Wifibot 4G Quick Start Manual

Quick Start Guide

Thank you for choosing WiFiBoT 4G for your robotic application.

• Before using the robot, please read with care this manual

• Keep this manual in a safe place for any future reference

• For updated information about this product visit the official

site of wifibot http://www.wifibot.com

Index

Package contents

Connectors overview

Powering the robot

Power connectors

Battery installation

Camera installation

General structure

Communication interfaces

Embedded sensors

Networking

Configuring the robot

Connecting to the robot

Robot programming

The CDROM

…………………………………………………………………2

…………………………………………………………………2

…………………………………………………………………3

…………………………………………………………………4

…………………………………………………………………5

…………………………………………………………………6

…………………………………………………………………7

…………………………………………………………………8

....………………………………………………………………9

…….………………………………………………………….10

……….……………………………………………………….12

…………….………………………………………………….16

……………….……………………………………………….21

………………….…………………………………………….22

1

Package contents

Make sure to be in possession of all the articles mentioned below. If

any of them should be missing, contact your reseller as soon as

possible.

Robot

IP camera

Two battery packs

Battery charger

Wifibot CD-ROM

Camera CD-ROM and documentation

4x charging cables

1x RJ45 cable for the IP camera

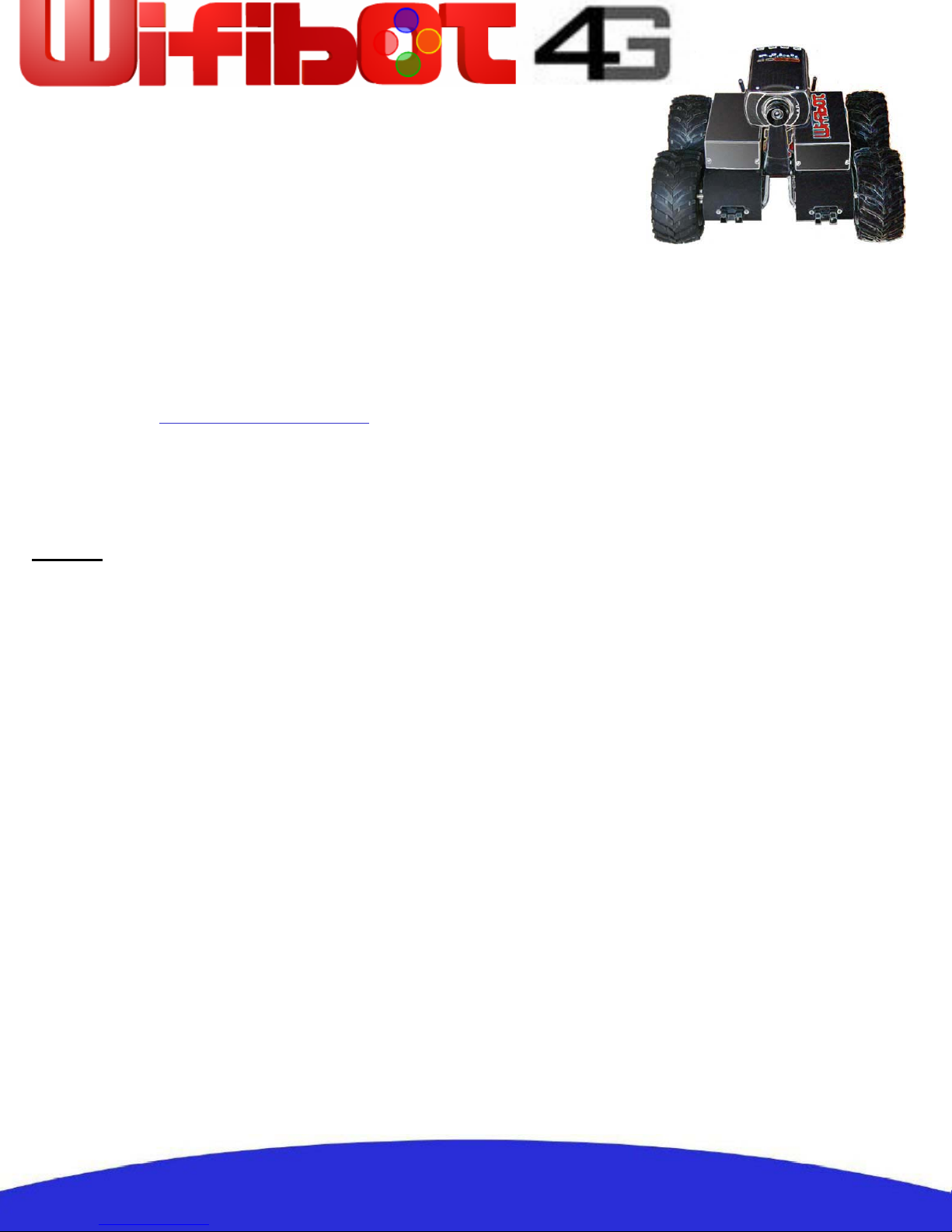

Connectors overview

This diagram shows the signal pinout

of the DSUB-9 connectors. The

RS232 signals are found on the

connector located on the left while

the I²C signals can be found on the

connector located on the right of the

robot. (see the other diagram below)

The figure below shows the location of

the different connectors of the robot:

Battery

connector +

Serial

Number

Battery

connector -

Ethernet

switch

Power

ON/OFF

External power and

charging connector

Battery

connector +

I²C

RS232

Battery

connector -

2

Powering the robot

Powering the robot with batteries:

The robot gets its power normally from two battery

packs with four Ni-MH cells each, with a capacity of

9500 mAH and a total nominal voltage of 9,6V.

Located on the upper part of the platform, their

location and clamping have been especially

designed to facilitate their removal and replacement

in an easy and simple way. It is enough to insert the

packs in their connectors, their shape preventing any

error, the only thing left is to close the clamps and

the robot is ready to go. The robot comes with only

two packs, additional packs are available separately.

Powering the robot from an external source:

When developing custom applications it is often

more practical to use an external power source rather

than to have to constantly charge the batteries. Take

out the batteries, then plug the included cable into

the connector located next to the power switch of the

robot and connect the robot to a lab DC power

source at a voltage between 9 and 12 V. Make sure

the power source can deliver several amps,

especially if you plan to test the motors.

3

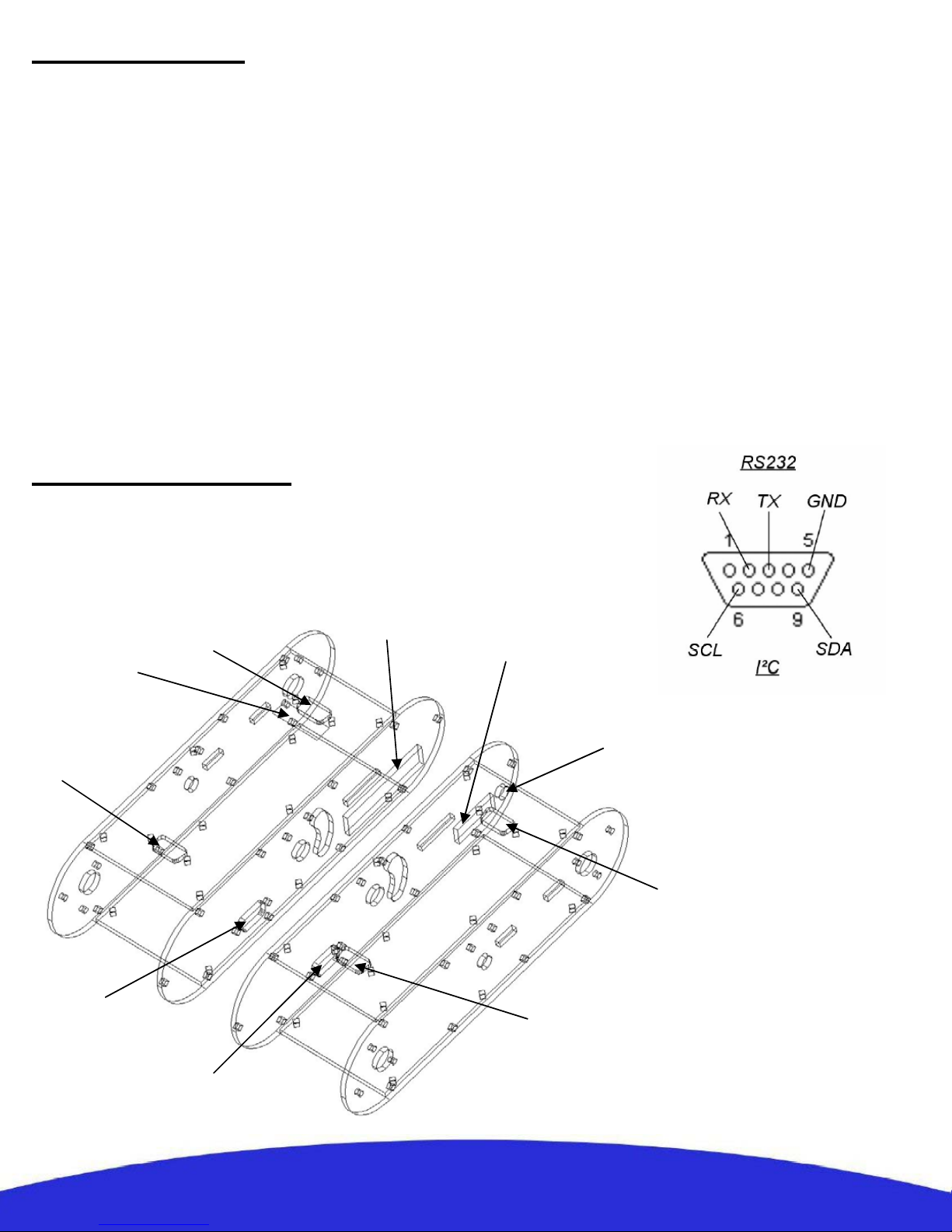

Power connectors

The 5V/9.6V power output:

The robot is equipped with two 5V 2A DC/DC

converters. One of the converters is reserved

exclusively to power the different internal

components of the robot. The second converter is

available to the user through the general power

connector dedicated to external modules such an IP

camera. A direct connection to the batteries is

made available on this connector as well. The 5V

output can’t give more than 2A and a maximum of

10A is recommended for the 9.6V output. An

incorrect use of this connector beyond those values

(short circuit or other) can provoke a malfunction

of the robot or of the DC/DC converter and even

damage those.

Note: The WiFiBoT company will not in any case be considered responsible for any damage

provoked by any incorrect use of this connector. Any reparation necessary for any damage caused

by the incorrect use of this connector will not be covered by the warranty.

The external power and charging connector:

This connector presents directly the + and – of the robot

and has a double use. On one side it allows to directly

power the robot with an external source without having

to use the batteries. The second use is to charge the

batteries on the robot itself when no additional packs are

available.

Note : When charging the robot make sure the power

switch is OFF so the charger does not find the robot in

march.

4

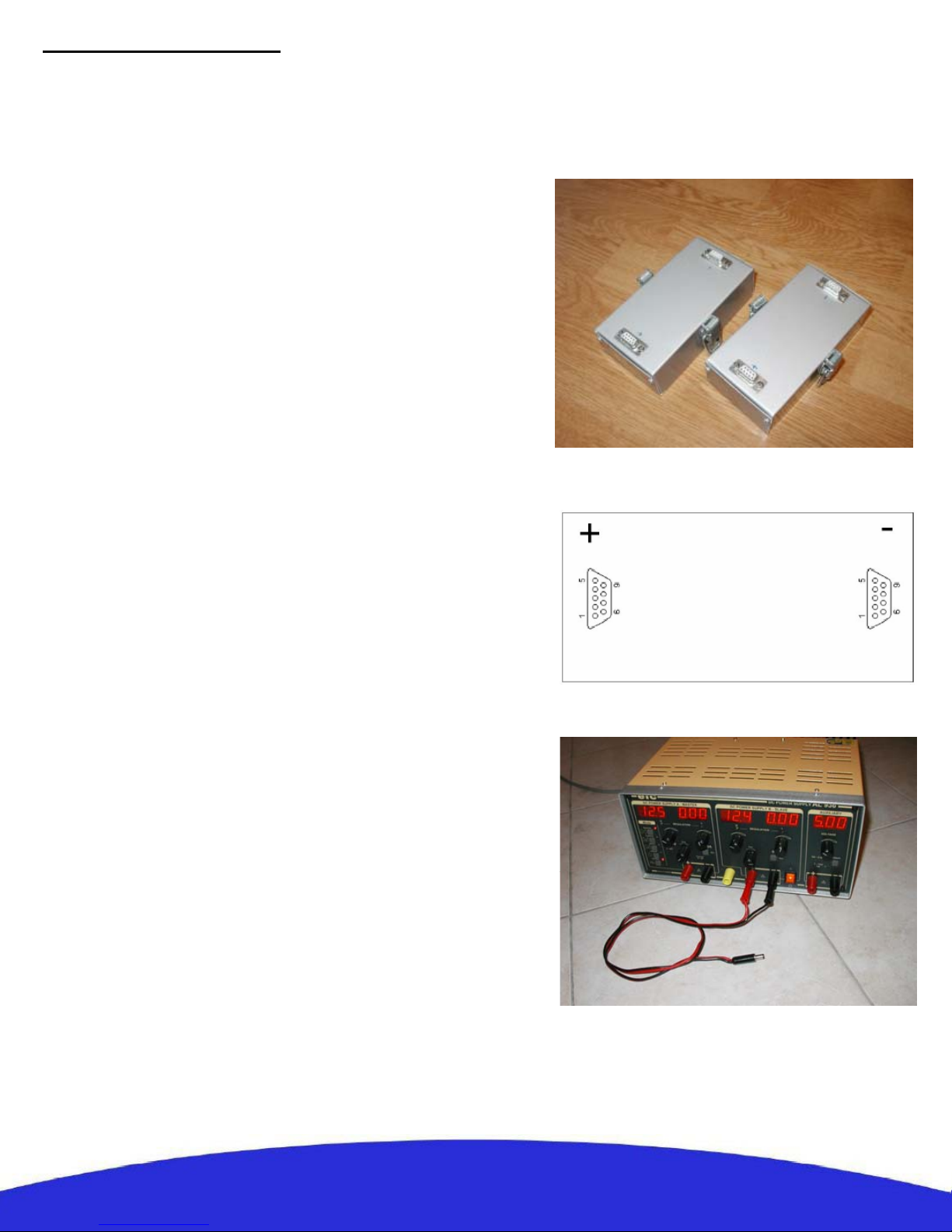

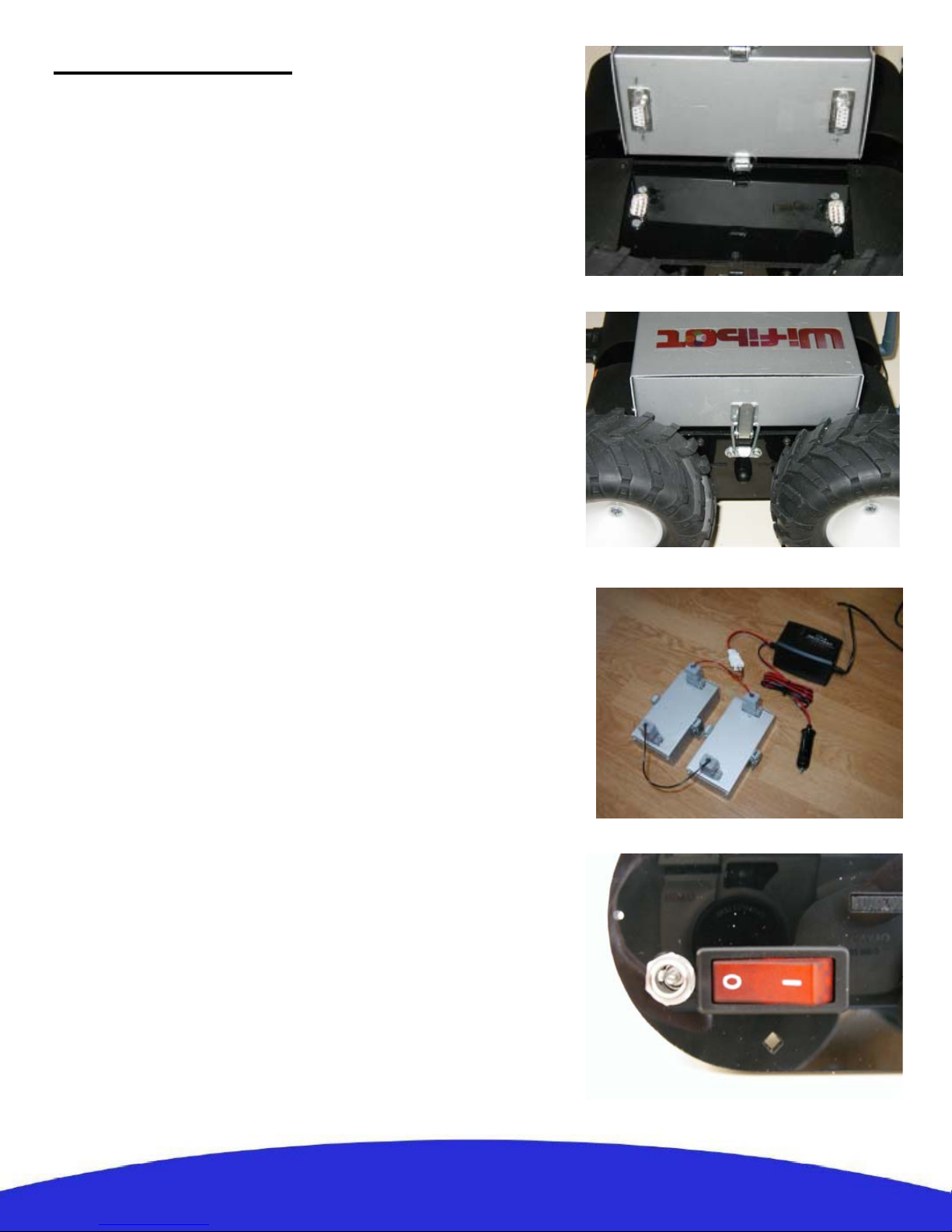

Battery installation

Insertion:

Locate the connectors and their direction on both the

robot and the two battery packs. Insert the batteries

till the end and secure them by closing the lateral

clamps.

Extraction:

Open the clamps and pull the battery packs up.

Charge:

A battery charger is included with the robot and can

be used for charging the batteries in two different

ways:

Externally: This charging mode allows a continuous

use of the robot by doing a rotation of several battery

packs. Insert first each plug in the corresponding

color on the charger side and then connect the three

cables included for this purpose to the batteries as

shown on the photo. (red color with the battery +, see

page 3)

On the robot: This mode is recommended when the

user has only one set of battery packs. First make sure

the robot is OFF, then connect the plugs of the

charging cable on the side of the charger and then on

the charging connector located next to the power

switch of the robot.

5

Camera installation

The robot is sold with an IP camera which model can vary depending of the robot version, it

is a complement and is not part of the robot itself. It is an independent peripheral which can

be replaced by any other camera model or network peripheral. For more information about

your particular camera please refer to its manual included in the CD-ROM. Nevertheless its

installation is similar in all models.

Place the camera on the central support:

Screw the camera on its support and if it

applies, adjust manually the desired position

angle.

Connect the Ethernet cable to the camera :

Connect the included Ethernet cable to the

RJ45 port located at the back of the camera

and to one of the ports of the embedded

switch.

Connect the power cable of the camera:

Connect the proper power output (5V/9.6V) of

the robot to the camera power input located at

the back of the camera.

6

General structure of the robot

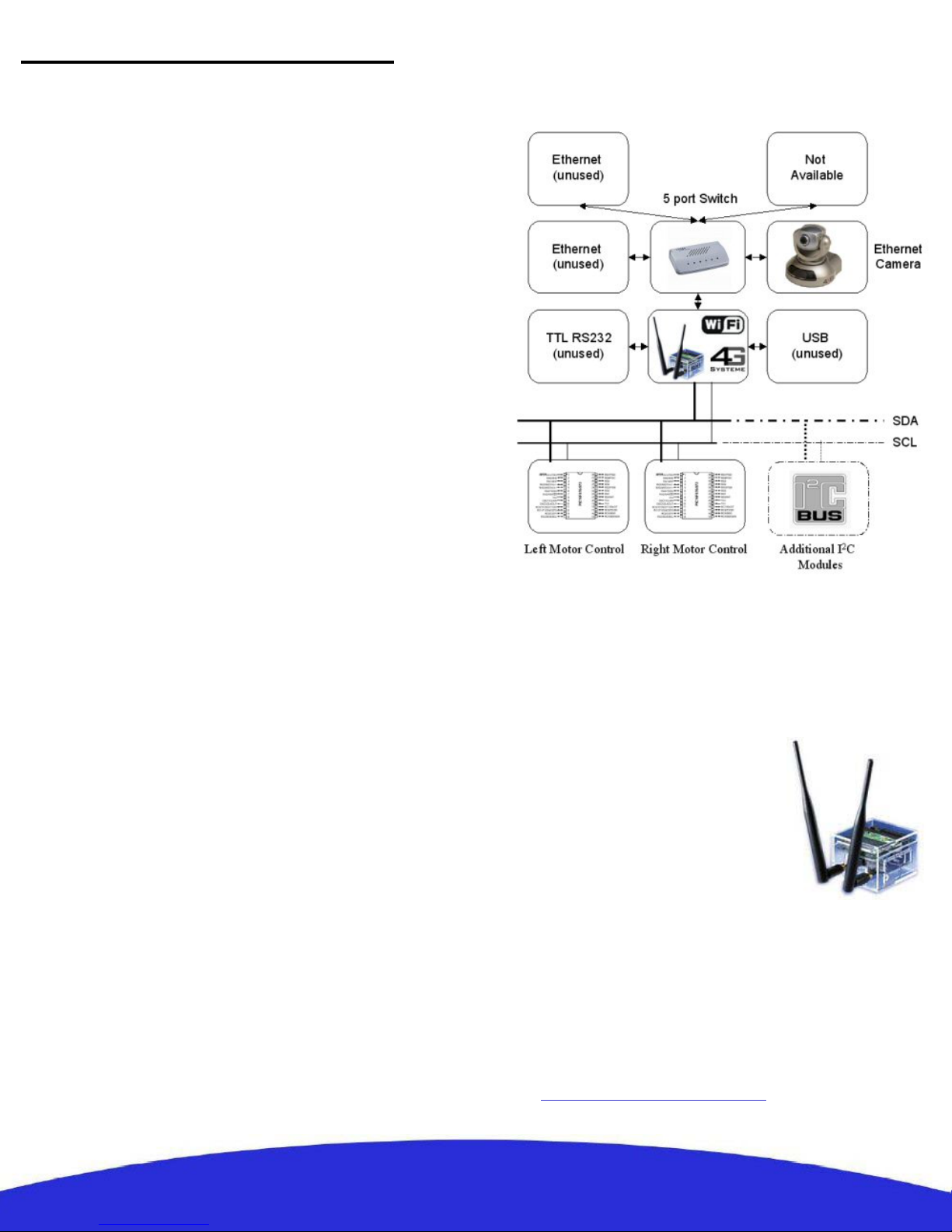

System architecture:

The system architecture is very simple, it is build

around a double bus Ethernet-I²C and a CPU that

acts as a bridge between the two. This same CPU

works as an access point and makes the Ethernet bus

accessible from the outside through Wi-Fi. In

general the embedded LAN is used for peripherals

of a certain importance such the IP camera while the

I²C bus is useful for connecting more simple

modules based on micro-controllers. To finish, the

robot features one RS232 port which can be bridged

to upper levels as well. This makes possible to add

to the robot commercial modules as well as “home

made” ones based on simple micro-controllers.

The embedded CPU:

The embedded CPU is a 4G Access Cube from 4Gsystems, some of its interesting features are:

• 400MHz MIPS processor AMD Alchemy Au1500

• 64 MB RAM

• 32 MB Flash

• 100Mbps Ethernet

• Power Over Ethernet Standard IEEE 802.3af

• USB host/USB device (no external plug on robot)

• Scope for installing up to 8 MiniPCI devices via 4

dual adapters.The robot has space for one MiniPCI.

• WLAN card with RP-SMA connection

• Dimensions 7 x 5 x 7 cm

• Power rating 4 W

• No moving parts

The operating software running on the Cube is a

specially adapted Linux distribution “Nylon”. It

provides several features including:

• Linux Kernel 2.4.27

• Mesh Routing (OLSR)

• Web Server

• DNS Server

• DHCP Server/DHCP Client

• Firewall (Shorewall)

•Perl

• Software updates via the Internet

It is totally programmable and all components are

available in source text format. Some

programming examples are included in the CD

and the web page for the distribution can be found

at: http://www.meshcube.org

7

Loading...

Loading...