Page 1

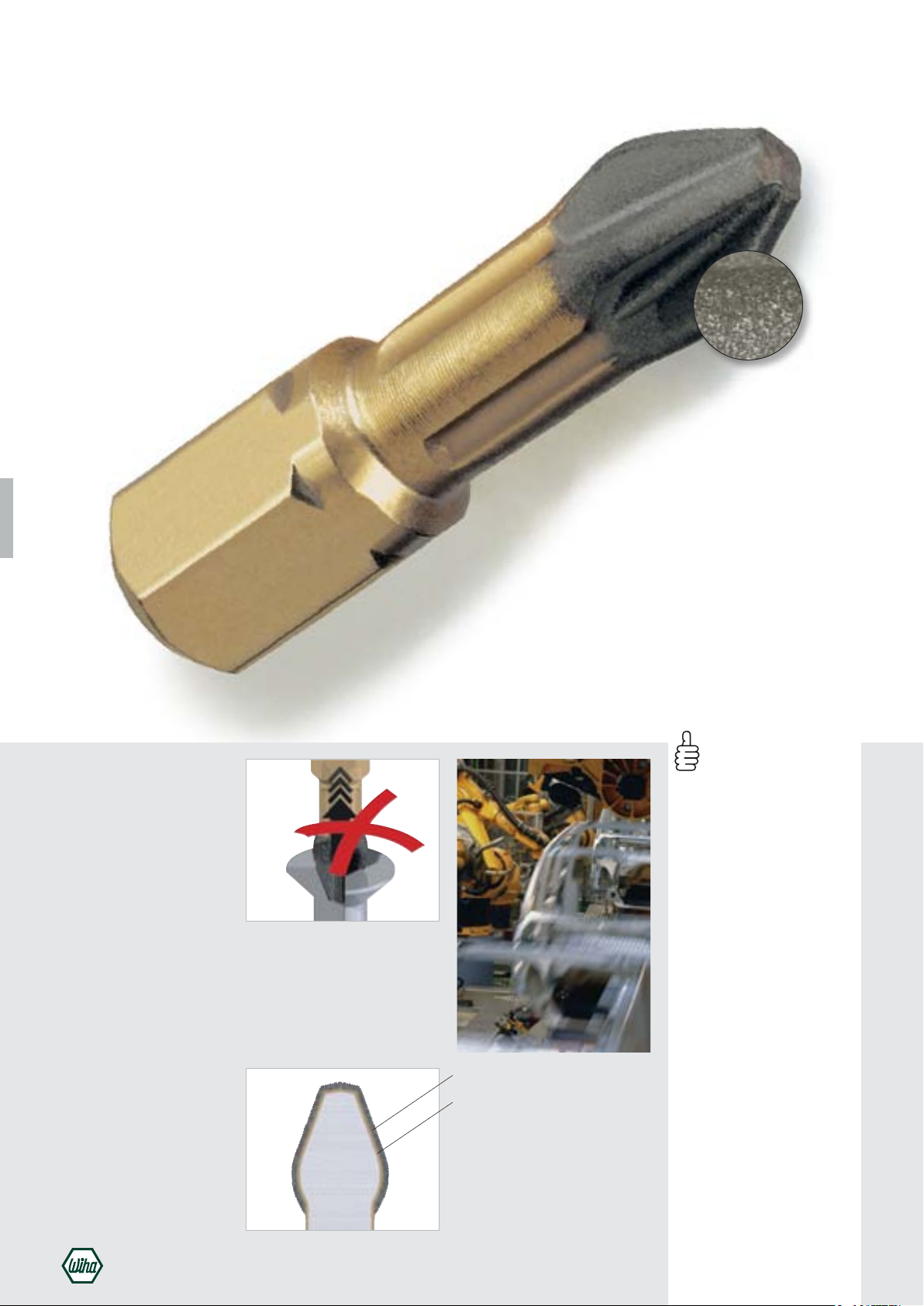

Wiha DuraBit.

A diamond among bits.

The extremely wear-resistant

hard-metal coating considerably

increases tool life.

With DuraBit, Wiha puts its innovative strength to the test. The tough

torsion bit has an extremely wearresistanthard-metalcoating that

gains a secure hold in the screw head.

This revolutionary coating technology

originates from the aerospace

industry and guarantees outstanding

gripping of the bit surface.

The user quickly comes to appreciate

the benefits: a longer tool life,

much reduced cam-out effects and

superior handling enable efficient

work, even with the most difficult of

applications.

The wolfram carbide particles are

permanently applied to the bit tip –

a breaking away of the particles

(as occurs with conventional,

diamond-coated bits) is therefore

significantly reduced.

112

The Dura coating reduces CamOut

effects to an unbeatable minimum –

no more slipping out of the bit from

the screw head.

Wolfram carbide particles.

Non-corroding nickel coating.

Long-lasting, durable wolfram carbide

coating increases service life of the bit

by many times when compared to a

diamond-coated bit. The subjacent nickel

coating ensures extra-long corrosion

resistance.

Wiha DuraBit.

Extremely wear-resistant

•

hard-metal coating also used

in the aerospace industry

gains a secure hold in the

screw head. Outstanding

reduction of CamOut forces

prevents slipping out of the bit

Wolfram carbide particles

•

guarantee a significantly

greater service life when

compared to conventional

diamond-coated bits

Nickel coating of the

•

entire bit for extra-long

corrosion resistance

Clear reduction in the cam-out

•

effect (slipping of the bit out

of the screw head) for:

– Fatigue-free work

(less force required)

– Less wear of bit and screw

– Safe work on delicate

surfaces

Work with Wiha DuraBits

•

featuring torsion zones

reduces the amount of time

for fastening and enables

economic and safe work

Loading...

Loading...