Page 1

Section K Index

K1

General Information/Sizing .............K2-K3

MTAB Assembly ....................................K4

Advantage Series “NEMA Type 3R”

Air Conditioners

2000 BTU “RP17” Series,

Side Mount, N3R.....................................K6

3000 BTU “RP28” Series,

Side Mount, N3R.....................................K7

4000 BTU “RP33” Series,

Side Mount, N3R.....................................K8

6000 BTU “RP36” Series,

Side Mount, N3R.....................................K9

8000 BTU “RP47” Series,

Side Mount, N3R...................................K10

12000 BTU “RP47” Series,

Side Mount, N3R...................................K10

TrimLine Series “NEMA Type 12”

Air Conditioners

2000 BTU “NP17” Series,

Side Mount, N12 ...................................K12

4000 BTU “NP28” Series,

Side Mount, N12 ...................................K13

4000 BTU “NP33” Series,

Side Mount, N12 ...................................K14

ENVIRONMENTAL CONTROL

4000 BTU “NP36” Series,

Side Mount, N12 ...................................K15

6000 BTU “NP36” Series,

Side Mount, N12 ...................................K15

7000 BTU “NP47” Series,

Side Mount, N12 ...................................K16

10000 BTU “NP47” Series,

Side Mount, N12 ...................................K16

13000 BTU “NP47” Series,

Side Mount, N12 ...................................K16

Micro-Mini Series “NEMA Type 12”

Air Conditioners

1000 BTU Micro Series,

Side Mount, N12 ...................................K17

Integrity Series “NEMA Type 4X”

Air Conditioners

4000 BTU “32 Series”,

Side Mount, N4X ...................................K19

7000 BTU “38 Series”,

Side Mount, N4X.................................. K20

10000 BTU “47 Series”,

Side Mount, N4X ...................................K20

Compact Top Mount Series, “NEMA

TYPE 12” Air Conditioners

4000 BTU “Top Mount Series”, N12... K21

Vortex Coolers.....................................K22

WPFB/WPFBE Series

Filtered Box Fans & Grilles...............K24/25

WAAXFN/WAGARD Series

Muffin Fans & Finger Guards ................K26

WAVK/WAFLT Series

Louver Plate & Filter Kits.......................K27

EHG Series Radiant Heaters ................K29

WHVL Series Fan Heaters....................K30

WCR Series Fan Heaters .....................K31

EGL Series Fan Heaters.......................K32

ETR/ETF/ZR Series Thermostats ....K33/34

WAFMP Series

Fan Mounting Plate ...............................K36

1800 Filtered Fan Series

Filter Fan/Exhaust Filter/Mats ...........K37/38

WPF Series Filterfans™...................K39/40

WPFA Series Exhaust Grille & Filter .....K41

WPFG/WPFM/WPG Series

Gaskets, Mats & Grilles ........................K42

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 2

K2

ENVIRONMENTAL CONTROLS

GENERAL INFORMATION

Wiegmann has always recognized

that our customers in the electrical

and electronic marketplace need reliable, high quality enclosures and

environmental control products to

meet their protection requirements.

Protection Requirements today not

only mandate NEMA TYPE 12, 3R, 4,

& 4X, but also require a broad mix of

BTU & size selections. Wiegmann is

proud to offer those choices via a

whole new line of A/C products. They

are: Advantage Series, Trim Line

Series, Micro-Mini Series, Integrity

Series, and the Top Mount Series.

Three Basic Cooling Methods

When selecting a cooling method

there are three types to consider.

1 Passive Ventilation — If there is

only a minimal heat gain in your

circumstance, use of louvers or

grilles with filters can be effective.

This method, however, usually provides less cooling effect than is

necessary with today’s components.

2 Forced Convection Air Cooling —

If the installation will be in a clean,

non-hazardous environment with

an acceptable ambient (outside the

enclosure) temperature range, a

simple forced-air cooling system

utilizing outside air is usually adequate. Combined with an air filter,

such devices generally meet the

heat removal needs of typical electronic equipment and many electrical applications (Fig. 1). Examples

of forced convection air cooling are

filtered fans, fan trays, and blowers

of various types.

FIGURE 1 — Forced Convection Method

Filter & Grille

Required

Ambient Air

with Heat

Load

3 Closed-Loop Cooling —Inharsh

environments involving high temperatures, wash-down requirements,

heavy particulate matter or the

presence of chemicals capable of

damaging components (NEMA 4 or

12 environments), ambient air must

be kept out of the enclosure. Closedloop cooling consists of two separate circulation systems. One system, sealed against the ambient air,

cools and recirculates the clean

cool air throughout the enclosure.

The second system uses ambient air

or water to remove and discharge

the heat. Examples of closed-loop

cooling equipment employed with

electronics and process controls

are heat exchangers and air

conditioners.

Fan or Blower

with filter &

grille

Ambient

Air with

Heat Load

Ambient

Air

Fan or

Blower with

filter & grille

Pressurized System — pushes air through enclosure

Fans and Blowers can be used to pressurize (preferred) or exhaust cabinet air.

The ambient air should be filtered before it enters the cabinet.

Heated

Air

Cooled Air

In an air-to-air heat exchanger, heat from air surrounding the

electronics is removed by a specially designed heat transfer

element before being routed back into the enclosure.

Cabinet

FIGURE 2 - Closed Loop Cooling Method

Blower

Ambient Air

with Heat

Load

Ambient Air

Heat Exchanger

Blower

Ambient Air

Filter & Grille

Required

Cabinet

Exhaust System — pulls air through enclosure

Condenser

Heated

Air

Chilled

Air

In air conditioners, a condenser, an evaporator, and two blowers combine to chill the air circulating in the enclosure.

Ambient Air

with Heat

Load

Ambient Air

Blowers

Evaporator

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 3

ENVIRONMENTAL CONTROLS

AIR CONDITIONERS-APPLICATION INFORMATION

K3

Cooling Control Cabinets

Most electrical & electronic control

systems generate a substantial

amount of heat during operation. This

heat factor is intensified as controls

are made more compact, perform

more functions, and are placed in more

confined areas. Additional problems

are encountered when the electronic

process control system is located onsite in an industrial setting, rather than

in a clean computer room. The factory

environment can be hostile to the

point that performance and effective

life of the electronic components are

materially reduced, or the control system fails completely. Ambient temperature might be excessively high, as

that found in a steel mill. Moistureladen air and air-borne particulate

matter might be present to adversely

affect the electronic components, as

in the paper manufacturing industry.

Air conditioners are designed to perform

reliably under many of these harsh

conditions and to provide the cooling

and environmental protection required

by sensitive electronic production

control systems.

Factors Affecting Model Selection

This selection is presented as a basic

outline or checklist of the various

conditions to be considered when

choosing a cooling unit for a certain

application. The following are factors

which must be considered when

selecting a cooling unit:

Internal Heat Load — This is the heat

dissipated by the electronic controls.

It is expressed in watts. One watt

equals 3.413 BTU/HR. Thus, to obtain

the approximate cooling capacity

required to remove a specific heat load,

the following formula can be used:

Watts x 3.413 = BTU/HR

For example, a heat load of 800 watts

requires an air conditioner capable of

removing at least 2,730 BTU/HR.

Resistance to Air Flow in the

Enclosure

Air Flow is measured in cubic feet per

minute (CFM). To create an air flow of

any desired velocity requires that

pressure be produced by the blower

in the air conditioner. Resistance to this

blower-produced air flow is created by

obstruction within the cabinet in the

air flow path. The resistance itself is

called pressure drop (P.D.) and is

measured in inches of water column.

The effect of significant restrictions in

the cabinet air flow path are as follows:

The obstructions cause pressure drops,

which leads to cool air flow reduction.

This reduction in cool air flow will

decrease the effective capacity of the

cooling unit. When selecting the

proper cooling unit, allowance must

be made for pressure drop.

Heat Load From The Surroundings

Ambient conditions can cause a heat

gain in the enclosure. The rated

capacity of the cooling unit must be

sufficient to handle this heat gain.

When evaluating the additional heat

load gained from the surroundings,

the subject more or less breaks down

into two situations: (1) the cabinet is

insulated and well sealed, or (2) the

cabinet is not insulated (most cabinets

are uninsulated.)

(1) Cabinet Insulated — Normally, well

insulated cabinets will not gain sufficient ambient heat to affect air conditioner’s operation. Maximum operating

temperature for our air conditioners is

125°F. When the air conditioner operaties in ambient temperatures below

125°F, the cooling capacity of the air

conditioner substantially increases.

(2) Cabinet Not Insulated —

Obviously, this design placed more of

a burden on the cooling unit. Heat is

conducted to the cool side. Thus,

high ambient heat will be readily

transmitted into the cooler enclosure.

To determine the additional capacity

required of our air conditioner installed

in an uninsulated cabinet, the surface

square footage of the enclosure must be

Cooling And Control Cabinets

STEP ONE

1 Watt = 3.413 BTU/HR.

Determine the internal

heat load in Watts that

must be dissipated.

STEP TWO

1 m2 = 10.76 ft.2

Calculate the exposed

surface area of the

enclosure: 2(h’ x w’) +

2(h’ x d’) + (w’ x d’) =

Area (ft2)

calculated to obtain the total effective

heat transfer area. For this calculation, use the surface area of the

sides, plus the area of the top, and

omit the bottom area of the cabinet.

Air movement outside the uninsulated

cabinet will increase the heat conducted from the ambient into the enclosure.

When there is little or no air circulation

outside the cabinet, the layer of air

immediately adjacent to the exterior

cabinet walls acts as an insulating

film. Exterior air movement dissipates

this insulating layer of air in proportion

to the velocity of the air flow. Substantial

am-bient air circulation will increase

the transmitted heat load imposed on

the cooling unit.

If the cabinet being cooled is not air

tight, then high ambient relative humidity

will adversely affect the cooling effectiveness of the air conditioner. When

humid air infiltrates a poorly sealed

enclosure, the air conditioner is required

to use up valuable BTU/HR capacity

just to condense the moisture from the

internal air. Conversely, if the cabinet

is well sealed, high ambient relative

humidity, has very little effect on the

heat capacity of the air conditioner.

Steps For Sizing an Air Conditioner

Proper selection of an air conditioner

is determined by the following criteria:

• Required cooling capacity BTU/hr.

(complete Steps #1-4)

• Mounting requirements (top or side

mounting options)

• Dimension of air conditioner and

enclosure

STEP THREE

1oC or 1oKΔT=1.8oF T

Determine the temperature differential by subtracting the maximum

allowable temperature

inside the enclosure

(Ti) from the maximum

ambient temperature

outside the enclosure

(To) To-Ti=ΔT

STEP FOUR

(Watts x 3.413) +

[1.25 x Area ft.2 x

ΔT(°F)]

=BTU/HR.

Capacity

Required BTU/HR.

Capacity Rating

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 4

K4

ENVIRONMENTAL CONTROLS

M/TAB MOUNTING TEMPLATE AND ASSEMBLY

FEATURES-SPECIFICATIONS

Description

highlight of the Panel-Mounted

A

TrimLine Series is an easy, revolutionary

system for installing Panel-Mounted

Air Conditioners and Heat Exchangers

onto electronic or electrical enclosures.

The M/TAB is standard on all TrimLine

Air Conditioners. This integral system

functions as a mounting template,

pre-installation hanger and final

assembly bracket.

The M/TAB was specifically designed

to assist in the difficult job of installing

enclosure Air Conditioners. It simplifies

the installation process by eliminating

the problem of handling flangemounted Air Conditioners. The solution is provided by following these

installation steps...

• Use the M/TAB as a template to

drill holes for mounting to the

enclosure

• Bolt M/TAB to enclosure

• Cut out the Supply and Return

openings

• Hang the Air Conditioner or Heat

Exchanger on the M/TAB

• Secure the unit to the M/TAB

The M/TAB also allows for the quick

removal and transportation of the Air

Conditioner or Heat Exchanger, separate from the equipment, for servicing

or change to a different capacity

same-size Air Conditioner or to a

same-size Heat Exchanger.

Features

• No exposed rails or mounting

flanges; aesthetically pleasing

while conserving cabinet space

• Reduction in installation time and

labor, with significant cost savings

• Ease of installation and one piece

design reduce mounting errors

• Allows the installer to operate independently

• Functions as a pre-installation

hanger and final assembly bracket

• Installation is totally outside the

enclosure; no clumsy mounting

from inside the enclosure

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

DATA SUBJECT TO CHANGE WITHOUT NOTICE

Page 5

ENVIRONMENTAL CONTROLS

INDOOR/OUTDOOR SIDE-MOUNTED AIR CONDITIONERS

FEATURES-SPECIFICATIONS

K5

NEMA

TYPE 3R & 12

MAINTAINED

Description

At last - air conditioners designed

specifically for cooling electronic

enclosures that can be used for both

indoor and outdoor applications right

out of the box!

No more bulky unattractive weatherhoods... No more worries over what

options to specify for outdoor

applications.

Expertly designed and crafted, the

ADVANTAGE Series boasts a stylish

appearance with rounded edges, no

visible hardware and a textured

baked powder finish to blend easily

with contemporary enclosure designs.

Serviceability has been made easier

by incorporating a “knock-down”

sheetmetal design which provides

quick access to internal components.

These air conditioners are available

in capcities from 2,000 to 22,000

BTU/H in seven heights, all utilizing

the exclusive M/TAB integral mounting system.

Features

• Capacities: 2,000 to 22,000 BTU/H

• Textured Beige Powder Finish

• Built-in Condensate Evaporator

• CFC-Free Refrigerant

• Closed-Loop Cooling

• Crankcase Compressor Heater

• Digital Temperature Display

• EMI/RFI Suppressor

• Head Pressure Control Switch

• Heavy-duty Steel Enclosure

• Low Temperature Control

Thermostat

• M/TAB Mounting System

• NEMA 3R and 12 Ratings

Maintained (UL50)

• Filters

• Six Foot [1.8m] (minimum) SJT

3-wire Cord

• UL/CUL Recognized

• Completelineofaccessories

RP17

2,000 BTU/H

17"H x 12"W x 11"D

RP28

3,000 BTU/H

28"H x 12"W x 11"D

RP33

4,000 BTU/H

33"H x 12"W x 11"D

RP36

6,000 BTU/H

36"H x 15"W x 11"D

RP47

8,000 & 12,000

BTU/H

47"H x 15"W x 13"D

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

RP52

18,000 BTU/H

52"H x 17"W x 16"D

DATA SUBJECT TO CHANGE WITHOUT NOTICE

RP55

22,000 BTU/H

55"H x 22"W x 17"D

Page 6

K6

ENVIRONMENTAL CONTROLS

ADVANTAGE “RP17” SERIES AIR-COOLED

SIDE-MOUNTED AIR CONDITIONERS

12.35

[313.7]

2

NEMA

TYPE 3R & 12

MAINTAINED

FEATURES-SPECIFICATIONS

Standard Features

• Condensate Evaporator

• CFC-Free Refrigerant

• Crankcase Compressor Heater

• Digital Temperature Display

• EMI/RFI Suppressor

• Head Pressure Control Switch

• Filters

• Low Temperature Control Thermostat

• M/TAB Mounting System

• NEMA 3R & 12 Rating Maintained

• UL/CUL Recognized

‡

• Textured Beige Powder Finish

Accessories and Options

•

Cooling Effect Detector

• Enclosure Heater

• Filter Recoating Adhesive

• Filters for replacement

• Internal corrosion protection

• Painted Metal Grille

• Power Loss Delayed

Compressor Start

• Short Cycle Protector

• Special paint finishes

3

4

17 .50

[444.5]

PERFORMANCE CHART

WA4C2RP17R

4000

3500

3000

2500

2000

1500

1000

500

Cooling Capacity (BTU/H)

0

70

Operation within shaded area not

Operation within shaded area not

recommended.

recommended.

KA4C2RP17R

Maximum enclosure

air temperature ºF

80

90 100 110 120 130

Ambient Temperature (ºF)

17 .14

[435.4]

1

10.94

[277.8]

12 5

120

110

10 0

90

75

80

ADVANTAGE SERIES RP17 ADVANTAGE AIR-COOLED PANEL-MOUNTED AIR CONDITIONERS

MODEL

RATED CAPACITY 95/95 RATING AMBIENT TEMP. °F VOLTS HZ RUNNING APPROX.

(BTU/H) (BTU/H) MAX./MIN. AMPS WEIGHT (LBS.)

WA4C2RP17R 2000 1200 120/50 115/100 60/50 7.0/7.5 64

W2A4C2RP17R 2000 1200 120/50 230/200 60/50 4.0 64

(6) .281 [7.0]

1.05

[26.7]

2.20

[55.9]

6.75

71.5]

[1

6.75

[171.5]

Dimensions, inches [metric], are for reference only and subject to change.

‡

UL/CUL Recognized models are available as Listed at added cost.

DIA. HOLES

10.25

[260.4]

3

4

9.31

[236.5]

7.00

[177.8]

6.25

[158.8]

1.53

[38.9]

2.06

[52.3]

[12.7]

0.50

17 .50

[444.5]

10.94

[277.9]

1.00 [25.4] DIA. HOLE

9.54

[242.3]

7.60

[193.0]

1.56

[39.6]

2

12.35

[313.7]

1

[1

6.18

57.0]

2.21

[56.1]

MOUNTING PLAN

1.00

[25.4]

1.06

[27.0]

6.75

[171.5]

15.13

[384.2]

6.75

[171.5]

0.56

[14.3]

9.31

[236.5]

3

4

10.25

[260.4]

11.25

[285.8]

7.00

[177.8]

6.25

[158.8]

(6) .281 [7.0]

DIA. HOLES

0.44

[11.4]

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

DATA SUBJECT TO CHANGE WITHOUT NOTICE

Page 7

ENVIRONMENTAL CONTROLS

ADVANTAGE “RP28” SERIES AIR-COOLED

SIDE-MOUNTED AIR CONDITIONERS

12.35

[313.7]

K7

FEATURES-SPECIFICATIONS

Standard Features

• Condensate Evaporator

• CFC-Free Refrigerant

• Crankcase Compressor Heater

• Digital Temperature Display

• EMI/RFI Suppressor

• Head Pressure Control Switch

• Filters

• Low Temperature Control Thermostat

• M/TAB Mounting System

• NEMA 3R & 12 Rating Maintained

• UL/CUL Recognized

‡

• Textured Beige Powder Finish

NEMA

TYPE 3R & 12

MAINTAINED

Accessories and Options

• Cooling Effect Detector

• Enclosure Heater

• Filter Recoating Adhesive

• Filters for replacement

• Internal corrosion protection

• Painted Metal Grille

• Power Loss Delayed Compressor

Start

• Short Cycle Protector

• Special paint finishes

27.75

[704.9]

4

3

PERFORMANCE CHART

WA4C3RP28R

6000

5250

4500

3750

3000

2250

1500

750

Cooling Capacity (BTU/H)

0

70

KA4C3RP28R

Maximum enclosure

air temperature ºF

80

90 100 110 120 130

Ambient Temperature (ºF)

Operation within shaded area not

recommended.

27.39

[695.6]

2

1

10.94

[277.8]

125

120

110

10 0

90

80

75

ADVANTAGE SERIES RP17 ADVANTAGE AIR-COOLED PANEL-MOUNTED AIR CONDITIONERS

MODEL

RATED CAPACITY 95/95 RATING AMBIENT TEMP. °F VOLTS HZ RUNNING APPROX.

(BTU/H) (BTU/H) MAX./MIN. AMPS WEIGHT (LBS.)

WA4C3RP28R 3000 2220 125/50 115/100 60/50 9.8/9.7 86

W2A4C3RP28R 3000 2220 115/50 230/200 60/50 5.5/5.6 86

1.91

[48.5]

8.00

[203.2]

TYP.

1. 1 8

[29.9]

9.00

[228.6]

4

3

10.00

[254.0]

1.67

[42.4]

[165.1]

12.88

[327.2]

5.00

[127.0]

6.50

1.78

[45.2]

27.75

[704.8]

10.94

[277.8]

10.17

[258.3]

8.64

[219.4]

8.59

[217.9]

1.50

[38.1]

6.21

[157.7]

2

12.35

[313.6]

1.00 [25.4] DIA. HOLE

MOUNTING PLAN

1.68

[42.7]

8.00

[203.2]

TYP.

27.75

[704.9]

1.84

[46.7]

1. 1 8

[30.0]

9.00

[228.6]

4

3

10.00

[254.0]

12.35

[313.7]

Dimensions, inches [metric], are for reference only and subject to change.

‡

UL/CUL Recognized models are available as Listed at added cost.

2.51

[63.7]

1

UNIT MUST BE 4" [100mm]

MINIMUM ABOVE FLOOR

FOR FILTER ACCESS

(8) .281 [7.0]

DIA. HOLES

6.50

[165.1]

12.88

[327.2]

5.00

[127.0]

1.78

[45.2]

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

DATA SUBJECT TO CHANGE WITHOUT NOTICE

Page 8

K8

ENVIRONMENTAL CONTROLS

ADVANTAGE “RP33” SERIES AIR-COOLED

SIDE MOUNT AIR CONDITIONERS

12.35

[313.7]

NEMA

TYPE 3R & 12

MAINTAINED

FEATURES-SPECIFICATIONS

Standard Features

• Built-in Condensate Evaporator

• CFC-Free Refrigerant

• Crankcase Compressor Heater

• Digital Temperature Display

• EMI/RFI Suppressor

• Head Pressure Control Switch

• Filters

• Low Temperature Control Thermostat

• M/TAB Mounting System

• NEMA 3R & 12 Rating Maintained

• UL/CUL Recognized

‡

• Textured Beige Powder Finish

Accessories and Options

• Cooling Effect Detector

• Enclosure Heater

• Filter Recoating Adhesive

• Filters for replacement

• Internal corrosion protection

• Painted Metal Grille

• Power Loss Delayed Compressor

Start

• Short Cycle Protector

• Special paint finishes

32.75

[831.9]

4

3

PERFORMANCE CHART

WA4C4RP33R

9600

8400

7200

6000

4800

3600

2400

1200

Cooling Capacity (BTU/H)

0

70

KA4C4RP33R

Maximum enclosure

air temperature ºF

80

75

80

90 100 110 120 130

Ambient Temperature (ºF)

Operation within shaded area not

recommended.

32.39

[822.7]

2

1

10.94

[277.8]

12 5

120

110

90

100

WDTS SERIES ENVIRONMENTAL CONTROLS 3500 BTU SIDE MOUNT AIR CONDITIONERS

MODEL

RATED CAPACITY 95/95 RATING AMBIENT TEMP. °F VOLTS HZ RUNNING APPROX.

(BTU/H) (BTU/H) MAX./MIN. AMPS WEIGHT (LBS.)

WA4C4RP33R 4000 2850 125/50 115/100 60/50 13.6/13.3 98

W2A4C4RP33R 4000 2850 125/50 230/200 60/50 5.8 98

10.2 5

2.04

[51.8]

9.62

[244.3]

TYP.

(8) .281 [7.0]

DIA. HOLES

1. 8 4

[46.7]

1. 1 8

[30.0]

Dimensions, inches [metric], are for reference only and subject to change.

‡

UL/CUL Recognized models are available as Listed at added cost.

[260.4]

4

3

9.00

[228.6]

10.0 0

[254.0]

1. 0 5

[26.7]

4.00

[101.6]

16.5 0

[419.1]

7. 7 5

[196.9]

1. 6 8

[42.7]

2.72

[69.1]

1. 7 8

[45.2]

32.75

[831.9]

10.9 4

[277.9]

1.00 [25.4] DIA.HOLE

MOUNTING PLAN

13.3 5

[339.1]

8.54

[216.9]

10.5 0

[266.7]

1. 5 6

[39.6]

2

12.3 5

[313.7]

1

6.18

[157.0]

2.04

[51.8]

9.62

[244.3]

TYP.

(8) .281 [7.0]

DIA. HOLES

1. 8 4

[46.7]

[30.0]

2.43

[61.7]

10.2 5

[260.4]

4

3

9.00

[228.6]

1. 1 8

10.0 0

[254.0]

UNIT MUST BE 4" [100mm]

MINIMUM ABOVE FLOOR

FOR FILTER ACCESS

1. 0 5

[26.7]

4.00

[101.6]

16.5 0

[419.1]

7. 7 5

[196.9]

1. 6 8

[42.7]

2.72

[69.1]

1. 7 8

[45.2]

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

DATA SUBJECT TO CHANGE WITHOUT NOTICE

Page 9

ENVIRONMENTAL CONTROLS

ADVANTAGE “RP36” SERIES AIR-COOLED

SIDE-MOUNTED AIR CONDITIONERS

15.3 5

[389.9]

K9

NEMA

TYPE 3R & 12

MAINTAINED

FEATURES-SPECIFICATIONS

Standard Features

• Built-in Condensate Evaporator

• CFC-Free Refrigerant

• Crankcase Compressor Heater

• Digital Temperature Display

• EMI/RFI Suppressor

• Head Pressure Control Switch

• Filters

• Low Temperature Control Thermostat

• M/TAB Mounting System

• NEMA 3R & 12 Rating Maintained

• UL/CUL Recognized

‡

• Textured Beige Powder Finish

Accessories and Options

• Cooling Effect Detector

• Enclosure Heater

• Filter Recoating Adhesive

• Filters for replacement

• Internal corrosion protection

• Painted Metal Grille

• Power Loss Delayed Compressor

Start

• Short Cycle Protector

• Special paint finishes

36.75

[955.5]

4

3

PERFORMANCE CHART

WA4C6RP36R

9600

8400

7200

6000

4800

3600

2400

1200

Cooling Capacity (BTU/H)

0

70

KA4C6RP36R

Maximum enclosure

air temperature ºF

80

90 100 110 120 130

Ambient Temperature (ºF)

Operation within shaded area not

recommended.

1

2

10.9 4

[277.8]

36.30

[922.0]

125

120

110

100

90

80

75

ADVANTAGE SERIES RP36 ADVANTAGE AIR-COOLED PANEL-MOUNTED AIR CONDITIONERS

MODEL

RATED CAPACITY 95/95 RATING AMBIENT TEMP. °F VOLTS HZ RUNNING APPROX.

(BTU/H) (BTU/H) MAX./MIN. AMPS WEIGHT (LBS.)

WA4C6RP36R 6000 4500 125/50 115/100 60/50 19.5/20.0 123

W2A4C6RP36R 6000 4500 115/50 230/200 60/50 19.5/20.0 123

MOUNTING PLAN

1. 1 0

[27.9]

(12) .281 [7.0]

DIA. HOLES

6.75

[171.5]

TYP.

5.75

[146.1]

1. 4 3

[36.3]

1.84

[46.7]

Dimensions, inches [metric], are for reference only and subject to change.

‡

UL/CUL Recognized models are available as Listed at added cost.

13.16

[334.3]

4

3

12.5 0

[317.5]

TYP.

7. 7 5

[196.9]

[124.0]

28.96

[735.6]

1. 8 4

[46.7]

4.88

36.75

[933.5]

13.2 5

[336.6]

36.30

[922.0]

1. 5 6

[39.6]

2

15.3 4

[389.6]

1

1. 1 0

[27.9]

(12) .281 [7.0]

DIA. HOLES

5.75

[146.1]

1. 4 3

[36.3]

1. 8 4

[46.7]

6.75

[171.5]

TYP.

UNIT MUST BE 4" [100mm]

MINIMUM ABOVE FLOOR

FOR FILTER ACCESS

13.16

[334.3]

4

3

12.5 0

[317.5]

TYP.

7. 7 5

[196.9]

[124.0]

28.96

[735.6]

1. 8 4

[46.7]

4.88

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

DATA SUBJECT TO CHANGE WITHOUT NOTICE

Page 10

K10

ENVIRONMENTAL CONTROLS

ADVANTAGE “RP47” SERIES AIR-COOLED

SIDE-MOUNTED AIR CONDITIONERS

15.3 5

[389.9]

NEMA

TYPE 3R & 12

MAINTAINED

Standard Features

• Built-in Condensate Evaporator

• CFC-Free Refrigerant

• Crankcase Compressor Heater

• Digital Temperature Display

• EMI/RFI Suppressor

• Head Pressure Control Switch

• Filters

• Low Temperature Control Thermostat

• M/TAB Mounting System

• NEMA 3R & 12 Rating Maintained

• UL/CUL Recognized

‡

• Textured Beige Powder Finish

36.75

[955.5]

4

3

Accessories and Options

• Cooling Effect Detector

• Enclosure Heater

• Filter Recoating Adhesive

• Filters for replacement

• Internal corrosion protection

• Painted Metal Grille

• Power Loss Delayed Compressor

Start

• Short Cycle Protector

• Special paint finishes

36.30

[922.0]

PERFORMANCE CHART

2

16000

14000

12000

10000

1

10.9 4

[277.8]

8000

6000

4000

2000

Cooling Capacity (BTU/H)

16000

14000

12000

10000

8000

6000

4000

2000

Cooling Capacity (BTU/H)

0

70

0

70

WA4C8RP47R

KA4C8RP47R

Maximum enclosure

air temperature ºF

80

90 100 110 120 130

Ambient Temperature (ºF)

WA4C12RP47R

KA4C12RP47R

Maximum enclosure

air temperature ºF

80

90 100 110 120 130

Ambient Temperature (ºF)

12 5

120

110

100

125

120

110

100

90

80

75

90

80

75

Operation within shaded area not

recommended.

ADVANTAGE SERIES RP47 ADVANTAGE AIR-COOLED PANEL-MOUNTED AIR CONDITIONERS

MODEL

RATED CAPACITY 95/95 RATING AMBIENT TEMP. °F VOLTS HZ RUNNING APPROX.

(BTU/H) (BTU/H) MAX./MIN. AMPS WEIGHT (LBS.)

WA3C8RP47R 8000 6600 125/50 115/100 60/50 12.2/12.7 150

W2A3C8RP47R 8000 6600 125/50 230/200 60/50 5.7/5.9 150

WA3C12RP47R 12000 8500 125/50 115/100 60/50 19.8/19.1 150

W2A3C12RP47R 12000 8500 125/50 230/200 60/50 9.1/9.0 150

15.3 5

[389.9]

1. 4 3

[36.3]

(14) .281 [7.0]

DIA. HOLES

7. 0 0

[177.8]

TYP.

3.13

[79.5]

1. 1 0

[27.9]

Dimensions, inches [metric], are for reference only and subject to change.

‡

UL/CUL Recognized models are available as Listed at added cost.

12.5 0

[317.5]

4

3

12.5 0

[317.5]

13.16

[334.3]

7. 0 0

[177.8]

27.75

[704.9]

7. 7 5

[196.9]

47.25

[1200.2]

1. 8 4

[46.7]

(14) .281 [7.0]

DIA. HOLES

7. 0 0

[177.8]

TYP.

1. 4 3

[36.3]

3.13

[79.5]

1. 1 0

[27.9]

12.5 0

[317.5]

4

3

12.5 0

[317.5]

13.16

[334.3]

7. 0 0

[177.8]

27.75

[704.9]

7. 7 5

[196.9]

1. 8 4

[46.7]

47.25

[1200.2]

13.2 5

[336.6]

46.81

[1189.0]

UNIT MUST BE 4" [100mm]

MINIMUM ABOVE FLOOR

FOR FILTER ACCESS

15.3 5

[389.9]

2

1

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

DATA SUBJECT TO CHANGE WITHOUT NOTICE

Page 11

FEATURES-SPECIFICATIONS

ENVIRONMENTAL CONTROLS

TRIMLINE SERIES AIR-COOLED

SIDE-MOUNTED AIR CONDITIONERS

NEMA

TYPE 12

MAINTAINED

K11

Description

Innovations in technology have resulted

in much denser components packaging and smaller available panel sizes

on which to mount Air Conditioners.

The TrimLine Series is the response to

these new packaging demands with

the Narrow 10", 12", 15" and 17" width

panel-mount air conditioners. In addition to being narrower than traditional

Air Conditioner units, the TrimLine

Series include the Condensate

Evaporator, Low Temperature Control

Thermostat and EMI/RFI Suppressor

as standard features and are available

in all popular voltages and frequencies.

The TrimLine Series consists of compact models in 2,000-2,500 BTU/H

capacities, mid-size models, 28", 33"

and 36" WITH up to 4,000, 5,000 and

6,000 BTU/H respectively and the fullsize model at 47" with 10,000 BTU/H.

Each model series is designed with a

minimum width to take up less cabinet

space on the exterior panel or door.

Integral to the TrimLine Series is the

M/TAB (Mounting Template and

Assembly Bracket) system which

makes installing Air Conditioners simple

and fast and interchangeable with corresponding TrimLine Heat Exchangers.

Outdoor or corrosive environments

require weather protection and/or

special internal and external protective features. For outdoor applications

see the Advantage and Integrity

Outdoor Series.

For extreme ambient temperatures

and/or severely contaminated environments, the use of TrimLine or other

Water-Cooled Air Conditioners are

recommended.

Features

• Capacities: 2,000 to 10,000 BTU/H;

six heights available

• CFC-free or Low ODP Refrigerant

• All models UL/CUL Listed or

Recognized

• Tested and approved by UL for

NEMA 12 Enclosures

• Compact design with slim 10",

12", 15" and 17" wide mounting

footprints

• Exclusive KOOLTRONIC M/TAB

integral mounting system for quick,

easy installation

• Built-in Condensate Evaporator

eliminates need for draining normal

condensate

• Thermostatic Low Temperature

Control prevents over-cooling and

provides energy-efficient operation

• EMI/RFI Suppressor minimizes transient line spikes during on/off cycling

• Field-reversible condenser outlet

blower provides choice of horizontal or vertical air discharge

• Heavy-duty steel enclosures with

gray baked powder finish

• Six foot (minimum) SJT 3-wire

power cord

• Complete line of accessories

NP17

2,000 BTU/H

17”H x 12”W x 9”D

Narrow-Mini

2,500 BTU/H

20”H x 10”W x 10”D

NP28

4,000 BTU/H

28”H x 11”W x 12”D

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

NP33

4,000 BTU/H

33”H x 12”W x 9”D

NP36

4,000 & 6,000 BTU/H

36”H x 15”W x 12”D

DATA SUBJECT TO CHANGE WITHOUT NOTICE

7,000, 8,000,

10,000 12,000

47”H x 15”W x 12”D

NP47

BTU/H

Page 12

K12

ENVIRONMENTAL CONTROLS

TRIMLINE “NP17” SERIES

SIDE-MOUNTED AIR CONDITIONERS

Standard Features

• Built-in Condensate Evaporator

• CFC-Free Refrigerant

• EMI/RFI Suppressor

• Low Temperature Control Thermostat

• M/TAB Mounting System

• NEMA 12 Rating Maintained (UL50)

• UL/CUL Listed

• Gray Powder Finish

Accessories and Options

• Cooling Effect Detector

NEMA

TYPE 12

MAINTAINED

• Filter Recoating Adhesive

• Filters for replacement

• Internal corrosion protection

• Lifting Eyes

• Low Ambient Kit

• Short Cycle Protector

‡

• Special materials or finishes

• Special motors, line cords, or

connectors

• Stainless or Aluminum Cabinet

• Weather Protection Kit

M/TAB

12.25

[311.2]

THERMOSTAT

ADJUSTMENT

ACCESS

3

4

PERFORMANCE CHART

WA4C2.0NP17L

4000

3500

3000

2500

2000

1500

1000

500

Cooling Capacity (BTU/H)

0

70

KA4C2.0NP17L

Maximum enclosure

air temperature ºF

80

90 100 110 120 130

Ambient Temperature (ºF)

Operation within shaded area not

recommended.

12.13

[308.1]

1

17.50

[444.5]

2

9.00

[228.6]

125

120

110

100

90

75

80

TRIMLINE SERIES NP17 AIR-COOLED PANEL-MOUNTED AIR CONDITIONERS

MODEL

RATED CAPACITY 95/95 RATING AMBIENT TEMP. °F VOLTS HZ RUNNING APPROX.

(BTU/H) (BTU/H) MAX./MIN. AMPS WEIGHT (LBS.)

WA4C20NP17L 2000 1420 125/50 115/100 60/50 6.7/6.5 59

W2A4C20NP17L 2000 1420 125/50 230/200 60/50 4.3 59

MOUNTING PLAN

12.25

[311.2]

(6)1/4-20 WELD NUTS

3

M/TAB

6' [1.83M] MIN.

POWER CORD

4

Dimensions, inches [metric], are for reference only and subject to change.

‡

UL/CUL Recognized models are available as Listed at added cost.

9.00

[228.6]

2

0.38 [9.5] O.D.

CONDENSATE DRAIN

17.50

[444.5]

0.50

[12.7]

FILTER

0.50

[12.7]

TYP.

1

8.13

[206.5]

TYP.

0.38

12.13

[308.1]

Weld nuts supplied for alternate mounting method to

maintain NEMA 12. Mounting Plans furnished on request.

[9.5]

(8) .312 [7.9]

DIA HOLES

6.13

[155.7]

11.25

[285.8]

4

3

8

5.75

[146.1]

3

8

3.13

[79.5]

5.00

[127.0]

4.13

[104.9]

6.38

[162.1]

0.38

[9.5]

0.38

[9.5]

17.50

[444.5]

0.88

[22.4]

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

DATA SUBJECT TO CHANGE WITHOUT NOTICE

Page 13

ENVIRONMENTAL CONTROLS

TRIMLINE “NP28” SERIES AIR-COOLED

SIDE-MOUNTED AIR CONDITIONERS

10.13

[257.3]

K13

NEMA

TYPE 12

MAINTAINED

Standard Features

• Built-in Condensate Evaporator

• CFC-Free Refrigerant

• EMI/RFI Suppressor

• Low Temperature Control

Thermostat

• M/TAB Mounting System

• NEMA 12 Rating Maintained (UL50)

• UL/CUL Listed

• Gray Powder Finish

Accessories and Options

• Cooling Effect Detector

• Filter Recoating Adhesive

• Filters for replacement

• Internal corrosion protection

• Lifting Eyes

• Low Ambient Kit

• Short Cycle Protector

• Special materials or finishes

• Special motors, line cords, or

connectors

• Stainless or Aluminum Cabinet

• Weather Protection Kit

M/TAB

2

28.50

[723.9]

THERMOSTAT

ADJUSTMENT

ACCESS

3

1

4

11.50

3

[292.1]

PERFORMANCE CHART

WA4C4NP28L

8000

7000

6000

5000

4000

3000

2000

1000

Cooling Capacity (BTU/H)

0

70

KA4C4NP28L

Maximum enclosure

air temperature ºF

80

90 100 110 120 130

Ambient Temperature (ºF)

75

125

120

110

100

90

80

Operation within shaded area not

recommended.

TRIMLINE SERIES NP28 AIR-COOLED PANEL-MOUNTED AIR CONDITIONERS

MODEL

RATED CAPACITY 95/95 RATING AMBIENT TEMP. °F VOLTS HZ RUNNING APPROX.

(BTU/H) (BTU/H) MAX./MIN. AMPS WEIGHT (LBS.)

WA4C4NP28L 4000 2520 125/50 115/100 60/50 13.0/12.0 85

W2A4C4NP28L 4000 2520 120/50 230/200 60/50 6.0 85

MOUNTING PLAN

6' [1.83M] MIN.

POWER CORD

M/TAB

11.50

[292.1]

CONDENSATE

DRAIN IN BOTTOM

1. 1 4

[28.9]

7.00

[177.8]

1.57

[39.8]

0.64

[16.2]

2

28.50

4

[723.9]

3

Dimensions, inches [metric], are for reference only and subject to change.

1

10.13

[257.3]

FILTER

3.41

[86.6]

7.75

[196.8]

4.19

[106.4]

2.76

[70.1]

7.75

[196.8]

1.50

[38.1]

3

4.30

[109.2]

4

3

7.00

[177.8]

8.00

[203.2]

2.92

[74.1]

1.07

[27.1]

7.50

[190.5]

TYP.

3.61

[91.6]

2.39

[60.7]

(8) .312 [7.9]

DIA. HOLES

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 14

K14

ENVIRONMENTAL CONTROLS

TRIMLINE “NP33” SERIES AIR-COOLED

SIDE-MOUNTED AIR CONDITIONERS

M/TAB

12.50

[317.5]

2

3

1

32.88

[835.2]

NEMA

TYPE 12

MAINTAINED

Standard Features

• Built-in Condensate Evaporator

• CFC-Free or Low ODP Refrigerant

• EMI/RFI Suppressor

• Low Temperature Control

Thermostat

• M/TAB Mounting System

• NEMA 12 Rating Maintained (UL50)

• Reversible Condenser Outlet Blower

• UL/CUL Listed

• Gray Powder Finish

Accessories and Options

• Cooling Effect Detector

• Enclosure Heater

• Filter Recoating Adhesive

• Filters for replacement

• Internal corrosion protection

• Lifting Eyes

• Low Airflow Detector

• Low Ambient Kit

• Short Cycle Protector

• Special materials or finishes

• Special motors, line cords, or

connectors

• Stainless or Aluminum Cabinet

• Weather Protection Kit

4

8000

7000

6000

5000

4000

3000

2000

1000

Cooling Capacity (BTU/H)

0

70

Operation within shaded area not

recommended.

9.50

[241.3]

PERFORMANCE CHART

WA4C4NP33L

KA4C4NP33L

Maximum enclosure

air temperature ºF

80

90 100 110 120 130

Ambient Temperature (ºF)

TRIMLINE SERIES NP33 AIR-COOLED PANEL-MOUNTED AIR CONDITIONERS

MODEL

RATED CAPACITY 95/95 RATING AMBIENT TEMP. °F VOLTS HZ RUNNING APPROX.

(BTU/H) (BTU/H) MAX./MIN. AMPS WEIGHT (LBS.)

WA4C4NP33L 4000 2680 125/50 115/100 60/50 12.8 90

W2A4C4NP33L 4000 2680 125/50 230/200 60/50 7.0 90

THERMOSTAT

ADJUSTMENT

ACCESS

75

125

120

110

100

90

80

1.05

[26.7]

[101.6]

16.50

[419.1]

[196.9]

[42.7]

2.04

[51.8]

9.62

[244.3]

TYP.

(8) .281 [7.0]

DIA. HOLES

1.84

[46.7]

[30.0]

1. 1 8

10.25

[260.4]

4

3

9.00

[228.6]

10.00

[254.0]

Dimensions, inches [metric], are for

reference only and subject to change.

4.00

7.75

1.68

2.72

[69.1]

1.78

[45.2]

32.75

[831.9]

13.35

[339.1]

10.94

[277.9]

1.00 [25.4] DIA.HOLE

8.54

[216.9]

10.50

[266.7]

1.56

[39.6]

2

12.35

[313.7]

1

6.18

[157.0]

(8) .281 [7.0]

DIA. HOLES

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

2.04

[51.8]

2.43

[61.7]

MOUNTING PLAN

10.25

[260.4]

9.62

[244.3]

TYP.

1.84

[46.7]

[228.6]

1. 1 8

[30.0]

10.00

[254.0]

4

3

9.00

1.05

[26.7]

4.00

[101.6]

16.50

[419.1]

7.75

[196.9]

1.68

[42.7]

2.72

[69.1]

1.78

[45.2]

DATA SUBJECT TO CHANGE WITHOUT NOTICE

Page 15

NEMA

TYPE 12

MAINTAINED

ENVIRONMENTAL CONTROLS

TRIMLINE “NP36” SERIES AIR-COOLED

SIDE-MOUNTED AIR CONDITIONERS

15.19

[385.8]

2

PERFORMANCE CHARTS

WA4C4NP36L

8000

1

12.25

[311.2]

36.75

[933.5]

3

4

7000

6000

5000

4000

3000

2000

1000

Cooling Capacity (BTU/H)

0

70

KA4C4NP36L

80

90 100 110 120 130

Ambient Temperature (ºF)

K15

Maximum enclosure

air temperature ºF

125

120

110

100

90

80

75

Standard Features

• Built-in Condensate Evaporator

• CFC-Free Refrigerant

• EMI/RFI Suppressor

• Low Temperature Control Thermostat

• M/TAB Mounting System

• NEMA 12 Rating Maintained(UL50)

• Reversible Condenser Outlet Blower

• UL/CUL Listed/Recognized

‡

• Gray Powder Finish

Accessories and Options

• Cooling Effect Detector

• Filter Recoating Adhesive

• Filters for replacement

• Internal corrosion protection

• Lifting Eyes

• Low Ambient Kit

• Low Airflow Detector

• Short Cycle Protector

• Special materials or finishes

• Special motors, line cords, or

connectors

• Stainless or Aluminum Cabinet

• Weather Protection Kit

WA4C6NP36R

8000

7000

6000

5000

4000

3000

2000

1000

Cooling Capacity (BTU/H)

0

70

KA4C6NP36R

80

90 100 110 120 130

Ambient Temperature (ºF)

Operation within shaded area not

recommended.

TRIMLINE SERIES NP36 AIR-COOLED PANEL-MOUNTED AIR CONDITIONERS

MODEL

RATED CAPACITY 95/95 RATING AMBIENT TEMP. °F VOLTS HZ RUNNING APPROX.

(BTU/H) (BTU/H) MAX./MIN. AMPS WEIGHT (LBS.)

WA4C4NP36L 4000 3700 125/50 115/100 60/50 13.5 125

W2A4C4NP36L 4000 3700 125/50 230/200 60/50 7.5 125

WA4C6NP36R 6000 4100 125/50 115/100 60/50 16.5/17.0 125

W2A4C6NP36L 6000 4100 125/50 230/200 60/50 8.2 125

(OPTIONAL)

6' [1.82M] MIN.

POWER CORD

M/TAB

12.25

[311.2]

2

MOUNTING PLAN

1.50

[38.1]

[382.6]

[304.8]

15.06

12.00

2

36.75

[933.5]

3

4

CONDENSATE DRAIN

Dimensions, inches (metric), are for reference only and subject to change.

‡

UL/CUL Recognized models are available as Listed at added cost.

FILTER

1

15.19

[385.8]

THERMOSTAT

(10) .312 [7.9]

DIA. HOLES

6.75

[171.5]

TYP.

8.25

[209.6]

1.25

[31.8]

0.88

[22.2]

3

4

12.50

[317.5]

13.31

[338.1]

[304.8]

[492.1]

0.75

[19.1]

Maximum enclosure

air temperature ºF

125

120

110

100

90

80

75

12.00

36.75

[933.5]

19.38

3.00

[76.2]

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

DATA SUBJECT TO CHANGE WITHOUT NOTICE

Page 16

ENVIRONMENTAL CONTROLS

K16

TRIMLINE “NP47” SERIES AIR-COOLED

SIDE-MOUNTED AIR CONDITIONERS

Standard Features

• Built-in Condensate Evaporator

• CFC-Free or Low ODP Refrigerant

• EMI/RFI Suppressor

• Low Temperature Control Thermostat

• M/TAB Mounting System

• NEMA 12 Rating Maintained (UL50)

• Reversible Condenser Outlet Blower

• UL/CUL Listed/Recognized

‡

• Gray Powder Finish

Accessories and Options

• Cooling Effect Detector

• Deep Drain Pan Kit

THERMOSTAT

ADJUSTMENT

ACCESS

3

NEMA

TYPE 12

MAINTAINED

4

• Enclosure Heater

• Filter Recoating Adhesive

• Filters for replacement

• Internal corrosion protection

• Lifting Eyes

• Low Airflow Detector

• Low Ambient Kit

• Short Cycle Protector

• Special materials or finishes

• Special motors, line cords, or

connectors

• Stainless or Aluminum Cabinet

• Weather Protection Kit

M/TAB

2

1

15.19

[385.8]

12.25

[311.2]

47.25

[1200.2]

PERFORMANCE CHARTS

WA4C7NP47L

12000

10500

9000

7500

6000

4500

3000

1500

Cooling Capacity (BTU/H)

13500

12000

10500

9000

7500

6000

4500

3000

Cooling Capacity (BTU/H)

1500

0

70

70

KA4C8NP47R

80

90 100 110 120 130

Ambient Temperature (ºF)

WA4C10NP47R

KA4C12NP47R

80

90 100 110 120 130

Ambient Temperature (ºF)

Operation within shaded area not

recommended.

Maximum enclosure

air temperature ºF

125

120

110

100

90

80

75

Maximum enclosure

air temperature ºF

125

120

110

100

90

80

75

TRIMLINE SERIES NP47 AIR-COOLED PANEL-MOUNTED AIR CONDITIONERS

MODEL

RATED CAPACITY 95/95 RATING AMBIENT TEMP. °F VOLTS HZ RUNNING APPROX.

(BTU/H) (BTU/H) MAX./MIN. AMPS WEIGHT (LBS.)

WA4C7NP47R 7000 4750 125/50 115/100 60/50 16.5 150

W2A4C7NP47L 7000 4750 125/50 230/200 60/50 8.6 150

WA3C10NP47R 10000 7250 120/50 115/100 60/50 19.2/18.6 160

W2A4C10NP47L 10000 7250 125/50 230/200 60/50 11.8 160

WA3C13NP47R 13000 7250 120/50 115/100 60/50 19.2/18.6 160

W2A4C13NP47R 13000 7250 125/50 230/200 60/50 11.8 160

MOUNTING PLAN

14.81

[376.2]

13.31

7.00

[177.8]

TYP.

0.88

[22.4]

1.50

[38.1]

10.13

[257.1]

1.25

[31.8]

[338.1]

12.00

[304.7]

4

12.50

[317.5]

3

Dimensions, inches [metric], are for

reference only and subject to change.

‡

UL/CUL Recognized models are

available as Listed at added cost.

FILTER

2

1

15.19

[385.8]

(OPTIONAL)

2

47.25

[1200.2]

12.25

[311.2]

OPTIONAL

CONDENSATE DRAIN

M/TAB

3

4

CONDENSATE

DRAIN

6' [1.82M] MIN.

POWER CORD

(12) .312 [7.9]

DIA. HOLES

0.75

[19.0]

18.00

[457.2]

23.88

[606.3]

3.00

[76.2]

46.63

[1184.4]

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

DATA SUBJECT TO CHANGE WITHOUT NOTICE

Page 17

ENVIRONMENTAL CONTROLS

MICRO-MINI SERIES AIR-COOLED

SIDE-MOUNTED AIR CONDITIONERS

K17

FEATURES-SPECIFICATIONS

Standard Features

• Ball-bearing Motors

• CFC-Free Refrigerant

• EMI/RFI Suppressor

• Low Temperature Control Thermostat

• NEMA 12 Rating Maintained (UL50)

• UL/CUL Listed

• Gray Powder Finish

NEMA

TYPE 12

MAINTAINED

Accessories and Options

• Adapter Plate for rack mounting

• Compressor Heater

• Condensate Evaporator

• Cooling Effect Detector

• Filter Recoating Adhesive

• Filters for replacement

• Internal corrosion protection

• Lifting Eyes

THERMOSTAT

ADJUSTMENT

ACCESS

• Low Ambient Kit and Compressor

• Mounting Hinge

•ShortCycleProtector

• Special materials or finishes

• Special motors, line cords, or

• Stainless or Aluminum Cabinet

• Weather Protection Kit

14.13

[358.9]

Heater

connectors

13.25

[336.6]

6.25

[158.8]

12.88

[327.2]

MICRO-MINI SERIES AIR-COOLED PANEL-MOUNTED AIR CONDITIONERS

MODEL

RATED CAPACITY 95/95 RATING AMBIENT TEMP. °F VOLTS HZ RUNNING APPROX.

(BTU/H) (BTU/H) MAX./MIN. AMPS WEIGHT (LBS.)

WA4C10MML 1000 600 125/50 115/100 60/50 4.5 43

W2A4C10MML 1000 600 125/50 230/200 60/50 2.3 43

MOUNTING PLAN

14.13

13.6 3

[346.1]

4.44

[112.7]

2.75

[69.9]

9.81

[249.2]

4.44

[112.7]

DIA.

0.81

[20.6]

3.25

[82.6]

3

4

7. 9 4

[201.6]

3.25

[82.6]

1. 5 0

[38.1]

Dimensions, inches [metric], are for

reference only and subject to change.

(4) .281 [5.5]

DIA. HOLES

4.88

[123.8]

4.00

[101.6]

6.26

[158.8]

0.68

[17.3]

0.63

[15.9]

12.0 0

[304.8]

2

1

14.13

[358.8]

13.2 5

[336.6]

(4) .312 [8.0]

DIA. HOLES

12.8 8

[327.2]

OPTIONAL POWER

CORD EXIT

CONDENSATE

DRAIN

4.88

[123.8]

4.00

[101.6]

1. 5 0

[38.1]

1.50 [38.1] DIA.

POWERCORDHOLE

0.25

[6.4]

[358.8]

13.6 3

[346.1]

[112.7]

4.50

[114.3]

8.00

[203.2]

4.44

3

4

0.81

[20.6]

4.31

[109.5]

4.50

[114.3]

1. 0 0

[25.4]

2.75

[69.9]

12.8 8

[327.2]

1. 0 0

[25.4]

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 18

ENVIRONMENTAL CONTROLS

K18

FEATURES-SPECIFICATIONS

INTEGRITY SERIES NEMA4/4X AIR-COOLED

SIDE-MOUNTED AIR CONDITIONERS

NEMA

TYPE 4/4X

MAINTAINED

Description

Designed

and 4X Enclosure applications that

require washdown or are subject to

outdoor storm conditions, Integrity

NEMA 4/4X Air Conditioners protect

the ratings of NEMA 4 or 4X Enclosures.

These exclusive patented UL/CUL

Recognized Panel-Mounted Air

Conditioners provide superior closedloop cooling and also protect against

the hazards specified for both Indoor

and Outdoor NEMA 4 and 4X

Enclosures. Tested and rated by

universally recognized Underwriters

Laboratories, these uniquelydesigned 304-2B Stainless Steel Air

Conditioners prevent unwanted environmental penetration of NEMA 4 and

4X Enclosures as they provide a

clean, cool internal environment.

With the design advantages of the

Integrity NEMA 4/4X Series and the

inclusion of the unique Mounting

Template and Assembly Bracket

(M/TAB), modified for this design,

this series offers the finest in cooling

innovation and technology.

specifically for NEMA 4

Features

• Capacities range from 2,000 to

10,000 BTU/H in 32", 38", 47" and

59" heights

• UL/CUL Listed or Recognized

• Tested and approved by UL for

NEMA 4 and 4X Enclosures

• CFC-free Refrigerant

• Gasketed flanges on all four mount-

ing edges for positive leakproof seal

• Exclusive modified integral

Mounting Template and Assembly

Bracket (M/TAB) for quick, easy

installation.

©

• Thermostatic Low Temperature

Control prevents over-cooling and

provides energy-efficient operation

• Internal Corrosion Protection

• EMI/RFI Suppressor minimizes transient line spikes during on/off

cycling

• Separate blower-driven evaporator

and condenser air systems penetrate

high static pressure applications

• Rugged heavy duty stainless steel

exterior

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 19

ENVIRONMENTAL CONTROLS

INTEGRITY “32” SERIES AIR-COOLED

SIDE-MOUNTED AIR CONDITIONERS

13.12

[333.2]

K19

M/TA B

32.25

[819.2]

31.50

[800.1]

3

NEMA

TYPE 4/4X

MAINTAINED

4

3

14.50

[368.3]

2

1

13.00

[330.2]

PERFORMANCE CHART

Standard Features

• CFC-Free Refrigerant

• EMI/RFI Suppressor

• Internal corrosion protection

• Low Temperature Control Thermostat

• M/TAB Mounting System

• NEMA 4/4X Rating Maintained

(UL50)

• Stainless Steel Cabinet

• UL/CUL Recognized

‡

Accessories and Options

• Cooling Effect Detector

• Filter Recoating Adhesive

• Filters for replacement

• Lifting Eyes

• Low Ambient Kit & Compressor

Heater

• Short Cycle Protector

• Special materials or finishes

WNA4C4P32R

8000

7000

6000

5000

4000

3000

2000

1000

Cooling Capacity (BTU/H)

0

70

KNA4C4P32R

Maximum enclosure

air temperature ºF

80

90 100 110 120 1 30

Ambient Temperature (ºF)

Operation within shaded areas not

recommended.

INTEGRITY SERIES 32 AIR-COOLED PANEL-MOUNTED AIR CONDITIONERS

MODEL

RATED CAPACITY 95/95 RATING AMBIENT TEMP. °F VOLTS HZ RUNNING APPROX.

(BTU/H) (BTU/H) MAX./MIN. AMPS WEIGHT (LBS.)

WNA4C4P32L 4000 2650 125/50 115/100 60/50 13.0/12.0 105

W2NA4C4P32L 4000 2650 120/50 230/200 60/50 6.0 105

THERMOSTAT

ADJUSTMENT

ACCESS

125

120

110

100

90

80

75

MOUNTING PLAN

UNIT M/TAB & CUTOUTS

TYP.

10.5 0

[266.7]

TYP.

3

4

3

11.5 0

[292.1]

TYP.

1. 5 0

[38.1]

8.00

[20.3]

8.00

[20.3]

(6) .312 [8.0]

DIA. HOLES

2.18

[55.4]

2.18

[55.4]

3.81

[96.8]

(24) .203 [5.0]

DIA. HOLES

M/TA B

OUTLINE

14.5 0

1 .25

[31 .7]

4.00

[10 1.6]

4.25

[107.9]

TYP.

1 .37

[34.8]

0.37

[9.4]

Dimensions, inches [metric], are for reference only and subject to change.

‡

UL/CUL Recognized models are available as Listed at added cost.

[368.3]

4

13.7 5

[349.2]

(24) .250 [6.3]

DIA. HOLES

3

[31 .7]

31 .50

[800.1]

3

0.37

[9.4]

UNIT

OUTLINE

1. 2 5

4.62

[1 17.3]

2.00

[50.8]

[130.0]

3.50

[88.9]

5.12

13.0 0

[330.2]

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

3.12

[79.2]

4.00

[101.6]

TYP.

POWER

CORD

26.00

[660.4]

12.88

[327.2]

5.00

[127.0]

4

30.19

[766.8]

3

0.88

[22.4]

0.81

[20.6]

UNIT MUST BE 12" (300mm)

MINIMUM ABOVE FLOOR

FOR FILTER ACCESS

[331.7]

M/TA B

13.06

32.25

[819.2]

14.50

[368.3]

13.13

[333.2]

13.75

[349.3]

1

1. 0 0

[25.4]

4.00

[101.6]

4.25

[108.0]

TYP.

1. 3 8

[35.1]

0.38

[9.7]

2

Page 20

ENVIRONMENTAL CONTROLS

K20

INTEGRITY SERIES 38 & 47 AIR-COOLED PANEL-MOUNTED AIR CONDITIONERS

MODEL

WNA4C7P38L 7000 6000 131/50 115/100 60/50 20 180

W2NA4C7P38L 7000 6000 131/50 230/200 60/50 9.3/9.9 180

W2NA4C10P47L 10000 7750 131/50 230/200 60/50 10.9/12.5 205

INTEGRITY “38 & 47” SERIES AIR-COOLED

SIDE-MOUNTED AIR CONDITIONERS

17.06

[433.3]

NEMA

TYPE 4/4X

MAINTAINED

M/TA B

A

3

2

1

18.56

4

[471.4]

RATED CAPACITY 95/95 RATING AMBIENT TEMP. °F VOLTS HZ RUNNING APPROX.

(BTU/H) (BTU/H) MAX./MIN. AMPS WEIGHT (LBS.)

2

18.00

[457.2]

K

THERMOSTAT

ADJUSTMENT

PERFORMANCE CHARTS

WNA4C7P38R

KNA4C7P__R

80

90 100 110 120 130

Ambient Temperature (ºF)

W2NA4C10P47R

K2NA4C10P__R

80

90 100 110 120 130

Ambient Temperature (ºF)

Cooling Capacity (BTU/H)

Cooling Capacity (BTU/H)

13500

12000

10500

9000

7500

6000

4500

3000

1500

16000

14000

12000

10000

8000

6000

4000

2000

70

0

70

Operation within shaded areas not recommended.

Maximum enclosure

air temperature ºF

75

Maximum enclosure

air temperature ºF

125

120

110

100

90

80

75

125

120

110

100

90

80

DIMENSIONS INCHES (METRIC)

MODEL A B C D E

SERIES 38 37.75 (958.8) 36.69 (931.9) 12.75 (323.8) 12.75 (323.8) 18.12 (463.5)

SERIES 47 47.00 (1193.8) 45.93 (1166.6) 12.25 (311.1) 11.25 (285.7) 27.37 (695.1)

MODEL F G H J K

SERIES 38 2.50 (63.5) 4.34 (110.2) 6.00 (152.4) 27.00 (685.8) 37.00 (939.8)

SERIES 47 2.50 (63.5) 4.00 (101.6) 8.00 (203.2) 33.00 (838.2) 46.25 (1174.7)

MOUNTING PLAN

UNIT M/TAB & CUTOUTS

18.56

1.25

[31.7]

[471.4]

33

G

TYP.

34

17.75

[450.8]

5.18

[131.5]

TYP.

1.50

[38.1]

1.50

[38.1]

Dimensions, inches [metric], are for

reference only and subject to change.

( J) .250 [6.3]

DIA. HOLES

[72.8]

B

A

[80.7]

0.68

[17.2]

UNIT

OUTLINE

(H) .312 [7.9]

HOLES

DIA.

15.00

[38.1]

33

12.81

[307.8]

12.12

[325.3]

2.87

3.18

1. 7 5

[44.4]

TYP.

C

D

34

5.56

9.87

[141.2]

[250.6]

M/TAB

OUTLINE

APPROXIMATE WEIGHT (LBS.)

Series 38 180

Series 47 205

9.75

[247.6]

E

F

0.69

[17.5]

1. 5 0

[38.1]

18.56

[471.4]

12.31

[

312.7

]

B

15.25

[387.4]

5.19

[131.8]

16.88

[428.6]

9.31

[236.5]

7. 4 4

[188.9]

A

6.69

[169.9]

1. 6 3

[169.9]

[20.6]

UNIT MUST BE 12" (300mm)

MINIMUM ABOVE FLOOR

FOR FILTER ACCESS

M/TAB

0.81

18.13

[460.4]

8.81

[223.8]

45∞

K

1. 2 8

[32.5]

DRAIN

G

1. 5 0

[38.1]

4.00

[10 1.6]

TYP.

17.75

[450.9]

31

17.13

[435.0]

(J)

.250 DIA.

HOLES

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 21

ENVIRONMENTAL CONTROLS

COMPACT SERIES AIR COOLED

TOP-MOUNT AIR CONDITIONERS

POWER

CORD

THERMOSTAT

JUSTMENT

AD

1

FILTER

2

4

3

17.00

[431.8]

2

20.00

[508.0]

4

DRAIN

K21

10.25

[260.4]

Standard Features

• Built-in Condensate Evaporator

• CFC-Free Refrigerant

• EMI/RFI Suppressor

• Low Temperature Control Thermostat

• UL/CUL Listed

• Gray Powder Finish

Accessories and Options

• Cooling Effect Detector

• Enclosure Heater

• Filter Recoating Adhesive

• Filters for replacement

• Internal corrosion protection

• Lifting Eyes

• Low Airflow Detector

• Low Ambient Kit

• Short Cycle Protector

• Special materials or finishes

• Special motors, linecords or

protectors

• Stainless or Aluminum Cabinet

PERFORMANCE CHART

WA4C4HTL

6000

5250

4500

3750

3000

2250

1500

750

Cooling Capacity (BTU/H)

0

70

KA4C4HTL

Maximum enclosure

air temperature ºF

80

Ambient Temperature (ºF)

75

90 100 110 120 1 30

Operation within shaded areas not

recommended.

COMPACT SERIES AIR-COOLED TOP-MOUNTED AIR CONDITIONERS

MODEL

RATED CAPACITY 95/95 RATING AMBIENT TEMP. °F VOLTS HZ RUNNING APPROX.

(BTU/H) (BTU/H) MAX./MIN. AMPS WEIGHT (LBS.)

WA4C4HTR 4000 2200 125/50 115/100 60/50 13.1 85

W2A4C4HTR 4000 2200 115/50 230/200 60/50 5.9 85

20.00

[508.0]

0.75

[19.1]

2.50

[63.5]

10.50

[266.7]

(4) .25 [6.3]

WELD NUTS

MOUNTING PLAN

17. 00

[431.8]

15.5 0

[393.7]

13.5 0

[342.9]

3

4.50

[114.3]

TYP.

4

4

4.50

[114.3]

1. 7 5

[44.5]

7. 7 5

[196.9]

5.75

[146.1]

1. 7 5

[44.5]

2.00

[50.8]

4.00

[101.6]

20.00

[508.0]

1. 7 5

[44.5]

5.00

[127.0]

2.00

[50.8]

8.00

[203.2]

1. 5 0

[38.1]

17. 00

[431.8]

4.50

[114.3]

2

12.6 3

[320.7]

1

POWER

CORD

4.50

[114.3]

2.19

[55.6]

0.50

[12.7]

TYP.

10. 25

[260.4]

POWER

CORD

125

120

110

100

90

80

5' [1.52] CONDENSATE

DRAIN TUBE

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 22

K22

ENVIRONMENTAL CONTROLS

VORTEX COOLERS

Industry Standards

UL Listed

NEMA 12, 4or4X

NEMA 4/4X NEMA 12

FEATURES-SPECIFICATIONS

Applications

Compressed air cooling is used

where conventional enclosure cooling

(air conditioners or heat exchangers)

is not possible. Example: Small to

medium size enclosures; nonmetallic

enclosures; areas where the size of

cooling devices is restricted.

Features

• Suitable for harsh environments

• Small physical size

• Creates cool air without refrigerants

(no CFC’s, HFC’s)

• Exceptionally reliable— no moving

parts

• Virtually no maintenance

Requirements

• Clean, dry, oil-free compressed air

(100 PSIG / 70ºF or below) required

to achieve published BTU/hr. ratings.

Lower pressures and higher temperatures will reduce BTU/hr. ratings

• A 5 micron water and particulate

removal filter must be installed prior

to operating any Vortex Cooler

(included in kits)

• An oil removable filter can be

installed between the 5 micon

filter and the Vortex cooler if oil is

present in the compressed air line

• Mounting holes:

– NEMA 12 kits — (1) 1-3/32"

(28mm) or 3/4" knockout hole

for cooling tube and (1) 11/16"

hole for thermostat

–NEMA4&NEMA4Xkits—

(1) 1-5/16" (49mm) or 1-1/2"

knockout hole for cooling tube

and (2) #8 holes for thermostat

How Enclosure Coolers Create Cold Air

Vortex Coolers are powered by a vortex tube – a unique device

that creates a vortex from compressed air and separates it into

hot and cold airstreams. Here’s how it works. The vortex tube’s

cylindrical generator causes the input compressed air to rotate,

reaching speeds up to 1,000,000 rpm as it is forced down the

inner walls of the hot, or longer end of the vortex tube. At the end

of the hot tube, as small portion of this air exits through a needle

valve as hot air exhaust. The remaining air is forced back through

the center of the incoming air stream at a slower speed. The heat

in the slower moving air is transferred to the faster moving incoming air. This super-cooled air flows through the center of the

generator and exits through the cold air exhaust port.

UL File E32576

Kit Includes the Following

• Vortex Cooling Tube

• Solenoid Valve 120V 60Hz –

110V 50 Hz (230V available)

• 5 micron water and particulate

removal filter

• Ducting Kit

•Thermostat

Compressed Air In

Cold Air Out

Vortex Generation

Chamber

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Control Value

Hot Air Out

DATA SUBJECT TO CHANGE WITHOUT NOTICE

Page 23

ENVIRONMENTAL CONTROLS

VORTEX COOLERS

V ORTEX COOLERS

CATALOG

NUMBER

W750400 400 101 8 227 90°F ± 2° 150°F External 12 12 Aluminum

W740900 900 225 15 425 90°F ± 2° 150°F External 12 12 Aluminum

W7901500 1500 378 25 708 90°F ± 2° 150°F External 12 12 Aluminum

W7971700 1700 425 25 708 90°F ± 2° 150°F Internal 4 4 Aluminum

W797SS1700 1700 425 25 708 90°F ± 2° 150°F Internal 4X 4X Stainless Steel

CAPACITY AIR CONSUMPTION

BTUH KCAL/H SCFM SLPM (FACTORY SET)

THERMOSTAT

TUBE

SURFACE

TEMP AT BTU

THERMOSTAT NEMA UL COOLING TUBE

MOUNTING TYPE TYPE MATERIAL

K23

ACCESSORIES

CATALOG NUMBER FILTER TYPE AND SIZE

W38OILFILTER Auto-drain oil removal filter, 3/8" NPT (F), rated to 25 SCFM/708 SLPM

W12OILFILTER Auto-drain oil removal filter, 1/2" NPT (F), rated to 50 SCFM/1415 SLPM

Model W750400 Model W740900 & W7901500 Model W7971700 & W797SS1700

Note: Thermostats for Models W750400, W740900 and W7901500 mounts in an 11/16" (18mm) diameter hole.

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

DATA SUBJECT TO CHANGE WITHOUT NOTICE

Page 24

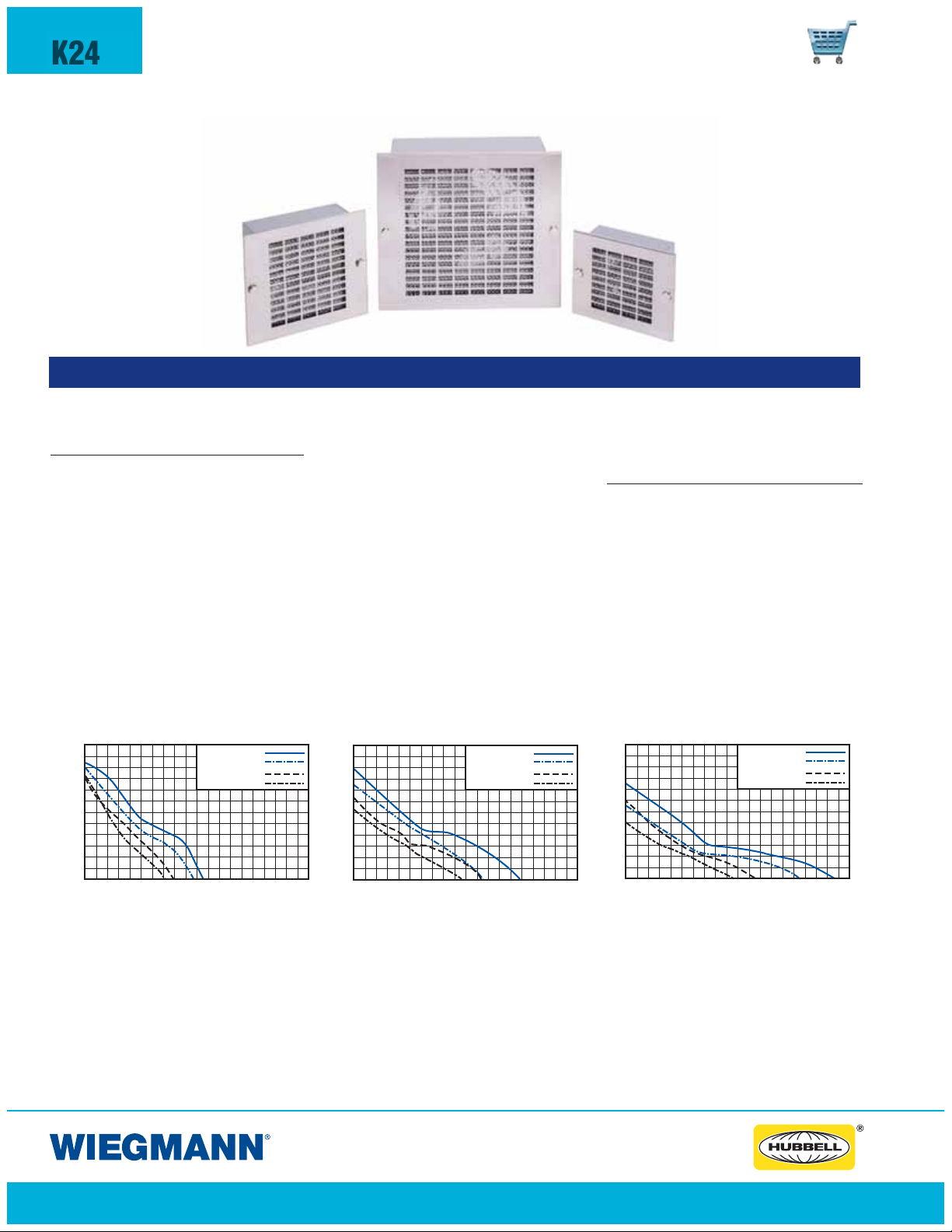

K24

KP

ENVIRONMENTAL CONTROLS

WPFB/WPFBE FILTERED BOX FANS & GRILLES

FEATURES-SPECIFICATIONS

Applications

Used for enclosure cooling in low static

pressure applications.

Features

• High airflow with low noise operation makes these versatile cooling

fans very popular in a wide range

of applications

• Reliable cooling is achieved particularly in areas with minimum space

requirements

• The cooling system incorporates the

filtered fan boxes as its air inlet, while

the exhaust grille is the air outlet

PERFORMANCE GRAPHS

WPFB100

.30

.15

STATIC PRESSURE

.03

10

50

AIRFLOW C.F.M.

KP40

60 Hz.

Fan:

50 Hz.

60 Hz.

Unit:

50 Hz.

100 15 00 200

• The washable aluminum filter grille

and air filter is easily accessible

and can be removed for cleaning

• Available in 115 VAC or 230 VAC

50/60 Hz versions

• Heavy gauge steel construction

• Attractive, ascetically appealing

grille design

• All models can pressurize or

exhaust

• Aluminum filter is coated with

adhesive baffle surfaces for dust

and dirt collection. Can be recoated

after cleaning for optimum performance

WPFB200

1. 0

.5

STATIC PRESSURE

.1

15

0 300

75

60

Fan:

Unit:

150 225

AIRFLOW C.F.M.

60 Hz.

50 Hz.

60 Hz.

50 Hz.

Note: One grille and filter are included with each fan package. Normally,

an additional exhaust grille and filter

required for each installation and

must be ordered separately.

Accessories

• Exhaust Grille and Filters

(see page L25)

• Filter Coat

WPFB500

.50

.25

STATIC PRESSURE

.05

30

150

AIRFLOW C.F.M.

KP100

60 Hz.

Fan:

50 Hz.

60 Hz.

Unit:

50 Hz.

300 4500 600

Static pressure is in inches of water.

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 25

ENVIRONMENTAL CONTROLS

WPFB/WPFBE SERIES FILTERED BOX FANS & GRILLES

K25

“WPFBE” Exhaust Grille with Filter Filter Coat“WPFB” Box Fan

FEATURES-SPECIFICATIONS

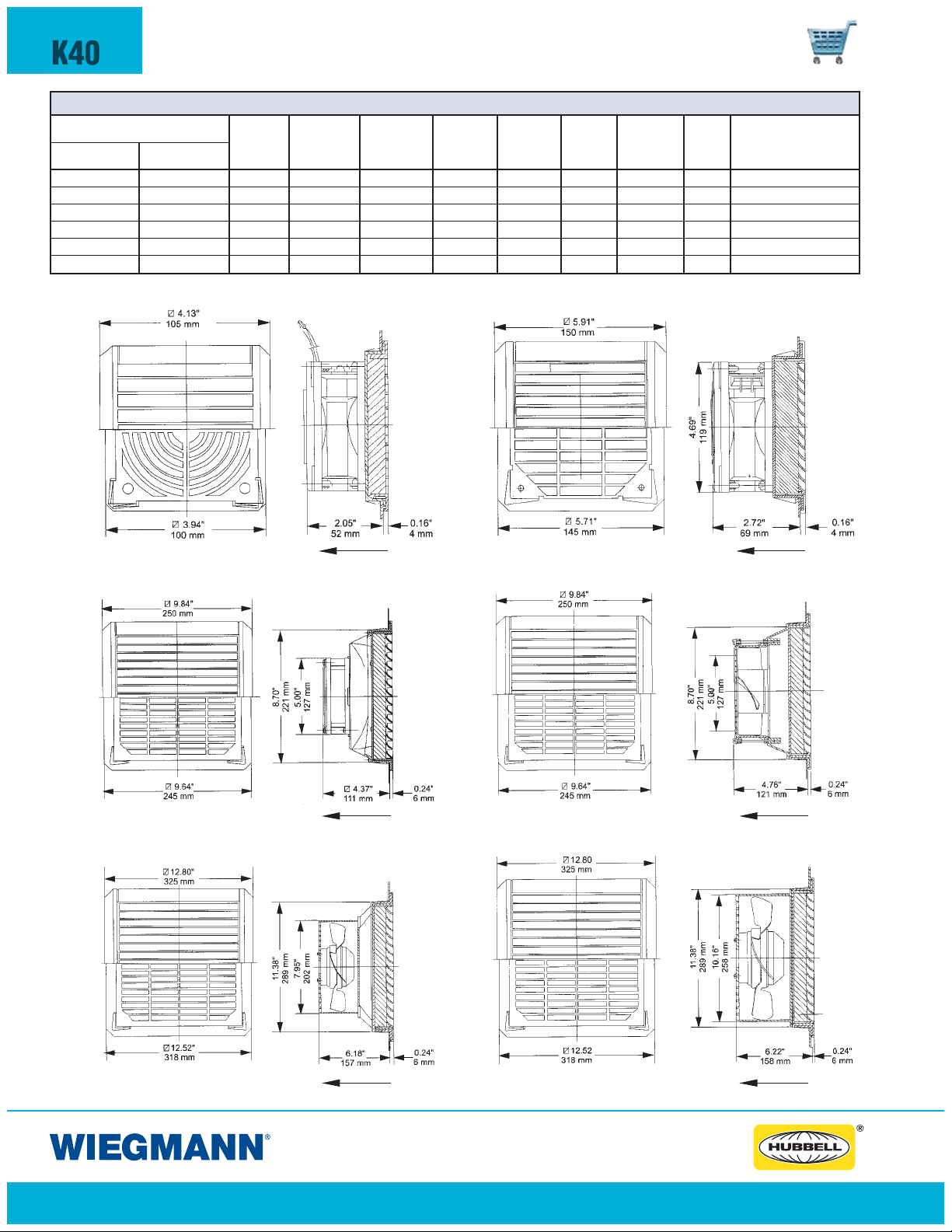

WPFB SERIES BOX FANS

CATALOG FREE-FLOW AIR RATED NOMINAL RUNNING

NUMBER DELIVERY (CFM) VOLTAGE (RPM) AMPS

WPFB100115 105 115 3000 0.18 15

WPFB100230 105 230 3000 0.18 15

WPFB200115 210 115 3300 0.29 33

WPFB200230 210 230 3300 0.29 33

WPFB500115 560 115 1600 0.87 60

WPFB500230 560 230 1600 0.87 60

WPFBE SERIES EXHAUST GRILLES WITH FILTERS

CATALOG NUMBER

WITH FILTER FILTER ONLY

WPFBE100 WPFBM100

WPFBE200 WPFBM200

WPFBE500 WPFBM500

ABDEFGW*

6.13 7.38 5.62 6.38 4.13 0.75 5.66

(156) (188) (143) (162) (105) (19) (144)

7.63 8.88 7.12 7.88 4.50 1.31 7.16

(194) (226) (181) (200) (114) (33) (182)

11.62 13.00 11.13 11.88 6.88 2.13 11.16

(295) (330) (283) (302) (175) (54) (283)

WATTS A B C D E F G H

Industry

Standards

UR, cUR, and CE recognized

6.13 7.38 2.38 5.62 6.38 4.13 0.75 7.00

(156) (188) (61) (143) (162) (105) (19) (178)

6.13 7.38 2.38 5.62 6.38 4.13 0.75 7.00

(156) (188) (61) (143) (162) (105) (19) (178)

7.63 8.88 3.00 7.12 7.88 4.50 1.31 8.50

(194) (226) (76) (181) (200) (114) (33) (216)

7.63 8.88 3.00 7.12 7.88 4.50 1.31 8.50

(194) (226) (76) (181) (200) (114) (33) (216)

11.62 13.00 4.56 11.13 11.88 6.88 2.13 12.50

(295) (330) (116) (283) (302) (175) (54) (318)

11.62 13.00 4.56 11.13 11.88 6.88 2.13 12.50

(295) (330) (116) (283) (302) (175) (54) (318)

FILTER COAT

CATALOG

NUMBER

WAX10 10 oz pump spray bottle

DESCRIPTION

C

D

H

E

0.19 DIA 4 PLACES

D

F

G

AIR

FLOW

B

A

0.36

D

E

F

D

G

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 26

K26

ENVIRONMENTAL CONTROLS

MUFFIN FANS & FINGER GUARDS

FEATURES-SPECIFICATIONS

WAGARD6WA4AXFN

MUFFIN FANS &

FINGER GUARDS

Applications

Designed for use in enclosures where

space is limited and reliable cooling

is required.

Features

• Fan furnished standard with 24"

lead wire. 90 degree plug attached

• Black color

• Impeller and frame are glass

reinforced thermoplastic, UL94-VO

• Die cast aluminum housing

WAXFN SERIES MUFFIN FANS & WAGARD SERIES FINGER GUARDS

CATALOG NUMBER

FAN

WA4AXFN WAGARD4 115 17/15 50/60 2500/3000 37 ± 2 2.5/3.1 88/110 5.8/7.0 4.71x4.71x1.50 (120x120x38)

WA4AXFN2 WAGARD4 230 17/15 50/60 3500/3000 37 ± 2 2.5/3.1 88/110 5.8/7.0 4.71x4.71x1.50 (120x120x38)

WA6AXFN WAGARD6 115 26/35 50/60 2800/3500 46 ± 2 5.4/6.6 190/235 5.4/6.6 6.77x6.77x2.01 (172x172x51)

WA6AXFN2 WAGARD6 230 26/35 50/60 2800/3500 46 ± 2 5.4/6.6 190/235 5.4/6.6 6.77x6.77x2.01 (172x172x51)

WA10AXFN WAGARD10 1 15 35 5 0/ 60 1650 5 5 547 10 10.00x10.00x3.50 (254x254x89)