Page 1

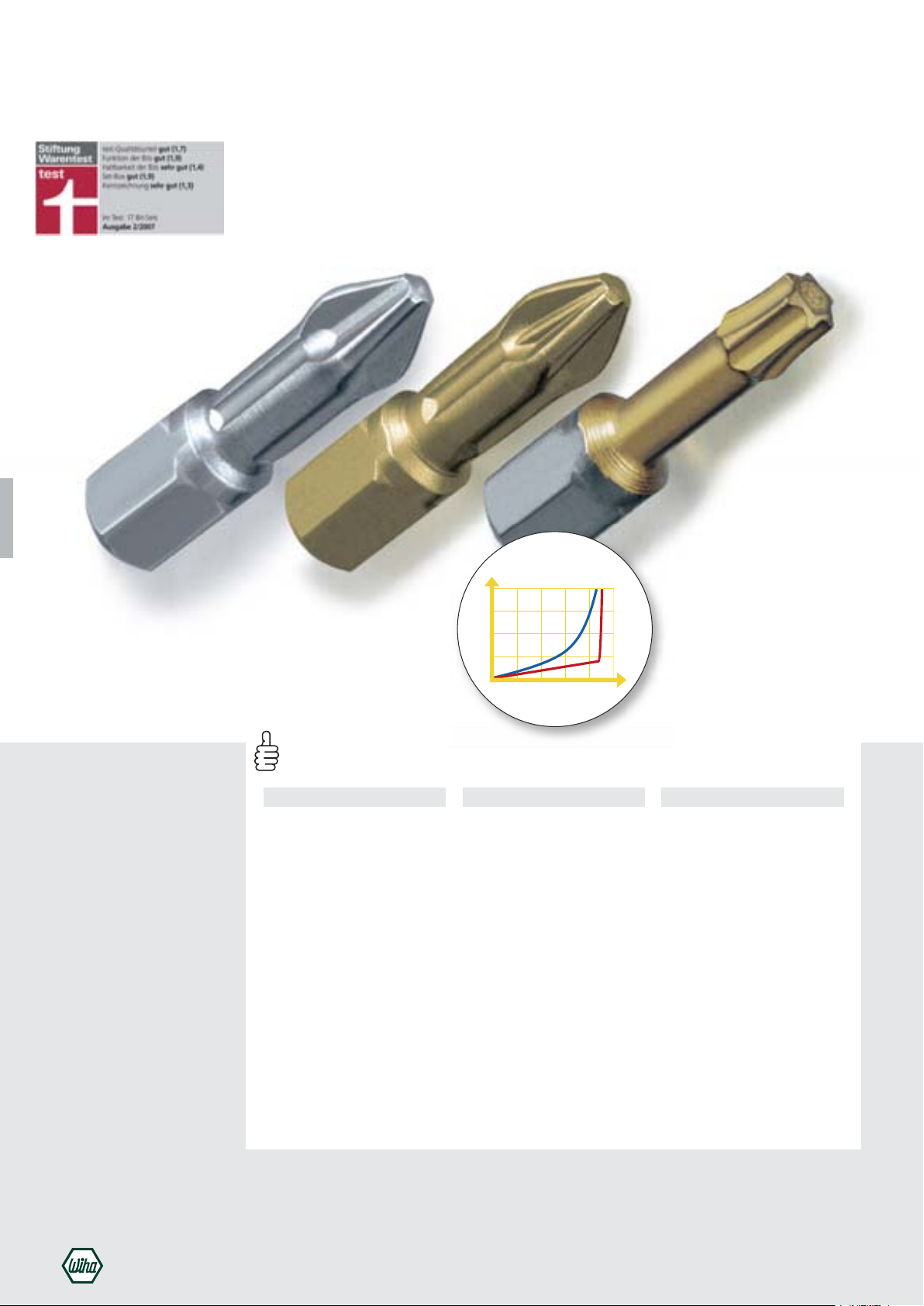

Wiha Torsion bit.

Patented torsion zone for longer service life.

The main cause ofwearwithsoft

fasteningapplicationssuch as in

wood for example isthewearofthe

profile edges because the bit rattles

through. A hard bit needs to be used

here: Wiha HOT.

With hard fastening jobs such as

hitting metal surfaces the main

reason for wear is breakage of the

bits. These usually occur with torque

peaks near to the end of the fastening

process.A tough-but-flexible bit is

the answer: Wiha ZOT.

The special assortment of Wiha

torsion bits with torsion zones offers

optimal products for both soft and

hard fastening tasks.

Wiha Torsion bit.

Wiha ZOT Torsion bits

• Tough, hard Torsion quality for

hard applications

• Ideal for screw applications

in metal and hard materials

• Elastic Torsion zone absorbs

the strong torque peaks in the

final phase of the application

(red line)

•

Highly resistant to wear and tear

due to special heat treatment

• Hardness 61-2 HRC.

• For trade and DIY

Torque

Time

Wiha HOT Torsion bits

• Extra hard Torsion quality for

soft applications

• Ideal for screw applications

in wood and soft materials

• Average requirements

concerning elasticity are used

to optimise performance and

resistance to wear and tear

(blue line)

• Hardness 63-2 HRC.

• For trade and DIY

The red line indicates the steep

increase in torque with hard

applications, e.g. in metal.

The blue line shows a steady

torque increase in soft applications,

e.g. in wood working.

Wiha TiN Torsions bits

• Tough, hard Torsion quality

with very hard titanium-nitride

(TiN) coating

• Optimum resistance to wear

and tear due to very hard TiN

coating

• Combines the advantages

of Wiha HOT bits and ZOT bits

in one outstanding bit

• For trade and DIY,

especially for industry

116

Loading...

Loading...