Page 1

BA000256 12/2012 (Rev. I)

Multifunctional Safety

Switching Device

Modular Electronic

Safety System

with Coding

Page 2

Contents

1 Contents

samos

Safety System

3 About this Manual

41 Terminal Assignment

Assignment of outputs to inputs

Safety-related information, Conditions

of installation

5 Safety Function Blocks

Features of the Safety System

6 samos Overview

System and components

7 Coding of modules

9 Summary Analysis and samos

Guide

Risk assessment and risk

minimization

11 System Functions

Overview of system functions

Relay Output Modules SA-OR

42 Relay Output Module Data

Connection diagram, Notes, Technical

data

44 Interfaces and Operation

Interfaces, Meaning of LEDs

Glossary

45 System Functions

Safety inputs, OR, Muting, Bypass,

Reset, Feedback circuit monitoring,

Enable, Output, Communication,

Diagnosis

Base Modules SA-BM

13 Base Module Data

Connection diagram, Notes,

Technical data, Function diagrams

17 Interfaces and Operation

49

samos

and IEC/EN 61508/EN 62061

Definition of safety integrity level and

demand rate

50 Characteristic safety values

52 Applications and Pictograms

Interfaces, Meaning of LEDs, First

installation and Accepting

configuration, Handling errors

19 Input Circuit Functions

Overview of applications, Evaluating

input circuits, General structure and

signal flow, OR function, Muting

Logic Functions

53 AND Links

of safety inputs, function groups,

function blocks

55 OR Links

of safety inputs

function, Special functions

24 Control Circuit Functions

Starting inhibit, Restarting inhibit,

Reset function, Off delay,

Applications

58 Application Examples

A253, A254, A267, A258, A259, A268

Retriggering, Control inputs

28 Function Blocks

Applications, Terminal assignment,

Overview

Annex

63 Anti-Manipulation Measures,

Error Codes

64 Installing / Removing

Input Module SA-IN

32 Input Module Data

Connection diagram, Notes, Technical

data, Function diagrams

35 Interfaces and Operation

Interfaces, Meaning of LEDs

36 Input Circuit Functions

Evaluating inputs, Standard functions,

Logic functions, Expansion function

Screw terminals pluggable, Spring

force terminals pluggable, Switch

cover SA-COVER

66 Dimensions

67 General Technical Data

Data, Approvals

69 Overview of Devices / Order

Numbers

71 Index

74 Configuration List

___________________________________________________________________________

Validity of the manual as from module revision:

SA-BM : F-01

SA-IN : F-01

SA-OR : D-01

2

© 2010 Wieland Electric GmbH | BA000256 | 12/2012 (Rev. I)

Page 3

A

bout this manual

2 About this manual

About this manual

What Does This Manual Describe?

This manual provides an overview of the functionalities of the modular samos safety

system as a safety processing unit for plant and machines. It describes the individual

modules and the way they function together in the system as a whole with safety sensors,

switches and actuators.. As well as the specific configurations of switches and terminals,

the fundamental methods by which the functions work are also explained in detail.

Relevant application examples help you to use samos in practice, especially in hierarchical

safety zones. The manual also includes installation information, instructions and rules that

must be observed, technical data and interface descriptions, error information, error

handling and instructions for risk analysis.

___________________________________________________________________________

Who Is This Manual For?

This manual contains the information required for proper use of the devices described in it.

The system and its modules must only be installed by properly qualified personnel. The

applicable national norms and regulations must be observed (in Germany VDE). For that

reason this manual is aimed at technically qualified personnel such as mechanical and

electrical engineers, safety reps, PLC programmers, enclosure makers, electrical fitters,

machine and plant operators, setup staff, and service and maintenance personnel.

___________________________________________________________________________

Safety-related Information

The “Caution” symbol is used at various places in this manual.

“Caution” indicates a potentially dangerous situation or state that could – if not avoided –

lead to minor or medium injury. “Caution” is also used to warn against uncertain

operation and potential misuse. “Caution” is also used to indicate situations where

property damage could occur without causing personal injury.

Please observe the following safety rules:

Only trained professional electricians may install, startup, modify, and retrofit this

equipment!

Disconnect supply voltage to the equipment / system prior to starting any work! If

installation or system errors occur, line voltage may be present at the control circuit in

devices without DC isolation!

Observe all electrical safety regulations issued by the appropriate technical authorities or

the trade association.

Opening the housing or any other manipulation will void the warranty.

If the device has been subjected to improper or incorrect use it must no longer be used,

and the guarantee loses its validity. Impermissible conditions include: strong mechanical

stress, for example through a fall, or voltages, currents, temperatures or humidity

outside of the specifications.

Before starting up your machine/plant for the first time, please be sure to check all the

safety functions according to valid regulations, and observe the specified test cycles for

safety equipment.

Take the following safety measures prior to installation, assembly, or disassembly:

Disconnect supply voltage to the equipment / system prior to starting any work!

Lockout/tag the equipment/system to prevent accidental activation!

Confirm that no voltage is present!

Ground the phases and short to ground!

Protect against adjacent live components using guards and barriers!

© 2010 Wieland Electric GmbH | BA000256 | 12/2012 (Rev. I)

3

Page 4

A

bout this manual

Protection type according to EN 60529.

Limited contact protection!

Housing/terminals: IP 40 / IP 20.

Finger-proof (DIN EN 50274).

___________________________________________________________________________

Proper Use

The samos safety system described in this manual serves to protect people, the

environment, the machine and the material according to the valid EU occupational health

and safety directive 89/391/EEC, the machinery directive 2006/42/EC, the use of work

equipment directive 89/655/EEC as well as the statutory regulations and standards

applicable in other countries (e.g. USA with OSHA 29 CFR 1910.xxx safety standards,

OSHA 3067 concepts and technologies for machine safety and NPFA 70, NFPA 79, ANSI

B11 product liability).

If the safety system is properly maintained and used for its intended purpose it will not

normally cause damage to property or present health hazards. However, improper

configuration, installation, maintenance or operation of the system or machine, ignoring the

instructions in this manual, or intervention by insufficiently qualified personnel may result

in connected actuators (such as motors, hydraulic units, etc.) becoming a source of

danger.

The safety system is a state-of-the-art product and is manufactured to recognized safety

requirements. All the same, its use can cause danger to the health and safety of operators

and others, or damage machines, systems or other property.

The safety system must only be used in perfect technical condition for its intended

purpose, with attention given to safety and danger, and observing the information and

instructions given in this manual and the operating instructions supplied with the devices.

Correct transport, storage, installation, operation and maintenance of the system are all

prerequisites for smooth and safe operation of the control system. Malfunctions, in

particular those which may affect safety, must be immediately resolved.

___________________________________________________________________________

Conditions of Installation

The devices must be installed in an enclosure with at least IP54 protection.

The devices must be installed on a mounting rail (EN 50022-35).

The mounting rail must be connected to protective earth (PE).

The system and the system inputs must always be powered by a common power supply

unit.

The external power supply unit must comply with the regulations for safety and

protection extra low voltage systems (SELV, PELV acc. to IEC 60536) and DIN EN 50178

(Electronic Equipment for Use in Power Installations).

___________________________________________________________________________

Exclusion of Liability

The application examples and circuitry suggestions have been developed to the state of

the art and our best knowledge. Nonetheless, Wieland cannot accept liability for the

correctness and completeness of the information. The information does not have the legal

status of guarantees or guaranteed qualities.

___________________________________________________________________________

samos® is a registered brand name of Wieland Electric GmbH.

All rights reserved.

4

© 2010 Wieland Electric GmbH | BA000256 | 12/2012 (Rev. I)

Page 5

samos Safety System

3 samos Safety System

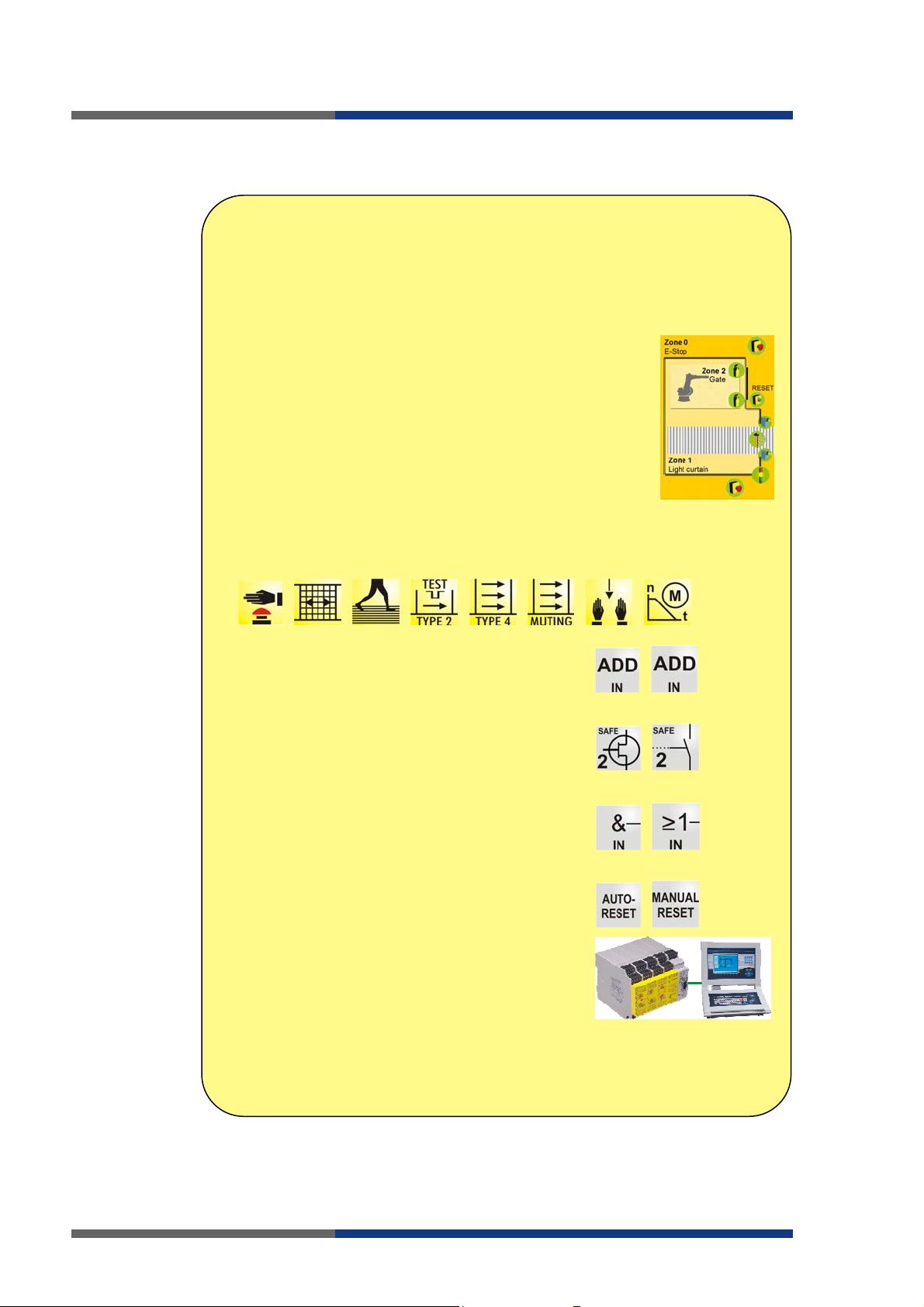

Safety Function Blocks

The

samos

safety system consists of a small number of multifunctional modules and an

optional field bus coupler. This

you add modules as the safety task grows. Sensibly coordinated, combinable function

blocks take the place of singular solutions and isolated specialists.

samos

combines all the safety sensors that monitor your machine/plant safety singly, in

combination or all together.

replaces special devices for monitoring – for example – emergency stop, position

switches, two-hand switches and light barriers.

allows you to create dependent/independent safety zones.

sa

fety modular system is, as the name suggests, modular –

Even a single 22.5 mm base module can operate independently and replace two safety

switching devices. Two

samos

modules replace up to 6 safety switching devices. In the

maximum configuration you can monitor up to 50 dual-channel safety sensors – up to EN

ISO 13849-1 PL e / category 4 or EN 61508/EN 62061 SIL 3.

Handling and function will be familiar from conventional safety switching devices. You

can set all the safety functions simply using a screwdriver – no programming software –

and read them off on the device. If required, you can expand the inputs or outputs using

additional modules.

___________________________________________________________________________

Functions

Emergency stop, with or without cross-circuit monitoring

Safety door monitoring, also with coded electromagnetic switches

Controlled stopping with settable off delay up to 5 minutes, with or without retriggering

Light barrier monitoring with testable/self-testing sensors (non-contact safety device type 2

and 4)

Position monitoring with testable inductive sensors (PDF)

Static valve monitoring

Two-hand applications to EN 574, type IIIA and IIIC

Jog mode

4-wire switching mat monitoring

Muting and bypass

Enabling function for cascading and grouping

Automatic or manual Reset, starting and restarting inhibit

© 2010 Wieland Electric GmbH | BA000256 | 12/2012 (Rev. I)

5

Page 6

samos Safety System

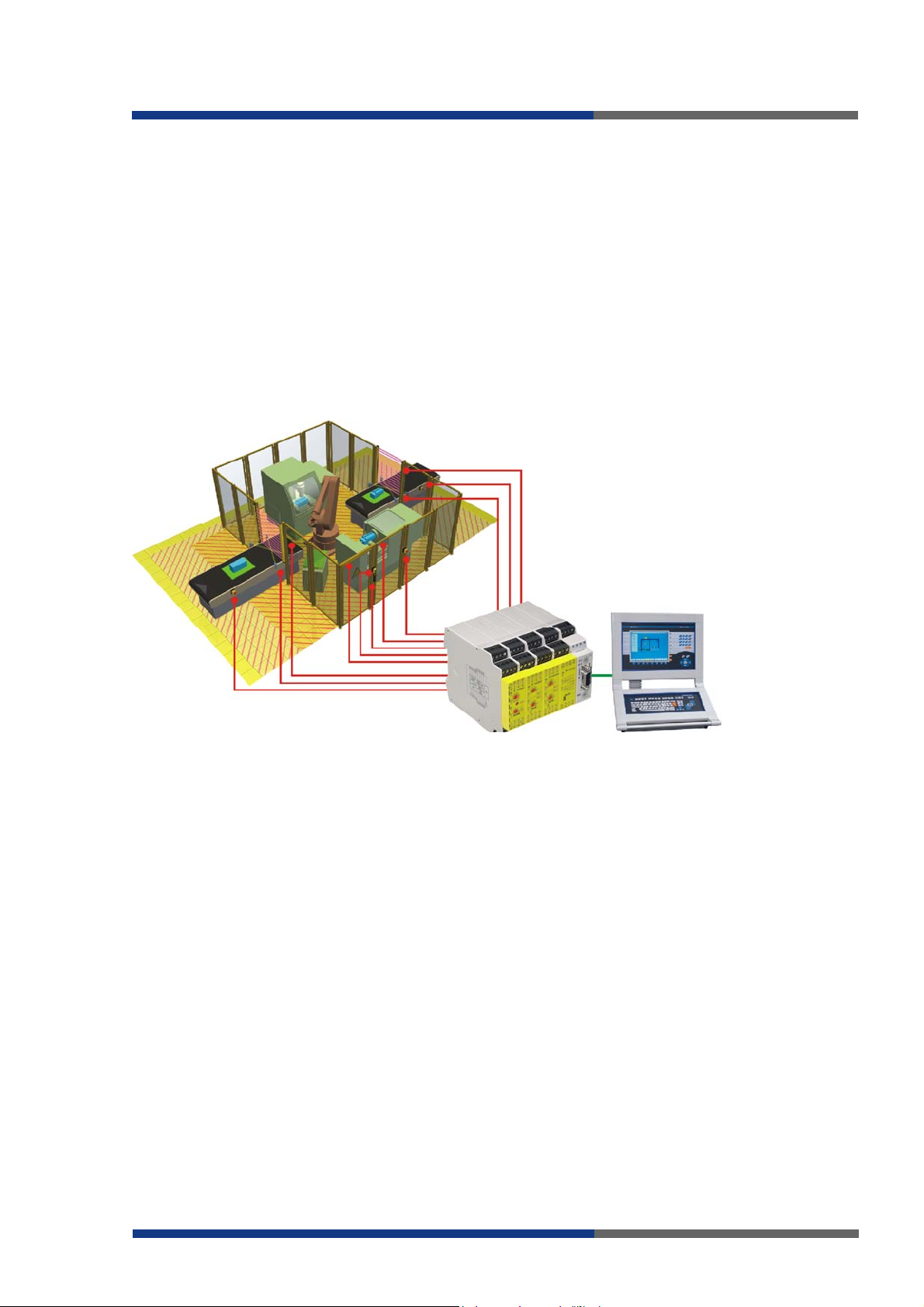

The samos System

Configuration

.

The samos modular safety system is a programmable electronics PE) element of an

electrical/ electronic/programmable electronic system (E/E/PES) as described in IEC/EN

61508/EN 62061. The system comprises base modules, input and output modules, and

bus coupler modules.

The minimum configuration is one SA-BM master base module. You can connect other

active safety modules, passive safety modules and bus coupler modules to the master to

create a system.

Up to 12 active safety modules (SA-IN input modules)

Additionally up to 4 SA-OR passive relay output modules

Additionally 1 bus coupler module

All SA-BM base modules can be expanded with SA-IN inputs and SA-OR relay outputs.

The system groups formed in this way are functionally autonomous and can be wired

together as required.

Structure

In a system the master base module is at the left-hand end, the optional bus coupler

module at the right-hand end. The modules are connected by means of a connector with

proper coding, integrated in the housing. The 24 V power supply is fed in through the

master base module.

6

© 2010 Wieland Electric GmbH | BA000256 | 12/2012 (Rev. I)

Page 7

The coded modules of the samos system

samos Safety System

Accordingly to the applications in a samos overall system hard-coded system groups can

be assembled, whose codings are different and whose logical functions are independent

from each other. Every system group of the overall system consists of a distinctly coded

basic module, which can be amended with input modules of the same coding.

Example of one system group

Basic module

Master (SA-BM-S1)

Input module

(SA-IN-S1)

Input module

(SA-IN-S1)

Output module

Bus interconnection

System group 1

More safety via coding

In our enhanced

samos

IN) is hard-coded according to its system group (1-3) and cannot be applied in other

system groups. Equally coded basic modules cannot be stuck together. Modules SA-BM,

and/or SA-IN in combination with

Germany in an overall system with two or more basic modules of the same coding and at

least one input module, prior to the 17th of April in 2012 (till construction level E-01)

mustn't be applied without approval of the patentee of the German patent 100 20 075.

(more information at http://register.dpma.de/DPMAregister/pat/einsteiger?lang=en)

module

system, every basic module (SA-BM) and every input module (SA-

samos

system modules, which have been delivered in

Coding

© 2010 Wieland Electric GmbH | BA000256 | 12/2012 (Rev. I)

7

Page 8

samos Safety System

Master base module (Coding 1)

The master base module is the obligatory basic element of the samos system. On its own

it functions as a complete safety switching device for monitoring up to 2 safety circuits. It

offers 8 function blocks for inputs and logic functions (set on rotary switch on front), 8

inputs and 4 wear-free semiconductor safety outputs. The system configuration is saved in

the master. Errors and unauthorized alterations cause safety shutdown of the whole

system.

___________________________________________________________________________

Input module (Coding 1)

The input module adds additional input circuits or logic functions to a base module on its

left. The module has two function groups, A and B, each with 4 inputs. You have to set

one of 10 functions for each group using the rotary switch.

___________________________________________________________________________

Relay output module

The output module adds potential-free output safety circuits with positively driven relay

contacts to expand the base module outputs. The module does not function as a slave on

the internal safety bus of the samos system. Instead it is integrated in the functions via

external wiring. It can therefore be positioned anywhere between the master base module

and the (optional) bus coupler module.

___________________________________________________________________________

Bus coupler module

The bus coupler module for the Profibus-DP field bus allows system information for

diagnosis purposes (input levels, error and status information) to be sent to other bus

stations (e.g. higher-order controller). There is a separate manual for the bus coupler

modules (see page 70).

___________________________________________________________________________

8

© 2010 Wieland Electric GmbH | BA000256 | 12/2012 (Rev. I)

Page 9

samos Safety System

Summary Analysis

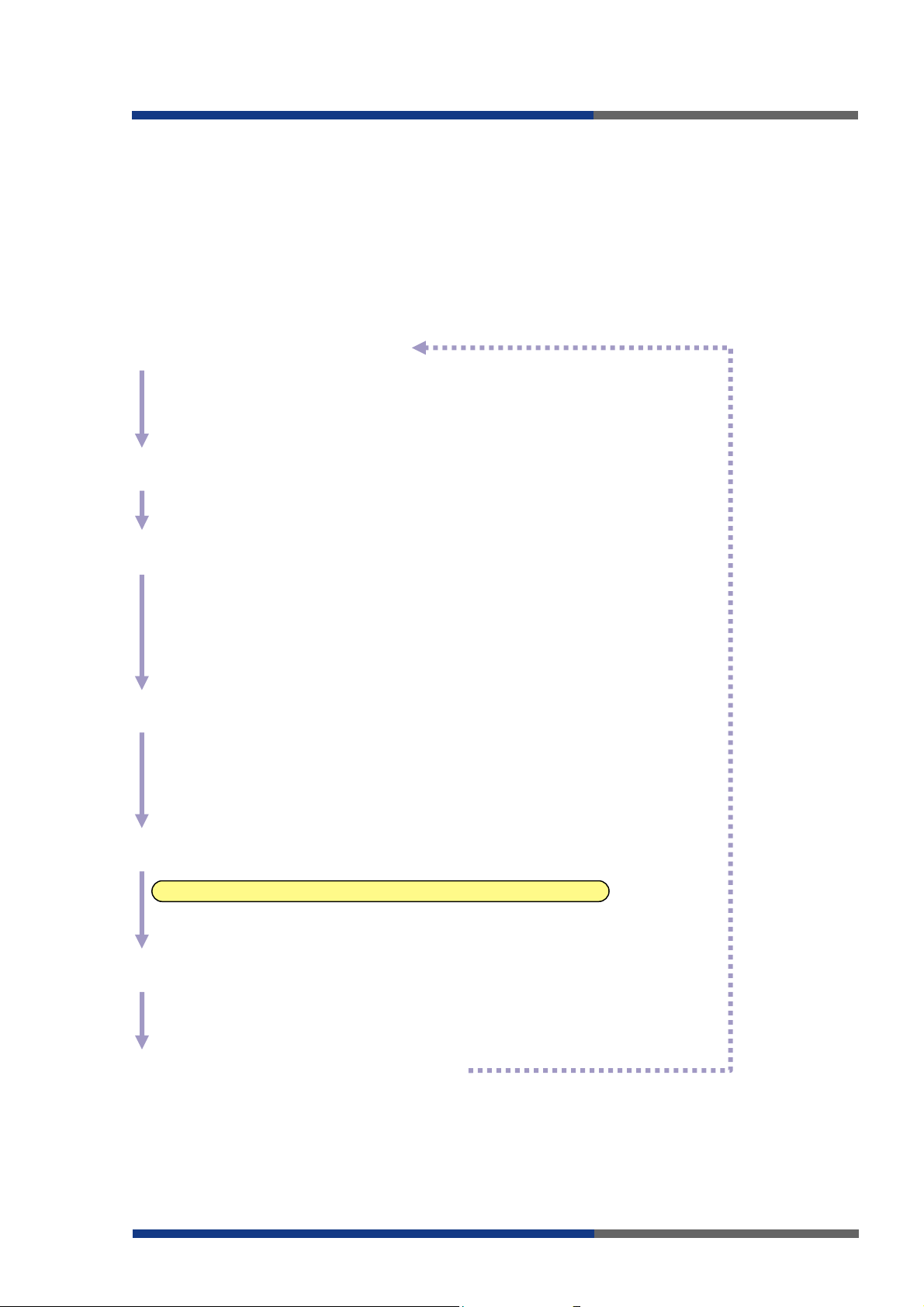

Risk assessment and risk minimization for plant and machines

This simplified description outlines the basics of risk analysis for planners and designers.

For more detailed information please consult the relevant norms.

Determining the limits of a machine

Proper use

Spatial limits (transport, assembly, installation, power supply, material feed)

Temporal limits (working life, servicing intervals, ...)

Identifying dangers

Crushing, shearing, electric shock, poisoning, burns, ...

Assessment of all danger situations

Operator-machine relationship

Operating states

Servicing, maintenance, disassembly, disposal

Wear

Predictable misuse, ...

Risk assessment

Extent of damage

Persons in danger zone

Probability of danger occurring

Possibilities of avoiding/limiting damage

Select measures for risk minimization

Design measures

Technical measures

User information, warnings, operating hints, ...

Determine residual risks

Test effectiveness of safety measures

Validate acc. to EN ISO 13849-2

If necessary introduce additional measures

to reduce residual risk to an acceptable level.

Risk analysis

e.g. as per

EN ISO 12100

Risk assessment

and minimization

e.g. as per

EN ISO 14121

© 2010 Wieland Electric GmbH | BA000256 | 12/2012 (Rev. I)

9

Page 10

samos Safety System

You can find examples

for logic functions on

page 53ff.

You can find an overview

of applications on page

19 and 36.

You can find descriptions

of input modules on page

32ff.

You can find descriptions

of base modules on page

13ff,

relay output modules on

page 42ff.

You can find examples

for logic functions on

page 53ff.

You can find the

descriptions of reset

behavior on page 24ff.

Bus coupler modules are

described in a separate

manual. You can find the

order numbers on page

70.

samos

Guide

The technical measures for reducing the risk of dangerous states and damage to the

machine or material include the electrical equipment. The required level of risk

minimization and consequently the requirements of the safety-related parts on the

controller are determined for example according to EN ISO 13849-1 (here controller

category.

Creating safety zones

In risk analysis the machine is often divided into different safety

zones, which may have different risk potentials. The zones are

linked by safety logic functions so that only the necessary parts

of the machine are shut down when a safety event occurs.

Selecting safety devices and safety functions

for monitoring the safety equipment and safety zones. Selection

of stop category 0 and/or 1 (EN 60204-1).

Select function blocks and input circuit functions for the application on the samos

base module.

How many safety sensors and safety circuits

must also be monitored?

Select input expansions.

How many additional safety outputs are needed?

Select outputs on base module (semiconductor)

or output expansion (relay contacts)

Link safety zones

and function blocks in the samos system.

Select Reset behavior

for powering up and after safety event.

Select optional field bus function

as diagnosis function.

10

© 2010 Wieland Electric GmbH | BA000256 | 12/2012 (Rev. I)

Page 11

samos Safety System

System Functions

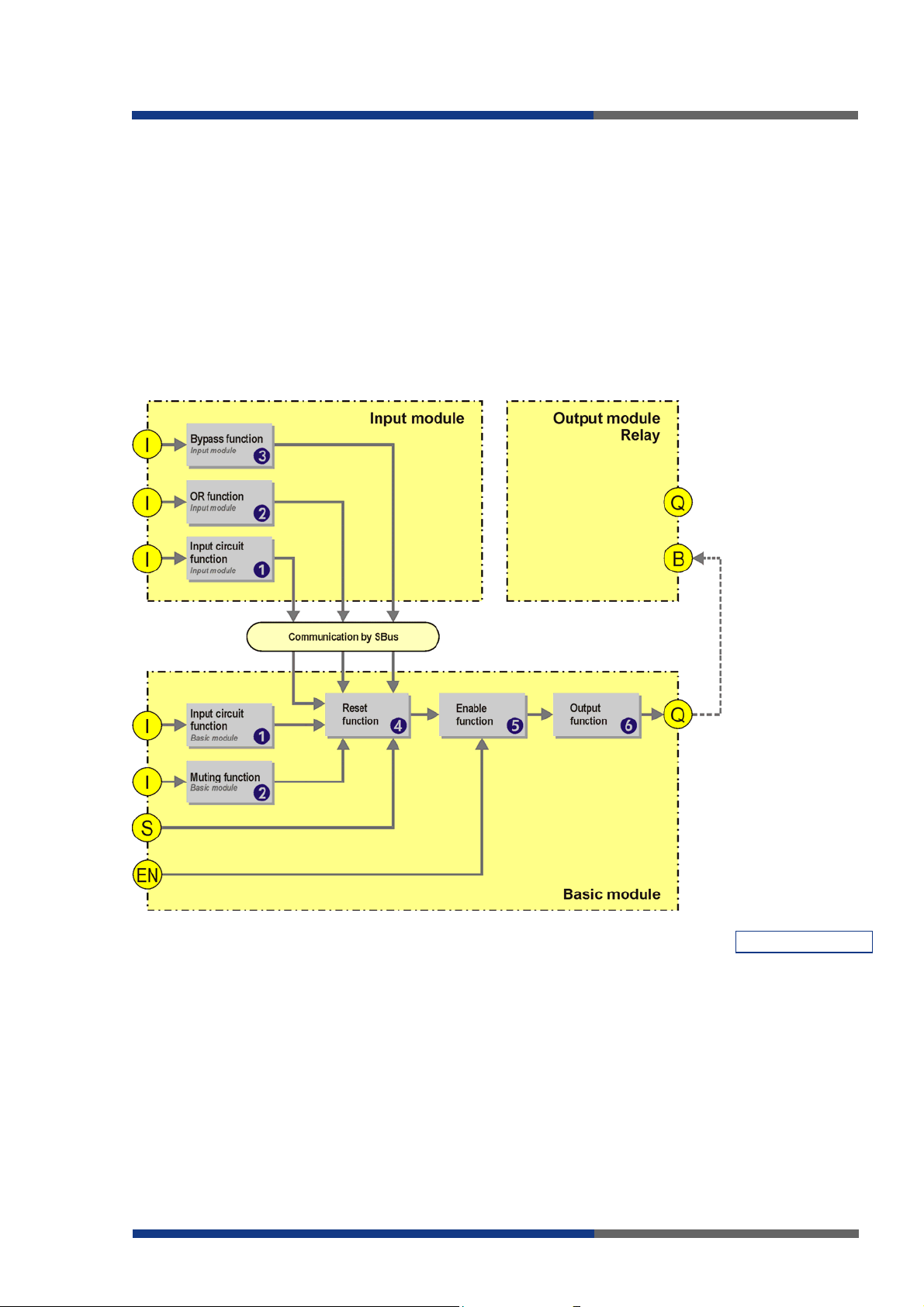

The samos safety system is for monitoring sensors as part of the safety equipment of

machines. The safety function (e.g. an emergency stop function) is implemented by

switching outputs Q on or off safely in relation to the state of the sensors on inputs I, EN

(enable) and S (Reset condition). Switching these outputs on/off prevents dangerous states

occurring in the plant/ machine.

The safety function is made up of a chain of logically linked functions. The input

modules communicate with the associated base module (on the left) via the internal safety

bus (SBus). The relay output modules are not integrated directly via the SBus in the samos

safety communication system. However, indirect monitoring is possible via the feedback

circuits.

Input circuit function

The input circuit function logically links input signals for further processing. There are

different methods for activation:

Input circuit function single-channel via NC contact

Input circuit function with dual-channel equivalent activation,

with/without cross-circuit monitoring, with/without synchronous time monitoring

Input circuit function with dual-channel non-equivalent activation,

with/without cross-circuit monitoring, with/without synchronous time monitoring

Two-hand function with activation by one NO contact per hand (EN 574, IIIA)

Two-hand function with activation by NO/NC combination for each hand (EN 574, IIIC)

Dual-channel equivalent activation by semiconductor

© 2010 Wieland Electric GmbH | BA000256 | 12/2012 (Rev. I)

Safety inputs

11

Page 12

samos Safety System

OR

Muting

Bypass

Reset

Enable

Safety outputs

Diagnosis

OR function and muting function

The off signal of an input function can be bridged with an OR signal. For example, in setup

mode a safety function can be bridged using an enabling button; an OR operation can also

link two safety functions.

The muting function is a special case of the OR function. For example, muting sensors

allow a conveyor belt to transport material through a light curtain by briefly bridging the

light curtain function.

___________________________________________________________________________

Bypass function

With a bypass signal the OFF signal of a Reset function (see page 47) can be changed into

an ON signal in the base module. Bypass is used when the system is to be switched on

after a power shutdown but a light barrier is obstructed by material. Bypass cancels the

safety function of the safety device, allowing the blockage to be cleared. In normal

operation the muting function bridges automatically (see above).

___________________________________________________________________________

Reset function

The Reset function defines which (Reset) conditions must be fulfilled if, for example, an

ON signal is to be passed on to the Reset function output. All input and muting signals

from the base module and the associated input modules, and the bypass/OR signals from

the input modules are logically linked (AND/OR). The terminal configuration with bridges

and feedback circuits is also evaluated.

___________________________________________________________________________

Enable function

The enable function enables the ON signal in the Reset function if there is H-level on the

EN input. The H-level for enabling can be generated, for example, by a semiconductor

output Q

applications (EN ISO 13849-1) the module that generates the enabling signal must be in the

same enclosure. If the EN input is open or on L-level the following Q

outputs are locked.

on the base module for logic operations or a PLC output. For category 4

n

___________________________________________________________________________

Output function

The time behavior of the safety ON/OFF signal is defined in the output function. Depending

on the function, you can set a off delay for outputs Q3 or Q3/Q4 between 0 and 5 minutes

(depending on module version).

___________________________________________________________________________

Communication

With the communication function system data is exchanged between the different

modules in a system via the internal safety bus (SBus).

___________________________________________________________________________

Diagnosis and display function

The diagnosis function allows internal system data to be provided to external systems via a

diagnosis module or bus coupler module.

semiconductor

n

NOTE

12

For detailed explanations of system functions and other hints and examples please refer to

the glossary on page 45ff.

© 2010 Wieland Electric GmbH | BA000256 | 12/2012 (Rev. I)

Page 13

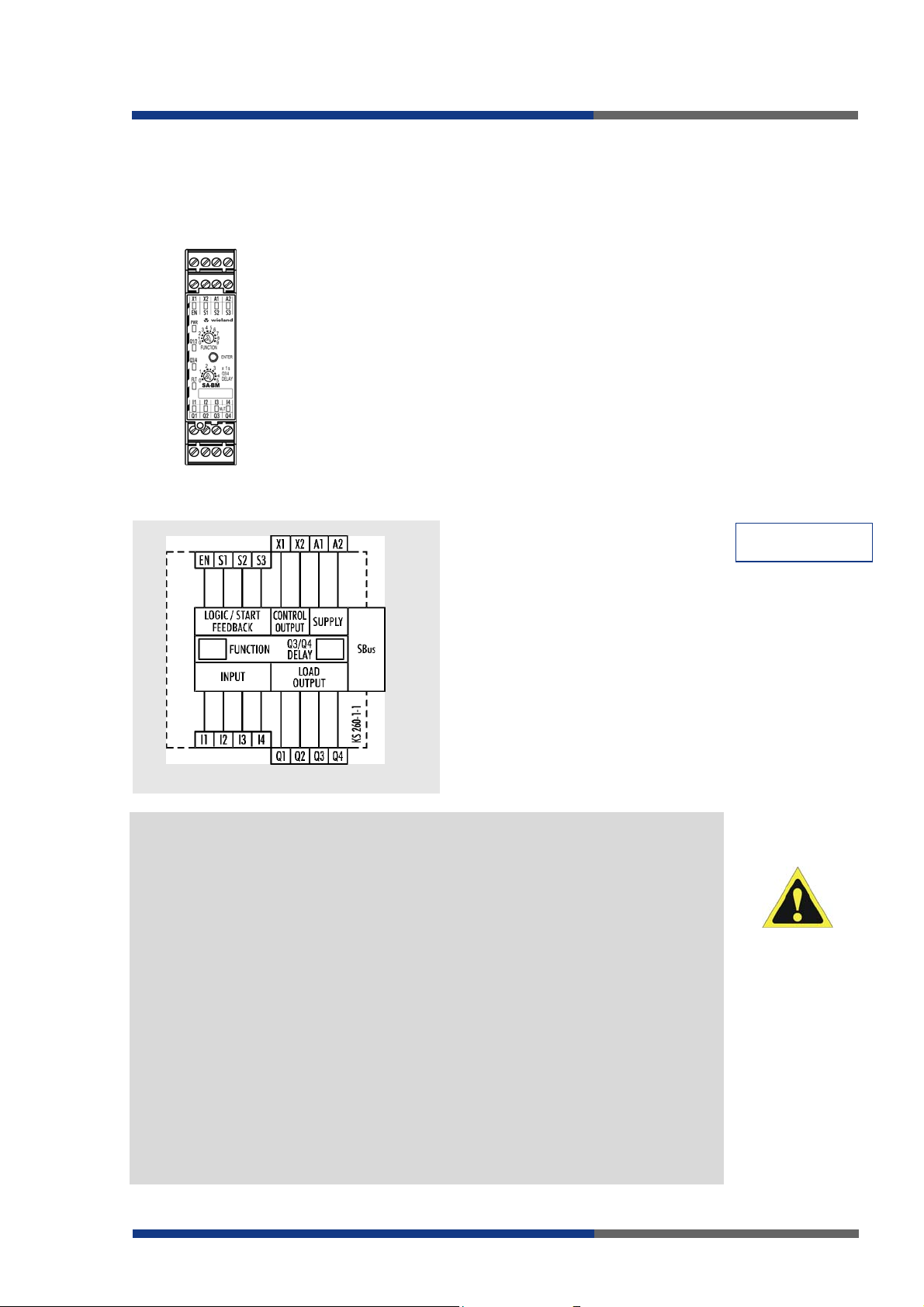

4 SA-BM Base Module

Base Module Data

SA-BM-S1

SA-BM-S1

SA-BM-S1

The controller category (EN ISO 13849-1) or SIL (EN 61508/EN 62061) depends on the

external circuitry, the wiring, the choice of control devices and their location on the

machine.

In the event of single-channel control of a contact extension (e.g. SA-OR) through a base

module (SA-BM), category 4 according to EN ISO 13849-1 can be achieved if both

devices are installed in the same enclosure.

The SA-BM must be protected with a 6 A fuse of utilization category gG or a 6 A (4 A)

circuit-breaker (tripping characteristic B or C).

The rotary switches for selecting function and time must only be adjusted when power is

off.

Never connect or disconnect modules while the operating voltage is switched on.

If external contactors or relays are connected, the feedback circuits (NC contacts) must

be connected to the base module.

When inductive loads are connected (e.g. valves, contactors) a suppressor circuit must

be set up (e.g. RC combination).

Internal samos module addresses are assigned automatically when the system starts up.

Manual addressing is unnecessary (and not possible).

The safety system must be installed in an enclosure with at least IP 54 protection.

Each base module forms a system group within the overall system (sometimes together

with associated input expansion modules; see diagram on page 8).

Master base module

The SA-BM master base module is the obligatory

module of the samos system. On its own it functions

as a complete safety switching device for monitoring

up to 2 safety circuits.

Connection

diagram

Notes

© 2010 Wieland Electric GmbH | BA000256 | 12/2012 (Rev. I)

13

Page 14

SA-BM Base Module

A

S

SA-BM

technical data

* For the times, see the

function diagram at the

end of the table

The sum of currents,

which are drained from

the outputs X1, X2 of all

Base modules to supply

external sensors, may not

exceed 600 mA!

-BM-S1

Function

Function display 11 green LEDs, 1 red LED

Controls 2 10-position switches, 1 1-position button

Terminals Plug-in terminals with screws / spring force

Max. number of modules / status in system 1 / SBus master

Max. number of parallel-connected module inputs

that can be controlled from one module

In or S

n

output X

or Qn

n

___________________________________________________________________________

Power circuitry (

Operating voltage U

Residual ripple V

Rated power, DC

Peak current I

Ready time t

Device fuse

___________________________________________________________________________

Input circuit (I1..I4, EN, S1..S3) Min. Typical Max.

Input voltage, U

(LOW)

Input current, I

(LOW)

Cyclical peak input current, I

Input capacitance, C

Input resistance, R

ON period* t

OFF period* t

Break time of U

Break time period

Synchronous time t

Synchronous time t

Duration of operation Reset inuts S1, S2

___________________________________________________________________________

Output circuit (

Output voltage

Output current

Wire capacitance, C

Wire resistance, R

Type of outputs / short-circuit behavior Semiconductor / absolutely short-circuit-proof

Base module in the samos system

8

A1, A2

) Min. Typical Max.

, DC 19.2 V 24 V 30.0 V

B

3.0 V

SS

1.8 W

P

(after connecting UB) 10 s

ON

25 A

6 A (gG)

(HIGH)

E

13.0 V

30.0 V

–0.5 V

(HIGH)

E

2.4 mA

–2.5 mA

E,Peak

IN

IN

E

A

(test pulses) 1.0 ms

E

15 mA

200 nF

70 ms

> tAN

3.0 mA

8 k

20 ms

(Function 2)

S

(Functions 4, 5.2)

S

1500 ms

500 ms

50 ms 5 s

X1, X2

) Min. Typical Max.

18.0 V 30.0 V

150 mA

L

L

500 nF

100

5.0 V

3.8 mA

2.1 mA

14

© 2010 Wieland Electric GmbH | BA000256 | 12/2012 (Rev. I)

Page 15

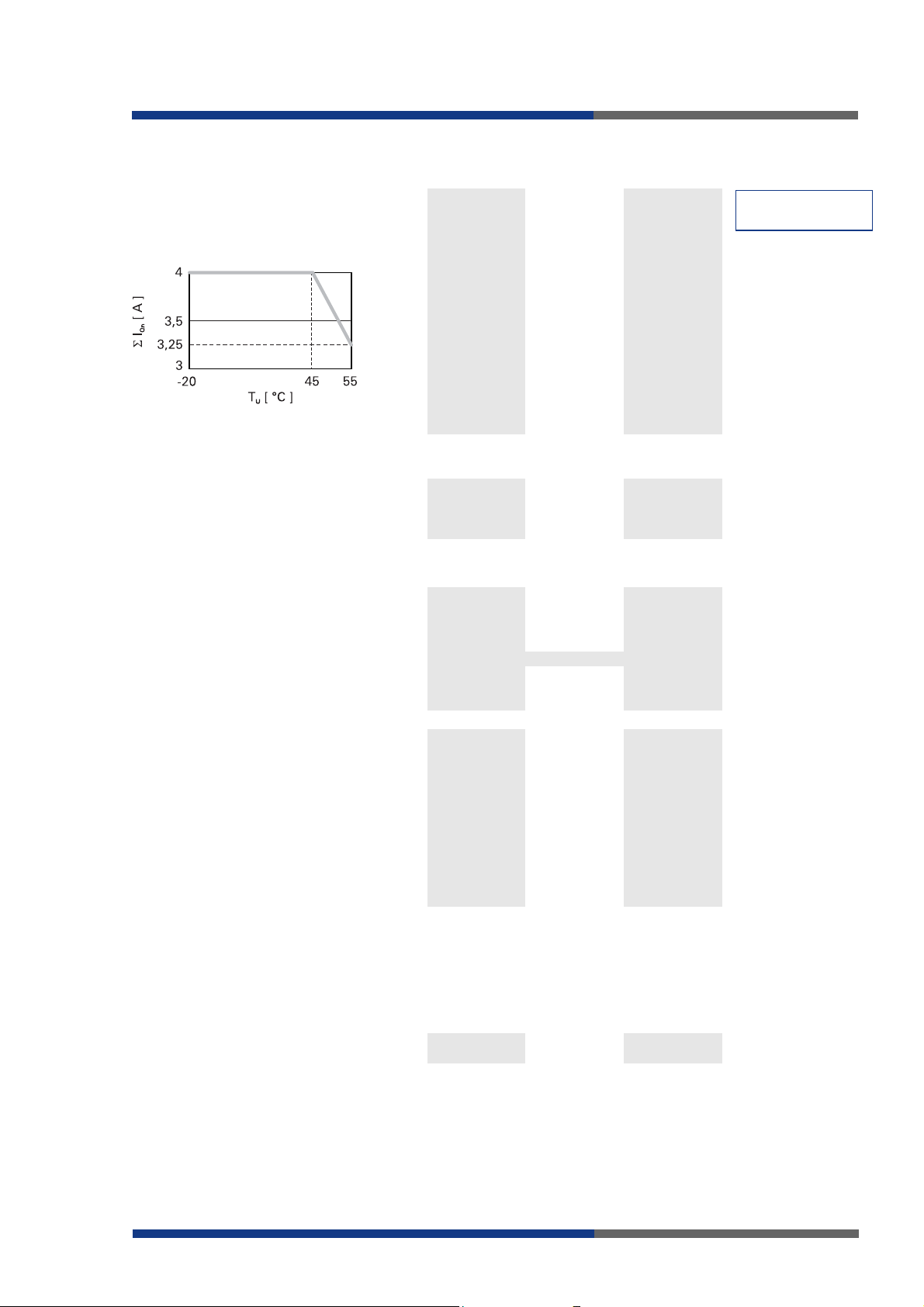

Output circuit (

Output voltage

Output current (with U

Total current (see diagram)

Q1..Q4

) Min. Typical Max.

= DC 24 V) res./ind. 2.0 A

N

SA-BM Base Module

18.0 V 30.0 V

4.0 A

SA-BM

technical data

Diagram "Total current

vs. Temperature"

Inductive switching off energy E (E=0,5*L*I²)

Settable off delay

Q3/Q4 or Q4, t

RV

(depending on device version)

Test pulse width, t

Test pulse period, t

Load capacitance, C

TI,HL

TP,HL

L

Conductor length (single, 1.5 mm

370 mJ

0 / 0.5 / 1 /1.5 / 2 / 2.5 / 3 / 3.5 / 4 / 5 s

0 / 5 / 10 / 15 / 20 / 25 / 30 / 35 / 40 / 50 s

0 / 0.5 / 1 / 1.5 / 2 / 2.5 / 3 / 3.5 / 4 / 5 min

500 μs

32 ms 80 ms

2

)

500 nF

100 m

Type of outputs / short-circuit behavior Semiconductor / absolutely short-circuit-proof

Parallel connection of outputs not allowed

___________________________________________________________________________

Input test tTI, typ. tTD, typ. tTP, typ.

Test pulse width* t

Test duration** t

Test pulse period t

;

TI

;

TD

TP

Function 3.1, 7, 8

Function 3.2 (BWS type 2)

Function 3.2 (PDF sensors)

Functions 1, 2, 4, 5, 6, 9

no test pulses

12 ms

52 ms

12 ms

20 ms

70 ms

20 ms

40 ms

384 ms

40 ms

___________________________________________________________________________

Response times Min. Typical Max.

Response time*** t

Functions 3.1, 7, 8

Function 3.2 (BWS type 2)

Function 3.2 (PDF sensors)

Functions 1 (except safety mat), 2, 4, 5.1, 6, 9

Function 1 (safety mat)

Function 5.2

DISABLE (via EN input)

OR off to Qx off

Function 3 (MUTING off to Qx off)

EN off to Qx off

(normal operation)

AN

13 ms

32 ms

79 ms

20 ms

38 ms

29 ms

13 ms

9 ms

65 ms

13 ms

___________________________________________________________________________

Safety parameters at ambient temperature TB +55 °C

PFD 1.7 x 10

PFH 7.9 x 10-9 h

SFF 96 %

DC 93 %

MTTFd 158 years

-5

-1

___________________________________________________________________________

General data Min. Typical Max.

Enter button ON period

Isolation

Power circuitry – input circuit

Power circuitry – output circuit

Input circuit – output circuit

Weight 0.16 kg

General technical data See page 65.

Order numbers See page 69.

3 s

no

no

no

* Signal changes are not

detected during the test

pulse.

** Signal changes from

HIGH to LOW are not

detected during the test

pulse.

For the times see the

function diagrams at the

end of the table.

*** The response time tAN

is the time between the

OFF signal arriving at the

input terminals and the

outputs actually being shut

down (in normal

operation).

The response times of

any assigned input

modules must also be

taken into consideration.

See input module data,

page 33.

For information on

safety-related

parameters, see glossary

p. 49

© 2010 Wieland Electric GmbH | BA000256 | 12/2012 (Rev. I)

15

Page 16

SA-BM Base Module

A

___________________________________________________________________________

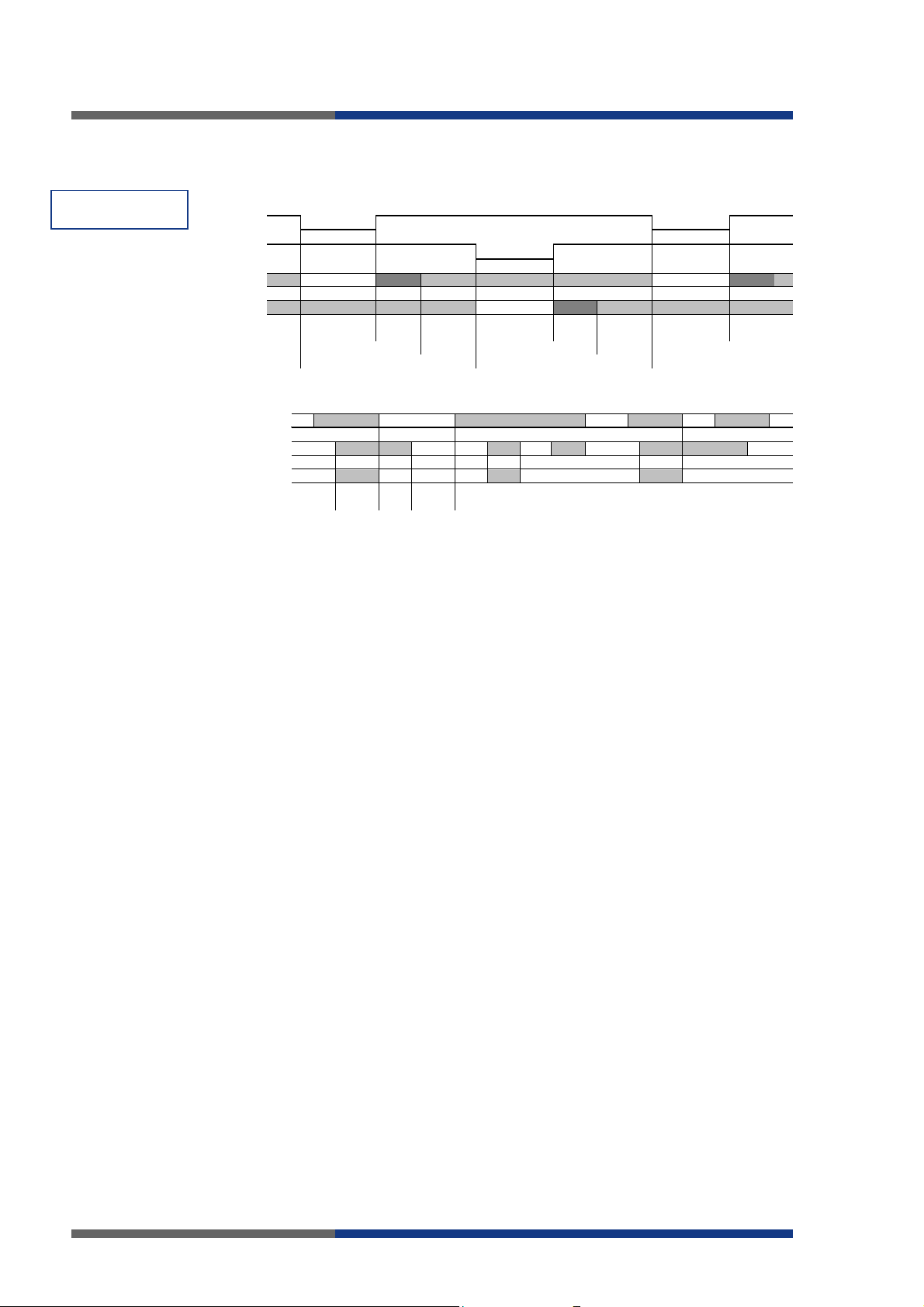

Function

diagrams

tTI : Test pulse width

tTD : Test duration

tTP : Test pulse period

tE : ON period

tA : OFF period

QIN: see page 47

Input test function diagram (with cross circuit monitoring)

Output X1

Output X2

Input I1/I3

Input I2/I4

___________________________________________________________________________

Input circuit function diagram (equivalent activation)

Input I1

Input I2

QIN (good state)

t

TI

t

TD

approx. 0.5

t

E

t

TP

t

t

TI

t

TD

approx. 0.5

t

TP

t

TI

16

© 2010 Wieland Electric GmbH | BA000256 | 12/2012 (Rev. I)

Page 17

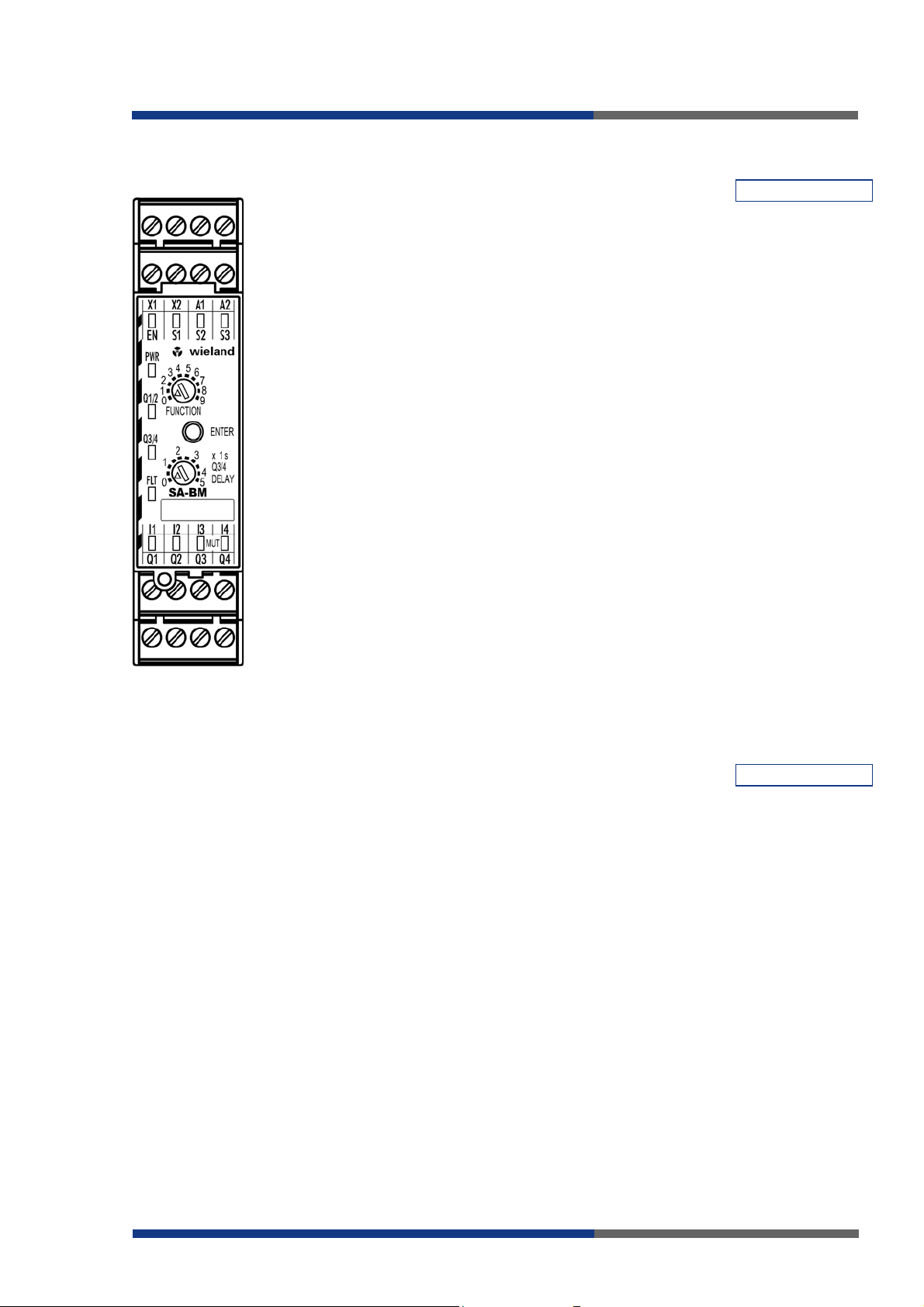

Interfaces and Operation

SA-BM Base Module

Clamps

A1, A2

X1, X2

EN

S1, S2, S3

I1, I2, I3

Q1, Q2, Q3

SBus

Voltage supply of the basic module and the

corresponding extension module (Plus

voltage at A1)

Outputs only for voltage supply of inputs of

the module or rather the control of the

sensors

Input for enabling the outputs

Control inputs for the configuration of mode

of operation and the connection of reset

buttons / feedback circuits

Inputs for the connection of signal

transmitters / sensors

Outputs for the controlling of actuators

10-pin connector for safety bus

- SA-BM: just nut (coded)

Push-buttons

FUNCTION

Q3/4 DELAY

ENTER

S1, S2, S3

LEDs

EN, S1 .. S3, I1.. I4

(green)

PWR (green)

Q1/2, Q3/4 (green)

FLT (red)

8-staged torque switch for adjustment of an

input circuit function

10-staged torque switch for adjustment of

the fall-back delay time

Button for the assumption of system

configuration (just SA-BM)

Indicators of according inputs

Voltage supply

Switching status of the semiconductor

outputs

Indicator of flawed operating modes

(see FLT error codes page 63)

___________________________________________________________________________

PWR on

I1-I4 on

I1, I2 flash simultaneously

I3, I4 flash simultaneously

I1, I2 flash alternately

I3, I4 flash alternately

I1 oder I2 flashes

I3 oder I4 flashes

EN, S1..S3 on

S1..S3 flashes

Q1/2, Q3/4 on

FLT off

Power supply to module electronics is on

H-level on corresponding input

Cross-circuit between I1 and I2

Cross-circuit between I3 and I4

Sequence error on I1, I2

Sequence error on I3, I4

Synchronous time error. The input that flashes is the one

that achieves good state too late.

Synchronous time error. The input that flashes is the one

that achieves good state too late.

H-level on corresponding input

Feedback circuit open

H-level on corresponding outputs, Q3/4 flashes during off

delay time

No fault states

Interfaces

Meaning of LEDs

© 2010 Wieland Electric GmbH | BA000256 | 12/2012 (Rev. I)

17

Page 18

SA-BM Base Module

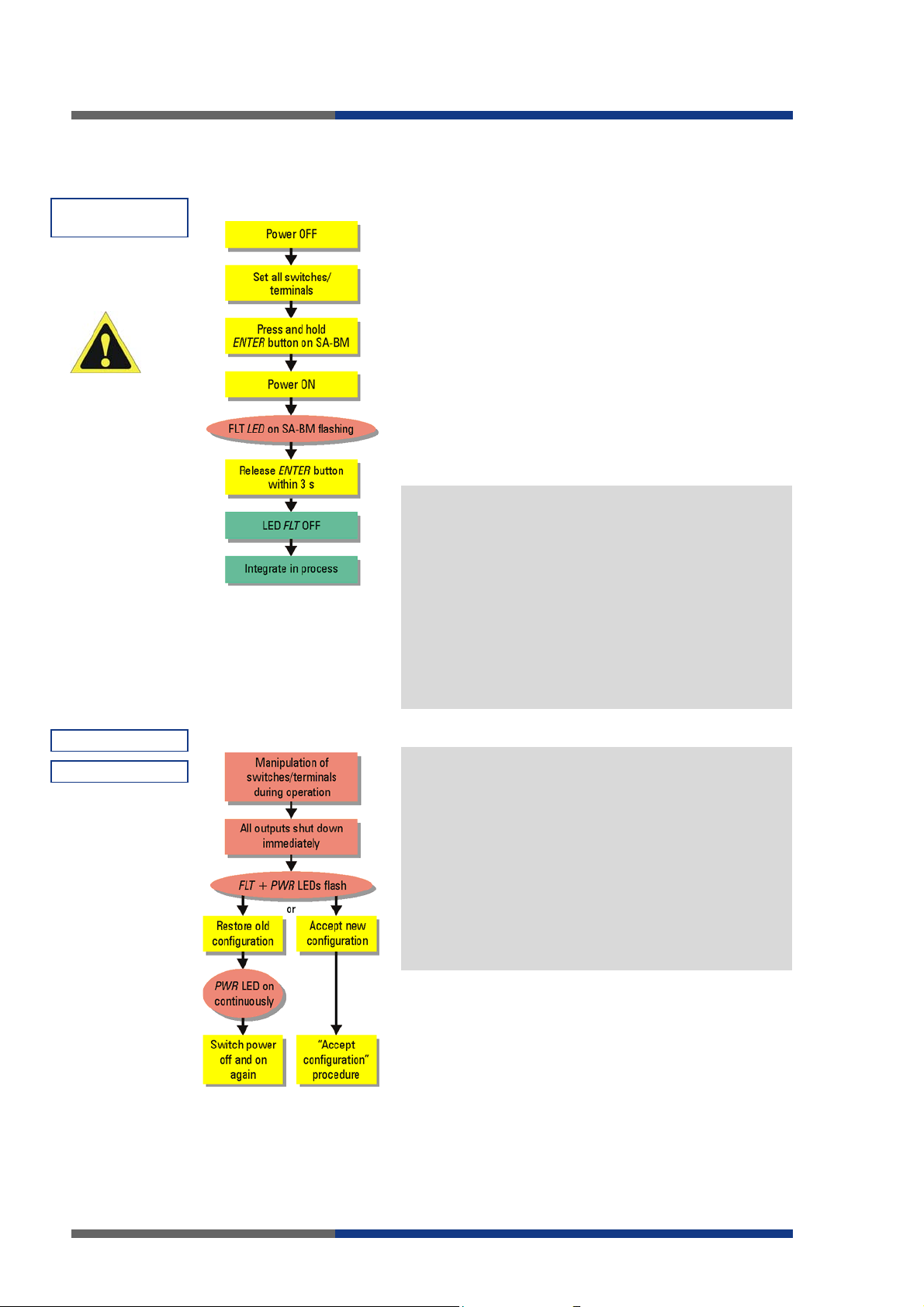

Interfaces and Operation

Accepting

configuration

NOTES

Handling errors

NOTES

There is a blank configuration list for copying

inside the back cover.

Notes on downloading an

online version on page 74.

First installation and Accepting the system configuration

___________________________________________________________________________

Manipulation, handling errors and operating errors during operation

Configurations can only be set or altered using the switches

and terminals when the whole system is switched off, i.e.

when there is no operating voltage on terminals A1/A2 on

any base module. After the required functions and control

circuit functions have been set on all the modules in the

system (using the rotary switches and external circuitry on

terminals S1, S2, S3 respectively), operating voltage must

be connected while the ENTER button on the SA-BM base

module is pressed and held. As soon as the FLT indicator

starts blinking the ENTER button must be released within 3

seconds. Then the selected mode is saved in non-volatile

form and active. If the ENTER button is pressed for longer

than 5 seconds after the LED has started blinking, the FLT

display will indicate a fault (blinking light).

Terminals S1, S2, S3 serve not only to set the mode; they

can also be used for feedback-circuit monitoring of

connected relays and contactors. This means that the

terminal signals change during operation (opened

contact). The set mode remains unaffected because it is

only detected, checked and saved when the system is

switched on or restarted.

Because the relay expansion modules are not directly inte-

grated in the communication or diagnosis of the samos

system via the internal safety bus, changes in their

input/output circuitry are registered only indirectly via the

feedback circuits.

Manipulating the system configuration (e.g. operating a

rotary switch or adding or removing modules causes

immediate canceling of enabling. To assist in setting the

valid configuration the green PWR LED on the module

changes from blinking to continuous when the respective

switch position has been restored. A restart (switch off

and on again) under the set Reset condition is possible

when the former configuration has been restored. The

ENTER key has no effect during operation.

If the new configuration is to be adopted you have to go

through the “accept configuration” procedure described

above.

We recommend keeping a record of the configuration

with the documentation or in a clearly visible place in the

enclosure. One way to check the system configuration is to

output a checksum of the configuration data via a connected

bus coupler module.

There is a separate manual for the bus coupler modules

(see page 70).

18

© 2010 Wieland Electric GmbH | BA000256 | 12/2012 (Rev. I)

Page 19

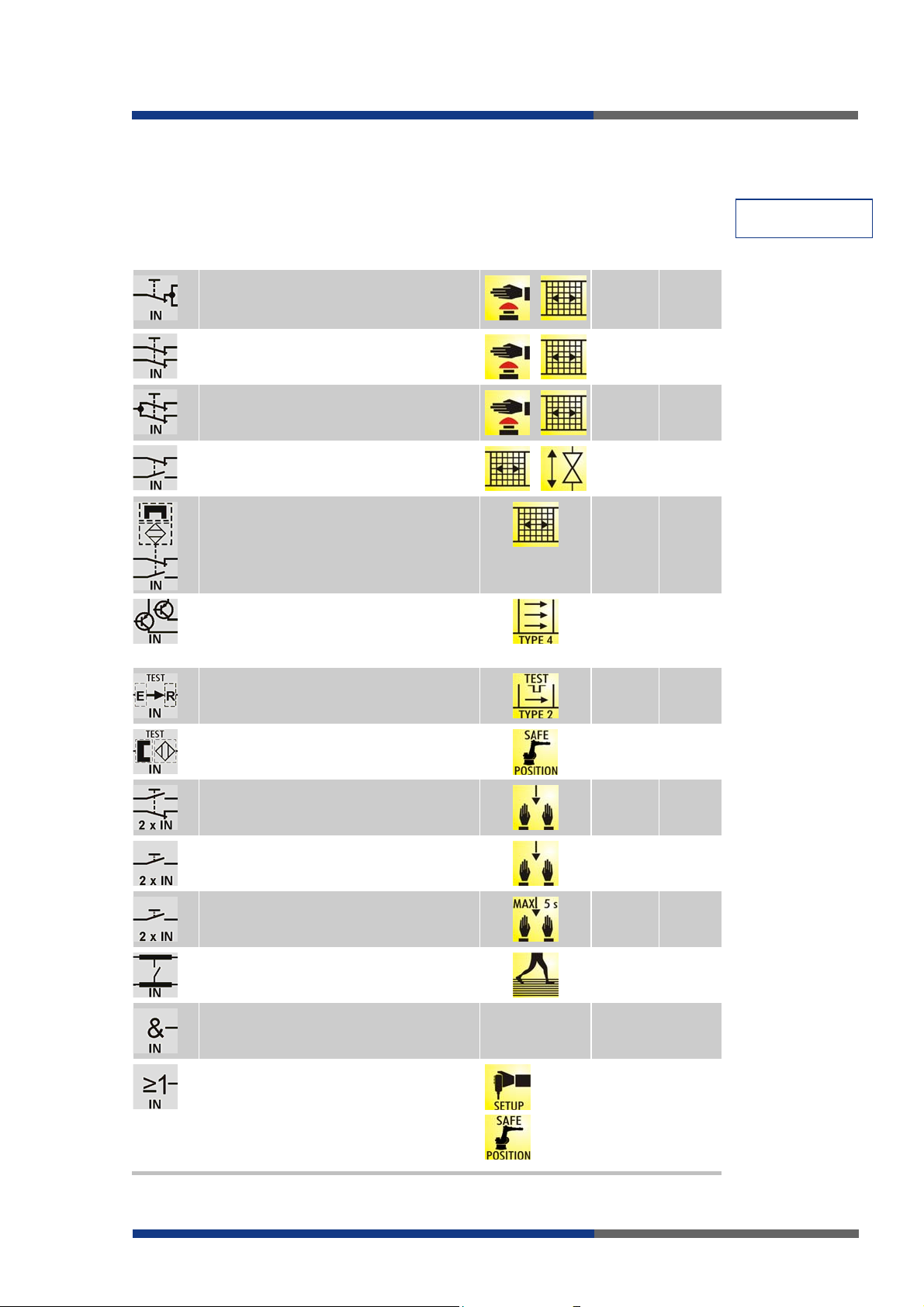

Input Circuit Functions

Overview of possible applications and corresponding sensor connections

Sensor

connection

Emergency stop / safety door

Single-channel NC

Emergency stop / safety door

Dual-channel equivalent NC

Cross-circuit monitoring

Emergency stop / safety door

Dual-channel three-wire equivalent NC

Safety door or valve

Dual-channel equivalent NC/NO

Coded electromagnetic switch

on safety door

Dual-channel non-equivalent NC/NO

Access monitoring with self-testing sensors

(e.g. outputs from light curtain type 4)

dual-channel single-ended positive switching

semiconductor

Access monitoring with testable sensors (e.g.

type 2 light barriers) or potential-free contacts

Single-channel NC/semiconductor outputs

Position monitoring with testable inductive

sensors (PDF)

Single-channel NC/semiconductor outputs

Two-hand control

acc. to EN 574 IIIC or safety door

2x dual-channel non-equivalent NO/NC

Two-hand control acc. to

EN 574 IIIA (not for press control)

2x single-channel NO

Jog mode max. 5 s (e.g. setup mode)

2x single-channel NO

Access monitoring with short-circuiting

switching mats

Four-wire

AND operation

Enabling input for cascading and grouping

OR operation

Muting, OR, bypass

for bridging safety functions for setup mode,

clearing, alternative safety function

Application e.g. Module/

group *

3AB

7A/7B

8A/8B

1AB

5A

6A/6B

3AB

7A/7B

8A/8B

2AB 4

2AB 4

3AB

7A/7B

8A/8B

3AB 2

3AB 4

4AB 4

5B 2

5B 2

1AB 3

In base module:

Sensor inputs:

Muting:

Bypass:

all function blocks

input module

3AB

OR:

1AB, 2AB,

input module

input module

SA-BM Base Module

Overview of

applications

Category

up to **

2

4

3

4

* Availability of

applications/sensor

connections in function

blocks (1 to 8) and

function groups (A, B).

See page 20.

** Maximum control

category (depends on

sensor, wiring and

installation

Please also note the

information on page 13.

© 2010 Wieland Electric GmbH | BA000256 | 12/2012 (Rev. I)

19

Page 20

SA-BM Base Module

Input Circuit Functions

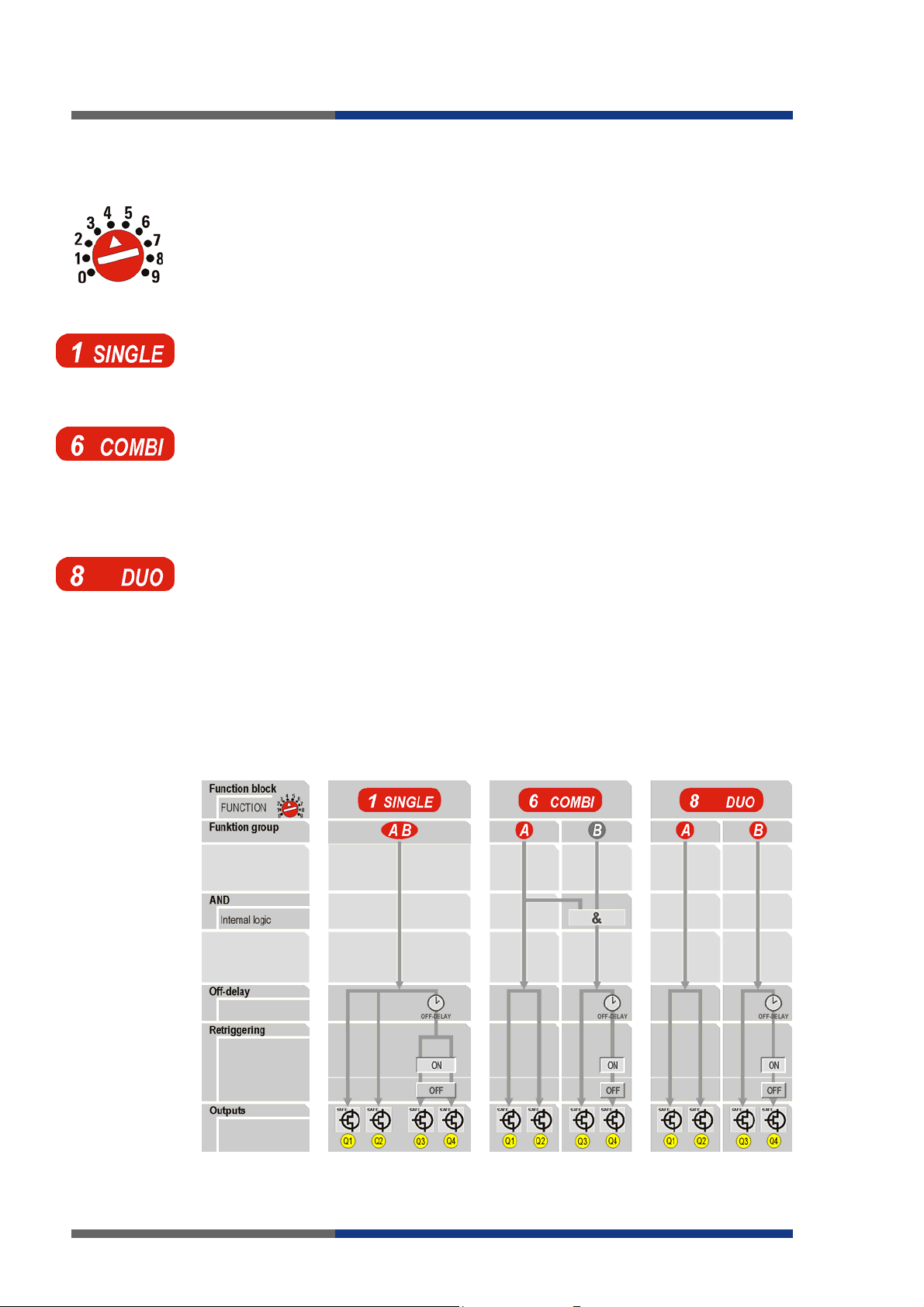

Using the rotary FUNCTION switch on the front you can set 8 function blocks as single,

combination or dual functions. On their own or in appropriate combinations these function

blocks cover the main fields of safety application. Using terminal combinations you can set

Reset behavior for manual/automatic Reset (page 24), off delay retriggering (page 25) and

special functions (page 23). Switch positions 0 and 9 are without function and must not be

used.

Single functions 1 to 4

The input circuits of function groups A and B act jointly on output circuits Q1 to Q4

(exception: function 3 with Q3 as muting lamp / Reset required output). In functions 1

and 2 settable off delay and retriggering act jointly on outputs Q3 and Q4; in function 3

only on Q4; in function 4 no off delay can be set.

Combination functions 5 to 7

The input circuits of function group A act directly on all output circuits Q1 to Q4; the input

circuits of function group B act on output circuits Q3 and Q4.

They are AND-linked via the internal logic with input circuits A. This allows the safety

concept found on many machines (two safety zones, one group subordinate) to be

reproduced within the device. With the exception of function 5 (for which no off delay is

settable) the settable off delay and retriggering act only on output Q4.

Dual function

The input circuits of function groups A and B act separately on output circuits Q1, Q2 or

Q3, Q4. This means that with one base module you can monitor two independent safety

groups on a machine or system. Settable off delay and retriggering act only on output

Q4.

Evaluating input circuits / function blocks

The diagram shows three different types of evaluation and the signal flows between inputs

and outputs for single function 1, combination function 6 and dual function 8. The diagram

is an excerpt from the function overview (see page 30).

together linked separate

20

© 2010 Wieland Electric GmbH | BA000256 | 12/2012 (Rev. I)

Page 21

A

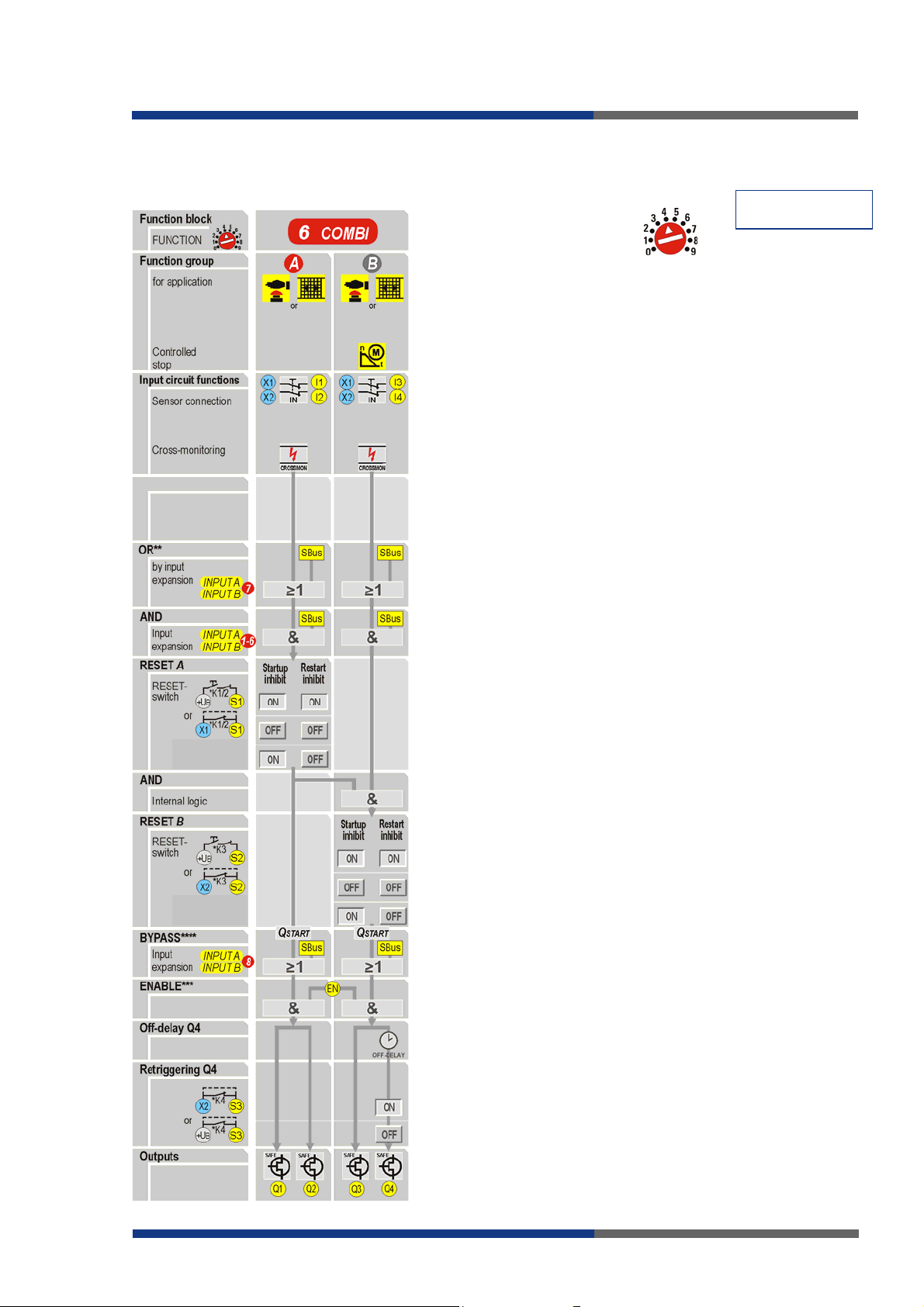

General structure and signal flow using the example of function block 6

Select function block with

FUNCTION switch

Function groups A and B

Applications for ... (e.g. emergency stop)

Controlled stopping possible via off delay

Sensor connection to input terminals

I1/I2 (group A) or I3/I4 (group B) and

supply terminals (clock outputs) X1/X2

With cross-circuit monitoring

OR link with input expansion

+

via SBus

AND link with input expansion

internal safety bus (SBus)

Reset function configuring

(starting/restarting inhibit) for function group

via terminal S1++ (Reset button, bridge or

feedback circuit)

Internal logic module, AND link between

function group B and function group A

Reset function configuring

(starting/restarting inhibit) for function group

B via terminal S2

++

(Reset button, bridge or

feedback circuit)

OR link with input expansion

+

function via SBus

AND operation with ENABLE input EN for

external group formation and cascading

Settable off delay for output Q4

Configuring of retriggering via terminal

++

S3

(bridge or feedback circuit)

Safe semiconductor outputs Q1, Q2, Q3,

Q4

SA-BM Base Module

Structure and

signal flow

+

OR function

+

signals via

BYPASS

+

For input module

functions see page 32ff.

++

See control circuit

functions, page 24.

© 2010 Wieland Electric GmbH | BA000256 | 12/2012 (Rev. I)

21

Page 22

SA-BM Base Module

Input Circuit Functions

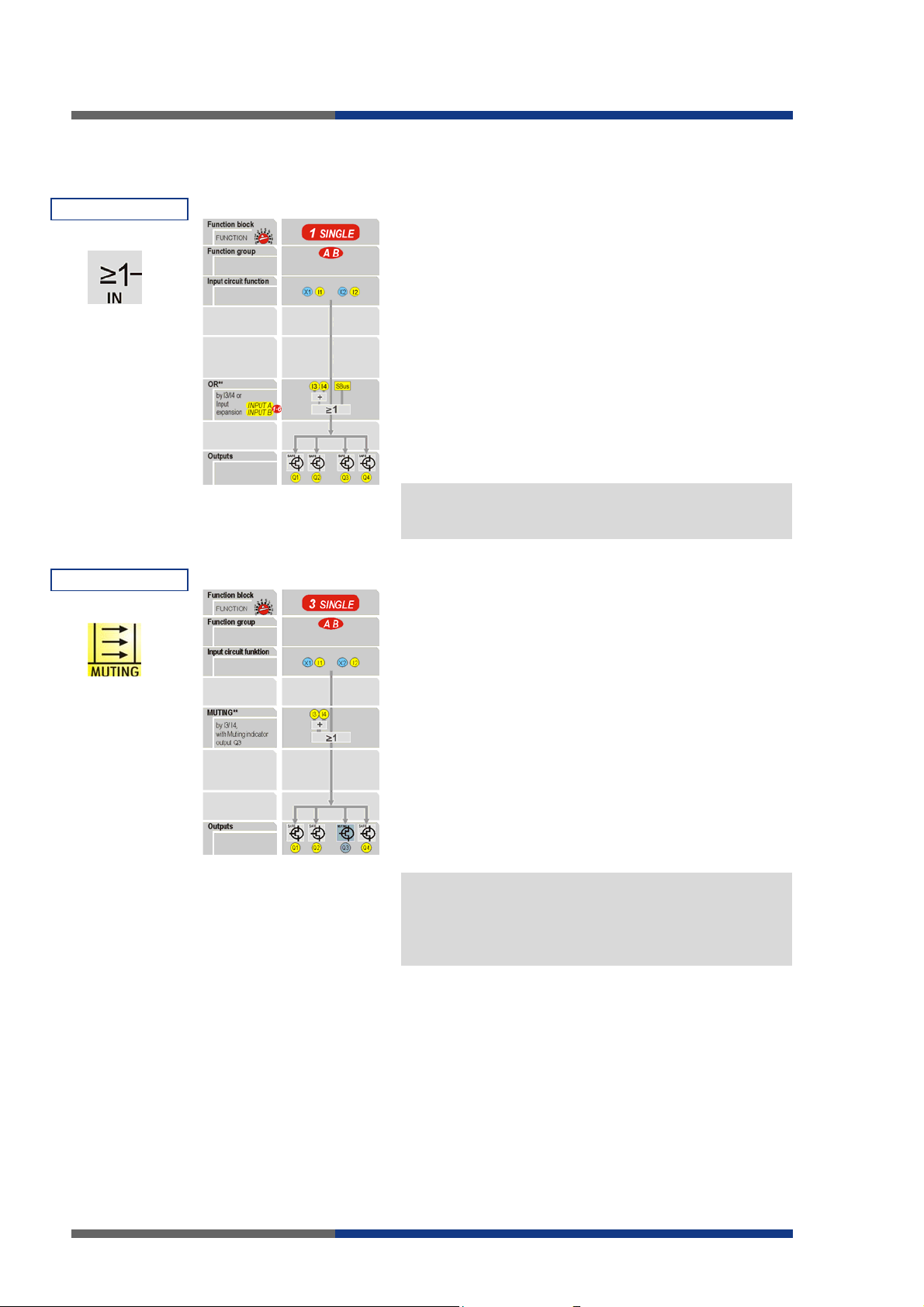

OR function

NOTE

OR function of function blocks 1 and 2

The off signal of an input function can be bridged with a OR

signal, for example with an enabling button for setup mode.

All the function blocks offer the possibility to link OR

function signals on the SA-IN input modules (function 7, see

page 39) with base module input signals by logical OR via

the SBus.

Additionally, the single function blocks 1 and 2 offer use of

the OR function on the base module itself via the two inputs

I3 and I4. U

+

is expected as the signal. Generation of an ON

x

signal (H-level) depends on several functions (see "System

Functions", page 46).

The OR function corresponds to an input circuit function

with dual-channel equivalent activation without cross-circuit

monitoring.

With a constant Ux signal+ on I3 and I4 and outputs Q1 to

Q4 switched on, the outputs remain switched on regardless

of the condition of the monitored safety sensors.

Muting function

NOTE

___________________________________________________________________________

Muting function of function block 3

The muting function is a conditional OR function, with

which for example muting sensors can briefly bridge a light

curtain function to allow material to be transported through a

light curtain.

Muting is only possible on base modules with single

function block 3, via inputs I3 and I4. U

+

is expected as the

x

signal. Generation of an ON signal (H-level) depends on

several functions (see “System Functions”, page 46).

Output Q3 controls the corresponding muting lamp. If

manual Reset is configured, the Q3 output additionally

indicates via periodical ON/OFF (0.5 s/0.5 s) that Reset is

expected at input S1 (Reset-Required).

The muting function in the base device corresponds to

an input circuit function with dual-channel equivalent

activation without cross-circuit monitoring.

With a constant Ux signal+ on I3 and I4 and outputs Q1, Q2

and Q4 switched on, the outputs remain switched on

regardless of the condition of the monitored safety sensors.

Muting of a safety function must not be dependent on a

single signal!

+

The Ux signal can come from

supply voltage +UB,

the Qx semiconductor outputs on the base modules,

the OSSD outputs of muting light barriers (muting

function only).

22

© 2010 Wieland Electric GmbH | BA000256 | 12/2012 (Rev. I)

Page 23

SA-BM Base Module

Special functions

Single function 3 and combination function 5 allow the use of special functions that are

activated via a corresponding configuration on control circuit terminal S2.

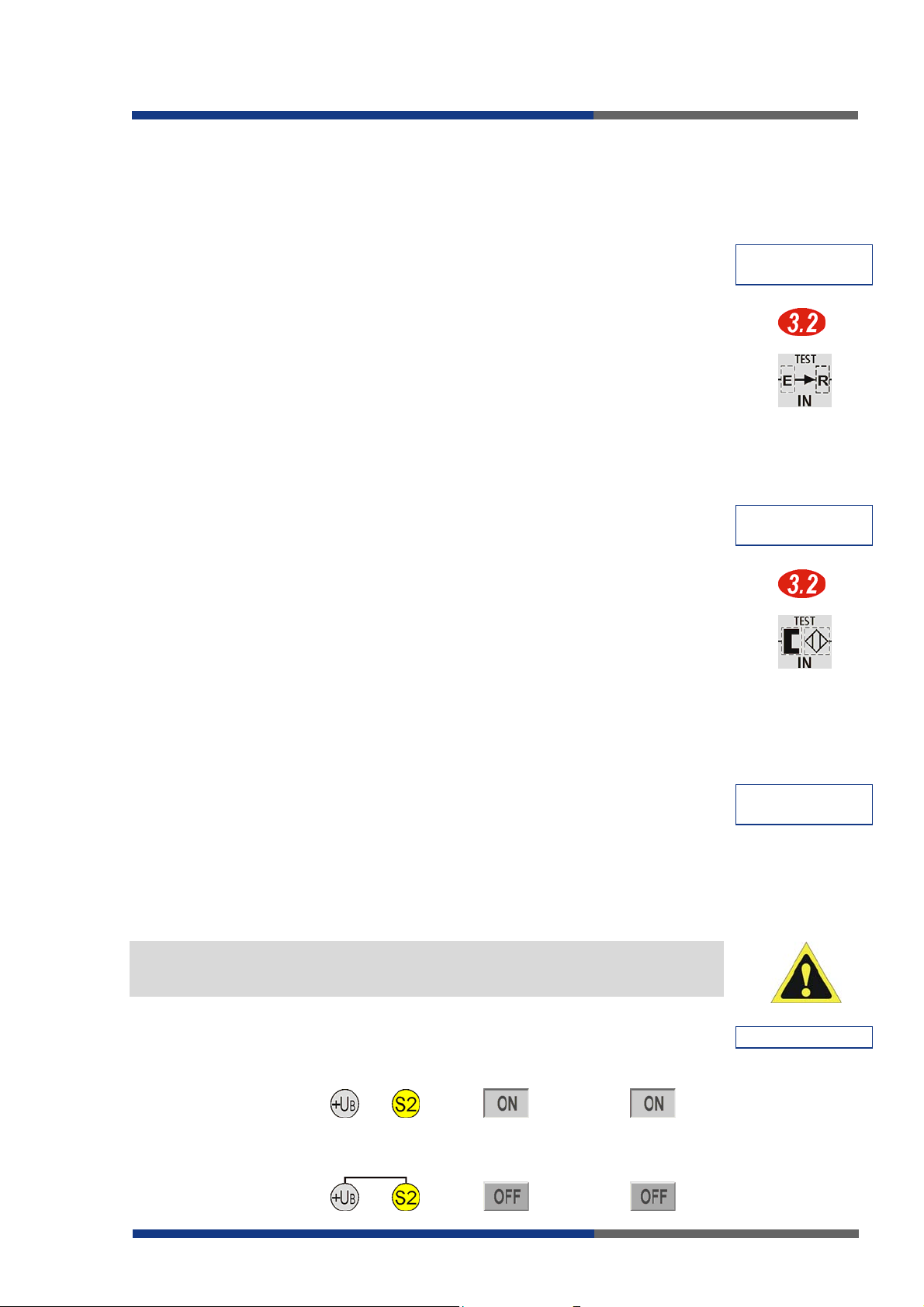

Single function 3

This function block offers the possibility of monitoring with an external test not only

emergency stop, safety door and non-contact safety device type 4 applications (acc. to EN

61496-x) but also sensors (e.g. non-contact safety device type 2) and potential-free

contacts. When the inputs are activated in this way the test function is activated by

leaving terminal S2 unactivated. Otherwise S2 is bridged with the supply voltage

(functions 3.1 and 3.2, see the “Control circuit functions” table on page 26 and the

“Function blocks” table on page 28).

Testable sensors on X1-I1 (terminal S2 open):

If time conditions are observed several sensors can be cascaded. Testable sensors

such as non-contact safety device type 2 light barriers (EN 61496-x) have separate

activation inputs on the transmitters. The activation inputs are used to test the sensor

function with a low signal; the base module analyses the response signal generated by

the receiver.

Testable sensors on X2-I2 (terminal S2 open):

If time conditions are observed up to four sensors can be cascaded. The time

conditions are matched specially for the GM 504S and GM 505S non-contact inductive

sensors (PDF acc. to EN 60947-5-3) made by ifm. The connection is only available on base

modules, not on input modules.

If one of the inputs I1 or I2 in not used a bridge must be installed to the respective

control output.

Inputs I3/I4 can be used as muting inputs specially for use with light curtains. They

are AND-linked to one another and OR-linked to the other inputs. The muting inputs only

act if the corresponding internal output signals of the Reset function Q

module were previously high (see also pages 22 and 46).

Output Q3 functions as a muting lamp output and as sigalling output „ResetRequired“. In this single function off delay for controlled stopping and retriggering act

only on output Q4.

___________________________________________________________________________

Combination function 5

Function group B can be used to monitor normal two-hand operation (synchronous

operation of two buttons within 0.5 s, function 5.1*) or two-hand operation in jog mode

(function 5.2*), e.g. for clearing a system. Here an output signal is only generated while

the controls are being pressed. Jog mode is restricted to 5 s. Releasing both controls

resets the time; repeated Reset is possible.

To activate jog mode terminal S2 remains unactivated. For other two-hand and safety

door applications S2 is bridged with the supply voltage +U

The two-hand function with two NO contacts cannot be used for operating presses,

because the safety level usually required (category 4) is not achieved. Function block 4

should be selected for press operation (EN 574 Type IIIC).

.

B

on the base

START

Special function

type 2

Special function

Testable PDF

Special function

two-hand

* For the functions see

also the "Control circuit

function" table on page

26 and the "Function

block overview" table on

page 30).

___________________________________________________________________________

Single function 3.2 Combination

function 5.2

S2 and supply voltage

unbridged

___________________________________________________________________________

Single function 3.1 Combination

function 5.1

Bridge between S2 and

supply voltage

© 2010 Wieland Electric GmbH | BA000256 | 12/2012 (Rev. I)

Configuration

23

Page 24

SA-BM Base Module

Control Circuit Functions

You can set the Reset behavior of the base modules by configuring terminals S1/S2 and

connecting Reset buttons, bridges or feedback circuits from external contactors/relays.

___________________________________________________________________________

Starting lockout

ON

When power is switched on and the inputs are in safe state the base module expects a

Reset (if restarting inhibit ON) or actuation on at least one input circuit (if restarting

inhibit OFF).

NOTE

Restarting lockout

NOTE

NOTE

Reset function

The enabling input does not act as an input circuit on the monitored sensors, i.e. the

starting inhibit is not canceled by switching the EN signal off and on again. In combination

functions 5, 6, 7 the starting inhibit in group B is not canceled by a signal change on the

Reset function in group A; the signal change must occur in group B.

OFF

The outputs switch on immediately after power is switched on and the inputs are in safe

state.

___________________________________________________________________________

ON

For resetting the safety function after a safety event the base module expects the Reset

button to be operated. This realizes the required manual Reset after emergency stop (or

switching back on after the safety zone has been entered and left again).

The Reset button must be operated for between 50 ms and 5 s. In combination functions

5, 6, 7 the restarting inhibit in group B must always be canceled by the Reset button.

In function 3, the expected Reset signal is indicated via blinking output Q3 (ResetRequired).

OFF

Automatic Reset after safety event and restoration of safe state of inputs.

Elimination of a cross circuit is also immediately defined as restoration of safe state of

inputs.

___________________________________________________________________________

The Reset function of manual and automatic Reset is defined by connecting terminals

S1/S2 with supply voltage +U

or the module’s own clock output X1. (Here terminal S1 is

B

shown; in functions with separate evaluation of function groups A and B terminal S2 and

clock output X2 are used equivalently for group B; see the table on page 26).

Starting inhibit Restarting inhibit

Manual reset

Reset button and feedback

circuit between S1 and

supply voltage

___________________________________________________________________________

Automatic reset

Bridge or feedback circuit

between S1 and clock

output

NOTE

24

During the configuration phase (after power on) of manual Reset (with Reset button) the

corresponding S output must be open or connected to a high-ohm output (e.g. a PLC).

High or low potential will result in incorrect configuration.

© 2010 Wieland Electric GmbH | BA000256 | 12/2012 (Rev. I)

Page 25

SA-BM Base Module

pag

On the front of the base modules you can set a off delay of 0..5 s, 0..50 s or 0..5 min,

depending on the device version. In position 0 release time = t

Technical Data, page 15). Depending on the selected function block, the off delay acts on

outputs Q3 and Q4, only on Q4, or on none of the outputs.

for undelayed outputs (see

R

Release delay

In functions without off delay (4 and 5) the delay switch must be set to 0 s, otherwise a

fault will be indicated. Contactors and/or relay output modules connected to the delayed

outputs are monitored separately via the feedback circuits (see “Control Circuit Functions”,

e 26).

___________________________________________________________________________

The behavior of off delay (retriggering) can be influenced by configuring terminal S3.

Bridge or feedback

circuit between S3 and

clock output X1

Auto mode (restarting inhibit OFF)

Manual mode (restarting inhibit ON)

Bridge or feedback

circuit between S3 and

supply voltage

Manual mode (restarting inhibit ON)

).

Auto mode (restarting inhibit OFF)

Auto mode (restarting inhibit OFF)

ON

If the safe input state (“good state”) of

the input circuits is reached again

before the delay has expired, the

delayed output circuits do not alter and

the delay time is reset (

In restarting inhibit mode the Reset

button has to be actuated additionally

during retriggering time (

Example: In automatic mode the safety

door is opened and the off delay starts

for the corresponding enabling paths. If

the door is closed again before the time

has expired the enabling paths do not

shut down and the machine continues to

operate without interruption.

OFF

Regardless of the state of the input

circuits, the delayed output circuits open

after expiry of the off delay time

(

and ).

With automatic Reset and “good state”

before expiry of the off delay time, the

delayed output circuits shut down for

400 ms and then switch on again (

Example: In manual mode the

emergency stop button is operated and

the off delay starts for the corresponding

enabling paths. If the emergency stop

button is released before the time has

expired and the Reset button operated,

the enabling paths shut down anyway.

The delay time must expire before

enabling via the Reset input is possible

again.

).

).

NOTE

Retriggering

EXAMPLE

EXAMPLE

© 2010 Wieland Electric GmbH | BA000256 | 12/2012 (Rev. I)

25

Page 26

SA-BM Base Module

Control Circuit Functions

Control inputs

The table provides an overview of the use of control circuit terminals in connection with

the selected function block:

S1 – Reset function (RESET), feedback circuit monitoring (FEEDBACK)

S2 – Reset function, special functions, feedback circuit monitoring

S3 – Retriggering (RETRIGGER), feedback circuit monitoring

NOTE

Control inputs S1 and S3 must always be connected.

Reset, feedback and retrigger

S1 S2 S3

FUNCTION RESET FEEDBACK* RESET FEEDBACK* RETRIGGER FEEDBACK*

Switch position not allowed

Man. /

Auto

Q1 / Q2 unactivated Q3 / Q4 Q3 / Q4

Man. /

Auto

Man. /

Auto

Man. /

Auto

Q1 / Q2 unactivated Q3 / Q4 Q3 / Q4

Q1 / Q2

Q1 / Q2 unactivated

+U

FUNCTION 3.1**

B

open FUNCTION 3.2**

Q4 Q4

No function

Q3 / Q4

NOTE

Man. /

Auto

Q1 / Q2

Man. /

Auto

Man. /

Q1 / Q2

Q1 / Q2

Auto

Man. /

Q1 / Q2

Auto

Man. /

Q1 / Q2

Auto

FUNCTION 5.1**

+U

B

open FUNCTION 5.2**

Man. / Auto

Man. / Auto

Man. / Auto

Man. / Auto

Q3 Q4 Q4

Q3 Q4 Q4

Q3 Q4 Q4

Q3 Q4 Q4

No function

Q3 / Q4

* With off delay 0 s all the associated outputs of the group do not switch back on until all

feedback circuits in the group are closed.

** For special functions see page 23.

26

© 2010 Wieland Electric GmbH | BA000256 | 12/2012 (Rev. I)

Page 27

Reset and feedback – activation of control inputs

S1 S2

S1

and

S2

SA-BM Base Module

Feedback

via S1, S2

Without

FEEDBACK

With

FEEDBACK

Bridge or

feedback circuit

Q1/Q2

Without

FEEDBACK

With

FEEDBACK

Bridge or

feedback circuit

Q3

Manual reset

(restarting inhibit)

Automatic reset

without starting

inhibit

___________________________________________________________________________

Retrigger and feedback – activation of control input

Retrigger OFF

Without

FEEDBACK

S3

With

FEEDBACK

Bridge or

feedback circuit

Q1/Q2 resp. Q4

S3

Feedback

via

S3

Retrigger ON

In functions without cross-circuit monitoring (see “Function Blocks – Overview”, page 30)

dynamic signals on outputs X1 and X2 are generated only during the configuring phase after

power on.

During the configuration phase (after power on) of manual Reset (with Reset button)

the corresponding S output must be open or connected to a high-ohm output (e.g. a PLC).

High or low potential will result in incorrect configuration.

___________________________________________________________________________

In order to monitor external contactors (FEEDBACK) that may be connected to outputs Q1 Q4 the NC contacts of the respective contactors or output expansions must be connected

in series with the associated control inputs (see the tables here and page 47).

NOTE

Feedback circuit

monitoring

© 2010 Wieland Electric GmbH | BA000256 | 12/2012 (Rev. I)

27

Page 28

SA-BM Base Module

y

A

Function blocks

FUNCTION

Function

group

Application e.g.

Switch position not allowed

Emergency stop, safety door, 4-wire switching mat

Dual-channel NC/NC with cross monitoring, stop category 0

OR

Safety door monitoring with electromagnetic switches,

valve position monitoring

Dual-channel NC/NO with cross monitoring, stop category 0 and 1

OR

3.1* Non-contact safety device type 4, emergency stop, safety door

Dual-channel NC/NC, single-channel NC, stop category 0 and 1

3.2* PDF, Stop category 0 and 1

Non-contact safet

device type 2, Stop category 0 and 1

Muting

* For special functions

see page 23.

Two-hand function EN 574 Type IIIC, safety door

2x dual-channel NC/NO with cross monitoring

Emergency stop, safety door

Dual-channel NC/NC with cross monitoring

5.1* Two-hand function EN 574 Type III

NO/NO with cross monitoring

5.2* Jog mode with 5 s operating time restriction

NO/NO with cross monitoring

Emergency stop, safety door

Dual-channel NC / NC with cross monitoring, stop category 0 and 1

Emergency stop, safety door

Dual-channel NC / NC with cross monitoring, stop category 0 and 1

Emergency stop, safety door, non-contact safety device type 4

Dual-channel NC/NC, single-channel NC, stop category 0 and 1

Emergency stop, safety door, non-contact safety device type 4

Dual-channel NC/NC, single-channel NC, stop category 0 and 1

Emergency stop, safety door, non-contact safety device type 4

Dual-channel NC/NC, single-channel NC, stop category 0

Emergency stop, safety door, non-contact safety device type 4

Dual-channel NC/NC, single-channel NC, stop category 0 and 1

Emergency stop, safety door

Dual-channel NC / NC with cross monitoring, stop category 0 and 1

Emergency stop, safety door, non-contact safety device type 4

Dual-channel NC/NC, single-channel NC, stop category 0 and 1

28

© 2010 Wieland Electric GmbH | BA000256 | 12/2012 (Rev. I)

Page 29

Function block terminal assignment

Terminal

assignment

Q1 Q2 Q3 Q4

X1 – I1

X2 – I2

U

U

– I3

x

– I4

x

NO

DELAY

X1 – I1

X2 – I2

U

U

U

U

– I3

x

– I4

x

– I1

x

– I2

x

(PDF) X1 – I1

(Type 2) X2 – I2

U

U

– I3

x

– I4

x

NO

DELAY

NO

DELAY

**X1 – I1 (NO contact)

X1 – I2 (NC contact)

X2 – I3 (NO contact)

NO

DELAY

X2 – I4 (NC contact)

X1 – I1

X2 – I2

NO

DELAY

X1 – I3

X2 – I4

X1 – I3

X2 – I4

X1 – I1

X2 – I2

X1 – I3

X2 – I4

U

U

U

U

U

U

U

U

– I1

x

– I2

x

– I3

x

– I4

x

– I1

x

– I2

x

– I3

x

– I4

x

X1 – I1

X2 – I2

U

U

Ux – Signal from Qx or UB or semiconductor outputs from sensors

QE – Cross-circuit monitoring

– I3

B

– I4

B

NO

DELAY

NO

DELAY

NO

DELAY

NO

DELAY

Output function / off delay

NO

DELAY

NO

DELAY

NO

DELAY

NO

DELAY

NO

DELAY

NO

DELAY

NO

DELAY

NO

DELAY

NO

DELAY

NO

DELAY

Muting lamp/

Reset-Required

NO

DELAY

NO

DELAY

NO

DELAY

NO

DELAY

NO

DELAY

NO

DELAY

SA-BM Base Module

** not actuated

NO

DELAY

NO

DELAY

In combination functions 5 to 7 the signals on I1, I2 shut down all outputs Q1 to Q4, the

signals on I3, I4 shut down only the outputs Q3 and Q4.

© 2010 Wieland Electric GmbH | BA000256 | 12/2012 (Rev. I)

NOTE

29

Page 30

SA-BM Base Module

Function Blocks – Overview

Function block

FUNCTION

Function group

Application example

Cat. acc. to EN 954-1

Stop category. 1

(Controlled Stop)

Input circuit functions

Sensor connection

Synchronous time

monitoring

Cross-circuit

monitoring

4

5

6

3

2

7

1

8

9

0

4

or

3

or

2

SINGLE

1

X1

X2

X1

X2

AB

n

t

I1

I2

I1

I2

CROSSMON

MUTING**

by I3/ I4,

Output Q3 for indicator

Muting/ Reset required

OR**

by I3/I4 or

input

expansion

INPUT A

INPUT B

7

I4

I3

+

>

1

AND

Input

expansion

RESET FB Q1/2AB,

RESET

switch

or

INPUT A

INPUT B

*K1/2

+U

B

*K1/2

X1

1-6

S1

S1

Startup

inhibit

ON

OFF

&

Restart

inhibit

ON

OFF

AND

Internal logic

Special function

S2

+U

B

or

S2

+U

BYPASS****

Input

expansion

ENABLE***

B

INPUT A

INPUT B

8

Q

START

SBus AB

>

1

EN

&

Off-delay

Retriggering, FB Q3/4

*K3/4

X2

S3

or

*K3/4

+UB

S3

Outputs

SAFE

Q1

Internal safety bus for function group

A or B or AB

*K1/2 Bridge or feedback circuit Q1/2

*K3/4 Bridge or feedback circuit Q3/4

*K3 Bridge or feedback circuit Q3

*K4 Bridge or feedback circuit Q4

OFF-DELAY

ON

OFF

SAFE

SAFE

SAFE

Q2

Q4

Q3

SINGLE

SINGLE

2

X1

X2

X1

X2

AB

n

t

I1

I2

CH1

t

sync

CH2

I1

I2

CROSSMON

3

AB

SAFE

POSITION

TYPE 4

n

t

I1

X1

I2

I1

Ux

Ux

X2

I2

I1

I2

I4

I3

+

>

1

I4

I3

SBus AB SBus AB SBusABSBus AB

+

>

1

SBus AB SBus AB SBusABSBus AB

&

Restart

Startup

inhibit

inhibit

ON

ON

OFF

OFF

Q

START

SBus AB SBus AB SBusAB

>

1

EN

&

OFF-DELAY

ON

SAFE

SAFE

Q1

OFF

SAFE

SAFE

Q2

Q4

Q3

>

1

&

Restart

Startup

inhibit

inhibit

ON

OFF

OFF

TEST

3.2

3.1

OFF

Q

START

>

1

EN

&

SAFE

Q1

MUTING

SAFE

Q2

**For signal supply to MUTING and OR

inputs I3/I4 see page 22.

**For signal supply to ENABLE input EN

see page 48.

SINGLE

4

AB

TEST

TYPE 2

n

t

TEST

or

TEST

ER

or

I1

I2

I1

X1

I2

I3

X2

I4

>

1

CH1

t

sync

CH2

CROSSMON

X1

X2

&

Startup

inhibit

ON

OFF

Q

ON

ON

Restart

Startup

inhibit

inhibit

OFF

ON

fix fix

*K1/2

+U

B

S1

Q

START

>

1

EN

&

OFF-DELAY

ON

OFF

SAFE

SAFE

Q4

Q3

SAFE

Q1

****BYPASS limited to max. 60 s.

Signal Ux from supply voltage +UB or the Qx

semiconductor outputs on the base module or the

OSSD of light barriers/light

*K3/4

+U

B

S3

SAFE

SAFE

SAFE

Q4

Q2

Q3

Q1

A

>

&

START

>

&

5

CROSSMON

1

Restart

inhibit

SBus A

1

SAFE

Q2

COMBI

I1

I2

ON

OFF

EN

X1

X2

CH1

t

sync

CH2

Startup

inhibit

ON

5.1

OFF

Q

+U

B

Q3

B

>

&

&

tmax

5s

START

>

&

*K3/4

MAX. 5s

CROSSMON

SBus BSBus A

1

SBus BSBus A

Restart

inhibit

OFF

5.2

ON

SBus B

1

S3

SAFESAFE

Q4

I3

I4

30

© 2010 Wieland Electric GmbH | BA000256 | 12/2012 (Rev. I)

Page 31

A

t

t

Function block

FUNCTION

Function group

Application example

Cat. acc. to EN 954-1

Stop category 1

(Controlled Stop)

Input circuit functions

Sensor connection

Cross-circuit

monitoring

2

1

SA-BM Base Module

4

5

6

3

7

8

9

0

4

or

3

or

2

X1

X2

A

6

CROSSMON

COMBI

I1

I2

COMBI

7

B

n

t

I3

X1

I4

X2

CROSSMON

A

TYPE 4 TYPE 4 TYPE 4

I1

I2

I1

Ux

I2

I1

Ux

I2

B B

TYPE 4 TYPE 4

n

t

I3

I4

I3

Ux

Ux

Ux

I4

I3

Ux

I4

DUO

8

A

I1

I2

I1

I2

I1

I2

B

n

t

I3

X1

I4

X2

I3

Ux

I4

I3

Ux

I4

A

9

CROSSMON

COMBI

I1

I2

n

t

I3

I4

I3

Ux

I4

I3

Ux

I4

OR**

by input

expansion

INPUT A

INPUT B

AND

Input

expansion

INPUT A

INPUT B

RESET FB Q1/2A,

RESET

switch

*K1/2

+U

B

or

*K1/2

X1

AND

Internal logic

RESET FB Q3B,

RESET

switch

*K3

+U

B

or

*K3

X2

BYPASS****

Input

expansion

INPUT A

INPUT B

ENABLE***

Off-delay Q4

Retriggering, FB Q4

SBus A

7

>

1

SBus A SBus ASBus B SBus B SBusSBus A SBus B

&

1-6

Restart

Startup

inhibit

inhibit

S1

ON

ON

S1

OFF

OFF

>

1

&

Startup

inhibit

ON

OFF

>

&

1

Restart

inhibit

ON

OFF

>

1

& &

Startup

inhibit

ON

OFF

>

&

1

Restart

inhibit

ON

OFF

>

1

&

Startup

inhibit

ON

OFF

>

&

SBus ASBus ASBus B SBus B SBusSBus A SBus B

1

SBus A

Restart

inhibit

ON

OFF

>

1

& & &

Restart

Startup

inhibit

inhibit

S2

S2

Q

START

8

>

1

&

ON

ON

OFF

OFF

Q

SBus A SBus ASBus B SBus B SBusSBus A SBus B

START

>

1

EN ENEN EN

&

OFF-DELAY

Q

START

>

1

&

Restart

Startup

inhibit

inhibit

ON ON

ON ON

OFF OFF

OFF OFF

Q

START

>

1

& &

OFF-DELAY OFF-DEL

Q

START

>

1

&

Startup

inhibit

ON

OFF

Q

Restart

inhibit

START

>

1

&

OFF-DELAY

ON

OFF

Restar

Startup

inhibi

inhibit

Q

Q

START

SBus A

>

1

&

START

>

1

*K4

X2

S3

or

*K4

+U

B

S3

SAFE

Q1

SAFE

Q2

Outputs

Starting inhibit ON: Manual Reset after supply ON.

Starting inhibit OFF: Automatic Reset after supply ON.

Restarting inhibit ON: Manual Reset after safety event.

Restarting inhibit OFF: Automatic Reset after safety event (see page 24).

© 2010 Wieland Electric GmbH | BA000256 | 12/2012 (Rev. I)

Q3

SAFESAFE

ON

OFF

Q4

SAFE

Q1

SAFE

Q2

Q3

Q3

SAFESAFE

ON

OFF

Q4

SAFE

SAFE

Q1

Q2

Q3

Q4

ON ON

OFF OFF

Q4

SAFE

Q1

SAFE

Q2

SAFE SAFESAFE SAFE

Retriggering ON: Delayed outputs remain in ON condition if safe

state of inputs has been restored when the delay has expired.

Retriggering OFF: Unconditional time delay period (see page 25).

31

Page 32

SA-IN Input Module

Y

5 SA-IN Input Module

Input Module Data

SA-IN-S1,

SA-IN-S1

Input Module

The input module adds additional input circuits or logic

functions to a base module on its left (SA-BM master).

ou can operate several input modules on one base

module.

There are two function groups, A and B, each with

four inputs and four sensor supplies. You can set one of

10 functions for each group independently, using the

rotary switches on the front. The configuration will be

permanently saved in the master base module. The

device operates as a slave on the internal safety bus.

Connection

diagram

Notes

Accepting

configuration

SA-IN

The controller category (EN ISO 13849-1) or SIL (EN 61508/EN 62061) depends on the

external circuitry, the wiring, the choice of control devices and their location on the

machine.

The rotary switches for selecting function must only be adjusted when power is off.

Never connect or disconnect modules while the operating voltage is switched on.

Internal samos module addresses are assigned automatically when the system starts up.

Manual addressing is unnecessary (and not possible).

The safety system must be installed in an enclosure with at least IP 54 protection.

Input modules are always assigned functionally to the next connected base module to

the left. Each base module forms a system group within the overall system (sometimes

together with associated input expansion modules; see diagram on page 8).

Base modules and input modules are uniquely coded depending on their system system

group (see diagram on page 8).