Wigam ELD-H User Manual

ELD-H

Refrigerant Gas Leak

Detector

User’s Guide

English

1

Congratulations on the purchase of the Wigam ELD-H Refrigerant Gas Leak Detector, the most

technologically advanced of its kind. The ELD-H’s low power requirements, small size and high sensitivity

combine to create a tool which is easy to handle and ultra effective at locating even the most difficult-to-find

leaks.

Fully SAE J1627 compliant, the ELD-H will detect leaks as small as 0.1 oz/yr (3g/year) in R12, R22, R134a

and other halogen refrigerant systems.

The ELD-H should not be used on systems that contain flammable refrigerants such as Propane, Isobutane,

etc.

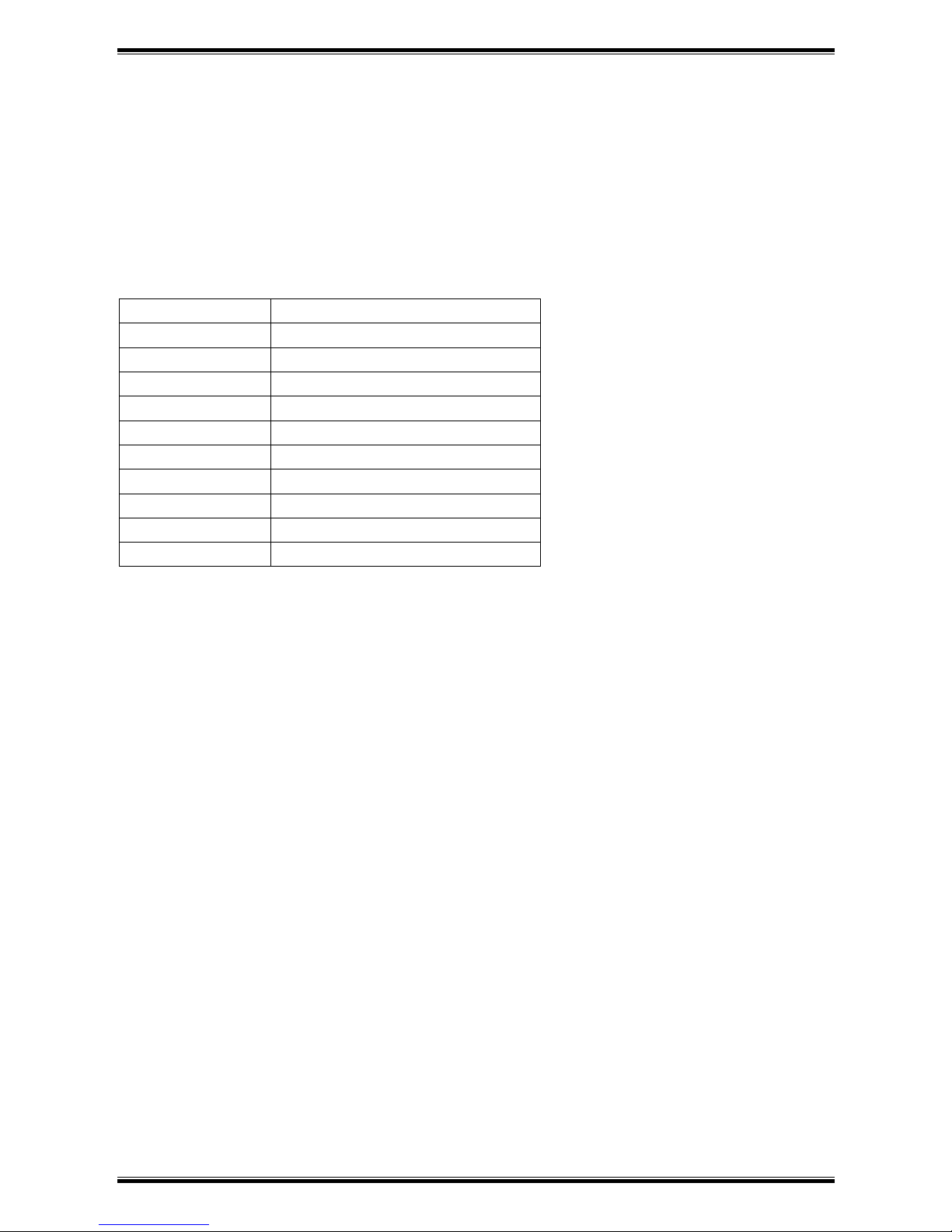

TECHNICAL DATA

Dimensions 7.25” x 2.25” x 1.5” (19 cm x 5.7 cm x 3.8 cm)

Weight 7 oz. (190 grams)

Batteries 2 x 1.5V 'AA' Alkaline Batteries (3 VDC)

Battery Life 40 hours

Sensitivity < 3g/year (0.1 oz/yr)

Sensor lifetime approx. 30 hours

Operating temperature 32 – 122°F (0 – 50°C)

Warm up time < 2 sec.

Response time instantaneous

Reset time instantaneous

Probe length 12” (30 cm)

English

2

INSTRUCTIONS

1. Press the button to turn the unit on.

2. The LED will flash orange for a short moment to indicate auto-reset, afterwards the unit will begin beeping

and flashing green.

3. To reset the unit to the existing level of ambient refrigerant, press and release the button. The LED will

flash orange briefly to indicate the reset. All levels of refrigerant less than the reset level will be ignored.

4. Unit turns on in the low sensitivity level, which is adequate for most leaks. Press the button twice (doubleclick like a computer mouse). The LED will fade from red to green and a sweeping sound effect of low to

high pitch will be heard. The sensitivity is now set for 3g/year (0.1oz/yr). This mode sh ould only be used

for looking for leaks of less than 14g/year (0.5 oz/yr).

5. Double click again to change back to low sensitivity.

6. Move the probe towards a suspected refrigerant leak at a rate of less than 2 inches (50 mm) per second,

no more than ¼ inch (5 mm) away from the suspected source.

7. If a leak exists, the sound will increase in rate and pitch and the LED will start flashing rapidly.

8. To turn the ELD-H off, press and hold the button for 3 seconds.

English

3

FEATURES

y If the sensor is damaged, a sweeping alarm and a red-green flash will indicate the problem.

y A flashing LED duri ng normal operation also reflects the battery level:

Green: batteries are fresh

Orange: batteries should be changed

• If the batteries are nearly empty, the LED will turn solid red and a two-tone alarm will be noted for 5

seconds, before the ELD-H will power itself off.

y If the unit is left on unattended, it will automatically turn off after about 5 minutes to conserve batteries.

BATTERY INSTALLATION AND REPLACEMENT

1. Turn the power off.

2. Remove the battery cover from the back of the instrument by loosening the battery cover screw and lifting

the battery cover off. Be careful not to lose the extra sensor stored in the battery compartment.

3. Insert 2 size ‘AA’ alkaline batteries, observing proper battery polarity.

4. Replace battery cover and tighten battery cover screw.

English

4

SENSOR

An ELD-H sensor will last between 25 and 30 hours of continuous use. A failed or failing sensor will be

indicated in one of the following ways:

1. Unstable or erratic operation of the unit and many false alarms, even in pure air.

2. A continuous “siren” sound.

SENSOR REPLACEMENT

In either case, replacement of the sensor is necessary:

1. Turn the power off.

2. Locate the replacement sensor in the battery compartment.

3. Unscrew (turn counter clockwise) the old sensor from the end of the probe.

4. Screw (turn clockwise) the new sensor into place.

Replacement sensors

Part Number ELS-H

MAINTENANCE

The ELD-H should provide years of service with little maintenance aside from changing batteries and sensors.

The case may be cleaned with a shop towel moistened with water and a mild detergent. Do not use solvent of

any kind.

English

5

SAE J1628 RECOMMENDED PROCEDURES

For the purpose of Automot ive A/C Testing with respect to the SAE J1627 standard, the following leak testing

procedure applies:

1. Operate the ELD-H in high sensitivity mode.

2. Leak test with the engine not in operation.

3. The air conditioning system shall be charged with sufficient refrigerant to have a gauge pressure of at

least 340 kPa when not in operation. At temperatu re s belo w 15°C, leaks may not be measurable, since

this pressure may not be reached.

4. Take care not to contaminate the detector probe tip. If the part is particularly dirty, it should be wiped off

with a dry shop towel or blown off with shop air. No cleaners or solvents shall be used, since many

electronic detectors are sensitive to their ingredients.

5. Visually trace the entire refrigerant system, and look for signs of ai r-conditioning lubricant leakage,

damage, and corrosion on all lines, hoses, and components. Each questionable area shall be carefully

checked with the detector probe, as well as all fittings, hose to line couplings, refrigerant controls, service

ports with caps in place, brazed or welded areas, and areas aroun d attachment points and hold-downs on

lines and components.

6. Always follow the refrigerant system around in a continuous path so that no areas of potential leaks are

missed. If a leak is found, always continue to test the remainder of the system.

7. At each area checked, the probe shall be moved around the location, at a rate no more than 25-50 mm/s

and no more than 5 mm from the surface completely around the position. Slower and closer movement of

the probe often helps locate the exact position of the leak.

8. An apparent leak shall be verified at least once by blowing shop air into the area of the suspected leak, if

necessary, and repeating the check of the area. In cases of very large leaks, blowing out the area with

shop air often helps locate the exact position of the leak.

9. Leak testing of the evaporator core while in the air conditioning module shall be accomplished by turning

the air conditioning blower on high for a period of 15 sec. minimum, shutting it off, then waiting for the

refrigerant to accumulate in the case for time specified by paragraph 10, then inserting the leak detector

probe into the blower resistor block or condensate drain hold if no water is present, or into the closest

opening in the heating/ventilation/air conditioning case to the evaporator, such as the heater duct or a vent

duct. If the detector alarms, a leak apparently has been found.

10. The accumulation time shall be 10 minutes.

11. Following any service to the refrigerant system of the vehicle, and any other service which disturbs the

refrigerant system, a leak test of the repair and of the service ports of the refrigerant system shall be done.

Français

6

Félicitations pour l’achat du détecteur de fuites Wigam ELD-H, le plus à la pointe de la technologie de son

type. Ses petites dimensions et sa haute sensibilité en font un appareil facile à manipuler et très efficace pour

localiser les fuites même les plus difficiles .

Conforme à la norme SAE J1627, l’ELD-H localise des petites fuites de 3 g/an pour les réfrigérants R12, R22,

R134 et autres systèmes réfrigérants halogénés.

L’ELD-H ne doit pas être utilisé sur des systèmes contenant des réfrigérants inflammables, come le propane,

l’isobutane, etc…

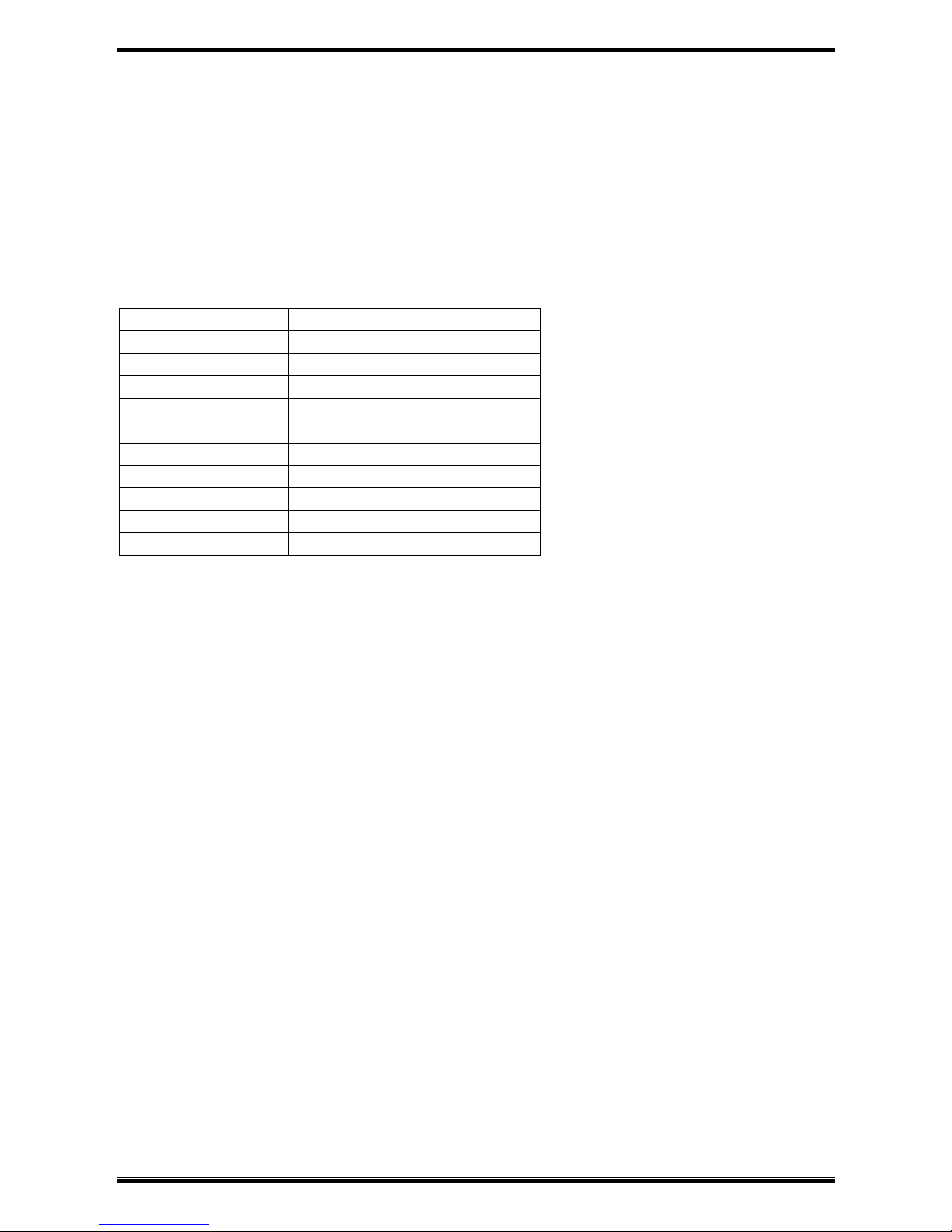

DONNÉES TECHNIQUES

Dimensions: 19 x 5,7 x 3,8 cm

Poids: 190 grammes

Batteries: 2 x batteries alcalines AA 1,5 V

Durée batteries: 40 heures

Sensibilité: < 3g/an

Durée senseur: environ 30 heures

Température d’utilisation: 0 – 50°C

Temps de réchauffement: < 2 secondes

Temps de réponse: immédiat

Temps de mise à zéro: immédiat

Longueur de la sonde: 30 cm

Français

7

INSTRUCTIONS POUR L’UTILISATION

1. Appuyer sur la touche pour allumer l’instrument.

2. Le LED de couleur orange clignotera pendant un instant pour indiquer l’auto -re mise à zéro, après quoi

l’instrument commencera à émettre un Bip et à clignoter en vert.

3. Pour régler le détecteur de fuite au niveau du réfrigérant ambiant du moment, appuyer et relâcher la

touche. Le LED de couleur orange commencera à clignoter brièvement pour indiquer la mise à zéro.

Tous les niveaux de réfrigérant, excepté le niveau mis à zéro, seront ignorés.

4. A l’allumage, le détecteur de fuites se place automatiquement sur la sensibilité basse, qui est adaptée

pour la plupart des fuites. Pour changer le niveau de sensibilité, appuyer deux fois sur la touche (cliquer

deux fois comme avec la souris de l’ordinateur). Le LED passera du rouge au vert et l’on entendra un son

qui ira en crescendo. La sensibilité sera maintenant de 3g/an. Ce mode devrait être utilisé uniquement

pour localiser des fuites de moins de 14g/an.

5. Pour retourner en mode sensibilité basse, appuyer à nouveau deux fois sur la touche.

6. Avancer la sonde vers une probable fuite de réfrigérant, à la vitesse de moins de 50mm par secon de, à

une distance de 5mm de la source.

7. S’il y a vraiment une fuite, le son deviendra plus fort et plus rapide et le LED commencera à clignoter

rapidement.

8. Pour éteindre l’instrument, appuyer sur la touche pendant 3 secondes.

CARACTÉRISTIQUES

• Si le senseur est endommagé, une alarme et un clignotement rouge-vert indiquera le problème.

• Un LED qui clignote durant l’utilisation normale indique également le niveau des batteries:

vert : les batteries sont neuves

orange: les batteries doivent être changées

• Si les batteries sont quasiment terminées, le LED deviendra rouge vif et une alarme à deux tonalités

sonnera pendant 5 secondes, avant que le détecteur de fuites ne s’éteigne tout seul.

• L’instrument s’éteint automatiquement après 5 minutes si il reste inutilisé, ceci pour économiser les

batteries.

INSTALLATION ET REMPLACEMENT DES BATTERIES

1. Eteindre le détecteur de fuites.

2. Enlever le couvercle des batteries (au dos de l’instrument) en dévissant la vis du couvercle. Enlever les

batteries usées. Attention de ne pas perdre le senseur de rechange qui se trouve dans le compartiment

des batteries.

3. Introduire des nouvelles batteries alcalines AA, en respectant les polarités.

4. Remettre le couvercle et revisser la vis du couvercle.

SENSEUR

Le senseur du ELD-H a une durée d’env. 25 à 30 heures d’utilisation continue. Un senseur usagé ou d éjà

hors usage est également indiqué de la manière suivante:

1. Les opérations de l’instrument sont instables ou erronées et il y a beaucoup de fausses alarmes, même

dans l’air pur.

2. Un son continu type « sirène » se fait entendre.

Loading...

Loading...