice the working pressure. The working pressure in all

cases should be limited to 75% of the gauge range. Where alternating pressure and pulsation are encountered,

working pressure should be limited to 2/3 of the gauge range.

Pulsation/Vibration: Pressure pulsation and vibration could result in fatigue failure of the measuring system.

Therefore, dampening provisions such as liquid filling of the gauge, installing flow restricting devices or isolating

from the vibration source should be considered.

Temperature: Excessive temperature exposure may result in damage to the measuring system and/or gauge

outer parts, case, gasket, and window. Preventive temperature lowering devices such as the WIKA cooling element or a pigtail siphon should be considered.

LiquidFill: Be sure that the filling liquid can safely mix with the process fluid.

®

) (0.6 mm I.D.) 0607797 0607797

Operating&Installation

Instructions

XSELTMProcessGauge

Type2XX.34

SIZE4½"&6"SOLIDFRONT

WIKAInstrumentCorporation

1000 Wiegand Boulevard

Lawrenceville, Georgia 30043-5868

1-888-WIKA USA, (770) 513-8200 (in Georgia)

FAX (770) 338-5118

http://www.wika.com

In keeping with and for purposes of product improvement,

WIKA reserves the right to make design changes without notice.

Instruction Sheet – 03/10 P/N 2207290 Rev 5 Instruction Sheet available at http://www.wika.com

Revision Date: March 1, 2010

R

Page 2

I.General

WIKA gauges are designed and

built to deliver long and reliable

service under conditions of severe

stress. For inquiries concerning

gauge selection and operation,

the American Society of Mechanical Engineers specification ASME

B40.100 should be consulted.

Additional information can be

obtained from WIKA Instrument

Corporation, Lawrenceville, Georgia, or from any authorized WIKA

distributor.

II.Installation

Gauges should always be mounted

by using the wrench flats (squares)

provided on the pressure connection. Under no circumstances

should the pressure connection be

tightened by applying force to the

gauge case.

It is preferable to mount gauges in

a location free of mechanical vibration. If this is not possible, a liquid

filled gauge or a flexible tube connection may be necessary.

The gauge should be located so

that it is not exposed to abnormally

low or high temperatures. This may

cause an additional temperature

error, depending on the deviation

from the reference temperature of

73°F (23°C). For steam service,

the gauge must be protected by a

water-filled siphon.

If severe pulsation is present, the

gauge should be equipped with a

properly sized orifice restrictor.

III.Maintenance

All gauges should be checked regularly for wear and tear, accuracy,

and proper functioning by comparing them to a precision test gauge

or a dead weight tester. Replace

all broken or damaged parts immediately.

IV.Disassembly

Tools Needed

- Bench vise

- Flat head screwdriver

- Threaded Ring Tool: WIKA p/n

1031589 (4.5”); 2206226 (6”)

- Pointer Puller Tool: WIKA p/n

9091823

- Pointer Puller Handle: WIKA

p/n 2246954

- Arbor Press: WIKA p/n 1325116

- Press Plate: WIKA p/n

1410946

NOTE: WIKA has developed special service tools which make

gauge repair and conversion much

easier. Tools are available from

WIKA or your local distributor for a

nominal charge.

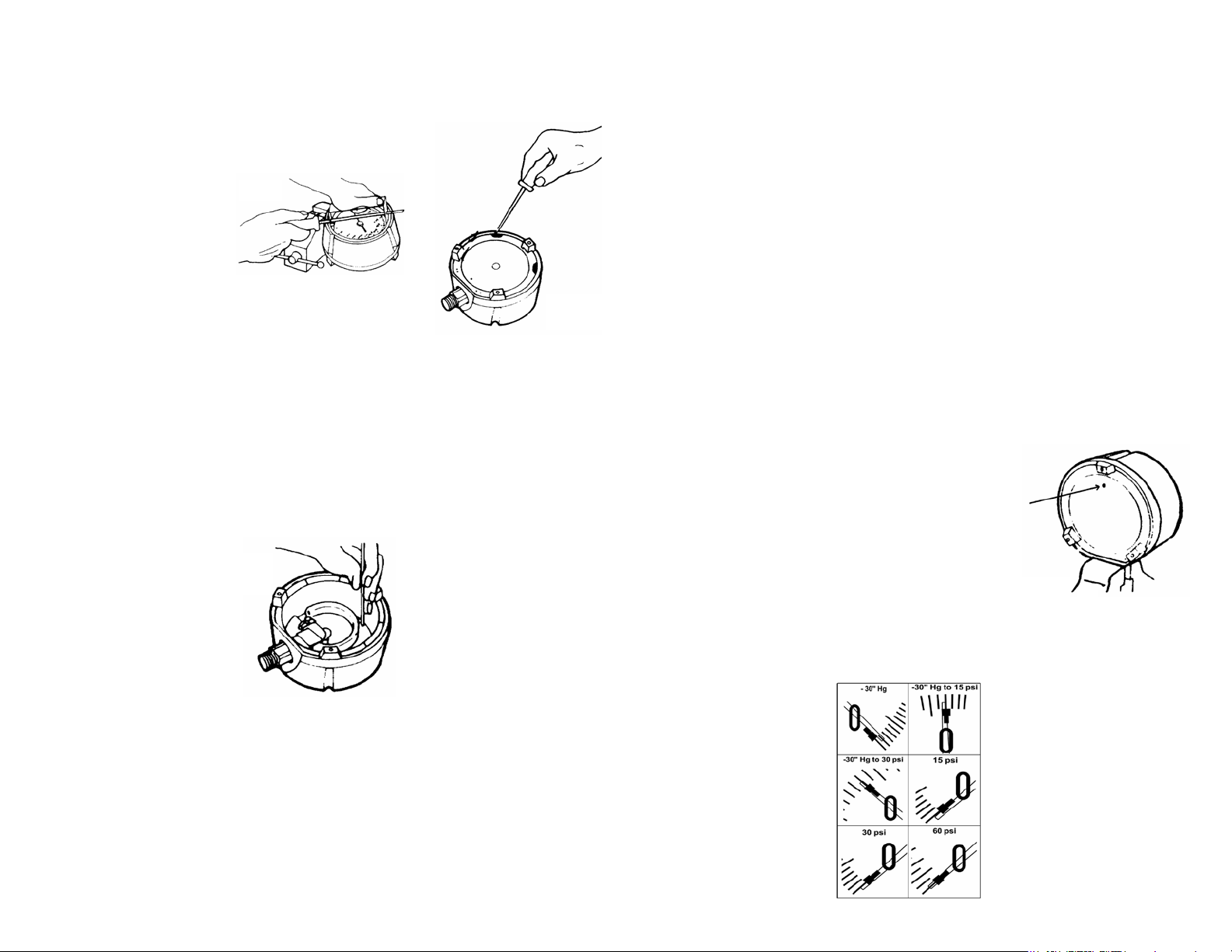

1.ThreadedRingRemoval

Place the gauge into the bench

vise face-up by clamping the connection (gauge stem) firmly on the

wrench's flat sides.

FIG. 1

Seat the Threaded Ring Tool into

the ring between the tightening

notches. Insert the screwdriver

into the Threaded Ring Tool for

better leverage, and loosen the

threaded ring counterclockwise.

You can unscrew the ring once it is

loose by using the Threaded Ring

Tool without the screwdriver.

2.WindowRemoval

If the window sticks to the o-ring

and will not come out, you will

have to remove the blow-out back.

See step 3.

There is an overflow hole located

on the "solid front" wall on the

gauge at the 12 o'clock position.

Insert a small screwdriver into

FIG. 2

this hole, and carefully push the

window out.

3.Blow-outBackRemoval

To remove the blow-out back,

you will need a bench vise and a

screwdriver. Before starting, look

at the back of the gauge. Please

note the two small openings next

to the two upper snap-in tabs in

the blow-out back.

Insert the screwdriver into the

opening and pry out the tab (Fig.

3). Repeat this step on the other

side and the blow-out back will

pop out.

4.PointerRemoval

To remove the adjustable pointer

you will need to use the Pointer

Puller Tool (WIKA p/n 9091823)

and Pointer Puller Handle (WIKA

p/n 2246954). Remove the tip of

FIG. 3

the Pointer Puller Handle so that

it functions similar to that of pliers. Insert the tip of the Pointer

Puller Handle into the center of

the pointer. Then insert the notch

of the Pointer Puller Tool between

the pointer shaft and the other end

above the Pointer Puller Handle.

Squeeze gently on the Pointer

Puller Tool and the adjustable

pointer should pop upward.

5.DialRemoval

To remove the dial, you will need

a small flat head screw driver. On

both sides of the pointer shaft

there are two small screws. Remove both of these screws and

the dial can then be lifted straight

up from the case.

6.DialRotation

To rotate the dial on the gauge,

remove both screws on each side

of the pointer shaft. Rotate the dial

in increments of 90 degrees until

you reach the desired position.

Line up the holes of the dial with

those of the case and then insert

the screws and tighten.

7.RestrictorRemoval&Cleaning

To remove the restrictor, insert a

small flat headed screwdriver into

the bottom center of the socket.

Turn the restrictor counterclockwise to loosen and remove. To

clean debris from the restrictor,

push a thin metal wire through one

end until it protrudes out the other

side. If this is not possible, the

restrictor should be replaced. See

"Replacement Parts" for restrictor

material and part number.

V.Assembly

1.DialAssembly

To assemble the dial, place it back

into the case in the same position

as it was originally removed. Line

up the screw holes of the dial and

case. Place the screws into the

holes and tighten.

2.PointerAssemblyand

Adjustment

To install the pointer, gently place

the pointer onto the shaft. Rotate

the pointer until the tip is exactly

on zero. Lightly tap the center

of the pointer with the end of a

screw driver to secure the pointer

to the shaft. If, after installing

the pointer, it is not exactly on

zero, there is an adjustment screw

located on the pointer. While gently holding the pointer, turn the

adjustment screw clockwise to

increase pressure or counterclockwise to decrease pressure

until the pointer tip is exactly on

the zero mark.

3.ThreadedRingAssembly

First make sure the O-ring is properly seated in the groove located

just below the window thread

rings. Place the window such that

the flat side comes in contact with

the O-ring and the window mold

mark circle in the 6 o'clock position. Then place the threaded ring

on the gauge and turn it in a clockwise direction until the threaded

ring comes in contact with the

grooved part of the window. The

threaded ring tabs should face up.

The threaded should turn easily

without binding. If you encounter

resistance before the threaded ring

touches the window, the threaded

ring has not been seated correctly.

Unscrew the threaded ring and repeat the step above. You can use

the Threaded Ring tool to hand

thighten the threaded ring. To seat

it firmly, insert a screwdriver in the

Threaded Ring Tool and tighten the

threaded ring by one-quarter turn

with 16 ft.-lbs of torque.

4.Blow-OutBackAssembly

First make sure the o-ring or membrane (for liquid filling) is seated

properly on the blow-out back

(lubricate the sealing surface of

the case or membrane with glycerine or silicone when installing a

membrane). Engage the two large

tabs near the base of the gauge

and press the back down with

your hands. Place the gauge in the

Arbor Press (p/n 1325116) and

align it underneath the press plate

(WIKA p/n 1205838). Press the

blow-out back onto the case until

all four tabs are engaged and the

blowout back is flush with the rear

of the case.

5.RestrictorAssembly

A restrictor is recommended for

all applications that will encounter

pressure surges, pulsations or fluctuations. To install a restrictor, locate

the bottom center of the socket

where you will notice a threaded

bore. Place the pointed end of

the threaded restrictor into the

bore and turn clockwise until tight

using a small flat headed screwdriver. Once tight, hand torque the

restrictor with 0.5 to 1.0 ft.-lbs of

torque to ensure it will not come

loose during operation.

VI.PreparedforLiquidFilling

Effective July 2007 all Lower

Mount (LM) process gauges will

come equipped with a membrane

so the gauge can be field-filled

without the addition of extra parts.

All process gauges prepared for

liquid filling will have printed on the

warning label “MEMBRANE INSTALLED FOR LIQUID FILLING”.

For all Lower Back Mount (LBM)

process gauges the membrane

(WIKA p/n 1654250) needs to be

installed to convert to a liquid-filled

gauge.

VII.Liquid-FilledConversion

To convert process gauges manufactured prior to July 2007 and all

Lower Back Mount (LBM) process

gauges to the liquid-filled case,

the membrane will need to be installed. First remove the blow-out

back as described in Section IV,

Item 3 (Blow-Out Back Removal).

Then replace the o-ring with the

membrane (WIKA p/n 1053019).

Lubricate the case or membrane

sealing surface with glycerine or

silicone. Then press the blow-out

back into the case as described in

Section V, Item 4, (Blow-Out Back

Assembly).

FIG. 4

VIII.LiquidFillingOfDryCase

For gauges with pressure ranges

of 60 psi or less, the pointer must

be pre-adjusted before liquid filling. To adjust the pointer, use the

adjustment screw on the pointer

as described in Section V, Item

2 (Pointer Assembly and Adjustment). Follow Fig. 4 in order to

compensate for the liquid fill.

Note that for the -30” Hg, set the

pointer above zero. For all other

ranges, set the pointer below zero

by the amount shown in Fig. 4.

Remove the filling plug from the

top of the gauge (12 o'clock) with a

small screwdriver. Turn the gauge

over onto its face. On the back

cover of the gauge, you will see

a small vent hole on the blow-out

back (Fig. 5). If you have the liquid

filling kit, use the vent plug provided with the kit to close the vent

hole. If you do not have the kit, you

can seal the hole with a piece of

tape or cover it with your finger

while filling. This allows the membrane to maintain an air–pocket

which will help alleviate temperature induced zero shifts.

FIG. 5

Fill the gauge with the correct fluid

for your application using a small

funnel or tube. The gauge must

be filled in an upright position. Be

careful not to touch the Bourdon

tube, as this may cause a shift in

the gauge calibration. The fluid

level should be as full as possible

Once you have the correct fluid

level, clean the area around the

filling hole, and insert the filling

plug. Make sure the plug is seated

squarely. Next, remove the vent

plug or object used to block the

vent hole located on the blow-out

back. The final step is to check the

zero position of the pointer. If the

pointer is not within the tolerance

field of the zero mark, the pointer

must be readjusted. To do this,

drain the gauge, reversing the

steps above, adjust the pointer

and then repeat the procedure

from the start.

Loading...

Loading...