Page 1

EN_s072-093_Dreh_2012 16.02.12 09:58 Seite 72

Wiha torque screwdrivers.

Wiha makes it possible: Optimum fitting for perfect work.

Drive

Torque screwdrivers

Torque VDE screwdrivers

Torque ESD screwdrivers

Slotted Phillips PHXeno PH Pozidriv

48 80, 82 80, 82 80, 83 80, 83 80, 82

85 – 87 85 –87 86 86 – 87 86 –87 86 – 87

89 89 89 89

Xeno PZ

PZ

T-handle torque tools

72

TORX®TORX

95 95 95

PLUS

®

For inter-

nal hex

screws

For internal

square

screws

86

Page 2

EN_s072-093_Dreh_2012 16.02.12 09:58 Seite 73

Torque screwdriver assortment

www.wiha.com

NEW

NEW

Wiha torque screwdrivers.

Torque Exact and with high repeat precision.

....................................................................................

Wiha torque screwdrivers.

Diverse areas of application in trade and industry.

Wiha torque screwdrivers.

For every application the correct model.

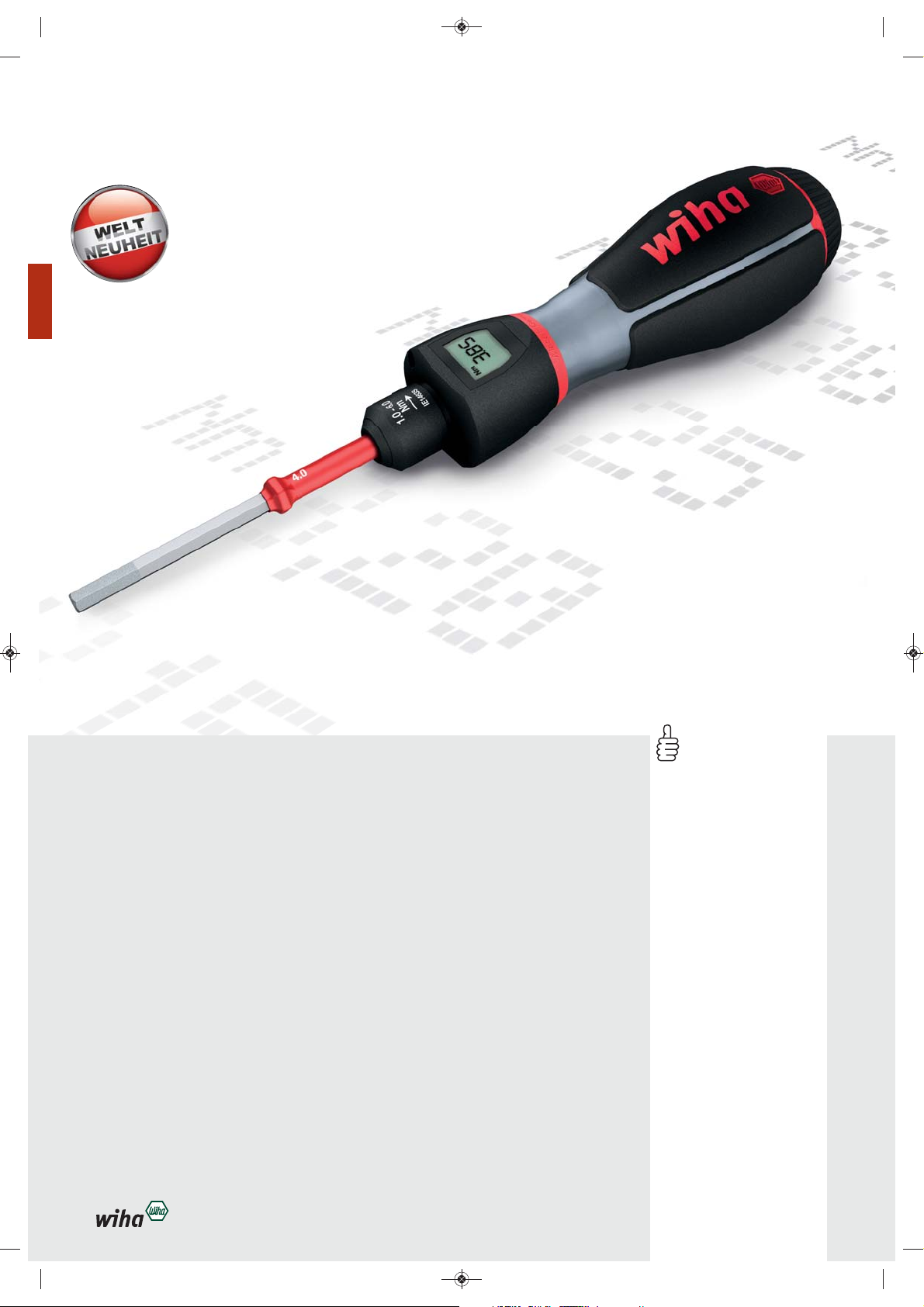

Wiha iTorque.

The intelligent torque tool

TorqueVario®-S with scale.

TorqueFix®.

easyTorque.

.........................................................................................................................................................

........................................................................................................................................................

Torque Wechselklingen.

Wiha VDE torque range.

......................................................................................................................

....................................................................................................................

...........................................................................................................................

...........................................................................................................................

......................................................................

74 – 75

76 – 77

78 – 89

78 – 79

80

81

81

82 – 83

84 – 87

Wiha ESD torque range.

...........................................................................................................................

Wiha T-handle torque tools.

For screw applications requiring a specific amount of force.

................................................

88 – 89

90 – 93

73

Page 3

EN_s072-093_Dreh_2012 16.02.12 09:58 Seite 74

Wiha torque screwdrivers.

Exact and with high repeat precision.

A convincing concept.

The exact torque!

This is more and more vital

for accurate and efficient work,

especially when such

accuracy must be maintained and

repeated, as with fastening and

unfastening sensitive and expensive

components, in assembly or in final

inspections and quality assurance

applications.

These are all perfect tasks for

the new Wiha torque tools with

their ergonomic handles, a unique

interchangeable blade system and

practical problem solutions.

Torque specialist

• Long-term application experience

• Comprehensive range

• Innovation down to the smallest detail

• Single unit adjustment based on customer specifications

Wiha Services – Calibration and Co.

• Wide spectrum of recalibration services

• Quick, competent processing

• Repeat precision and reliability

Nm

Nm +30%

A wide spectrum of products / services

• Industry, ESD and VDE applications

Highest quality standards and

latest production technology

• Individual unit testing with calibration certificate

• Individual unit designation with identification number

Perceptible ergonomics

• Award-winning Wiha handle size concept

• Comfortable multi-component handles

74

Page 4

EN_s072-093_Dreh_2012 16.02.12 09:58 Seite 75

www.wiha.com

Wiha torque screwdrivers.

Quality is the guiding principle

• Use of innovative materials for maximum service life

• Complies with all common standards

• Torque accuracy ± 6% of the pre-set scale value

• Maximum precision with special calibration and

labelling systems

Innovation down to the smallest detail

• Simple, intuitive operation

• Distinctly audible and perceptible click signal

• Numerical, stepless display of torque values enable

rapid identification without reading errors

• Limited loosening and tightening torque

The right tool for every application

• Wide product assortment: Industry, ESD and VDE

• User-oriented development of problem solutions

• Flexible exchange blade system with colour coding

iTorque

TorqueVario

TorqueFix

®

-S

®

TorqueVario®-S VDE

TorqueVario

TorqueVario

TorqueFix

®

®

®

-Tplus

-S ESD

-STplus

easyTorque

75

Page 5

EN_s072-093_Dreh_2012 16.02.12 09:59 Seite 76

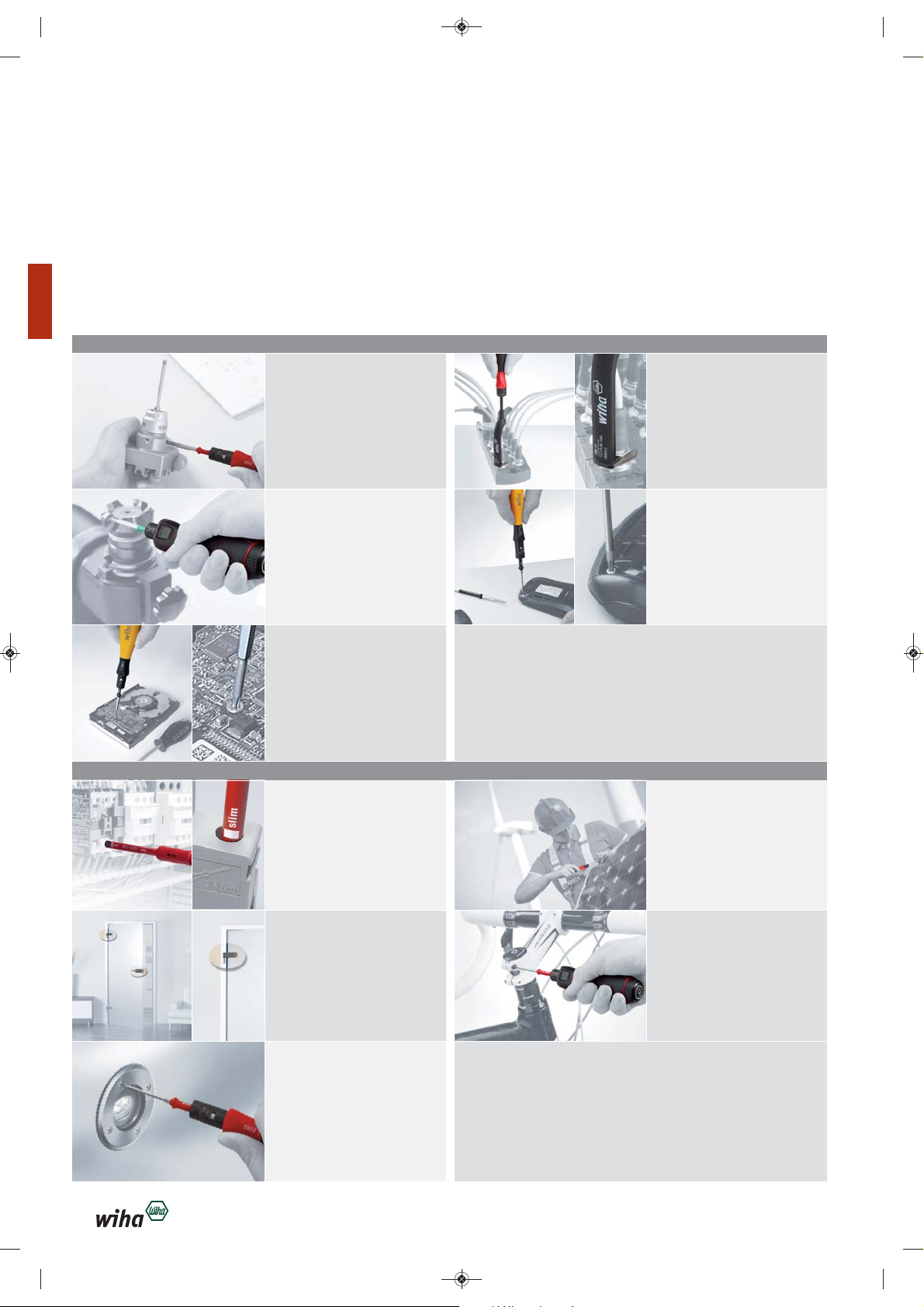

Wiha torque screwdrivers.

Diverse areas of application in trade and industry.

New materials –

sensitive electronic components

in extremely tight spaces –

automated processes in production

technology – just a few of many

examples that illustrate how

rapidly industrial and trade

applications are developing.

The demands for correct fastening

Industrial applications:

of components also grow with

these changes. Only in this way for

example is it possible to eliminate

protection from humidity or

the danger of damage to

materials in production processes.

Industrial installations

Using torque tools is vital to assure an

uniformly high quality in manufacturing.

Circular plug connector -

rotection class IP67

p

For correct functioning of distributions

systems on machines, the correct torque

must be observed when connecting the

circular plug connectors. Otherwise the

protection class IP67 cannot be complied

Trade applications

Fastening of indexable cutter inserts

In the metal cutting industry, great

importance is attached to process

safety. When changing indexable cutter

inserts, this can only be ensured by

using

torque tools.

Sensitive fastenings in the

ESD protected zone

Printed circuit boards and

electronic semiconductor components

react extremely sensitively to mechanical

loads. The correct torque guarantees

secure installation of cost-intensive

materials.

Type-tested switching devices

For type-tested switching devices,

the torque to be observed is specified by

all manufacturers to prevent the

formation of glowing contact areas.

Installation of glass elements

Particularly for materials such as glass

which react sensitively to pressure and

tension, fastening with the recommended torque is a prerequisite.

Smartphones and Co.

Today's electronic devices are always

smaller and more efficient.

This makes smaller screws necessary

which are fastened in sensitive materials

such as plastic. Without the correct

torque, these screws are damaged or

the plastic

Solar technology

Overtightened screws can damage the

sensitive photovoltaic modules.

In contrast, secure fastening cannot

be guaranteed with screws which

are not tightened enough.

Composite materials

The use of new materials such as

carbon make using torque tools vital.

The carbon structure is damaged by the

incorrect torque during fastening. Because of this, the material no longer withstands the requirements.

Electrical devices in outdoor areas

This type of device must be protected

from penetrating humidity and are e.g.

subject to the protection class IP67.

In order to ensure this, all housing

screws must be tightened with the

torque according to man

76

Page 6

EN_s072-093_Dreh_2012 16.02.12 09:59 Seite 77

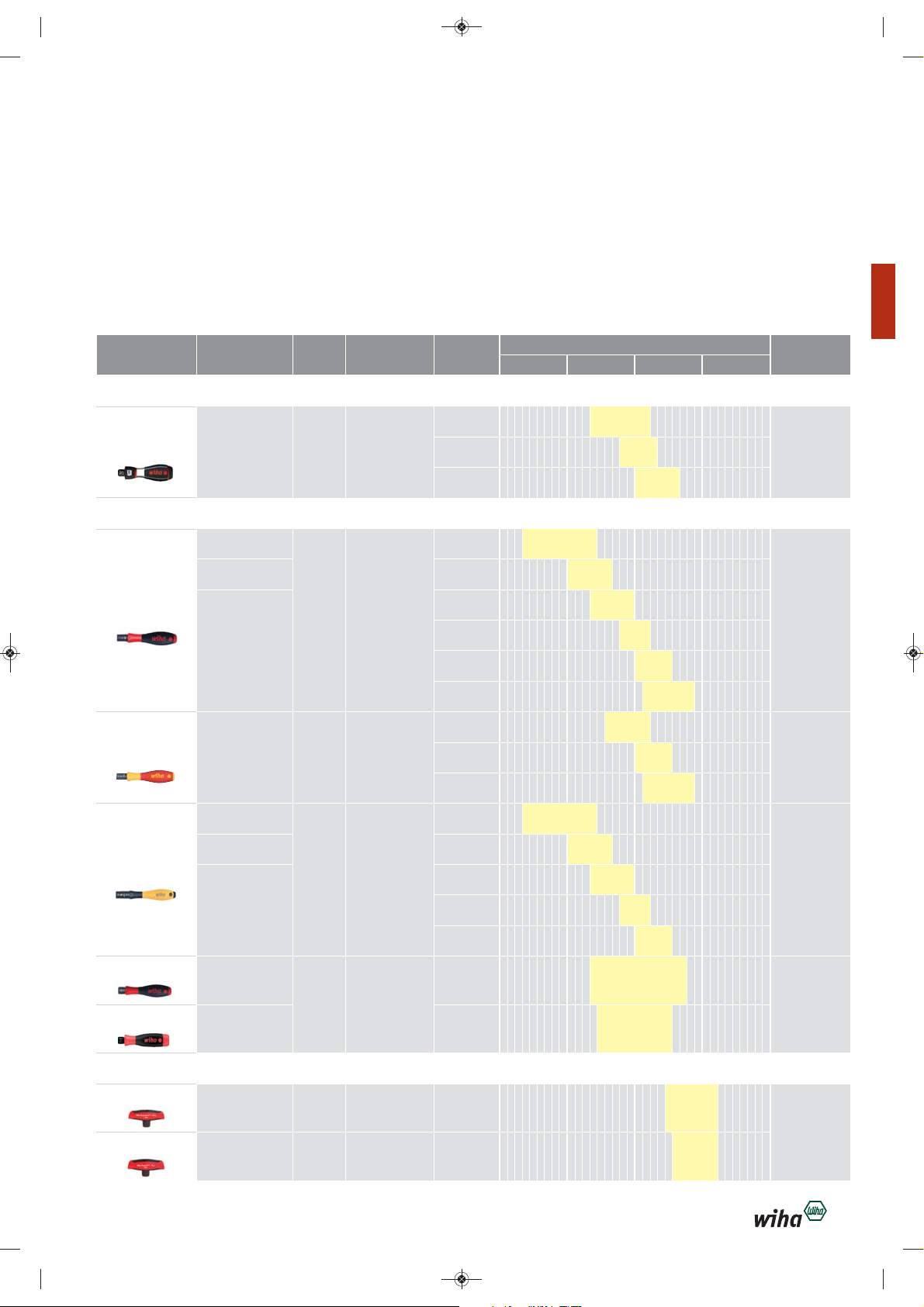

Overview of Wiha torque tools

www.wiha.com

Precision Setting Special feature Nm range

Mechatronic torque screwdriver

iTorque

2835

Mechanical torque screwdriver

±10% (0,1-0,46 Nm)

±6% / ±10% 0,1 - 0,6

TorqueVario®-S

2852

TorqueVario®-S VDE

2872

±6%

±6%

±6% Adjustable

Adjustable

Adjustable Numeric scale

Digital display

Click control

Calibration alert

Can be

recalibrated

VDE certification

Numeric scale

0,4 - 1,5

1,0 - 6,0

0,04 - 0,46

0,4 - 1,0

0,8 - 2,0

1,0 - 5,0

2,0 - 8,0

0,6 - 2,0

1,0 - 5,0

2,0 - 8,0

Torque range

0,01 Nm 0,1 Nm 1 Nm 10 Nm

Suitable

blade range

Series 28590,8 - 3,0

Series 2859

slimBits

Series 2831

±10% (0,1-0,46 Nm)

TorqueVario®-S ESD

2882

®

TorqueFix

2850

easyTorque

292

Mechanical Torque T-handle

TorqueVario®-STplus

2893

TorqueFix®Tplus

2891

0,04 - 0,46

±6% / ±10% 0,1 - 0,6

Adjustable

±6%

±6%

Fixed Pre-set at factory

±10%

±6% Adjustable Numeric scale 5 - 14 Nm

±6% Fixed Pre-set at factory

ESD safe

Numeric scale

0,4 - 1,0

0,8 - 2,0

1,0 - 5,0

16 ranges

0,4 - 7,2 Nm

13 ranges

0,5 - 5,0 Nm

6 ranges

6 - 14 Nm

Series 2889

Series 2859

Series 2899

77

Page 7

EN_s072-093_Dreh_2012 16.02.12 09:59 Seite 78

Wiha iTorque.

The intelligent torque tool

"i" as in "intelligent" the iTorque

Mechatronic version,

highly precise and convenient

to use - the intelligent iTorque

screwdriver sets new standards

in the torque world.

Technology down to

the smallest detail

iTorque, superior design from A to

Z. Operation could not be simpler

or more efficient: the required

value on the display is rapidly set

with the setting wheel at the handle end, completely without tools.

The digital display impresses with

a clear display: no more reading

errors, but simple, individual

setting options.

Especially practical: A short click

and all units are switched over

according to needs (Nm in.lb)

The plastic metal compound

handle also convinces:

with perceptible ergonomics,

high quality robust materials and

optimal distribution of soft zones.

And of course handle sizes

optimally matched to specific

torque ranges.

Modern, efficient testing equipment monitoring: All applications

count!

iTorque also sets new quality

assurance standards. Its integrated

counter records all applications

and shows their actual number.

An integrated alert function

promptly reminds the user of the

pre-specified calibration cycle that

can be individually set with

ordering.

And for practical purposes that

means: the calibration interval can

be optimally matched to the

number of applications according

to user and application.

Further practical details round off

the profile of the all-rounder: with

the test equipment marking that

cannot be lost and that can be

freely specified, each iTorque

becomes a unique object. And

thanks to the interchangeable

blade system the blades of all

Wiha torque screwdrivers can be

randomly changed.

All in all: innovative mechatronics

paired with sophisticated operating comfort.

The new iTorque.

Large digital display

with numeric display

prevents reading errors

Wiha iTorque.

Mechatronic technology

•

Nm-setting via digital display

•

ClickControl

•

Calibration alert (testing

•

equipment monitoring)

Long service life –

•

can be recalibrated

Release accuracy ±6%

•

Individual product can be

•

customised

78

Page 8

EN_s072-093_Dreh_2012 16.02.12 09:59 Seite 79

Can be set without

separate tool

Nm +

Nm –

Large digital display with numeric

display prevents reading errors

Units can be switched

(Nm in.lb | Ncm in.oz).

Torque accuracy ± 6% of the pre-set

scale value

ClickControl counting function

records every single use and

optimises testing equipment

monitoring

Calibration alert after 5.000 uses for

absolute process safety with testing

equipment monitoring. Calibration

alert cycles can be individually

adjusted when ordering the product.

www.wiha.com

iTorque with scale.

NEW

2835

Handle: Torque can be conveniently set directly via push button integrated in

Standards: EN ISO 6798, BS EN 26789, ASME B107.14M.

ccuracy: ±6%, traceable to national standards.

A

Holder: Torque bit universal holder exchange blade for accommodating

Application: For applications where recommended torque settings are important.

Extra: Click Control - integrated counter records all applications.

Order-No.

36886 40-150 Ncm 60-210 in.oz 6% 4 134 34 1

36887 0.8-3.0 7-26 in.Ibs 6% 4 134 34 1

36888 1.0-6.0 9-50 in.Ibs 6% 4 134 40 1

iTorque mechatronic torque screwdriver.

Torque value can be set via a digital scale.

Automatic release with calibration alert.

handle.

Ergonomic plastic/metal compound handle of quality, robust materials.

Handle sizes proportioned to optimise torque setting.

Distinctly audible and perceptible click signal when set toque is reached.

C 6.3 and E 6.3 (1/4") bits (included in delivery).

Use in combination with a Wiha torque interchangeable blade.

Calibration alert following 5,000 applications

(normative reference value/resettable)

Large digital display for simple stepless setting of torque value.

Units can be simply switched - Nm

A high service life: Can be recalibrated by Wiha Services

Can be individualised in the order process –

information available at mytorque.wiha.com.

in.lbs / Ncm in.oz.

Individual permanent lasering of

customer information (e.g. testing

equipment number, workplace

designation, company logo)

Wiha Services

Can be recalibrated by

Wiha Services

79

Page 9

EN_s072-093_Dreh_2012 16.02.12 09:59 Seite 80

Wiha torque screwdrivers.

TorqueVario®-S with scale.

2852

Handle: Torque infinitely adjustable with Torque-Setter setting tool (also supplied).

Standards: EN ISO 6798, BS EN 26789, ASME B107.14M.

Accuracy: ±6%, tracing to national standards (see table for other tolerances).

Application: For applications where recommended torque settings are important.

Extra: Delivered in practical plastic box, incl. factory calibration certificate.

Order-No.

36849 0.04-0.46 •10% 4 127 23 1

6888

2

36850 0.1-0.6 6% 4 127 23 1

26461 0.4-1.0 6% 4 127 23 1

26462 0.8-2.0 6% 4 131 30 1

26463 1.0-5.0 6% 4 138 36 1

26464 2.0-8.0 6% 4 142 41 1

• Accuracy ±10% in the range from 0.1-0.46 Nm

TorqueVario®-S Torque screwdriver.

Torque value can be set via window scale.

Automatic release.

Ergonomic multi-component handle, particulary light and compact.

Handle sizes proportioned to optimise torque setting.

Audible and perceptible click when the pre-set torque has been attained.

Use in combination with a Wiha torque interchangeable blade.

.1-0.6

0

0%

1

4 1

2723

NEW

1

NEW

TorqueVario®-S sets.

852 S10

2

Handle: Model 1.0-5.0 Nm.

Standards: EN ISO 6798, BS EN 26789, ASME B107.14M.

Accuracy: ±6%, traceable to national standards.

Application: For applications where recommended torque settings are important.

Extra: Delivered in robust metal box, incl. factory calibration certificate.

Order-No. Series

26893 2852 S10 1

TorqueVario®-S Torque screwdriver set, 13 pcs.

Torque value can be set via window scale.

With bit universal holder and 10 Phillips / Pozidriv / TORX

hex Standard bits.

Torque infinitely adjustable with Torque-Setter setting tool (also supplied).

Ergonomic multi-component handle, particulary light and compact.

Audible and perceptible click when the pre-set torque has been attained.

2852 TorqueVario®-S Torque screwdriver,

Modell 1,0-5,0 Nm

2859 Torque bit universal holder

285-900 Torque-Setter.

7011 Z PH1x25 PH2x25

7012 Z PZ1x25 PZ2x25

7015 Z T10x25 T15x25 T20x25 T25x25

7013 Z 3.0x25 4.0x25

®

/

285-900

Blade: Octagonal blade, through hardened, zinc-plated.

Handle: Cellulose acetate with micro-fine surface structure.

Supplement: Included in every torque screwdriver delivery.

Order-No.

26864 150 80 1

80

Torque-Setter.

Setting tool for variable torque screwdrivers.

Included in every torque screwdriver delivery.

2852 S10-01

Order-No. Series

34614 2852 S10-01 1

TorqueVario®-S Torque screwdriver set, 13 pcs.

Torque value can be set via window scale.

With bit universal holder and 10 TORX

especially for applications with indexable cutter inserts.

2852 TorqueVario®-S Torque screwdriver,

Modell 1,0-5,0 Nm

2859 Torque bit universal holder

285-900 Torque-Setter.

7015 Z T7x25 T8x25 T9x25 T10x25 T15x25

7016 Z 7IPx25 8IPx25 9IPx25 10IPx25 15IPx25

®

/ TORX PLUS®Standard bits

Page 10

EN_s072-093_Dreh_2012 16.02.12 09:59 Seite 81

www.wiha.com

TorqueFix®and Torque cable key.

2850

Handle: Ergonomic multi-component handle, particulary light and compact.

Standards: EN ISO 6798, BS EN 26789, ASME B107.14M.

Accuracy: ±6%, traceable to national standards.

Application: For applications where recommended torque settings are important.

Extra: Delivered in practical plastic box, incl. factory calibration certificate.

Note: The below articles are available from stock.

Order-No.

26925 0.4 6% 4 112 23 1

26127 0.5 6% 4 112 23 1

26047 0.6 6% 4 112 23 1

26327 0.8 6% 4 112 23 1

26048 0.9 6% 4 112 23 1

26133 1.1 6% 4 119 30 1

26049 1.2 6% 4 119 30 1

26901 1.5 6% 4 119 30 1

26051 2.0 6% 4 119 30 1

26128 2.5 6% 4 119 30 1

26052 3.0 6% 4 126 36 1

26129 3.8 6% 4 126 36 1

26053 5.0 6% 4 132 41 1

26130 5.5 6% 4 132 41 1

34533 6.0 6% 4 132 41 1

26131 7.2 6% 4 132 41 1

TorqueFix®torque screwdriver.

With a fixed torque value pre-set by Wiha.

Automatic release.

Handle sizes proportioned to optimise torque setting.

Audible and perceptible click when the pre-set torque has been attained.

Use in combination with a Wiha torque interchangeable blade.

Further articles with pre-set, customer torque values

of between 0.15 and 8 Nm are available on request.

NEW

NEW

easyTorque.

NEW

292

Handle: Multi-component handle optimally designed for the hand

Accuracy: ±10%

Application: For applications where recommended torque settings are important.

Order-No.

36229 0.5 10% 4 130 34 1

36230 0.6 10% 4 130 34 1

36240 0.9 10% 4 130 34 1

36231 1.1 10% 4 130 34 1

36233 1.2 10% 4 130 34 1

36234 2.0 10% 4 130 34 1

36235 2.0 10% 4 130 34 1

36236 2.5 10% 4 130 34 1

36237 3.0 10% 4 130 34 1

36238 3.8 10% 4 130 34 1

36320 4.0 10% 4 130 34 1

36321 4.5 10% 4 130 34 1

36239 5.0 10% 4 130 34 1

easyTorque torque screwdriver.

With a fixed torque value ex-factory.

enables optimal power transmission.

Audible and perceptible click when the pre-set torque has been attained.

Rapid identification with imprint on handle end.

Unlimited loosening torque.

Mechanism insensitive to industrial lubricants.

se in combination with a Wiha torque interchangeable blade.

U

NEW

2850 S2

Handle: TorqueFix

Material: Robust, glass-fibre reinforced plastic combines the high quality hexagonal

Application: For controlled fastening of circular plug connectors with hexagonal head

Order-No.

36846 0.4 9 230 78 112 23 1

36847 0.6 13 230 78 112 23 1

36848 1.5 22 240 90 119 30 1

Torque cable key for circular plug connectors.

For Wiha torque screwdrivers.

®

Ergonomic multi-component handle, particulary light and compact.

stainless steel insert with the blade tang of chrome-vanadiummolybdenum steel.

according to specified torque.

torque screwdrivers.

81

Page 11

EN_s072-093_Dreh_2012 16.02.12 09:59 Seite 82

Wiha torque screwdrivers.

Torque interchangeable blades.

2859

Blade: High quality chrome-vanadium-molybdenum steel,

tandards: Blade tip DIN ISO 2380-1.

S

Application: For applications where recommended torque settings are important.

Order-No.

26227 0.25 1.5 4 175 42 0.15 10

26228 0.4 2.0 4 175 42 0.4 10

26151 0.4 2.5 4 175 42 0.4 10

26277 0.5 3.0 4 175 42 0.6 10

26278 0.6 3.5 4 175 42 1.1 10

26279 0.8 4.0 4 175 42 2.5 10

2859

Blade: High quality chrome-vanadium-molybdenum steel,

Standards: Blade tip DIN ISO 8764-1.

Application: For applications where recommended torque settings are important.

Order-No.

26199 PH000 4 175 42 0.4 10

26196 PH00 4 175 42 0.4 10

26197 PH0 4 175 42 0.9 10

26058 PH1 4 175 42 3.8 10

27079 PH2 4 175 42 5.5 10

Torque slotted interchangeable blade.

For Wiha torque screwdrivers.

through hardened, chrome-plated.

Wiha ChromTop

Colour-coding: grey.

Torque Phillips interchangeable blade.

For Wiha torque screwdrivers.

through hardened, chrome-plated.

Wiha ChromTop

Colour-coding: dark blue.

®

finish on tip for a perfect fit every time.

®

finish on tip for a perfect fit every time.

Torque interchangeable blades.

2859

Blade: High quality chrome-vanadium-molybdenum steel,

tandards: Blade tip DIN ISO 8764-1.

S

Application: For applications where recommended torque settings are important.

Order-No.

26198 PZ0 4 175 42 0.9 10

26148 PZ1 4 175 42 3.8 10

26889 PZ2 4 175 42 5.5 10

2859

Blade: High quality chrome-vanadium-molybdenum steel,

Application: For applications where recommended torque settings are important.

Order-No.

26544 1.3 4 175 42 0.4 10

26200 1.5 4 175 42 0.9 10

26060 2.0 4 175 42 1.8 10

26061 2.5 4 175 42 3.8 10

26062 3.0 4 175 42 5.5 10

26063 4.0 4 175 42 8.0 10

Torque Pozidriv interchangeable blade.

For Wiha torque screwdrivers.

through hardened, chrome-plated.

Wiha ChromTop

Colour-coding: light blue.

Torque hex interchangeable blade.

For Wiha torque screwdrivers.

through hardened, chrome-plated.

Wiha ChromTop

Colour-coding: red.

®

finish on tip for a perfect fit every time.

®

finish on tip for a perfect fit every time.

NEW

2859

Material: Robust, glass-fibre reinforced plastic combines the high quality hexagonal

Application: For controlled fastening of circular plug connectors with

Order-No.

36414 8 4 78 218 1 10

36415 9 4 78 218 1 10

36416 12 4 78 218 1.5 10

36417 13 4 78 218 1.5 10

36418 14 4 78 218 1.5 10

36419 17 4 78 218 1.5 10

36421 18 4 78 218 1.5 5

36422 22 4 90 233 2 5

36423 24 4 90 233 2 5

36413 ½ 4 78 218 1.5 10

82

Torque cable key for circular plug connectors.

For Wiha torque screwdrivers.

stainless steel insert with the blade tang of chrome-vanadiummolybdenum steel.

hexagonal head according to specified torque.

2859

Blade: High quality chrome-vanadium-molybdenum steel,

Application: For applications where recommended torque settings are important.

Extra: The ball end enables the user to work at angles up to 25°.

Order-No.

26221 1.5 4 175 42 0.4 10

26222 2.0 4 175 42 0.9 10

26223 2.5 4 175 42 2.0 10

26224 3.0 4 175 42 3.8 10

26225 4.0 4 175 42 8.0 10

Torque ball end hex interchangeable blade.

For Wiha torque screwdrivers.

through hardened, chrome-plated.

Wiha ChromTop

Colour-coding: red.

®

finish on tip for a perfect fit every time.

Page 12

EN_s072-093_Dreh_2012 16.02.12 09:59 Seite 83

www.wiha.com

Torque interchangeable blades.

2859

Blade: High quality chrome-vanadium-molybdenum steel,

pplication: For applications where recommended torque settings are important.

A

Extra: Very slim blade diameter for hard-to-reach screws.

Order-No.

30852 T4 4 175 42 0.25 10

26158 T5 4 175 42 0.4 10

26064 T6 4 175 42 0.6 10

26065 T7 4 175 42 0.9 10

26066 T8 4 175 42 1.3 10

26059 T9 4 175 42 2.5 10

26067 T10 4 175 42 3.7 10

26068 T15 4 175 42 5.5 10

26069 T20 4 175 42 8.0 10

26070 T25 4 175 42 8.0 10

Torque TORX®interchangeable blade.

For Wiha torque screwdrivers.

through hardened, chrome-plated.

Wiha ChromTop

®

finish on tip for a perfect fit every time.

Colour-coding: dark green.

Torque interchangeable blades.

2859

Blade: High quality chrome-vanadium-molybdenum steel,

pplication: For applications where recommended torque settings are important.

A

Extra: Very slim blade diameter for hard-to-reach screws.

Order-No.

26159 5IP 4 175 42 0.5 10

26071 6IP 4 175 42 0.8 10

26152 7IP 4 175 42 1.3 10

26072 8IP 4 175 42 2.0 10

26154 9IP 4 175 42 3.0 10

26155 10IP 4 175 42 4.5 10

26073 15IP 4 175 42 6.6 10

26156 20IP 4 175 42 8.0 10

26157 25IP 4 175 42 8.0 10

Torque TORX PLUS®interchangeable blade.

For Wiha torque screwdrivers.

through hardened, chrome-plated.

Wiha ChromTop

®

finish on tip for a perfect fit every time.

Colour-coding: light green.

2859

Torque TORX®MagicSpring®interchangeable blade.

For Wiha torque screwdrivers.

Retaining spring holds TORX

®

screws in place.

Blade: High quality chrome-vanadium-molybdenum steel,

through hardened, chrome-plated.

Wiha ChromTop

®

finish on tip for a perfect fit every time.

Colour-coding: dark green.

Application: For applications where recommended torque settings are important.

Extra: Very slim blade diameter for hard-to-reach screws.

Order-No.

27818 T6 4 175 42 0.6 10

27812 T7 4 175 42 0.9 10

27813 T8 4 175 42 1.3 10

27814 T9 4 175 42 2.5 10

27815 T10 4 175 42 3.8 10

27816 T15 4 175 42 5.5 10

27817 T20 4 175 42 8.0 10

29467 T25 4 175 42 8.0 10

2859

Torque bit universal holder.

For Wiha torque screwdrivers.Suitable for C 6.3 and E 6.3 (1/4") bits.

Blade: High quality chrome-vanadium-molybdenum steel,

through hardened, chrome-plated.

Sleeve: Made of stainless steel, blue plastic coated.

Application: For applications where recommended torque settings are important.

2859

Torque TORX PLUS®MagicSpring®interchangeable blade.

For Wiha torque screwdrivers.

Retaining spring holds TORX PLUS

®

screws in place.

Blade: High quality chrome-vanadium-molybdenum steel,

through hardened, chrome-plated.

Wiha ChromTop

®

finish on tip for a perfect fit every time.

Colour-coding: light green.

Application: For applications where recommended torque settings are important.

Extra: Very slim blade diameter for hard-to-reach screws.

Order-No.

29553 6IP 4 175 42 0.8 10

29554 7IP 4 175 42 1.3 10

29555 8IP 4 175 42 2.0 10

29556 9IP 4 175 42 3.0 10

29557 10IP 4 175 42 4.5 10

29558 15IP 4 175 42 6.6 10

29559 20IP 4 175 42 8.0 10

29560 25IP 4 175 42 8.0 10

2859

Torque adapter blade.

For Wiha torque screwdrivers.Suitable for 1/4" square sockets.

Blade: High quality chrome-vanadium-molybdenum steel,

through hardened, chrome-plated.

Head: Nickel-plated, spring-mounted ball.

Application: For applications where recommended torque settings are important.

Order-No.

27526 1/4 4 162 11 10

Order-No.

26229 1/4 4 155 10

83

Page 13

EN_s072-093_Dreh_2012 16.02.12 09:59 Seite 84

Wiha Torque VDE screwdrivers.

Precise and high repeat accuracy.

slim

TECHNOLOGY

TorqueVario®-S VDE.

The world's only completely

certified VDE torque system.

The TorqueVario

integrated scale in combination

with the slimTorque VDE bit holder

and slimBits offer controlled

tightening of screws with

simultaneous user safety fo

84

®

-S VDE with

slim

TECHNOLOGY

Up to 33% reduction of the blade diameter

in the critical working area allows effortless

access to low-lying fastening/ spring

elements.

:

For type-tested switching devices,

the torque to be observed is specified

by all manufacturers.

Wiha Torque VDE

screwdrivers.

The world's only completely

•

certified VDE torque system

Clearly audible and perceptible

•

click on attaining the preset torque

Torque accuracy ± 6% of

•

the pre-set scale value

Delivered with factory

•

calibration certificate

Safety when working with live

•

equipment up to 1000 V AC

and 1500 V DC

Fulfills all accuracy require-

•

ments as defined by EN ISO

6789, BS EN 26789 and

ASME B 107.14M

Wiha slimTorque

VDE Bithalter.

• Absolute safety even if

mistakes are made:

no metal connection between

the bit holder and blade tang

Page 14

EN_s072-093_Dreh_2012 16.02.12 10:00 Seite 85

www.wiha.com

TorqueVario®-S VDE. slimTorque VDE bit holder.

2872

Handle: Torque infinitely adjustable with Torque-Setter setting tool (also supplied).

Standards: Manufactured acc. to IEC 60900:2004.

Accuracy: ±6%, traceable to national standards.

Holder: slimTorque VDE bit holder (included in delivery) for 6 mm slimBits.

Application: For controlled fastening on live parts up to 1,000 V AC,

Extra: Delivered in practical plastic box, incl. factory calibration certificate.

Order-No.

26625 0.6-2.0 6% 3.8 131 30 1

26626 1.0-5.0 6% 3.8 138 36 1

26627 2.0-8.0 6% 3.8 142 41 1

TorqueVario®-S VDE torque screwdriver.

Insulation up to 1000 V AC, GS-mark.

Torque value can be set via window scale.

Automatic release.

Ergonomic multi-component handle, insulation up to 1000 V AC, GS mark.

Handle sizes proportioned to optimise torque setting.

Audible and perceptible click when the pre-set torque has been attained.

EN ISO 6798, BS EN 26789, ASME B107.14M.

for use only in combination with a slimTorque VDE bit holder

for 6 mm slimBits.

slimTorque kit. Torque setter.

2879 B7

Bits: Protective insulation moulded directly onto the bit and

Holder: ClicFix quick release holder securely locks bits.

Application: Set for starting Wiha slimTECHNOLOGY,

Extra: Individually tested protective insulation 1,000 V AC, VDE and GS tested.

Order-No. Series

36079 2879 B7 1

slimTorque kit, 7-pcs.

With slimTorque VDE bit holder for 6 mm slimBits.

completely integrated into the bit in the lower area.

Only for 6 mm slimBits.

for existing TorqueVario-S VDE torque screwdrivers.

2879_slimTorque slimTorque VDE bit holder for 6 mm slimBits.

2831-10 1x4.0 1x5.5

2831-11 1xPH1 11xPH2

2831-12 1xPZ1 11xPZ2

2879

Blade: High quality chrome-vanadium-molybdenum steel,

Standards: Manufactured acc. to IEC 60900:2004.

Bit holder: ClicFix quick release holder securely locks bits.

Application: For use of Wiha 6 mm slimBits with Wiha VDE torque screwdrivers.

Attention: Not for use with bit styles C 6.3 and E 6.3.

Order-No.

35870 6 3.8 170 13 5

slimTorque VDE bit holder for 6 mm slimBits.

Insulation up to 1000 V AC, GS-mark.

Exclusively for Wiha VDE torque screwdrivers.

through hardened, black-finish.

Insulation moulded directly onto blade.

Only for 6 mm slimBits.

285-900

Blade: Octagonal blade, through hardened, zinc-plated.

Handle: Cellulose acetate with micro-fine surface structure.

Supplement: Included in every torque screwdriver delivery.

Order-No.

26864 150 80 1

Torque-Setter.

Setting tool for variable torque screwdrivers.

Included in every torque screwdriver delivery.

When working with VDE tools,

observe the national safety and

accident prevention regulations!

85

Page 15

EN_s072-093_Dreh_2012 16.02.12 10:00 Seite 86

Wiha Torque VDE screwdrivers.

slimBits.

2831-10

Standards: Manufactured acc. to IEC 60900:2004.

Material: High-quality chrome vanadium steel, through-hardened, bronzed.

Application: For all work on or around electrical components up to 1000 V AC.

Extra: The integrated protective insulation enables low-lying fastening and

Attention: 6 mm slimBits only to be used in the slimVario bit holder and

Order-No.

34578 2.5 90 0.4 6.0 no slim version 1

4579

3

34580 4.0 90 0.8 6.0 1

34581 5.5 90 1.0 6.0 1

34582 6.5 90 1.2 6.0 1

SoftFinish®electric slimBit, slotted.

ndividually tested protective insulation 1,000 V AC,

I

VDE and GS tested.

Protective insulation moulded directly onto the bit and

completely integrated into the blade in the lower area from size 4.0.

spring elements to be reached and manipulated.

The slim form of the bit allows easy reaching of the screws

below the finger and hand guards.

slimTorque VDE bit holder (VDE torque system).

.0

3

900.56

.0

o slim version

n

1

slimBits.

EW

N

2831-13

Order-No.

34587 SL/PH1 90 6.0 1

34588 SL/PH2 90 6.0 1

2831-14

Order-No.

34589 SL/PZ1 90 6.0 1

34590 SL/PZ2 90 6.0 1

SoftFinish®electric slimBit, Xeno,

for terminal screws (slotted/ Phillips)

Individually tested protective insulation 1,000 V AC,

VDE and GS tested.

SoftFinish®electric slimBit for terminal screws (slotted/Pozidriv).

Individually tested protective insulation 1,000 V AC,

VDE and GS tested.

2831-11

Order-No.

34583 PH1 90 6.0 1

34584 PH2 90 6.0 1

2831-12

Order-No.

34585 PZ1 90 6.0 1

34586 PZ2 90 6.0 1

SoftFinish®electric slimBit, Phillips.

Individually tested protective insulation 1,000 V AC,

VDE and GS tested.

SoftFinish®electric slimBit, Pozidriv.

Individually tested protective insulation 1,000 V AC,

VDE and GS tested.

NEW

2831-15

Order-No.

35506 T8 90 6.0 1

35507 T10 90 6.0 1

35508 T15 90 6.0 1

35509 T20 90 6.0 1

36071 T25 90 6.0 1

NEW

2831-17

Order-No.

35510 Robertson 1 2.3 90 6.0 1

35511 Robertson 2 2.8 90 6.0 1

SoftFinish®electric slimBit, TORX

Individually tested protective insulation 1,000 V AC,

VDE and GS tested.

SoftFinish®electric slimBit, square (Robertson).

Individually tested protective insulation 1,000 V AC,

VDE and GS tested.

®

86

Page 16

EN_s072-093_Dreh_2012 16.02.12 10:00 Seite 87

www.wiha.com

slimTorque starter set.

2872 T9

Handle: VDE torque handle 1.0 - 5.0 Nm, steplessly adjustable

Bit holder: ClicFix quick release holder securely locks bits.

Bits: Protective insulation moulded directly onto the bit and

pplication: For controlled fastening on live parts up to 1 000 V AC.

A

Extra: 100% safety from fastening with torque according to specification of

slimTorque starter set, 9-pcs.

Torque value can be set via window scale.

With slimTorque VDE bit holder for 6 mm slimBits.

with Torque Setter adjusting tool (included in delivery).

Only for 6 mm slimBits.

completely integrated into the bit in the lower area.

Individually tested protective insulation 1,000 V AC, VDE and GS tested.

manufacturer type-tested switching devices according to EN 60439-1.

Effortless access to low-lying fastening elements.

Arranged clearly in a high quality, rugged and durable bag.

slim selection set.

2872 T10

Handle: VDE torque handle 1.0 - 5.0 Nm, steplessly adjustable.

Bit holder: ClicFix quick release holder securely locks bits.

Bits: Protective insulation moulded directly onto the bit and

pplication: For controlled fastening on live parts up to 1 000 V AC.

A

Extra: 100% safety from fastening with torque according to specification of

slim selection set, 10-pcs.

VDE complete set with torque screwdriver, bit holder and slimBits.

Slotted/Phillips/Pozidriv.

Bit holder with SoftFinish

Only for 6 mm slimBits.

completely integrated into the bit in the lower area.

Individually tested protective insulation 1,000 V AC, VDE and GS tested.

manufacturer type-tested switching devices according to EN 60439-1.

Effortless access to low-lying fastening elements.

Arranged clearly in a high quality, rugged and durable bag.

®

electric multi-component handle.

Order-No. Series

36080 2872 T9 1

2872 T18

Order-No. Series

36791 2872 T18 1

2872 TorqueVario®-S VDE torque screwdriver.

Modell 1.0 – 5.0 Nm

2879_slimTorque slimTorque VDE bit holder for 6 mm slimBits.

285-900 Torque-Setter.

2831-10 1x4.0 1x5.5

2831-11 1xPH1 1xPH2

2831-12 1xPZ1 1xPZ2

slimTorque starter set, 18-pcs.

Torque value can be set via window scale.

With slimTorque VDE bit holder for 6 mm slimBits.

2872 TorqueVario®-S VDE torque screwdriver.

Modell 1.0 – 5.0 Nm

2879_slimTorque slimTorque VDE bit holder for 6 mm slimBits.

285-900 Torque-Setter.

2831-10 1x3.0 2x4.0 2x5.5 1x6.5

2831-12 1xPZ1 22xPZ2

2831-14 1xSL/PZ1 1xSL/PZ2

2831-15 1xT10 1xT15 1xT20 1xT25

Order-No. Series

36078 2872 T10 1

2872 TorqueVario®-S VDE torque screwdriver.

Modell 1,0 – 5,0 Nm

2831-00 SoftFinish®electric slimVario bit holder

with handle and ClicFix, 6.0 mm.

2879_slimTorque slimTorque VDE bit holder for 6 mm slimBits.

285-900 Torque-Setter.

2831-10 1x4.0 1x5.5

2831-11 1xPH1 1xPH2

2831-12 1xPZ1 1xPZ2

87

Page 17

EN_s072-093_Dreh_2012 16.02.12 10:00 Seite 88

Wiha Torque ESD torque range.

Wiha SoftFinish® ESD

screwdrivers have a surface

resistance of 106 – 109 ohms.

Wiha TorqueVario®-S ESD

with integrated scale.

Specially designed for applications

on electrostatic sensitive

components and devices that may

be damaged by electrostatic fields

or discharges. The dissipative

handle and blade coating,

with a surface resistance of

6

10

- 109Ohms, controls electrostatic energy discharge.

Four models cover torque ranges

from 0.1 Nm up to 5.0 Nm.

Safety Notice:

Wiha ESD screwdrivers are

noninsulated, therefore

not suitable for working on live parts.

88

Wiha Torque ESD

torque range.

Dissipative handle designed

•

to discharge uniformly,

surface resistance 10

6

-10

ohms

Meets ESD standard

•

IEC 61340-5-1

Ergonomic SoftFinish

•

®

multicomponent handle

guarantees comfortable work

and optimised handling

Ergonomic handle sizes that

•

are proportional to the

torque ranges

Each tool is individually

•

tested and marked with

an identification number

Clearly audible and perceptible

•

click on attaining the

pre-set torque

Fulfills all accuracy require-

•

ments as defined by

EN ISO 6789, BS EN 26789 and

ASME B 107.14M

Torque accuracy ± 6% of the

•

pre-set scale value

Delivered with factory

•

calibration certificate

TorqueVario®-S ESD with scale.

2882

9

Handle: Torque infinitely adjustable with Torque-Setter setting tool (also supplied).

Standards: IEC 61340-5-1.

Accuracy: ±6%, tracing to national standards (see table for other tolerances).

Application: For ESD applications where recommended torque settings are important.

Extra: Delivered in practical plastic box, incl. factory calibration certificate.

Order-No.

36851 0.04-0.46 •10% 4 127 23 1

26865 0.1-0.6 10% 4 127 23 1

36852 0.1-0.6 6% 4 127 23 1

26629 0.4-1.0 6% 4 127 23 1

26866 0.8-2.0 6% 4 131 30 1

30495 1.0-5.0 6% 4 138 36 1

• Accuracy ±10% in the range from 0.1-0.46 Nm

TorqueVario®-S ESD torque screwdriver.

Torque value can be set via window scale.

Automatic release.

Ergonomic multi-component handle,

made of ESD-safe dissipative material.

Handle sizes proportioned to optimise torque setting.

Audible and perceptible click when the pre-set torque has been attained.

Surface resistance 10

EN ISO 6798, BS EN 26789, ASME B107.14M.

Use in combination with a Wiha Torque ESD interchangeable blade.

6

- 109ohms.

NEW

NEW

Page 18

EN_s072-093_Dreh_2012 16.02.12 10:00 Seite 89

www.wiha.com

Torque ESD interchangeable blades.

2889

Blade: High quality chrome-vanadium-molybdenum steel,

Standards: IEC 61340-5-1, DIN ISO 2380.

Application: For ESD applications where recommended torque settings are important.

Order-No.

26869 0.25 1.5 4 175 42 0.15 10

26870 0.4 2.0 4 175 42 0.4 10

26871 0.5 3.0 4 175 42 0.6 10

26872 0.6 3.5 4 175 42 1.1 10

26873 0.8 4.0 4 175 42 2.5 10

2889

Standards: IEC 61340-5-1, DIN ISO 8764.

Order-No.

26877 PH000 4 175 42 0.4 10

26876 PH00 4 175 42 0.4 10

26875 PH0 4 175 42 0.9 10

26878 PH1 4 175 42 3.8 10

Torque ESD slotted interchangeable blade.

For Wiha ESD torque screwdrivers.

through hardened, chrome-plated.

Wiha ChromTop

Moulded with static dissipative, black plastic material.

Surface resistance 10

®

finish on tip for a perfect fit every time.

6

- 109ohms.

Torque ESD Phillips interchangeable blade.

For Wiha ESD torque screwdrivers.

Bit holder. Torque-Setter. ESD-Set.

2889

Blade: High quality chrome-vanadium-molybdenum steel,

Sleeve: Made of stainless steel, moulded with dissipative, black plastic material.

Application: For ESD applications where recommended torque settings

Order-No.

27711 1/4 4 162 11 10

88-900

2

Blade: Octagonal blade, through hardened, zinc-plated.

Handle: Made of static dissipative plastic material.

Standards: IEC 61340-5-1.

Supplement: Included in every torque screwdriver delivery.

Order-No.

27279 80 150 1

Torque ESD bit universal holder.

For Wiha ESD torque screwdrivers.

Suitable for C 6.3 and E 6.3 (1/4") bits.

through hardened, chrome-plated.

Surface resistance 10

6

- 109ohms.

are important.

Torque-Setter ESD.

Setting tool for variable Torque ESD screwdrivers.

ncluded in every torque ESD screwdriver delivery.

I

2889

Torque ESD Pozidriv interchangeable blade.

For Wiha ESD torque screwdrivers.

Standards: IEC 61340-5-1, DIN ISO 8764.

Order-No.

26879 PZ0 4 175 42 0.9 10

26880 PZ1 4 175 42 3.8 10

2889

Torque ESD TORX®interchangeable blade.

For Wiha ESD torque screwdrivers.

Standards: IEC 61340-5-1.

Extra: Very slim blade diameter for hard-to-reach screws.

Order-No.

26881 T5 4 175 42 0.4 10

26882 T6 4 175 42 0.6 10

26868 T7 4 175 42 0.9 10

26883 T8 4 175 42 1.3 10

26884 T9 4 175 42 2.5 10

26885 T10 4 175 42 3.8 10

2882 S10

TorqueVario®-S ESD torque screwdriver set, 13 pcs.

Torque value can be set via window scale.

With universal bit holder and 10 straight-blade / Phillips / Poszdriv /

®

TORX

Standard bits.

Handle: Model 0.8-2.0 Nm.

Torque infinitely adjustable with Torque-Setter setting tool (also supplied).

Ergonomic multi-component handle,

made of ESD-safe dissipative material.

Standards: IEC 61340-5-1.

EN ISO 6798, BS EN 26789, ASME B107.14M.

Accuracy: ±6%, traceable to national standards.

Application: For ESD applications where recommended torque settings are important.

Extra: Delivered in robust metal box, incl. factory calibration certificate.

Order-No. Series

27687 2882 S10 1

2882 TorqueVario®-S ESD, Model 0,8-2,0 Nm

2889 Torque ESD bit universal holder

288-900 Torque-Setter ESD

7010 Z 4.0x25 5.5x25

7011 Z PH0x25 PH1x25

7012 Z PZ0x25 PZ1x25

7015 Z T7x25 T8x25 T9x25 T10x25

89

Page 19

EN_s072-093_Dreh_2012 16.02.12 10:00 Seite 90

Wiha T-handle torque tools.

For screw applications requiring a specific amount of force.

Tightening screws properly!

Even in higher torque ranges?

No problem with the new ergonomic

T-handle torque tools from Wiha.

Tightening screws to a pre-set

torque has never been so easy,

comfortable and economical!

Perfectly shaped.

The special feature of these tools is

the ergonomic, multi-component

T-handle with the striking soft

zones that allow particularly

comfortable and effortless power

transmission, even at higher

torques.

90

Sophisticated mechanism.

The T-handle’s extremely light,

multi-component plastic sleeve

conceals a precise torque

mechanism. This is sealed in an

oil-lubricated bearing and is thus

extremely low-wear with a long

tool life. As soon as the pre-set

torque has been attained, there is

a clearly audible and perceptible

click to prevent exceeding the

pre-set value. Overtightening of

the pre-set value is therefore

eliminated. Release accuracy is

±6% of the pre-set scale value,

as required by EN ISO 6789.

To prevent users from breaking

the blade or damaging the screw

when loosening the screw,

the tools limit the tightening

torque, as well as apply a special

limit to the loosening torque;

this is approximately 30 % greater

than the tightening torque.

Fixed or variable setting of torque

value.

Depending on the intended

application, we recommend one

of the TorqueFix

with a pre-set, fixed torque value or

the TorqueVario

and a variable torque value from

5 - 14 Nm. In the case of the

variable T-handle tool, the torque

value is continuously adjustable

on the handle via the adjustment

tool supplied with it.

The numerical display of the

setting value in the upper handle

enables the pre-set value to be

easily read-off in Nm; this virtually

eliminates incorrect readings.

®

-Tplus models

®

-STplus with scale

Page 20

EN_s072-093_Dreh_2012 16.02.12 10:00 Seite 91

The ergonomically shaped

multi-component T-handle ensures

fatigue-resistant power transfer.

www.wiha.com

With slipping clutch precise, ergonomic, robust.

Universal and flexible.

6-mm interchangeable blades

made of high-quality, toughbut flexible chrome-vanadium

molybdenum steel are available

to match the handles.

Two adapter blades for nuts

(1/4" and 3/8"), together with

a plastic-coated universal bit

holder for all C 6.3 and E 6.3

(1/4") bits, complete the product

range.

Safety first.

Before it leaves the factory,

each T-handle torque tool is

inspected, calibrated and allotted

an identification number.

The result of the calibration

is documented in a factory

calibration certificate, which

is included free of charge with

each tool. This factory calibration

certificate also documents

compliance with national

standards.

Wiha T-handle

torque tools.

T-handle with soft zones is

•

comfortable to hold

High-quality and robust,

•

precision construction

Variable design with

•

easy-to-read, numerical scale

Each handle is individually

•

tested, laser-calibrated and

marked with an identification

number

Limit to the tightening and

•

loosening torque prevents

damage to the tool and screw

Torque accuracy ± 6% of

•

the pre-set scale value

Large selection of interchange-

•

able blades, adapter blades

for nuts and bit holders

Supplied with factory

•

calibration certificate

Wiha's new T-handle torque tools.

Easy to adjust, durable and comfortable.

91

Page 21

EN_s072-093_Dreh_2012 16.02.12 10:00 Seite 92

Wiha T-handle torque tools.

T-handle torque tools with scale.

with scale with scale

2893

Handle: Window scale displays torque value numerically.

Standards: Based on EN ISO 6789, BS EN 26789, ASME B107.14M.

Accuracy: ±6%, traceable to national standards.

Application: For applications where recommended torque settings are important.

Extra: Delivered in practical plastic box, incl. factory calibration certificate.

Order-No.

29233 5-14 6 56 120 1

TorqueVario®-STplus T-handle torque tool.

Torque can be set via numerical scale.

With slipping clutch.

Torque infinitely adjustable with Torque-Setter setting tool (also supplied).

Soft-grip T-handle for extreme comfort and optimal torque transmission.

udible and perceptible click when the pre-set torque has been attained.

A

Use in combination with an interchangeable 6 mm blade for

Wiha T-handle torque tools.

Pre-set T-handle torque tools.

2891

Handle: Soft-grip T-handle for extreme comfort and optimal torque transmission.

Standards: Based on EN ISO 6789, BS EN 26789, ASME B107.14M.

ccuracy: ±6%, traceable to national standards.

A

Application: For applications where recommended torque settings are important.

Extra: Delivered in practical plastic box, incl. factory calibration certificate.

Order-No.

29228 6 6 56 120 1

29229 8 6 56 120 1

29230 10 6 56 120 1

29231 12 6 56 120 1

29236 12.5 6 56 120 1

29232 14 6 56 120 1

TorqueFix®-Tplus T-handle torque tool.

With a fixed torque value pre-set by Wiha.Automatic release.

With slipping clutch.

Audible and perceptible click when the pre-set torque has been attained.

Use in combination with an interchangeable 6 mm blade for Wiha Thandle torque tools.

with scale

2893 S01

Handle: Model 5-14 Nm.

Standards: Based on EN ISO 6789, BS EN 26789, ASME B107.14M.

Accuracy: ±6%, traceable to national standards.

Application: For applications where recommended torque settings are important.

Extra: Delivered in robust metal box, incl. factory calibration certificate.

Order-No. Series

29234 2893 S01 1

TorqueVario®-STplus T-handle torque tool set, 11 pcs.

With bit universal holder, 6 TORX

2 adapter blades for nuts.

Window scale displays torque value numerically.

Torque infinitely adjustable with Torque-Setter setting tool (also supplied).

Soft-grip T-handle for extreme comfort and optimal torque transmission.

2893 TorqueVario®-STplus T-handle torque tool,

Model 5-14 Nm

289-900 Torque-Tplus Setter

2899 Torque-Tplus adapter blade

2899 Torque-Tplus bit universal holder

7015 Z T25x25 T30x25 T40x25

7013 Z 4.0x25 5.0x25 6.0x25

®

/ hex Standard bits and

92

Page 22

EN_s072-093_Dreh_2012 16.02.12 10:00 Seite 93

www.wiha.com

Torque-Tplus Setter and interchangeable blades.

289-900

Blade: Octagonal profile with drilled tip,

Handle: Made of impact resistant cellulose acetate.

Order-No.

28691 80 150 1

2899

Blade: High quality chrome-vanadium-molybdenum steel,

Application: For applications where recommended torque settings are important.

Order-No.

28734 T15 6 130 53 5.5 49 10

28735 T20 6 130 53 10 88 10

28736 T25 6 130 53 15 132 10

28737 T27 6 130 53 15 132 10

28738 T30 6 130 53 15 132 10

28739 T40 6 130 53 15 132 10

Torque-Tplus Setter.

Setting tool for variable T-handle torque tools.

Included in every T-handle torque tool delivery.

through hardened, zinc-plated.

Torque-Tplus TORX®interchangeable blade.

For T-handle torque tools.

through hardened, chrome-plated.

Wiha ChromTop

®

finish on tip for a perfect fit every time.

Colour-coding: dark green.

Interchangeable blades.

2899

Blade: High quality chrome-vanadium-molybdenum steel,

Application: For applications where recommended torque settings are important.

Order-No.

28746 3 6 130 53 5.5 49 10

28747 4 6 130 53 15 132 10

28748 5 6 130 53 15 132 10

28749 6 6 130 53 15 132 10

2899

Blade: High quality chrome-vanadium-molybdenum steel,

Sleeve: Quick release bit holder for T-handle torque tools.

Application: For controlled turning of screws with bits at a prescribed torque.

Order-No.

28758 1/4 6 125 11 105 mm visible length 10

Torque-Tplus hex interchangeable blade.

For T-handle torque tools.

through hardened, chrome-plated.

Wiha ChromTop

olour-coding: red.

C

®

finish on tip for a perfect fit every time.

Torque-Tplus bit quick release holder.

For T-handle torque tools.

Suitable for C 6.3 and E 6.3 (1/4") bits.

through hardened, chrome-plated.

Enables ultra fast bit changes.

2899

Torque-Tplus TORX PLUS®interchangeable blade.

For T-handle torque tools.

Blade: High quality chrome-vanadium-molybdenum steel,

through hardened, chrome-plated.

Wiha ChromTop

®

finish on tip for a perfect fit every time.

Colour-coding: light green.

Application: For applications where recommended torque settings are important.

Order-No.

28740 15IP 6 130 53 6.6 59 10

28741 20IP 6 130 53 13 115 10

28742 25IP 6 130 53 15 132 10

28743 27IP 6 130 53 15 132 10

28744 30IP 6 130 53 15 132 10

28745 40IP 6 130 53 15 132 10

2899

Torque-Tplus adapter blade.

For T-handle torque tools.

Suitable for 1/4" respc. 3/8" square sockets.

Blade: High quality chrome-vanadium-molybdenum steel,

through hardened, chrome-plated.

Head: Nickel-plated, spring-mounted ball.

Application: For controlled turning of screws with nuts at a prescribed torque.

Order-No.

28756 1/4 6 120 53 100 mm visible length 10

28757 3/8 6 120 53 100 mm visible length 10

93

Loading...

Loading...