Page 1

samos

®

PRO

samos

®

PRO

COMPACT

Manual

Doc. no. BA000966

Last Update: 07/2016 (Rev. C)

-Hardware

Page 2

Info

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

2

Info

810920587

Copyright

This document is copyright-protected. The rights derived from this copyright are reserved for

Wieland Electric GmbH. Reproduction of this document or parts of this document is only permissible within the limits of the statutory provision of the Copyright Act. Any modification or

abridgment of the document is prohibited without the express written agreement of Wieland

Electric GmbH.

samos is a registered trademark of WIELAND Electric GmbH

Allen-Bradley, CompactBlock Guard I/O, CompactLogix, ControlFLASH, ControlLogix, DH+,

FactoryTalk, FLEX, GuardLogix, Kinetix, Logix5000, MicroLogix, PanelBuilder, PanelView, PhaseManager, PLC-2, PLC-3, PLC-5, POINT I/O, POINT Guard I/O, Rockwell Automation, Rockwell

Software, RSBizWare, RSFieldbus, RSLinx, RSLogix 5000, RSNetWorx, RSView, SLC, SoftLogix, Stratix, Stratix 2000, Stratix 5700, Stratix 6000, Stratix 8000, Stratix 8300, Studio 5000,

Studio 5000 Logix Designer, SynchLink, and Ultra are registered trademarks of Rockwell Automation, Inc.

ControlNet, DeviceNet, and EtherNet/IP are registered trademarks of ODVA, Inc.

TwinCAT is a registered trademark of Beckhoff Automation GmbH.

EtherCAT registered trademark and patented technology, licensed by Beckhoff Automation

GmbH.

Microsoft, Windows 98, Windows NT, Windows 2000, Windows XP, Windows 7, Windows 8,

and .NET Framework are registered trademarks of the Microsoft Corporation.

Any other product or trade names listed in this manual are the trademarks or registered trademarks of the respective owners.

Subject to change.

Subject to technical changes for reasons of continued development.

Page 3

Table of Contents

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

3

1

About this document

7

1.1

Function of this document

7

1.2

Target group

7

1.3

Information depth

8

1.4

Scope of application

8

1.5

Abbreviations used

8

1.6

Symbols/icons and writing style/spelling standard used

9

2

Safety

10

2.1

Qualified persons

10

2.2

Areas of application of the device

10

2.3

Proper use

11

2.4

General safety information and protective measures

12

2.5

Environmentally friendly behavior

13

2.5.1

Disposal

13

2.5.2

Sorting of materials

13

3

Product description

14

3.1

System properties

14

3.2

System setup

15

3.3

Version, compatibility, and features

17

3.4

COMPACT module SP-COP1

18

3.4.1

Description

18

3.4.2

Display elements, interfaces, and terminal description

18

3.4.3

Internal circuits

19

3.4.4

Limited short-circuit detection in the input circuits

20

3.4.5

Deactivating the test pulses at the outputs of the SP-COP1

20

3.4.6

Single-channel use of outputs on the SP-COP1

20

3.5

COMPACT module SP-COP2-EN

21

3.5.1

Description

21

3.5.2

Display elements, interfaces, and terminal description

21

3.5.3

Internal circuits

23

3.5.4

Limited short-circuit detection in the input circuits

24

3.5.5

Deactivating the test pulses at the outputs of the SP-COP2

24

3.5.6

Single-channel use of outputs on the SP-COP2

25

Table of Contents

Page 4

Table of Contents

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

4

3.6

COMPACT module SP-COP2-ENI

26

3.6.1

Description

26

3.6.2

Display elements, error codes, and terminal description

26

3.7

COMPACT SP-COP-CARD1 removable storage

26

3.7.1

Description

26

3.8

SP-SDIO input/output expansion module

27

3.8.1

Description

27

3.8.2

Display elements and terminal assignment

28

3.8.3

Internal circuits

29

3.8.4

Deactivating the test pulses at the outputs of the SP-SDIO

30

3.8.5

Single-channel use of outputs on the SP-SDIO

30

3.9

SP-SDI input/output expansion module

31

3.9.1

Description

31

3.9.2

Display elements and terminal assignment

32

3.9.3

Internal circuits

32

3.10

SP-DIO input/output expansion module

33

3.10.1

Description

33

3.10.2

Display elements and terminal assignment

34

3.10.3

Internal circuits

35

4

Connecting devices

37

4.1

Safety command devices and electromechanical safety switches

39

4.1.1

Emergency stop buttons (e.g. SNH series)

39

4.1.2

Electromechanical safety switch without lock (e.g. SMS series)

39

4.1.3

Electromechanical safety switch with lock (e.g. SIN series)

40

4.1.4

Enable switch

41

4.1.5

Two-hand control

42

4.1.5.1

Type IIIA

42

4.1.5.2

Type IIIC

42

4.1.6

Safety mats and bumper

43

4.1.7

Diode pairs for safety mats

43

4.1.8

Mode selection switch

44

4.1.9

Potential-free contacts

44

4.2

Contactless safety sensors

45

4.2.1

Magnetic safety switches (e.g. SMA series)

45

4.2.1.1

Magnetic safety switches with equivalent inputs

45

4.2.1.2

Magnetic safety switches with complementary inputs

45

4.2.2

Inductive safety switches

45

4.2.3

Transponder switches

46

Page 5

Table of Contents

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

5

4.3

Testable single-beam safety light barriers

47

4.3.1

Testable type 2 single-beam safety light barriers

47

4.3.2

Testable type 4 single-beam safety light barriers

47

4.3.3

Customer-specific testable single-beam safety light barriers

48

4.3.4

Information on installing testable single-beam safety light barriers

48

4.4

ESPE – Electro-sensitive protective equipment

50

4.5

Safety outputs

50

5

Special functions

51

5.1

Muting

51

6

Installing/removing

52

6.1

Installing modules on standard rail

52

6.2

Removing modules from normal rail

55

7

Electrical installation

57

7.1

Requirements for electrical installation

57

7.2

Internal wiring of the supply voltage

59

8

Configuration

60

9

Commissioning

61

9.1

Total acceptance of the application

61

9.2

Tests before initial commissioning

61

10

Diagnostics

62

10.1

What to do in the event of an error

62

10.2

Error statuses

62

10.3

Error displays in the state LEDs, error messages, and measures for

error elimination

63

10.3.1

Device state and LED displays in the COMPACT modules (SP-COP1,

SP-COP2-ENx)

63

10.3.2

Device state and LED displays in the expansion modules (SP-SDIO, SPSDI)

65

10.3.3

Device state and LED displays of the expansion module (SP-DIO)

65

10.4

Wieland Support

67

10.5

Expanded diagnostics

67

11

Maintenance

68

11.1

Regular testing of the safety equipment by qualified persons

68

11.2

Replacing devices

69

11.2.1

Safety measures when replacing devices

69

Page 6

Table of Contents

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

6

12

Technical data

70

12.1

samosPRO system response times

70

12.1.1

Minimum switch-off time

71

12.1.2

Response time of the state flag

71

12.1.3

Default values for non-secure or secure data

72

12.2

Safety technology reference values

73

12.2.1

samosPRO COMPACT (SP-COPx without I/O expansion)

73

12.2.2

samosPRO COMPACT (SP-COPx with I/O expansion SP-SDI and/or SPSDIO)

74

12.3

Data sheet

75

12.3.1

SP-COP1 and SP-COP2-ENx modules

75

12.3.2

SP-SDIO input/output expansion module

79

12.3.3

SP-SDI input/output expansion module

82

12.3.4

SP-DIO input/output expansion module

84

12.4

Dimensional drawings

86

12.4.1

SP-COP1-xxx / SP-COP2-xxx controller modules

86

12.4.2

SP-SDIO and SP-DIO input/output expansion / SP-SDI input expansion

86

12.4.3

WKFN 2.5 E/35 GO-URL Level terminal

87

13

Order data

88

13.1

samosPRO – COMPACT – modules and accessories

88

13.2

Modules for contact expansion

90

13.3

Other safety-related products

90

14

Appendix

91

14.1

Declaration of Conformity

91

14.2

Checklist for manufacturers

95

14.3

Complete list of error messages

96

Page 7

About this document

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

7

technical personnel of the machine manufacturer

machine operator

not

designers, developers,

operators

1

1.1

1.2

About this document

887957259

Please read this section and the

working with the modular samosPRO safety control with COMPACT modules.

Function of this document

888316683

There are two sets of manuals with clearly delineated areas of application as well as installation

instructions and brief instructions for each module for the samosPRO system with COMPACT

modules.

• All samosPRO modules that can be used in connection with COMPACT modules and their

functions are extensively described in this "samosPRO Hardware" manual. Use the hardware manual mainly for planning samosPRO safety controls.

This hardware manual will guide

and/or

maintenance of the modular samosPRO safety control.

This hardware manual does

the safety control is or will be integrated. Instructions on how to operate the machine are

provided for this purpose.

• The "samosPLAN5+ Software" manual (BA000968) describes the software-supported configuration and parameterization of the samosPRO safety control with COMPACT modules.

In addition, the software manual contains a description of the important diagnostic functions for operation and detailed information for identifying and eliminating errors. Use the

software manual mainly when configuring, commissioning, and operating samosPRO safety controls.

• Each samosPRO module contains the installation instructions/brief instructions. These instructions provide information on the fundamental technical specifications of the modules

and contain simple installation instructions. Use the installation instructions/brief instructions when installing the samosPRO safety control.

This Manual is a translation of the original documentation within the meaning of the Machinery

Directive.

Safety [ch. 2, p. 10]

on safe installation, electric installation, commissioning, and

provide instructions for operating the machine into which

section carefully before documenting or

Target group

888318219

This manual is targeted toward

be safeguarded by a modular samosPRO safety control. They are also targeted toward persons

integrating a samosPRO safety control into a machine, commissioning it for the first time, or

maintaining such a system.

and

of systems that are to

Page 8

About this document

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

8

NOTICE

You can also use the website on the Internet and the CD

Further information:

Order data [ch. 13, p. 88]

Contactless

safety device

EDM

External Device Monitoring

PFHD

Probability of Dangerous Failure per Hour

OSSD

Output Signal Switching Device

SIL

Safety Integrity Level

PLC

Programmable Logic Controller

1.3

1.4

1.5

Information depth

888319755

This manual contains information on the modular samosPRO safety control with respect to the

following topics:

• Installation

• Electrical installation

• Hardware commissioning

• Error diagnostics and error elimination

• Item numbers

• Conformity and approval

• Maintenance

Furthermore, specialized technical knowledge that is not provided in this document is required

when designing and using Wieland safety equipment.

Essentially, the government and legal regulations must be adhered to when operating the modular samosPRO safety control.

• http://www.wieland-electric.com

• samosPRO-COMPACT CD

There you will find the following:

• samosPLAN5+ software

• "samosPLAN5+ Software" manual (BA000968)

• This manual (BA000966) is available for display and printing in various languages

Scope of application

888321291

This manual is valid for all samosPRO safety control modules that are operated in connection

with COMPACT modules and samosPLAN5+.

Abbreviations used

888322827

Contactless Safety Device

Page 9

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

9

NOTICE

These are notes that provide you with information regarding particularities of a device or a

software function.

Warning!

Please read and follow the warnings carefully!

to occur.

bold font

Edit

File

1.6

ATTENTION

About this document

Symbols/icons and writing style/spelling standard used

840010507

A warning lets you know about specific or potential hazards. It is intended to protect you

from accidents and help prevent damage to devices and systems.

•

Failure to do so may negatively impact the safety functions and cause a hazardous state

Menus and commands

The names of software menus, submenus, options, and commands, selection fields, and

windows are written in

. Example: Click on

in the

menu.

Page 10

Safety

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

10

and

and

and

2

2.1

2.2

Safety

888325899

This section is intended to support your safety and the safety of the system users.

Please read this section carefully before you work with the modular samosPRO safety con-

trol or with a machine protected by a samosPRO.

Qualified persons

888327435

The modular samosPRO safety control may only be installed, commissioned, and maintained

by qualified persons.

Qualified persons are those who

• have suitable technical training

• have been trained by the machine operator in the operation and applicable safety guidelines

• have access to the samosPRO operating instructions and have read said instructions and

have duly noted these

• have access to the operating instructions for the safety devices connected to the safety

control (e.g. safety light curtain) and have read them and duly noted them.

Areas of application of the device

888328971

The modular samosPRO safety control is an adjustable control for safety applications. It is

usable

• as per EN 61508 up to SIL 3

• as per EN 61131-6 up to SIL 3

• as per EN 62061 up to SIL CL 3

• as per EN ISO 13849-1:2006 to performance level e / category 4

• as per EN 81-1

• as per EN 50156-1

– The safety function must be tested at least once annually

– A consistent redundant structure must be implemented

– If relay expansion modules are used, the correct switching of the relays must be moni-

tored using feedback contacts (EDM)

– The requirements of EN 50156-1, Section 10.5.6, must be considered

The level of safety actually achieved depends on the external wiring, the implementation of the

wiring, the parameterization, the selection of the command encoder, and their arrangement on

the machine.

Opto-electronic and tactile safety sensors (e.g. light curtains, laser scanners, safety switches,

sensors, emergency stop switches) are connected and logically linked at the modular safety

control. The corresponding actuators on the machine or systems can be securely switched off

via the switch outputs of the safety control.

Page 11

Safety

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

11

ATTENTION

Do not use in private areas

private areas.

NOTICE

The safety functions are not evaluated by UL. The approval corresponds to UL508, general

applications.

2.3

Proper use

888330507

The modular samosPRO safety control may only be operated under the following conditions:

• You are operating the control within the specified operating limits for voltage, temperature,

etc. (see the following for further information:

• You are operating the control within the specified areas of application. (Further information:

Areas of application of the device [ch. 2.2, p. 10]

The control may only be operated by qualified personnel and may only be used on a machine

on which it has been installed and commissioned for the first time by a qualified person in accordance with this manual.

In the event of any other use or any changes to the device – including within the scope of installation – this shall nullify any sort of warranty claim with respect to Wieland Electric GmbH.

• The external power supply of the devices must able to bridge a short-term power outage

of 20 ms in accordance with EN 60204. Suitable PELV- and SELV-capable power packs

can be obtained as accessories from Wieland Electric.

• The modules for the samosPRO system correspond to class A, group 1, in accordance with

EN 55011. Group 1 includes all ISM devices in which intentionally generated and/or wired

HF power, which is required for the internal function of the device itself, occurs.

The samosPRO system fulfills the requirement for class A (industrial applications) according

to the "Emitted interference" basic trade standard.

Thus, the samosPRO system is only suitable for use in an industrial environment and not in

Technical data [ch. 12, p. 70]

)

)

UL/CSA applications:

• Use lines that are suitable for a temperature range of 60 to 75°C.

• Tighten the screw terminals with a torque of 5-7 lbs/in.

• Only use in a pollution degree 2 environment.

• The modules must be supplied by a voltage source with protective isolation, which is protected by a fuse in accordance with UL 248 with a nominal power of 100 V, wherein V corresponds to the direct current power supply with a maximum value of 42.4 V DC, which

means that the requirements of UL 508 for the current and voltage limits are met.

• The maximum permissible total current for the SP-SDIO modules with outputs Q1 to Q4 is

= 3.2 A.

I

total

Page 12

Safety

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

12

ATTENTION

Note the safety information and protective measures!

2.4

General safety information and protective measures

888331531

Note the following points in order to ensure proper use of the samosPRO safety control.

• Please follow the standards and guidelines valid in your country when installing and using

the samosPRO safety control.

• The national/international legal regulations apply to the installation and use of the samosPRO safety control as well as for the commissioning and repeated technical testing,

particularly the following:

– Machinery Directive 2006/42/EC

– EMC Directive 2014/30/EC

– Work Equipment Directive 2009/104/EC

– Low-Voltage Directive 2014/35/EC

– The accident prevention regulations/safety rules

– RoHS (Restriction of Hazardous Substances) Directive 2011/65/EC

• Manufacturers and operators of a machine on which a samosPRO safety control is being

used are responsible for coordinating with the proper authorities with regard to applicable

safety guidelines/rules and complying with these.

• The notices, particularly the test notices, must be observed without fail.

Further information:

Requirements for electric installation [ch. 7.1, p. 57]

The tests must be conducted by qualified persons or by those who are personally authorized and commissioned to do so and must always be fully documented at all times by a

third-party.

• This manual must be provided to the operator of the machine on which the samosPRO safety control is being used. The machine operator must be trained by qualified persons and

is required to read this manual.

Page 13

Safety

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

13

NOTICE

We will be happy to help you in disposing of these devices.

Simply contact us.

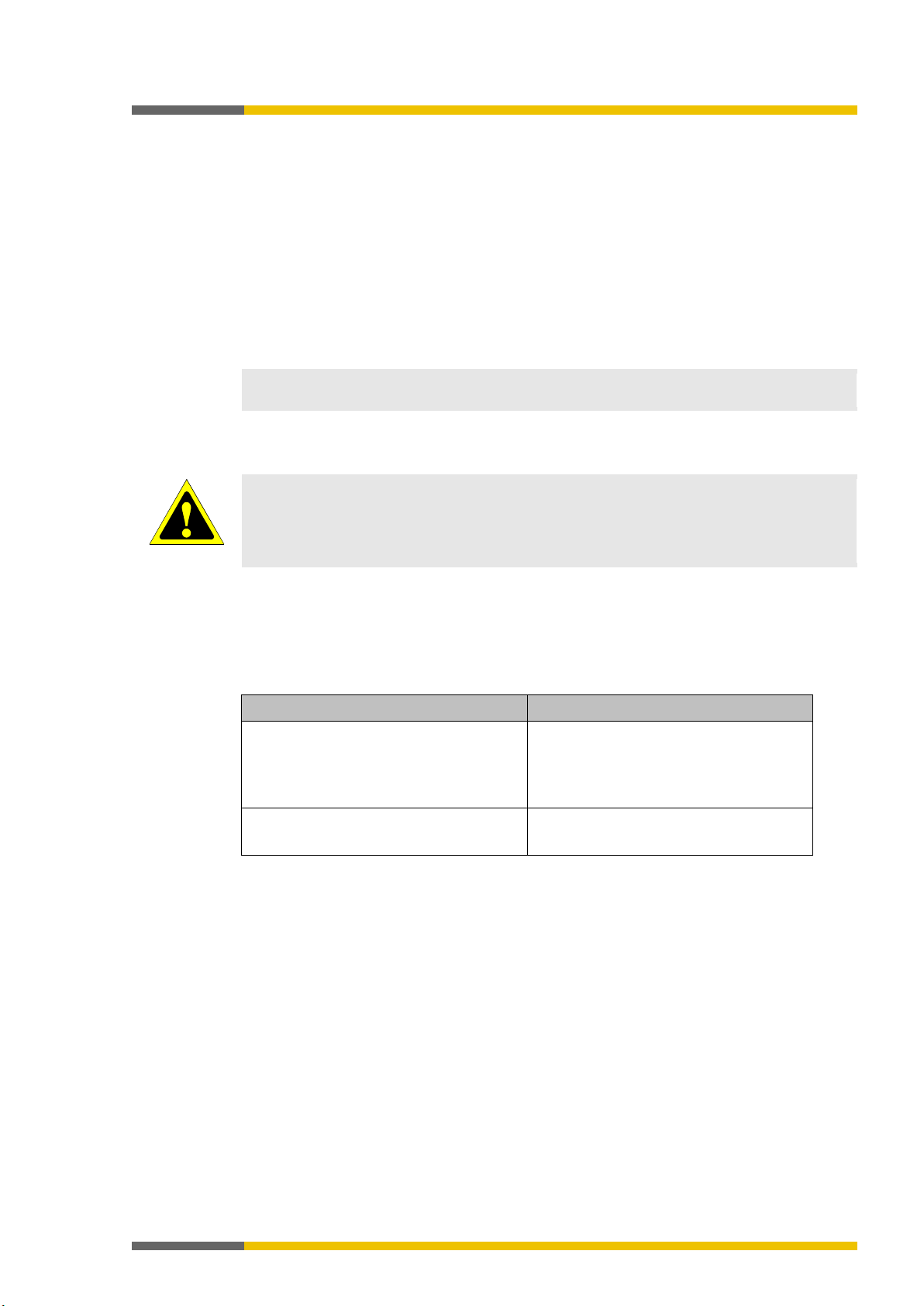

ATTENTION

Important information

Components

Disposal

electric connecting pieces

Cardboard, paper

Paper/cardboard recycling

2.5

2.5.1

2.5.2

Environmentally friendly behavior

888332555

The modular samosPRO safety control is designed such that it stresses the environment as little as possible. It uses only a minimum of power and resources.

Make sure that you also carry out work while always considering the environment.

Disposal

888334091

The disposal of unusable or irreparable devices should always be done in accordance with the

respectively valid country-specific waste-elimination guidelines (e.g. European Waste Code 16

02 14).

Sorting of materials

888335627

• The sorting of materials may only be carried out by qualified persons!

• Care must be used when disassembling the devices. There is a risk of injuries during this

process.

Before you can route the devices to the environmentally-friendly recycling process, it is necessary to sort the various samosPRO materials.

Separate the housing from the rest of the components (particularly from the PC board).

Place the separated components into the corresponding recycling containers (see the

following table).

Table 1: Overview of disposal according to components

Product

Housing

PC boards, cables, connectors, and

Packaging

Plastic recycling

Electronics recycling

Page 14

Product description

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

14

3

3.1

Product description

888337163

This section will provide you with information on the properties of the samosPRO system and

describes the setup and function.

System properties

888338699

Illustration 1: Modular samosPRO safety control

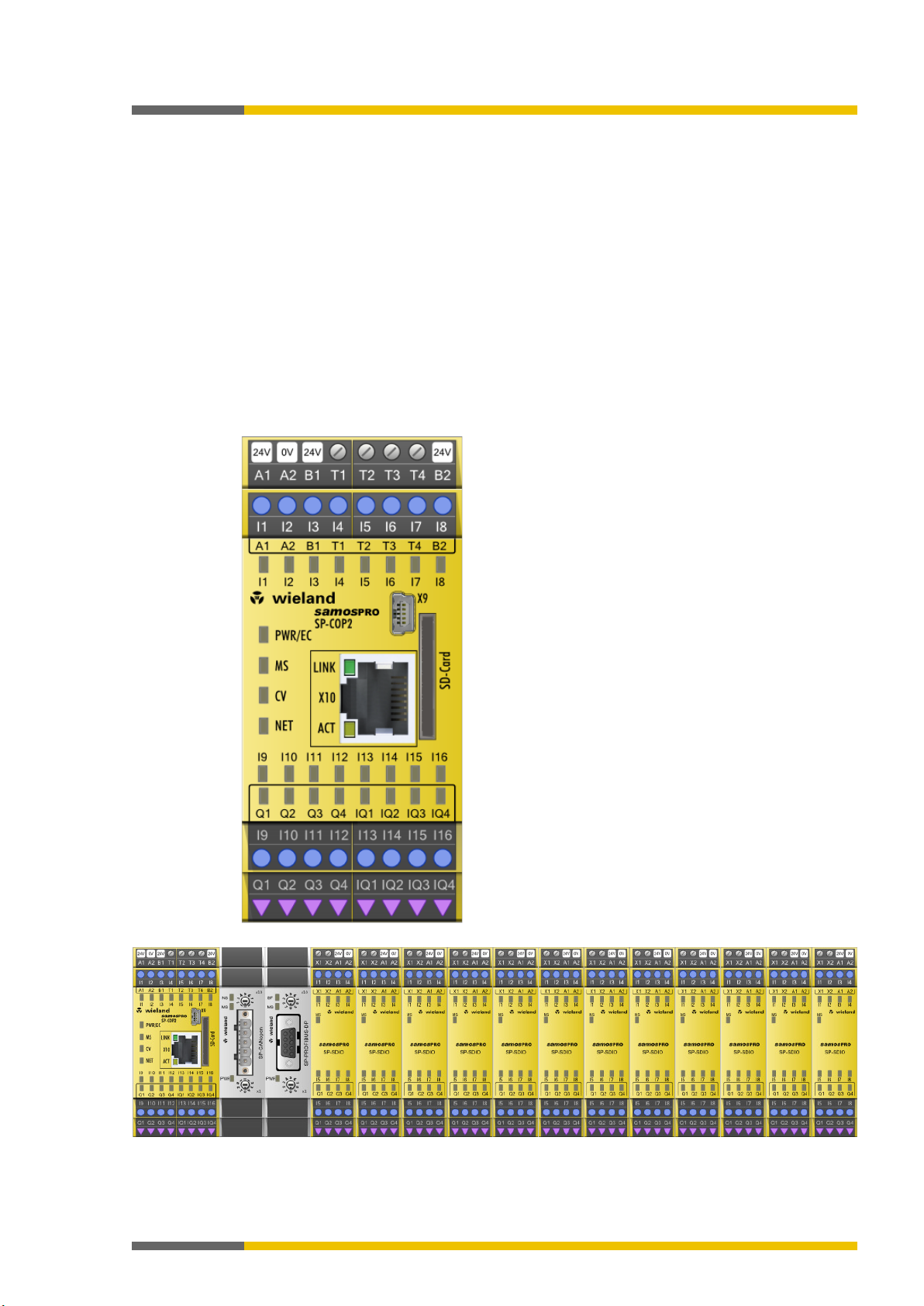

The samosPRO system is characterized by the following system properties:

• Modular setup: 1 COMPACT module and up to 12 input/output expansion modules, each

of which has an overall width of 22.5 mm

• 16 to 116 inputs and 4 to 56 outputs

• Programmable using samosPLAN5+

• Can use up to 300 standard and application-specific logical blocks

• Standard logical blocks: AND, OR, NOT, XNOR, XOR

• Application-specific logical blocks: Emergency stop, two-hand, muting, operating mode

selection switch, reset, restart

• Can be integrated into different networks using gateways (e.g. ProfibusDP, CANopen,

Modbus/TCP, etc.)

The samosPLAN5+ programming software is available for configuring the control tasks.

You can find the programming software on the Internet or on CD:

• http://www.wieland-electric.com

or

samosPLAN5+ CD [ch. 13, p. 88]

•

Page 15

Product description

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

15

3.2

System setup

888341643

A samosPRO COMPACT system consists of the following modules and/or components:

• One COMPACT module

• One program removable storage

• The samosPLAN5+ programming software

• Up to two gateway modules

• Up to 12 additional SP-SDIO, SP-SDI and SP-DIO input/output modules

• In addition, SP-XX expansion modules can be used. This may be for example the SA-OR-Sx

relay output expansions or the SNS4084K standstill monitor. These modules are shown in

the report from samosPLAN5+ but cannot be logically connected to the modules of the

Samos PRO COMPACT system.

Further information on positioning this module: "samosPLAN5+ software" (BA000968)

manual, section "Special case: SP-XX expansion module"

Illustration 2: Example of a minimum samosPRO system setup with SP-COP2

Illustration 3: Maximum samosPRO system setup

Page 16

Product description

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

16

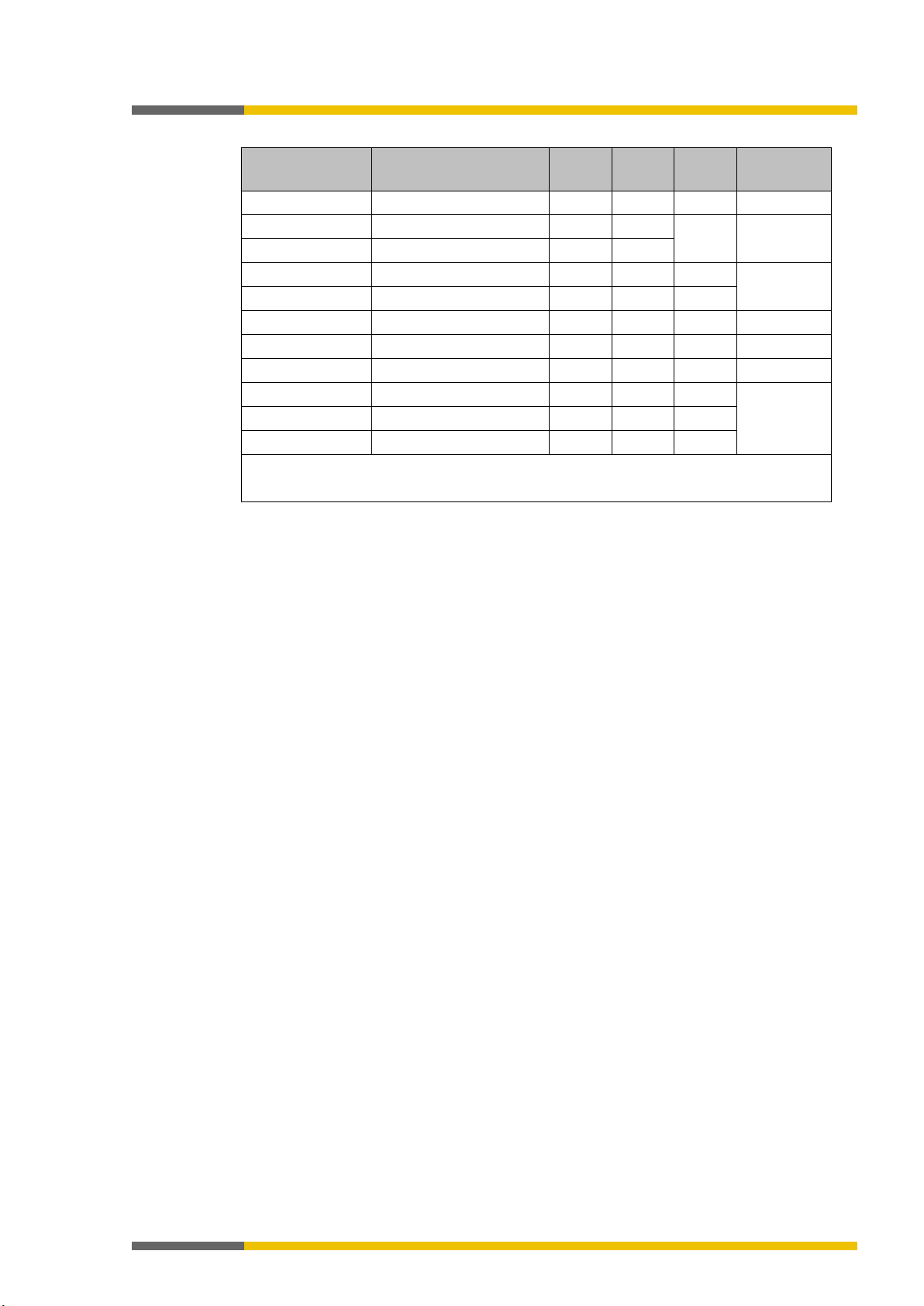

Type

Description

Inputs

Outputs

Logical

blocks

Max. occurrence

SP-COP1

Controller module

20 4 300

1×

SP-COP2-EN

Controller module

16-20 1)

4-81)

SP-COP2-ENI

Controller module

16-20 1)

4-81)

SP-SDIO

Input/output expansion

8 4 –

SP-SDI

Input expansion

8 – –

SA-OR-S1

Relay output expansion

– 4 –

4×2)

SA-OR-S2

Relay output expansion

– 2 –

8×2)

SP-DIO

Input/output expansion

81)

81) – 12×

SP-PROFIBUS-DP

PROFIBUS DP gateway

– – –

SP-CANopen

CANopen gateway

– – –

SP-EN-ETC

EtherCAT Gateway

– – –

Maximum 16 safe relay outputs

Table 2: Overview of modules (without program removable storage)

300 1×

12×

2×

1)

4 inputs or 4 outputs can be configured as an option

2)

Page 17

Product description

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

17

Available from module version

Feature / functionality

SP-COP1-x

SP-COP2-ENx

SP-COP2ENI-x

samosPLAN5

+

Modbus TCP

---

---

A-01

V1.0

Non-secure I/O (SP-DIO)

C-01.xx

C-01.xx

C-01.xx

V1.3

EtherCAT (SP-EN-ETC)

C-01.xx

C-01.xx

C-01.xx

V1.3

EtherNet/IP

---

---

D-01.xx

V1.4

Press functions1)

D-01.xx

D-01.xx

D-01.xx

V1.4 1) only available with module variants -P (example: SP-COP2-EN-P-x)

File menu

About

3.3

Version, compatibility, and features

840060811

There are various module versions and function packages for the samosPRO product family

that enable various functions. This section will give you an overview as to which module version, which function package, and/or which version of the samosPLAN5+ you will need to be

able to use a certain function or a certain device.

Table 3: Module and software versions required

Safe I/O (SP-SDIO, SP-SDI) A-01 A-01 A-01 V1.0

Profinet IO --- --- B-01.xx V1.2

Info

• You will find the module version on the type plate of the samosPRO modules.

• You can find the samosPLAN5+ version in the green

under

.

• You can obtain the latest version of the samosPLAN5+ on the Internet at

http://www.wieland-electric.de.

• Newer modules are backwards-compatible, which means that each module can be replaced with a module having a higher module version.

• You can find the date of manufacture for a device on the type plate in the S/N field in the

format <Product no.>yywwnnnnn (yy = year, ww = calendar week).

Page 18

Product description

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

18

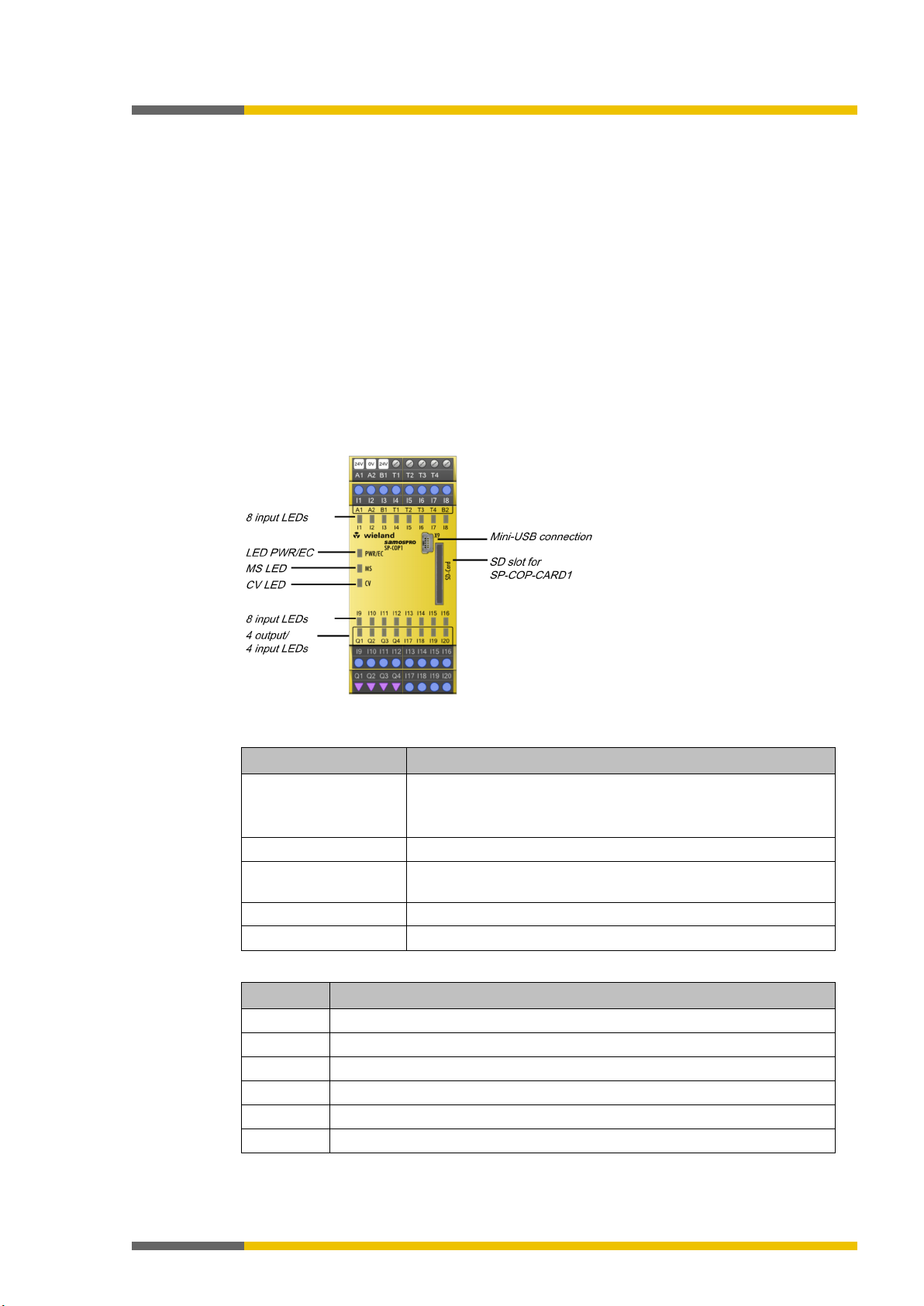

P

LED

Meaning

Flashing codes [ch. 10.3.1, p.

63]

MS

Display of the

Module state [ch. 10.3.1, p. 63]

Control project [ch. 10.3.1,

p. 63]

Input LED I1 to I20

State display of the

Inputs [ch. 10.3.1, p. 63]

Output LED Q1 to Q4

State display of the

Outputs [ch. 10.3.1, p. 63]

Pin

assignment

A1

24 V supply voltage for all modules, except for supply of outputs

A2

GND of supply voltage

I1 - I20

Safe, digital inputs

Q1 - Q4

Safe, digital outputs

B1

24 V supply voltage of outputs Q1 - Q4

T1 - T4

Test signal outputs

3.4

3.4.1

3.4.2

COMPACT module SP-COP1

888347531

Description

888349067

COMPACT module SP-COP1 is a central processing unit for the entire system in which all of

the signals are monitored and logically processed according to the configuration stored in the

SP-COP-CARD1 program removable storage. The module has safe inputs and outputs as well

as test signal outputs. The system outputs are switched as a result of the processing. The internal safety bus in this case serves as a data interface.

Module versions

In addition to the basic version there is the SP-COP1-

compact module.

This has additional press control functions.

Display elements, interfaces, and terminal description

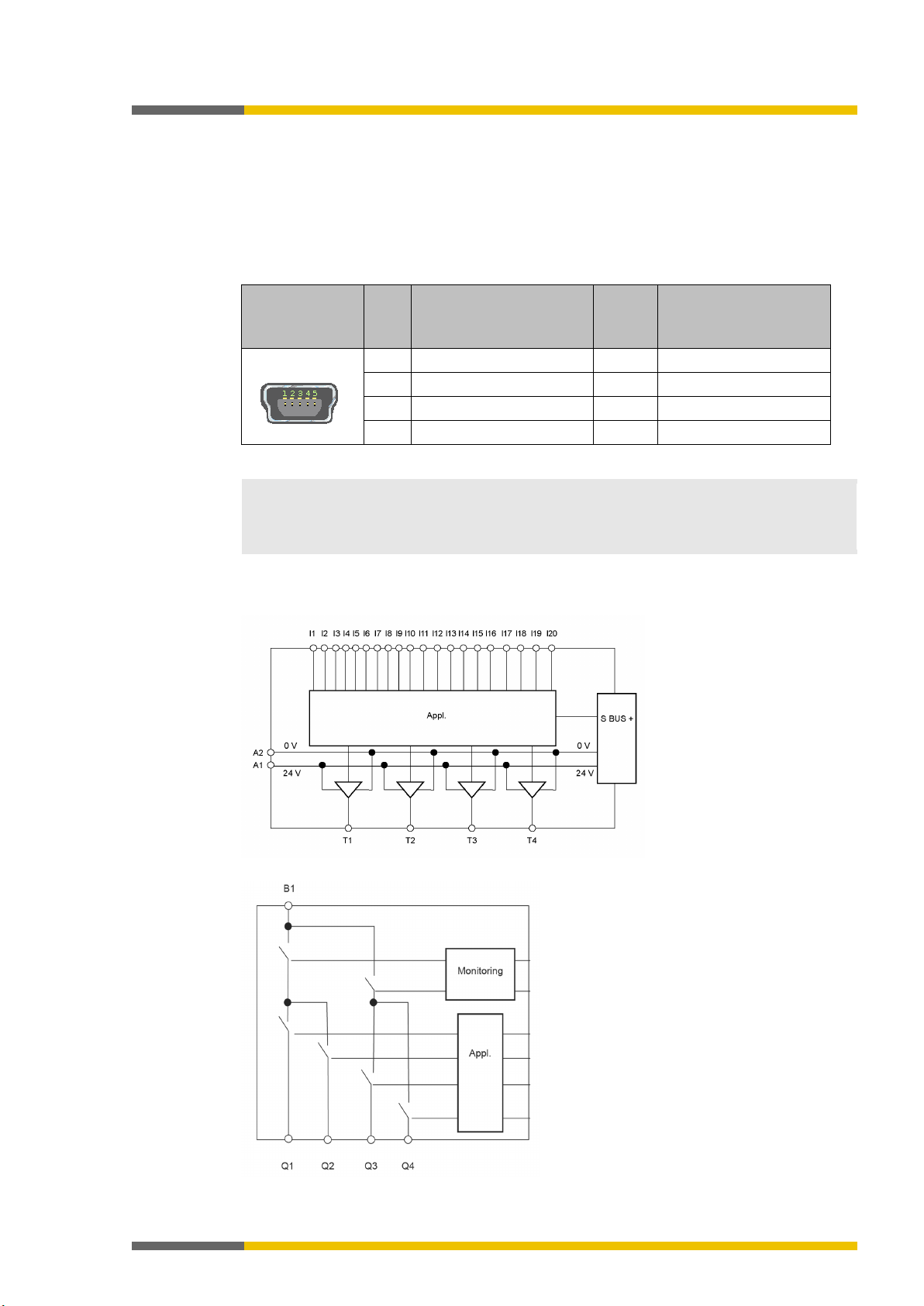

888350603

Illustration 4: SP-COP1 display elements

Table 4: 4 LED displays

PWR/EC Display of the supply voltage state

Display of an error through various

CV Display of the verification state of the

Table 5: SP-COP1 pin assignment

Page 19

Product description

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

19

Connector/bushing

USB mini

Pin

Signal

Color

Assignment PC-side

1

+5V 2 - data

3

+ data

5

GND

NOTICE

• If the USB interface of the main module is permanently connected, then the maximum

main module, e.g. by using optocouplers.

3.4.3

USB interface

The main module has a mini-USB interface with the following functions:

• Transfer of the configuration from samosPLAN5+ to the program removable storage

• Reading of configuration from program removable storage in samosPLAN5+

• Diagnostics of the samosPRO systems with samosPLAN5+

Table 6: USB interface pin assignment

permissible cable length is 3 m.

• Avoid using ground loops between the USB interface GND and the A2 connection of the

Internal circuits

888354955

Illustration 5: Inputs and test pulses at an SP-COP1 module

Illustration 6: Outputs at an SP-COP1 module

Page 20

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

20

• One SP-COPx has four test signal generators T1 – T4.

DC (after high) at inputs that are connected to test outputs are

Make note of this during wiring (e.g. through separate routing or protected lines)!

Switching off the test pulses at one of the two outputs of an output pair will switch off

the test pulses of the entire output pair!

Safety technology

reference values [ch. 12.2, p. 73]

Be sure to use protected or separate cabling!

off output, which will influence the capability of switching off the outputs.

Carry out cyclic tests when the test pulses at one or more safety outputs are deactivated!

• Restart the samosPRO system by switching off the supply voltage.

Edit

Activation of test pulses of this output

ATTENTION

Be sure to consider a potential brief switch to high with single-channel safety outputs!

Otherwise, there is a hazard for the operator of the machine.

3.4.4

3.4.5

3.4.6

ATTENTION

ATTENTION

Product description

Limited short-circuit detection in the input circuits

895385995-1

• Short-circuits between test signal generators of an SP-COPx are detected. Between different modules the short circuit detection is then only ensured if the test gaps of the test

signal generators are < 4 ms, the test periods ≥ 200 ms. In addition, the short circuit de-

tection is only ensured if no more than 9 modules (SP-SDI / SP-SDIO) have been plugged

in. Short-circuits after 24 V

detected independently of the length of the test gaps.

Deactivating the test pulses at the outputs of the SP-COP1

888356491

It is possible to deactivate the test pulses at one or more output pairs. The outputs are combined into two output pairs with the SP-COP1. Q1/Q2 and Q3/Q4. The test pulses each act upon

the two outputs of an output pair.

Deactivating the test pulses at one or more safety outputs of an SP-COP reduces the safety

parameters of both safety outputs of the respective output pair of this module.

• Be aware of this in order to ensure that your application corresponds to an appropriate

risk analysis and risk avoidance strategy.

• You can find more detailed information on the safety parameters here:

ATTENTION

ATTENTION

• If you deactivate the test pulses at one or more safety outputs, short-circuits at other

output circuits cannot be detected. This affects the safety function!

• In the event of a short-circuit after 24 V, it will no longer be possible to switch off the

output.

Furthermore, it will not be possible to prevent reverse current from going into a switched-

Once you deactivate the test pulses at one or more safety outputs, conduct the following

tests once a year:

• Switch off all of the safety outputs without test pulses simultaneously for at least one

second via the logic program of the COMPACT module.

OR

You will thus deactivate the test pulses at an output of the SP-COP1:

Connect an output element to the SP-COP module.

Using the right mouse key, click on the output element and select the

command in

the context menu.

Deactivate the

option. The test pulses of this output will be switched off. A corresponding note will be displayed in the hardware configuration area under the respective SP-COP module.

Single-channel use of outputs on the SP-COP1

888357515

In the event of an internal hardware error, single-channel safety outputs can switch to high

once for 10 ms after the error has been detected.

• Consider this during your risk analysis and reduction strategy.

Page 21

Product description

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

21

P

LED

Meaning

Flashing codes [ch. 10.3.1, p.

63]

MS

Display of the

Module state [ch. 10.3.1, p. 63]

Control project [ch. 10.3.1,

p. 63]

to IQ4

Pin

assignment

A2

GND of supply voltage

Q1 - Q4

Safe, digital outputs

IQ1 - IQ4

Safe, digital inputs or outputs (configurable through samosPLAN5+)

3.5

3.5.1

3.5.2

COMPACT module SP-COP2-EN

888359051

Description

888360587

COMPACT module SP-COP2-EN is the central processing unit for the entire system in which all

of the signals are monitored and logically processed according to the configuration stored in

the SP-COP-CARD1 program removable storage. The module has safe inputs and outputs as

well as test signal outputs. The system outputs are switched as a result of the processing. The

internal safety bus in this case serves as a data interface.

Module versions

In addition to the basic version there is the SP-COP2-EN-

compact module.

This has additional press control functions.

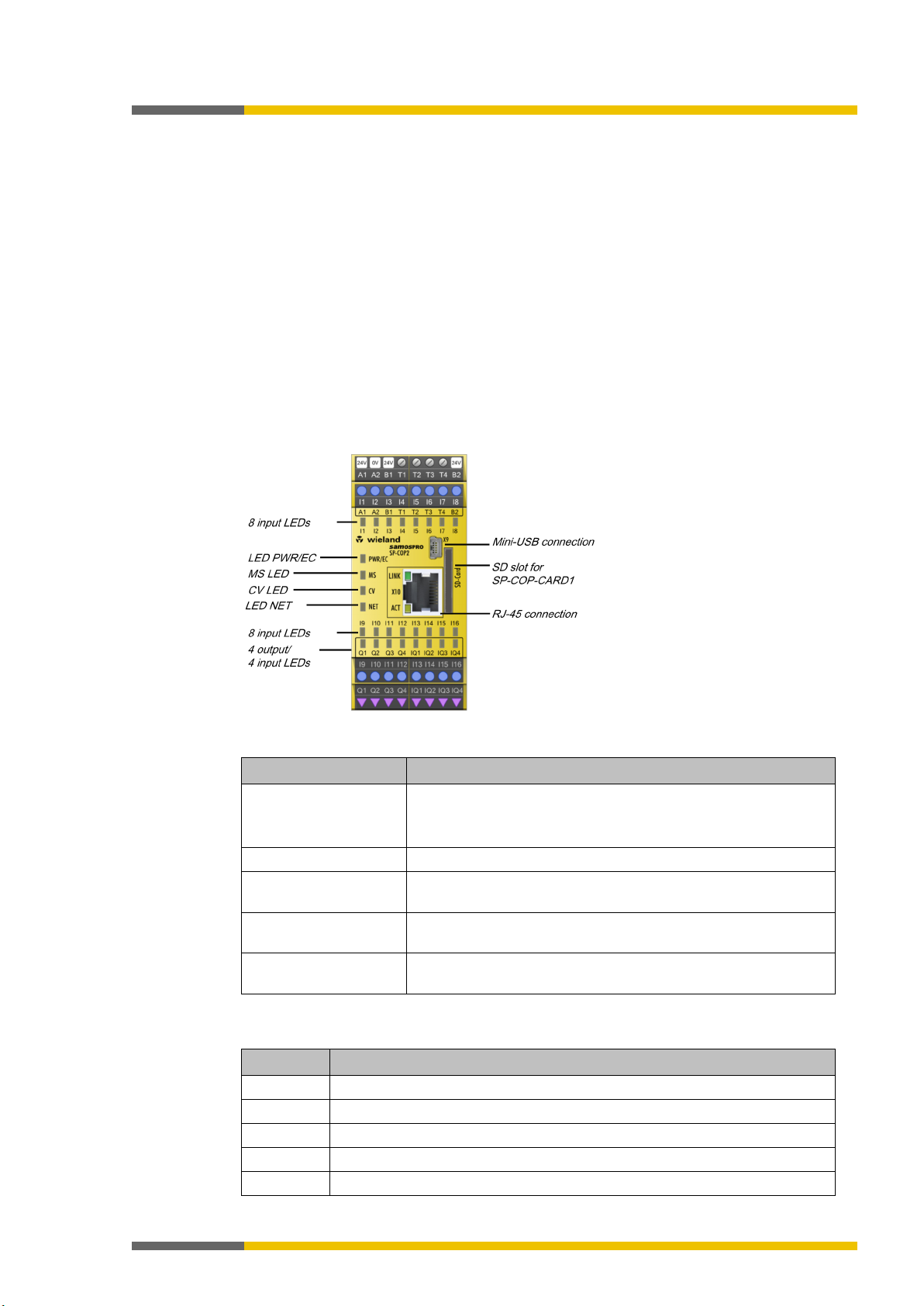

Display elements, interfaces, and terminal description

888362123

Illustration 7: SP-COP2-EN display elements

Table 7: SP-COP 2 LED displays

PWR/EC Display of the supply voltage state

Display of an error through various

CV Display of the verification state of the

Input LED I1 to I16, IQ1

Output LED Q1 to Q4,

State display of the

State display of the

Inputs [ch. 10.3.1, p. 63]

Outputs [ch. 10.3.1, p. 63]

IQ1 to IQ4

Table 8: Pinout SP-COP2

A1 24 V supply voltage for all modules, except for supply of outputs

I1 - I16 Safe, digital inputs

Page 22

Product description

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

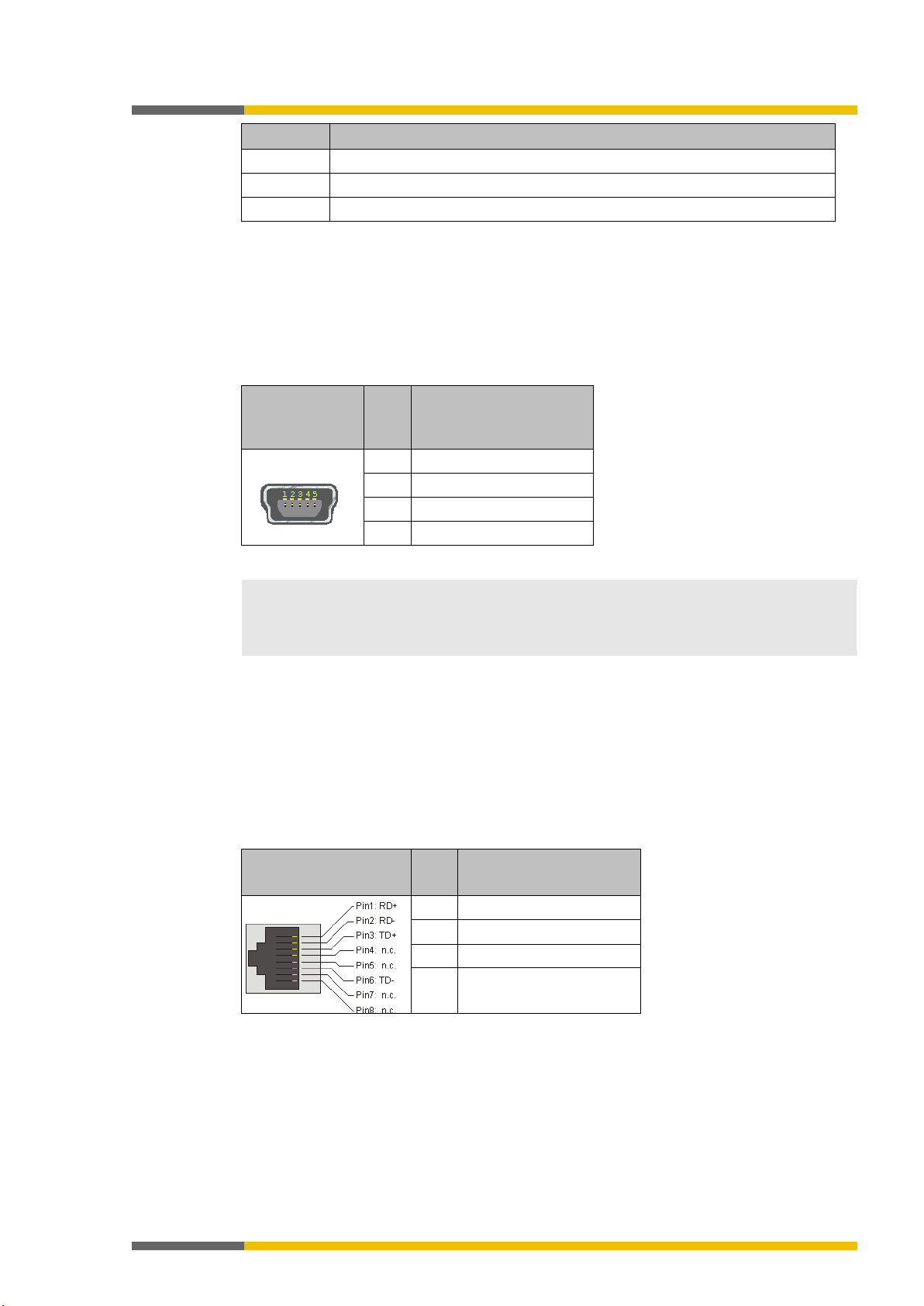

22

Pin

assignment

B1

24 V supply voltage of outputs Q1 - Q4

B2

24 V supply voltage of configurable outputs IQ1 - IQ4

T1 - T4

Test signal outputs

Connector/bushing

USB

Pin

Signal

1

+5V 2 - data

3

+ data

5

GND

NOTICE

• If the USB interface of the main module is permanently connected, then the maximum

main module, e.g. by using optocouplers.

Connector/bushing

RJ45

Pin

Signal (Auto MDI-X)

1

RD+ / TD+

2

RD- / TD-

3

TD+ / RD+

USB interface

The main module has a mini-USB interface with the following functions:

• Transfer of the configuration from samosPLAN5+ to the program removable storage

• Reading of configuration from program removable storage in samosPLAN5+

• Diagnostics of the samosPRO systems with samosPLAN5+

Table 9: USB interface pin assignment

permissible cable length is 3 m.

• Avoid using ground loops between the USB interface GND and the A2 connection of the

Ethernet interface

The main module has an Ethernet interface with the following functions:

• Transfer of the configuration from samosPLAN5+ to the program removable storage

• Reading of configuration from program removable storage in samosPLAN5+

• Diagnostics of the samosPRO systems with samosPLAN5+

• Continuous diagnostics of the samosPRO system via a connected PLC.

Table 10: RJ 45 bushing pin assignment

6 TD- / RD-

The device itself detects which cable type, patch cable or cross-link cable, is being used (Auto

MDI-X), which is why the pin assignment does not matter with regard to the RD or TD signals.

Page 23

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

23

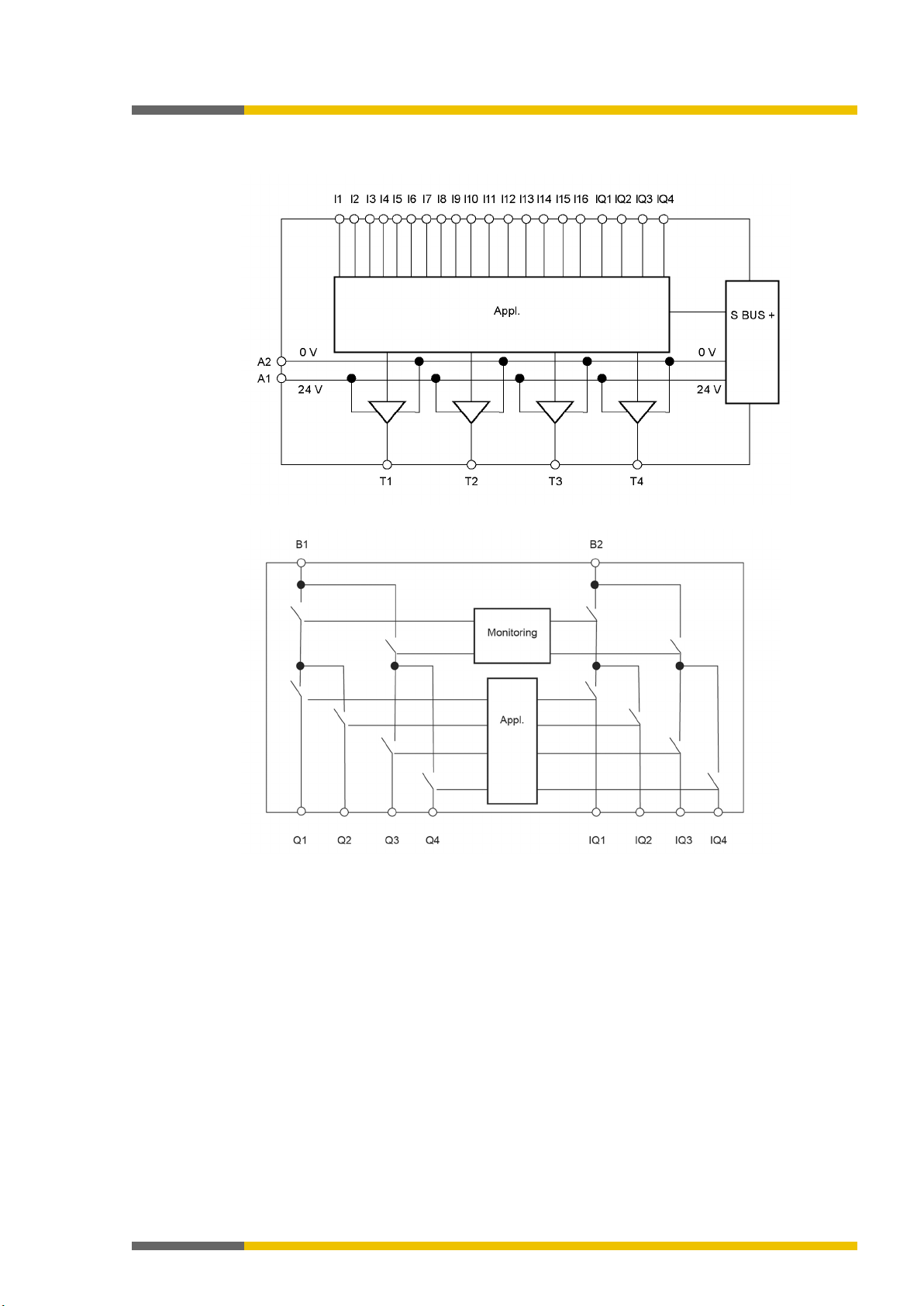

Internal circuits

3.5.3

888365195

Product description

Illustration 8: Inputs and test pulses at an SP-COP2-EN module

Illustration 9: Outputs at an SP-COP2-EN module

Page 24

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

24

• One SP-COPx has four test signal generators T1 – T4.

DC (after high) at inputs that are connected to test outputs are

Make note of this during wiring (e.g. through separate routing or protected lines)!

Switching off the test pulses at one of the two outputs of an output pair will switch off

the test pulses of the entire output pair!

Safety technology

reference values [ch. 12.2, p. 73]

ATTENTION

Be sure to use protected or separate cabling!

output.

Carry out cyclic tests when the test pulses at one or more safety outputs are deactivated!

• Restart the samosPRO system by switching off the supply voltage.

Edit

Activation of test pulses of this output

3.5.4

3.5.5

ATTENTION

ATTENTION

Product description

Limited short-circuit detection in the input circuits

895385995-2

• Short-circuits between test signal generators of an SP-COPx are detected. Between different modules the short circuit detection is then only ensured if the test gaps of the test

signal generators are < 4 ms, the test periods ≥ 200 ms. In addition, the short circuit de-

tection is only ensured if no more than 9 modules (SP-SDI / SP-SDIO) have been plugged

in. Short-circuits after 24 V

detected independently of the length of the test gaps.

Deactivating the test pulses at the outputs of the SP-COP2

888366731

It is possible to deactivate the test pulses at one or more output pairs. The outputs are combined into four output pairs with the SP-COP2: Q1/Q2, Q3/Q4, IQ1/IQ2, and IQ3/IQ4. The test

pulses each act upon the two outputs of an output pair.

Deactivating the test pulses at one or more safety outputs of an SP-COP reduces the safety

parameters of both safety outputs of the respective output pair of this module.

• Be aware of this in order to ensure that your application corresponds to an appropriate

risk analysis and risk avoidance strategy.

• You can find more detailed information on the safety parameters here:

ATTENTION

• If you deactivate the test pulses at one or more safety outputs, short-circuits at other

output circuits cannot be detected. This affects the safety function!

• In the event of a short-circuit after 24 V, it will no longer be possible to switch off the

Once you deactivate the test pulses at one or more safety outputs, conduct the following

tests once a year:

• Switch off all of the safety outputs without test pulses simultaneously for at least one

second via the logic program of the COMPACT module.

OR

You will thus deactivate the test pulses at an output of the SP-COP2:

Connect an output element to the SP-COP module.

Using the right mouse key, click on the output element and select the

command in

the context menu.

Deactivate the

option. The test pulses of this output will be switched off. A corresponding note will be displayed in the hardware configuration area under the respective SP-COP module.

Page 25

Product description

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

25

ATTENTION

Be sure to consider a potential brief switch to high with single-channel safety outputs!

Otherwise, there is a hazard for the operator of the machine.

3.5.6

Single-channel use of outputs on the SP-COP2

888368267

In the event of an internal hardware error, single-channel safety outputs can switch to high

once for 10 ms after the error has been detected.

• Consider this during your risk analysis and reduction strategy.

Page 26

Product description

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

26

P

NOTICE

• The data stored in the SP-COP-CARD1 program removable storage will be retained even

a module, make sure that the program removable storage is inserted into

dules.

3.6

3.6.1

3.6.2

3.7

3.7.1

COMPACT module SP-COP2-ENI

888369803

Description

888371339

COMPACT module SP-COP2-ENI has the same functionality and has the same connections

and the same displays as the

SP-COP2-EN [ch. 3.5, p. 21]

.

In addition, this module has the following gateway functionality on-board:

• Modbus/TCP interface

• PROFINET IO interface

• EtherNet/IP interface

Module versions

In addition to the basic version there is the SP-COP2-ENI-

compact module.

This has additional press control functions.

Display elements, error codes, and terminal description

888372363

The displays of the MS and CV LEDs as well as the terminal assignment of the USB and Ethernet interface are identical to those for the SP-COP2-EN controller module.

Further information:

Display elements, interfaces, and terminal description [ch. 3.5.2, p. 21]

COMPACT SP-COP-CARD1 removable storage

888373387

Description

888374923

The system configuration of the entire samosPRO system is stored in the SP-COP-CARD1 program removable storage. This has the advantage that the samosPRO system does not have to

be reconfigured when modules are replaced.

The COMPACT SP-COP-CARD1 removable storage is an SD card that is produced and formatted specially for use in COMPACT modules.

if the supply voltage is interrupted.

• When replacing

the appropriate COMPACT module. Mark all of the connection lines and plug connectors

on the samosPRO system clearly to prevent mixups.

• Commonly available SD cards cannot be used/inserted in samosPRO and COMPACT mo-

Page 27

Product description

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

27

Limited short-circuit detection in the input circuits

Make note of this during wiring (e.g. through separate routing or protected lines)!

NOTICE

• The LEDs of inputs I1 to I8 indicate the state of the inputs at an update rate of about 64

ms.

3.8

3.8.1

SP-SDIO input/output expansion module

888376459

Description

888377995

The SP-SDIO module is an input/output expansion with eight safe inputs and four safe outputs.

It has two test signal generators: one for test output X1 and one for test output X2.

The SP-SDIO module offers the following functions:

• Monitoring of connected safety devices

For further information:

Connecting devices [ch. 4, p. 37]

• Forwarding the input information to the main module

• Receipt of control signals from the main module and corresponding switching of outputs

• Fast shut-off: Direct switch-off of the actuators connected on the module. This results in a

significant reduction in the response time of the entire system. Only 8 ms are needed in

the response times of the devices at the inputs and outputs in order to switch-off the outputs. The runtimes on the internal SBUS+ bus and the Logic Execution Time do not play

any role in this case.

Further information:

samosPRO system response times [ch. 12.1, p. 70]

• Activating or deactivating test pulses at the outputs (Q1–Q4) with firmware version V2.00.0

and higher.

Module SP-SDIO cannot be operated alone; it always requires an SP-COP COMPACT module

(see "samosPLAN5+" programming software).

It is possible to use multiple SP-SDIO84 modules simultaneously (see

15]

). The voltage of the internal logic and the test outputs is supplied via the system connector

System setup [ch. 3.2, p.

and the internal SBUS+ bus. The voltage of the Q1–Q4 outputs of the SP-SDIO must be supplied directly via A1/A2 at the respective module.

ATTENTION

• One SP-SDIO has two test signal generators, X1 and X2.

• Short-circuits between test signal generators of an SP-SDI or SP-SDIO expansion module

are detected. Between different modules the short circuit detection is then only ensured

if the test gaps of the test signal generators are < 4 ms, the test periods ≥ 200 ms and no

more than 9 modules (SP-SDI / SP-SDIO) have been plugged in. Short-circuits after 24

V DC (after high) at inputs that are connected to test outputs are detected independently

of the length of the test gaps.

Page 28

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

28

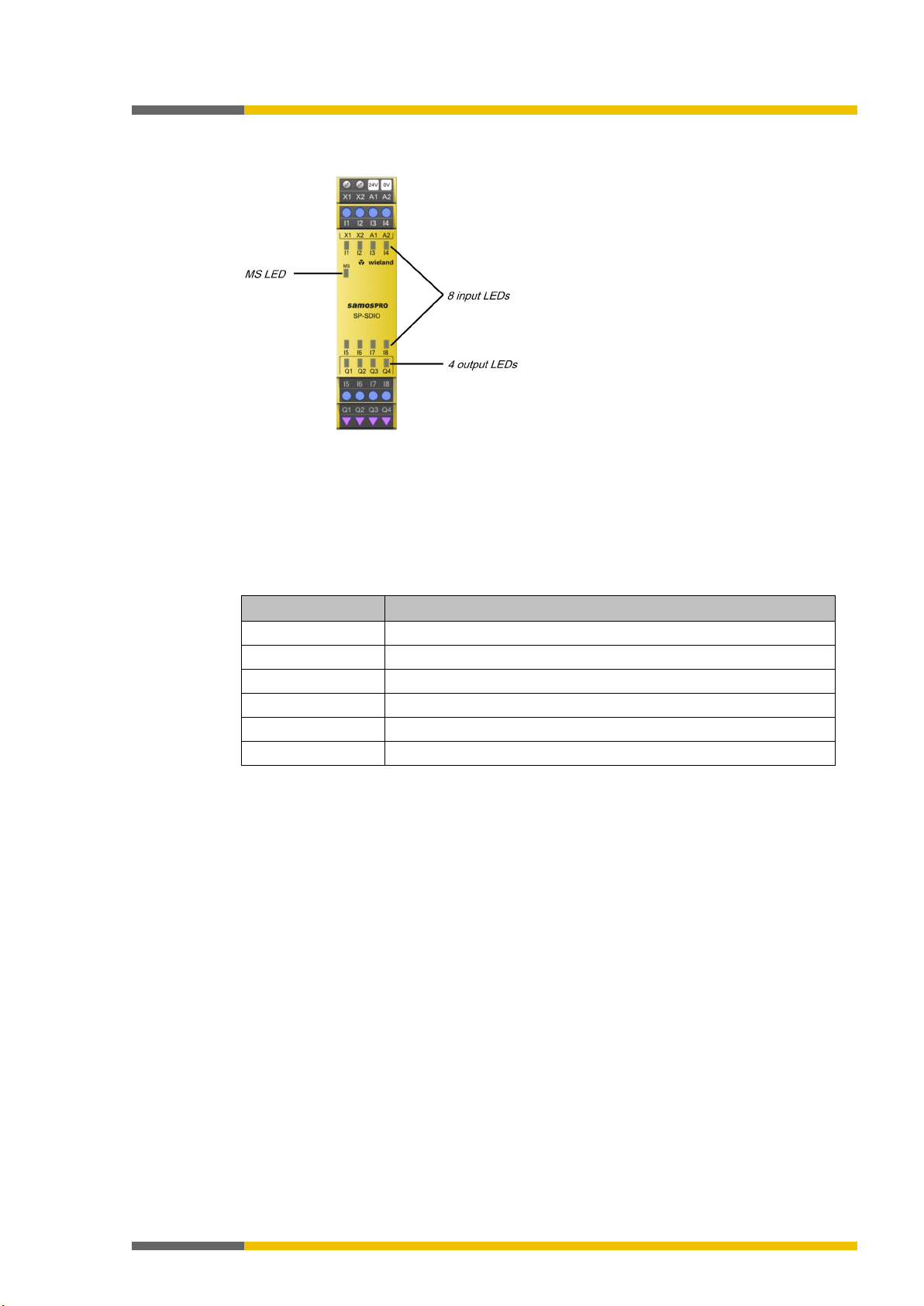

Display elements and terminal assignment

Terminal

assignment

X1/X2

Test output 1 / test output 2

I1–I4

Inputs 1 to 4

A1

24 V

A2

GND

I5–I8

Inputs 5 to 8

Q1–Q4

Outputs 1 to 4

3.8.2

888379019

Product description

Illustration 10: SP-SDIO display elements

Flashing codes

Further information:

SDI) [ch. 10.3.2, p. 65]

Terminal assignment

Table 11: SP-SDIO terminal assignment reference

Device state and LED displays in the expansion modules (SP-SDIO, SP-

Page 29

Product description

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

29

3.8.3

Internal circuits

888388363

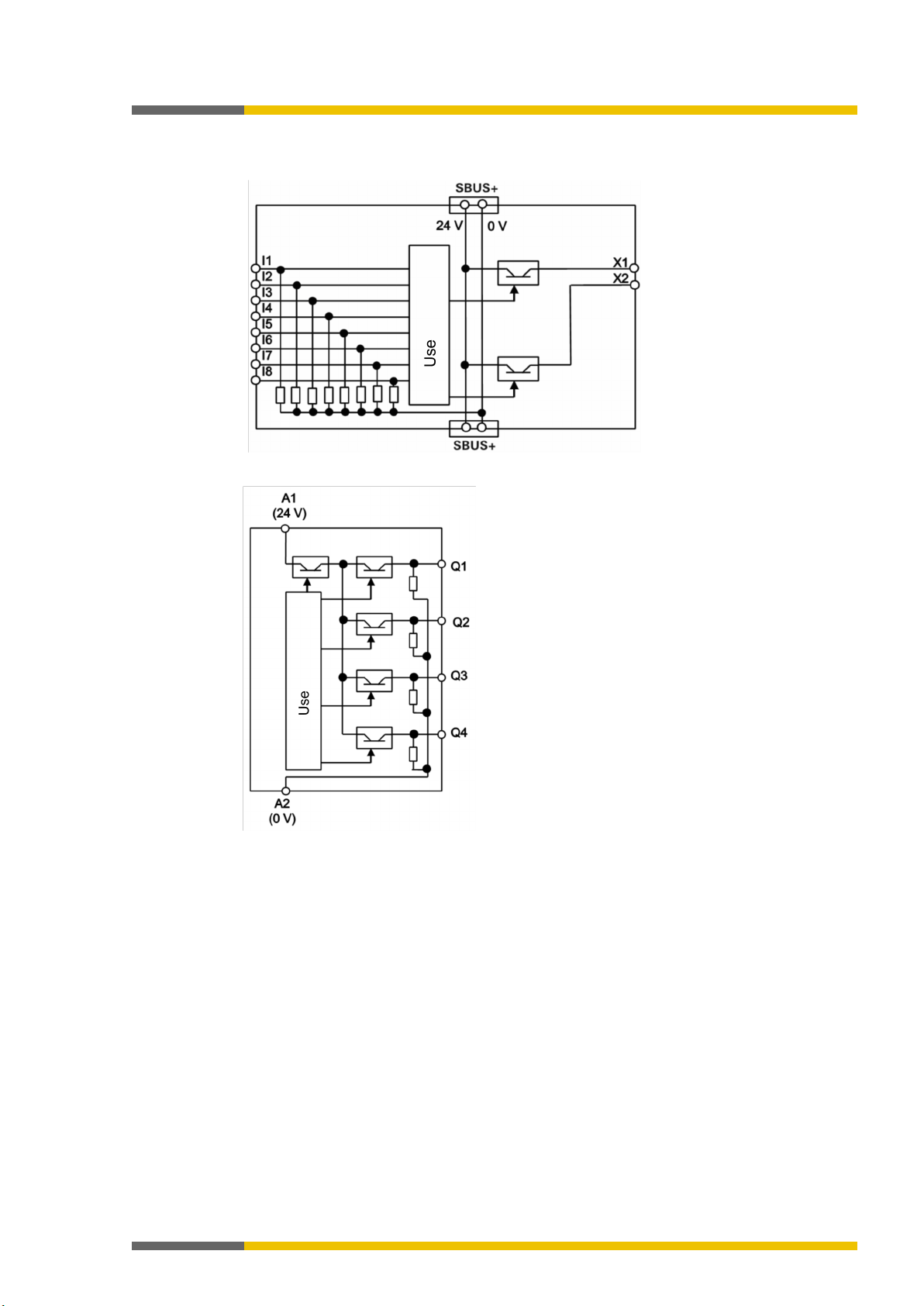

Illustration 11: Internal SP-SDIO circuits: Safe inputs and test outputs

Illustration 12: Internal SP-SDIO circuits: Safety outputs

Page 30

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

30

Deactivating the test pulses at any output reduces the safety parameters of all outputs!

Technical data [ch.

12, p. 70]

Be sure to use protected or separate cabling!

off output, which will influence the capability of switching off the outputs.

Carry out cyclic tests when the test pulses at one or more safety outputs are deactivated!

• Restart the samosPRO system by switching off the supply voltage.

Edit

Activation of test pulses of this output

ATTENTION

Be sure to consider a potential brief switch to high with single-channel safety outputs!

chine.

3.8.4

3.8.5

ATTENTION

ATTENTION

Product description

Deactivating the test pulses at the outputs of the SP-SDIO

888394763

With firmware version V2.00.0 and higher, it is possible to deactivate the test pulses at one or

more outputs of SP-SDIO84-P1 modules.

Deactivating the test pulses at one or more safety outputs of an SP-SDIO module reduces the

safety parameters of all Q1 to Q4 safety outputs of this module.

• Be aware of this in order to ensure that your application corresponds to an appropriate

risk analysis and risk avoidance strategy.

• You can find more detailed information on the safety parameters here:

• If you deactivate the test pulses at one or more safety outputs, short-circuits at other

output circuits cannot be detected. This affects the safety function!

• In the event of a short-circuit after 24 V, it will no longer be possible to switch off the

output.

Furthermore, it will not be possible to prevent reverse current from going into a switched-

ATTENTION

Once you deactivate the test pulses at one or more safety outputs, conduct the following

tests once a year:

• Switch off all of the safety outputs without test pulses simultaneously for at least one

second via the logic program of the COMPACT module.

OR

You will thus deactivate the test pulses at an output of the SP-SDIO:

Connect an output element to the SP-SDIO module.

Using the right mouse key, click on the output element and select the

command in

the context menu.

Deactivate the

option. The test pulses of this output will be switched off. A corresponding note will be displayed in the hardware configuration area under the respective SP-SDIO module.

Single-channel use of outputs on the SP-SDIO

888395787

In the event of an internal hardware error, single-channel safety outputs (Q1 to Q4) can

switch to high once for 10 ms after the error has been detected. Consider this during your

risk analysis and reduction strategy. Otherwise, there is a hazard for the operator of the ma-

Page 31

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

31

Limited short-circuit detection in the input circuits

DC (after High) at inputs that are connected to test outputs are detected independently

Make note of this during wiring (e.g. through separate routing or protected lines)!

3.9

3.9.1

ATTENTION

Product description

SP-SDI input/output expansion module

888397323

Description

888398859

The SP-SDI module is an input expansion with eight safe inputs. If fulfills the following tasks:

• Monitoring of connected sensors

For further information:

Connecting devices [ch. 4, p. 37]

• Forwarding of input information to the COMPACT module

Module SP-SDI cannot be operated alone; it always requires an SP-COP COMPACT module

(see "samosPLAN5+" programming software).

It is possible to use multiple SP-SDI modules simultaneously (see

15]

). The voltage of the internal logic and the test outputs is supplied via the program remo-

vable storage and the internal SBUS+.

• One SP-SDI has two test signal generators. One test signal generator is responsible for

the odd-numbered test outputs (X1, X3, X5, and X7), while the other is responsible for

the even-numbered test outputs (X2, X4, X6, and X8).

• Short-circuits between test signal generators of an SP-SDI or SP-SDIO expansion module

are detected. Between different modules the short circuit detection is then only ensured

if the test gaps of the test signal generators are < 4 ms, the test periods ≥ 200 ms and no

more than 9 modules (SP-SDI / SP-SDIO) have been plugged in. Short-circuits after 24

V

of the length of the test gaps.

• Please ensure that the odd-numbered test outputs (X1, X3, X5, and X7) at the SP-SDI are

connected to a common test signal generator and that the even-numbered test outputs

(X2, X4, X6, and X8) are connected to another common test signal generator. Therefore,

short-circuits between the odd-numbered test outputs (X1, X3, X5, and X7) cannot be detected. The same applies accordingly to the even-numbered test outputs (X2, X4, X6, and

X8).

System setup [ch. 3.2, p.

Page 32

Product description

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

32

NOTICE

• The LEDs of inputs I1 to I8 indicate the state of the inputs at an update rate of about 64

ms.

Terminal

assignment

X1/X3

Test signal 1

X2/X4

Test signal 2

I1 – I4

Inputs 1 to 4

X5/X7

Test signal 1

3.9.2

3.9.3

Display elements and terminal assignment

888399883

Illustration 13: SP-SDI display elements

Flashing codes

Further information:

SDI) [ch. 10.3.2, p. 65]

Terminal assignment

Table 12: SP-SDI terminal assignment reference

I5 – I8

X6/X8 Test signal 2

Internal circuits

888402571

Device state and LED displays in the expansion modules (SP-SDIO, SP-

Inputs 5 to 8

Illustration 14: Internal SP-SDI circuits: Safety inputs and test outputs

Page 33

Product description

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

33

3.10

3.10.1

SP-DIO input/output expansion module

1126263051

Description

1126271883

The SP-DIO module is an input/output expansion with four non-secure inputs, four non-secure

outputs and 4 non-secure input/output combinations whose function is configured using the

samosPLAN5+ software.

The SP-DIO module offers the following functions:

• Monitoring of connected devices and sensors

For further information:

Connecting devices [ch. 4, p. 37]

• Forwarding the input information to the main module

• Receipt of control signals from the main module and corresponding switching of outputs

The SP-DIO module cannot be operated alone; it always requires an SP-COP COMPACT module (see "samosPLAN5+" programming software).

It is possible to use multiple SP-DIO modules simultaneously (see

15]

). The voltage of the internal logic is supplied via the system connector and the internal

System setup [ch. 3.2, p.

SBUS+ bus. The voltage of the Y1–Y4 and IY5–IY8 outputs of the SP-DIO must be supplied directly via A1/A2 at the respective module.

Refresh rate

The LEDs of the I1–I4 inputs and the Y1–Y4 outputs or the inputs/outputs combination show

the state with a refresh rate of approx. 4 ms.

Restricted selection of inputs

Only the single-channel inputs are available to be selected in the configuration for the SP-DIO

expansion module, for example:

Illustration 15: Single-channel inputs for the 'SP-DIO' expansion module

Page 34

Product description

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

34

Terminal

assignment

A1

24 V

A2

GND

I1–I4

non-secure inputs 1 to 4

IY5–IY8

non-secure inputs/outputs combination 5 to 8

Y1–Y4

non-secure outputs 1 to 4

3.10.2

Display elements and terminal assignment

1126324875

Illustration 16: SP-DIO display elements

Flashing codes

Further information:

10.3.3, p. 65]

Terminal assignment

Table 13: SP-DIO terminal assignment reference

Device state and LED displays of the expansion module (SP-DIO) [ch.

Page 35

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

35

Internal circuits

3.10.3

1126341003

Product description

Illustration 17: Internal switching circuit of the SP-DIO: non-secure inputs

Illustration 18: Internal switching circuit of the SP-DIO: non-secure outputs

Illustration 19: Internal switching circuit of the SP-DIO: non-secure inputs/outputs combination

Page 36

Product description

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

36

ATTENTION

Use of the IY5–IY8 inputs/outputs

When using the combination connections as input, the signal input voltage to IY5–IY8 may

never be greater than the supply voltage to A1/A2.

Page 37

Connecting devices

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

37

Loss of safety function due to incorrect configuration!

The configuration of the safety application must be precisely adapted to the circumstances of the system or machine to be monitored.

off time of the connected sensors must be longer than the

the sensors.

Protect single-channel inputs against short-circuits and cross-connections!

Because of this, note the following specifications for single-channel signals with test pulses:

This must be noted in particular for the following inputs:

4

Connecting devices

888405259

This section describes the connection of safety sensors and actuators to the samosPRO system and provides setup information for selected functions.

The samosPRO system supports applications up to Performance Level PL e (as per EN ISO

13849-1) and up to Safety Integrity Level SIL CL3 (as per EN 62061).

The level of safety actually achieved depends on the external wiring, the implementation of the

wiring, the parameterization, the selection of the safety sensors, and their arrangement on the

machine. To this end, consider all of the required boundary conditions and evaluate them, for

example, in a Failure Modes and Effects Analysis (FMEA).

You can find additional information to be noted during the electrical installation here:

installation [ch. 7, p. 57]

Electrical

ATTENTION

ATTENTION

Important information

Carefully plan and implement configuration!

• Check to ensure that the configured safety application monitors the machine or system

as you have planned and whether the safety of a configured application is being ensured

at all times. This must be ensured in all operating modes and for all sub-applications.

Document the results of this test!

• Be sure to note the instructions for commissioning and daily testing in the operating instructions for the safety equipment integrated into the safety application.

• Note the warning information and function descriptions for the safety equipment connected to the safety control. When in doubt, contact the respective manufacturer of the safety equipment.

• Note that the minimum switchexecution time of the logic function (for further information, see the "samosPLAN5+

Software" manual (BA000968), Time values and logic execution time).

In this way you will ensure that the samosPRO system can detect the switching of sensors. The minimum switch-off time of sensors is typically listed in the technical data for

When a short-circuit to high occurs at a single-channel input with test pulses that were previously low, this signal can then look like a pulse for the logic. A short-circuit to high means

that the signal is first to high and then is back to low after the error detection time. A pulse

can be generated due to the error detection.

• If the short-circuit to high occurs at a single-channel input with test pulses that was previously high, this signal for the logic then looks like a delayed falling edge (transition from

high to low).

• When a single-channel input is used and an unexpected pulse or a delayed falling edge

(high to low) at this input can lead to a state causing a risk, then you must undertake the

following measures:

– Protected cabling for the signal in question (in order to prevent cross-connections with

other signals)

– No cross-connection detection, i.e. no connection with a test output

– Input reset at the function block reset

– Input restart at the function block restart

– Input restart at the function blocks for press applications (eccentric press contact mo-

nitor,

– contact monitor for universal presses, cycle mode, press setup, single stroke monito-

ring, press automatic mode)

Page 38

Connecting devices

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

38

NOTICE

• When using an odd-numbered test output, odd-numbered inputs must be used, while

You have to use the test outputs of the module at which the device to be tested has been

connected.

– Input override at a function block for muting

– Input reset at a function block for valve monitoring

– Resetting of inputs to zero and setting at a start value on an event counter function

Report function in samosPLAN5+

After project planning, you will receive the following documentation in samosPLAN5+ under

"Info -> Report":

• Logic report

• List of parts

• Wiring information

Table 14: Excerpt from exemplary documentation in samosPLAN5+

block

even-numbered inputs must be used when using an even-numbered test output.

•

Page 39

Connecting devices

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

39

Electrical connection: Example from samosPLAN5+

without testing

Channel 2: Contact between 24 V and I4

Function

Info

Testing

Possible

tion/cascading

max. line resistance of 100 Ω

NOTICE

You can find additional information in the operating instructions for the SNH emergency stop

button.

Electrical connection: Example from samosPLAN5+

Channel 2: Contact between Ub and I4

Channel 2: Contact between T2 and I6

4.1

4.1.1

4.1.2

Safety command devices and electromechanical safety switches

888411275

Emergency stop buttons (e.g. SNH series)

888412811

Table 15: Connection

Single-channel,

Contact between 24 V and I1

Single-channel,

Contact between T2 and I2

with testing

Two-channel,

without testing

Two-channel,

with testing

Channel 1: Contact between 24 V and I3

Channel 1: Contact between T1 and I5

Channel 2: Contact between T2 and I6

The pre-configured two-channel emergency stop buttons in samosPLAN5+ have equivalent

switching contacts. In order to implement two-channel complementary switching contacts,

you can find corresponding elements in the element window under the group of potential-free

contacts.

Table 16: Functions

Series connec-

Max. number of emergency stop buttons switched in series: note

Synchronous time 4 ms to 30 ms

Electromechanical safety switch without lock (e.g. SMS series)

888420491

Table 17: Electromechanical safety switch connection

Single-channel,

Contact between Ub and I1

without testing

Single-channel,

Contact between T2 and I2

with testing

Two-channel,

Channel 1: Contact between Ub and I3

without testing

Two-channel,

Channel 1: Contact between T1 and I5

with testing

Page 40

Connecting devices

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

40

Electrical connection: Example from samosPLAN5+

Inductor at Q1

Inductor at Q3

Inductor at Q1

Function

Info

tion/cascading

determined by the max. line resistance of 100 Ω.

Synchronous time

4 ms–30 s

NOTICE

You can find additional information in the operating instructions for the electromechanical

safety switches.

4.1.3

Electromechanical safety switch with lock (e.g. SIN series)

888428171

Table 18: Connection of locks

Single-channel,

without testing

Contact between Ub and I1

Single-channel,

with testing

Contact between T2 and I2

Two-channel,

without testing

Inductor at Q2

Channel 1: Contact between Ub and I3

Channel 2: Contact between Ub and I4

Two-channel,

with testing

Channel 1: Contact between T1 and I1

Channel 2: Contact between T2 and I2

Table 19: Functions with electromechanical safety switches and locks

Testing Possible

Series connec-

The max. number of emergency stop buttons switched in series is

Page 41

Connecting devices

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

41

Electrical connection: Example from samosPLAN5+

NC 2: between Ub and I2

NO 2: between Ub and I4

Function

Info

Series connection

Not possible

Synchronous time

4 ms–30 s

NOTICE

You can find additional information in the operating instructions for the respective devices.

4.1.4

Enable switch

888442507

Table 20: Enable switch connection

2 positions,

NC 1: between Ub and I1

without testing

2 positions,

with testing

3 positions,

without testing

NC 1: between T1 and I3

NC 2: between T2 and I4

NC 1: between Ub and I1

NC 2: between Ub and I2

NO 1: between Ub and I3

3 positions,

with testing

NC 1: between Ub and I5

NC 2: between Ub and I6

NO 1: between T1 and I7

Table 21: Functions

NO 2: between T2 and I8

Testing Possible

Page 42

Connecting devices

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

42

Electrical connection: Example from samosPLAN5+

NOTICE

You can find additional information in the operating instructions for two-hand control.

4.1.5

4.1.5.1

4.1.5.2

Two-hand control

888450187

Table 22: Two-hand control connection

Type IIIA,

without tes-

Channel 1: Contact between 24 V and I1

Channel 2: Contact between 24 V and I2

ting

Type IIIC,

without testing

NO (normally open contact) between 24 V

and I6 (I8)

NC (normally closed contact) between 24

V and I5 (I7)

888454539

Type IIIA

With type IIIA, two equivalent inputs (make NC contacts for both two-hand buttons) are monitored.

A valid input signal is only generated when the ON state (H level) is present at both inputs

within a time of 0.5 seconds (synchronous change, both two-hand buttons actuated) and both

were previously in the OFF state (L level).

888456075

Type IIIC

With type IIIC, two pairs of equivalent inputs (NC (normally closed contact)/NO (normally open

contact) contact pairs for both two-hand buttons) are monitored.

A valid input signal is only generated when the ON state (H/L level) is present at both inputs

within a time of 0.5 seconds (synchronous change, both two-hand buttons actuated) and both

were previously in the OFF state (L/H level).

Page 43

Connecting devices

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

43

Electrical connection: Example from samosPLAN5+

T2 and I2

T2 and I2

Function

Info

Parallel connection

Possible

Series connection

Possible

ATTENTION

Make sure that the switch-off condition is sufficient!

NOTICE

You can find additional information in the operating instructions for the safety mats.

4.1.6

4.1.7

Safety mats and bumper

888457611

Table 23: Safety mats connection

Short-circuit-forming

safety mat in 4-conductor

technology, at test output

Short-circuit-forming

multi-safety mat in 4conductor technology, at

test output

Table 24: Function of safety mats

Channel 1: Contact between

T1 and I1

Channel 2: Contact between

Channel 1: Contact between

T1 and I1

Channel 2: Contact between

The actuation period for safety mats and bumper must be at least as high as the maximum

value for the "test period" of both test outputs used in order to ensure that the switch-off

condition will be detected and that a sequencing error will not occur.

Diode pairs for safety mats

888461963

In order to connect multiple short-circuit safety mats to an SP-COP, SP-SDI, or SP-SDIO module, you have to use the following Wieland terminal block:

Type: WKFN 2.5 E/35 GO-URL

Order No.: 56.703.8755.9

The two internal diodes of this terminal block have a common anode that has to be connected

to a test output (Tn or X) of the SP-COP, SP-SDI, or SP-SDIO module.

In order to connect to independent safety mats, you will need two terminal blocks.

Illustration 20: Block diagram of the internal wiring WKFN 2.5 E/35 GO-URL

Page 44

Connecting devices

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

44

Electrical connection: Example from samosPLAN5+

between 24 V and I2

Function

Info

Testing

Possible

NOTICE

• Operating mode selection switches without test pulses enable 2 to 8 operating modes;

numbered inputs (I2, I4,

selection switches.

Function

Info

Testing

Possible

(BA000968)

4.1.8

4.1.9

Mode selection switch

888464651

Operating mode selection

switch (1 from 2) to 24 V

Channel 1: Contact

between 24 V and I1

Channel 2: Contact

Operating mode selection

switch (1 from 2)

to test

output

Channel 1: Contact

between T1 and I3

Channel 2: Contact

between T2 and I4

operating mode selection switches with test pulses enable 2 to 4 operating modes.

• When wiring the tested operating mode selection switches, note that when using an oddnumbered test output (X1, X3, X5, X7), odd-numbered inputs (I1, I3, I5, I7) must be used;

when using an even-numbered test output (X2, X4, X6, X8), evenI6, I8) must also be used.

• You can find additional information in the operating instructions for the operating mode

Potential-free contacts

888469003

The samosPLAN5+ software provides a series of potential-free contacts for "free" designing of

contact elements. In this manner, you can implement different NO (normally open contact)/NC

(normally closed contact) combinations with and without testing. In addition, there are elements for a start and stop button, reset button, and device monitoring (EDM).

Table 25: Function of potential-free contacts

Series connection Possible

Discrepancy time Further information: "samosPLAN5+ Software" manual

Page 45

Connecting devices

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

45

Electrical connection: Example from samosPLAN5+

Channel 2: Contact between T2 and I4

Electrical connection: Example from samosPLAN5+

NC contact between T2 and I2

Function

Info

Testing

Possible

tion/cascading

test pulse time

Discrepancy time

Preset at 1500 ms

NOTICE

You can find additional information in the operating instructions for the magnetic safety switches.

Electrical connection: Example from samosPLAN5+

Output A at I1

OSSD2 at I4

Function

Info

Inductive switches (serial):

and the correct setting of the test

Inductive switch: No cascading possible

NOTICE

You can find additional information in the operating instructions for the inductive safety switches.

4.2

4.2.1

4.2.1.1

4.2.1.2

4.2.2

Contactless safety sensors

888470539

Magnetic safety switches (e.g. SMA series)

888472075

888473611

Magnetic safety switches with equivalent inputs

Table 26: Connection of magnetic safety switches with equivalent inputs

With testing

888476299

Channel 1: Contact between T1 and I3

Magnetic safety switches with complementary inputs

Table 27: Connection of magnetic safety switches with antivalent inputs

With testing

NO contact between T1 and I1

Table 28: Functions with magnetic safety switches

Series connec-

Inductive safety switches

888478987

Possible; note max. line resistance of 100 µ and correct setting of

Table 29: Inductive safety switch connection

Inductive switch

(serial)

Inductive switch

Table 30: Functions with inductive safety switches

Test input TE at T1

OSSD1 at I3

Testing Necessary with serial inductive switches

Series connection/cascading

Up to six sensors per input. Maximum OFF-ON delay of the cascade

is 10 ms (otherwise, the test gap will lead to switch-off). Note the

maximum line resistance of 100 Ω

pulse time.

Page 46

Connecting devices

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

46

Electrical connection: Example from samosPLAN5+

OSSD2 at I2

Function

Info

tion/cascading

NOTICE

You can find additional information in the operating instructions for the respective transponder switch.

.2.3

4

Transponder switches

888483339

Table 31: Transponder connection

With OSSD

Table 32: Functions with transponders

Series connec-

Possible, depending on type used

OSSD1 at I1

Page 47

Connecting devices

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

47

Electrical connection: Example from samosPLAN5+

Output Q (receiver) at I3

ATTENTION

Note the safety information and protective measures!

Function

Info

Testing

Possible

Note the maximum line resistance of 100 Ω.

NOTICE

You can find additional information in the operating instructions for the type 2 single-beam

safety light barriers.

Electrical connection: Example from samosPLAN5+

Output Q (receiver) at I4

ATTENTION

Route the transmitter and receiver lines outside of the switchbox so that a short-circuit

Function

Info

Note the maximum line resistance of 100 Ω.

NOTICE

You can find additional information in the operating instructions for the type 4 single-beam

safety light barriers.

4.3

4.3.1

4.3.2

Testable single-beam safety light barriers

888486027

Testable type 2 single-beam safety light barriers

888487563

Table 33: Connecting testable type 2 single-beam safety light barriers

SLB type 2

Test input TE (transmitter) at T1

Route the transmitter and receiver lines outside of the switchbox so that a short-circuit

between these lines can be avoided, e.g. route them separately in separate sheathed cables

or protected areas.

Table 34: Functions with testable type 2 single-beam safety light barriers

Series connec-

Possible, depending on the safety light barrier type used

tion/cascading

Testable type 4 single-beam safety light barriers

888490251

SLB type 4

Test input TE (transmitter) at T2

between these lines can be avoided, e.g. route them separately in separate sheathed cables

or protected areas.

Table 35: Functions with testable type 4 single-beam safety light barriers

Testing Required

Series connec-

Maximum of seven pairs per inputs

tion/cascading

Page 48

Connecting devices

Wieland Electric GmbH | BA000966 | 07/2016 (Rev. C)

48

NOTICE

• Select the minimum value for the desired test gap in the settings of the customer-specific

prevent error detection by this test.

NOTICE

Note the installation information in the operating instructions for the respective sensors

and particularly the following points:

tion must absolutely be adhered to.

receiver

4.3.3

4.3.4

Customer-specific testable single-beam safety light barriers

888492939