Page 1

samos

®

PRO

samos

®

PRO

COMPACT

Manual

Doc. no. BA000970

Last Update: 11/2016 (Rev. F)

-Gateways

Page 2

Info

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

2

Info

810920587

Copyright

This document is copyright-protected. The rights derived from this copyright are reserved for

Wieland Electric. Reproduction of this document or parts of this document is only permissible

within the limits of the statutory provision of the Copyright Act. Any modification or abridgment of the document is prohibited without the express written agreement of Wieland Electric.

samos is a registered trademark of WIELAND Electric GmbH

Allen-Bradley, CompactBlock Guard I/O, CompactLogix, ControlFLASH, ControlLogix, DH+,

FactoryTalk, FLEX, GuardLogix, Kinetix, Logix5000, MicroLogix, PanelBuilder, PanelView, PhaseManager, PLC-2, PLC-3, PLC-5, POINT I/O, POINT Guard I/O, Rockwell Automation, Rockwell

Software, RSBizWare, RSFieldbus, RSLinx, RSLogix 5000, RSNetWorx, RSView, SLC, SoftLogix, Stratix, Stratix 2000, Stratix 5700, Stratix 6000, Stratix 8000, Stratix 8300, Studio 5000,

Studio 5000 Logix Designer, SynchLink, and Ultra are registered trademarks of Rockwell Automation, Inc.

ControlNet, DeviceNet, and EtherNet/IP are registered trademarks of ODVA, Inc.

TwinCAT is a registered trademark of Beckhoff Automation GmbH.

EtherCAT is a registered trademark and a patented technology licensed by Beckhoff Automation GmbH.

Microsoft, Windows 98, Windows NT, Windows 2000, Windows XP, Windows 7, Windows 8,

and .NET Framework are registered trademarks of the Microsoft Corporation.

Any other product or trade names listed in this manual are the trademarks or registered trademarks of the respective owners.

Subject to change.

Subject to technical changes for reasons of continued development.

Page 3

Table of Contents

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

3

1

About this manual

8

1.1

Function of this document

8

1.2

Scope of validity and applicable documents

9

1.3

Target audience

9

1.4

Information depth

10

1.5

Abbreviations and Definitions

11

1.6

Symbols/icons and writing style/spelling standard used

14

2

Safety

15

2.1

Qualified persons

15

2.2

Proper use

15

2.3

Environmentally friendly behavior

16

2.3.1

Disposal

16

2.3.2

Sorting of materials

16

3

Product description

17

3.1

Version, compatibility, and features

17

3.2

Equipment variants

18

3.3

Data transferred to the network (network input data sets)

19

3.3.1

Direct gateway output values

22

3.3.2

Module state / input and output values

22

3.3.3

Transmission of data from a second network

23

3.3.4

Configuration test values (CRCs)

23

3.3.5

Error and state information for the modules

23

3.4

Data received from the network (network output data sets)

27

4

Installation and basic configuration

28

4.1

Installing/removing

28

4.1.1

Installing modules on standard rail

28

4.1.2

Removing modules from normal rail

31

4.2

Electrical installation

33

4.3

Initial configuration steps

34

5

Configuration of gateways

35

5.1

The graphic user interface (‘Gateway’ view)

35

5.1.1

When the "Gateway" view is active

35

5.1.2

Work area

37

Table of Contents

Page 4

Table of Contents

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

4

5.1.3

Sidebars

39

5.1.4

Commands

41

5.2

Function and basic settings

42

5.2.1

Routing

42

5.2.2

Basic settings for the operating data

42

5.3

Configuring the gateway output values (tab 1)

44

5.4

Editing the gateway input values (tab 2)

46

5.5

Monitoring operating data

48

6

Modbus TCP gateway

49

6.1

Interfaces and operation

49

6.2

Basic configuration – allocation of an IP address

50

6.3

Configuration of the Modbus-TCP interface to the PLC - how the

data are transferred

52

6.4

Diagnosis and troubleshooting

59

6.5

State bits

61

7

PROFINET IO-Gateway

62

7.1

Interfaces and operation

62

7.2

Basic configuration - Assigning a device name and an IP address

63

7.3

PROFINET configuration of the gateway - how the data are transferred

65

7.4

PROFINET configuration of the gateway - which data are transferred

68

7.5

Diagnostics and troubleshooting

73

7.6

Deactivation of the PROFINET IO function

75

7.7

State bits

75

8

EtherNet/IP gateway

76

8.1

Interfaces and operation

76

8.2

Datasheet

76

8.3

Basic setup

77

8.3.1

Basic configuration of PLC

77

8.3.2

Basic configuration of the controller module

81

8.3.3

Configuring the data to PLC

82

8.3.4

Configuring the usage of data from PLC

83

8.4

Supported CIP Objects

84

8.4.1

Identity Object

84

8.4.2

Assembly Object

85

8.4.3

Discrete Input Point Object

86

Page 5

Table of Contents

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

5

8.4.4

Discrete Output Point Object

88

8.4.5

Discrete Input Group Object

89

8.4.6

Discrete Output Group Object

90

8.4.7

PCCC Object

91

8.4.7.1

PCCC Telegram Structure

91

8.4.7.2

Word Range Write

92

8.4.7.3

Word Range Read

92

8.4.7.4

Typed Write

93

8.4.7.5

Typed Read

93

8.4.7.6

Protected Typed Logical Read with 2 Address Fields

95

8.4.7.7

Protected Typed Logical Write with 2 Address Fields

95

8.4.7.8

Protected Typed Logical Read with 3 Address Fields

96

8.4.7.9

Protected Typed Logical Write with 3 Address Fields

96

8.4.8

Vendor Object

97

8.4.8.1

Instance 1

97

8.4.8.2

Instance 2

97

8.4.8.3

Instance 3

97

8.4.8.4

Instance 4

97

8.4.8.5

Instance 5

97

8.4.8.6

Instance 6

98

8.4.8.7

Instance 7

98

8.5

Supported Assembly data

101

8.5.1

List of Assembly data

101

8.5.2

Assembly Instances for Logic Output Bytes

103

8.5.2.1

Assembly Instance 37 = 0x25

103

8.5.2.2

Assembly Instances 138 = 0x8a to 141 = 0x8d

103

8.5.3

Assembly Instances for Logic Input Bytes

104

8.5.3.1

Assembly Instance 57 = 0x39

104

8.5.3.2

Assembly Instances 167 = 0xa7

104

8.6

Accessing to CIP objects

106

8.6.1

Explicit Messaging

106

8.6.2

Implicit Messaging

106

8.6.3

Symbolic Addressing

107

8.7

Adjust Performance

108

8.8

Connection with more than one PLC

108

8.9

Diagnostics and troubleshooting

109

8.9.1

Notifications via network

109

8.9.1.1

Explicit Message Connection

109

8.9.1.2

Implicit Message Connection

109

Page 6

Table of Contents

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

6

8.9.2

LED States

109

8.9.2.1

MS (Module Status)

109

8.9.2.2

NET (Network Status)

110

8.9.2.3

LINK

111

8.9.2.4

ACT (Activity Status)

111

8.9.3

Diagnostic functions in the configuration software

112

8.10

State bits

113

9

PROFIBUS DP gateway

114

9.1

Interfaces and operation

114

9.2

Projecting

118

9.3

PROFIBUS configuration of the gateway - how the data are transferred

121

9.4

Diagnosis and troubleshooting

127

10

CANopen gateway

129

10.1

Interfaces and operation

129

10.2

CANopen configuration of the gateway - how the data are transferred

134

10.3

CANopen configuration of the gateway - which data are transferred

137

10.4

NMT – network management

138

10.5

SYNC

139

10.6

Emergency

140

10.7

Node guarding

144

10.8

PDO communication

145

10.9

SDO communication

147

10.10

SDO object directory

149

10.11

Guarding protocols

155

10.12

Error objects

157

10.13

CANopen diagnostic examples

160

10.14

Diagnosis and troubleshooting

163

11

EtherCAT Gateway

166

11.1

Interfaces and operation

167

11.2

EtherCAT basics

170

11.3

EtherCAT state machine

172

11.4

Bus topology and cabling

174

Page 7

Table of Contents

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

7

11.5

Data transferred into the network

175

11.5.1

Data set 1

176

11.5.2

Data set 2

180

11.5.3

Data set 3

181

11.6

Data received from the network

183

11.7

Configuring an EtherCAT network

185

11.8

EtherCAT configuration of the gateway - how the data are transferred

186

11.9

Diagnostic LEDs on the gateway and troubleshooting

189

12

Technical data

192

12.1

Modbus TCP, PROFINET IO and EtherNet/IP gateway

192

12.2

EtherCAT gateway

192

12.3

PROFIBUS DP

192

12.4

CANopen gateways

193

12.5

Technical data for supply circuit

193

12.6

General technical data

194

12.7

Dimensional drawings

195

12.7.1

Controller module

195

12.7.2

CANopen and PROFIBUS gateways

196

12.7.3

EtherCAT gateway

197

13

Order data

198

13.1

Hardware modules and accessories

198

13.2

Modules for contact expansion

200

Page 8

About this manual

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

8

gateway manual

not

software manual

Hardware manual

installation instructions/brief instructions

1

1.1

About this manual

910719883

Please read this section carefully before you work with these operating instructions and the

samosPRO gateways.

Function of this document

910721419

There are three manuals for the samosPRO system with clearly delineated areas of application

as well as installation instructions and brief instructions for each module.

• This

• The

• The

• Each module contains the

This manual contains original operating instructions in accordance with the Machinery Directive.

describes all samosPRO gateways and their functions in detail. It instructs the technical staff of the machine manufacturer or machine operator in the safe installation, configuration, electrical installation, commissioning, operation and maintenance

of the samosPRO gateways.

This manual does

provide operating instructions for the machine, which incorporates

modular samosPRO safety controls and a samosPRO gateway. Information in this regard is

provided in the operating instructions for each machine.

This manual is only valid in combination with the other samosPRO manuals (see

validity and applicable documents [ch. 1.2, p. 9]

describes the software-supported configuration and parameterizati-

).

Scope of

on of the samosPRO safety control. In addition, the software manual contains a description

of the important diagnostic functions for operation and detailed information for identifying

and eliminating errors. Use the software manual mainly when configuring, commissioning

and operating samosPRO safety controls.

describes all of the modules and their functions in detail. Use the

hardware manual mainly for designing devices.

. These instructions

provide information on the fundamental technical specifications of the modules and contain simple installation instructions. Use the installation instructions/brief instructions when

installing the samosPRO safety control.

Page 9

About this manual

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

9

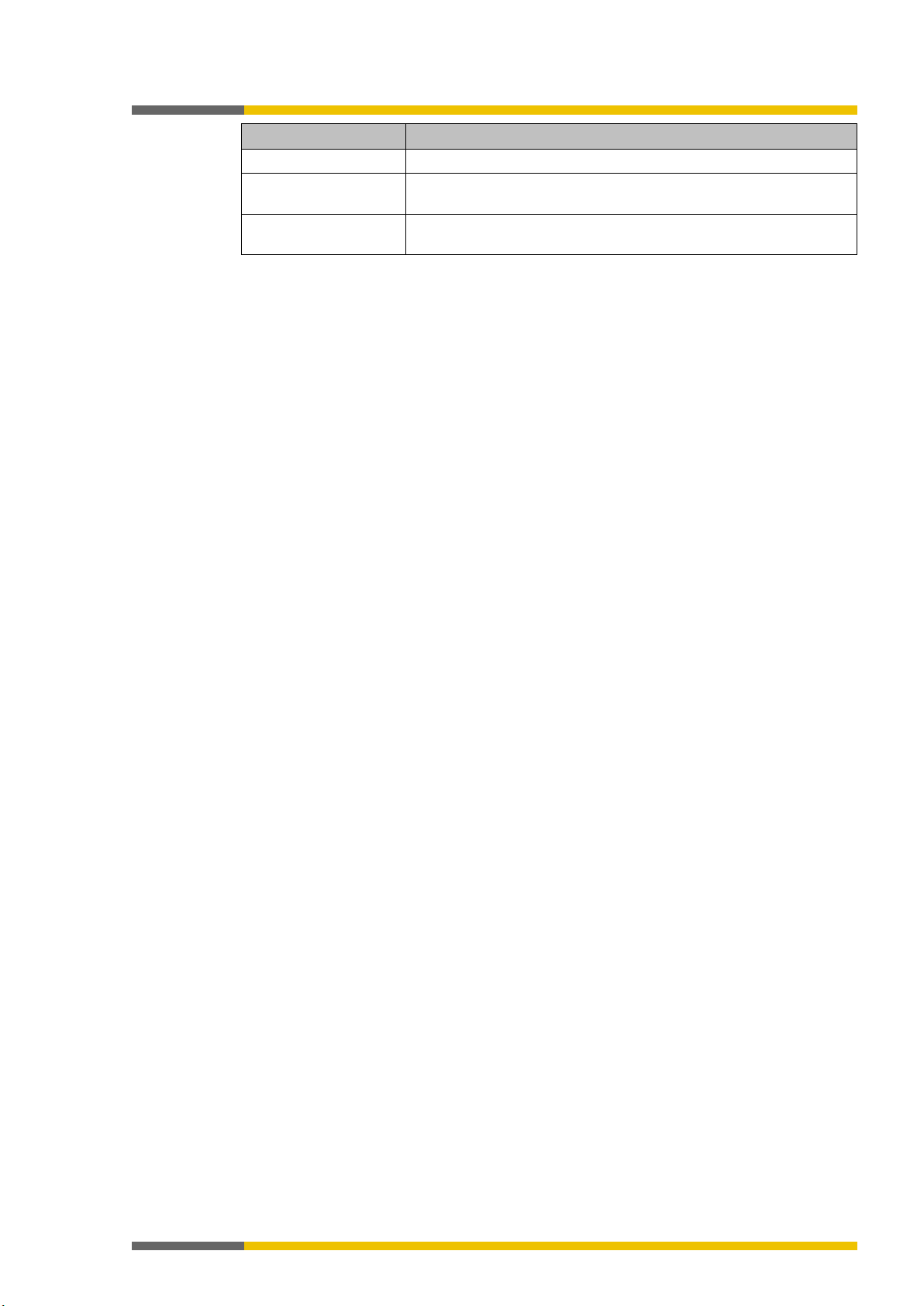

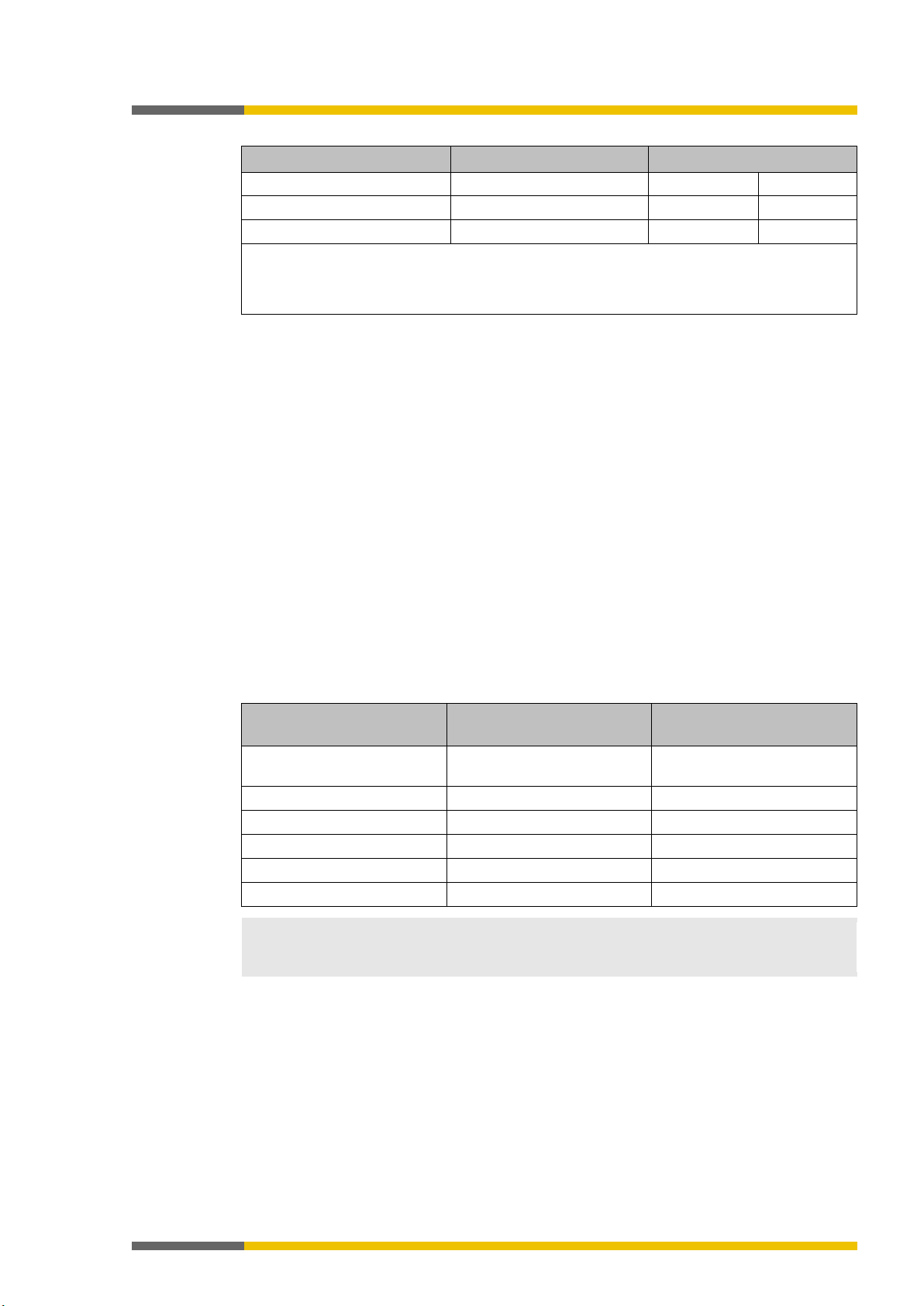

Document

Title

Item number

Software manual

samosPLAN5+ software

BA000968

Hardware manual

samosPRO hardware

BA000966

Gateway manual

samosPRO gateways

BA000970

samosPRO)

fety control)

control)

(samosPRO-PROFIBUS-DP gateway)

(samosPRO-CANopen gateway)

(samosPRO EtherCAT gateway)

planners, developers

operators

1.2

1.3

Scope of validity and applicable documents

910727051

This manual applies to the following gateway modules:

• SP-EN-MOD

• SP-EN-PN

• SP-EN-IP

• SP-PROFIBUS-DP

• SP-CANopen

• SP-EN-ETC

Table 1: Overview of the samosPRO documentation

Operating instructions

Operating instructions

Operating instructions

Operating instruc-

SP-COPx

(Controller modules of the modular safety control

SP-SDI/SP-SDIO

(Expansion modules of the modular samosPRO sa-

SP-DIO

(Expansion module of the modular samosPRO safety

SP-PROFIBUS-DP

BA000978

BA000515

BA001033

BA000572

tions

Operating instruc-

SP-CANopen

BA000683

tions

Operating instruc-

SP-EN-ETC

BA000959

tions

Target audience

910723979

This manual is aimed at the

modular samosPRO safety controls and that want to exchange data with a field bus (controls)

via a gateway.

It is also aimed at persons commissioning a samosPRO gateway system for the first time or

maintaining such a system.

and

of systems that incorporate

Page 10

About this manual

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

10

ATTENTION

Observing safety information and protective measures

1.4

Information depth

910725515

This manual contains information about the following topics related to samosPRO gateways:

• Installation

• Integration into the network

• Configuration with the samosPLAN5+ software

• Data transmission to and from the network

• State information, projection and associated mapping

• Item numbers

Observe the safety information and protective measures for the samosPRO gateways described in this manual.

Downloads are provided at the following link http://www.wielandinc.com/

Also consult our website on the Internet. At the following link http://www.wielandinc.com/,

you will find:

• the samosPLAN5+ software

• The samosPRO manuals available for display and printing in various languages:

– This gateway manual (BA000970)

– The hardware manual (BA000966)

– The software manual (BA000968)

• The GSD file of the SP-PROFIBUS-DP for PROFIBUS-DP

Important information

• The EDS file of the SP-CANopen for CANopen

Page 11

About this manual

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

11

Term

Explanation

0b

The following are specified in binary format

ACD

Address Collision Detection

ANSI

American National Standards Institute, specified character coding

AOI

Add On Instruction

AOP

Add On Profile

API

Actual Packet Interval

NET IO between the PLC and the device

Attribute

Characteristic or property of an object

Bit

Data unit with a value of 0 or 1

which each of the 8 bits is viewed individually

CIP

Common Industrial Protocol

Cyclic Redundancy Check, a type or the result of a hash function for

revealing errors in the area of data storage or transmission

12 bytes of the relevant data set (depending

on the gateway used).

state data. A data set can consist of several data blocks.

I/O

Input/output

EPATH

Encoded Path, especially for CIP applications

technologies with CIP

Net/IP, PROFIBUS DB, CANopen, Modbus TCP, etc.

ID

An identifier or an identity

specification, version 3.18)

attribute values. (Reference: CIP specification, version 3.18)

ment

1.5

Abbreviations and Definitions

1127430283

{ } An element array or an element structure

0x The following are specified in hexadecimal format

Procedure error A procedure error occurs if, in redundant input circuits, the two

input signals are not equal. Monitoring of inequality is frequently

carried out within a tolerated time window.

AR Application Relation, unique communication relationship in PROFI-

BOOL Data type specified for CIP devices; stands for a value of 1 byte, in

Byte, BYTE Data unit, representing a sequence of 8 bits; without a plus/minus

sign, if not specified

Controller module Controller from the samosPRO COMPACT product family

CRC

Data block A data block contains 2-

Data set Describes a quantity of associated data, e.g. logic values or system

EtherNet/IP Industrially-used Ethernet network, combines standard Ethernet

Gateway Connection module for industrially-used networks, such as Ether-

Instance The physical representation of an object within a class. It stands for

one of several objects within the same object class. (Reference: CIP

IP Internet protocol

Class A series of objects representing a similar system component. A

class is a generalization of the object, a template for defining variables and methods. All the objects within a class are identical with

regard to function and behavior. However, they may have differing

LSB Low Significant Byte

MPI Measured Packet Interval; shows the API at the time of measure-

Page 12

About this manual

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

12

Term

Explanation

MSB

Most Significant Byte

O→T

Originator to Target (sender to target device)

ODVA

Open Device Vendor Association

PC

Personal Computer

PLC

Programmable Logic Controller

RX

Receive

modules.

Examples: GetAttributeSingle, SetAttributeSingle

byte per character, 1 byte length code)

sion gateways and I/O modules.

puts and gateway functions, amongst other things

( PLC)

input circuits or using test pulses in input and output circuits.

immediate error recognition.

T→O

Target to Originator

transport layer specified in RFC 793

offs / interruptions in input

nuous basis.

ve test result and thus switch-off of the affected safety circuits.

TX

Transmit / Send

UCMM

Unconnected Message Manager

Data type specified for CIP applications

col, Internet standard protocol for the transport

layer specified in RFC 793

PCCC Programmable Controller Communication Command

RPI Requested Packet Interval

S/N Serial number

samosPLAN5+ Configuration software for controller modules of type SP-COP. The

software can be run on a PC and communicates with the controller

Service Service to be performed

SHORT_STRING Data type specified for CIP devices; stands for a character string (1

SINT Short integer = 1 byte

SP-COP Safety controller consisting of a controller module of the samosPRO

COMPACT product family, as well as optionally connectable expan-

SP-COP2-ENI Controller module, which is equipped with safety inputs and out-

PLC Programmable Logic Controller

Stuck-at high Stuck-at high is an error in which the input or output signal gets

stuck at On. The causes for a Stuck-at high can be short-circuits to

other input and output lines, often called cross-references, or defective switching elements. Stuck-at high errors are discovered

through plausibility tests, such as sequence errors in two-channel

Stuck-at low Stuck-at low is an error in which the input or output signal gets

stuck at Off. The causes of a stuck-at low can be line interruptions

in input circuits or defect switching elements. Stuck-at low errors

are discovered through plausibility tests and usually do not require

TCP Transmission Control Protocol, Internet standard protocol for the

Test pulses or scan

gaps

Test pulse error Test pulse errors are undetected test pulses, which lead to a negati-

Test pulses or scan gaps are brief switchand output circuits, which are generated in a targeted manner to

detect stuck-at high errors quickly. Test pulses check the switch-off

ability of switching elements during operation on an almost conti-

UDINT Unsigned double integer = 4 Bytes = 2 Words

UDP User Datagram Proto

Page 13

About this manual

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

13

Term

Explanation

UDT

User Defined Type

Data type specified for CIP applications

without a plus/minus symbol

UINT Unsigned double integer = 2 Bytes = 1 Word

USINT Data type specified for CIP applications, which stands for 1 byte

Page 14

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

14

NOTICE

These are notes that provide you with information regarding particularities of a device or a

software function.

Warning!

Please read and follow the warnings carefully!

to occur.

bold font

Edit

File

1.6

ATTENTION

About this manual

Symbols/icons and writing style/spelling standard used

840010507

A warning lets you know about specific or potential hazards. It is intended to protect you

from accidents and help prevent damage to devices and systems.

•

Failure to do so may negatively impact the safety functions and cause a hazardous state

Menus and commands

The names of software menus, submenus, options, and commands, selection fields, and

windows are written in

. Example: Click on

in the

menu.

Page 15

Safety

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

15

and

and

ATTENTION

Do not operate a samosPRO gateway on a safety field bus!

related field bus data (state bytes) for control and diagnostic

cation within a safety network.

Do not use data from a samosPRO gateway for safety-related applications!

checked by a safety specialist.

ATTENTION

The safety instructions and precautions for use of samosPRO gateways must be adhered

to!

NOTICE

• Please follow the standards and guidelines valid in your country when installing and ope-

2

2.1

2.2

Safety

910731659

This section is intended to support your safety and the safety of the system users.

Please read this section carefully before you work with a samosPRO system.

Qualified persons

911377675

A safety controller with samosPRO gateways may only be installed, commissioned, and maintained by qualified persons.

Qualified persons are those who

• have suitable technical training

• have been trained by the machine operator in the operation and applicable safety guidelines

• have access to the samosPRO system operating instructions and have read them and duly

noted their contents.

Proper use

911379211

The samosPRO gateways can only be operated in conjunction with a samosPRO safety controller. The firmware version of the connected controller modules must be at least V1.0.0 and the

version of the samosPLAN5+ configuration software must be at least 1.0.0.

The samosPRO gateways do not have their own power supply.

The gateway modules are not suitable for operation with a safety field bus!

They do not only generate safetypurposes. They do not support any safety mechanisms that would be required for communi-

The samosPRO gateways can be used to integrate non-safety-related data into the logic editor in such a way that the safety function of the samosPRO system may be adversely affected.

ATTENTION

• Never integrate a gateway into a samosPRO system without having this source or risk

These modules may only be operated by qualified staff and may only be used on a machine on

which they have been installed and commissioned for the first time by a qualified person in accordance with this manual.

In the event of any other use or any changes to the device – including within the scope of

installation – this shall nullify any warranty claim with respect to Wieland Electric GmbH.

rating the samosPRO gateways.

• The national/international legal regulations apply to the installation and use of the modular samosPRO safety controls as well as for the commissioning and repeated technical

testing, particularly the following:

– EMC Directive 2004/108/EC,

– the Use of Work Equipment Directive 2009/104/EC,

– the accident prevention / safety regulations.

• The manual must be provided to the operator of the machine on which the samosPROsystem is to be used. The machine operator must be trained by qualified persons and is

required to read this manual.

Page 16

Safety

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

16

ATTENTION

May only be used in an industrial environment

NOTICE

We will be happy to help you in disposing of these devices.

Simply contact us.

ATTENTION

Important information

Components

Disposal

electric connecting pieces

Cardboard, paper

Paper/cardboard recycling

2.3

2.3.1

2.3.2

The samosPRO system fulfills the requirements for class A (industrial applications) according

to the "Emitted interference" basic technical standard. The samosPRO system is therefore

only suitable for use in an industrial environment.

Environmentally friendly behavior

888332555

The modular samosPRO safety control and the corresponding modules are designed such that

they stress the environment as little as possible. They use only a minimum of power and resources.

Make sure that you also carry out work while always considering the environment.

Disposal

888334091

The disposal of unusable or irreparable devices should always be done in accordance with the

respectively valid country-specific waste-elimination guidelines (e.g. European Waste Code 16

02 14).

Sorting of materials

888335627

• The sorting of materials may only be carried out by qualified persons!

• Care must be used when disassembling the devices. There is a risk of injuries during this

process.

Before you can route the devices to the environmentally-friendly recycling process, it is necessary to sort the various materials of the samosPRO devices.

Separate the housing from the rest of the components (particularly from the PC board).

Place the separated components into the corresponding recycling containers (see the

following table).

Table 2: Overview of disposal according to components

Product

Housing

PC boards, cables, connectors, and

Packaging

Plastic recycling

Electronics recycling

Page 17

Product description

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

17

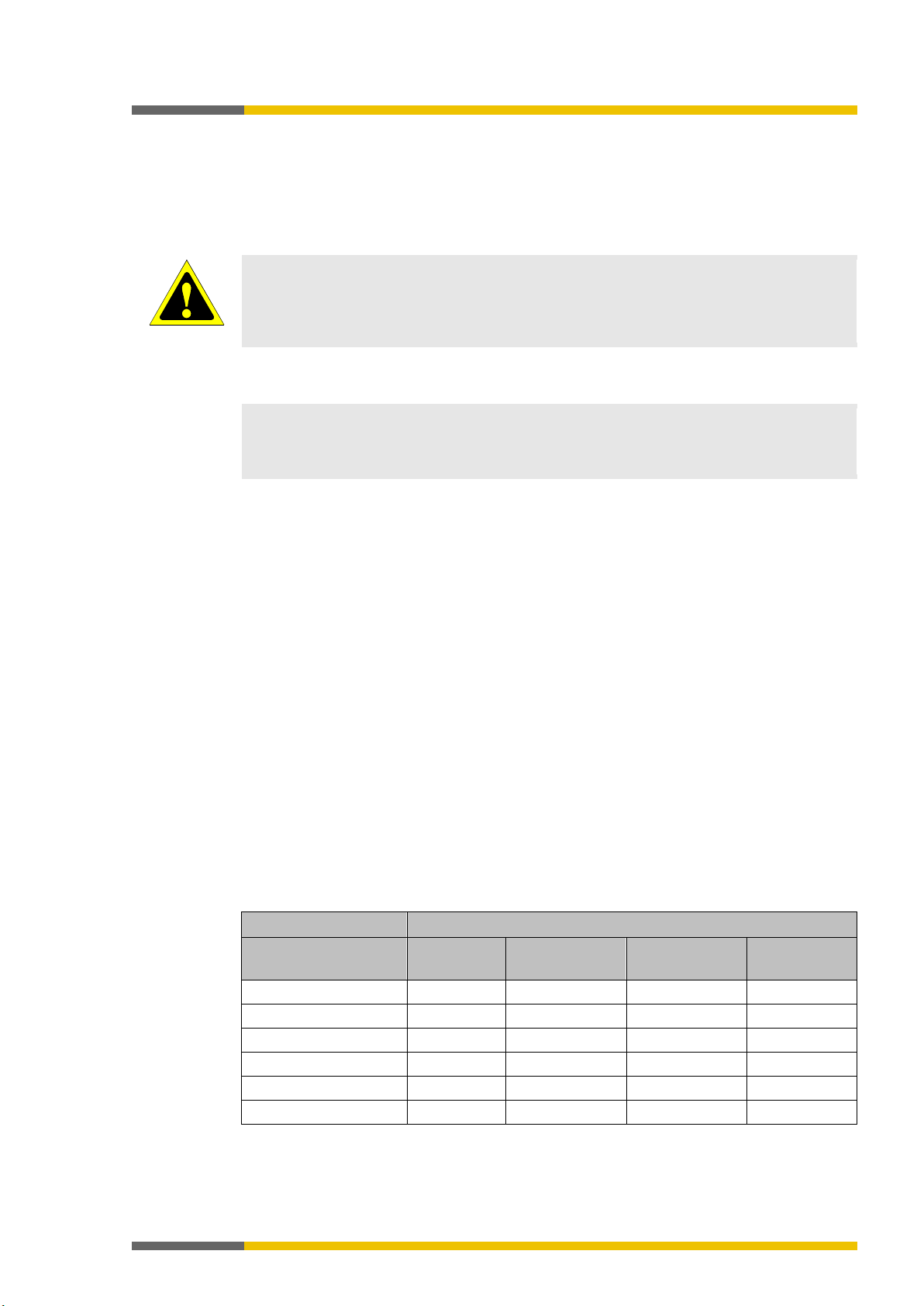

ATTENTION

Do not operate a samosPRO gateway on a safety field bus!

related field bus data (state bytes) for control and diagnostic

cation within a safety network.

NOTICE

Where not otherwise indicated, this manual always considers the data exchanged between

system and the relevant network from the point of view of the network master

data received from the network is termed output data.

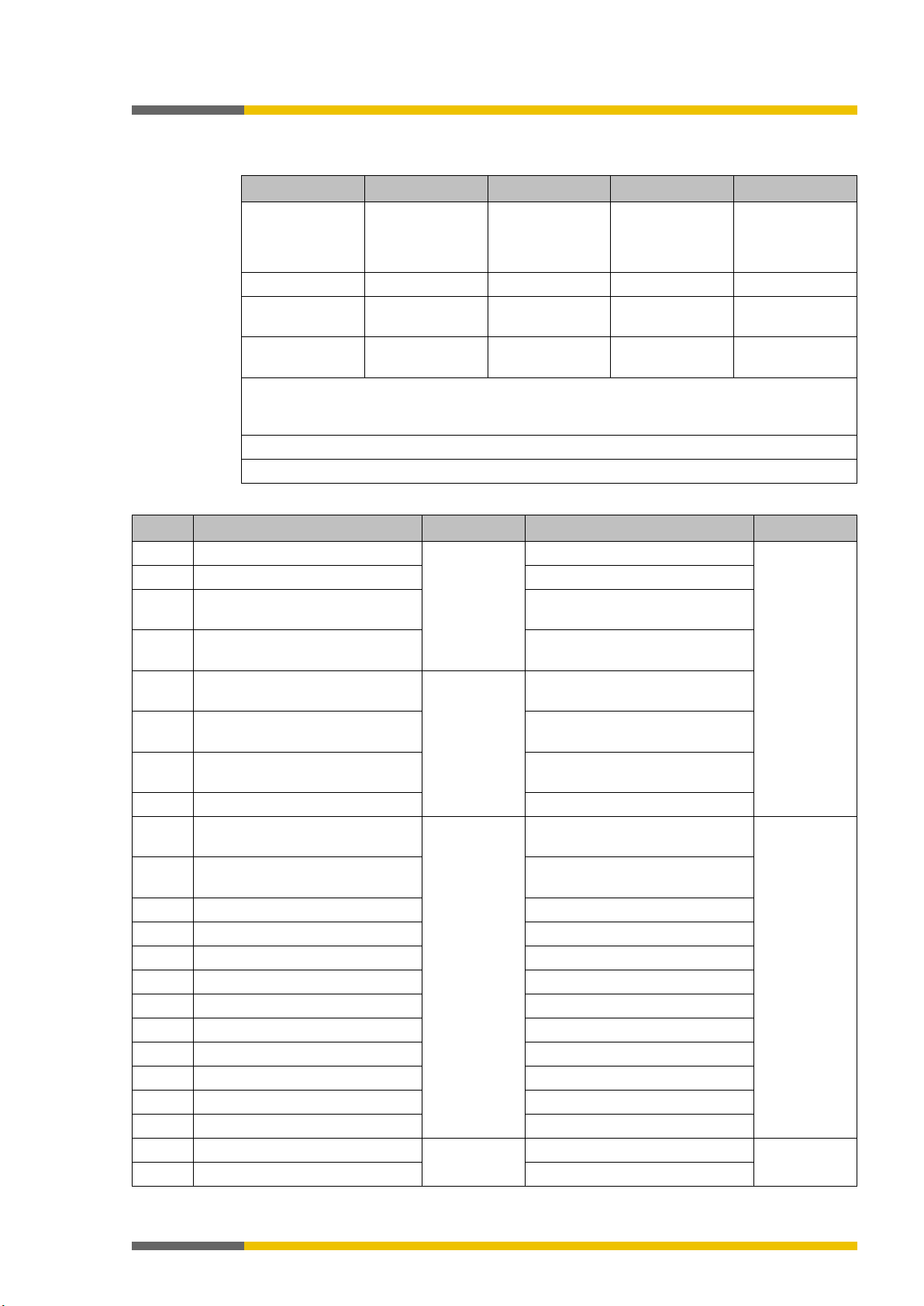

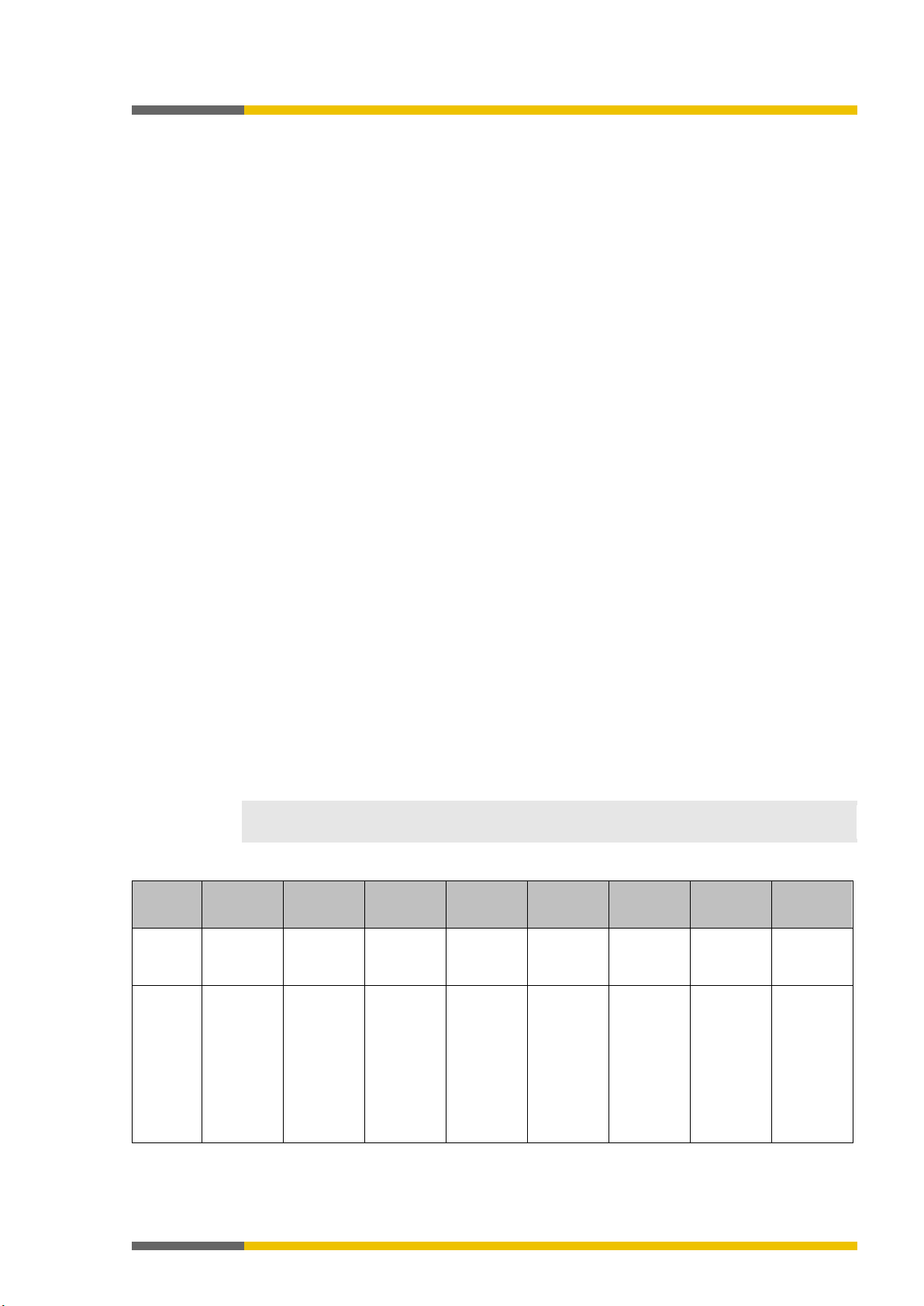

Available with controller module version and higher

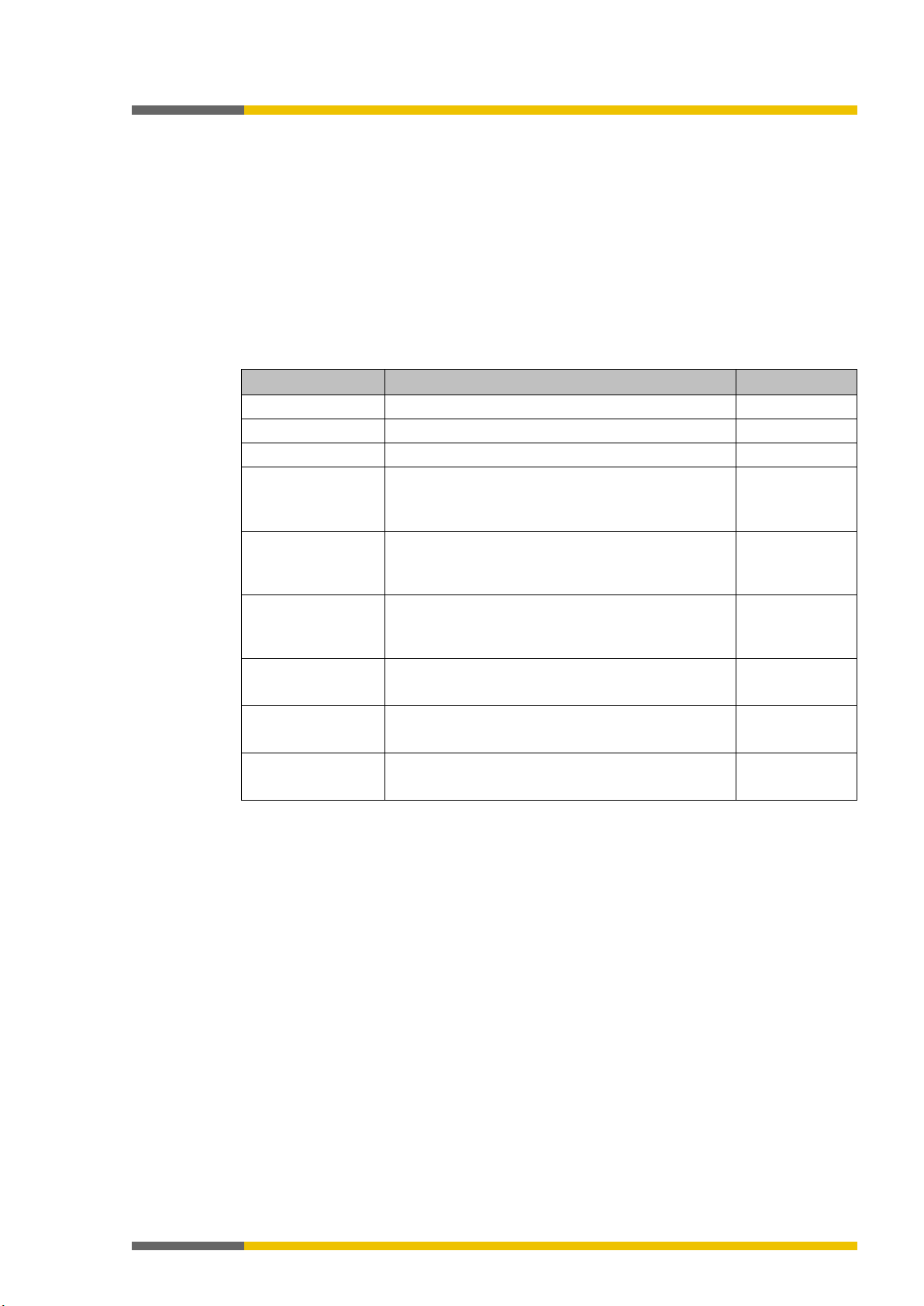

Feature/

functionality

SP-COP1-x

SP-COP2-EN-x

SP-COP2-ENI-x

samosPLAN5+

Modbus TCP

---

---

A-01

V1.0

PROFINET IO

---

---

B-01.xx

V1.2

EtherCAT (SP-EN-ETC)

C-01.xx

C-01.xx

C-01.xx

V1.3

EtherNet/IP

---

---

D-01.xx

V1.4

PROFIBUS DP

A-01

A-01

A-01

V1.0

CANopen

A-01

A-01

A-01

V1.0

3

3.1

Product description

910740875

samosPRO gateways allow a samosPRO system to transmit non-safety-related data for control

and diagnostic purposes to the external field bus system and to receive them.

The gateway modules are not suitable for operation with a safety field bus!

They do not only generate safety-

Important safety information

purposes. They do not support any safety mechanisms that would be required for communi-

Information on the function, configuration and designations

the samosPRO

(PLC). Thus data sent to the network from the samosPRO system is termed input data, while

Configuration of samosPRO gateways takes place via the samosPLAN5+ configuration software, using a PC or Notebook connected to the SP-COPx main module via the USB interface

or RJ45 Ethernet interface.

The safety-related logic of the samosPRO system works independently of the gateway. However, if the system has been configured in such a way that non-safety-related information from

the field bus can be integrated into the logic editor, switching off the gateway may result in

availability problems.

A samosPRO gateway can only be operated on a samosPRO system. It does not have its own

power supply. A maximum of two samosPRO gateways can be operated simultaneously for

each system.

The gateway for Modbus TCP, PROFINET IO or EtherNet/IP is integrated into the SP-COP2-ENI

controller module, while the gateways for Profibus-DP, CANopen or EtherCAT are housed in a

22.5 mm wide installation housing for 35 mm standard rails in accordance with EN 60715.

Order information:

Order data [ch. 13, p. 198]

Version, compatibility, and features

1184672907

There are various module versions and function packages for the samosPRO product family

that enable various functions. This section will give you an overview as to which module version, which function package, and/or which version of the samosPLAN5+ software you will

need to be able to use a certain function or a certain device.

Table 3: Required versions of the controller module

Page 18

Product description

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

18

Gateway

Module name

Versions

EtherCAT

SP-EN-ETC

A-011)

A-021)

PROFIBUS DP

SP-PROFIBUS-DP

A-02

A-03

CANopen

SP-CANopen

A-01

A-02

CANopen emergency messages are fully functional.

S/N

Gateway

Network type

Ethernet TCP/IP socket interface

slave operation

SP-EN-PN

PROFINET IO device

-

SP-EN-IP

EtherNet/IP device

-

SP-PROFIBUS-DP

PROFIBUS DP slave

–

SP-EN-ETC

EtherCAT slave

-

NOTICE

You will find the manufacturing date of a device on the type label in the S/N field in the for-

calendar week).

3.2

Table 4: Versions of the gateway modules

1)

The EtherCAT node ID cannot be saved in the gateway.

2)

The manufacturer-specific expanded diagnostics are fully functional.

3)

2)

3)

Info

• You can find the module version on the type plate of the modules.

• You will find the samosPLAN5+ software version in the main menu.

• The latest software version is available in the Internet at the following address

http://www.wielandinc.com/.

• Newer modules are backwards-compatible, which means that each module can be replaced with a module having a higher module version.

• You can find the date of manufacture for a device on the type plate in the

format <Product no.>yywwnnnnn (yy = year, ww = calendar week).

field in the

Equipment variants

910741899

There are three samosPRO gateways for various network types.

The Modbus TCP / PROFINET IO and EtherNet/IP gateway of the SP-COP2-ENI controller module or the external SP-EN-ETC gateway are suitable for Ethernet networks. The SPPROFIBUS-DP gateway and the SP-CANopen gateway are external field bus gateways without

an Ethernet function.

Table 5: Equipment variants and their main characteristics

SP-EN-MOD Modbus TCP with master and

Client/Server on Port 502

SP-CANopen CANopen slave –

mat yywwnnnn (yy = year, ww = calendar week, nnnn = consecutive serial number within a

Page 19

Product description

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

19

Logic results from

Input values

Output values

Output data

Test values

Error and state information

Data set 1

Data set 2

Data set 3

Data set 4

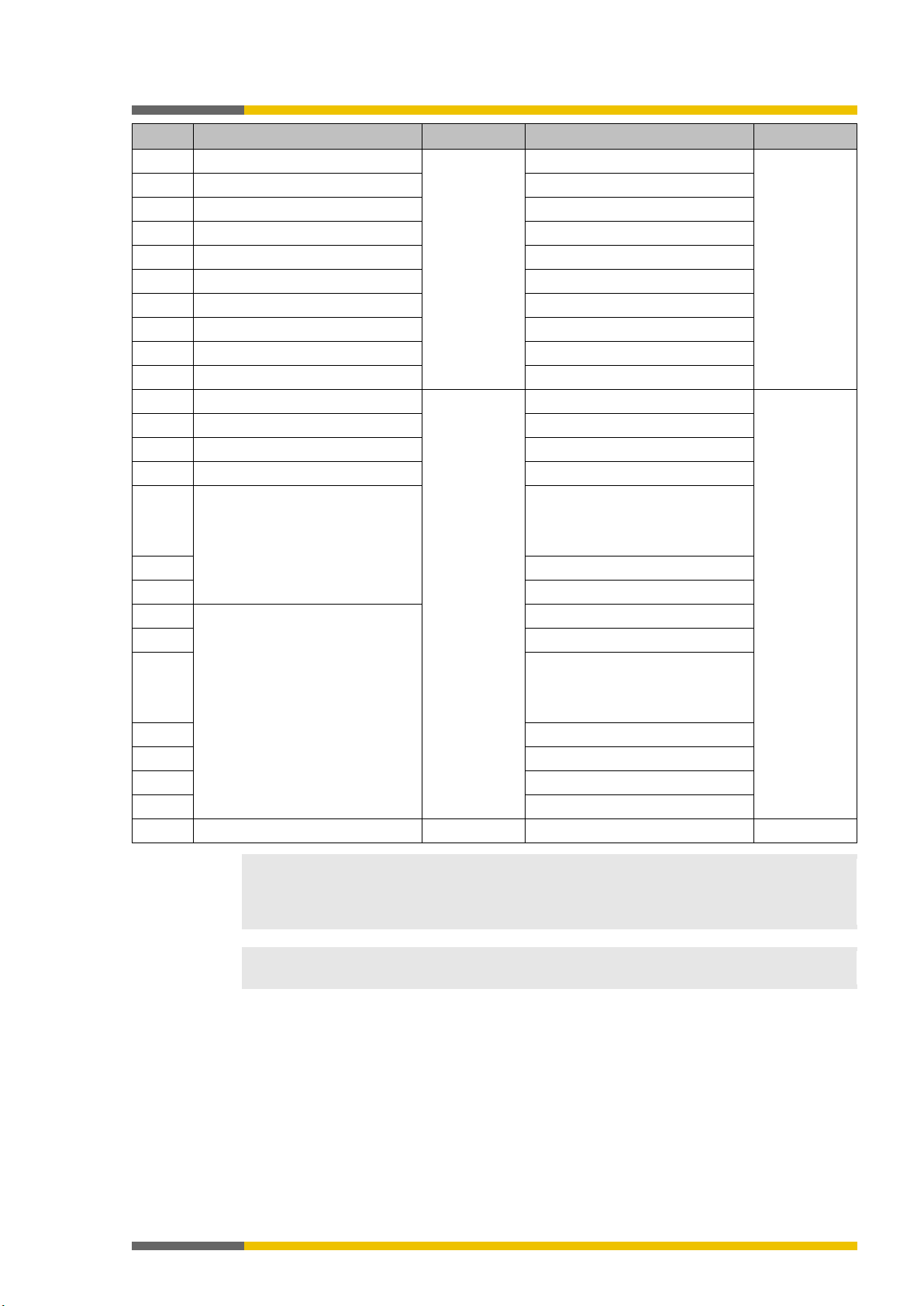

3.3

Data transferred to the network (network input data sets)

910743435

Available data

The samosPRO gateways can provide the following data:

• Operating data

–

37]

)

–

–

Module state / input and output values [ch. 3.3.1, p. 22]

–

samosPRO system (see

• Diagnostics

–

–

23]

Data sets

The physical modules are not presented as typical hardware modules in the network. Instead,

the data provided by the samosPRO system has been arranged in four

•

samosPLAN5+. In the form in which it is delivered, the content of data set 1 is preconfigured; it can be freely modified.

Details: see table

For the SP-PROFIBUS-DP gateway, data set 1 was divided into five input data blocks, with

data blocks 1–4 each containing 12 bytes and data block 5 two bytes.

For the SP-CANopen gateway, data set 1 was divided into four blocks, each with 8 bytes.

You will find more detailed information in the corresponding section for each gateway.

•

See table "Overview of input data sets 1-3 (basic settings for Modbus TCP)" below

•

four (4) bytes per module, with the controller module comprising 3 x 4 bytes. Details: see

table

"Meaning of module state bits" [ch. 3.3.5, p. 23]

•

(CRCs): (see

(max. 50 bytes) contains the operating data. It can be compiled with the aid of

(32 bytes) contains the test values (CRCs) for the system configuration.

(60 bytes) contains the state and diagnostic data for the various modules, with

(60 bytes) is currently filled with reserved values.

the samosPRO safety controller (see

(HIGH/LOW) for all samosPRO input expansion modules in the system

(HIGH/LOW) for all samosPRO input/output expansion modules (see

from another network, i.e. data received from a second gateway in the

Routing table [ch. 5.1.2, p.

)

Transmission of data from a second network [ch. 3.3.3, p. 23]

Configuration test values (CRCs) [ch. 3.3.4, p. 23]

:

Error and state information for the modules [ch. 3.3.5, p.

"Overview of input data sets" [ch. 3.3, p. 20]

input data sets

)

.

)

Page 20

Product description

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

20

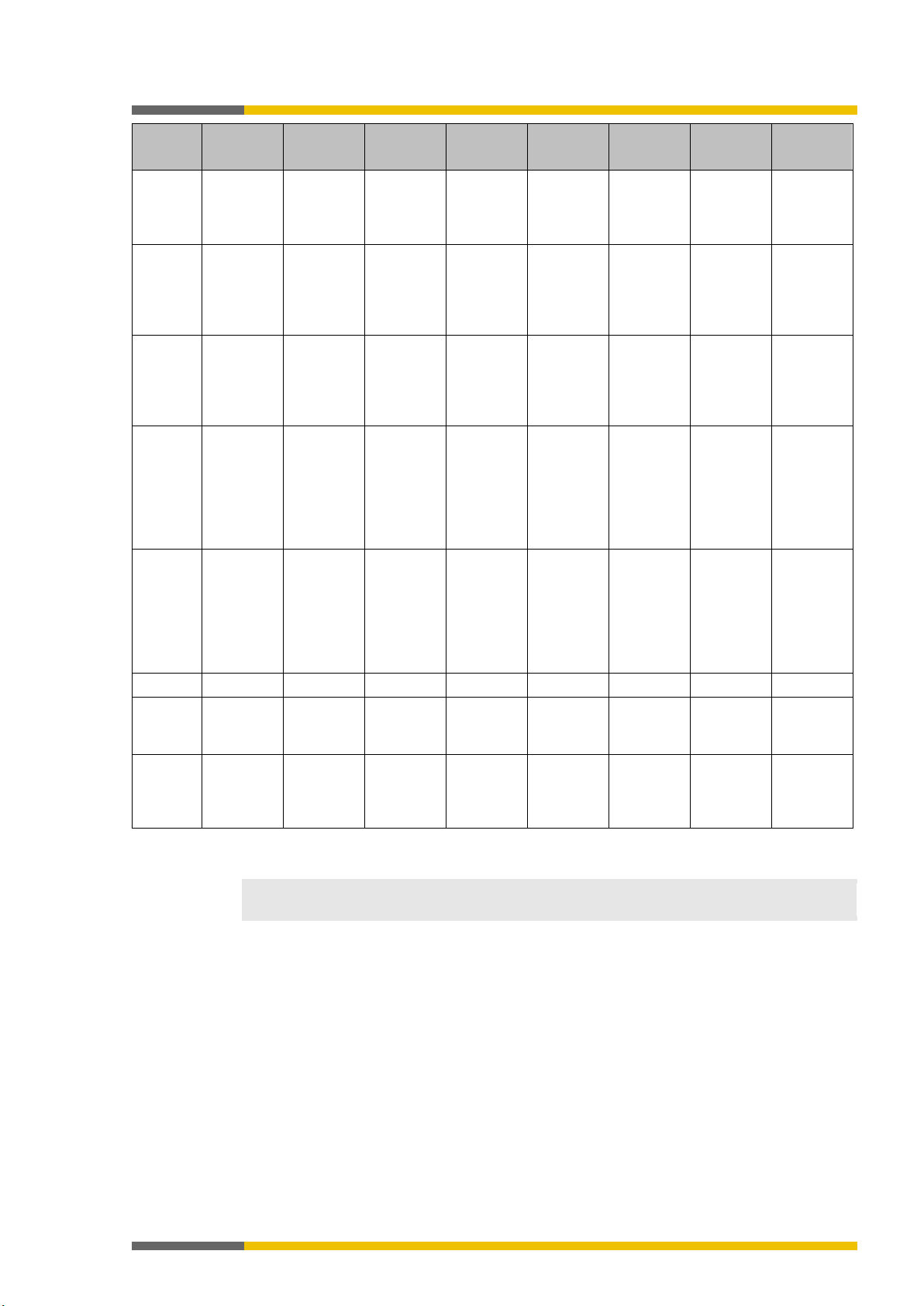

Data set 1

Data set 2

Data set 3

Data set 4

EtherNet/IP

EtherNet/IP

EtherNet/IP

DP

(SDOs)1)

(SDOs)1)

CANopen gateway may be found here:

CANopen gateway [ch. 10, p. 129]

Readable with instance 2 of class 120

Readable with instance 3 of class 120 and byte 52 to 111 of assembly 167

Data set 1

Data set 2

Data set 3

Data set 4

Byte 0

Input values for Module 0 (I1..I8)

Module state SP-COPx

(IQ1..IQ4)

module inputs

(Q1..Q4, IQ1..IQ4)

module inputs

module inputs

module inputs

module inputs

Byte 7

Direct data (Off) 3

Reserved

le outputs

Byte 10

Direct data (Off) 6

Reserved

Byte 12

Input values for Module 1

State of Module 1

Byte 14

Input values for Module 3

State of Module 1

Byte 15

Input values for Module 4

State of Module 1

Byte 16

Input values for Module 5

State of Module 2

Byte 17

Input values for Module 6

State of Module 2

Byte 18

Input values for Module 7

State of Module 2

Byte 19

Input values for Module 8

State of Module 2

Byte 20

Input values for Module 9

State of Module 3

Byte 21

Input values for Module 10

State of Module 3

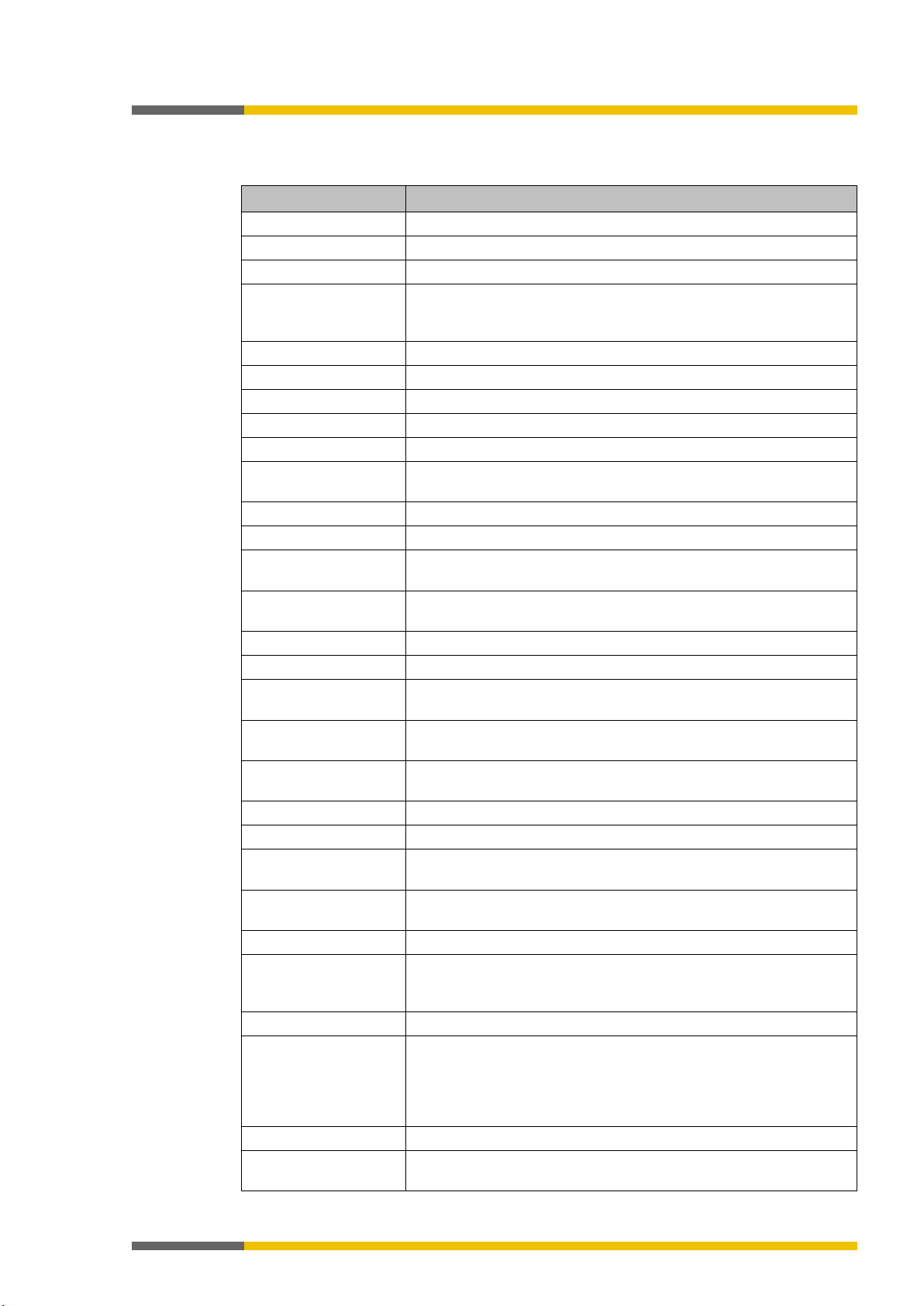

The following table provides an overview of which data sets are provided by which gateway.

Table 6: Availability of data sets 1–4

SP-COP2-ENI Modbus TCP

PROFINET IO

SP-EN-ETC EtherCAT EtherCAT EtherCAT -

SP-PROFIBUS-

PROFIBUS DP – – –

SP-CANopen CANopen CANopen

1)

The SP-CANopen is used to provide diagnostic data via CANopen SDO (service data ob-

jects). More information about how to provide state and diagnostic data with the aid of the

2)

3)

Table 7: Overview of input data sets 1–3 (basic setting for Modbus TCP)

Byte 1 Input values for Module 0 (I9..I16)

Byte 2 Input values for Module 0

Byte 3 Output values for Module 0

Modbus TCP

PROFINET IO

Project CRC

Modbus TCP

PROFINET IO

CANopen

Module state SP-COPx

Test pulse comparison, controller

Test pulse comparison, controller

Modbus TCP

PROFINET IO

–

Reserved

Byte 4 Direct data (Off) 0 System CRC

Test pulse comparison, controller

(PROFIBUS

Byte 5 Direct data (Off) 1 State of two-channel controller

DP and

EtherCAT)

Byte 6 Direct data (Off) 2 State of two-channel controller

Byte 8 Direct data (Off) 4 Reserved Stuck-at error at controller modu-

Byte 9 Direct data (Off) 5 Stuck-at error at controller modu-

le outputs

Byte 11 Direct data (Off) 7 Reserved

Byte 13 Input values for Module 2 State of Module 1

Reserved

Reserved

Reserved

Page 21

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

21

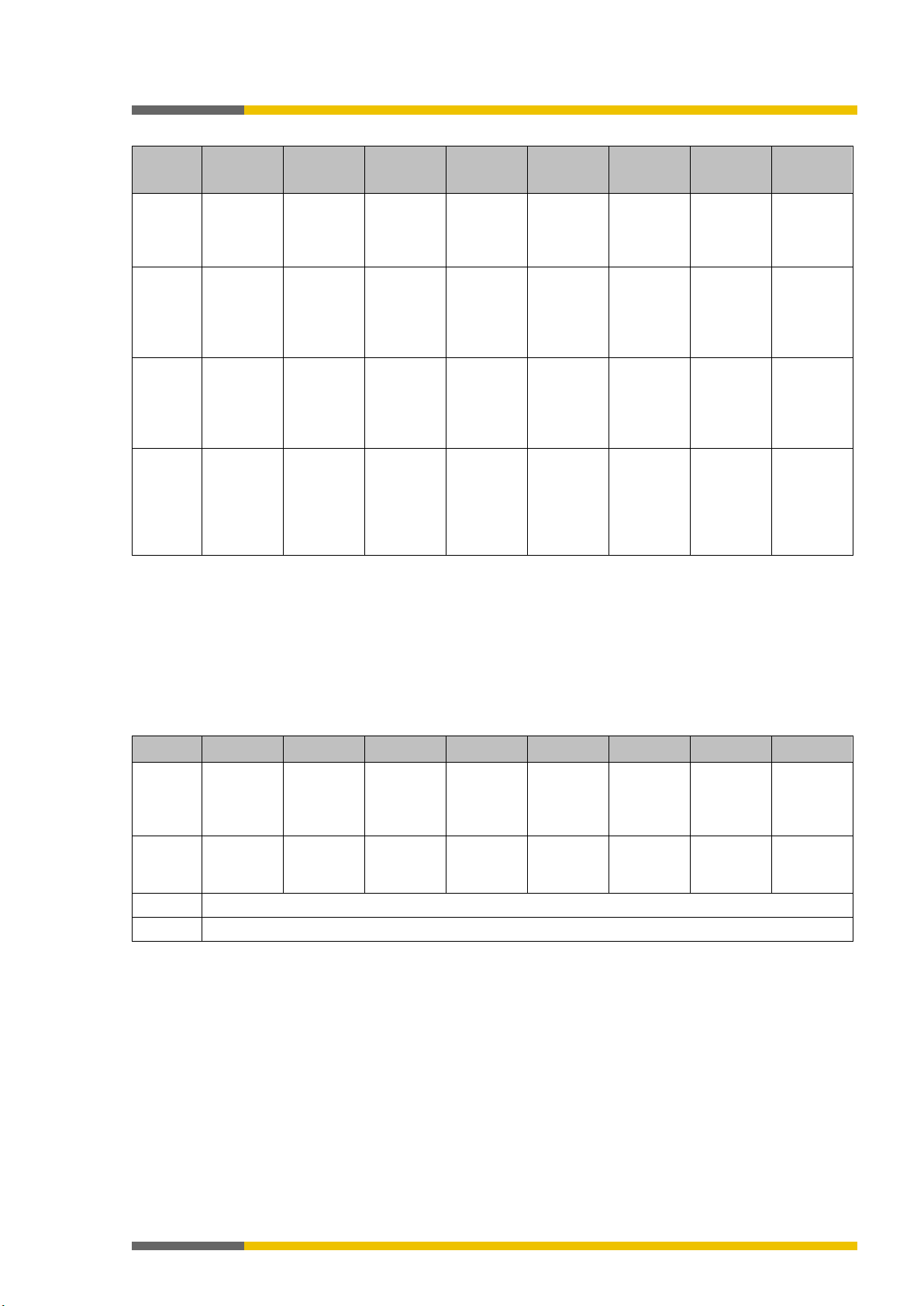

Data set 1

Data set 2

Data set 3

Data set 4

Byte 22

Input values for Module 11

State of Module 3

Byte 23

Input values for Module 12

State of Module 3

Byte 24

Output values for Module 1

State of Module 4

Byte 25

Output values for Module 2

State of Module 4

Byte 26

Output values for Module 3

State of Module 4

Byte 27

Output values for Module 4

State of Module 4

Byte 28

Output values for Module 5

State of Module 5

Byte 29

Output values for Module 6

State of Module 5

Byte 30

Output values for Module 7

State of Module 5

Byte 31 Output values for Module 8 State of Module 5

Byte 32

Output values for Module 9

State of Module 6

Byte 34

Output values for Module 11

State of Module 6

Status of Module 9

Byte 48

State of Module 10

Byte 49

State of Module 10

Byte 50

State of Module 10

Byte 51

State of Module 10

Status of Module 11

Byte 56

State of Module 12

Byte 57

State of Module 12

Byte 58

State of Module 12

Byte 59

State of Module 12

Length

50 bytes

32 bytes

60 bytes

60 bytes

NOTICE

When two-channel input or output elements have been configured for an I/O module, only

put or output state (on/off) for the corresponding element. It is

put/output.

NOTICE

The input values in data set 1 do not represent the physical state at the input terminals, but

the pre-processed input values that are used for logic processing.

Not available

Byte 33 Output values for Module 10 State of Module 6

Byte 35 Output values for Module 12 State of Module 6

Byte 36

…

Not allocated State of Module 7

…

Byte 47

Product description

Reserved

Byte 52

…

Byte 55

Not available

State of Module 11

…

the lowest bit constitutes the in

represented by the tag name of the element. The highest bit represents the state of this in-

Page 22

Product description

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

22

Module state

Size

Meaning

Assignment

Input data state

0 = error 1 = no error

reserved

Output data state

NOTICE

The input and output states of the SP-SDI and SP-SDIO modules is only available from firmware version V2.00.0.

Input values for I/O modules

Output values for I/O modules

3.3.1

3.3.2

Direct gateway output values

910745483

It is possible to write values directly from the logic editor to a gateway. Four bytes have been

reserved for this purpose in the basic settings for data set 1; however, up to the total number

of 50 bytes of data set 1 may be configured as direct gateway output values. You can obtain

additional information at:

Module state / input and output values

910746507

Direct gateway output values [ch. 5.3, p. 44]

The samosPRO gateways can transmit the input and output states of all modules connected to

the samosPRO system to the network. Data set 3 contains a non-modifiable configuration. Moreover, data set 1 can be adapted to contain up to 4 bytes of collective state information. Only

the input and output values for data set 1 have been predefined and these can be freely adapted. You will find more detailed information in the section on the relevant gateway, as well as

in the following section:

Configuration of gateways [ch. 5, p. 35]

Module state

The samosPRO gateways can transfer the state of the linked modules to the network. A total

of 4 bytes are available for this purpose.

Table 8: Module state

.

2 bytes One sum bit per module for the state

of the module inputs

Bit 0 = SP-COPx

Bit 1 = 1.

Extension module

2 bytes One sum bit per module for the state

of the module outputs

0 = error 1 = no error

Bit 2 = 2.

Expansion module …

Bit 13 = 1.

Gateway Bit 14 = 2.

Gateway Bit 15 =

You will find information about the meaning of the state bits at: software manual, Status bits

for controller modules (reference)

Input and output values for the modules

•

1 byte for data set 1 is available for every expansion module. The input values show the

state of the preliminary evaluation of the I/O module. This corresponds to the state of the

element in the controller module logic. The level at the associated terminal cannot be

clearly detected from this, as the data may be set to low, irrespectively of the level at the

input terminal, by means of the cross-connection detection or two-channel evaluation (e.g.

I1-18).

When two-channel input elements have been configured for an I/O module, only the lower-value bit represents the pre-evaluation state of the corresponding element (e.g. bit 0

for I1 and I2, bit 2 for I3 and I4, bit 4 for I5 and I6, bit 6 for I7 and I8). The higher-value bit

(bit 1, 3, 5 and 7) is used as follows in this case:

0 = error 1 = no error

•

1 byte for data set 1 is available for every module with outputs. The output values indicate

the state of the control information from the logic of the controller module for the relevant

element of the I/O module. The level of the associated terminals cannot be clearly detected

from this, as the output may be switched off via the cross-connection detection or the

overload connection function.

When two-channel output elements have been configured for an I/O module, only the lo-

Page 23

Product description

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

23

NOTICE

You can find an explanation of the technical terms used below here:

Abbreviations and Defi-

nitions [ch. 1.5, p. 11]

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Byte 0

shut-off

state

state

Byte 1

current

current

current

current

3.3.3

3.3.4

3.3.5

wer-value bit represents the control information (e.g. bit 0 for Q1 and Q2, bit 2 for Q3 and

Q4, bit 4 for Q5 and Q6, bit 6 for Q7 and Q8). The higher-value bit (bit 1, 3, 5 and 7) is not

used as follows in this case (low):

Transmission of data from a second network

910747531

If your samosPRO system contains two gateways, it is possible to forward information which

the first gateway receives from a network (e.g. from a Modbus PLC) via the second gateway to

a second network (e.g. to a PROFIBUS master) and vice versa.

Configuration test values (CRCs)

910749067

Data set 2 contains the following configuration check values of the samosPRO system:

• Project CRC of the project file created with samosPLAN5+

• System-CRC, uniquely assigned to a module version, consisting of internal software and

hardware version

The CRCs are each 4 bytes in length. Data set 2 can be read only.

The project CRC with Modbus/TCP is transmitted in Big Endian format.

The system CRC is available from module version B-01.01 for PROFIBUS DP and EtherCAT.

Error and state information for the modules

910750603

Data set 3 and 4 contain the state information for the modules that will be transferred to the

network.

Ten bytes are transmitted for SP-COPx controller module. For each SP-SDI and SP-SDIO I/O

module, four bytes are transmitted in the Little Endian format, e.g. as a 32-bit word, with the

first byte being placed into the least significant byte of the whole number (extreme left) and

the fourth byte into the most significant byte of the whole number (extreme right).

Data sets 3 and 4 cannot be adapted.

Module state bits of the controller module SP-COPx

The module state bits have the following meaning, if not otherwise indicated:

0 = error

1 = no error

Reserved bits have the value 1

B2 state Collective

Module

Table 9: Meaning of module state bits of controller module SP-COPx (only for Modbus)

state output data

error fast

Module

state of

input data

B1 state Configura

tion state

Reserved Reserved IQ3+IQ4

A1 state External

module

IQ1+IQ2

power

requirement

0: Excess

current

1: no

excess

power

require-

ment

0: Excess

current

1: no

excess

Internal

module

Q3+Q4

power

requirement

0: Excess

current

1: no

excess

Reserved

Q1+Q2

power

requirement

0: Excess

current

1: no

excess

Page 24

Product description

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

24

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Byte 2

son

son

son

son

son

son

son

son

Byte 3

son

son

son

son

son

son

son

Byte 4

son

son

son

son

Byte 5

not used

not used

not used

not used

not used

not used

not used

not used

Byte 6

not used

not used

Byte 7

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Byte 8

low

high

low

high

low

high

low

high

Byte 9

low

high

low

high

low

high

low

high

NOTICE

The module state bits for the SP-SDI and SP-SDIO modules are only fully supported from

firmware version 1.2.x.

I8 vs. T2/4

test pulse

compari-

I16 vs.

T2/4 test

pulse

compari-

Reserved Reserved Reserved Reserved IQ4 vs.

I15/I16

twochannel

state

0: Error

1: ok or

I7 vs. T1/3

test pulse

compari-

I15 vs.

T1/3 test

pulse

compari-

I13/I14

twochannel

state

0: Error

1: ok or

I6 vs. T2/4

test pulse

compari-

I14 vs.

T2/4 test

pulse

compari-

I11/I12

twochannel

state

0: Error

1: ok or

I5 vs. T1/3

test pulse

compari-

I13 vs.

T1/3 test

pulse

compari-

I9/I10

twochannel

state

0: Error

1: ok or

I4 vs. T2/4

test pulse

compari-

I12 vs.

T2/4 test

pulse

compari-

T2/4 test

pulse

compari-

I7/I8

twochannel

state

0: Error

1: ok or

I3 vs. T1/3

test pulse

compari-

I11 vs.

T1/3 test

pulse

compari-

IQ3 vs.

T1/3 test

pulse

compari-

I5/I6

two-

channel

state

0: Error

1: ok or

I2 vs. T2/4

test pulse

compari-

I10 vs.

T2/4 test

pulse

compari-

IQ2 vs.

T2/4 test

pulse

compari-

I3/I4

twochannel

state

0: Error

1: ok or

Reserved Reserved Reserved Reserved Reserved Reserved IQ3/IQ4

twochannel

state

0: Error

1: ok or

I1 vs. T1/3

test pulse

compari-

I9 vs. T1/3

test pulse

comparison

IQ1 vs.

T1/3 test

pulse

compari-

I1/I2

twochannel

state

0: Error

1: ok or

IQ1/IQ2

twochannel

state

0: Error

1: ok or

Q4

Stuck at

IQ4 (Out-

put)

Stuck at

Q4

Stuck at

IQ4 (Output)

Stuck at

Q3

Stuck at

IQ3 (Output)

Stuck at

Q3

Stuck at

IQ3 (Output)

Stuck at

Q2

Stuck at

IQ2 (Output)

Stuck at

Q2

Stuck at

IQ2 (Out-

put)

Stuck at

Q1

Stuck at

IQ1 (Output)

Stuck at

Q1

Stuck at

IQ1 (Output)

Stuck at

Module state bits of the I/O modules SP-SDI and SP-SDIO

The module state bits have the following meaning, if not otherwise indicated:

0 = error

1 = no error

Page 25

Product description

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

25

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Byte 0

valid.

Byte 1

I7–I8

I5–I6

I3–I4

I1–I2

Byte 2

X2

X1

X2

X1

X2

X1

X2

X1

Byte 3

stuck-at

stuck-at

stuck-at

stuck-at

stuck-at

stuck-at

stuck-at

stuck-at

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Byte 0

IY5-IY8

Byte 1

put data

data

Byte 2

Reserved

Byte 3

Reserved

Reserved Collective

Module

Test im-

Q4 Stuck-

Table 10: Meaning of the module state bits of the safe I/O modules SP-SDI and SP-SDIO

state of

output

data

pulse

comparison I8 vs.

at low

0: Stuck-at

error

1: no

error fast

shut-off

Module

state of

input data

Test impulse

comparison I7 vs.

Q4 Stuckat high

0: Stuck-at

error

1: no

Power

supply for

Q1 .. Q4

Reserved Reserved Two-

Test impulse

comparison I6 vs.

Q3 Stuckat low

0: Stuck-at

error

1: no

Configuration of this

module is

Test impulse

comparison I5 vs.

Q3 Stuckat high

0: Stuck-at

error

1: no

Not used

(error history flag)

channel

evaluation

of input

Test impulse

comparison I4 vs.

Q2 Stuckat low

0: Stuck-at

error

1: no

External

module

state

Two-

channel

evaluation

of input

Test im-

pulse

compari-

son I3 vs.

Q2 Stuck-

at high

0: Stuck-at

error

1: no

Internal

module

state

Twochannel

evaluation

of input

Test impulse

comparison I2 vs.

Q1 Stuckat low

0: Stuck-at

error

1: no

Not used

("executing state")

Twochannel

evaluation

of input

Test impulse

comparison I1 vs.

Q1 Stuckat high

0: Stuck-at

error

1: no

Module state bits of the SP-DIO I/O module

The module state bits have the following meaning if not otherwise indicated; normally only the

first byte of the total state is transmitted:

0 = error

1 = no error or reserved

Reserved Reserved Power

Module

Table 11: Meaning of the module state bits of the SP-DIO expansion module

state out-

Module

state input

Configura-

supply Y1-

tion state

Y4 and

Reserved Reserved Reserved Reserved Reserved Reserved

Not used

(error history flag)

External

module

state

Internal

module

state

Not used

("executing state")

Page 26

Product description

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

26

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Byte 0

data

flag)

Byte 1

Reserved

Byte 2

Reserved

Byte 3

Reserved

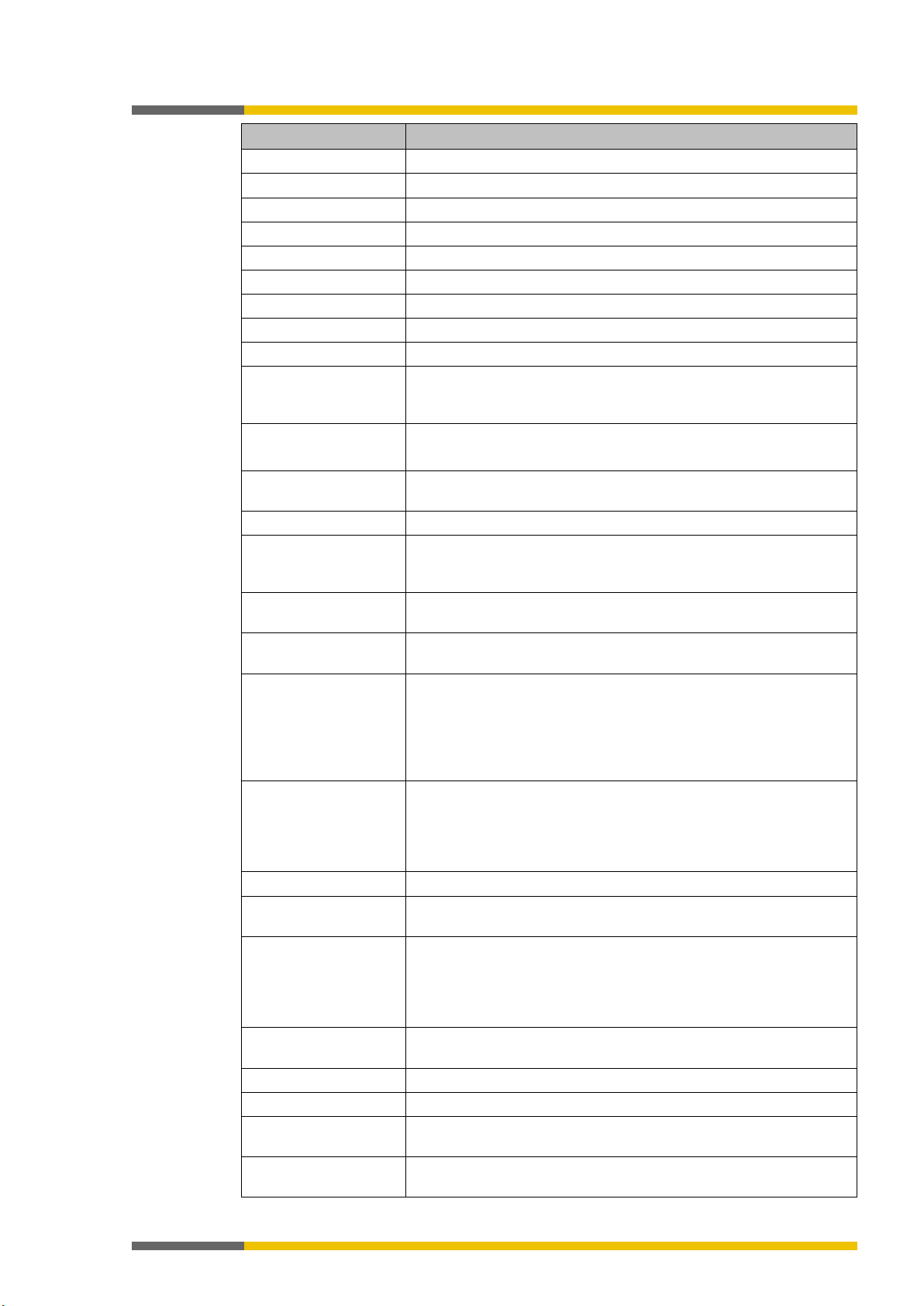

Byte address

00

01

02 … 03

11

04

12

05

13

06

14

07

15

08

16

09

17

10

18

11

19

…

Byte

0

… 0 11

Value

EF

FB

FB

EF

Meaning

SDIO)

State of module 2 (

SDIO)

Bit # 7 6 5 4 3 2 1 0

Value 1 1 1 1 1 0 1 1

Bit # 7 6 5 4 3 2 1 0

Value 1 1 1 0 1 1 1 1

NOTICE

• Reserved (for future use) = static 1 (no state change)

• If there is no module, all values - including the reserved values - are set to logical 1.

Module state bit of the gateways

The module state bits have the following meaning if not otherwise indicated; normally only the

first byte of the total state is transmitted:

0 = error

1 = no error

Table 12: Meaning of gateway module state bits

Reserved Module

state

output

Module

state

input data

Configuration state

Not used

(error

history

Reserved Internal

module

state

Not used

("executing state")

Example

Module 2 (SP-SDIO) has a short-circuit after high (24 V) at output 3. The following module state is transmitted to the network (only the first 20 of 60 bytes are shown):

3

FF FF FF FF FF FF FF FF

CPU state State of module 1 (SP-

2 1 1

3 0 2 1 1 2 0 3 3 0 2 1 1 2 0 3 …

FF FF

SP-

…

…

The first relevant byte for the module 2 error described above is module state byte 0 for module 2. This is byte 11 with the hexadecimal value FB (1111 1011):

This corresponds to the error message "Summary of bits 0.5 ibs 0.7 (external error)", byte 0, bit

2 in the following table:

25]

"Meaning of module state bits of the secure I/O modules" [ch. 3.3.5, p.

The second relevant byte is the module state byte 3 for module 2. This is byte 08 with the hexadecimal value EF (1110 1111):

This corresponds to the error message "Short circuit monitoring of output 3, short circuit after

high", byte 3, bit 4 in the following table:

dules" [ch. 3.3.5, p. 25]

"Meaning of module state bits of the secure I/O mo-

• Not used (can be 0 or 1 ), both values occur.

Page 27

Product description

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

27

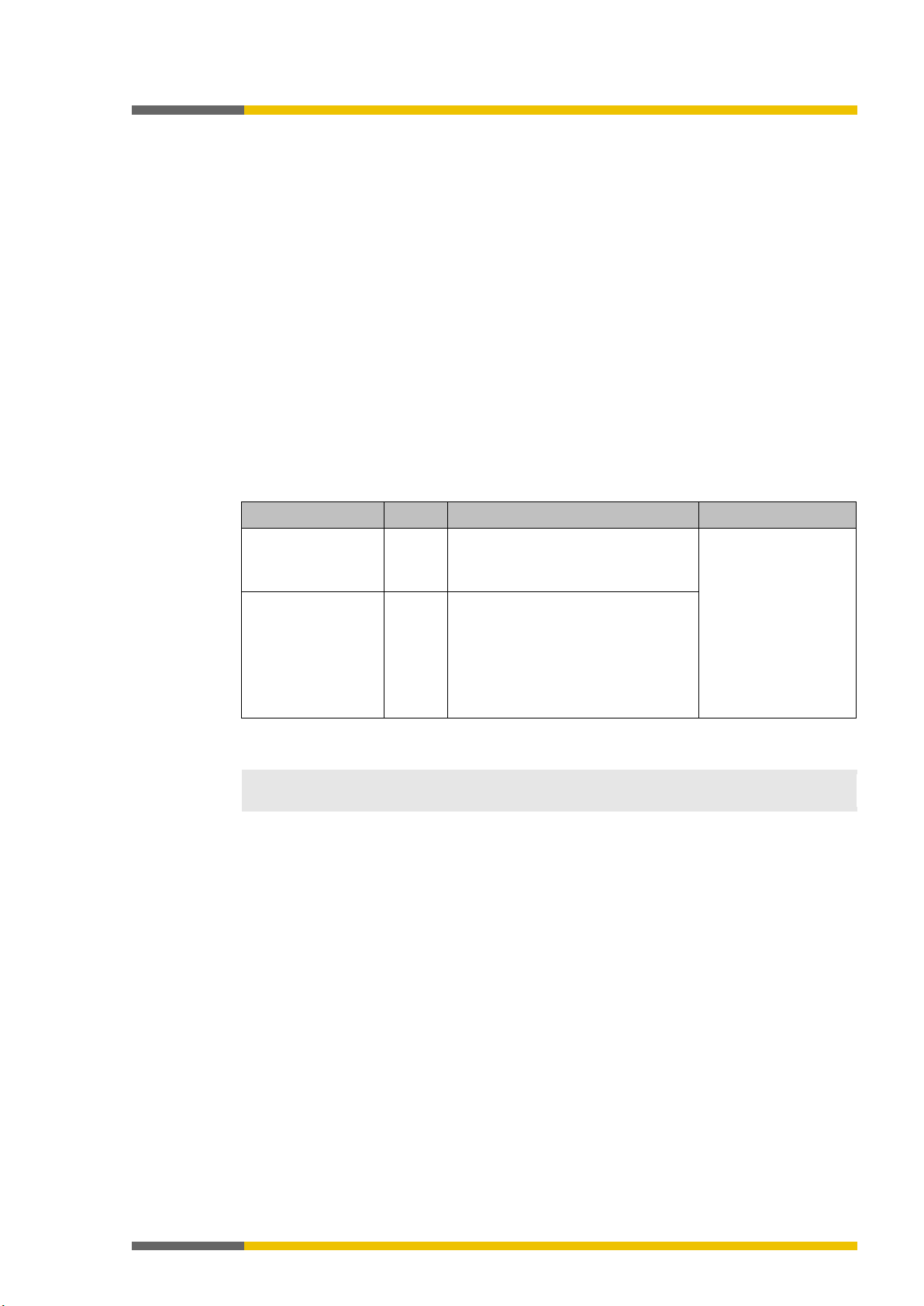

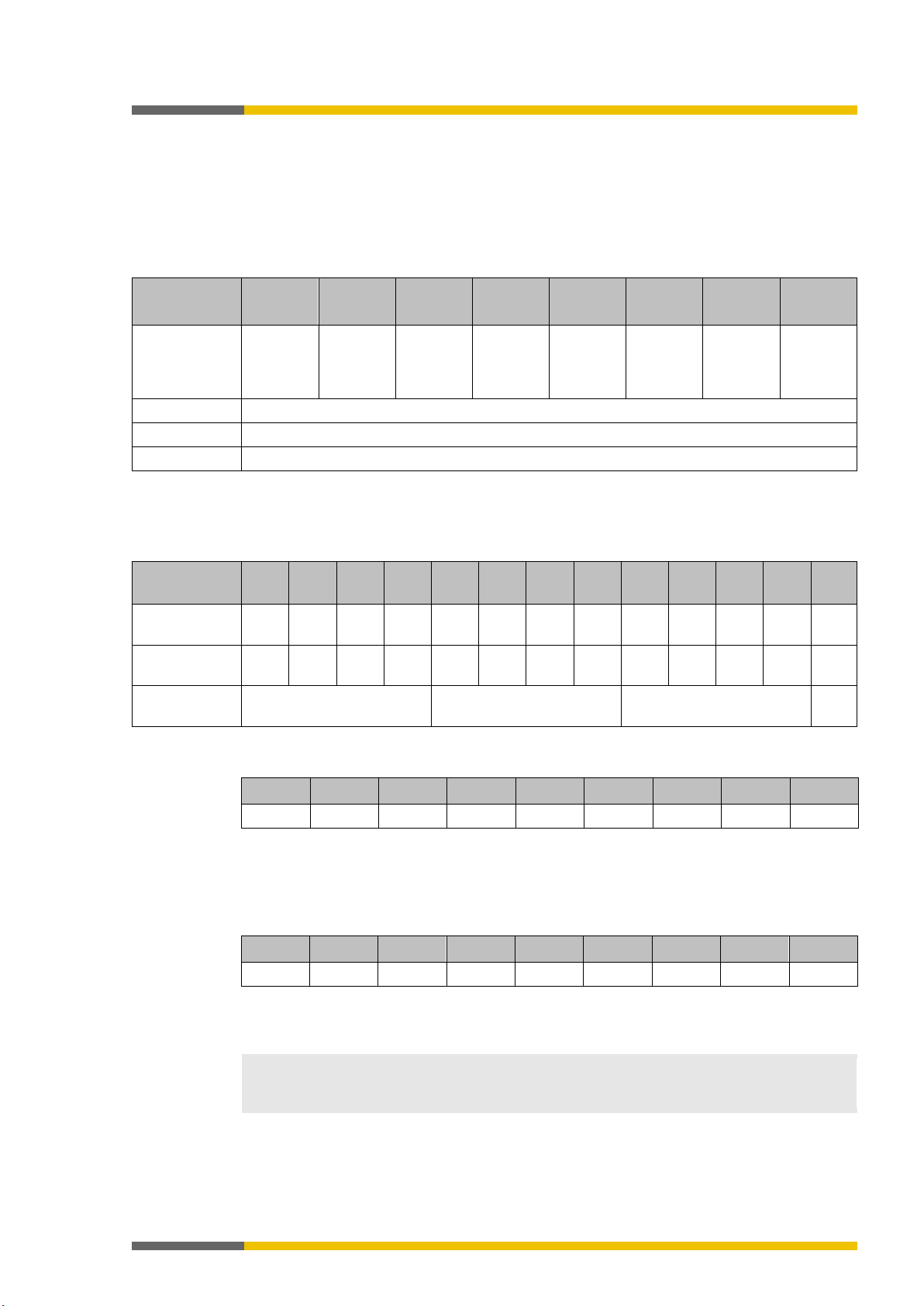

Size of output data block

Gateway

Block 1

Block 2

Block 3

Block 4

Block 5

PROFINET IO

SP-CANopen

8 bytes

8 bytes

8 bytes

8 bytes

–

EtherNet/IP

NOTICE

• In order to use network data in the logic editor or as input for another network, you must

Bits without specific tag names will not be available in the logic editor or for routing via a

You can monitor current communication with the network with the aid of input data state

hen a connection is closed while others remain available, the LED MS or LED state will

flash red/green for a total of 10 seconds and an entry will be made in the error log. In this

case the state bits are not affected.

Do not use the same output data block number for two different PLC connections or

TCP/IP sockets!

te the data received earlier.

3.4

Data received from the network (network output data sets)

910751627

The data from data set 1 (max. 50 bytes) received from the network may be differently arranged, depending on the protocol. For the Modbus TCP, this data set was divided into five data

blocks, each with 10 bytes. In the SP-PROFIBUS-DP gateway, output data blocks 1-4 each

contain 12 bytes, while output data block 5 contains 2 bytes. CANopen only defines 4 data

blocks, each with 8 bytes.

Table 13: Output data block 1–5 of the various gateways

SP-PROFIBUS-DP /

SP-EN-ETC /

12 bytes 12 bytes 12 bytes 12 bytes 2 bytes

10 bytes 10 bytes 10 bytes 10 bytes 10 bytes

Modbus TCP /

The content of the output data blocks can be used in the logic editor, as well as made available

for another network via a second gateway within the samosPRO system.

assign a tag name for each bit to be used.

•

second gateway. Detailed information about how to assign tag names for the data received may be found in the corresponding sections of the chapters on the various gateways.

•

bits for receiving data from the network and the output data state bit for transmitting data to the network in the logic editor. When the gateway detects a communication error,

both the content of the data sets and the associated state bit are set to zero (logical 0).

• When all communication fails, the data of the output data sets and the input data state

bit are set to zero (logical 0).

• W

The output data block of the Ethernet gateways can be described in parallel via all communication interfaces or TCP/IP sockets (e.g. Modbus TCP/IP and Ethernet TCP/IP) if they make

ATTENTION

use of the same output data block number. In this case the last message will always overwri-

Page 28

Installation and basic configuration

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

28

ATTENTION

This is only for switchboxes with protection class IP 54 or higher!

4

4.1

4.1.1

Installation and basic configuration

910753163

Installing/removing

910754699

Installing modules on standard rail

888512651

The samosPRO system is only suitable for installations in a switchbox having at least protection class IP 54.

Info

• Basic safety

Gateways must not be removed or added when the operating voltage is switched on.

• Grounding

The DIN rails must be conductively connected to the protective conductor (PE).

• ESD protection measures

Note the suitable ESD protection measures during installation.

Failure to do so could result in damage to the bus (internal safety bus).

• Protect connector openings

Undertake suitable measures so that no foreign bodies can penetrate connector openings,

particularly those for the program removable storage.

• Module width:

The modules are placed in a mounting box that is 22.5 mm or 45 mm wide depending on

type.

• Quality of standard rail

The mounting boxes are suitable for 35-mm standard rails as per EN 60715.

• Sequence of modules:

The SP-COPx controller module is inserted all the way to the left in a samosPRO system.

The two optional gateways follow directly to the right next to the controller module.

• Save space for subsequent model replacement

The modules are connected via the plug connection integrated into the housing. Note that

the samosPRO modules must be pulled about 10 mm apart for a module replacement before the corresponding module can be removed from the standard rail.

• Standards to be considered

Installation according to EN 50274

Page 29

Installation and basic configuration

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

29

Important!

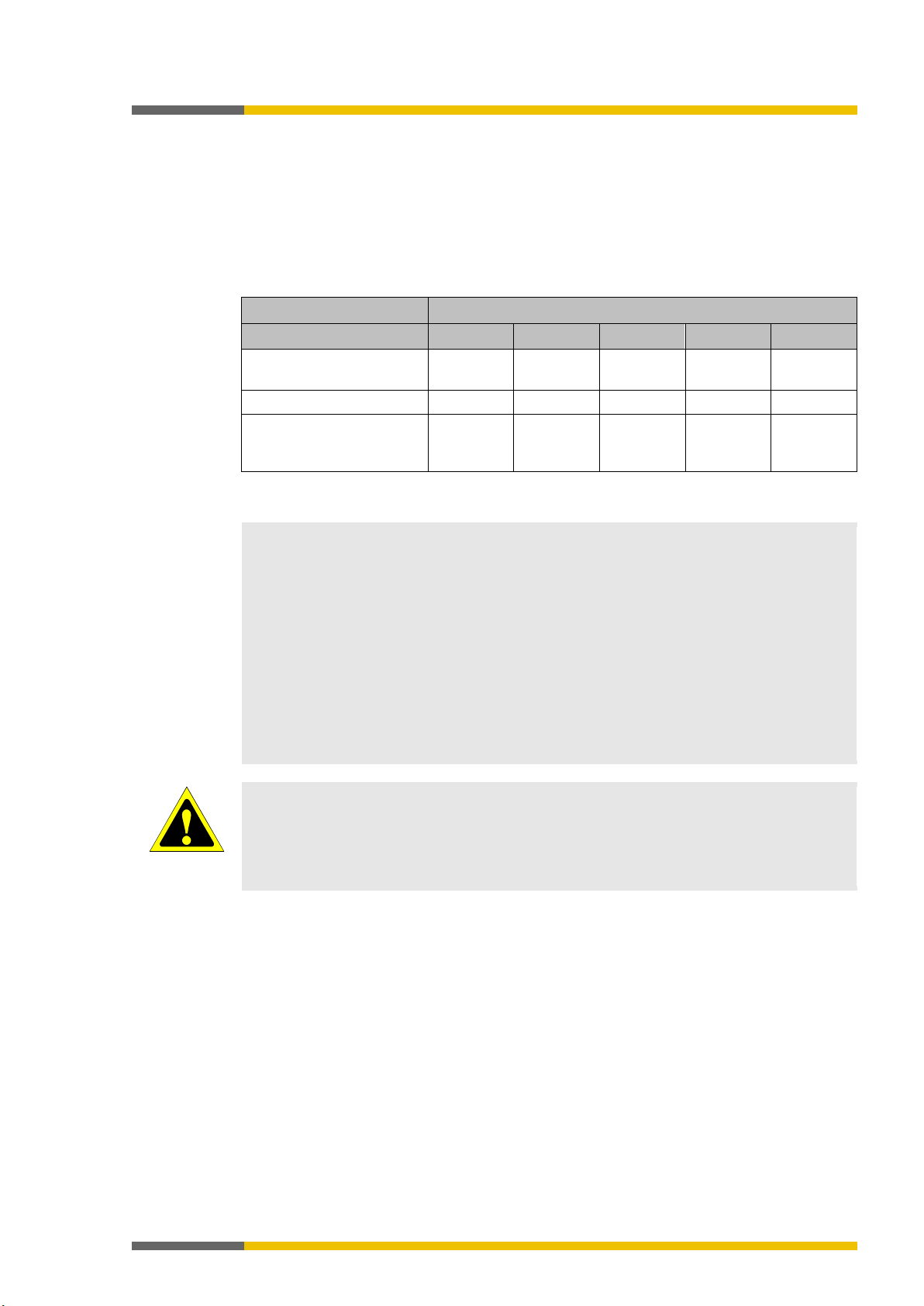

Step 1: Installing a controller module

Using a screwdriver, pull the snap-on foot outward.

Hang the module on the standard rail.

The shielding spring of the module must be placed on the standard rail so that it is secure

and has good electrical conduction.

Make sure that the shielding spring is seated correctly.

Fold the module onto the standard rail.

Using a screwdriver, move the snap-on foot against the standard rail until the snap-on foot

latches into position with an audible click.

Make sure that the module is securely seated on the standard rail.

Attempt to pull the module from the standard rail using slight pressure. If the module stays

connected to the rail during this test, then the installation is correct.

Page 30

Installation and basic configuration

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

30

Important!

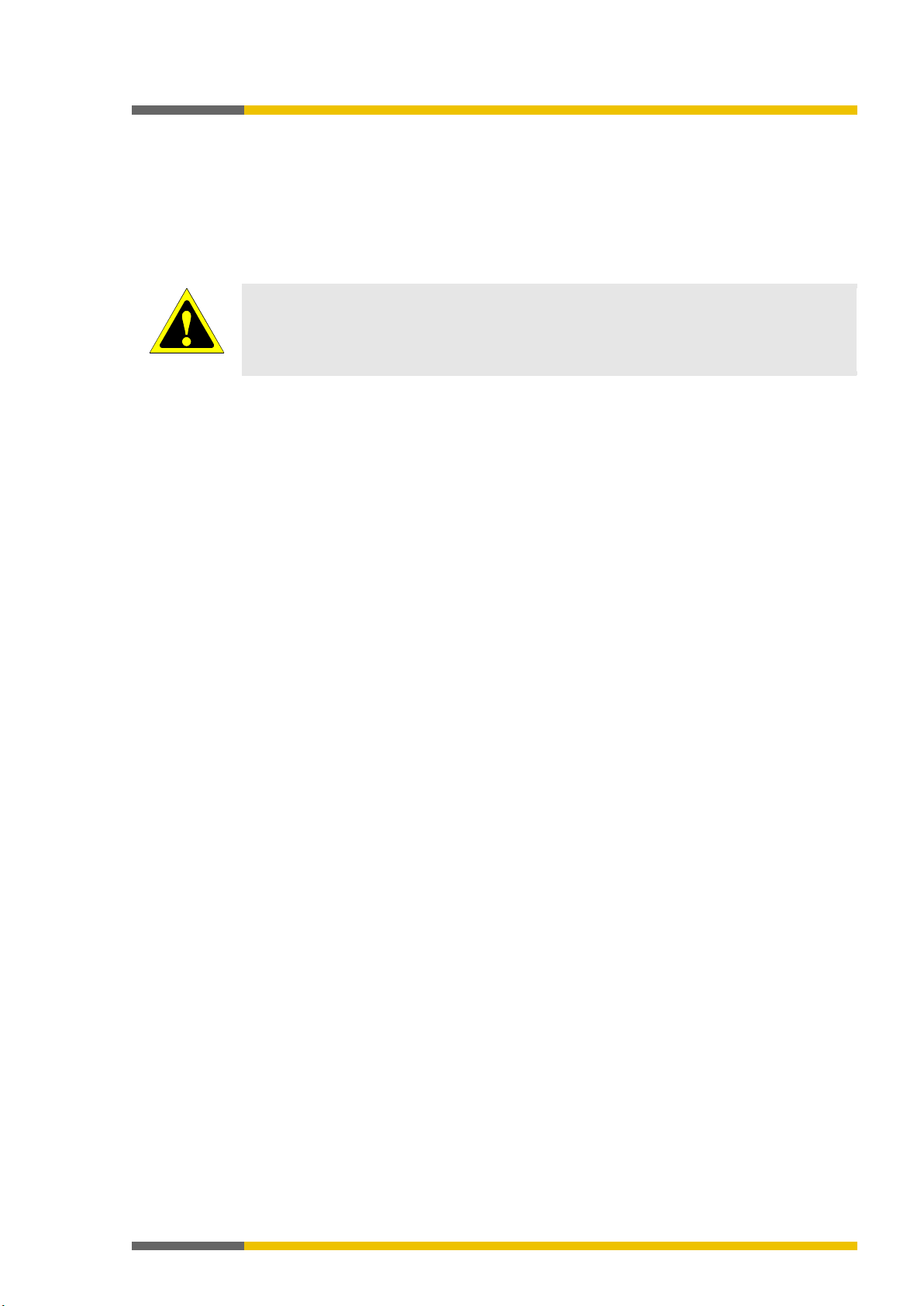

Step 2: Installation of gateways or expansion modules

Hang the module on the standard rail.

The shielding spring of the module must be placed on the standard rail so that it is secure

and has good electrical conduction.

Make sure that the shielding spring is seated correctly.

Using slight pressure, fold the module onto the rail in the direction of the arrow until the

module audibly latches into position.

Make sure that the module is securely seated on the standard rail.

Attempt to pull the module from the standard rail using slight pressure. If the module stays

connected to the rail during this test, then the installation is correct.

If you are installing multiple modules:

Push the modules together individually in the direction of the arrow until the lateral plug

connection between the modules audibly latches into position.

Install an end terminal into the module furthest to the left and another end terminal into

After installation

Once you have installed the modules, the following steps are required:

• Connect the modules electrically.

• Configure modules (see: software manual).

• Check the installation before first commissioning.

the module furthest to the right.

Page 31

Installation and basic configuration

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

31

4.1.2

Removing modules from normal rail

888517003

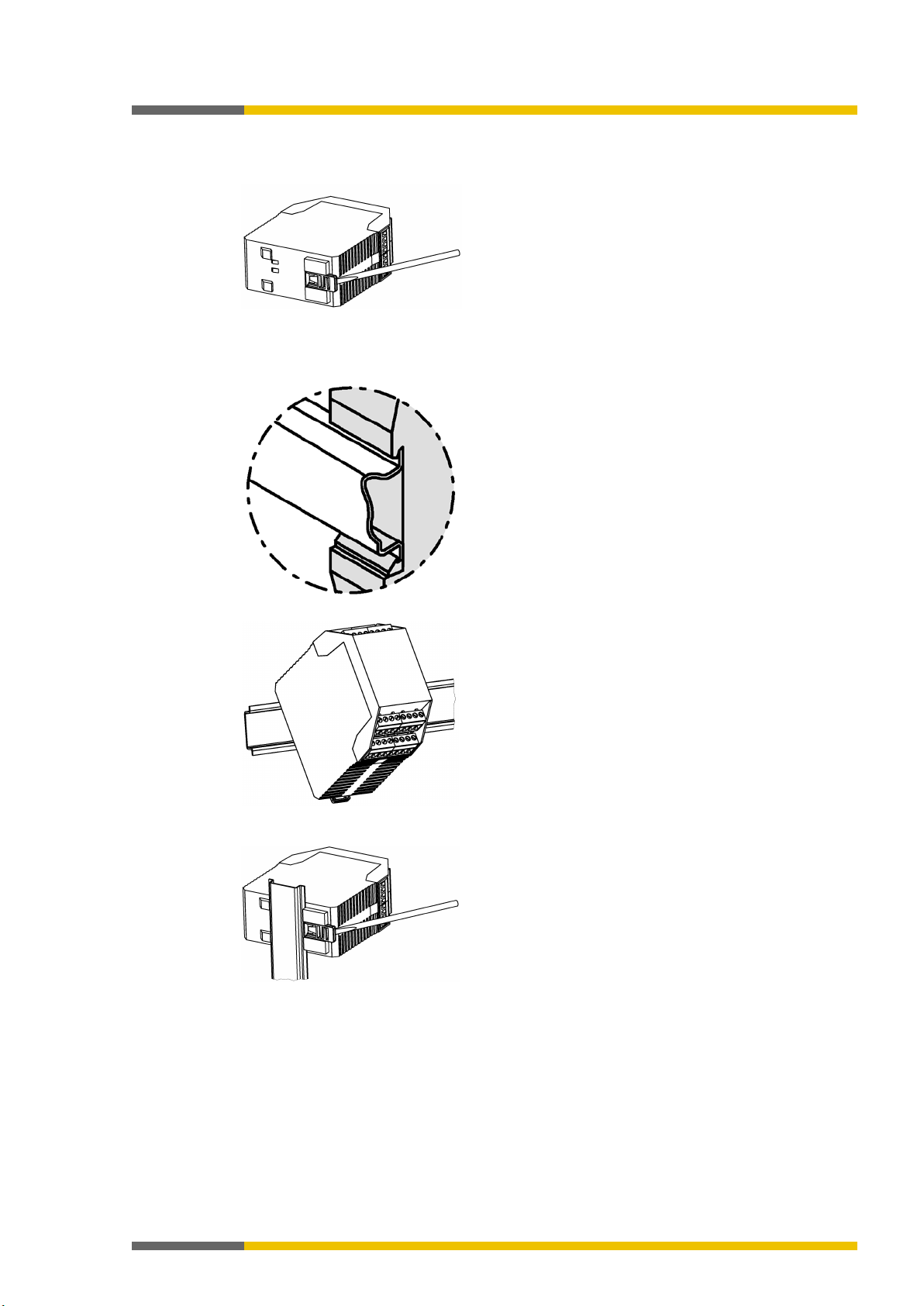

Step 1: Removing a controller module

Deenergize the samosPRO system.

Remove plug-in terminals with wiring and remove the end terminal.

If expansion mode or gateways are used:

Slide the controller module in the direction of the arrow until the lateral plug connection is

disconnected.

Unlock the module.

To do this, pull the snap-on foot of the module outward using a screwdriver.

Page 32

Installation and basic configuration

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

32

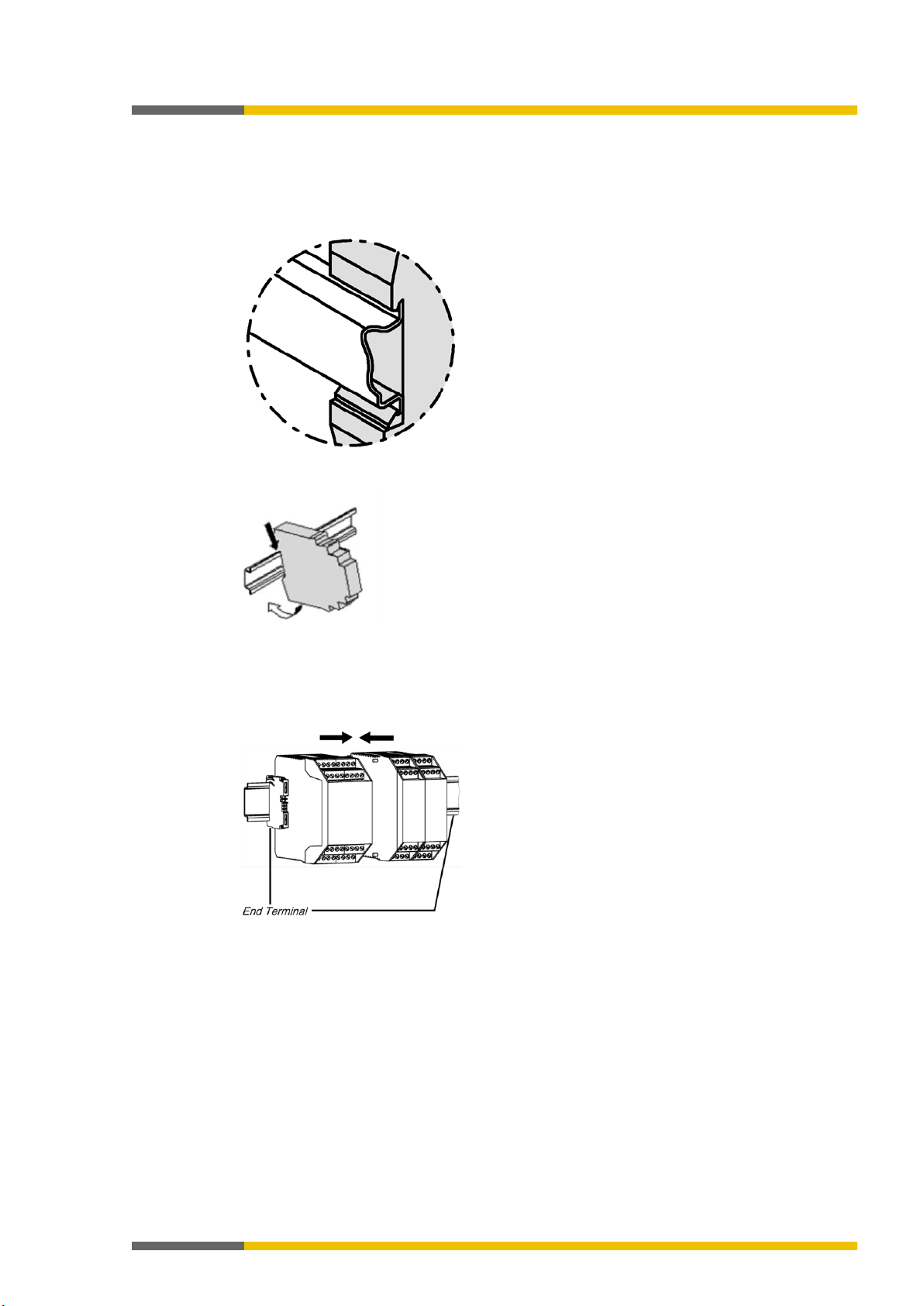

Fold the module away from the standard rail and remove it from the rail.

Step 2: Removing gateways and expansion modules

Deenergize the samosPRO system.

Remove plug-in terminals with wiring and remove the end terminals.

Pull the modules apart from one another individually in the direction of the arrow until the

lateral plug connection is disconnected.

Press on the module from above and fold the module away from the standard rail while it

is in the pressed-down state.

Page 33

Installation and basic configuration

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

33

ATTENTION

Switch off the power supply to the system!

NOTICE

• samosPRO gateways meet EMC conditions as set out in the EN 61000-6-2 specification

4.2

Electrical installation

910756235

It is possible for the system to be unexpectedly started while you are connecting the devices.

for use in an industrial environment.

• In order to ensure complete EMC safety, the standard rail must be connected to functional earth (FE).

• The switch box or installation housing for the samosPRO system must meet at least the

requirements of protection class IP 54.

• Installation according to EN 50274.

• Electrical installation as per EN 60204-1.

• The external power supply of the devices must be able to bridge a short-term power outage of 20 ms in accordance with EN 60204-1.

• The power supply must meet the regulations for low-voltage with safe disconnection

(SELV, PELV) in accordance with EN 60664 and EN 50178 (equipping high-voltage systems with electronic equipment).

• Ensure that all modules of the samosPRO system, the connected protective devices and

the power supplies are connected to the same ground connection. The ground of the

RS-232 interface is internally connected to the ground of the power supply for the controller module (A2).

• Connect the shielding of all field bus and Ethernet cables to functional earth (FE) just before they lead into the switch box.

Page 34

Installation and basic configuration

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

34

Step

Description

Establishing a link between the gateway and PC

Software manual, chapter "Connect with the safety control"

Configure gateway

•

EtherCAT Gateway [ch. 11, p. 166]

Transmitting and verifying the configuration

Software manual, chapter "Transferring the system configuration"

4.3

Initial configuration steps

910757771

How do you configure gateways? This chapter provides some brief guidelines.

Table 14: Guidelines for gateway configuration

1

See here for more detailed information:

2

You will find detailed information in this regard at the following points in the

gateway manual:

•

Modbus TCP gateway [ch. 6, p. 49]

PROFINET IO-Gateway [ch. 7, p. 62]

•

EtherNet/IP gateway [ch. 8, p. 76]

•

PROFIBUS DP gateway [ch. 9, p. 114]

•

CANopen gateway [ch. 10, p. 129]

•

3

See here for more detailed information:

Page 35

Configuration of gateways

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

35

Gateways

NOTICE

You will find more detailed information about the graphic user interface in the software manual.

Gateway

Hardware

Scenario 1: You are using a gateway module

Hardware

5

5.1

5.1.1

Configuration of gateways

918186507

The

gateways.

This section explains

• how the graphic user interface for the gateway configuration in samosPLAN5+ is laid out,

• how you can carry out typical configuration tasks connected to gateways in samosPLAN5+.

The graphic user interface (‘Gateway’ view)

918201995

When the "Gateway" view is active

918189195

There are two ways of making use of the gateway function in samosPLAN5+. The

view is only active, if you make use of one of these options in the

An SP-CAN module in the

view in the samosPLAN5+ software has been provided for the configuration of

view.

view has been selected in this example:

Illustration 1: Hardware configuration with gateway module

Page 36

Configuration of gateways

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

36

Scenario 2: You are using the gateway function on the module

SP-COP2-ENI

The gateway function on the SP-COP2-ENI module can be adjusted in the right side bar, in the

module configuration dialog (the module must first have been selected in the work area):

Illustration 2: SP-COP2-ENI module with activated gateway function

Page 37

Configuration of gateways

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

37

Gateway

When you are using several gateways

Select data set

view

When the program window is very small

5.1.2

Work area

918246795

Depending on the hardware configuration, you can see two or three tabs in the work area of

the

view. You can configure the gateways in these tabs.

Illustration 3: Gateway configuration with three tabs

Display notes

•

The work area only ever shows a single gateway configuration. If you are using several gateways, you can toggle between the configurations by making use of the

menu:

•

If the window in which you have opened samosPLAN5+ is very small, not all tabs may be

shown.

In this case an arrow symbol will appear, allowing you to toggle between the tabs:

Tab 1: Routing table with output values (data bytes)

Transmission direction: samosPRO COMPACT -> Network/field bus

Illustration 4: Routing table with output values

Page 38

Configuration of gateways

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

38

NOTICE

Allocation of input and output data

Output data

(to the PLC)

data set 1

output data block 1

Input data

(to the PLC)

Data set 1

data set 5

input data block 1

input data block 5

2.

Tab 2: Routing table with input values (data bytes)

Transmission direction: Network/field bus -> samosPLAN5+

When you are working with several gateways: This shows the mapping (the bits used are highlighted in blue), while the input data for the various gateways are shown in online mode (byte

display 0x00 at the beginning of the relevant line).

Illustration 5: Routing table with input values

Tab 3: "Gateway configuration"

Tab 3 only appears when you have activated the gateway function on the SP-COP2-ENI module.

Illustration 6: "Gateway configuration" tab

The output and input data listed here refer directly to the data blocks in tab 1 and tab 2.

•

•

group

Only

group

to

:

can be configured. This refers directly to

:

refer directly to

to

in tab 1.

in tab

Page 39

Configuration of gateways

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

39

Library

NOTICE

You can make use of the same data byte several times in the routing table.

Overview

5.1.3

Sidebars

918250507

Left sidebar | Library

The

output data in the work area.

tab in the left side bar is only active when you have selected the first tab with the

Illustration 7: Library in the "Gateway" view

Drag hardware data bytes from the library into empty fields in the routing table.

Illustration 8: Use drag&drop to move the data bytes to the routing table.

Left sidebar | Overview

In the

tab of the left sidebar, you can see all of the project components used as a

hierarchical tree structure.

Illustration 9: Overview of the left sidebar

Page 40

Configuration of gateways

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

40

Right sidebar

The right side bar shows the configuration dialog for the data byte you have selected in the

work area. Depending on the data byte, you can configure individual parameters.

You can also allocate tag names here.

Illustration 10: Configuration dialog in the right sidebar

Page 41

Configuration of gateways

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

41

Element

Description

Zoom

This determines the size of the display in the work area.

Data set view selection

way configurations.

Importing/exporting

Gateway

Notes

Caution:

You can use the import/export function to import the tag names

Import button is only available for the routing configuration

in the "network/field bus to gateway" direction.

Undo

This renders the last action undone.

Redo

This makes an action that has been undone redone.

Standard

Also see:

Basic settings for the operating data [ch. 5.2.2, p. 42]

Delete

This deletes the currently selected element.

5.1.4

Commands

918252427

Via the command bar, you have access to the following view-specific functions:

Table 15: Key

When you are using several gateways: Changes between the gate-

Allows for the import/export of the configuration defined in the

view.

:

•

When you import a configuration, all changes made

before that have not been saved will be lost. You cannot undo

this command.

• Available storage formats: *SPG, *XML, *CSV

used for a project into a PLC program or to export them from a

PLC program into samosPLAN5+.

• The

This resets the configuration of the gateways to the basic settings.

Page 42

Configuration of gateways

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

42

Data set

Content

Size

Configurable

1

Operating data

50 bytes

Yes 2 CRCs

32 bytes

No 3 State and diagnosis

60 bytes

No 4 Reserved

60 bytes

No

Modbus TCP

PROFIBUS DP

Byte

Preset allocation

Initial data

set

Preset allocation

Initial data

block

0

Input values for Module 0 (I1..I8)

Input values for Module 0 (I1..I8)

1

Input values for Module 0 (I9..I16)

Input values for Module 0 (I9..I16)

(IQ1..IQ4)

(IQ1..IQ4)

(Q1..Q4,IQ1-IQ4)

(Q1..Q4,IQ1-IQ4)

4

Direct data (Off) 0

Direct data (Off) 0

5

Direct data (Off) 1

Direct data (Off) 1

6

Direct data (Off) 2

Direct data (Off) 2

7

Direct data (Off) 3

Direct data (Off) 3

8

Direct data (Off) 4

Direct data (Off) 4

9

Direct data (Off) 5

Direct data (Off) 5

10

Direct data (Off) 6

Direct data (Off) 6

11

Direct data (Off) 7

Direct data (Off) 7

12

Inputs for Module 1

Continued

Inputs for Module 1

#2

5.2

5.2.1

5.2.2

Function and basic settings

925675019

Routing

910850443