Wijas POW-LCD 12, POW-LCD 15, POW-LCD 18, POW-LCD 21, POW-LCD 24 Installation And Operation Manual

Flow water heaters type

POW-LCD 12, 15, 18, 21, 24

INSTALLATION

AND OPERATION

MANUAL

2

Before using the heater, please read the instructions carefully. In the future

it will benet by its failure-free operation for a long time.

Flow water heaters series POW 12, 15, 18, 21, 24 – LCD are intended for heating tap water.

They can supply hot water to several water outlets located in different rooms. These heaters

are equipped with heating coils which are directly washed by water. Such direct process of

heating prevents scale formation and ensures high efciency and speed of heating water. The

microprocessor system analyses the temperature of inlet and outlet water, the set temperature,

and water consumption of the user. Based on the collected data, it increases or decreases

the heating power in such a way that the water temperature at the outlet corresponded to

the temperature set by the user. Such control of the heater operation ensures the comfort of

use and energy saving. Additionally, the heater is equipped with air lock sensors which limit,

to the minimum, the possibility of damage of the heating elements due to air locking of the

water distribution system, as well as the system adjusting the temperature drop caused by

the drop of supply voltage.

Heaters can additionally heat water that was pre-heated, e.g. with the use of the solar system

which at the heater inlet cannot exceed 60OC.

• The device cannot be installed in rooms in which the temperature may

fall below 0OC and in which there is the risk of explosion.

• This equipment is not intended to be used by persons (including children) of lower physical, sensory or mental capability, unless they operate

it under supervision.

• Attention should be paid to children not playing with the equipment.

Installation instructions

The installation and start-up of the POW-LCD heater should be done by a person qualied in

accordance with the guidelines contained in the Manual. All installation works should be carried out with disconnected power and water supplies. The heater electrical installation should

be conducted in accordance with the binding regulations. The device should be permanently

connected to electrical wiring with ground terminal. The electrical wiring should be equipped

with residual current circuit breaker protecting against electric shock and with a switch ensuring the disconnection of the device from the power source, in which the distance between the

contacts should be not less than 3 mm.

1. To the place in which the heater is to be installed lead electrical wiring and water distribu-

tion system, using for that the mounting template.

2. Drill holes and mount expansion plugs.

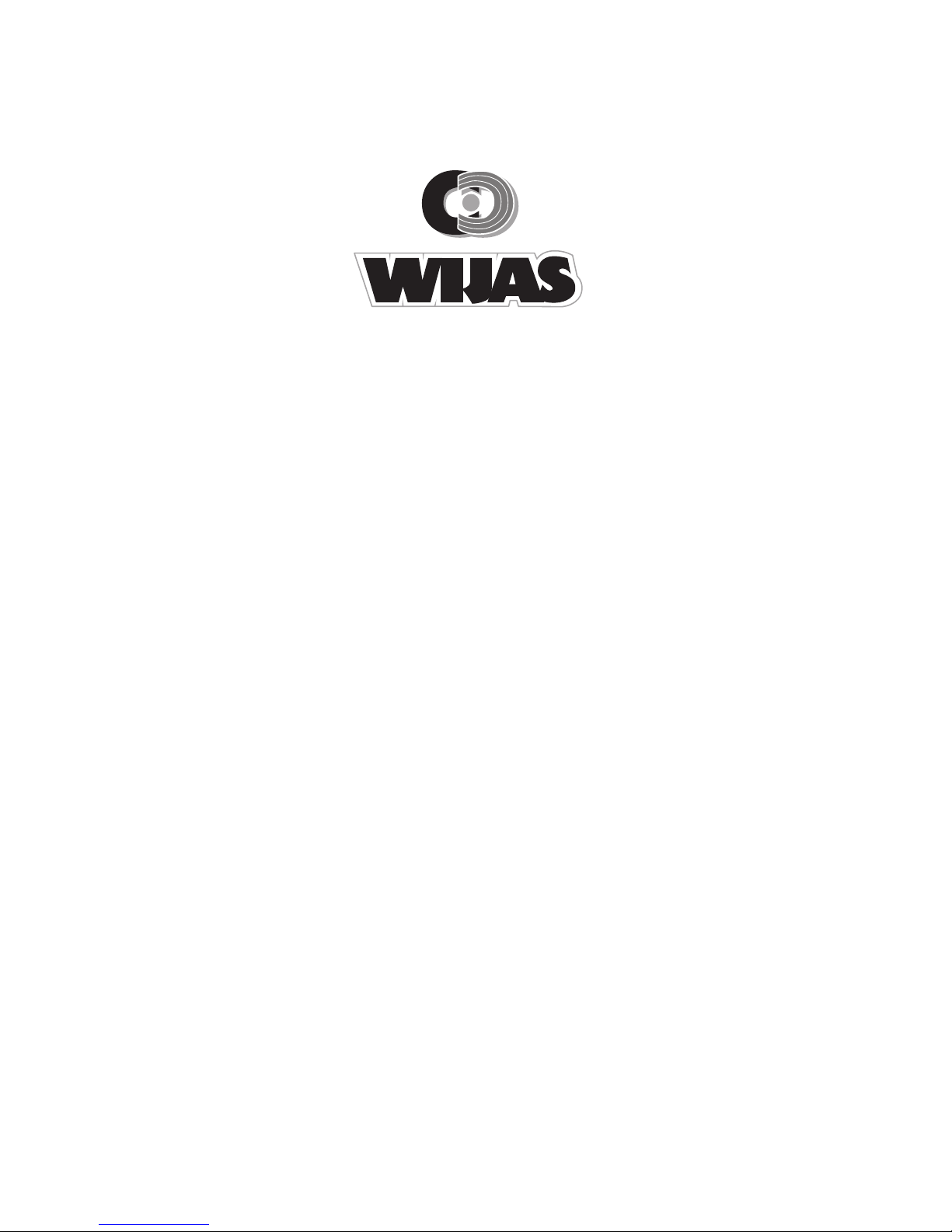

3. Install the control valve with a lter on cold water supply (Fig. 3).

4. Unscrew the fastening screw which holds the housing of the heater located at the bottom

of it (Fig. 1), take off the cover and disconnect the ribbon cable by taking the plug out of

the socket marked “LCD” (Fig. 2).

5. Screw the heater to the wall with the use of fastening screws, having earlier run the ower

cable through the hole.

3

6. Check the starting of pressure switch.

7. Remove the securing blanking plugs from water pipes.

8. Connect the heater to the water distribution system (Fig. 5 outlet service line marked 14,

outlet marked 15)

9. Switch on the water supplying the heater and check the tightness of the connections.

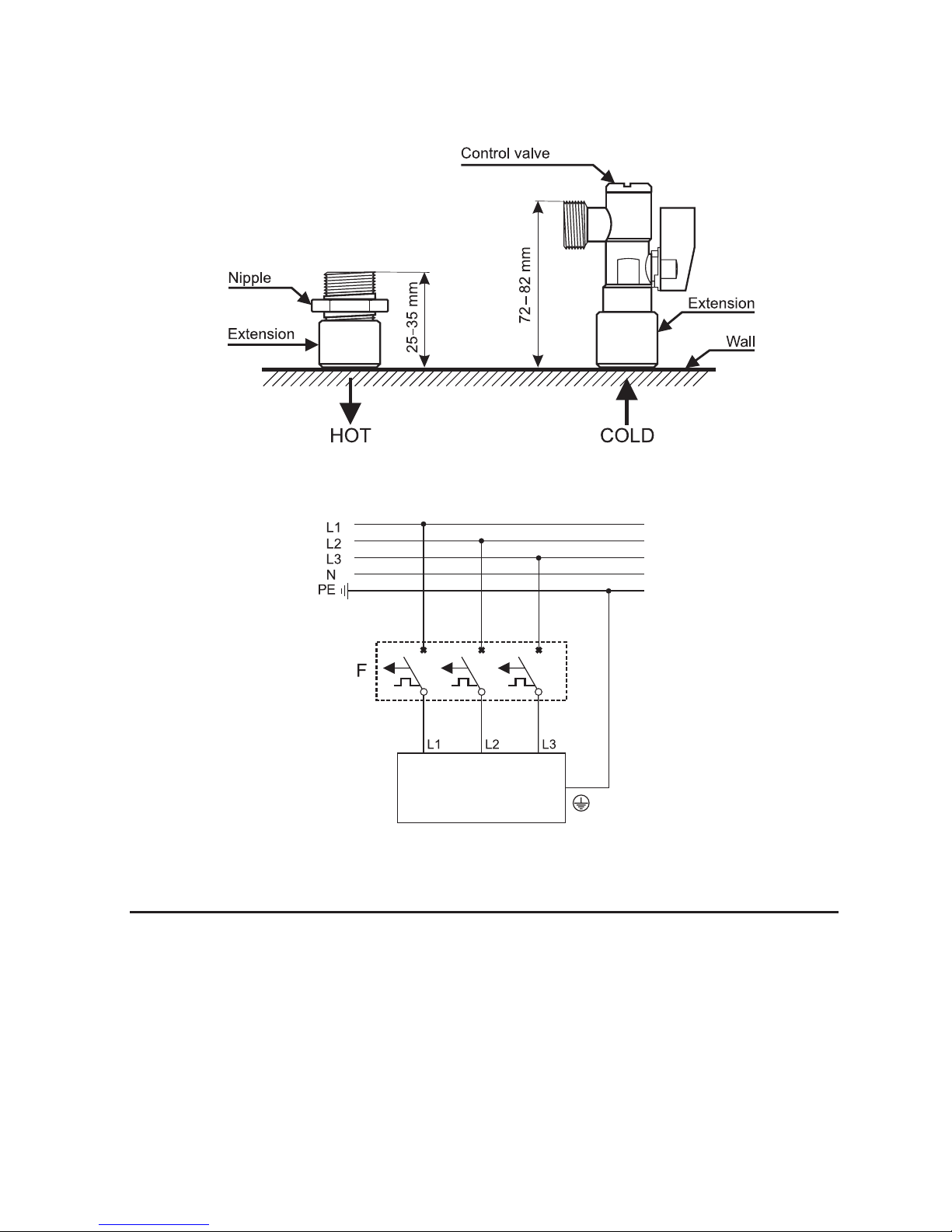

10. Connect the heater to the electrical wiring in accordance with Figure 4.

11. Connect the ribbon cable by inserting the plug with the proper side to the socked marked

“LCD”, see (Fig. 2).

12. Put on the housing and screw it with a fastening screw.

Fig. 2 Display board

with ribbon cable

1. Plug

2. Socket marked “LCD”

3. Display board

Fig. 1 Heater housing

1. Display

2. Button increasing the set temperature

3. Button decreasing the set temperature

4. Memory buttons of the set temperature

5. The screw fastening the housing

4

Fig. 3.

Fig. 4 Diagram of electrical wiring

Start-up

In order to remove air from the water distribution system and the heater, before turning the

power on, open the hot water valve for approx. 20 seconds in order to remove air bubbles

from the system. Then, turn the power on. Open the hot water valve waiting till the device has

achieved full operational readiness (approx. 5 seconds) beginning the process of heating – in

the lower part of display lines will be shown indicating (in percent) the heating power of the

heater. Close the hot water valve. The heating process is automatically turned off – the lines

previously indicating the heating power will disappear from the display.

Water heater

5

Use

Setting the temperature of water is done by pressing one of the buttons located under the

display marked “–” and “+ ” (Fig. 1) in the range from 30OC to 60OC accurate every 0.5OC.

Detecting the ow greater than 2.7 l/min by the heater system will result in switching off the

device.

The lines of the barograph (lower part of the display) show the power with the heater heats

the water. The appearance of one line means the heater is heating with the power not smaller

than 10% and not greater than 20% of the rated power. The appearance of ve lines means

the heater is heating with the power not smaller than 50% and not greater than 60% of the

rated power. The appearance of all ten lines means the heater is heating with full power.

The signalling by the heater that it is heating with full power is the information for the user

to decrease the consumption of water or decrease the set temperature because the power

of the device at a given moment is not small to heat up water to the desired temperature.

After each start or change of the set temperature, the heater measures temperature of outlet

water every 10 seconds.

If two temperature measurements are the same it means the temperature has stabilized and

the electronic system can compare it with the set temperature. In case when the obtained

temperature is smaller from the set temperature due to the drop of the mains voltage, the heater

increases the power automatically, so that the water temperature achieved the desired value.

In case when the inlet temperature exceeds 55OC, the heater will turn off till the moment when

the temperature of supply water will fall below 55OC.

Programming T1, T2, T3 buttons

The heater can save three values of temperatures selected by the user. To save, as well as

select temperatures the buttons marked T1, T2, T3 are used. In order to assign the temperature value to any of the buttons (T1, T2, T3):

1. Set the desired temperature on the display by pressing “–” or “ + ”

2. Hold down any of the selected buttons ( T1, T2, T3) for approx. 4 seconds till the moment

when the digits on the display will go out for a moment signalizing by that that the value of

the temperature set on the display has been assigned to the memory of the pressed button.

After short pressing of any of the buttons (T1, T2, T3), the programmed temperature will be

displayed, and thereby the set temperature with which the heater is to heat the water.

In order to re-program any of the buttons (T1, T2, T3), follow the instructions given in points

1 and 2.

Water

temperature

at the inlet

Water temperature at the outlet

40OC 50OC

12 kW 15kW 18kW 21kW 24kW 12kW 15kW 18kW 21kW 24kW

5OC 4,9 6,2 7,4 8,7 9,9 3,9 4,8 5,8 6,7 7,7

10OC 5,8 7,2 8,6 10 11,5 4,3 5,4 6,5 7,6 8,7

15OC 6,9 8,7 10,5 12,1 13,8 4,9 6,2 7,4 8,7 9,9

Hot water capacity (in litres per minute) depending on the temperature of inlet water

6

Display service mode

The simultaneous pressing of buttons marked “–” and “ + ” for about 1 second will make the

display shift from the basic mode (the information about the set temperature and power is

displayed) to the service mode enabling to show such data as:

– ow rate

– inlet water temperature

– outlet water temperature

– installed power

– staring additional sensors (air lock sensors)

In the service mode the display shows different data for approx. 3 separating them by shortly

displaying “0.0”. After displaying the last piece of data, the display automatically shifts to the

basic mod.

Flow

0.0

Input water temperature

0.0

Output water temperature

0.0

Installed power

0.0

Installation of airlock sensors

Basic mode

7

Cleaning the water lter

In a situation when the lter has become fully or partially blocked:

1. Disconnect the power supply.

2. Unscrew the fastening screw located at the bottom of the housing (Fig. 1), then take off

the housing holding it at such a distance from the heater that the ribbon cable connecting

the display with the heater was not tightened, and then disconnect the cable by plugging

it out of the socket marked “LCD” (Fig. 2).

3. Close the control valve (marked 1).

4. Unscrew the control valve plug (marked 2).

5. Take out the mesh lter (marked 3).

6. Remove dirt.

7. Insert the mesh lter.

8. Screw the valve plug.

9. Open the control valve and check the tightness of connections.

10. Connect the ribbon cable of the display board (Fig. 2).

11. Close the housing.

12. Remove entrapped air from the heater, and then start it in accordance with chapter

“Starting”.

Fig. 4 Control valve with the lter

1. Control valve knob

(position: ow closed)

2. Valve plug

3. Mesh lter

Malfunctioning of the heater

Removing the causes of the malfunctioning of the heater given below is not included in the

manufacturer’s guaranty. Should none of the following occur, please contact the service point.

Display does not light:

– disconnected ribbon cable connecting the controller board with the display (Fig. 2).

– failure of the electrical wiring powering the heater.

8

Too small ow of water:

– blocked water lter.

– too small water pressure.

– control valve closed too tightly.

– main valve not completely open.

The heater does not heat or heats poorly:

– wrong hydraulic, failure of the electrical wiring powering the heater.

The heater does not heat the water to the set temperature:

– too big drop of the mains voltage after the start of the heater.

– too big ow of water (see: point “Use”).

The display shows the number bigger than or equal to 75.0 – the heater is blocked.

– the heater has an additional thermal protection which works in the following way: when

outlet water reaches the temperature equal to or higher than 75OC the electrical system

will block. Not until it is turned off and then turned on again after the fall of temperature

below 75OC it will unblock. If such a situation occurred due to supplying pre-heated water

of the temperature higher than the permissible temperature, it needs to be decreased. In

other cases, please contact the service point.

Heater POW-LCD 12 15 18 21 24

Rated power kW 12 15 18 21 24

Supply voltage 400 V 3~

Frequency Hz 50

Power consumption A 17,3 21,6 26 30,3 34,6

Minimum cross-section

of connecting cables

mm

2

4 x 2,5 4 x 2,5 4 x 4 4 x 4 4 x 6

Maximum cross-section

of connecting cables

mm

2

4 x 10

Rated power of the

miniature circuit breaker

A 20 25 32 40 40

Minimum water resistance at 15OC

Ωcm

1300

Pressure of the supplying water MPa 0,1 – 0,7

Minimum starting ow l/min 2,7

Maximum temperature

of the supplying water

O

C 60

Water pipe G ½”

Dimensions

(height x width x depth)

mm 447 x 235 x 104

Weight kg 3,8

Technical data

9

Internal structure of the device

1. Lower housing.

2. Upper housing (g. 1)

3. Display board with keyboard.

4. Heating unit.

5. Flow switch.

6. Air lock sensors.

7. Inlet water temperature probe.

8. Outlet water temperature probe.

9. Outlet water thermal switch.

10. Pressure switch.

11. Terminals will be parts of the pressure

switch.

12. Hole for inserting the power cord.

13. Controller board.

14. Supply water pipe (cold)

15. Outlet water pipe (hot)

16. Protective conductor terminal.

10

Fig. 7 Schematic diagram of POW 12

1 – thermal switch

2 – display board and keyboard

3 – ow switch (turbine)

4 – inlet water temperature probe

5 – outlet water temperature probe

6, 7 – ow switch and air lock sensor

8 – heating unit

9 – heater controller

10 – pressure switch

PE – protective conductor terminal

E – electrode

G1, G2, G3 – heating elements

11

Fig. 8 Schematic diagram of POW 15, 18, 21, 24

1 – thermal switch

2 – display board and keyboard

3 – ow switch (turbine)

4 – inlet water temperature probe

5 – outlet water temperature probe

6, 7 – ow switch and air lock sensor

8 – heating unit

9 – heater controller

10 – pressure switch

PE – protective conductor terminal

E – electrode

G1, G2, G3, G4 – heating elements

12

Contents of the packaging

Heater POW-LCD pcs. 1

Control valve pcs. 1

Fastening screws with expansion plugs pcs. 3

Gaskets pcs. 2

Template pcs. 1

Operating instructions pcs. 1

Guaranty card pcs. 1

IMPORTANT INSTRUCTIONS

CONCERNING THE DETERIORATED DEVICE

Pursuant to the provisions of the Act dated 29 July 2005 on waste electric and elec-

tronic equipment, it is forbidden to put together with municipal waste the deteriorated

equipment marked with the symbol of the crossed out bin.

A user who intends to get rid of the product, should take the waste electric or

electronic equipment to the point collecting the waste equipment. Collection points are

run, among others, by wholesalers or retailers of such equipment as well as by gmina

organizational units conducting the activity in the scope of collecting waste.

The above statutory obligations have been introduced in order to limit the amount

of waste created from deteriorated electric and electronic equipment, as well as to

ensure the proper level of collecting, recovering and recycling the waste equipment.

In the equipment there are no dangerous elements which have a particularly negative

effect on health and the environment.

The materials used in the device are re-usable. Thanks to re-use, re-use of materi-

als, or other forms of use of the deteriorated devices, you contribute signicantly to the

protection of our environment.

Loading...

Loading...