Page 1

Operating

instructions

GB

Pressure gauge models 1 and 213

per directive 94/9/EC (ATEX)

II 2 GD c TX

31014275.01 08/2011 GB/D

Contents

1. Safety

2. Description

3. Specications and intended use

4. Commissioning

5. Maintenance and cleaning

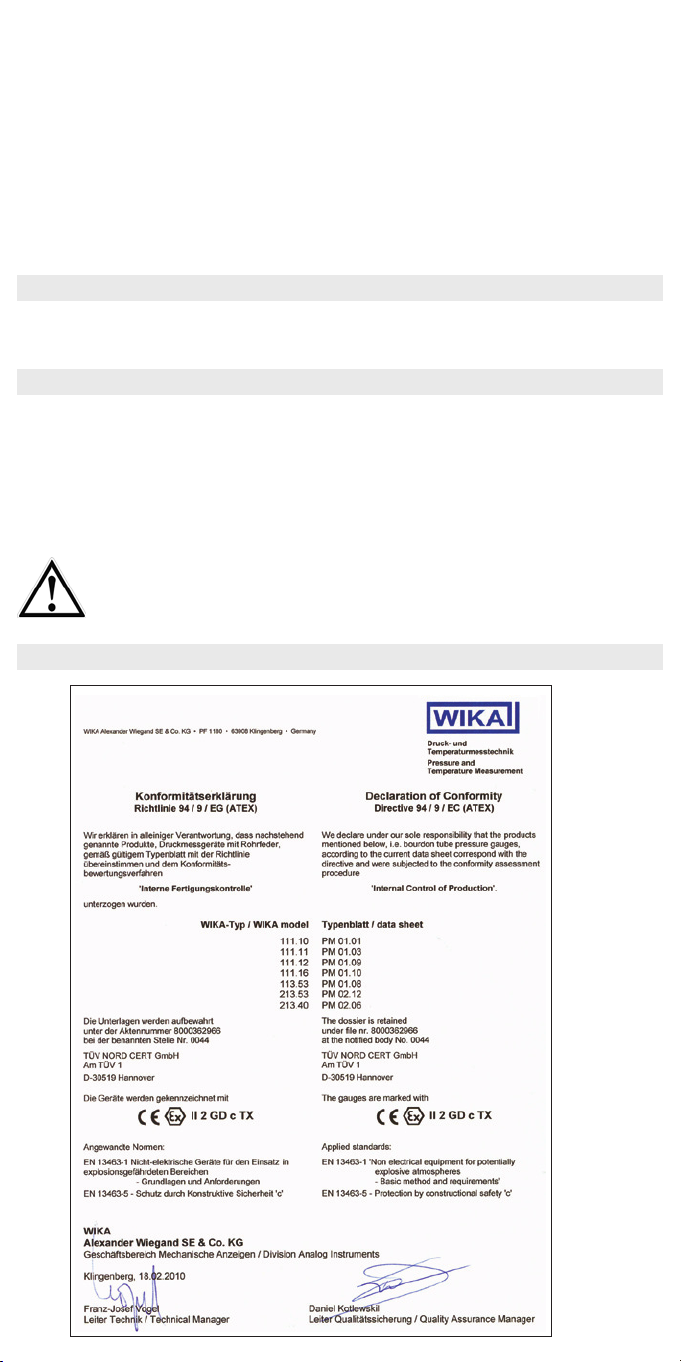

Appendix 1: Declaration of conformity for

models 111.xx, 113.53, 213.40 and 213.53

Declarations of conformity see www.wika.com

Specications: see data sheet on www.wika.com

Subject to technical modications.

© 2011 WIKA Alexander Wiegand SE & Co. KG

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg • Germany

Tel. (+49) 9372/132-0

Fax (+49) 9372/132-406

E-Mail info@wika.de

www.wika.de

1. Safety

WARNING!

Before installation, commissioning and operation, ensure that the appropriate

pressure gauge has been selected in terms of measuring range, design and

specic measuring conditions.

■

Check the compatibility with the medium of the materials subjected to pressure!

■

In order to guarantee the measuring accuracy and long-term stability specied, the

corresponding load limits must be observed.

■

Non-observance can result in serious injury and/or damage to the equipment.

■

Only qualied persons authorised by the plant manager are permitted to install, maintain

and service the pressure gauges.

2. Description

■

Nominal sizes

Model 111.10: NS 40, 50, 63, 80, 100, 160 Model 113.53: NS 40, 80, 100

Model 111.11/16: NS 40, 50, 63 Model 213.40: NS 63, 80

Model 111.12: NS 40, 50, 63, 80, 100 Model 213.53: NS 50, 63

■

The instruments measure the pressure by means of resilient Bourdon tube pressure

elements

■

The measuring characteristics are in accordance with the EN 837-1 standard

3. Specications and intended use

Pressure limitation

Steady: 3/4 x full scale value

Fluctuating: 2/3 × full scale value

Short time: Full scale value

Mechanical connection

In accordance with the general technical regulations for pressure gauges (e.g. EN 837-2

"Selection and installation recommendations for pressure gauges").

When screwing gauges in, the force

required for this must not be applied through

the case, but rather through the spanner

ats (using a suitable tool) provided for this

purpose on the square shaft of standard

connections.

Installation with

open-ended

spanner

Page 2

Correct sealing of pressure gauge connections with parallel threads must be made using

suitable at gaskets, sealing rings or WIKA prole sealings. The sealing of tapered threads

(e.g. NPT threads) is made by providing the thread with additional sealing material such

as, for example, PTFE tape (EN 837-2).

Spanner ats

Sealing face

Sealing in the

thread

The torque depends on the seal used. Connecting the gauge using a clamp socket or a

union nut is recommended, so that it is easier to orientate the gauge correctly.

When a blow-out device is tted to a pressure gauge, it must be protected against being

blocked by debris and dirt.

After mounting, set the compensating valve (if available) from CLOSE

to OPEN.

Temperature eect

When the temperature of the measuring system deviates from the reference temperature

(+20 °C):

max. ±0.4%/10 K of full scale value

Ingress protection per EN 60529 / IEC 529

Model 111.xx: IP 42

Models 113.53, 213.40 and 213.53: IP 65

Permissible temperatures

Ambient:

Model 111.xx: -40 ... +60 °C

Models 113.53, 213.40 and 213.53: -20 ... +60 °C

Medium: max.

+60 °C

Attention! With gaseous substances, the temperature may increase as a result of

compression warming. In these cases it may be necessary to throttle the rate of change

of pressure or reduce the permissible medium temperature.

The eective maximum surface temperature is not only dependant upon these instruments,

but mainly on the respective medium temperature!

Materials

Wetted parts: Cu-alloy

Movement: Cu-alloy

Dial: NS 40, 50, 63: Plastic

NS 80, 100, 160: Aluminium

Pointer: Plastic (NS 160: Aluminium)

Case: Models 111.10, 111.12, 111.16: Plastic

Model 111.11: Steel

Models 113.53, 213.53: Stainless steel

Model 213.40: Forged brass

Window: Plastic (NS 160: Instrument glass)

Installation

■

Nominal position per EN 837-1 / 9.6.7 Figure 9: 90° ( ⊥ )

■

Process connection lower mount (LM) or back mount (BM)

■

In order to avoid any additional heating, the instruments must not be exposed to direct

solar irradiation while in operation!

■

Pressure gauges must be earthed via the process connection!

Permissible ambient and operating temperatures

When mounting the pressure gauge it must be ensured that, taking into consideration the

inuence of convection and heat radiation, no deviation above or below the permissible

ambient and medium temperatures can occur. The inuence of temperature on the

indication accuracy must be observed.

Page 3

Permissible vibration load at the installation site

■

The instruments should always be installed in locations free from vibration.

■

If necessary, it is possible to isolate the instrument from the mounting point by installing

a exible connection line between the measuring point and the pressure gauge and

mounting the instrument on a suitable bracket.

■

If this is not possible, the following limit values must not be exceeded:

Dry gauges: Frequency range < 150 Hz

(Model 111) Acceleration < 0.7 g (7 m/s

Liquid-lled gauges: Frequency range < 150 Hz

(Model 113, 213) Acceleration < 4 g (40 m/s

2

)

2

)

The liquid lling must be checked on a regular basis.

The liquid level must not drop below 75 % of the gauge diameter.

4. Commissioning

During the commissioning process pressure surges must be avoided at all costs. Open the

shut-o valves slowly.

5. Maintenance and cleaning

■

The instruments are maintenance-free.

■

The indicator should be checked once or twice every year. For this the instrument must

be disconnected from the process to check with a pressure testing device.

■

Clean the pressure gauge with a moist cloth.

■

Repairs must only be carried out by the manufacturer or appropriately qualied skilled

personnel.

■

When dismounting, close the compensating valve (if available).

WARNING!

Residual media in dismounted pressure gauges can result in a risk to persons,

the environment and equipment.

Take sucient precautionary measures.

Appendix 1: Declaration of conformity

Loading...

Loading...