Page 1

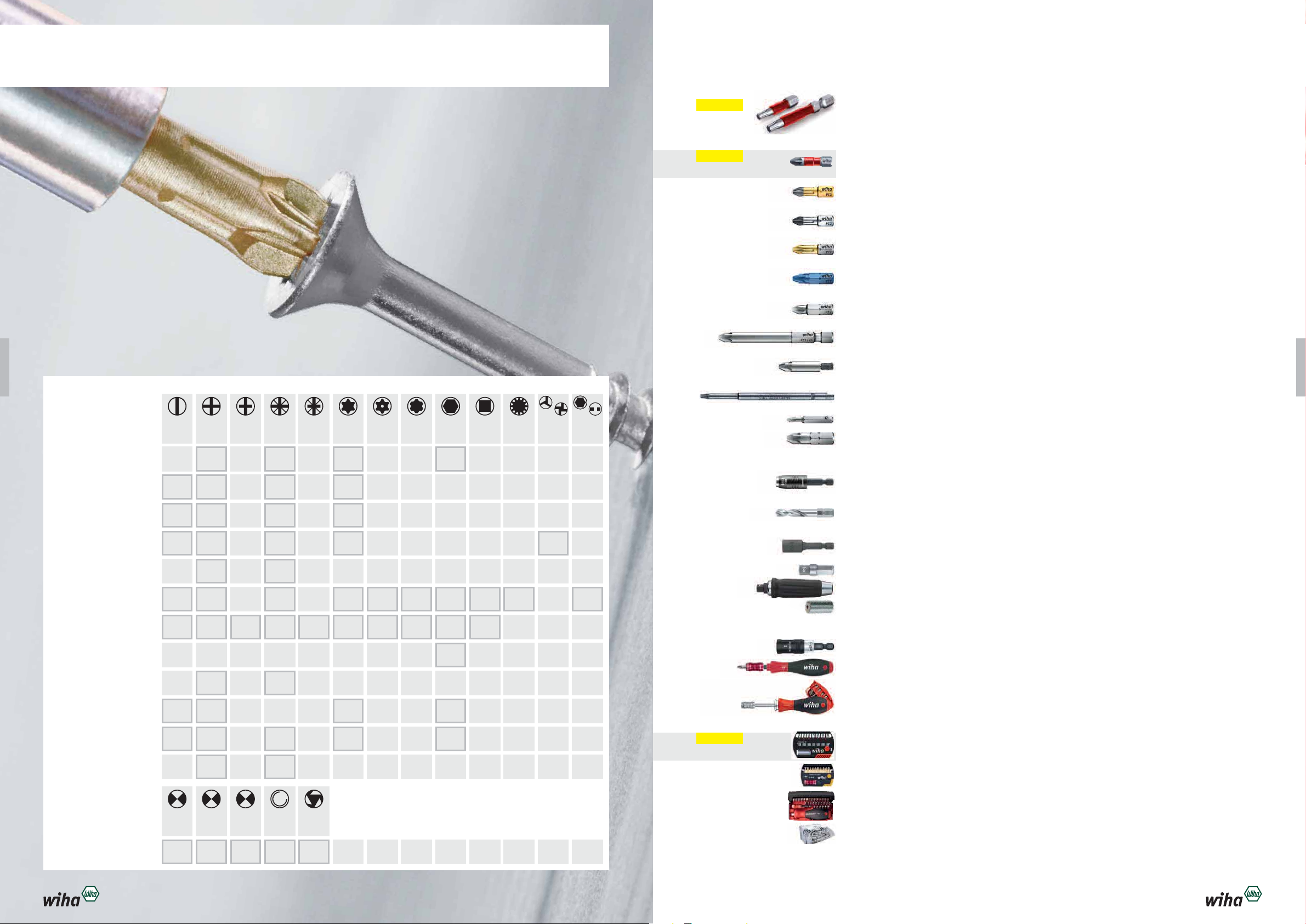

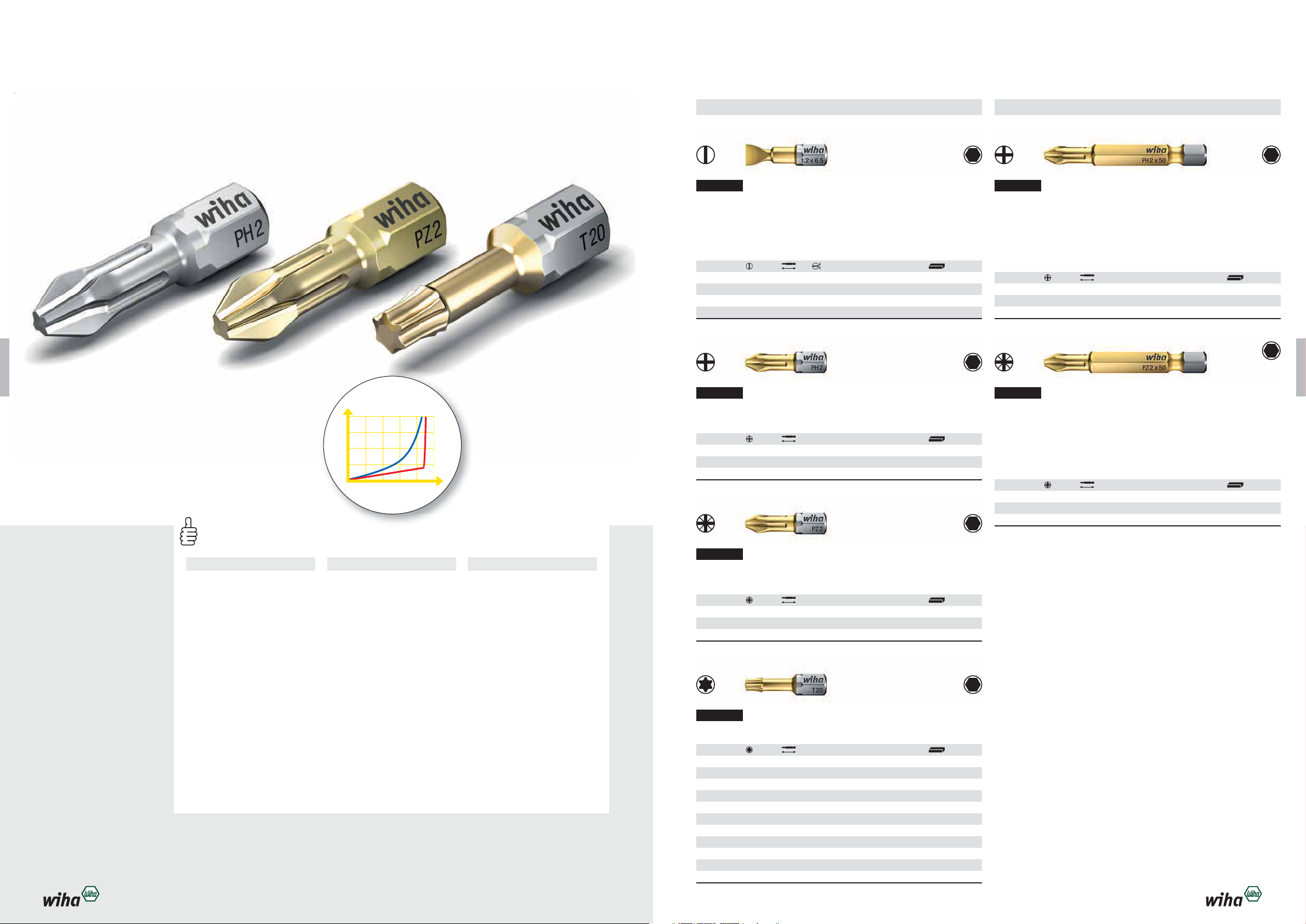

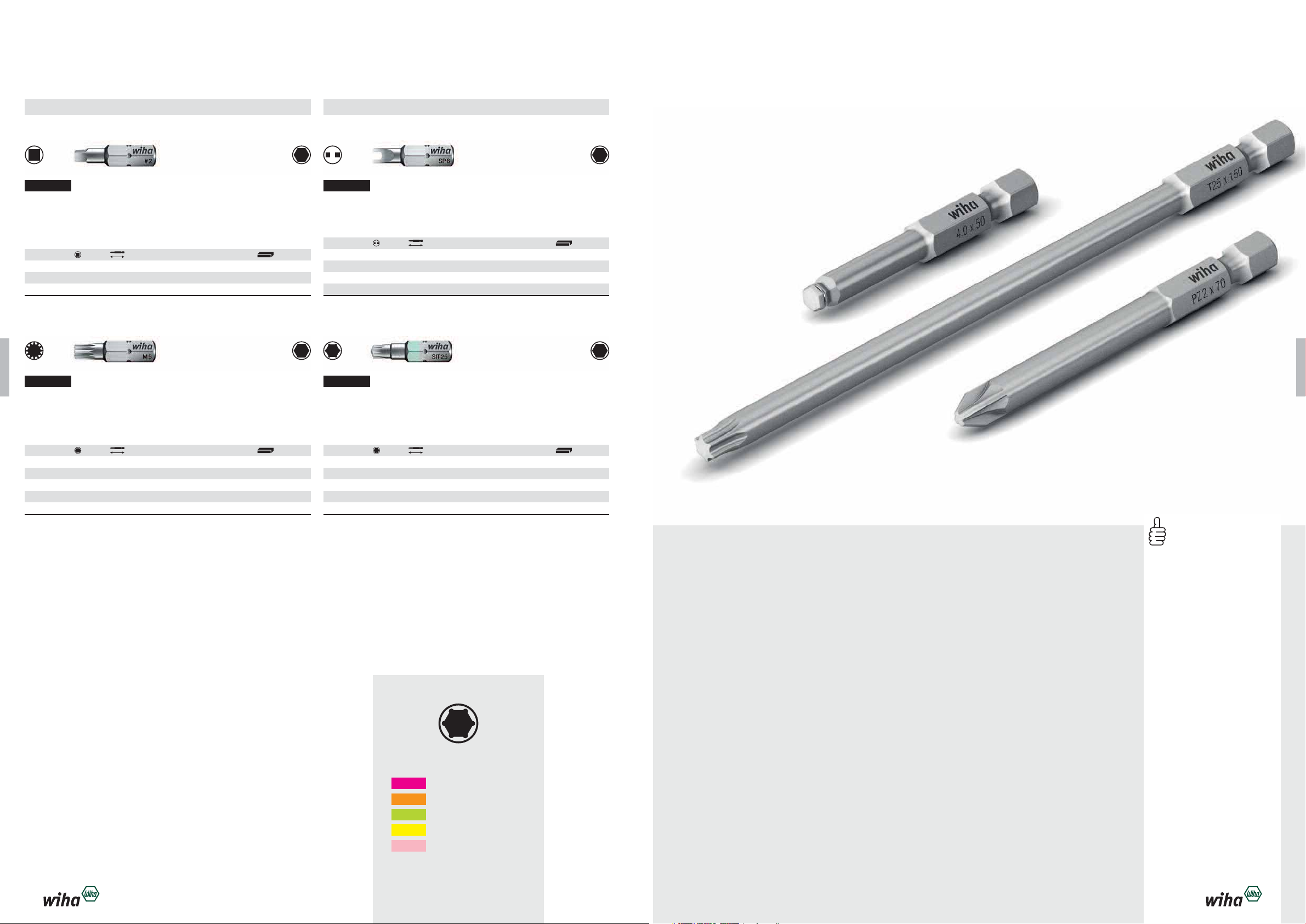

Wiha bits.

www.wiha.com

Wiha makes it possible: Perfect technic for professional work.

Drive

lottedPhillips

S

PH

eno

X

SL/PH

ozidriv

P

Xeno

SL/PZ

PZ

TORX

®

ORX

T

Tamper

Resistant

Bits assortment

NEW

NEW

Available from

1. September 2012

®

TORX

PLUS

ex Square Multi-

H

®

tooth

Tri-Wing

+

Torq-Set

®

®

IT

S

+

Spanner

MaxxTor family.

Maximum torsion

.....................................................................................................................................................

Individual bits, Wiha drive system C 6.3 and E 6.3

Wiha MaxxTor-Bits.

The 2-component bit.

.................................................................................................................................

Wiha DuraBit.

A diamond among bits.

.............................................................................................................................

Wiha diamond bit.

Saves strength, time & money.

...........................................................................................................

Wiha Torsion bit.

Patented torsion zone for longer service life.

..........................................................................

Wiha Inkra bit.

The specialist for every angle.

.............................................................................................................

Wiha Standard bit.

Full programme range in outstanding quality.

........................................................................

Wiha Professional bits.

Wiha Professional Bits - everything but standard.

..............................................................

Wiha threaded bit.

For optimised use in stationary screw systems.

....................................................................

Wiha special bits.

Customised for your application.

Wiha bits for drive system C 4.

......................................................................................................

...........................................................................................................

Wiha bits for drive system style C 8 (5/16") and style G 7.

.........................................

160 – 161

162 – 163

164 – 165

166 – 167

168 – 172

173

174 – 178

179 – 183

184

185

186 – 187

188

MaxxTor-Bits

DuraBits

Diamond torsion bits

Torsion bits

Inkra bits

Standard bits

Professional-Bits

Bits with MagicRing

®

Threaded bit

Bits for drive system C 4

Bits for drive system C 8 5/16"

Bits for drive system G 7

163 163 163 163

165 165 165 165

167 167 167 167

169

–

169

171

–

172

169

172

–

169

171

–

172

173 173

175 175 175 176 176 176 177 178 178 178

181

180 180 180

180

180

182

–

182 182 183 182

177,

183

184 184

186 –

187

186 –

187

186 –

187

186 –

187

188 188 188 188 188

188 188

Wood twist

drill

Twist drill Universal

drill

Combination

drill

Counte r -

sink

NEW

Available from

1. September 2012

Wiha CentroFix system. Quick and professional.

Wiha CentroFix.

One for all.

..........................................................................................................................................................

Wiha drill bits.

Just keep on working.

.................................................................................................................................

Wiha power nut driver product line.

The entire line for hand and machine use.

– Adapters.

.........................................................................................................................................................

– Impact screwdriver assortment.

Wiha Gripper.

Siezes everything

...........................................................................................

...................................................................................................

.

...............................................................................................................

Wiha bit holder

–

Bit holder for power machines

–

Bit holder with handle

–

Offset screwdriver

–

Wiha magazine bit holder

.

.................................................................................................................................

.

...................................................................................................

.

......................................................................................................................

. Everything in the palm of your hand.

Bit ranges

Wiha BitBuddy.

Maximum efficiency by direct insert of bits.

Wiha XSelector and XLSelector.

Couldn't be smaller!

....................................................................................................................................

Wiha Collector.

Everything in one box.

Wiha bit cassette and bulk packs.

...............................................................................................................................

...................................................................................................

...........................................................................

.....................

.............................................................................

189

189

190 – 191

192 – 195

196

197

198

199 – 201

202

203

204 – 207

208 – 211

212 – 219

220 – 221

222 – 223

BohrerBits

190 190 191 191 191

Wiha SB bit programme.

Full programme range in outstanding quality.

...................................................................................

224 – 229

158 159

Page 2

www.wiha.com

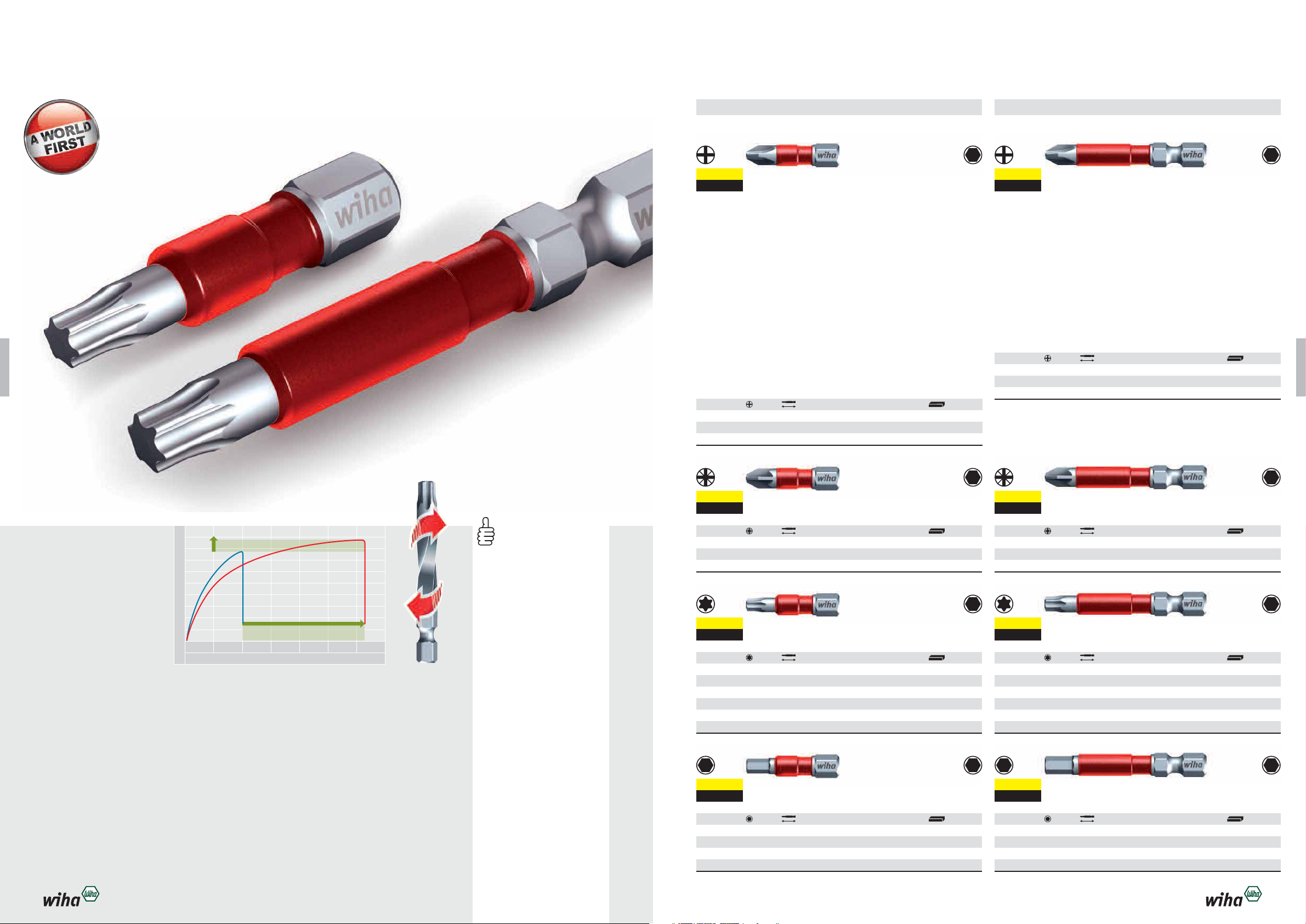

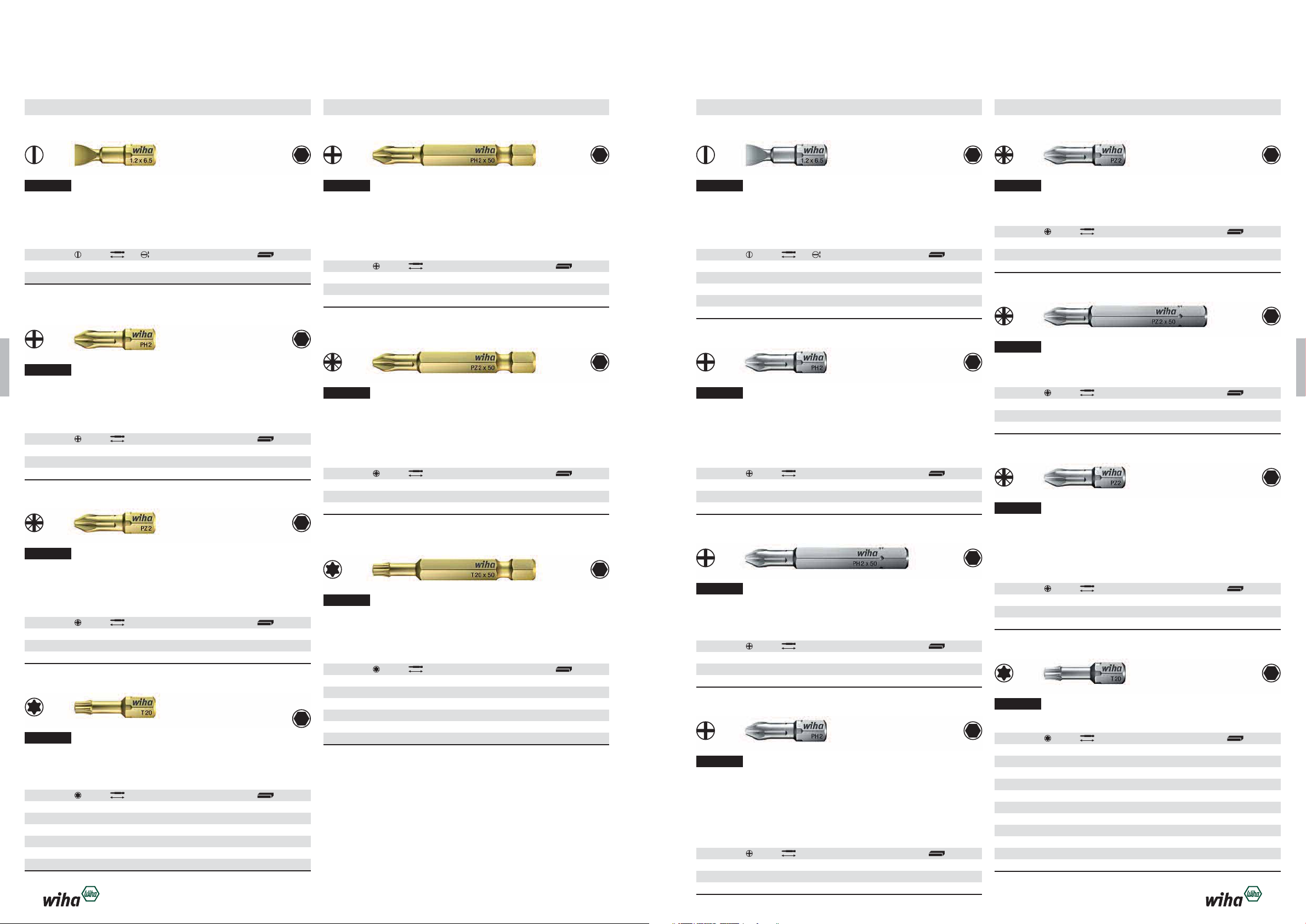

Wiha MaxxTor Family

Maximum torsion

Wiha BitBuddy

Maximum efficiency by direct insert of bits.

Dual component construction

Plastic coating for increased

work safety

29er

The ultimate torsion bit –

plus 4mm length

• Optimal access to low-lying

fastening elements

• A better view of the bit tip

• Simple handling with bit

changing and bit storage

• E6.3 drive

Torque (Nm)

0 10 20 30 40 50 60

49er

The ultimate impact bit

• X-times longer tool life

with impact use

• Greater work safety, no flying

chips

• E6.3 drive

Angel of twist

Wiha MaxxTor family

• Maximum torsion zone

• Service life several times

longer than standard or

torsion bits

• Optimised for tough fastening –

impact applications

• Ideal for high-performance drill

and impact screwdrivers

• Dual component construction –

CA coating for increased work

safety

• E6.3 drive –

perfect functionality in

modern impact screwdrivers

• Impact-tested

er 49er

29

Plug

Work

Store

Wiha BitBuddy

• Maximum efficiency: Direct bit

insertion, Plug & Work & Store

• Single-hand opening mechanism

• Functional sorting system

• Compact – handy

• Design tried and tested a million times

160 161

Page 3

Wiha MaxxTor bits.

The 2-component bit.

www.wiha.com

29-series MaxxTor bit.

NEW

7011 M9T

Material: High quality alloyed tool steel, optimally hardened.

Geometry: Maximum length torsion zone individually matched to the profile.

Drive: DIN 3126, ISO 1173, Form C 6.3, also compatible with bit mount for E 6.3

Packaging: 5 Bits in a plastic box.

Application: Service life several times longer than 25 mm standard bits.

Extra: Plus 4 mm length.

Order-No.

36812 PH1 29 5

36813 PH2 29 5

36814 PH3 29 5

29er MaxxTor bit, Phillips, style C 6.3.

Casing of transparent, impact resistant plastic.

Precision-milled profile for perfect fit and maximum performance.

bits.

Plastic box, reusable and dust repellent.

The ultimate torsion bit. Ideally suited for high-performance drill and

impact screwdrivers.

Additional range.

A better view of the bit tip.

Simpler bit change with extended grip zone.

Two-component construction – Plastic coating for increased work safety.

Practical laser marking for easy identification of size.

49-series MaxxTor bit.

7041 M9T

Material: High quality alloyed tool steel, optimally hardened.

Geometry: Extremely long torsion zone individually matched to the profile.

Drive: DIN 3126, ISO 1173, style C 6.3.

Packaging: 5 Bits in a plastic box.

Application: Service life several times longer than 50 mm standard bits with impact

Extra: Two-component construction – Plastic coating for increased work safety.

O

3

36829 PH2 49 5

36830 PH3 49 5

NEW

49er MaxxTor bit, Phillips, style E 6.3.

Casing of transparent, impact resistant plastic.

Precision-milled profile for perfect fit and maximum performance.

Plastic box, reusable and dust repellent.

use.

The ultimate impact bit.

Ideally suited for high-performance impact screwdrivers.

Practical laser marking for easy identification of size.

rder-No.

6828 PH1 49

5

Thanks to innovative 2-component

technology, equipped for increasing demands: the MaxxTor bits

offer a level of safety and service

life unknown until now.

High-performance drill and impact

screwdrivers place tough demands

on bits, for example via changing

loads with impact screwdrivers or

especially tough fastenings. Thus

standard bits are quickly unable to

meet the challenge.

That's not the case with MaxxTor

bits! With their maximum torsion

zone (MaxxTor), the service life of

the bits is significantly increased.

162

Torque (Nm)

0 10 20 30 40 50 60

Angel of twist

A further plus factor: with length

extension from 25 to 29 mm the

bits now reach low-lying fastening

elements. Thanks to the length extension, direct insertion into the

E6.3 drives of impact screwdriver

machines is simple.

And the impact-tested quality and

hardness is dependable. Added to

this is optimal guidance and high

work safety with the CA cover. This

protects from injuries due to flying

parts with shattering.

Together with the innovative BitBuddy bit holder, the bits can be

easily changed with one hand and

securely stored.

Perfectly adapted: with its 2-component construction the MaxxTor

bit solves problems where standard bits fail.

In a word: top performance, especially with tough fastenings.

Wiha MaxxTor bits.

Maximum service life thanks to

•

maximum torsion zone

The ideal torsion bit: 29-series

•

and 49-series

Optimal hardness for high loads

•

and especially tough fastenings

For high-performance drill and

•

impact screwdrivers

29 mm: an additional 4 mm for

•

significantly improved access

Innovative 2-component con-

•

struction

Maximum safety due to pro-

•

tective CA cover

For all applications: PH, PZ, Torx

•

and hexagon

NEW

7012 M9T

Order-No.

36815 PZ1 29 5

36816 PZ2 29 5

36817 PZ3 29 5

NEW

7015 M9T

Order-No.

36822 T10 29 5

36823 T15 29 5

36824 T20 29 5

36825 T25 29 5

36826 T30 29 5

36827 T40 29 5

NEW

7013 M9T

Order-No.

36818 3.0 29 5

36819 4.0 29 5

36820 5.0 29 5

36821 6.0 29 5

Available from 1. September 2012

29er MaxxTor bit, Pozidriv, style C 6.3.

5 Bits in a plastic box.

29er MaxxTor bit, TORX®, style C 6.3.

5 Bits in a plastic box.

29er MaxxTor bit, hexagon, style C 6.3.

5 Bits in a plastic box.

NEW

7042 M9T

Order-No.

36831 PZ1 49 5

36832 PZ2 49 5

36833 PZ3 49 5

NEW

7045 M9T

Order-No.

36838 T10 49 5

36839 T15 49 5

36840 T20 49 5

36841 T25 49 5

36842 T30 49 5

36843 T40 49 5

NEW

7043 M9T

Order-No.

36834 3.0 49 5

36835 4.0 49 5

36836 5.0 49 5

36837 6.0 49 5

49er MaxxTor bit, Pozidriv, style E 6.3.

5 Bits in a plastic box.

49er MaxxTor bit, TORX®, style E 6.3.

5 Bits in a plastic box.

49er MaxxTor bit, hexagon, style E 6.3.

5 Bits in a plastic box.

163

Page 4

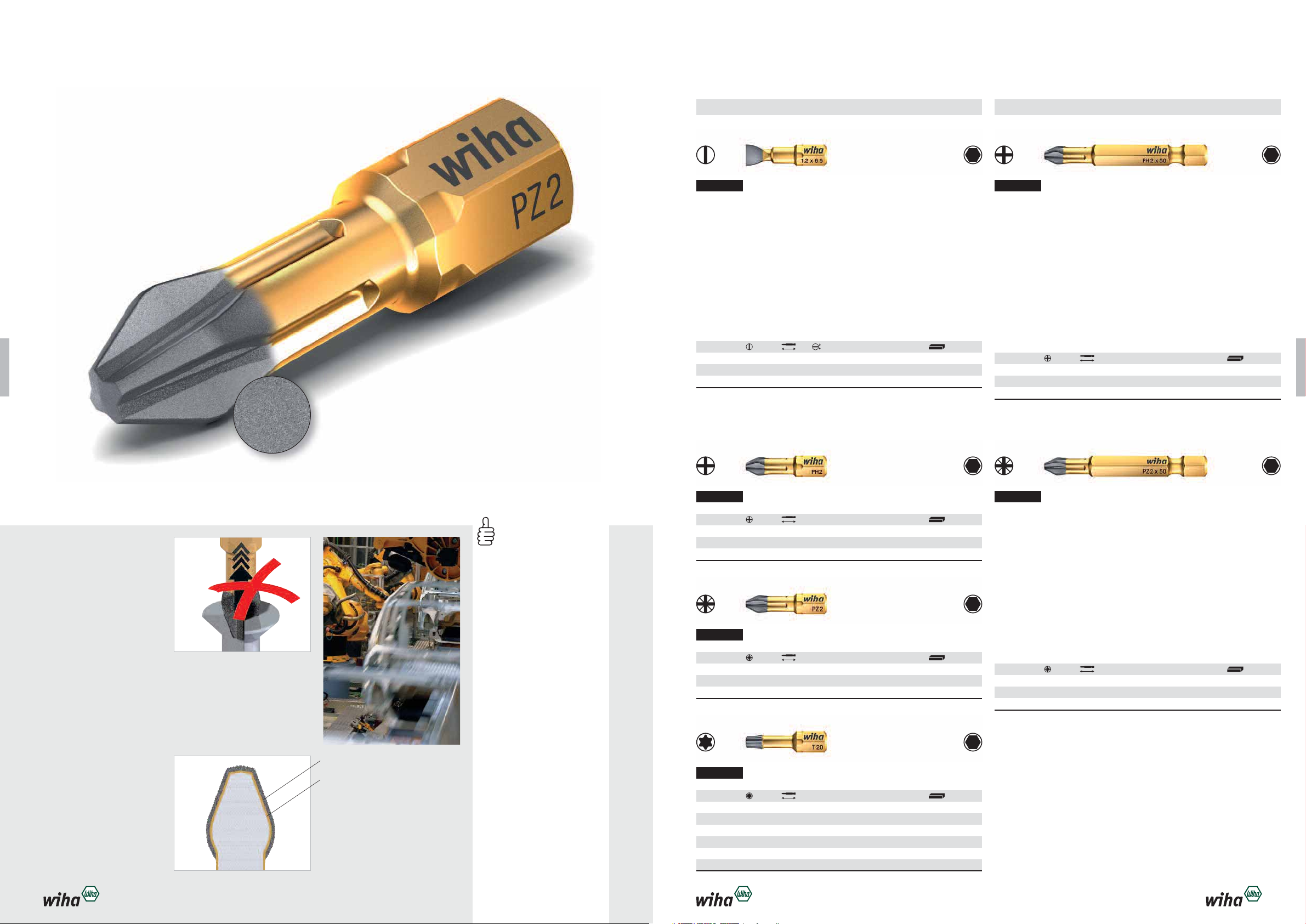

Wiha DuraBit.

A diamond among bits.

www.wiha.com

The extremely wear-resistant

hard-metal coating considerably

increases tool life.

Style C 6.3 (1/4").

7010 DR

aterial: High grade chrome-vanadium steel, through hardened.

M

eometry: Torsion zone for protecting against premature breakage of bits under load.

G

oating: Hard-metal coating, extremely wear-resistant.

C

Drive: DIN 3126, ISO 1173, style C 6.3.

Application: For effortless, safe working in demanding industrial applications and

xtra: Non-corroding nickel coating in combination with wolfram carbide particles.

E

Order-No.

23104 4.5 25 0.6 10

23106 5.5 25 0.8 10

23110 6.5 25 1.2 10

DuraBit with torsion zone, slotted, style C 6.3.

on delicate surfaces.

xtremely wear-resistant, hard-metal coated DuraBit tip gains a secure

E

hold in the screw head and guarantees a significantly greater service life

when compared to conventional diamond-coated bits.

Outstanding reduction of CamOut forces prevents slipping out of the bit

rom the screw.

f

Style C 6.3 and E 6.3 (1/4").

7041 DR

Material: High grade chrome-vanadium steel, through hardened.

Geometry: Patented torsion zone to prevent premature breaking of the bit when

Coating: Hard-metal coating, extremely wear-resistant.

Drive: DIN 3126, ISO 1173, style E 6.3.

Application: For effortless, safe working in demanding industrial applications and on

Extra: Non-corroding nickel coating in combination with wolfram carbide particles.

Order-No.

23388 PH1 50 5

23390 PH2 50 5

23392 PH3 50 5

DuraBit with torsion zone, Phillips, style E 6.3.

under stress.

delicate surfaces.

Extremely wear-resistant, hard-metal coated DuraBit tip gains a secure

hold in the screw head and guarantees a significantly greater service life

when compared to conventional diamond-coated bits.

Outstanding reduction of CamOut forces prevents slipping out of the bit

from the screw.

With DuraBit, Wiha puts its innovative strength to the test. The tough

torsion bit has an extremely wearresistant hard-metal coating that

gains a secure hold in the

screw head.

This revolutionary coating

technology originates from the

aerospace industry and guarantees

outstanding gripping of the bit

surface. The user quickly comes

to appreciate the benefits: a longer

tool life, much reduced cam-out

effects and superior handling

enable efficient work, even with

the most difficult of applications.

The wolfram carbide particles are

permanently applied to the bit tip a breaking away of the particles

(as occurs with conventional,

diamond-coated bits) is therefore

significantly reduced.

164

The Dura coating reduces CamOut

effects to an unbeatable minimum no more slipping out of the bit from

the screw head.

Wolfram carbide particles.

Non-corroding nickel coating.

Long-lasting, durable wolfram carbide

coating increases service life of the bit

by many times when compared to a

diamond-coated bit. The subjacent nickel

coating ensures extra-long corrosion

resistance.

Wiha DuraBit.

Extremely wear-resistant

•

hard-metal coating also used

in the aerospace industry

gains a secure hold in the

screw head. Outstanding

reduction of CamOut forces

prevents slipping out of the bit

Wolfram carbide particles

•

guarantee a significantly

greater service life when

compared to conventional

diamond-coated bits

Nickel coating of the

•

entire bit for extra-long

corrosion resistance

Clear reduction in the cam-out

•

effect (slipping of the bit out

of the screw head) for:

– Fatigue-free work

(less force required)

– Less wear of bit and screw

– Safe work on delicate

surfaces

Work with Wiha DuraBits

•

featuring torsion zones

reduces the amount of time

for fastening and enables

economic and safe work

7011 DR

Order-No.

23114 PH1 25 10

23116 PH2 25 10

23118 PH3 25 10

7012 DR

Order-No.

23120 PZ1 25 10

23122 PZ2 25 10

23124 PZ3 25 10

7015 DR

Order-No.

23133 T10 25 10

23135 T15 25 10

23137 T20 25 10

23139 T25 25 10

23141 T30 25 10

23143 T40 25 10

DuraBit with torsion zone, Phillips, style C 6.3.

DuraBit with torsion zone, Pozidriv, style C 6.3.

DuraBit with torsion zone, TORX®, style C 6.3.

7042 DR

Material: High grade chrome-vanadium steel, through hardened.

Geometry: Patented torsion zone to prevent premature breaking of the bit when

Coating: Hard-metal coating, extremely wear-resistant.

Drive: DIN 3126, ISO 1173, style E 6.3.

Application: For effortless, safe working in demanding industrial applications and on

Extra: Non-corroding nickel coating in combination with wolfram carbide particles.

Order-No.

23394 PZ1 50 5

23396 PZ2 50 5

23398 PZ3 50 5

DuraBit with torsion zone, Pozidriv, style E 6.3.

under stress.

delicate surfaces.

Extremely wear-resistant, hard-metal coated DuraBit tip gains a secure

hold in the screw head and guarantees a significantly greater service life

when compared to conventional diamond-coated bits.

Outstanding reduction of CamOut forces prevents slipping out of the bit

from the screw.

165

Page 5

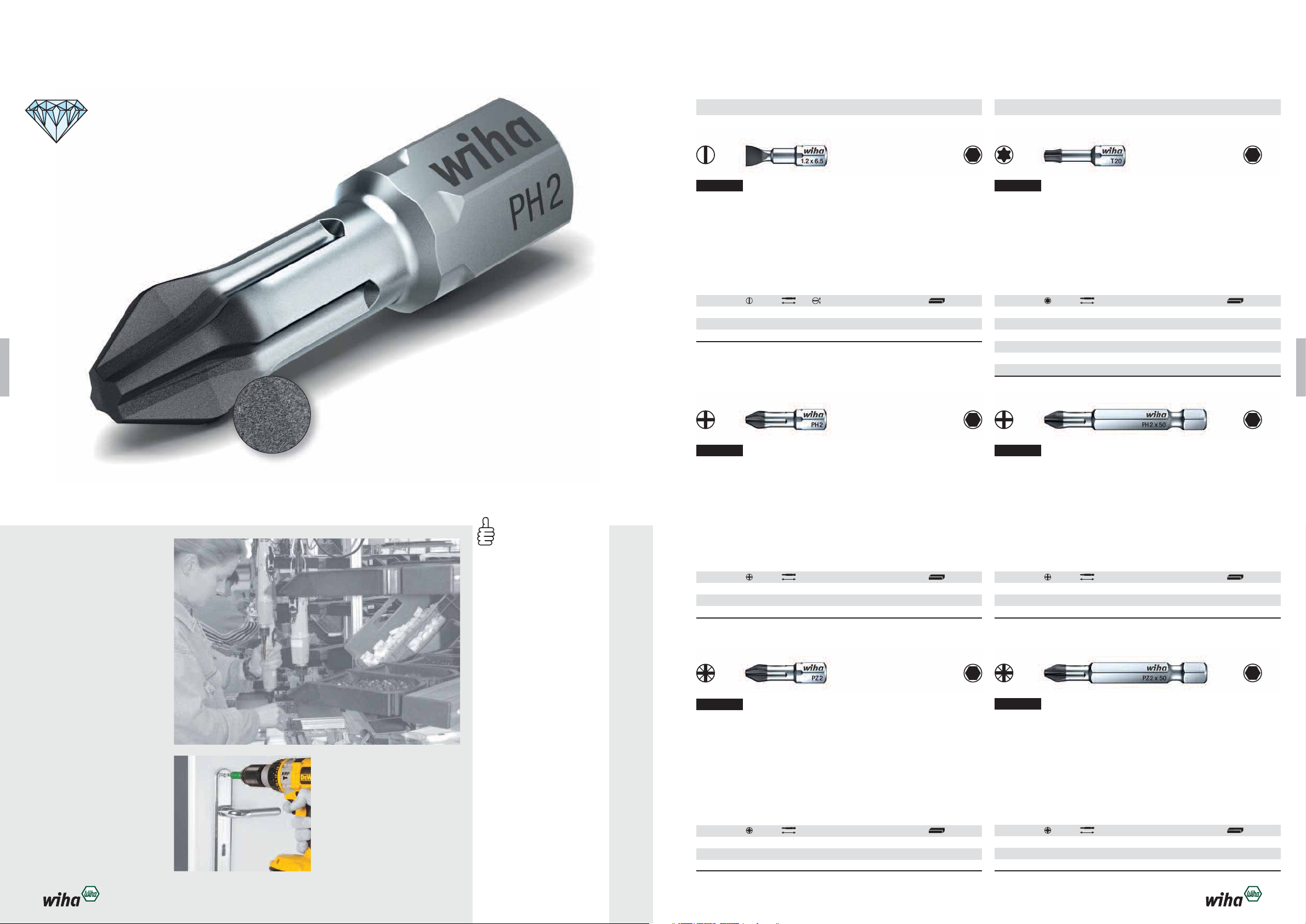

Wiha diamond bit.

Saves strength, time & money.

www.wiha.com

Diamond torsion bits supplement

Wiha’s range of high-quality special bits. In the area of mechanical

fastening the significantly greater

tool life means substantial cost

reductions. The new Wiha diamond

torsion bits are recognisable by

their silver look and striking black

tip and offer an impressively

secure grip in the screw.

Finest diamond particles

and sapphire particles

ensure a firm grip a

thousand times over.

The Diamond torsion bit from Wiha scores

on two accounts:

it reduces the amount of pressure that has

to be applied and increases the tool life.

The torsion zone protects against torque

peaks.

Wiha diamond bit.

Reduction of:

•

- Pressure forces to be applied

- Wear and tear of bit and screw

head

- The amount of time to

turn the screw and thus

reduction in the costs of

screw applications

- Cam-out effect

Extended service life as

•

a result of the improved

torsion zone

Nickel coating of the entire

•

bit for extra-long corrosion

resistance

Style C 6.3 (1/4").

7010 D

Material: High grade chrome-vanadium steel, through hardened.

Geometry: Torsion zone for protecting against premature breakage of bits under load.

Coating: Extremely wear-resistant diamond-sapphire coating with a long service life.

Drive: DIN 3126, ISO 1173, style C 6.3.

Application: For fatigue-free work; ideal bit for frequent working.

Extra: Non-corrosive coating.

Order-No.

21272 4.5 25 0.6 10

21216 5.5 25 0.8 10

21220 6.5 25 1.2 10

7011 D

Material: High grade chrome-vanadium steel, through hardened.

Geometry: Patented torsion zone to prevent premature breaking of the bit when

Coating: Extremely wear-resistant diamond-sapphire coating with a long service life.

Drive: DIN 3126, ISO 1173, style C 6.3.

Application: For fatigue-free work; ideal bit for frequent working.

Extra: Non-corrosive coating.

Order-No.

21193 PH1 25 10

21194 PH2 25 10

21196 PH3 25 10

7012 D

Material: High grade chrome-vanadium steel, through hardened.

Geometry: Patented torsion zone to prevent premature breaking of the bit when

Coating: Extremely wear-resistant diamond-sapphire coating with a long service life.

Drive: DIN 3126, ISO 1173, style C 6.3.

Application: For fatigue-free work; ideal bit for frequent working.

Extra: Non-corrosive coating.

Order-No.

21198 PZ1 25 10

21200 PZ2 25 10

21202 PZ3 25 10

Diamond torsion bit, slotted, style C 6.3.

Diamond particles and sapphire particles for optimum torque transfer and

a secure grip in the screw head.

Diamond torsion bit, Phillips, style C 6.3.

under stress.

Diamond particles and sapphire particles for optimum torque transfer and

a secure grip in the screw head.

Diamond torsion bit, Pozidriv, style C 6.3.

under stress.

Diamond particles and sapphire particles for optimum torque transfer and

a secure grip in the screw head.

Style C 6.3 and E 6.3 (1/4").

7015 D

Material: High grade chrome-vanadium steel, through hardened.

Geometry: Torsion zone for protecting against premature breakage of bits under load.

Coating: Extremely wear-resistant diamond-sapphire coating with a long service life.

Drive: DIN 3126, ISO 1173, style C 6.3.

Application: For fatigue-free work; ideal bit for frequent working.

Extra: Non-corrosive coating.

Order-No.

21204 T10 25 10

21206 T15 25 10

21208 T20 25 10

21210 T25 25 10

21212 T30 25 10

21214 T40 25 10

7041 D

Material: High grade chrome-vanadium steel, through hardened.

Geometry: Patented torsion zone to prevent premature breaking of the bit when

Coating: Extremely wear-resistant diamond-sapphire coating with a long service life.

Drive: DIN 3126, ISO 1173, style E 6.3.

Application: For fatigue-free work; ideal bit for frequent working.

Extra: Non-corrosive coating.

Order-No.

23376 PH1 50 5

23378 PH2 50 5

23380 PH3 50 5

7042 D

Material: High grade chrome-vanadium steel, through hardened.

Geometry: Patented torsion zone to prevent premature breaking of the bit when

Coating: Extremely wear-resistant diamond-sapphire coating with a long service life.

Drive: DIN 3126, ISO 1173, style E 6.3.

Application: For fatigue-free work; ideal bit for frequent working.

Extra: Non-corrosive coating.

Order-No.

23382 PZ1 50 5

23384 PZ2 50 5

23386 PZ3 50 5

Diamond torsion bit, TORX®, style C 6.3.

Diamond particles and sapphire particles for optimum torque transfer and

a secure grip in the screw head.

Diamond torsion bit, Phillips, style E 6.3.

under stress.

Diamond particles and sapphire particles for optimum torque transfer and

a secure grip in the screw head.

Diamond torsion bit, Pozidriv, style E 6.3.

under stress.

Diamond particles and sapphire particles for optimum torque transfer and

a secure grip in the screw head.

166

167

Page 6

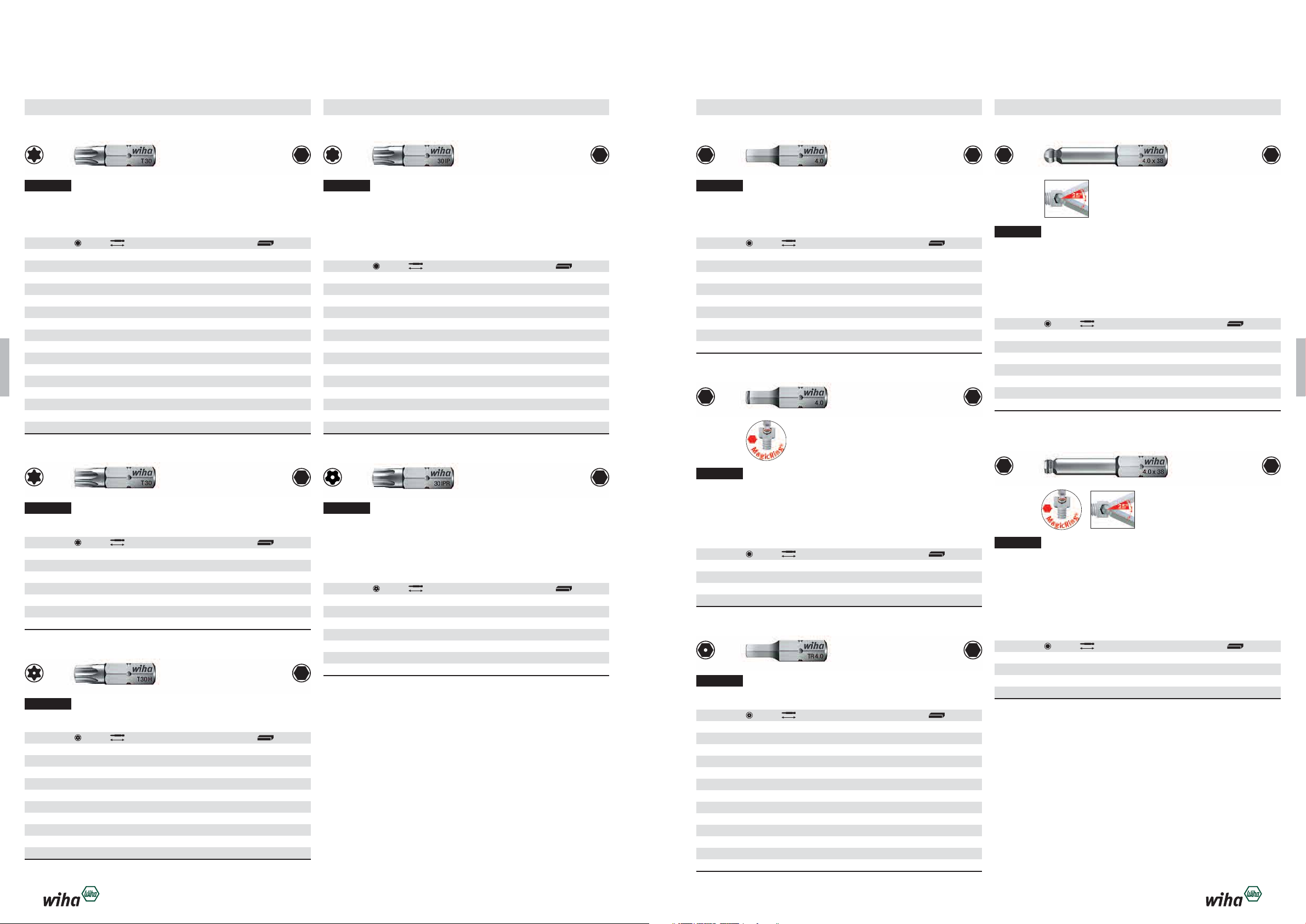

Wiha Torsion bit.

Patented torsion zone for longer service life.

www.wiha.com

Torque

Time

The red line indicates the steep

increase in torque with hard

applications, e.g. in metal.

The blue line shows a steady

torque increase in soft applications,

e.g. in wood working.

Style C 6.3 (1/4").

7010 TiN

Material: High grade chrome-vanadium steel, through hardened.

Geometry: Torsion zone for protecting against premature breakage of bits under load.

Coating: Titanium nitride for extended tool life.

Drive: DIN 3126, ISO 1173, style C 6.3.

Application: Particularly suitable for screws that require frequent working.

Order-No.

04743 4.5 25 0.6 10

04744 5.5 25 0.8 10

04745 6.5 25 1.2 10

04746 8.0 25 1.2 10

7011 TiN

Geometry: Patented torsion zone to prevent premature breaking of the bit when

Order-No.

04654 PH1 25 10

04655 PH2 25 10

04656 PH3 25 10

TiN Torsion bit, slotted, style C 6.3.

TiN Torsion bit, Phillips, style C 6.3.

under stress.

Style E 6.3 (1/4").

7041 TiN

Material: High grade chrome-vanadium steel, through hardened.

Geometry: Patented torsion zone to prevent premature breaking of the bit when

Coating: Titanium nitride for extended tool life.

Drive: DIN 3126, ISO 1173, style E 6.3.

Application: Particularly suitable for screws that require frequent working.

Order-No.

04861 PH1 50 5

04862 PH2 50 5

04863 PH3 50 5

7042 TiN

Material: High grade chrome-vanadium steel, through hardened.

Geometry: Patented torsion zone to prevent premature breaking of the bit when

Coating: Titanium nitride for extended tool life.

Drive: DIN 3126, ISO 1173, style E 6.3.

Application: Particularly suitable for screws that require frequent working.

Order-No.

04864 PZ1 50 5

04865 PZ2 50 5

04866 PZ3 50 5

TiN Torsion bit, Phillips, style E 6.3.

under stress.

TiN Torsion bit, Pozidriv, style E 6.3.

under stress.

The main cause of wear with soft

fastening applications such as in

wood for example is the wear of the

profile edges because the bit

rattles through. A hard bit needs to

be used here: Wiha HOT.

With hard fastening jobs such as

hitting metal surfaces the main

reason for wear is breakage of the

bits. These usually occur with

torque peaks near to the end of

the fastening process.

A tough-but-flexible bit is the

answer: Wiha ZOT.

The special assortment of Wiha

torsion bits with torsion zones

offers optimal products for both

soft and hard fastening tasks.

Wiha Torsion bit.

Wiha ZOT Torsion bits

• Tough, hard Torsion quality for

hard applications

• Ideal for screw applications

in metal and hard materials

• Elastic Torsion zone absorbs

the strong torque peaks in the

final phase of the application

(red line)

Highly resistant to wear and tear

•

due to special heat treatment

• Hardness 61-2 HRC.

• For trade and DIY

Wiha HOT Torsion bits

• Extra hard Torsion quality for

soft applications

• Ideal for screw applications

in wood and soft materials

• Average requirements

concerning elasticity are used

to optimise performance and

resistance to wear and tear

(blue line)

• Hardness 63-2 HRC.

• For trade and DIY

Wiha TiN Torsions bits

• Tough, hard Torsion quality

with very hard titanium-nitride

(TiN) coating

• Optimum resistance to wear

and tear due to very hard TiN

coating

• Combines the advantages

of Wiha HOT bits and ZOT bits

in one outstanding bit

• For trade and DIY,

especially for industry

7012 TiN

Geometry: Patented torsion zone to prevent premature breaking of the bit when

Order-No.

04657 PZ1 25 10

04658 PZ2 25 10

04659 PZ3 25 10

7015 TiN

Geometry: Torsion zone for protecting against premature breakage of bits under load.

Order-No.

20964 T6 25 10

20966 T7 25 10

20968 T8 25 10

20970 T9 25 10

20972 T10 25 10

20974 T15 25 10

20976 T20 25 10

20978 T25 25 10

20980 T27 25 10

20982 T30 25 10

20984 T40 25 10

TiN Torsion bit, Pozidriv, style C 6.3.

under stress.

TiN Torsion bit, TORX®, style C 6.3.

168

169

Page 7

Wiha Torsion bit.

Patented torsion zone for longer service life.

www.wiha.com

Style C 6.3 (1/4").

7010 HOT

Material: High-grade chrome-vanadium steel, through-hardened, extra-hard.

Geometry: Torsion zone for protecting against premature breakage of bits under load.

Drive: DIN 3126, ISO 1173, style C 6.3.

Application: Particularly suitable for turning screws in wood and soft materials.

Order-No.

05295 5.5 25 0.8 10

05296 6.5 25 1.2 10

7011 HOT

Material: High-grade chrome-vanadium steel, through-hardened, extra-hard.

Geometry: Patented torsion zone to prevent premature breaking of the bit when

Drive: DIN 3126, ISO 1173, style C 6.3.

Order-No.

04486 PH1 25 10

04485 PH2 25 10

04484 PH3 25 10

7012 HOT

Material: High-grade chrome-vanadium steel, through-hardened, extra-hard.

Geometry: Patented torsion zone to prevent premature breaking of the bit when

Drive: DIN 3126, ISO 1173, style C 6.3.

Order-No.

04483 PZ1 25 10

04482 PZ2 25 10

04481 PZ3 25 10

7015 HOT

Material: High-grade chrome-vanadium steel, through-hardened, extra-hard.

Geometry: Torsion zone for protecting against premature breakage of bits under load.

Drive: DIN 3126, ISO 1173, style C 6.3.

Order-No.

31815 T10 25 10

31816 T15 25 10

31817 T20 25 10

31818 T25 25 10

31819 T30 25 10

31820 T40 25 10

170

HOT Torsion bit, slotted, style C 6.3.

HOT Torsion bit, Phillips, style C 6.3.

under stress.

HOT Torsion bit, Pozidriv, style C 6.3.

under stress.

HOT Torsion bit, TORX®, style C 6.3.

Style E 6.3 (1/4").

7041 HOT

Material: High-grade chrome-vanadium steel, through-hardened, extra-hard.

Geometry: Patented torsion zone to prevent premature breaking of the bit when

Drive: DIN 3126, ISO 1173, style E 6.3.

Application: Particularly suitable for turning screws in wood and soft materials.

Order-No.

04544 PH1 50 5

04543 PH2 50 5

04542 PH3 50 5

7042 HOT

Material: High-grade chrome-vanadium steel, through-hardened, extra-hard.

Geometry: Patented torsion zone to prevent premature breaking of the bit when

Drive: DIN 3126, ISO 1173, style E 6.3.

Application: Particularly suitable for turning screws in wood and soft materials.

Order-No.

04550 PZ1 50 5

04549 PZ2 50 5

04548 PZ3 50 5

7045 HOT

Material: High-grade chrome-vanadium steel, through-hardened, extra-hard.

Geometry: Torsion zone for protecting against premature breakage of bits under load.

Drive: DIN 3126, ISO 1173, style E 6.3.

Application: Particularly suitable for turning screws in wood and soft materials.

Order-No.

33666 T10 50 5

33667 T15 50 5

33668 T20 50 5

33669 T25 50 5

33670 T30 50 5

33671 T40 50 5

HOT Torsion bit, Phillips, style E 6.3.

under stress.

HOT Torsion bit, Pozidriv, style E 6.3.

under stress.

HOT Torsion bit, TORX®, style E 6.3.

Style C 6.3 (1/4").

7010 ZOT

Material: High-quality chrome-vanadium steel, through-hardened, hard but elastic.

Geometry: Torsion zone for protecting against premature breakage of bits under load.

Drive: DIN 3126, ISO 1173, style C 6.3.

Application: Particularly suitable for turning screws in metal and hard materials.

Order-No.

05288 4.5 25 0.6 10

05289 5.5 25 0.8 10

05290 5.5 25 1.0 10

05292 6.5 25 1.2 10

05293 8.0 25 1.2 10

7011 ZOT

Material: High-quality chrome-vanadium steel, through-hardened, hard but elastic.

Geometry: Patented torsion zone to prevent premature breaking of the bit when

Drive: DIN 3126, ISO 1173, style C 6.3.

Application: Particularly suitable for turning screws in metal and hard materials.

Order-No.

05299 PH1 25 10

05076 PH2 25 10

05077 PH3 25 10

7011 ZOT L

Material: High-quality chrome-vanadium steel, through-hardened, hard but elastic.

Geometry: Patented torsion zone to prevent premature breaking of the bit when

Order-No.

04699 PH1 50 10

04697 PH2 50 10

04695 PH3 50 10

7011 ACR

Material: High grade chrome-vanadium steel, through hardened.

Geometry: Patented torsion zone to prevent premature breaking of the bit when

Drive: DIN 3126, ISO 1173, style C 6.3.

Extra: Anti-Cam-Out ribs ensure a secure grip in the screw and

Order-No.

04919 PH1 25 10

04920 PH2 25 10

04921 PH3 25 10

ZOT Torsion bit, slotted, style C 6.3.

ZOT Torsion bit, Phillips, style C 6.3.

under stress.

ZOT Torsion bit, Phillips, style C 6.3.

under stress.

ACR®torsion bit, Phillips, style C 6.3.

under stress.

good force transfer.

Style C 6.3 (1/4").

7012 ZOT

Geometry: Patented torsion zone to prevent premature breaking of the bit when

Order-No.

05074 PZ1 25 10

05075 PZ2 25 10

05069 PZ3 25 10

7012 ZOT L

Geometry: Patented torsion zone to prevent premature breaking of the bit when

Order-No.

04693 PZ1 50 10

04691 PZ2 50 10

04689 PZ3 50 10

7012 ACR

Material: High grade chrome-vanadium steel, through hardened.

Geometry: Patented torsion zone to prevent premature breaking of the bit when

Extra: Anti-Cam-Out ribs ensure a secure grip in the screw and

Order-No.

04922 PZ1 25 10

04923 PZ2 25 10

04924 PZ3 25 10

7015 ZOT

Geometry: Torsion zone for protecting against premature breakage of bits under load.

Order-No.

20940 T6 25 10

20942 T7 25 10

20945 T8 25 10

20946 T9 25 10

20948 T10 25 10

20950 T15 25 10

20952 T20 25 10

20954 T25 25 10

20956 T27 25 10

20958 T30 25 10

20960 T40 25 10

ZOT Torsion bit, Pozidriv, style C 6.3.

under stress.

ZOT Torsion bit, Pozidriv, style C 6.3.

under stress.

ACR®torsion bit, Pozidriv, style C 6.3.

under stress.

good force transfer.

ZOT Torsion bit, TORX®, style C 6.3.

171

Page 8

www.wiha.com

Wiha Torsions-Bit.

Patented torsion zone for longer service life.

Style C 6.3 and E 6.3 (1/4").

7019 ZOT TW

Material: High-quality chrome-vanadium steel, through-hardened, hard but elastic.

Geometry: Torsion zone for protecting against premature breakage of bits under load.

Drive: DIN 3126, ISO 1173, style C 6.3.

Application: For Tri-Wing®security screws.

Order-No.

22603 0 25 10

22604 1 25 10

22605 2 25 10

22606 3 25 10

22607 4 25 10

22608 5 25 10

7019 ZOT TS

Material: High-quality chrome-vanadium steel, through-hardened, hard but elastic.

Geometry: Torsion zone for protecting against premature breakage of bits under load.

Drive: DIN 3126, ISO 1173, style C 6.3.

Application: For Torq-Set®security screws.

Order-No.

27030 0 25 10

27028 1 25 10

26249 2 25 10

26045 3 25 10

22591 4 25 10

22592 5 25 10

22593 6 25 10

22594 8 25 10

22595 10 25 10

25572 1/4 32 10

7041 ZOT

Material: High-quality chrome-vanadium steel, through-hardened, hard but elastic.

Geometry: Patented torsion zone to prevent premature breaking of the bit when

Drive: DIN 3126, ISO 1173, style E 6.3.

Application: Particularly suitable for turning screws in metal and hard materials.

Order-No.

04541 PH1 50 5

04540 PH2 50 5

04539 PH3 50 5

ZOT Torsion bit, Tri-Wing®, style C 6.3.

ZOT Torsion bit, Torq-Set®, style C 6.3.

ZOT Torsion bit, Phillips, style E 6.3.

under stress.

Style E 6.3 (1/4").

7042 ZOT

Material: High-quality chrome-vanadium steel, through-hardened, hard but elastic.

Geometry: Patented torsion zone to prevent premature breaking of the bit when

Drive: DIN 3126, ISO 1173, style E 6.3.

Application: Particularly suitable for turning screws in metal and hard materials.

Order-No.

04547 PZ1 50 5

04546 PZ2 50 5

04545 PZ3 50 5

7049 ZOT TW

Material: High-quality chrome-vanadium steel, through-hardened, hard but elastic.

Geometry: Torsion zone for protecting against premature breakage of bits under load.

Drive: DIN 3126, ISO 1173, style E 6.3.

Application: For Tri-Wing®security screws.

Extra: 90 mm bits with long spiralled torsion zone.

Order-No.

22609 3 50 5

33695 3 90 5

22610 4 50 5

33696 4 90 5

22611 5 50 5

33697 5 90 5

22612 6 50 5

33698 6 90 5

7049 ZOT TS

Material: High-quality chrome-vanadium steel, through-hardened, hard but elastic.

Geometry: Torsion zone for protecting against premature breakage of bits under load.

Drive: DIN 3126, ISO 1173, style E 6.3.

Application: For Torq-Set®security screws.

Extra: 90 mm bits with long spiralled torsion zone.

Order-No.

22596 4 50 5

33699 4 90 5

22597 5 50 5

33700 5 90 5

22598 6 50 5

33701 6 90 5

22599 8 50 5

33702 8 90 5

22600 10 50 5

ZOT Torsion bit, Pozidriv, style E 6.3.

under stress.

ZOT Torsion bit, Tri-Wing®, style E 6.3.

ZOT Torsion bit, Torq-Set®, style E 6.3.

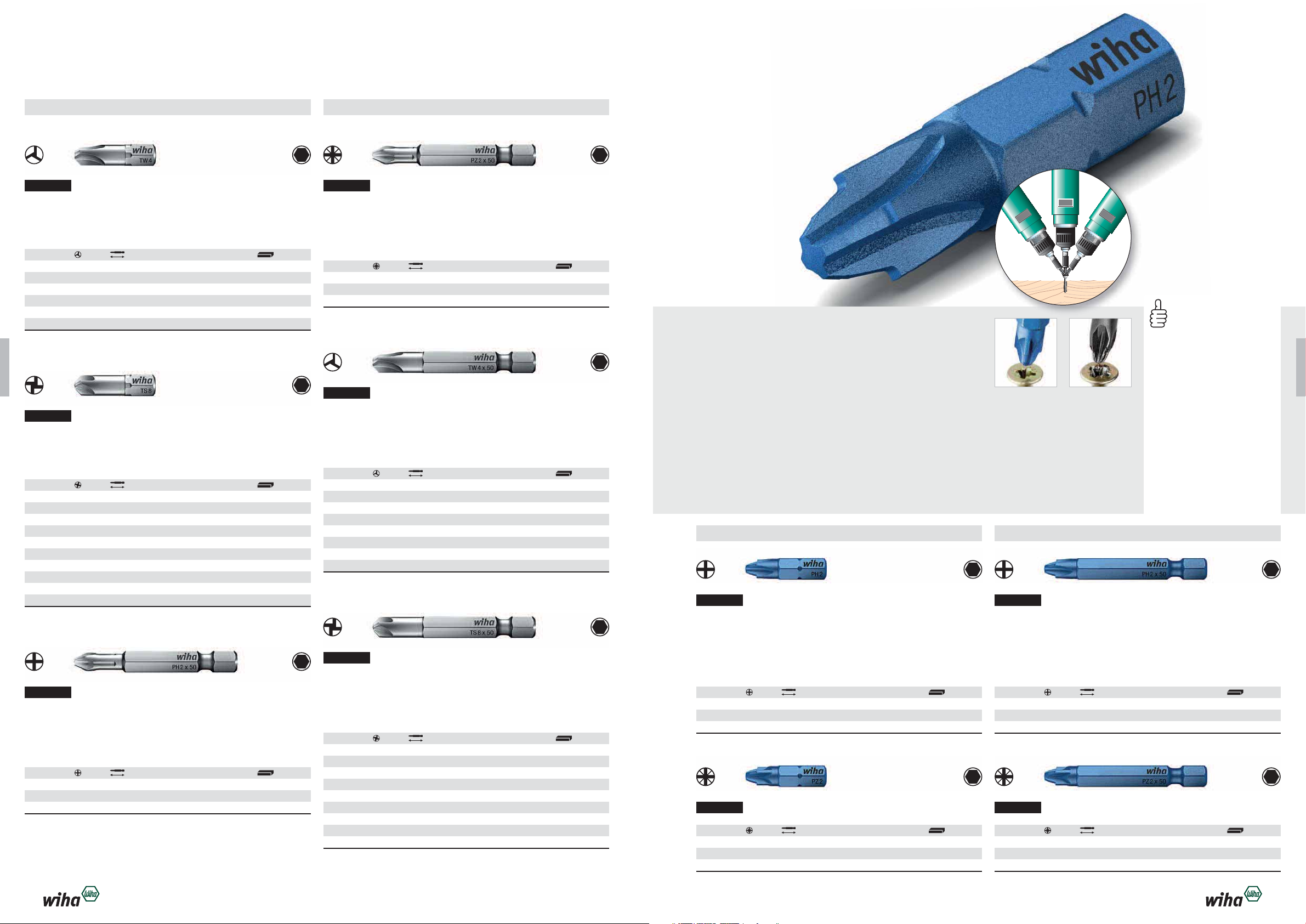

Wiha Inkra bit.

The specialist for every angle.

The innovation

for wood screws.

With the Inkra bit, Wiha has

developed a revolutionary product

for dry applications.

In practice, it is impossible to avoid

working with an inclined bit axis.

It is in such applications that the

Inkra bit comes into its own.

With its specially developed shape,

the penetration depth in the screw

head remains nearly constant,

even in an inclined position.

Style C 6.3 (1/4").

7011 Inkra

Material: High grade chrome-vanadium steel, through hardened.

Drive: DIN 3126, ISO 1173, style C 6.3.

Application: The ideal bit for areas that are difficult to access,

Extra: Non-corrosive coating.

Order-No.

21228 PH1 25 10

20834 PH2 25 10

21229 PH3 25 10

7012 Inkra

Order-No.

21231 PZ1 25 10

08461 PZ2 25 10

21233 PZ3 25 10

Inkra bit, Phillips, style C 6.3.

particularly suitable for wood screws.

Fastening possible at slightly oblique angles.

Inkra bit, Pozidriv, style C 6.3.

Optimum torque transmission

and a reduced cam-out effect are

the resulting advantages.

Craftsmen value this bit because it

makes their workmuch easier than

using a standard bit.

Wiha Inkra bit.

Even when the drill is at

•

an inclined position,

the penetration depth in

the screw head remains

User comfort and reduced pressure forces

even in inclined positions.

virtually constant

No slipping and rounding of

•

the bit tip and screw head

Slippage and rounding of the bit tip are

a thing of the past.

Especially long service life

•

The ideal bit for carpenters,

•

joiners and craftsmen

Style E 6.3 (1/4").

7041 Inkra

Material: High grade chrome-vanadium steel, through hardened.

Drive: DIN 3126, ISO 1173, style E 6.3.

Application: The ideal bit for areas that are difficult to access,

Extra: Non-corrosive coating.

Order-No.

32499 PH1 50 5

32500 PH2 50 5

32501 PH3 50 5

7042 Inkra

Order-No.

32502 PZ1 50 5

32503 PZ2 50 5

32504 PZ3 50 5

Inkra bit, Phillips, style E 6.3.

particularly suitable for wood screws.

Fastening possible at slightly oblique angles.

Inkra bit, Pozidriv, style E 6.3.

172

173

Page 9

Wiha Standard bit.

Full programme range in outstanding quality.

www.wiha.com

Style C 6.3 (1/4").

7010 Z

Material: High grade chrome-vanadium steel, through hardened.

Drive: DIN 3126, ISO 1173, style C 6.3.

Application: For all types of screw applications in trade and industry.

Order-No.

01623 4.5 25 0.6 10

01624 5.5 25 0.8 10

01626 6.5 25 1.2 10

01627 8.0 25 1.6 10

7010 Z L

Material: High grade chrome-vanadium steel, through hardened.

Drive: DIN 3126, ISO 1173, style C 6.3.

Application: For all types of screw applications in trade and industry.

Standard bit, slotted, style C 6.3.

Standard bit, slotted, style C 6.3.

Style C 6.3 (1/4").

7011 Z

Material: High grade chrome-vanadium steel, through hardened.

Drive: DIN 3126, ISO 1173, style C 6.3.

Application: For all types of screw applications in trade and industry.

Order-No.

05298 PH0 25 10

01657 PH1 25 10

01658 PH2 25 10

01659 PH3 25 10

01649 PH4 32 10

7012 Z

Material: High grade chrome-vanadium steel, through hardened.

Drive: DIN 3126, ISO 1173, style C 6.3.

Application: For all types of screw applications in trade and industry.

Standard bit, Phillips, style C 6.3.

Standard bit, Pozidriv, style C 6.3.

The Wiha Standard bits offer

impressive quality and they are

available in a versatile range.

The bits are subject to processoraided manufacture as well as

processor controlled heat

treatment. Wiha thus guarantees

a uniformly high product quality.

The high-quality basic material permits

torque values that are far beyond the

DIN standards:

• DIN 5261 for PH/PZ-bits

• DIN 5263 for slotted bits

• Camcar standards for TORX

and TORX PLUS®bits

®

Wiha Standard bit.

Robust and powerful

•

allrounder bits for trade,

industry and DIY

Suitable for all applications.

•

Thanks to ist hardness values

of HRC 59-61, it can be used

for both manual and machine

applications

Highly resistant to wear and

•

tear for a long tool life

Optimum fitting in DIN screws

•

for low wear and tear as well as

optimum torque transmission

Production based on

•

industrial quality criteria

according to the valid

ISO standards with uniformly

high product quality

Order-No.

01604 3.0 39 0.5 10

01607 3.5 39 0.6 10

01606 4.0 39 0.5 10

01610 4.0 39 0.8 10

01609 4.5 39 0.6 10

01612 5.5 39 0.8 10

01613 5.5 39 1.0 10

01617 6.5 39 1.2 10

01619 8.0 39 1.2 10

01621 8.0 39 1.6 10

Order-No.

05300 PZ0 25 10

01688 PZ1 25 10

01689 PZ2 25 10

01690 PZ3 25 10

01681 PZ4 32 10

174

This results in a long tool life at high

torque values; this is the ideal prerequisite

for standard applications.

Wiha Standard bits are the ideal multipurpose tool to meet high requirements

in terms of both quality and performance.

175

Page 10

Wiha Standard-Bit.

Full programme range in outstanding quality.

www.wiha.com

Style C 6.3 (1/4").

7015 Z

Material: High grade chrome-vanadium steel, through hardened.

Drive: DIN 3126, ISO 1173, style C 6.3.

Application: For all types of screw applications in trade and industry.

Order-No.

26250 T3 25 10

25097 T4 25 10

01711 T5 25 10

01712 T6 25 10

01713 T7 25 10

01714 T8 25 10

01715 T9 25 10

01716 T10 25 10

01717 T15 25 10

01718 T20 25 10

01719 T25 25 10

1720

0

01721 T30 25 10

01722 T40 25 10

01723 T45 35 10

01724 T50 35 10

Standard bit, TORX®, style C 6.3.

27

T

5

2

Style C 6.3 (1/4").

7016 Z

Material: High grade chrome-vanadium steel, through hardened.

Drive: DIN 3126, ISO 1173, style C 6.3.

Application: For all types of screw applications in trade and industry.

Extra: Reinforced profile cross-section transfers approx.

Order-No.

25994 3IP 25 10

25996 4IP 25 10

25998 5IP 25 10

23173 6IP 25 10

23175 7IP 25 10

23177 8IP 25 10

23179 9IP 25 10

23181 10IP 25 10

23183 15IP 25 10

0

1

3185

2

23187 25IP 25 10

23189 27IP 25 10

23191 30IP 25 10

23193 40IP 25 10

Standard bit, TORX PLUS®, style C 6.3.

25% more torque than with a TORX®profile.

0IP

2

5

2

0

1

Style C 6.3 (1/4").

7013 Z

Material: High grade chrome-vanadium steel, through hardened.

Drive: DIN 3126, ISO 1173, style C 6.3.

Application: For all types of screw applications in trade and industry.

Order-No.

04011 1.5 25 10

01703 2.0 25 10

01704 2.5 25 10

01705 3.0 25 10

01706 4.0 25 10

01707 5.0 25 10

01708 6.0 25 10

01709 8.0 25 10

01710 10.0 25 10

Standard bit, hex, style C 6.3.

Style C 6.3 (1/4").

7017 Z

Material: High grade chrome-vanadium steel, through hardened.

Drive: DIN 3126, ISO 1173, style C 6.3.

Application: For all types of screw applications in trade and industry.

Extra: The ball end enables the user to work at angles up to 25°.

Order-No.

01734 1.5 38 10

01735 2.0 38 10

01736 2.5 38 10

01737 3.0 38 10

01738 4.0 38 10

01739 5.0 38 10

01740 6.0 38 10

Standard bit, ball end hex, style C 6.3.

Especially for screws that are difficult to access.

Ideal for window constructors.

7015K Z

Extra: Conical profile.

Order-No.

04925 T10 25 10

04926 T15 25 10

04927 T20 25 10

04928 T25 25 10

04929 T27 25 10

04930 T30 25 10

04931 T40 25 10

7015 Z TR

Extra: Hole in the bit tip for TORX®Tamper Resistant security screws.

Order-No.

03115 T7H 25 10

03117 T8H 25 10

01726 T9H 25 10

01727 T10H 25 10

01728 T15H 25 10

01729 T20H 25 10

01730 T25H 25 10

01731 T27H 25 10

01732 T30H 25 10

01733 T40H 25 10

Standard bit, TORX®conic, style C 6.3.

Standard bit, TORX®H, style C 6.3.

7016 Z IPR

Material: High grade chrome-vanadium steel, through hardened.

Drive: DIN 3126, ISO 1173, style C 6.3.

Application: For all types of screw applications in trade and industry.

Attention: Security profile - sold only to authorised customers.

Order-No.

27530 8IPR 25 1

26346 10IPR 25 10

26347 15IPR 25 10

26348 20IPR 25 10

26349 25IPR 25 10

26350 30IPR 25 10

26351 40IPR 35 10

Standard bit, TORX PLUS®Security, style C 6.3.

Written proof of authorisation must be received.

7013R Z

Application: For all types of screw applications in trade and industry.

Extra: MagicRing®made from spring steel holds all standard screws

Order-No.

22955 3.0 25 10

22956 4.0 25 10

22957 5.0 25 10

22958 6.0 25 10

7013 Z TR

Extra: Hole in the tip of the bit for hex Tamper Resistant security screws.

Order-No.

25560 TR2.0 25 10

25561 TR2.5 25 10

25562 TR3.0 25 10

25563 TR4.0 25 10

25564 TR5.0 25 10

20556 TR3/32 25 10

20558 TR5/64 25 10

20559 TR7/64 25 10

20555 TR1/8 25 10

20560 TR9/64 25 10

20557 TR5/32 25 10

30050 TR3/16 25 10

26309 TR6.0 25 10

Standard bit, hex, style C 6.3.

Insert screws into or remove from boreholes,

especially in difficult to access areas.

in every position.

Standard bit, hex Tamper Resistant, style C 6.3.

NEW

NEW

NEW

NEW

NEW

NEW

NEW

NEW

7017R Z

Material: High grade chrome-vanadium steel, through hardened.

Drive: DIN 3126, ISO 1173, style C 6.3.

Application: For all types of screw applications in trade and industry.

Extra: MagicRing®made from spring steel holds all standard screws

Order-No.

22959 3.0 38 10

22960 4.0 38 10

22961 5.0 38 10

22962 6.0 38 10

Standard bit, ball end hex, style C 6.3.

Insert screws into or remove from boreholes,

especially in difficult to access areas.

in every position. Ball end allows a working angle up to 25°.

176

177

Page 11

www.wiha.com

Wiha Standard-Bit.

Full programme range in outstanding quality.

Style C 6.3 (1/4").

7018 Z

Material: High grade chrome-vanadium steel, through hardened.

Drive: DIN 3126, ISO 1173, style C 6.3.

Application: For all types of screw applications in trade and industry.

Extra: A tapered tip allows for easy insertion of the bit into the screw.

Order-No.

06634 1 25 5

06635 2 25 5

06636 3 25 5

Standard bit, Robertson, style C 6.3.

Style C 6.3 (1/4").

7019 Z SP

Material: High grade chrome-vanadium steel, through hardened.

Drive: DIN 3126, ISO 1173, style C 6.3.

Application: For security screws - snake eye.

Order-No.

27064 4 25 10

27065 6 25 10

27066 8 25 10

27067 10 25 10

Standard bit, spanner, style C 6.3.

Wiha Professional bits.

Wiha Professional Bits - everything but standard.

7019 Z XZN

Material: High grade chrome-vanadium steel, through hardened.

Drive: DIN 3126, ISO 1173, style C 6.3.

Application: For use in automotive applications.

Order-No.

26352 M3 25 10

26353 M4 25 10

26354 M5 25 10

26355 M6 25 10

26356 M8 35 10

Standard bit, multi-tooth, style C 6.3.

7019 Z SIT

Material: High grade chrome-vanadium steel, through hardened.

Drive: DIN 3126, ISO 1173, style C 6.3.

Application: For ASSY®and Pias screws.

Extra: With colour-coding.

Order-No.

27256 SIT 10 25 pink 10

27257 SIT 20 25 orange 10

27258 SIT 25 25 green 10

27259 SIT 30 25 yellow 10

27260 SIT 40 25 light pink 10

Standard bit, SIT, style C 6.3.

Wiha Info

Colour-coding of SIT bits:

pink = SIT 10

orange = SIT 20

green = SIT 25

yellow = SIT 30

light pink = SIT 40

Wiha Professional Bits are high

quality bits for professional users

in trade and industry.

Complete assortment

Wiha Professional Bits are

characterised by an extremely wide

product spectrum. More than 200

profile and length variants are

available from stock. Of course

Wiha is an official licensee of all

common screw

®

Wiha – the TORX

Ranging from traditional TORX

specialist

®

with all its variants (classic, wedge,

tamper resistant) to a wide internal

®

spectrum and the latest

TORX

TORX PLUS

®

safety profile,

Wiha as a premium manufacturer

offers professional users a

complete program. Added to this

are the Wiha specials with ball end

and unique swivel angle as well as

MagicSpring

®

, a 'magic' spring

that securely holds screws.

Precise manufacturing

Production on extremely precise

and process-robust CNC systems

means high performance screw

bits. Modern manufacturing

technology ensures not only

a perfect fit of profile tips but

also outstanding rotation

characteristics and concentricity

of bits. Demanding customers

with automated fastening

processes looking for problem-free

applications hold this in high

regard.

Optimal heat treatment

Wiha Professional Bits are fundamentally through-hardened.

Heat treatment is carried out in

hardening systems with computercontrolled monitoring of hardening

parameters (time, temperature,

atmosphere). This enables

constant hardening results.

Wiha Professional Bits gain their

functional fine finishing with the

final annealing process, a second

heat treatment following hardening

that gives bits a specific characteristic. According to profile and

application area, a differentiation

is made between extra hard

wear-resistant, tough and

extra tough.

Wiha Professional bits.

Wiha Professional bits.

•

Powerful bits for

•

professional users.

Heat treatment matched

•

to the profile to extend

the service life

Optimum fit in screws

•

because of manufacturing

according to DIN or the original

specifications of well-known

licensors

Best rotation characteristics

•

for stable fastening processes

178

179

Page 12

Wiha Professional-Bit.

Wiha Professional Bits - everything but standard.

www.wiha.com

Style E 6.3 (1/4").

7040 Z

Material: High grade chrome-vanadium steel, through hardened.

Drive: DIN 3126, ISO 1173, style E 6.3.

Application: For all types of screw applications in trade and industry.

Order-No.

33961 2.5 70 0.4 5

01790 3.0 50 0.5 5

33962 3.0 70 0.5 5

01792 3.5 50 0.6 5

33963 3.5 70 0.6 5

01791 4.0 50 0.5 5

01794 4.0 50 0.8 5

33964 4.0 70 0.8 5

01793 4.5 50 0.6 5

01795 5.5 50 0.8 5

01796 5.5 50 1.0 5

33965 5.5 70 1.0 5

01798 6.5 50 1.2 5

33966 6.5 70 1.2 5

01799 8.0 50 1.2 5

01800 8.0 50 1.6 5

7041 Z

Extra: Overlength bits available in lengths of 50, 70, 90, 110, 127 and 150 mm.

Order-No.

31960 PH00 50 5

31961 PH00 70 5

31962 PH00 90 5

32105 PH0 50 5

35456 PH0 70 5

35457 PH0 90 5

33703 PH1 50 5

01803 PH1 70 5

04126 PH1 90 5

23213 PH1 110 5

23219 PH1 127 5

22509 PH1 150 5

33704 PH2 50 5

01805 PH2 70 5

04009 PH2 90 5

05800 PH2 110 5

06888 PH2 127 5

22510 PH2 150 5

33705 PH3 50 5

04010 PH3 70 5

04127 PH3 90 5

23215 PH3 110 5

23217 PH3 127 5

22511 PH3 150 5

180

Professional bit, slotted, style E 6.3.

Professional bit, Phillips, style E 6.3.

Style E 6.3 (1/4").

7049XH

Application: For fastening and unfastening positive/ negative screws

Order-No.

32490 SL/PH1 50 5

32491 SL/PH1 70 5

32686 SL/PH1 90 5

32492 SL/PH2 50 5

32493 SL/PH2 70 5

32687 SL/PH2 90 5

7042 Z

Extra: Overlength bits available in lengths of 50, 70, 90, 110, 127 and 150 mm.

Order-No.

31957 PZ0 50 5

31958 PZ0 70 5

31959 PZ0 90 5

33706 PZ1 50 5

01808 PZ1 70 5

01809 PZ1 90 5

23221 PZ1 110 5

23225 PZ1 127 5

23227 PZ1 150 5

33707 PZ2 50 5

01811 PZ2 70 5

01812 PZ2 90 5

05799 PZ2 110 5

06889 PZ2 127 5

23228 PZ2 150 5

33708 PZ3 50 5

04059 PZ3 70 5

04176 PZ3 90 5

23223 PZ3 110 5

23226 PZ3 127 5

22512 PZ3 150 5

7049XZ

Application: For fastening and unfastening positive/ negative screws

Order-No.

32494 SL/PZ1 50 5

32495 SL/PZ1 70 5

32688 SL/PZ1 90 5

32496 SL/PZ2 50 5

32497 SL/PZ2 70 5

32689 SL/PZ2 90 5

Professional bit, Xeno-slotted/Phillips, style E 6.3.

For terminal screws (slotted/ Phillips).

in switchboard systems, fuse boxes, terminal blocks and relays.

Professional bit, Pozidriv, style E 6.3.

Professional bit, Xeno-slotted/Pozidriv, style E 6.3.

For terminal screws (slotted/ Pozidriv).

in switchboard systems, fuse boxes, terminal blocks and relays.

Style E 6.3 (1/4").

7045R

Material: High grade chrome-vanadium steel, through hardened.

Drive: DIN 3126, ISO 1173, style E 6.3.

Application: For all types of screw applications in trade and industry.

Extra: MagicSpring®made of stainless steel holds TORX®screws tight

Attention: Screw must not be attached to the rotating bit.

Order-No.

34452 T10 50 5

34453 T15 50 5

4454 T20 50

3

4455

3

34456 T30 50 5

34457 T40 50 5

Professional bit, TORX®with MagicSpring®, style E 6.3.

at various angles.

25

T

0

5

5

5

Style E 6.3 (1/4").

7045BE

Material: High grade chrome-vanadium steel, through hardened.

Drive: DIN 3126, ISO 1173, style E 6.3.

Application: For all internal TORX®screws, especially in hard-to-reach places.

Extra: The TORX®ball end enables fastening and unfastening

Order-No.

32409 T9 50 5

32410 T10 50 5

2416 T10 70

3

32417 T15 50 5

32418 T15 70 5

32411 T20 50 5

32419 T20 70 5

32420 T20 90 5

32412 T25 50 5

32421 T25 70 5

32422 T25 90 5

32413 T27 50 5

32414 T30 50 5

32423 T30 70 5

32424 T30 90 5

32415 T40 50 5

7045BE 9570

Bits: 70 mm Standard bits.

Application: Extra long bits for all types of fastening in trade and industry.

Extra: Compact plastic bit band with belt clip.

Order-No. Series

32804 7045BE 9570 1

Professional bit, TORX®ball end, style E 6.3.

at an angle of up to 25°.

With elongated TORX®profile behind ball end.

5

Professional bits TORX®ball end in compact bit band, 10-pcs.

Blister packed.

7045BE 2xT10 2xT15 2xT20

2xT25 2xT30

181

Page 13

Wiha Professional-Bit.

Wiha Professional Bits - everything but standard.

www.wiha.com

Style E 6.3 (1/4").

7045 Z

Material: High grade chrome-vanadium steel, through hardened.

Drive: DIN 3126, ISO 1173, style E 6.3.

Application: For all types of screw applications in trade and industry.

Extra: Overlength bits in lengths of 50, 70, 90, 110 and 150 mm.

Order-No.

32299 T5 50 5

32302 T6 50 5

33709 T6 70 5

33717 T6 90 5

32303 T7 50 5

33710 T7 70 5

33718 T7 90 5

32304 T8 50 5

33711 T8 70 5

33719 T8 90 5

2305 T9 50

3

33712 T9 70 5

33720 T9 90 5

32306 T10 50 5

33713 T10 70 5

33721 T10 90 5

33725 T10 110 5

33726 T10 150 5

32307 T15 50 5

33714 T15 70 5

33722 T15 90 5

33727 T15 110 5

33728 T15 150 5

32308 T20 50 5

33715 T20 70 5

33723 T20 90 5

33729 T20 110 5

33730 T20 150 5

32309 T25 50 5

33716 T25 70 5

33724 T25 90 5

33731 T25 110 5

33732 T25 150 5

33920 T27 50 5

33921 T27 70 5

33922 T27 90 5

33923 T30 50 5

33924 T30 70 5

33925 T30 90 5

33926 T30 110 5

33927 T30 150 5

33928 T40 50 5

33929 T40 70 5

33930 T40 90 5

33931 T40 110 5

33932 T40 150 5

182

Professional bit, TORX®, style E 6.3.

5

Style E 6.3 (1/4").

7045 Z TR

Material: High grade chrome-vanadium steel, through hardened.

Drive: DIN 3126, ISO 1173, style E 6.3.

Application: For all types of screw applications in trade and industry.

Extra: Hole in the bit tip for TORX®Tamper Resistant security screws.

Order-No.

21045 T7H 50 5

21047 T8H 50 5

20218 T9H 50 5

20219 T10H 50 5

24867 T15H 50 5

20220 T20H 50 5

20221 T25H 50 5

20222 T27H 50 5

20223 T30H 50 5

0224

2

7046 Z

Material: High grade chrome-vanadium steel, through hardened.

Drive: DIN 3126, ISO 1173, style E 6.3.

Application: For all types of screw applications in trade and industry.

Extra: Reinforced profile cross-section transfers approx.

Order-No.

28481 5IP 50 5

26000 6IP 50 5

26002 7IP 50 5

23195 8IP 50 5

23197 9IP 50 5

23199 10IP 50 5

23201 15IP 50 5

23203 20IP 50 5

23205 25IP 50 5

23207 27IP 50 5

23209 30IP 50 5

23211 40IP 50 5

7048 Z

Material: High grade chrome-vanadium steel, through hardened.

Drive: DIN 3126, ISO 1173, style E 6.3.

Application: For all types of screw applications in trade and industry.

Extra: A tapered tip allows for easy insertion of the bit into the screw.

Order-No.

06637 1 50 5

06638 2 50 5

06639 3 50 5

Professional bit, TORX®H, style E 6.3.

40H

T

Professional bit, TORX PLUS®, style E 6.3.

25% more torque than with a TORX®profile.

Professional bit, Robertson, style E 6.3.

0

5

Style E 6.3 (1/4").

7047R Z

Material: High grade chrome-vanadium steel, through hardened.

Drive: DIN 3126, ISO 1173, style E 6.3.

Application: For all types of screw applications in trade and industry.

Extra: MagicRing®made from spring steel holds all standard screws

Order-No.

25739 3.0 50 5

25740 4.0 50 5

5

25741 5.0 50 5

25742 6.0 50 5

7043R Z

Material: High grade chrome-vanadium steel, through hardened.

Drive: DIN 3126, ISO 1173, style E 6.3.

Application: For all types of screw applications in trade and industry.

Extra: MagicRing

Order-No.

23145 3.0 50 5

23147 4.0 50 5

23149 5.0 50 5

23151 6.0 50 5

Professional bit, hexagon ball end, style E 6.3.

To insert and remove screws from holes or cavities,

specially in difficult to access areas.

in every position. Ball end allows a working angle up to 25°.

Professional bit, hexagon, style E 6.3.

To insert and remove screws from holes or cavities.

in every position.

®

made from spring steel holds all standard screws

Style E 6.3 (1/4").

7043 Z

Order-No.

05301 1.5 50 5

05302 2.0 50 5

34554 2.0 70 5

05303 2.5 50 5

34555 2.5 70 5

04194 3.0 50 5

34556 3.0 70 5

04195 4.0 50 5

34557 4.0 70 5

04196 5.0 50 5

34558 5.0 70 5

04197 6.0 50 5

34559 6.0 70 5

04198 8.0 50 5

34560 8.0 70 5

NEW

7041 VB1

Order-No.

36162 Acrylic glass display with 70 pieces.

Professional bit, hexagon, style E 6.3.

Single bits display, 90 mm bits.

Acrylic glass display with 70 pieces.

7041 Z 5xPH1 5xPH2 5xPH3

7042 Z 5xPZ1 5xPZ2 5xPZ3

7045 Z 5xT10 5xT15 5xT20

5xT25 5xT30 5xT40

7143 5x1/4 5x1/4

Wiha Info

NEW

7041 VB2

Order-No.

36163 Acrylic glass display with 70 pieces.

Wiha MagicRing®:

spring steel ring

reliably holds hex screws

in place.

Single bits display, 150 mm bits.

Acrylic glass display with 70 pieces.

7143 5x1/4 5x1/4

7041 Z 5xPH1 5xPH2 5xPH3

7042 Z 5xPZ1 5xPZ2 5xPZ3

7045 Z 5xT10 5xT15 5xT20

5xT25 5xT30 5xT40

183

Page 14

www.wiha.com

Wiha threaded bit.

For optimised use in stationary screw systems.

For M4 and M5.

7311 Z

Material: High grade chrome-vanadium steel, through hardened.

Drive: Screw thread M4.

Application: For optimised use in stationary screw systems.

Order-No.

01937 PH1 33 5.5 M4 8.00 10

01938 PH2 33 6.0 M4 8.00 10

7312 Z

Material: High grade chrome-vanadium steel, through hardened.

Drive: Screw thread M4.

Application: For optimised use in stationary screw systems.

Threaded bit M4, Phillips.

Threaded bit M4, Pozidriv.

For M6 and 10/32" UNF.

7331 Z

Material: High grade chrome-vanadium steel, through hardened.

Drive: Screw thread M6.

Application: For optimised use in stationary screw systems.

Order-No.

04678 PH2 33 8.0 M6 8.00 10

04677 PH2 45 8.0 M6 8.00 10

7332 Z

Material: High grade chrome-vanadium steel, through hardened.

Drive: Screw thread M6.

Application: For optimised use in stationary screw systems.

Threaded bit M6, Phillips.

Threaded bit M6, Pozidriv.

Wiha special bits.

Customised for your application.

Construction Kit

No.

C 4 = 0

C 6,3 = 1

C 8 = 2

A 5,5 = 3

E 6,3 = 5

G 7 = 6

Profile No.Drive

Slotted = 0

Phillips PH = 1

Pozidriv PZ = 2

Hex = 3

®

TORX

= 5

TORX PLUS

Ball end

hex = 7

Robertson = 8

Special profile = 9

Spanner = 9 SP

To rq - Se t

Tri-Wing

®

= 6

®

= 9 TS

®

= 9 TW

Length

for 25 mm - 152 mm

Order-No.

01939 PZ1 33 5.5 M4 8.00 10

01940 PZ2 33 6.0 M4 8.00 10

7321 Z

Material: High grade chrome-vanadium steel, through hardened.

Drive: Screw thread M5.

Application: For optimised use in stationary screw systems.

Order-No.

01942 PH2 33 7.0 M5 8.00 10

01943 PH2 45 6.0 M5 8.00 10

7322 Z

Material: High grade chrome-vanadium steel, through hardened.

Drive: Screw thread M5.

Application: For optimised use in stationary screw systems.

Order-No.

01945 PZ2 33 7.0 M5 8.00 10

01946 PZ2 45 6.0 M5 8.00 10

7325 Z

Material: High grade chrome-vanadium steel, through hardened.

Drive: Screw thread M5.

Application: For optimised use in stationary screw systems.

Order-No.

35400 T10 45 6.0 M5 8.00 10

35401 T15 45 6.0 M5 8.00 10

35402 T20 45 6.0 M5 8.00 10

35403 T25 45 6.0 M5 8.00 10

Threaded bit M5, Phillips.

Threaded bit M5, Pozidriv.

Threaded bit M5, TORX®.

Order-No.

04671 PZ2 33 8.0 M6 8.00 10

04670 PZ2 45 8.0 M6 8.00 10

7341 Z

Material: High grade chrome-vanadium steel, through hardened.

Drive: Screw thread 10/32" UNF.

Application: For optimised use in stationary screw systems.

Order-No.

01947 PH2 45 6.0 10/32 UNF 8.00 10

7342 Z

Material: High grade chrome-vanadium steel, through hardened.

Drive: Screw thread 10/32" UNF.

Application: For optimised use in stationary screw systems.

Order-No.

01948 PZ2 45 6.0 10/32 UNF 8.00 10

Threaded bit 10/32" UNF, Phillips.

Threaded bit 10/32" UNF, Pozidriv.

Make the most of our experience.

Our expertise in the manufacture

of all types of fastening tools

enables us to produce bits to

your specifications.

Sophisticated manufacturing

facilities with qualified employees,

state-of-the-art machinery and a

certified quality assurance system

guarantee you maximum quality

and flexibility.

The construction kit

of your special bit.

Profile

Lengt h

The Wiha special bit range is a

construction kit system

for your special bit.

Advantages:

• Attractive price

• No additional costs for technical

drawings

• Short delivery time

• Flexibility

Wiha industrial quality bits to the highest standard

Industrial quality expands the

Wiha construction kit. We adapt

the hardness, coating, form and

concentricity of the bits precisely

according to your requirements.

Drive

Hardness: 57 HRC - 63 HRC

Coating: Tungsten Carbide

(Dura), Diamond,

TiN

Form: According to specifi-

cation drawings

Straightness: Straightness with

a tolerance of

+/-0.05 mm

Perfect concentricity:

essential for bits in automated machines and/or with use of guide jackets.

Advantages:

• Screws easily located and

fastened securely.

• Low-vibration fastening thanks

to minimum imbalance.

• Idle times reduced.

Wiha special bits.

For ex., Wiha Halfmoon bits.

Halfmoon bits are predomi-

•

nantly used on production

lines for high-tech products,

such as hard disks and

mobile phones.

The halfmoon drive ensures

•

a secure fit and straightforward

bit exchange.

Our customers require an

•

exact fit and maximum truth

of running for a frictionless

production process.

Wiha bits are being used to

•

optimum effect by big-name

companies operating all over

the world.

Contact us.

We would be pleased to help.

184

185

Page 15

Wiha bits for drive system C 4.

For screw connections in miniature applications.

www.wiha.com

These bits fit directly in the machines of the manufacturers: Perret

7000 Z

Material: High grade chrome-vanadium steel, through hardened.

Drive: DIN 3126, ISO 1173, style C 4.

Application: For particularly small screws.

Order-No.

04728 0.8 28 0.20 10

04727 1.2 28 0.25 10

04726 1.5 28 0.25 10

04725 1.8 28 0.30 10

04724 2.0 28 0.40 10

04723 2.5 28 0.40 10

04722 3.0 28 0.50 10

04721 3.5 28 0.60 10

04729 4.0 28 0.80 10

7001 Z

Material: High grade chrome-vanadium steel, through hardened.

Drive: DIN 3126, ISO 1173, style C 4.

Application: For particularly small screws.

Order-No.

04720 PH000 28 10

04719 PH00 28 10

04718 PH0 28 10

04717 PH1 28 10

Standard bit, slotted, style C 4.

Standard bit, Phillips, style C 4.

7005 Z

Material: High grade chrome-vanadium steel, through hardened.

Drive: DIN 3126, ISO 1173, style C 4.

Application: For particularly small screws.

Order-No.

20842 T3 28 10

20843 T4 28 10

04716 T5 28 10

04715 T6 28 10

04714 T7 28 10

04713 T8 28 10

04712 T9 28 10

04711 T10 28 10

7003 Z

Material: High grade chrome-vanadium steel, through hardened.

Drive: DIN 3126, ISO 1173, style C 4.

Application: For particularly small screws.

Order-No.

04737 0.7 28 10

04736 0.9 28 10

04735 1.3 28 10

04734 1.5 28 10

04733 2.0 28 10

04732 2.5 28 10

04731 3.0 28 10

04730 4.0 28 10

Standard bit, TORX®, style C 4.

Standard bit, hex, style C 4.

Accessories for Wiha bits, style C 4.

2691

Handle: With 4 mm hex retainer for all SYSTEM 4 blades.

Application: Ideal for all precision work in the fields of electronics and mechanics.

Order-No.

30373 4.0 105 23 10

U759 00

Blade: Chrome-vanadium steel, through hardened, electro-plated.

Order-No.

09195 4.0 135 4.0 9 1

SYSTEM 4 SoftFinish®-telescopic handle.

Ergonomic multi-component handle with roll-off protection.

Enables adjustable blade lengths from 18 - 90 mm.

ClickStop ball clamp guarantees a secure hold and rapid blade exchange.

SYSTEM 4 bit holder.

Suitable for C 4 (4 mm) bits.

ESD-Safe •

Telescopic

ESD-Safe •

Telescopic

7000 EB26 ESD

Handle: SYSTEM 4 SoftFinish®-telescopic ESD handle.

Standards: DIN 3126, ISO 1173, style C 4.

Case: No danger to electronic components with use of ESD-safe materials.

Application: Universal set for especially small screws with electronic components.

Order-No. Series

33848 7000 EB26 ESD 1

SYSTEM 4 ESD bit set, 26 pcs.

Mixed sets.

ESD-safe (dissipative), surface resistance 106- 109ohms.

Enables adjustable bit holder blade length.

IEC 61340-5-1.

Tough, space-saving metal box.

Flexible working via adjustable blade length and

rapid replacement of bit inserts.

2691ESD S SYSTEM 4 SoftFinish®-telescopic ESD handle.

U759 00 SYSTEM 4 bit holder.

U750 1x1.51x2.01x3.0 1x4.0

U751 1xPH000 1xPH00 1xPH0 1xPH1

U757 1xT3 1xT4 1xT5 1xT6

1xT7 1xT8 1xT9 1xT10

U753 1x0.71x0.91x1.31x1.5

1x2.01x2.51x3.0 1x4.0

186

7110M

Suitable for: For bits according to DIN 3126, ISO 1173 style C 4.

Drive: DIN 3126, ISO 1173, style E 6.3.

Application: Suitable for 4 mm bits, e.g. Wiha 7000-7005 series.

Extra: With magnet.

Order-No.

32505 C4 1/4 60 10

Universal holder, magnetic, style E 6.3.

7000 EB16 ESD

Handle: SYSTEM 4 SoftFinish®-telescopic ESD handle.

Standards: DIN 3126, ISO 1173, style C 4.

Case: No danger to electronic components with use of ESD-safe materials.

Application: Bit set suitable for smallest screws with electronic components.

Order-No. Series

33503 7000 EB16 ESD 1

SYSTEM 4 ESD bit set, 16 pcs.

Mixed sets.

ESD-safe (dissipative), surface resistance 106- 109ohms.

Enables adjustable bit holder blade length.

IEC 61340-5-1.

Tough, space-saving metal box.

Flexible working via adjustable blade length and

rapid replacement of bit inserts.

2691ESD S SYSTEM 4 SoftFinish®-telescopic ESD handle.

U759 00 SYSTEM 4 bit holder.

U750 1x2.0 1x3.0

U751 1xPH000 1xPH00 1xPH0 1xPH1

U757 1xT3 1xT4 1xT5 1xT6

1xT8

U753 1x0.9 1x1.3 1x1.5

187

Page 16

www.wiha.com

Wiha bits for drive system

style C 8 (5/16") and style G 7.

Style C 8 (5/16").

7020 Z

Material: High grade chrome-vanadium steel, through hardened.

Drive: DIN 3126, ISO 1173, style C 8.

Order-No.

01741 5.5 41 0.8 10

01742 5.5 41 1.0 10

01744 6.5 41 1.2 10

01745 8.0 41 1.2 10

01746 8.0 41 1.6 10

01747 10.0 41 1.6 10

01748 12.0 41 2.0 10

7021 Z

Order-No.

01749 PH1 32 10

01750 PH2 32 10

01751 PH3 32 10

01753 PH4 38 10

7022 Z

Order-No.

01754 PZ1 32 10

01755 PZ2 32 10

01756 PZ3 32 10

01758 PZ4 38 10

7025 Z

Order-No.

01765 T25 35 10

01766 T27 35 10

01767 T30 35 10

01768 T40 35 10

01769 T45 35 10

01770 T50 35 10

01771 T55 35 10

7023 Z

Order-No.

01759 3.0 30 10

01760 4.0 30 10

01761 5.0 30 10

01762 6.0 30 10

01763 8.0 30 10

01764 10.0 30 10

Standard bit, slotted, style C 8.

Standard bit, Phillips, style C 8.

Standard bit, Pozidriv, style C 8.

Standard bit, TORX®, style C 8.

Standard bit, hex, style C 8.

Style G 7.

7081 ZOT

Material: High grade chrome-vanadium steel, through hardened.

Geometry: Patented torsion zone to prevent premature breaking of the bit when

Drive: DIN 3126, ISO 1173, style G 7.

Order-No.

04960 PH1 53 5

04961 PH2 53 5

04962 PH3 53 5

7082 ZOT

Material: High grade chrome-vanadium steel, through hardened.

Geometry: Patented torsion zone to prevent premature breaking of the bit when

Drive: DIN 3126, ISO 1173, style G 7.

Order-No.

04553 PZ1 53 5

04552 PZ2 53 5

04551 PZ3 53 5

7183

Sleeve: Stainless steel.

Suitable for: For bits according to DIN 3126, ISO 1173 style C 6.3.

Drive: DIN 3126, ISO 1173, style G 7.

Application: For applications where the bit must be held tight e.g. assembly lines.

Extra: With strong Neodym magnet.

Order-No.

01919 1/4 G7 72 10

ZOT Torsion bit, Phillips, style G 7.

under stress.

ZOT Torsion bit, Pozidriv, style G 7.

under stress.

Universal holder, magnetic/ retaining ring, style G 7.

Wiha CentroFix system.

Quick and professional.

Drilling, countersinking, driving

screws and cutting threads is

child’s play with the Wiha CentroFix

System. The innovative CentroFix

quick-release holder forms the

basis for a variety of hex-driven

tools.

With CentroFix System, Wiha once

again demonstrates that the user

is central. The trend towards

battery-powered drivers is

continuing undiminished.

Efficient models are greatly

increasing the number of

application areas and enabling