WIELANDER+SCHILL Inverta Puls IP6-2 ACT Operation Manual

Operation manual Inverta Puls IP6-2 ACT

Page 1 of 20

Operation manual

Inverta Puls IP6 – 2 ACT

May 2013

REV 2.0

Inverta Puls IP6-2 ACT Operation manual

Page 2 of 20

CONTENT

1 PREFACE ...................................................................................................................... 4

1.1 PRODUCT INTRODUCTION ........................................................................................... 4

1.2 ASSEMBLY REQUIREMENTS ......................................................................................... 4

1.3 SELECTING THE ACCESSORIES .................................................................................... 4

2 PUTTING INTO OPERATION ........................................................................................ 5

2.1 CONNECTING TO THE ELECTRIC NETWORK.................................................................... 5

2.2 CONNECTING THE MIG/MAG TORCH........................................................................... 5

2.3 S

ELECTING THE FEEDING WHEEL ................................................................................. 6

2.4 C

ONNECTING THE PRESSURE BOTTLE CONTAINING PROTECTIVE GAS .............................. 6

2.5 CONNECTING THE RETURN CABLE................................................................................ 7

2.6 MMA – TIG WELDING CONNECTION ............................................................................ 7

2.7 WELD AREA PREPARATION .......................................................................................... 7

3 SAFETY AND FIRE INSTRUCTION .............................................................................. 8

3.1 PROTECTION ............................................................................................................. 8

3.2 REMOVING THE FIRE HAZARD ...................................................................................... 8

3.3 HANDLING THE PRESSURE BOTTLES............................................................................. 9

3.4 PROTECTION AGAINST ELECTRICAL ACCIDENTS ............................................................. 9

3.5 EXTRAORDINARY MENACE DURING WELDING................................................................. 9

4 OPERATION ................................................................................................................ 10

4.1 TURNING THE DEVICE ON ......................................................................................... 10

4.1.1 Power-on sequence ....................................................................................... 10

4.2 OPERATING PANEL................................................................................................... 10

4.2.1 Manual wire inching & Gas testing ................................................................. 11

4.2.2 Welding mode selection ................................................................................. 11

4.2.3 Welding process selection.............................................................................. 11

4.2.4 Filler wire material selection ........................................................................... 11

4.2.5 Filler wire diameter selection.......................................................................... 11

4.3 S

ET UP, ADJUSTMENT AND DISPLAY DESCRIPTION ....................................................... 12

4.3.1 Material thickness window.............................................................................. 12

4.3.2 Amperage window.......................................................................................... 12

4.3.3 Voltage window .............................................................................................. 12

4.3.4 Wire speed window ........................................................................................ 12

4.4 JOB M

ODE ............................................................................................................. 13

4.4.1 Editing / saving the JOB ................................................................................. 13

4.5 MENU.................................................................................................................... 14

4.5.1 List of MENU parameters ............................................................................... 14

4.6 SELECTING THE ACTIVE FEEDER ................................................................................ 15

4.7 P

ARAMETERS SETUP FOR DIFFERENT FEED UNITS ....................................................... 15

4.8 2-TACT

MODE / 4-TACT MODE................................................................................ 15

4.9 NO ARC TIMEOUT ................................................................................................... 16

4.10 SPECIAL PULSE PARAMETERS ADJUSTMENT................................................................ 16

5 CARE AND MAINTENANCE ....................................................................................... 17

5.1 DISPOSAL OF THE MACHINE....................................................................................... 17

Operation manual Inverta Puls IP6-2 ACT

Page 3 of 20

6 TECHNICAL DATA ...................................................................................................... 18

7 TROUBLESHOOTING ................................................................................................. 19

Inverta Puls IP6-2 ACT Operation manual

Page 4 of 20

1 PREFACE

Dear customer!

Congratulation to purchasing of this quality inverter welding machine. Please read whole

Operation manual before you start.

1.1 Product introduction

Inevrta Puls IP6 -2 welding machine is compact pulse MIG-MAG welding inverter especially

developed for car body repair. The unique benefit is double wire feed unit which together

with its excellent brazing characteristic as well as good aluminum welding possibilities

enables to use this device to repair all kinds of vehicles with fine quality results.

Be aware of danger resulted from welding and follow the safety and fire instructions (see the

Part 7).

It is necessary to keep the device on a dry place, to protect device against moisture. It is not

advisable to use the device on the open air during rain.

1.2 Assembly requirements

It is necessary to set the device for welding in protection atmosphere on a dry place with the

sufficient area for cooling. The device is designed for use in covered area (under roof).

1.3 Selecting the accessories

Before using the machine, please make sure it was not damaged during transport!

All accessory equipment parts are present in the package or in wire feeding area.

List of accessories:

- front wheels set…………..1pc

- rear wheel…………………2pcs

- rear shaft…………………..1pc

- gas hose………………...…1pc

- belt for gas bottle fixing…..2pcs

- screw M10x35…………….4pcs

- spring washer M10….……4pcs

- plain washer M10………..4pcs

- plain washer M24…………2pcs

- splint 3.5x40……………….2pcs

Operation manual Inverta Puls IP6-2 ACT

Page 5 of 20

2 PUTTING INTO OPERATION

2.1 Connecting to the electric network

Check if the voltage stated on the device label complies with rated voltage of alternate voltage of your electric network.

The device can be connected to electric socket equipped with protective contact installed by

authorized electrician. Current circuit of socket must be protected with 16Amp melting safety

fuse or circuit breaker.

The device is delivered without plug. For connections can be used only plugs and sockets

according to CEE standard.

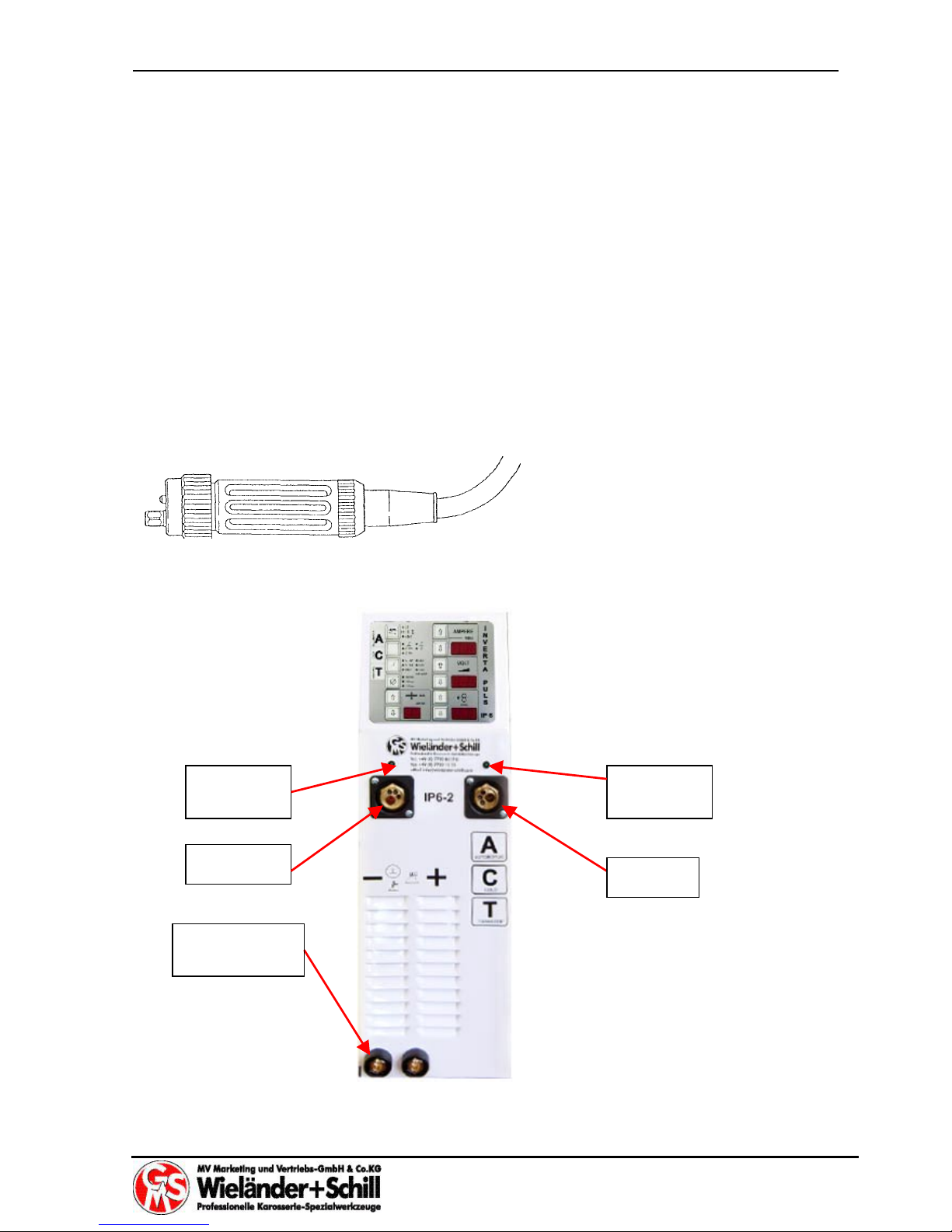

2.2 Connecting the MIG/MAG torch

For torch connecting is used EURO Standard torch connector.

Please, tighten the connector well to eliminate the conduction losses. A loose connection

can cause damage of the machine and torch.

Work piece

clamp

Torch A

Torch B

Torch B

state LED

Torch A

state LED

Inverta Puls IP6-2 ACT Operation manual

Page 6 of 20

Never use damaged torch!

Make sure the contact tip match the manufacturer’s recommendations for type and diameter

of used wire. Connect the welding conduction main connecting plug into the main socket on

the front side. Secure it with the lock nut.

In case Teflon liner is used is it necessary to use contact neck liner out of brass to provide

good current conduction to the fill wire.

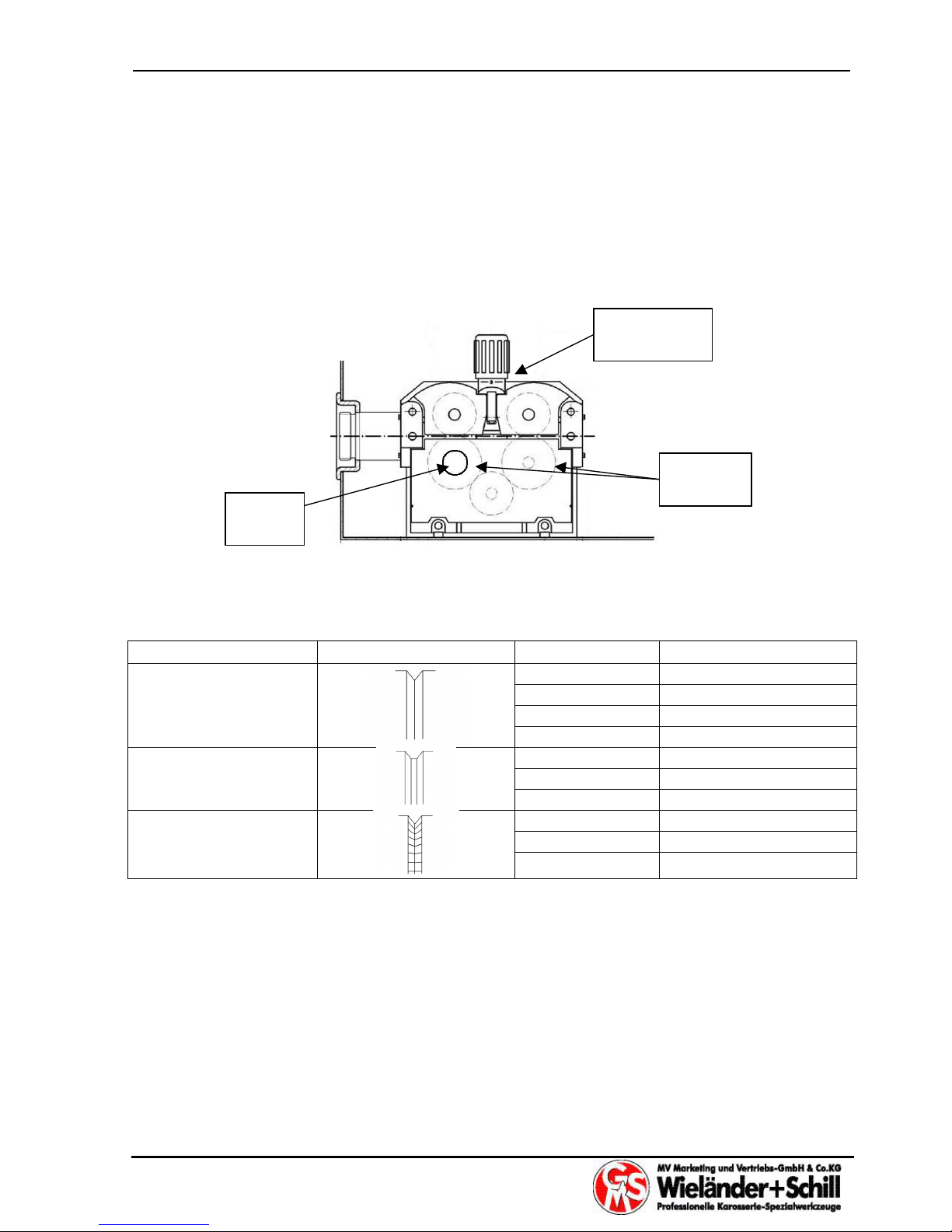

2.3 Selecting the feeding wheel

Please choose the feeding rolls correspond to used welding wire.

Materials Shape

φ

Ordering Nr.

0.6/0.8mm E017100008

0.8/1.0mm E017100015

1.0/1.2mm E017100018

Fe, SS, CuSi, CuAl

1.2/1.6mm E017100009

1.0/1.2mm E017100010

1.2/1.6mm E017100017

CuSi, CuAl, Al

1.6/2.4mm E017100011

1.0/1.2mm E017100055

1.2/1.6mm E017100056

Fe, MC, FC

When the feeding wheel is set up, you can see on the front side of wheel the assigned

welding wire diameter (value is in mm).

2.4 Connecting the pressure bottle containing protective gas

Make sure You are using right gas according welded material (see part 3.3.5)

Set the pressure bottle to the stand intended for it and fasten it by belt to the holder on the

back side of the device. Open a cover and after that open the bottle valve for a short time in

order that the gas flows away from your body. Screw a reduction valve on the pressure

Pressure

adjustment

Feeding

rolls

Fixing

point

Loading...

Loading...