Page 1

Section F Index

F1

SDN12 Series

NEMA 12 Flanged Single Door

Disconnects ..........................................F3

N412CD, N412CDSS, N412CDSSA Series

ULTIMATE Flanged Single Door

Disconnects ..........................................F6

N412CSTD, N412CSSSTD Series

ULTIMATE Slope-Top Flanged

Single Door Disconnects .........................F8

SN4 Series

NEMA 4 Flanged Single Door

Disconnects ........................................F10

DISCONNECTS

SSN4X Series

NEMA 4 Flanged Single Door

Disconnects ........................................F12

ABN12 Series (1494F & 1494D)

NEMA 12 Flanged Single Door

Disconnects ........................................F23

WAX-U & WACPX-U Series

NEMA 12 Floor-Mount Disconnects ......F28

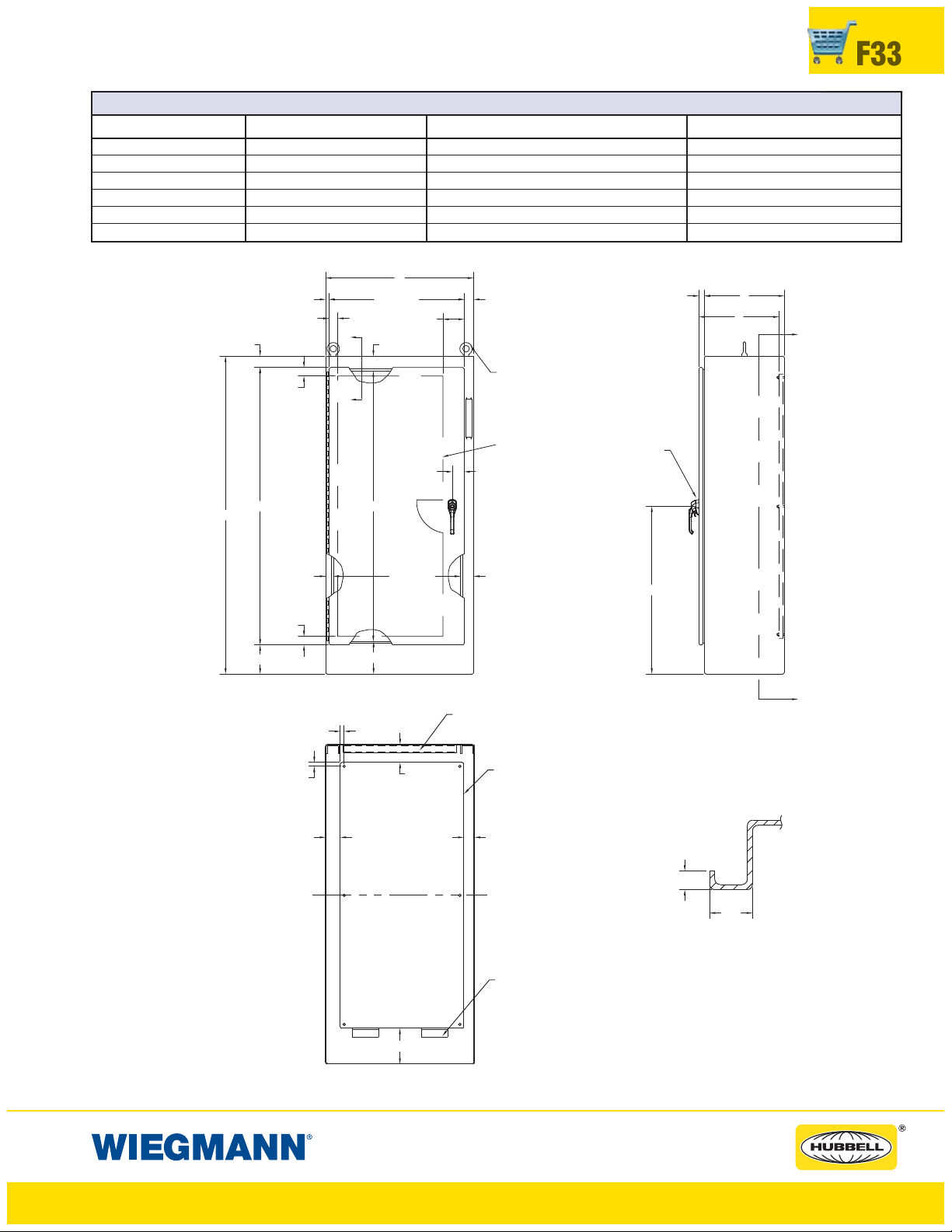

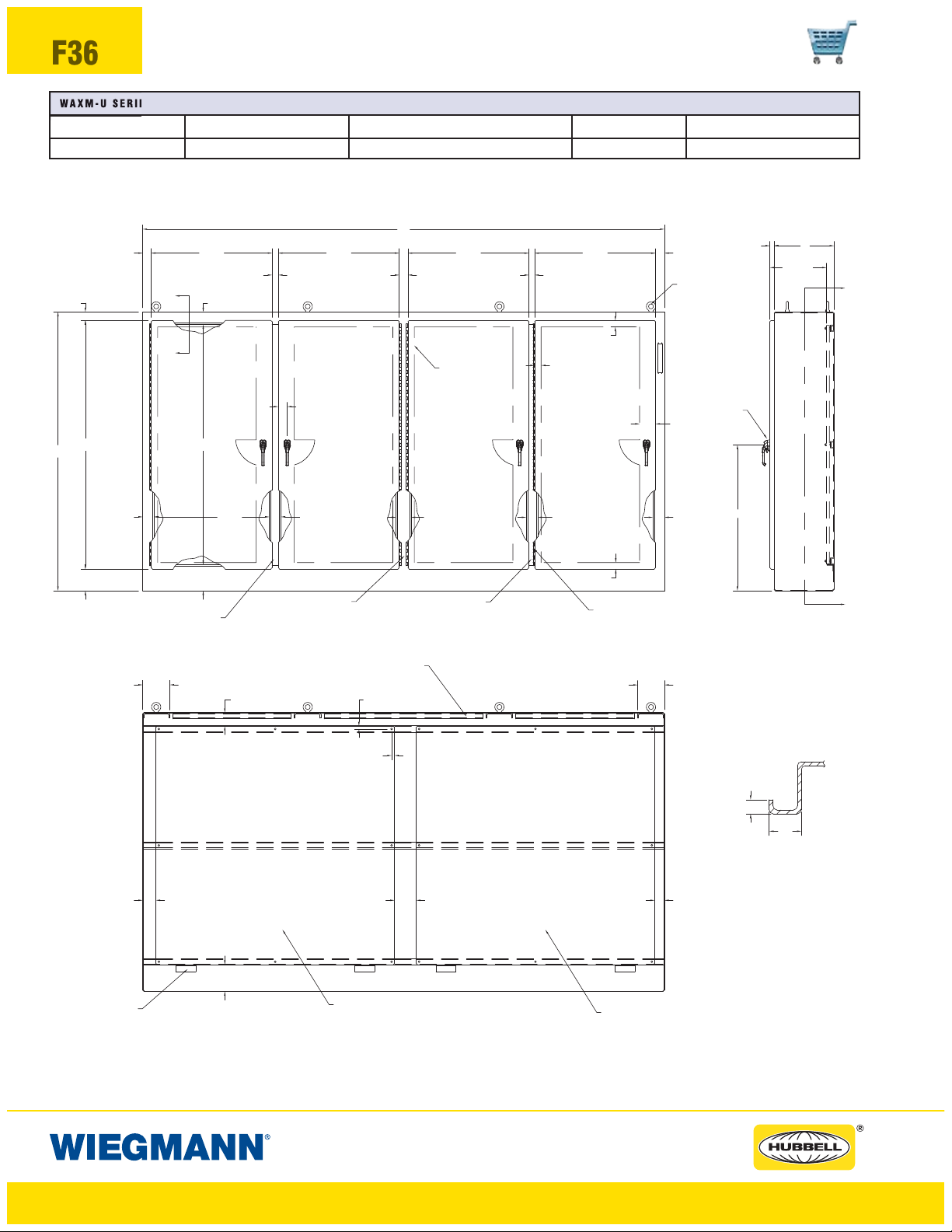

WAX-MU Series (1, 2, 3, 4, 5 Door)

NEMA 12 Heavy Duty Freestanding

Disconnects ..........................................F34

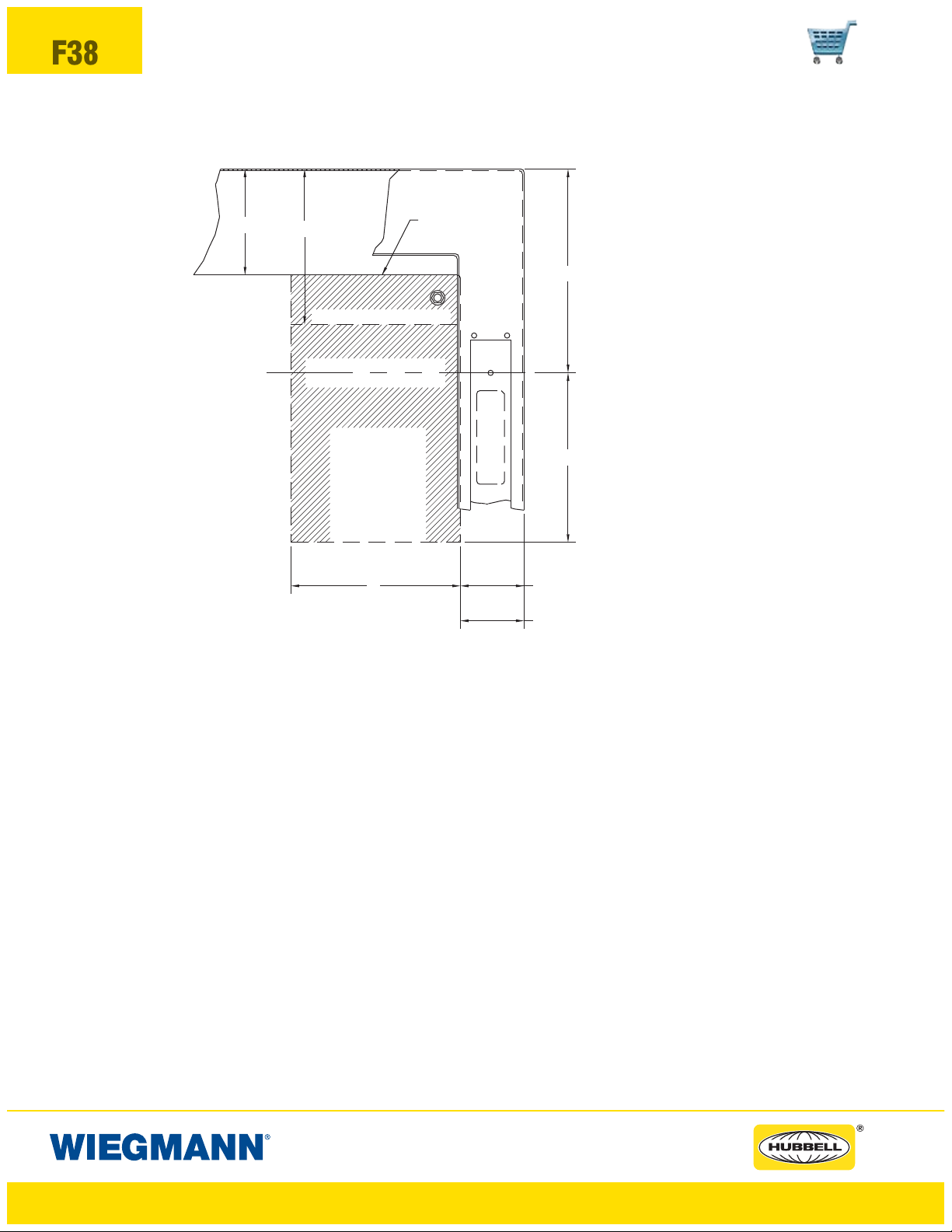

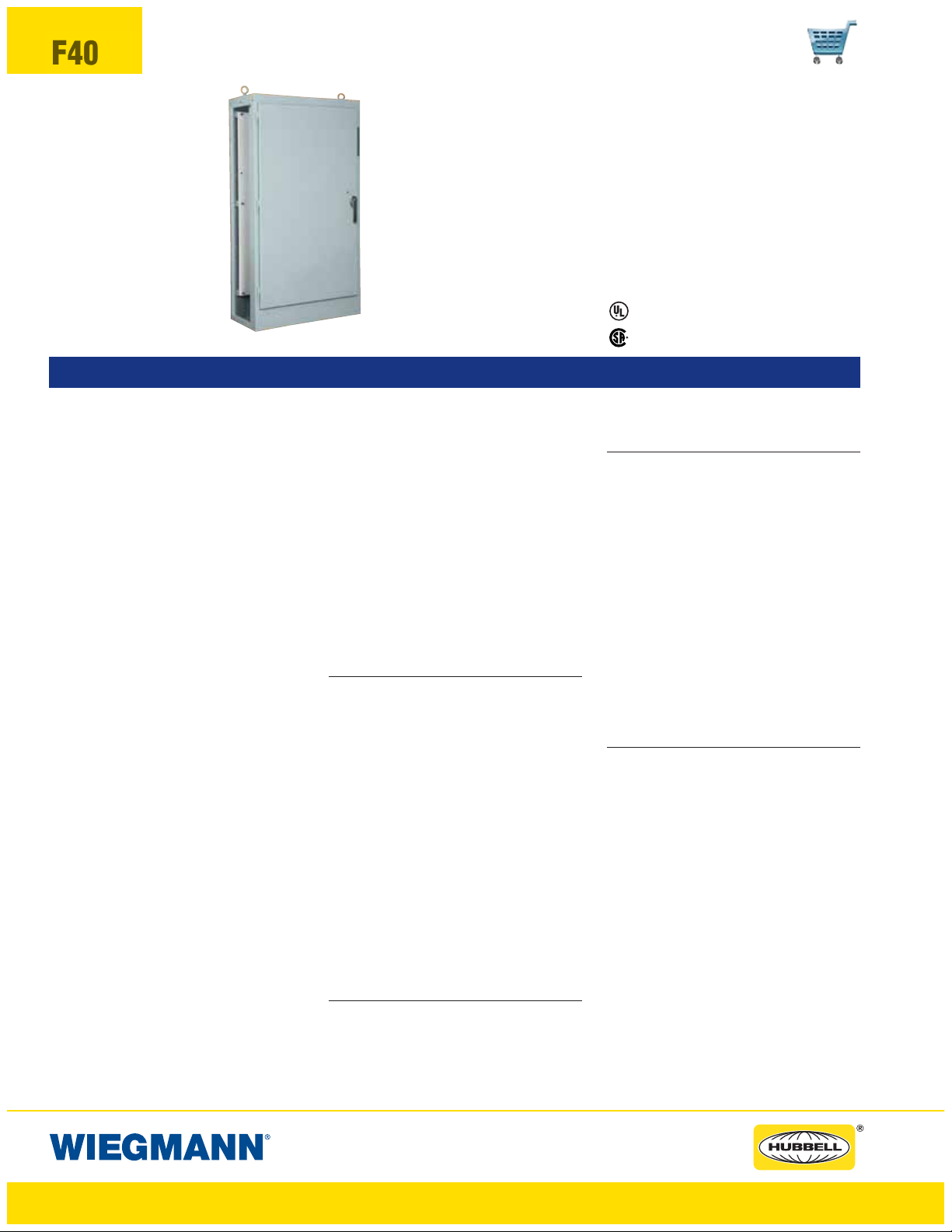

WMOD Series

NEMA 12 Modular Freestanding

Disconnects ........................................F40

WAX-SSN4, WACPX-SSN4 Series

NEMA 4X Floor Mount Disconnects .......F45

WAX-MSSN4 Series

NEMA 4X Freestanding Single & Double

Door Disconnects .................................F47

NEMA 12 Adapter Plates ....................F61

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 2

F2

ABN12 (V, U, C), & SDN12, SDN12PL, N412CD, N412CSTD, SN4, SSN4X SERIES

ENCLOSURES NEMA 12 FLANGED WALL MOUNT DISCONNECTS

• General Electric Type STDA flange handles and variable-

depth operating mechanisms for disconnect switches and

circuit breakers. Also SPECTRAFLEX

™

cable operators for

circuit breakers

• Siemens ITE Max-Flex

™

flange-mount variable-depth oper-

ating handles for circuit breakers.

• Schneider Square D

®

Class 9422 disconnect switches with

flange-mount variable-depth operating mechanisms or cable

mechanisms and Class 9422 flange-mount variable-depth

operating mechanism or cable mechanisms for circuit breakers.

These enclosures will not accept Schneider Square D

®

Class 9422 bracket-mounted disconnect devices, Class

9422TGI, or TG2 devices

“WM” PREFERRED CUTOUT

FEATURES-SPECIFICATIONS

Applications

These

General purpose disconnect enclosures accept major

brand disconnect switches and circuit breakers, available

with or without Wiegman-supplied defeater door handle and

handle hardware (door handle supplied on SDN12PL,

N412CD and N412CSTD models only).

Enclosures having the “WM” preferred cutout are sized for

use with up to 200A disconnect switches and up to 400A

circuit breakers unless otherwise specified. The “WM” preferred cutout accepts the smaller operating handle whose

mounting hole centers are 4.677 in. apart. “WM” preferred

cutouts are standard in mild steel wall-mount enclosures,

modular enclosures and some select large mild steel enclosures. They are also present on all standard stainless steel

offerings. Mild steel operator adapter plates with brand specific “WM” preferred cutouts are available for enclosures

with a rectangular universal cutout.

“WM” preferred cutouts are designed to house the following:

Allen-Bradley

• 1494V disconnect switches with flange-mount variable

depth operating mechanisms and 1494V flange-mounted

variable depth operating mechanisms for circuit breakers

• 140U flexible cable operating mechanisms and 140U

molded case circuit breakers

• 1494C cable-operated disconnect switches with flange-

mount handles

• 194RC cable-operated flange-mount handles for use with the

NFPA 79 compliant 194R IEC rotary disconnect switches

Allen-Bradley 1494V-R1, -R2 and -W2 operating handles and

Allen-Bradley 1494F disconnect devices or 1494D circuit

breaker operators will NOT fit these enclosures.

See Pages F20-F23 for ABN12 149F & 1494D models

• ABB Controls flange-mount variable-depth operating

mechanism for disconnect switches and circuit breakers.

Also the cable version for circuit breakers.

• Eaton Cutler-Hammer Type C361 flange-mount variable-

depth operating mechanisms with disconnect switches

and Type C371 flange-mount variable-depth operating

mechanisms for circuit breakers.

Important Ordering Information

Depending on model, order as follows:

On SDN12PL, N412 CD and N412CSTD Models

• Customer must order operating mechanism, operating

handle, and disconnect switch or circuit breakers from the

disconnect manufacturers (door handle and latching hardware included). See page F14 for ordering information.

On SDN12 and ABN12 V, U, C Models

• Customer must order operating mechanism and disconnect switch or circuit breakers, operating handle, and

door hardware from the disconnect manufacturers (see

page F14 for ordering information).

On SN4 and SSN4X Models

• Customer must order operating mechanism, operating

handle and disconnect switch or circuit breakers, from the

disconnect manufacturers (these models do NOT get

door hardware). See page F15 for ordering information.

Wire Bend Space

• See pages F16-F22 for wire bend space available when

various manufactures’ disconnect switches are installed.

Check the enclosure dimension drawings to verify the

chosen disconnect switch will fit in the enclosure.

Note:

E = 4.75 when Depth = 8.00

E = 7.09 when Depth = 10.00

E = 11.62 when Depth = 12.00 or 16.00

E = 18.38 for SDN 12603812A

WB = Wiring Space

See Pages F11-F19 for

various brands of disconnects for “F”, “G” & “WB”

dimensions.

Disconnects will occupy

space on panel shown by

dimensions “E”, “F” & “G”.

Wiring space “WB” is

available when disconnect

is installed in the enclosure.

Refer to National Electrical

Code article 430-10(b) for

wiring space required for

line side conductors to be

connected to disconnect.

Verify your application to

determine if wiring space

is adequate.

1.50

THIS SPACE IS

OCCUPIED BY

DISCONNECT

SWITCH AND

FUSE CLIP

(IF USED) OR

CIRCUIT

BREAKER

WB

G

TOP HOLE IN

R.H. FLANGE

E

FF

1.59

2.63

*Operator adapter plates are not required with these enclosures

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 3

FEATURES-SPECIFICATIONS

SDN12 & SDN12PL SERIES ENCLOSURES

NEMA 12 FLANGED SINGLE DOOR DISCONNECT

Industry Standards

UL 508

CSA Certified, Type 12

NEMA/EEMAC Types 12 & 13

,Types12&13

UL Files E64791

CSA File LL66078

F3

Construction

• Bodies and doors fabricated from

14 gauge steel

• Plasma welded seams

• Rolled lip around all sides of

enclosure opening excludes liquids

and contaminants

• Doors easily removed by pulling

continuous hinge pin

• Polyurethane poured-in-place gasket

• External mounting feet

• Collar studs for mounting optional

back panel

• Grounding provisions provided

• Holes are provided in body and

door for mounting operating handle,

operating mechanism, and door

closing mechanism

• Guide brackets and interlock door

catch are welded to the inside of

door

• A cover latch bar is also included

for door hardware

• Print pocket is provided

• Enclosures under 40" high require

2-point door hardware

• Enclosures 40" high and larger

require 3-point door hardware

• Instructions to locate and install

disconnect switches, circuit breakers, and operating mechanisms are

provided

• Enclosures available with or without

padlocking, defeater handle and

latching system

Fini sh

• ANSI 61 gray polyester powder

inside and out over phosphatized

surfaces

• Optional back panels are white

polyester powder over phosphatized surfaces

• Optional “G” panels have a con-

ductive finish

Acces sories

• Back panels (reference tables)

• Blank Adapter Plates on page F61

IMPORTANT Ordering Information

• See F2 for disconnect switch, circuit

breakers, operating handle and operating mechanism.

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 4

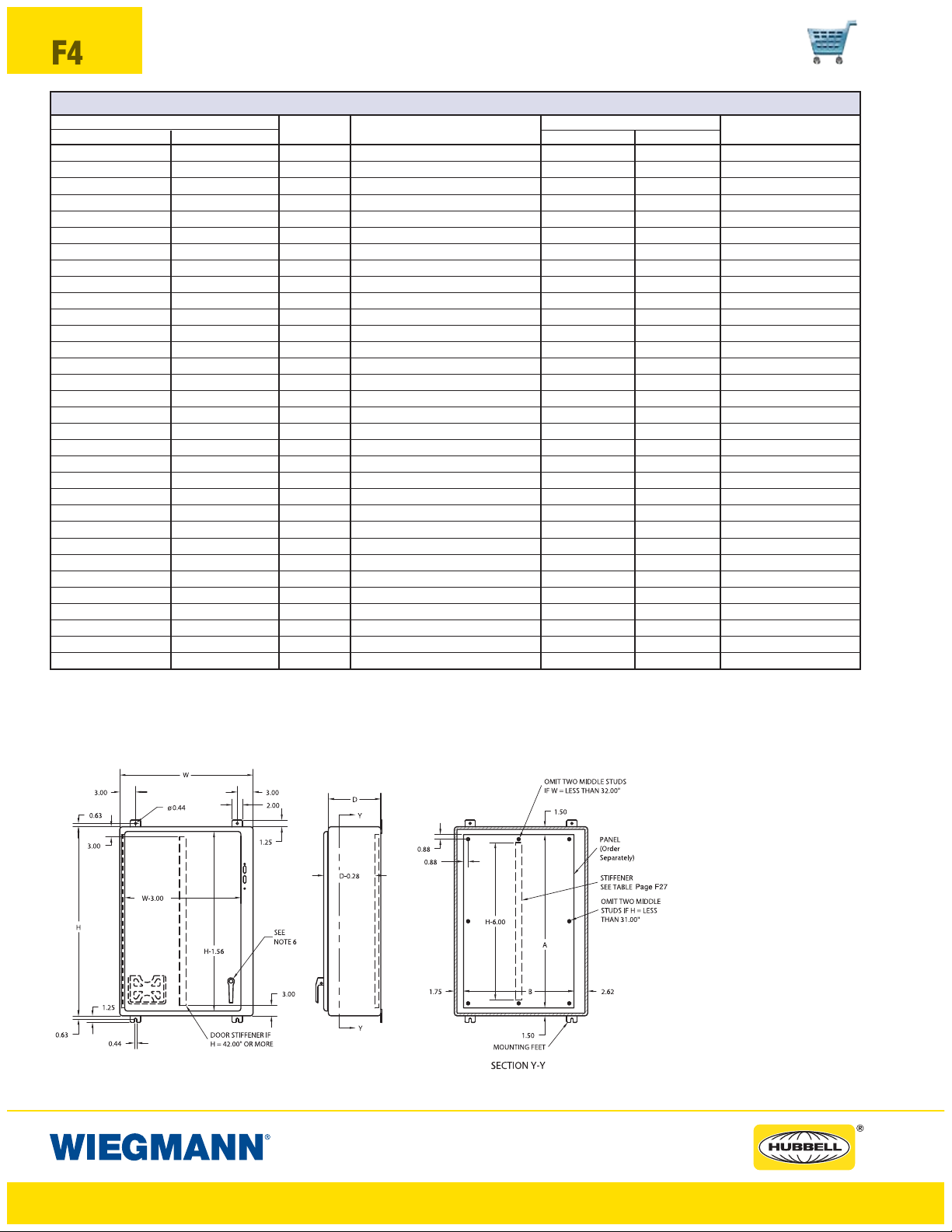

F4

SDN12 & SDN12PL SERIES ENCLOSURES

NEMA 12 FLANGED SINGLE DOOR DISCONNECT

SDN12 & SDN12PL SERIES WALL-MOUNT DISCONNECTS

CATALOG NUMBER BODY/DOOR ENCLOSURE SIZE BACK PANEL CATALOG NUMBER* BACK PANEL

WITH HANDLE WITHOUT HANDLE

STEEL GAUGE

H X W X D WHITE “G” SIZE A X B

SDN12202108PL SDN12202108 14/14 20.00x21.38x8.13 (508x543x206) NP2020 NP2020G 17.00x17.00 (432x432)

SDN12242108PL SDN12242108 14/14 24.00x21.38x8.13 (610x543x206) NP2420 NP2420G 21.00x17.00 (533x432)

SDN12242508PL SDN12242508 14/14 24.00x25.38x8.13 (610x645x206) NP2424 NP2424G 21.00x21.00 (533x533)

SDN12302108PL SDN12302108 14/14 30.00x21.38x8.13 (762x543x206) NP3020 NP3020G 27.00x17.00 (686x432)

SDN12302508PL SDN12302508 14/14 30.00x25.38x8.13 (762x645x206) NP3024 NP3024G 27.00x21.00 (686x533)

SDN12362508PL SDN12362508 14/14 36.00x25.38x8.13 (914x645x206) NP3624 NP3624G 33.00x21.00 (838x533)

SDN12363108PL SDN12363108 14/14 36.00x31.38x8.13 (914x797x206) NP3630 NP3630G 33.00x27.00 (838x686)

SDN12423208PL SDN12423208 14/14 42.00x31.38x8.13 (1067x797x206) NP4230 NP4230G 39.00x27.00 (991x686)

SDN12423708PL SDN12423708 14/14 42.00x37.38x8.13 (1067x949x206) NP4236 NP4236G 39.00x33.00 (991x838)

SDN12483708PL SDN12483708 14/14 48.00x37.38x8.13 (1219x949x206) NP4836 NP4836G 45.00x33.00 (1143x838)

SDN12603808PL SDN12603808 14/14 60.00x37.38x8.13 (1524x949x207) NP6036 NP6036G 57.00x33.00 (1448x838)

SDN12202110PL SDN12202110 14/14 20.00x21.38x10.25 (508x543x257) NP2020 NP2020G 17.00x17.00 (432x432)

SDN12242110PL SDN12242110 14/14 24.00x21.38x10.25 (610x543x257) NP2420 NP2420G 21.00x17.00 (533x432)

SDN12242510PL SDN12242510 14/14 24.00x25.38x10.25 (610x645x257) NP2424 NP2424G 21.00x21.00 (533x533)

SDN12302110PL SDN12302110 14/14 30.00x21.38x10.25 (762x543x257) NP3020 NP3020G 27.00x17.00 (686x432)

SDN12302510PL SDN12302510 14/14 30.00x25.38x10.25 (762x645x257) NP3024 NP3024G 27.00x21.00 (686x533)

SDN12362510PL SDN12362510 14/14 36.00x25.38x10.25 (914x645x257) NP3624 NP3624G 33.00x21.00 (838x533)

SDN12363110PL SDN12363110 14/14 36.00x31.38x10.25 (914x797x257) NP3630 NP3630G 33.00x27.00 (838x686)

SDN12423110PL SDN12423110 14/14 42.00x31.38x10.25 (1067x797x257) NP4230 NP4230G 39.00x27.00 (991x686)

SDN12423710PL SDN12423710 14/14 42.00x37.38x10.25 (1067x949x257) NP4236 NP4236G 39.00x33.00 (991x838)

SDN12483710PL SDN12483710 14/14 48.00x37.38x10.25 (1219x949x257) NP4836 NP4836G 45.00x33.00 (1143x838)

SDN12603710PL SDN12603710 14/14 60.00x37.38x10.25 (1524x949x257) NP6036 NP6036G 57.00x33.00 (1448x838)

SDN12302612PL SDN12302612 14/14 30.00x25.38x12.13 (762x645x308) NP3024 NP3024G 27.00x21.00 (686x533)

SDN12363212PL SDN12363212 14/14 36.00x31.38x12.13 (914x797x308) NP3630 NP3630G 33.00x27.00 (838x686)

SDN12423212PL SDN12423212 14/14 42.00x31.38x12.13 (1067x797x308) NP4230 NP4230G 39.00x27.00 (991x686)

SDN12423812PL SDN12423812 14/14 42.00x37.38x12.13 (1067x949x308) NP4236 NP4236G 39.00x33.00 (991x838)

SDN12483812PL SDN12483812 14/14 48.00x37.38x12.13 (1219x949x308) NP4836 NP4836G 45.00x33.00 (1143x838)

SDN12603812PL — 14/14 60.00x37.38x12.13 (1524x949x308) NP6036 NP6036G 57.00x33.00 (1448x838)

SDN12603812APL SDN12603812A** 14/14 60.00x37.38x12.13 (1524x949x308) NP6036 NP6036G 57.00x33.00 (1448x838)

SDN12363116PL SDN12363116 14/14 36.00x31.38x16.13 (914x797x410) NP3630 NP3630G 33.00x27.00 (838x686)

SDN12483816PL SDN12483816 14/14 48.00x37.38x16.13 (1219x949x410) NP4836 NP4836G 45.00x33.00 (1143x838)

SDN12603816PL SDN12603816 14/14 60.00x37.38x16.13 (1524x949x410) NP6036 NP6036G 57.00x33.00 (1448x838)

* Back panels must be ordered separately.

** Enclosure catalog number SDN12603812A will receive only 400 amp and 600 amp Allen-Bradley 1494V disconnect switches and Siemens ITE Max-Flex

800 amp and 1200 amp circuit breakers. The 400 amp and 600 amp Allen-Bradley disconnect switch will not fit any other size enclosure from the SDN12

family. Blank Adapter plates will not fit catalog number SDN12603812A. Enclosures 12" and 16" deep can be modified to accept Siemens ITE Max-Flex

800 amp and 1200 amp circuit breakers. (When using an Siemens ITE Max-Flex™circuit breaker and an enclosure with an “H” dimension of 30", 36" or 42",

™

verify the amount of wire bend space required for both the line and load sides.) Consult factory for details.

™

PL Version

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Notes:

1. Large print pocket (8"x10") is provided in each

enclosure

2. Panels are made from 12 Ga. steel

3. Panels have flanges along all sides when either

dimension exceeds 17"

4. Catalog number SDN12603812A has a larger

cutout in the enclosure flange to accommodate

the Allen-Bradley 1494V-H2 and I-T-E FHOHN

operating handles.

5. Enclosures under 40" high have 2-point door

hardware and enclosures 40"highandlarger

have 3-point door hardware.

6. The handle includes a zinc diecast padlocking

defeater handle and all latching hardware is

installed on disconnect enclosures ending in PL.

Order separately for other disconnect enclosures.

7.

See Page F27 for Stiffener Location.

Page 5

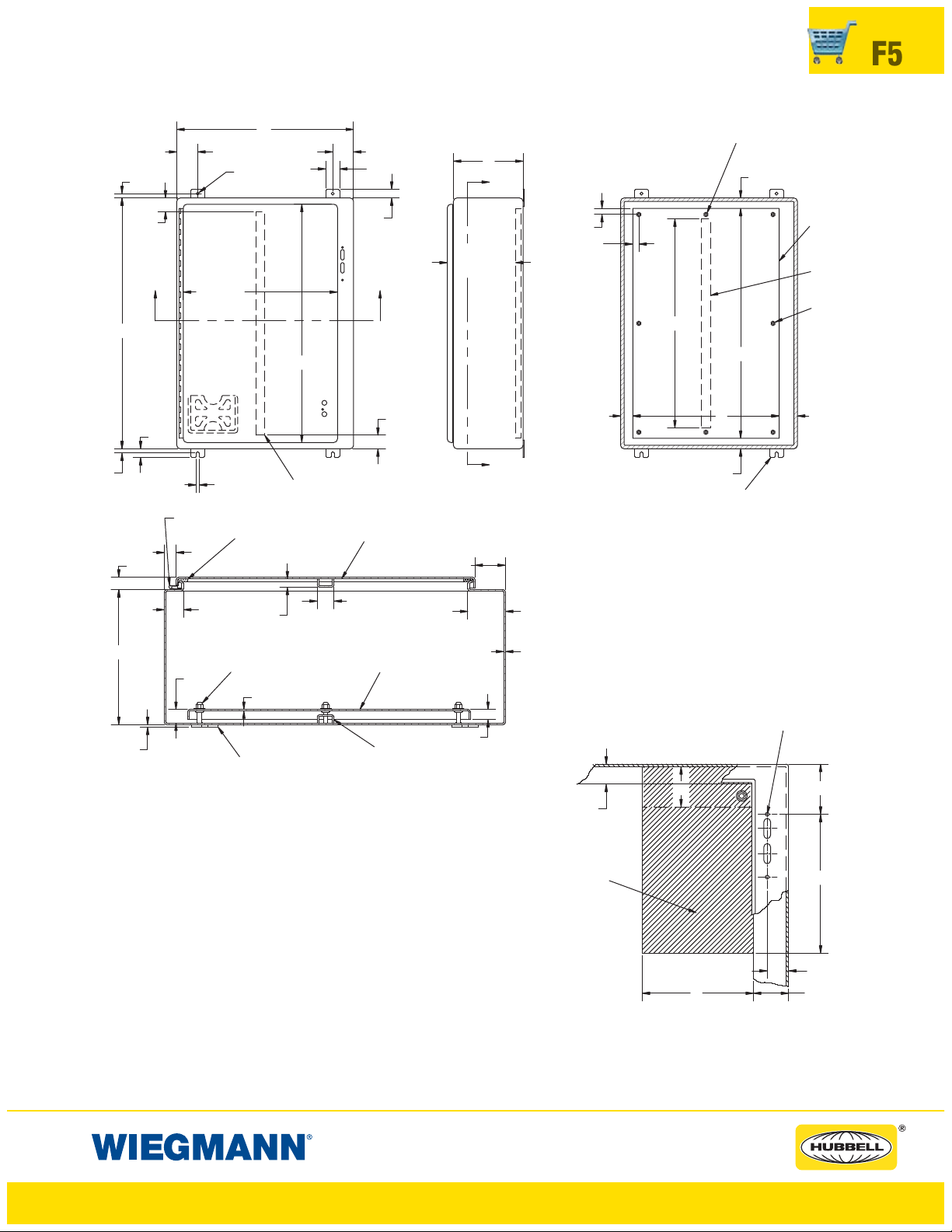

SDN12 & SDN12PL SERIES ENCLOSURES

NEMA 12 FLANGED SINGLE DOOR DISCONNECT

F5

0.63

W

3.00

W-3.00

Ø0.44

GASKET

H-1.56

DOOR STIFFENER IF

H = 42.00"OR MORE

0.63

3.00

X

H

1.25

0.44

CONTINUOUS

HINGE

0.63

0.88

3.00

2.00

1.25

X

3.00

DOOR

STIFFENER

2.38

D

Y

0.88

0.88

D-0.28

H-6.00

Y

MOUNTING FEET

SECTION Y-Y

Notes:

1. Large print pocket (8"x10") is provided in each enclosure.

OMIT TWO MIDDLE STUDS

IF W = LESS THAN 32.00"

1.50

A

B1.75 2.62

1.50

PANEL

(Order

Separately)

STIFFENER

SEEPageF27

OMIT TWO MIDDLE

STUDSIFH= LESS

THAN 31.00"

2. Panels are made from 12 Ga. steel.

1.31

D

1.09

0.69

TYP

3/8 - 16 COLLAR

STUD

12 GA.

1.25 TYP

PA NE L

(ORDER SEPARATELY)

2.75

14 GA.

3. Panels have flanges along all sides when either dimension

exceeds 17".

4. Catalog number SDN12603812A has a larger cutout in the

enclosure flange to accommodate the Allen-Bradley

1494V-H2 and I-T-E FHOHN operating handles.

5. Enclosures under 40" high require 2-point door hardware and

enclosures 40" high and larger require 3-point door hardware.

6. See Page F27 for Stiffener Location

0.19

MOUNTING

FEET

BODY

STIFFENER

SECTION X-X

Note:

E = 4.75 when Depth = 8.00

E = 7.09 when Depth = 10.00

E = 11.62 when Depth = 12.00 or 16.00

E = 18.38 for SDN12603812A

WB = Wiring Space

See Pages F16-F22 for various brands of disconnects

for “F”, “G”,&“WB” dimensions.

Disconnects will occupy space on panel shown by

dimensions “E”, “F”,&“G”. Wiring space “WB” is

available when disconnect is installed in the enclosure.

Refer to National Electrical Code article 430-10(b)

for wiring space required for line side conductors to be

connected to disconnect. Verify your application to determine

if wiring space is adequate.

0.75

1.50

THIS SPACE IS OCCUPIED

BY DISCONNECT SWITCH

AND FUSE CLIP (IF USED)

OR CIRCUIT BREAKER.

SDN12 Version

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

WB

TOPHOLEIN

R.H. FLANGE

E

FF

1.59

G

2.63

Page 6

F6

FEATURES-SPECIFICATIONS

N412-CD N412-CDSS ULTIMATE SERIES ENCLOSURES

NEMA 412 FLANGED SINGLE DOOR DISCONNECT

(CARBON, 304 AND 316L STAINLESS STEEL)

Industry Standards

UL 508,

CSA Certified, Type 12, 13,4&4X

NEMA/EEMAC Types 12, 13,4&4X

Types 12, 13,4&4X

UL Files E64791

CSA File LL66078

Construction

• CD enclosure version bodies and

doors fabricated from 14 gauge

carbon steel

• CDSS enclosure version bodies

and doors fabricated from 14

gauge 304 stainless steel 316L also

available)

• Continuously plasma welded seams

• Increased tub opening for better

access

• Concealed hinges

• Doors are interchangeable and

easily removable

• Grounding provisions provided

• Doors are sealed with poured-inplace polyurethane gasket

• Mounting holes in rear of enclosure

• Studs for mounting optional sub

panel

• Door latching system installed on

door with a slotted insert defeater

mechanism to open

• Latching system interlocks with the

disconnect handle for added safety

• 2pt latch system up to 36" in height

and 3pt latch system on enclosures

42" and higher

Finish

• ANSI 61 gray polyester powder

inside and out over phosphatized

surfaces

• Stainless steel enclosures #4 brush

finish

• Optional back panels are white

polyester powder over phosphatized surfaces

• Optional “G” panels have a con-

ductive finish

Accessories

• Back panels (reference tables)

• Blank Adapter Plates on page F61

IMPO RTANT Ordering Information

• See F2 for disconnect switch, circuit

breakers, operating handle and operating mechanism.

*See Page F27 for Stiffener Location.

A

B

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 7

N412-CD N412-CDSS ULTIMATE SERIES ENCLOSURES

NEMA 412 FLANGED SINGLE DOOR DISCONNECT

(CARBON, 304 AND 316L STAINLESS STEEL)

N412CD ULTIMATE SERIES WALLMOUNT DISCONNECTS CARBON STEEL, PAINTED ANSI 61 POLYESTER POWDER

CATALOG BODY/DOOR BACK PANEL CATALOG NUMBER* BACK PANEL

NUMBER STEEL GAUGE

N412202208CD 14/14 20.00 x 22.00 x 8.00 (508 x 559 x 203) NP2020C NP2020CG 18.2 x 18.2 (462 x 462)

N412242208CD 14/14 24.00 x 22.00 x 8.00 (610 x 559 x 203 NP2420C NP2420CG 22.2 x 18.2 (564 x 462)

N412242608CD 14/14 24.00 x 26.00 x 8.00 (610 x 660 x 203 NP2424C NP2424CG 22.2 x 22.2 (564 x 564)

N412302608CD 14/14 30.00 x 26.00 x 8.00 (762 x 660 x 203) NP3024C NP3024CG 28.2 x 22.2 (716 x 564)

N412362608CD 14/14 36.00 x 26.00 x 8.00 (914 x 660 x 203) NP3624C NP3624CG 34.2 x 22.2 (869 x 564)

N412363208CD 14/14 36.00 x 32.00 x 8.00 (914 x 813 x 203) NP3630C NP3630CG 34.2 x 28.2 (869 x 716)

N412423212CD 14/14 42.00 x 32.00 x 12.00 (1067 x 813 x 305) NP4230C NP4230CG 40.2 x 28.2 (1021 x 716)

N412423812CD 14/14 42.00 x 38.00 x 12.00 (1067 x 965 x 305) NP4236C NP4236CG 40.2 x 34.2 (1021 x 869)

N412483812CD 14/14 48.00 x 38.00 x 12.00 (1219 x 965 x 305) NP4836C NP4836CG 46.2 x 34.2 (1173 x 869)

N412603812CD 14/14 60.00 x 38.00 x 12.00 (1524 x 965 x 305) NP6036C NP6036CG 58.2 x 34.2 (1478 x 869)

N412CDSS ULTIMATE SERIES WALLMOUNT DISCONNECTS 304 STAINLESS STEEL

CATALOG BODY/DOOR BACK PANEL CATALOG NUMBER* BACK PANEL

NUMBER STEEL GAUGE

N412202208CDSS 14/14 20.00 x 22.00 x 8.00 (508 x 559 x 203) NP2020C NP2020CG 18.2 x 18.2 (462 x 462)

N412242208CDSS 14/14 24.00 x 22.00 x 8.00 (610 x 559 x 203 NP2420C NP2420CG 22.2 x 18.2 (564 x 462)

N412242608CDSS 14/14 24.00 x 26.00 x 8.00 (610 x 660 x 203 NP2424C NP2424CG 22.2 x 22.2 (564 x 564)

N412302608CDSS 14/14 30.00 x 26.00 x 8.00 (762 x 660 x 203) NP3024C NP3024CG 28.2 x 22.2 (716 x 564)

N412362608CDSS 14/14 36.00 x 26.00 x 8.00 (914 x 660 x 203) NP3624C NP3624CG 34.2 x 22.2 (869 x 564)

N412363208CDSS 14/14 36.00 x 32.00 x 8.00 (914 x 813 x 203) NP3630C NP3630CG 34.2 x 28.2 (869 x 716)

N412423212CDSS 14/14 42.00 x 32.00 x 12.00 (1067 x 813 x 305) NP4230C NP4230CG 40.2 x 28.2 (1021 x 716)

N412423812CDSS 14/14 42.00 x 38.00 x 12.00 (1067 x 965 x 305) NP4236C NP4236CG 40.2 x 34.2 (1021 x 869)

N412483812CDSS 14/14 48.00 x 38.00 x 12.00 (1219 x 965 x 305) NP4836C NP4836CG 46.2 x 34.2 (1173 x 869)

N412603812CDSS 14/14 60.00 x 38.00 x 12.00 (1524 x 965 x 305) NP6036C NP6036CG 58.2 x 34.2 (1478 x 869)

ENCLOSURE SIZE HXWXD

ENCLOSURE SIZE HXWXD

WHITE “G” SIZE A X B

WHITE “G” SIZE A X B

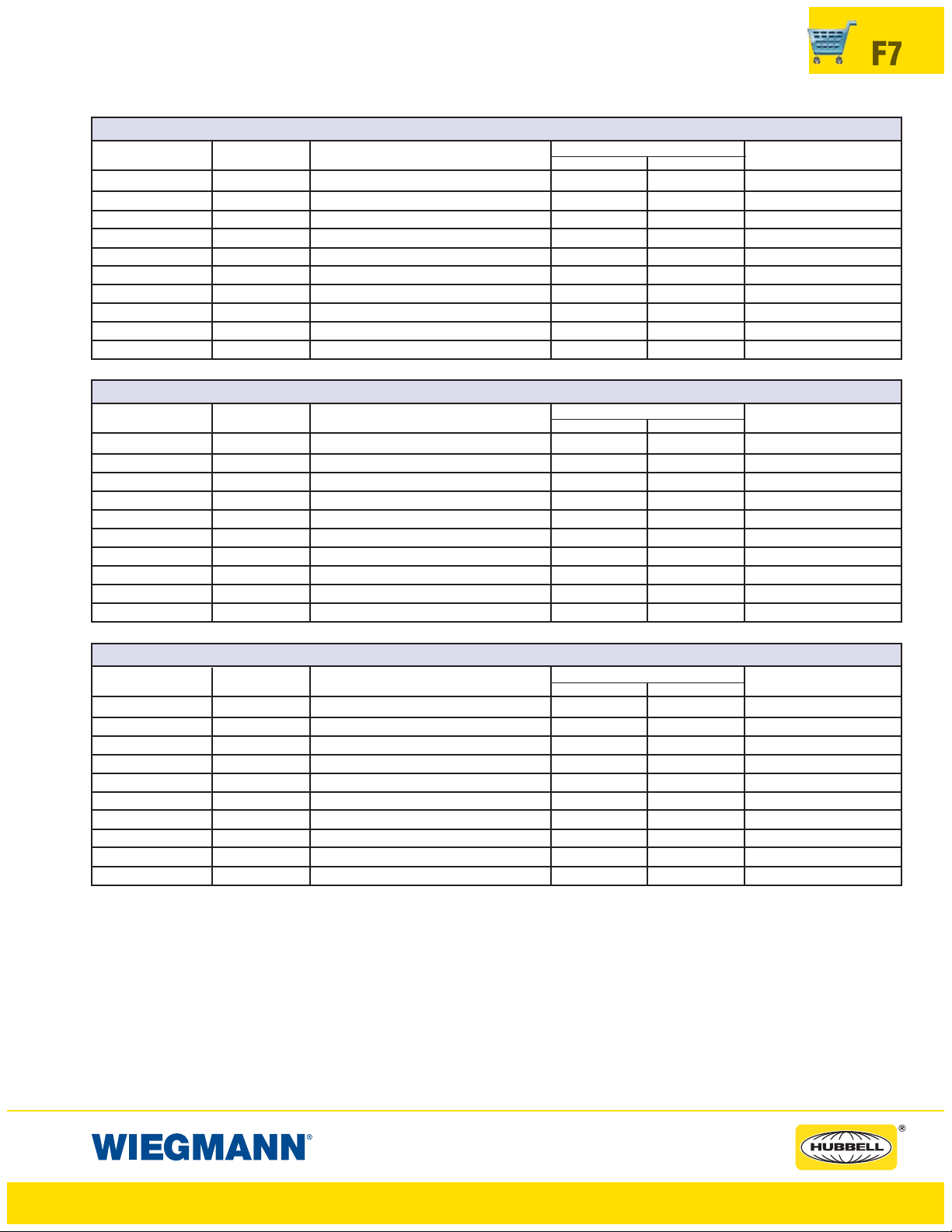

F7

N412CDSSA ULTIMATE SERIES WALLMOUNT DISCONNECTS 316L STAINLESS STEEL

CATALOG BODY/DOOR BACK PANEL CATALOG NUMBER* BACK PANEL

NUMBER STEEL GAUGE

N412202208CDSSA 14/14 20.00 x 22.00 x 8.00 (508 x 559 x 203) NP2020C NP2020CG 18.2 x 18.2 (462 x 462)

N412242208CDSSA 14/14 24.00 x 22.00 x 8.00 (610 x 559 x 203 NP2420C NP2420CG 22.2 x 18.2 (564 x 462)

N412242608CDSSA 14/14 24.00 x 26.00 x 8.00 (610 x 660 x 203 NP2424C NP2424CG 22.2 x 22.2 (564 x 564)

N412302608CDSSA 14/14 30.00 x 26.00 x 8.00 (762 x 660 x 203) NP3024C NP3024CG 28.2 x 22.2 (716 x 564)

N412362608CDSSA 14/14 36.00 x 26.00 x 8.00 (914 x 660 x 203) NP3624C NP3624CG 34.2 x 22.2 (869 x 564)

N412363208CDSSA 14/14 36.00 x 32.00 x 8.00 (914 x 813 x 203) NP3630C NP3630CG 34.2 x 28.2 (869 x 716)

N412423212CDSSA 14/14 42.00 x 32.00 x 12.00 (1067 x 813 x 305) NP4230C NP4230CG 40.2 x 28.2 (1021 x 716)

N412423812CDSSA 14/14 42.00 x 38.00 x 12.00 (1067 x 965 x 305) NP4236C NP4236CG 40.2 x 34.2 (1021 x 869)

N412483812CDSSA 14/14 48.00 x 38.00 x 12.00 (1219 x 965 x 305) NP4836C NP4836CG 46.2 x 34.2 (1173 x 869)

N412603812CDSSA 14/14 60.00 x 38.00 x 12.00 (1524 x 965 x 305) NP6036C NP6036CG 58.2 x 34.2 (1478 x 869)

*Back panels must be ordered separately.

ENCLOSURE SIZE HXWXD

WHITE “G” SIZE A X B

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 8

F8

N412-CSTD & N412-CSSSTD SLOPE TOP DISCONNECT

ULTIMATE SERIES ENCLOSURES

Industry Standards

UL 508,

CSA Certified, Types 4, 4x, 12, & 13

NEMA/EEMAC Types 4, 4x, 12, & 13

UL File E64791

Types 4, 4x, 12, & 13

N412242608CSSSTD

FEATURES-SPECIFICATIONS

Applications

Hubbell Wiegmann N412CDTD &

N412CSSSTD Ultimate Series

Disconnects are designed to house

and protect electrical and electronic

components from harsh, dirty environments. For use in installations where

dirt, dust, oil, water or other contaminants are present. Streamlined

styling, latching and attractive

durable finish complement any high

tech electronic equipment.

Construction

• Bodies and doors fabricated from

14 gauge steel (optional 304 also

available)

• Continuously Plasma welded seams

• Increased tub opening for better

access

• 20 Degree sloped top

• Sloped “Top tub flange”

• Concealed hinges

• Doors are interchangeable and

easily removable

• Grounding provisions provided

• 1/4-turn semi-flush oil tight latches

are supplied to hold door securely

closed

• Print pocket is provided

• Doors are sealed with poured-inplace polyurethane gasket

• Mounting holes in rear of enclosure

• Studs for mounting optional back

panel (the Ultimate back panels

have increased in size to accommodate larger foot-print installations)

• Ultimate Accessory Driven

• Door handle and latching hardware

are provided

• Door latching system installed on

door with slotted insert defeater

mechanism to open

• Latching system interlocks with the

disconnect handle for added safety

• 2pt latch system up to 36" in height

and 3pt latch system on enclosures

42" and higher

CSA File LL66078

Fini sh

• ANSI 61 gray polyester powder

inside and out over phosphatized

surfaces

• Stainless: interior = standard commercial finish, ext = standard

grained finish

• Optional back panels are white

polyester powder over phosphatized surfaces

• Optional “G” panels have a con-

ductive finish

Acces sories

• Back panels (reference tables)

• See pages J1-J22

IMPORTANT Ordering Information

• See F2 for disconnect switch, circuit

breakers, operating handle and operating mechanism.

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 9

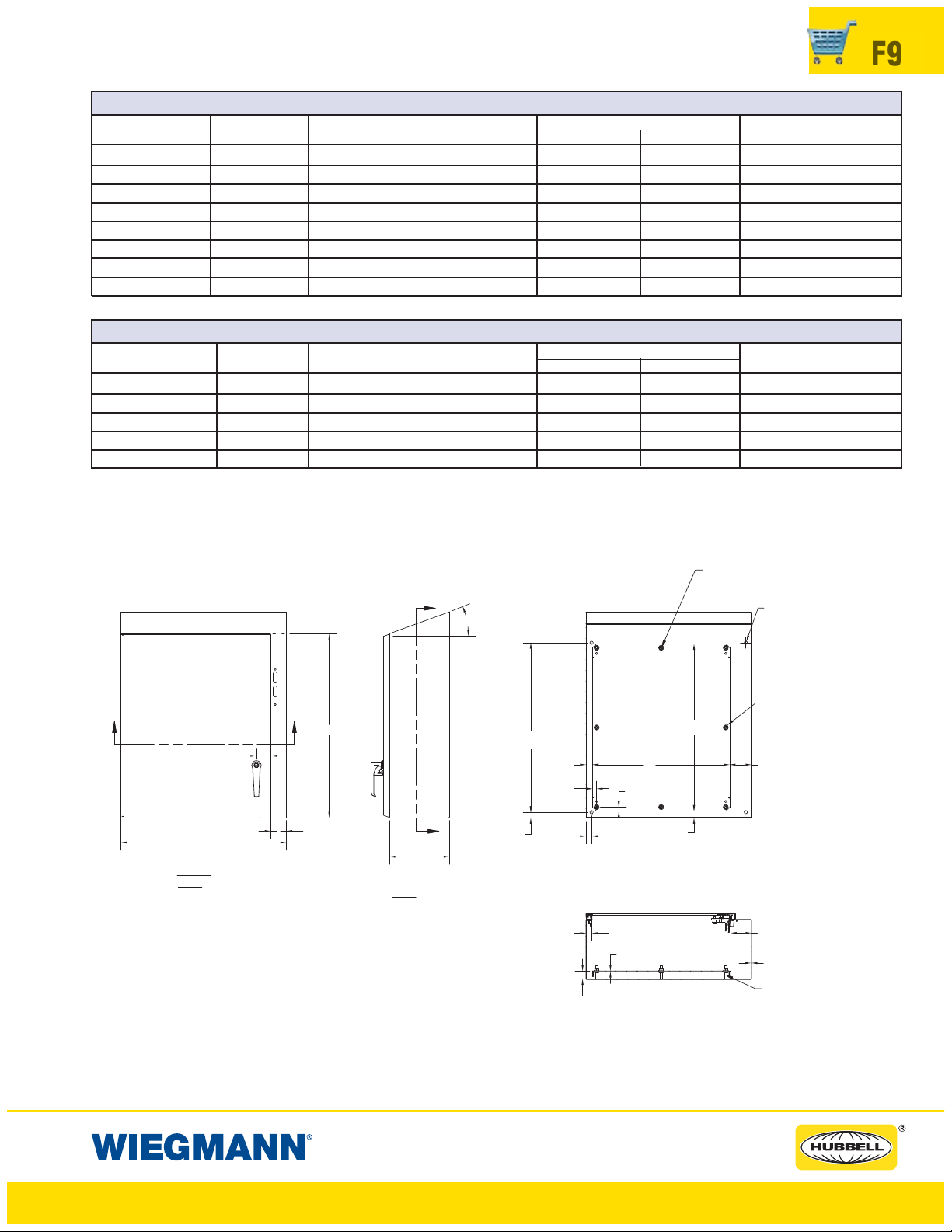

N412CSTD & N412CSSTD ULTIMATE SERIES ENCLOSURES

NEMA 4X SLOPE TOP SINGLE DOOR DISCONNECT

N412-CSTD ULTIMATE SERIES ENCLOSURES NEMA 4X SLOPE TOP SINGLE DOOR DISCONNECT

CATALOG BODY/DOOR BACK PANEL CATALOG NUMBER* BACK PANEL

NUMBER STEEL GAUGE

N412202208CSTD 14/14 20.00 x 22.00 x 8.00 (508 x 559 x 203) NP2020C NP2020CG 18.2 x 18.2 (462 x 462)

N412242208CSTD 14/14 24.00 x 22.00 x 8.00 (610 x 559 x 203 NP2420C NP2420CG 22.2 x 18.2 (564 x 462)

N412242608CSTD 14/14 24.00 x 26.00 x 8.00 (610 x 660 x 203 NP2424C NP2424CG 22.2 x 22.2 (564 x 564)

N412302608CSTD 14/14 30.00 x 26.00 x 8.00 (762 x 660 x 203) NP3024C NP3024CG 28.2 x 22.2 (716 x 564)

N412363210CSTD 14/14 36.00 x 32.00 x 10.00 (914 x 660 x 203) NP3630C NP3630CG 34.2 x 28.2 (869 x 716)

N412423212CSTD 14/14 42.00 x 32.00 x 12.00 (1067 x 813 x 305) NP4230C NP4230CG 40.2 x 28.2 (1021 x 716)

N412483812CSTD 14/14 48.00 x 38.00 x 12.00 (1219 x 965 x 305) NP4836C NP4836CG 46.2 x 34.2 (1173 x 869)

N412603812CSTD 14/14 60.00 x 38.00 x 12.00 (1524 x 965 x 305) NP6036C NP6036CG 58.2 x 34.2 (1478 x 869)

N412-CSSSTD ULTIMATE SERIES ENCLOSURES NEMA 4X SLOPE TOP SINGLE DOOR DISCONNECT

CATALOG BODY/DOOR BACK PANEL CATALOG NUMBER* BACK PANEL

NUMBER STEEL GAUGE

N412242608CSSSTD 14/14 24.00 x 26.00 x 8.00 (610 x 660 x 203 NP2424C NP2424CG 22.2 x 22.2 (564 x 564)

N412302608CSSSTD 14/14 30.00 x 26.00 x 8.00 (762 x 660 x 203) NP3024C NP3024CG 28.2 x 22.2 (716 x 564)

N412363210CSSSTD 14/14 36.00 x 32.00 x 10.00 (914 x 660 x 203) NP3630C NP3630CG 34.2 x 28.2 (869 x 716)

N412483812CSSSTD 14/14 48.00 x 38.00 x 12.00 (1219 x 965 x 305) NP4836C NP4836CG 46.2 x 34.2 (1173 x 869)

N412603812CSSSTD 14/14 60.00 x 38.00 x 12.00 (1524 x 965 x 305) NP6036C NP6036CG 58.2 x 34.2 (1478 x 869)

*Back panels must be ordered separately.

ENCLOSURE SIZE HXWXD

ENCLOSURE SIZE HXWXD

WHITE “G” SIZEAXB

WHITE “G” SIZEAXB

F9

FRONT

VIEW

OMIT TWO MIDDLE

STUDS IF W = LESS THAN 32.00"

A

20°

B

0.900

TYP.

A

H

BB

1.875

W

2.101

RIGHT

VIEW

A

D

0.750

TYP.

E

0.900

0.520

TYP.

0.750

TYP.

1.074

0.520

TYP.

SECTION A-A

0.812

12 GA.

Ø0.438 MOUNTING

PROVISION (4 PL.)

OMIT TWO MIDDLE STUDS

IF H = LESS THAN 31.00"

2.900

2.750

14 GA.

5/16-18 COLLAR

STUDS

SECTION B-B

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 10

F10

SN4 SERIES ENCLOSURES

NEMA 4 FLANGED SINGLE DOOR DISCONNECT

Industry Standards

UL 508

,Types4,12,&13

CSA Certified, Types 4 & 12

NEMA/EEMAC Types 3,4,12,&13

UL File E64791

SN4242108

CSA File LL66078

FEATURES-SPECIFICATIONS

Construction

• Bodies and doors fabricated from

14 gauge steel

• Plasma welded seams

• Rolled lip around all sides of enclosure opening excludes liquids and

contaminants

• All exterior hardware is stainless

steel

• Stainless steel door clamps are

provided around three sides of

doors for a watertight seal, additional door hardware is not required

• Body and door stiffeners provided

in larger enclosures for extra rigidity

• Doors easily removed by pulling

continuous hinge pin

SN4 SERIES WALL-MOUNT DISCONNECTS

CATALOG BODY/DOOR ENCLOSURE SIZE BACK PANEL CATALOG NUMBER* BACK PANEL

NUMBER STEEL GAUGE H X W X D WHITE “G” SIZE A X B

SN4242108 14/14 24.00x21.38x8.13 (610x543x207) NP2420 NP2420G 21.00x17.00 (533x432)

SN4242508 14/14 24.00x25.38x8.13 (610x645x207) NP2424 NP2424G 21.00x21.00 (533x533)

SN4302508 14/14 30.00x25.38x8.13 (762x645x207) NP3024 NP3024G 27.00x21.00 (686x533)

SN4363108 14/14 36.00x31.38x8.13 (914x797x207) NP3630 NP3630G 33.00x27.00 (838x686)

SN4423112 14/14 42.00x31.38x12.13 (1067x797x308) NP4230 NP4230G 39.00x27.00 (991x686)

SN4423712 14/14 42.00x37.38x12.13 (1067x949x308) NP4236 NP4236G 39.00x33.00 (991x838)

SN4483712** 14/14 48.00x37.38x12.13 (1219x949x308) NP4836 NP4836G 45.00x33.00 (1143x838)

SN4603712** 14/14 60.00x37.38x12.13 (1524x949x308) NP6036 NP6036G 57.00x33.00 (1448x838)

*Back panels must be ordered separately.

**Enclosures are supplied with closed cell neoprene gasket (not foam-in-place).

• Polyurethane poured-in-place gasket

• External mounting feet.

• Collar studs for mounting optional

back panel

• Grounding provisions provided

• Bracket welded to door for attaching disconnect interlock door catch

• Holes provided in body for mounting disconnect operating handle

and operating mechanism. These

enclosures are designed to operate

properly without the use of door

hardware

• Print pocket is provided

Fini sh

• ANSI 61 gray polyester powder

inside and out over phosphatized

surfaces

• Optional back panels are white

polyester powder over phosphatized surfaces

• Optional “G” panels have a con-

ductive finish

Acces sories

• Back panels (reference tables)

• Blank Adapter Plates on page F61

IMPORTANT Ordering Information

• See F2 & F15 for disconnect switch,

circuit breakers, operating handle

and operating mechanism.

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 11

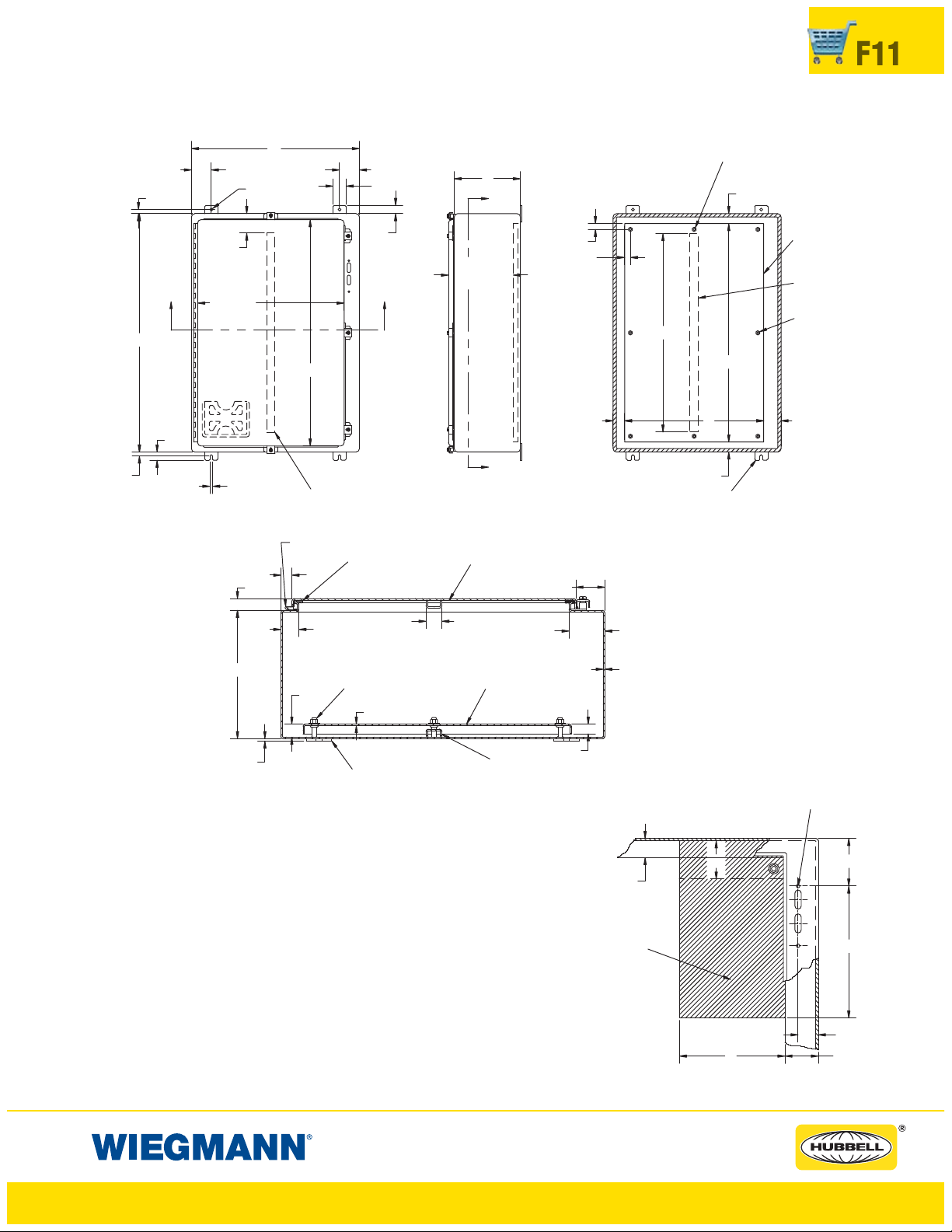

SN4 SERIES ENCLOSURES

NEMA 4 FLANGED SINGLE DOOR DISCONNECT

F11

0.63

W

1.25

3.00

2.00

D

Y

0.88

0.88

D-0.28

X

H-6.00

Y

MOUNTING FEET

3.00

3.00

TYP

W-3.13

Ø0.44

H-1.63

DOOR STIFFENER

IF H = 42.00"OR

MORE

0.63

X

H

1.25

0.44

OMIT TWO MIDDLE STUDS

IF W = LESS THAN 32.00"

1.50

A

B1.75 2.62

1.50

PANEL

(Order

Separately)

STIFFENER

SEE Page F27

OMIT TWO MIDDLE

STUDS IF H = LESS

THAN 31.00"

SECTION Y-Y

CONTINUOUS

HINGE

0.63

0.88

1.31

D

1.09

GASKET

3/8-16 COLLAR

STUD

12 GA.

DOOR

STIFFENER

1.25 TYP

PANEL

(ORDER SEPARATELY)

2.50

14 GA.

2.75

Notes:

1. Large print pocket (8" x 10") is

provided in each enclosure.

2. Panelsaremadefrom12Ga. steel.

3. Panels have flanges along all sides

when either dimension exceeds 17".

4. The number of door clamps is

dependent on size of enclosure.

Clamps are furnished along three

sides of door.

5. See page F27 for Stiffener Location.

0.19

MOUNTING

FEET

SECTION X-X

Space Occupied by Disconnect

E = 8.63 when Depth = 8.00

E = 11.62 when Depth = 12.00

WB = Wiring Space

See pages F16-F22 for various brands of disconnects

for “F”, “G”,&“WB” dimensions.

Disconnects will occupy space on panel shown by dimensions

“E”, “F”,&“G”. Wiring space “WB” is available when disconnect

is installed in the enclosure.

Refer to National Electrical Code article 430-10(b) for wiring

space required for line side conductors to be connected to disconnect.

Verify your application to determine if wiring space is adequate.

BODY

STIFFENER

0.75

1.50

THIS SPACE IS OCCUPIED

BY DISCONNECT SWITCH

AND FUSE CLIP (IF USED)

OR CIRCUIT BREAKER.

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

TOP HOLE IN

R.H. FLANGE

W

G

E

F

1.59

2.75

Page 12

F12

SSN4X SERIES ENCLOSURES

NEMA 4X FLANGED SINGLE DOOR DISCONNECT

Industry Standards

UL 508,

Types 4, 4X, 12, & 13

CSA Certified, Types 4 & 12

NEMA/EEMAC Types 4, 4X, 12, & 13

UL File E64791

SSN4X242108

CSA File LL66078

FEATURES-SPECIFICATIONS

Construction

• Bodies and doors fabricated from

14 gauge 304 stainless steel

• Continuously welded seams ground

smooth

• Rolled lip around all sides of enclosure opening excludes liquids and

contaminants

• All exterior hardware is stainless

steel

• All interior and exterior parts of

stainless steel enclosures are stainless steel except for print pocket

• Stainless steel door clamps are

provided around three sides of

doors for a watertight seal, additional door hardware is not required

• Body and door stiffeners provided

in larger enclosures for extra rigidity

• Doors removed by pulling stainless

steel continuous hinge pin

• Polyurethane poured-in-place gasket

• External mounting feet

• Collar studs for mounting optional

back panel

• Grounding provisions provided

• Bracket welded to door for attaching disconnect interlock door catch

• Holes are provided in body for

mounting disconnect operating

handle and operating mechanism.

These enclosures are designed to

operate properly without the use of

door hardware

Fini sh

• Enclosures have a grained finish on

all external surfaces

• Optional back panels are white

polyester powder over phosphatized

surfaces

• Optional “G” panels have a con-

ductive finish

Acces sories

• Back panels (reference tables)

• Blank Adapter Plates are on page

F61

IMPORTANT Ordering Information

• See F2 & F15 for disconnect switch,

circuit breakers, operating handle

and operating mechanism.

• Print pocket is provided

SSN4X SERIES STAINLESS WALL-MOUNT DISCONNECTS

CATALO G NU MB E R BODY/DOOR ENCLOSURE SIZE BACK PANEL CATALOG NUMBER* BACK PANEL

304 316L WHITE 304 SS “G”

SSN4X242108 SSN4X242108A 14/14 24.00x21.38x8.13 (610x543x207) NP2420 NP2420SS NP2420G 21.00x17.00 (533x432)

SSN4X242508 SSN4X242508A 14/14 24.00x25.38x8.13 (610x645x207) NP2424 NP2424SS NP2424G 21.00x21.00 (533x533)

SSN4X302508 SSN4X302508A 14/14 30.00x25.38x8.13 (762x645x207) NP3024 NP3024SS NP3024G 27.00x21.00 (686x533)

SSN4X362508 SSN4X362508A 14/14 36.00x25.38x8.13 (914x645x207) NP3624 NP3624SS NP3624G 33.00x21.00 (838x533)

SSN4X363108 SSN4X363108A 14/14 36.00x31.38x8.13 (914x797x207) NP3630 NP3630SS NP3630G 33.00x27.00 (838x686)

SSN4X423112 SSN4X423112A 14/14 42.00x31.38x12.13 (1067x797x308) NP4230 NP4230SS NP4230G 39.00x27.00 (991x686)

SSN4X423712 SSN4X423712A 14/14 42.00x37.38x12.13 (1067x949x308) NP4236 NP4236SS NP4236G 39.00x33.00 (991x838)

SSN4X483712 SSN4X483712A 14/14 48.00x37.38x12.13 (1219x949x308) NP4836 NP4836SS NP4836G 45.00x33.00 (1143x838)

SSN4X603712** SSN4X603712A** 14/14 60.00x37.38x12.13 (1524x949x308) NP6036 NP6036SS NP6036G 57.00x33.00 (1448x838)

*Back panels must be ordered separately.

**Enclosures are supplied with closed cell neoprene gasket (not foam-in-place).

STEEL GAUGE H X W X D SIZ E A X B

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 13

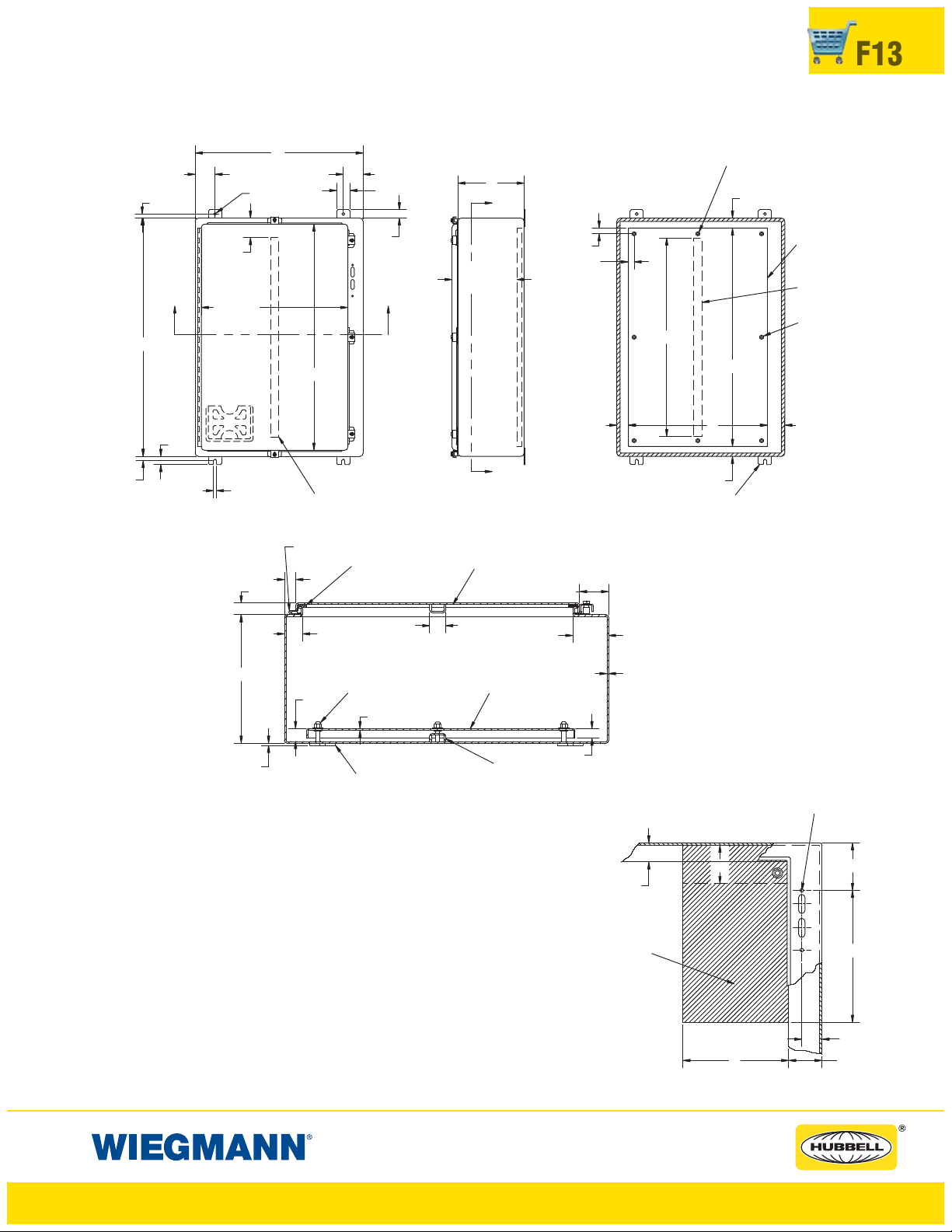

SSN4X SERIES ENCLOSURES

NEMA 4X FLANGED SINGLE DOOR DISCONNECT

F13

0.63

W

1.25

3.00

2.00

D

Y

0.88

0.88

D-0.28

X

H-6.00

Y

MOUNTING FEET

3.00

3.00

TYP

W-3.13

Ø0.44

H-1.63

DOOR STIFFENER

IF H = 42.00"OR

MORE

0.63

X

H

1.25

0.44

OMIT TWO MIDDLE STUDS

IF W = LESS THAN 32.00"

1.50

A

B1.75 2.62

1.50

PA NE L

(Order

Separately)

STIFFENER

SEE Page F27

OMIT TWO MIDDLE

STUDS IF H = LESS

THAN 31.00"

SECTION Y-Y

CONTINUOUS

HINGE

0.63

0.88

1.31

D

1.09

GASKET

3/8-16 COLLAR

STUD

12 GA.

DOOR

STIFFENER

1.25 TYP

PANEL

(ORDER SEPARATELY)

2.50

14 GA.

2.75

Notes:

1. Large print pocket (8" x 10") is

provided in each enclosure.

2. Panels are made from 12 Ga. steel.

3. Panels have flanges along all sides

when either dimension exceeds 17".

4. The number of door clamps is

dependent on size of enclosure.

Clamps are furnished along three

sides of door.

5. See page F27 for Stiffener Location.

0.19

MOUNTING

FEET

SECTION X-X

Space Occupied by Disconnect

E = 8.63 when Depth = 8.00

E = 11.62whenDepth= 12.00

WB = Wiring Space

See pages F16-F22 for various brands of disconnects

for “F”, “G”,&“WB” dimensions.

Disconnects will occupy space on panel shown by dimensions

“E”, “F”,&“G”. Wiring space “WB” is available when disconnect

is installed in the enclosure.

Refer to National Electrical Code article 430-10(b) for wiring

space required for line side conductors to be connected to disconnect.

Verify your application to determine if wiring space is adequate.

BODY

STIFFENER

0.75

1.50

THIS SPACE IS OCCUPIED

BY DISCONNECT SWITCH

AND FUSE CLIP (IF USED)

OR CIRCUIT BREAKER.

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

TOPHOLEIN

R.H. FLANGE

W

G

E

F

1.59

2.75

Page 14

F14

ABN12, SDN12, SDN12PL, N412CD, N412CSTD, & N412CSSSTD SERIES

ENCLOSURES NEMA 12 FLANGED SINGLE DOOR DISCONNECT

DISCONNECT ORDERING INFORMATION

When ordering wall-mounted disconnects from the various manufacturers, be sure to order

all of the necessary items. Each company has a different system, so care is required. Order

the following items from the disconnect manufacturer.

Allen-Bradley

• 1494V disconnect switches with flange-mount

variable depth operating mechanisms and

1494V flange-mounted variable depth operating

mechanisms for circuit breakers

• 140U flexible cable operating mechanisms and

140U molded case circuit breakers

• 1494C cable-operated disconnect switches with

flange-mount handles

• 194RC cable-operated flange-mount handles for

use with the NFPA 79 compliant 194R IEC rotary

disconnect switches

Allen-Bradley 1494V-R1, -R2 and -W2 operating

handles and Allen-Bradley 1494F disconnect

devices or 1494D circuit breaker operators will

NOT fit these enclosures.

When using a Bulletin 1494V disconnect

order:

* 1. A disconnect switch with operating

mechanism (Bulletin 1494V)

* 2. Bulletin 1494-H1 operating handle (Use

Bulletin 1494-H2 for enclosure catalog

number SDN12603812A)

* 3. A connecting rod [Bulletin 1494V-RA1 for

8.00" (203mm) and 10.00" (254mm) deep

enclosures; Bulletin 1494V-RA2 for 12.00"

(305mm) and 16.00" (406mm) deep

enclosures; two of Bulletin 1494-RB2 for

400 amp or 600 amp switch in a

SDN12603812A]

switch,

* 4. A trailer fuse block kit, if required (Bulletin 1494V)

* 5. A fuse clip kit, if required

6. Line and load connectors, if required

** 7. Door hardware (Bulletin 1494V-L1 for

2-point latching or Bulletin 1494V-L1

and 1494V-L2 for 3-point door latching)

When using a Bulletin 1494V circuit breaker

operating mechanism, order:

1. A circuit breaker (C-H)

2. A circuit breaker operating mechanism

(Bulletin 1494V)

3. An operating handle (Bulletin 1494V-H11)

4. A connecting rod [Bulletin 1494V-RA1 for

8.00" (203mm) and 10.00" (254mm) deep

enclosures or Bulletin 1494V-RA2 for 12.00"

(305mm) and 16.00" (406mm) deep enclosures]

** 5. Door hardware (Bulletin 1494V-L1 for

2-point latching or Bulletin 1494V-L1

and 1494V-L2 for 3-point door latching)

Allen-Bradley 1494 F Series See F23-F26

ABB Controls

When using a disconnect switch, order:

1. A flange operated switch (fusible or non-fusible)

2. A shaft [DSFHS-12 for 8.00” (203mm),

10.00" (254mm) and 12.00" (305mm) deep

enclosures or DSFHS-17 for 16.00”

(406mm) deep enclosures]

3. A handle (DSFGN-HS12)

** 4. Door hardware (FH-DHK for 2-point latching

or FH-DHK and FH-3RL for 3-point latching)

When using a circuit breaker, order:

1. A circuit breaker (ABB)

* 2. An operating mechanism

* 3. A shaft [FHS-12 for 8.00” (203mm), 10.00"

(254mm) and 12.00" (305mm) deep enclosures or FHS-17 for 16.00” (406mm) deep

enclosures]

* 4. Handle mechanism (FHN-HS12)

** 5. Door hardware (FH-DHK for 2-point latching

or FH-DHK and FH-3RL for 3-point latching)

Eaton Cutler-Hammer

When using a Type C361 disconnect switch, order:

* 1. A disconnect switch with an operating

mechanism

* 2. An operating handle (C361H1 or C361H3)

** 3. Door hardware (C361KJ4 or C361KJ6 for

2-point latching, C361KJ4 or C361KJ6 and

C361KR for 3-point latching)

When using a Type C371 circuit breaker

operating mechanism with a C-H circuit

breaker, order:

1. A circuit breaker

* 2. An operating mechanism

* 3. An operating handle

** 4. Door hardware (C361KJ4 or C361KJ6 for

2-point latching, C361KJ4 or C361KJ6 and

C361KR for 3-point latching)

When using a C-H circuit breaker with a Flex

™

Shaft

handle mechanism, order:

1. A circuit breaker

2. A complete Flex Shaft

** 3. Door hardware (C361KJ4 or C361KJ6 for

2-point latching, C361KJ4 or C361KJ6 and

C361KR for 3-point latching)

™

handle mechanism

General Electric

When using a disconnect switch, order:

1. A disconnect switch (Type QMR or QMW)

2. A fuse clip kit or no-fuse kit

3. A flange handle (STDA1 or STDA2)

4. A variable depth operating mechanism

** 5. Door hardware (TDV1 for 2-point latching

or TDV1 and TDV3 for 3-point latching)

When using a circuit breaker with a Spectra Flex

cable operator, order:

1. A circuit breaker

2. A flange-mounted handle mechanism

3. A breaker-mounted mechanism

4. An operating cable

** 5. Door hardware (TDV1 for 2-point latching

or TDV1 and TDV3 for 3-point latching)

When using a circuit breaker, order:

1. A circuit breaker

2. A flange handle (STDA1 or STDA2)

3. A variable depth operating mechanism

** 4. Door hardware (TDV1 for 2-point latching

or TDV1 and TDV3 for 3-point latching)

Siemens I-T-E Max-Flex

When using a disconnect switch, order:

1. A basic switch (right-hand)

2. A fuse or no-fuse kit

* 3. FHOHS flange-mounted handle

*4. Switchoperator

* 5. Cable, 36"

** 6. Door hardware (DKR2 for 2-point latching

or DKR3 for 3-point latching)

NOTE: Some I-T-E fixed depth switch operators can be

used. Contact Hubbell/Wiegmann for more information.

When using a circuit breaker, order:

1. A circuit breaker

2. Pressure wire connectors

* 3. FHOH flange-mounted handle (Use

FHOHN for enclosure catalog number

SDN12603812A)

™

Siemens ITE Max-Flex

™

(cont.)

* 4. A circuit breaker operator mechanism

* 5. An operating cable (standard 36.00" for 125

amp to 600 amp circuit breakers, and

48.00" for 800 amp to 1200 amp circuit

breakers)

** 6. Door hardware (DKR2 for 2-point latching or

DKR2 for 3-point latching)

Schneider Square D

®

When using a Class 9422 disconnect switch, order:

* 1. A disconnect switch with operating

mechanism (Class 9422)

* 2. A handle mechanism (Class 9422 Type A-1)

** 3. A door closing mechanism (Class 9423

Type M4 for 2-point latching, or Class 9423

Type M9 or M4 and Class 9423 Type M3 for

3-point latching)

When using a circuit breaker, order:

1. A circuit breaker (Schneider Square D

* 2. An operating mechanism (Class 9422)

* 3. A handle mechanism (Class 9422 Type A-1)

** 4. A door closing mechanism (Class 9423

Type M4 for 2-point latching, or Class 9423

Type M9 or M4 and Class 9423 Type M3

for 3-point latching)

When using a Class 9422 Type “T” disconnect

switch with a cable mechanism, order:

1. A disconnect switch with operating

mechanism (Class 9422, Type T)

2. A handle mechanism (Class 9422, Type A-1)

3. A cable mechanism (Class 9422, CFT_O)

3-, 5-, or 10-foot

** 4. A door closing mechanism (Class 9423

Type M4 for 2-point latching, or Class 9423

Type M9 or M4 and Class 9423 Type M3

for 3-point latching)

When using a circuit breaker with a cable

™

mechanism, order:

1. A circuit breaker (Schneider Square D

2. A handle mechanism (Class 9422, Type A-1)

3. A cable mechanism (Class 9422, CFT_O)

3-, 5-, or 10-foot

** 4. A door closing mechanism (Class 9423

Type M4 for 2-point latching, or Class 9423

Type M9 or M4 and Class 9423 Type M3

for 3-point latching)

* Items available from disconnect manufacturer as

complete kits.

** Enclosure “A” dimension less than 40.00" (1016mm)

requires a 2-point door closing mechanism.

Enclosures with an “A” dimension of 40.00" or more

require a 3-point latching mechanism.

PLEASE NOTE:

1. Operator adapter plates are not required with

enclosures on page F2-F13.

2. Various other switch accessories and circuit

breaker accessories are available from disconnect manufacturers. The information is subject

to change without notice. Please contact

Hubbell/Wiegmann or the disconnect manufacturer if there are further questions.

3. The “Space Occupied” tables (pages F16-F22)

are based upon information supplied by disconnect manufacturers. Hubbell/Wiegmann

does not assume responsibility for the accuracy

of these dimensions.

4. Check to make certain enclosure size is adequate for disconnect mechanisms and wire

bend space both above line lugs and below

load lugs.

®

)

®

)

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 15

SN4 & SSN4X SERIES ENCLOSURES

NEMA 4 FLANGED SINGLE DOOR DISCONNECT

DISCONNECT ORDERING INFORMATION

When ordering wall-mounted disconnects from the various

manufacturers, be sure to order all of the necessary items.

Each company has a different system, so care is required.

Order the following items from the disconnect manufacturer.

F15

Use a Type 4 & 4X disconnect operating handle on the

enclosure flange to provide corrosion resistance and maintain enclosure rating.

Allen-Bradley

When using a Bulletin 1494V disconnect switch, order:

1. A disconnect switch with operating

mechanism (Bulletin 1494V)

2. An operating handle (Bulletin

1494V-W1)

3. A connecting rod [Bulletin 1494VRA1 for 8.00" (203mm) deep enclosures; Bulletin 1494V-RA2 for

12.00" (305mm) deep enclosures]

4. A trailer fuse block kit, if required

(Bulletin 1494V)

5. A fuse clip kit, if required

6. Line and load connectors, if

required

When using a Bulletin 1494V circuit

breaker operating mechanism, order:

1. A circuit breaker (C-H)

2. A circuit breaker operating mechanism (Bulletin 1494V)

3. An operating handle (Bulletin

494V-W11)

4. A connecting rod [Bulletin 1494VRA1 for 8.00" (203mm) deep enclosures; Bulletin 1494V-RA2 for

12.00" (305mm) deep enclosures]

ABB Controls

When using a disconnect switch,

order:

1. A flange operated switch (fusible

or non-fusible)

2. A shaft [DSFHS-12]

3. A handle (DSFHN-HS4)

When using a circuit breaker, order:

1. A circuit breaker (ABB)

2. An operating mechanism

3. A shaft [FHS-12]

4. A handle (FHN-HS4)

Eaton Cutler-Hammer

When using a Type C361 disconnect

switch, order:

1. A disconnect switch with an

operating mechanism

2. An operating handle (C361H2 or

C361H4)

When using a Type C371 circuit breaker

operating mechanism with a C-H

circuit breaker, order:

1. A circuit breaker

2. An operating mechanism

3. An operating handle (C371H2 or

C371H4)

When using a C-H circuit breaker

with a Type 4/4X Flex Shaft

™

handle

mechanism, order:

1. A circuit breaker

2. A complete Flex Shaft

™

handle

mechanism

General Electric

When using a disconnect switch,

order:

1. A disconnect switch (Type QMR

or QMW)

2. A fuse clip kit or no-fuse kit

3. A flange handle (STDA1X)

4. A variable depth operating mechanism

When using a circuit breaker, order:

1. A circuit breaker

2. A flange handle (STDA1X)

3. A variable depth operating mechanism

When using a circuit breaker with a

Spectra Flex

™

cable operator, order:

1. A circuit breaker

2. A flange-mounted handle mechanism

3. A breaker-mounted mechanism

4. An operating cable

PLEASE NOTE:

1. Operator adapter plates and door hardware are not required with enclosures on page F2-F13.

2. Various other switch accessories and circuit breaker accessories are available from disconnect manufacturers. The above information is subject to change without notice. Please

contact Hubbell-Wiegmann or the disconnect manufacturer if there are further questions.

3. The “Space Occupied” tables (pages F16-F22) are based upon information supplied by

disconnect manufacturers. Hubbell-Wiegmann does not assume responsibility for the accuracy of these dimensions.

* Items available from disconnect manufacturer as complete kits.

Siemens ITE Max-Flex

™

When using a disconnect switch,

order:

1. A basic switch (right-hand)

2.Afuseorno-fusekit

3. A flange-mounted handle (FHOHS4)

4. Switch operator

5. Cable, 36.00"

When using a circuit breaker, order:

1. A circuit breaker

2. Pressure wire connectors

3. A flange-mounted handle (FH0H4)

4. A circuit breaker operator mechanism

5. An operating cable (standard 36.00")

Schneider Square D

®

When using a Class 9422 disconnect

switch, order:

1. A disconnect switch with operating

mechanism (Class 9422)

2. A handle mechanism (Class 9422

Type A-2 or A-1)

When using a circuit breaker, order:

1. A circuit breaker (Schneider Square D

2. An operating mechanism (Class

9422)

3. A handle mechanism (Class 9422

Type A-2 or A-1)

When using a Class 9422 Type “T”

disconnect switch with a cable mechanism, order:

1. A disconnect switch with operating

mechanism (Class 9422, Type T)

2. A handle mechanism (Class 9422

Type A-1)

3. A cable mechanism (Class 9422

CFT_O) 3-, 5-, or 10-foot

When using a circuit breaker with a

cable mechanism, order:

1. A circuit breaker (Schneider

Square D

®

)

2. A handle mechanism (Class 9422

Type A-1)

3. A cable mechanism (Class 9422

CFT_O) 3-, 5-, or 10-foot

®

)

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 16

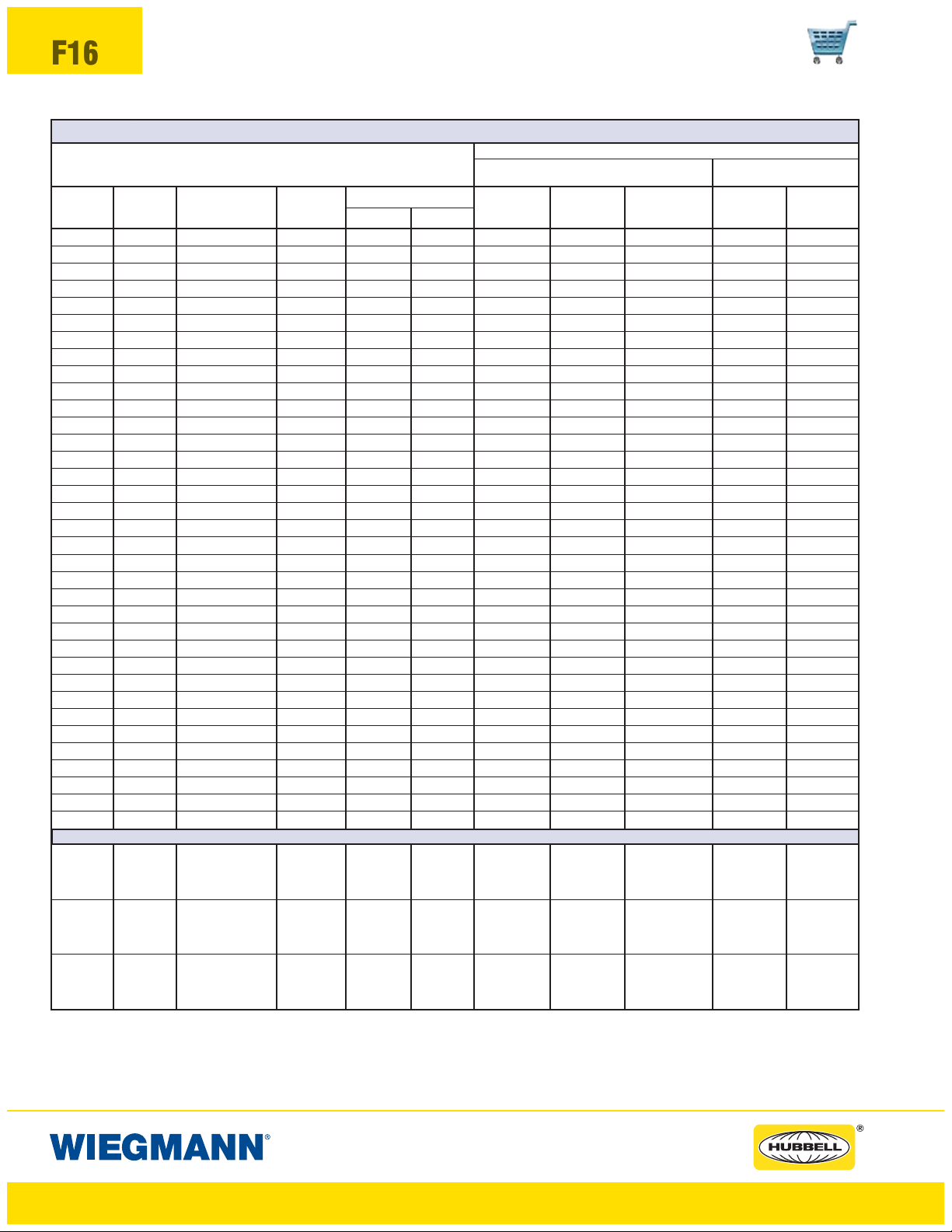

F16

ABN12, SDN12, SDN12PL, N412CD,

N412CSTD, N412CSSSTD, SN4 & SSN4X SERIES ENCLOSURES

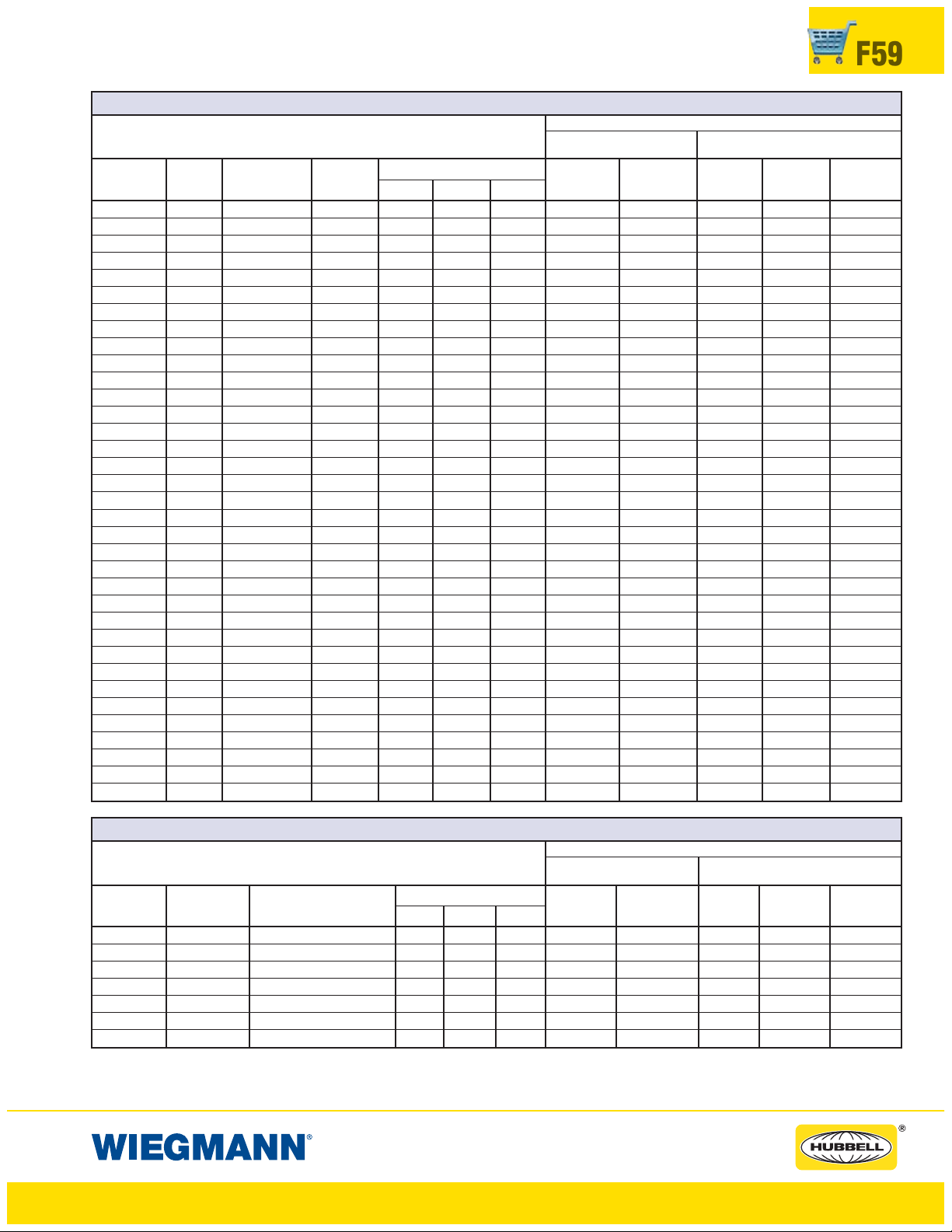

DISCONNECT SPACE OCCUPIED & AVAILABLE WIRING SPACE INFORMATION

ALLEN-BRADLEY BULLETIN 1494V DISCONNECTS

ABN12, SDN12, SDN12PL, N412CD, SN4 & SSN4X WALL-MOUNTS

N412CSTD & N412CSSSTD (PAGES F2-F9) (PAGES F10-F13)

TYPE AMP FUSE FUSE

NUMBER RATING CLIP CLASS

DS30 30A No fuse — 3.88 6.62 2.78 5.15 9.66 6.66 9.66

DS30 30A 30A-250V H, K, R 5.25 6.62 2.78 5.15 9.66 6.66 9.66

DS30 30A 30A-600V H, K, R 8.00 6.62 2.78 5.15 9.66 6.66 9.66

DS30 30A 30A-600V J 5.25 6.62 2.78 5.15 9.66 6.66 9.66

DS30 30A 60A-250V H, K 6.00 6.62 2.78 5.15 9.66 6.66 9.66

DS30 30A 60A-600V H, K 8.50 6.62 2.78 5.15 9.66 6.66 9.66

DS30 30A 60A-600V J 5.38 6.62 2.78 5.15 9.66 6.66 9.66

DS60 60A No fuse — 3.88 6.62 2.01 4.35 8.89 5.89 8.89

DS60 60A 60A-250V H, K, R 6.00 6.62 2.01 4.35 8.89 5.89 8.89

DS60 60A 60A-600V H, K, R 8.50 6.62 2.01 4.35 8.89 5.89 8.89

DS60 60A 60A-600V J 5.38 6.62 2.01 4.35 8.89 5.89 8.89

DS60 60A 30A-600V H, K, R 8.00 6.62 2.01 4.35 8.89 5.89 8.89

DS60 60A 100A-250V H, K 8.50 6.62 2.01 4.35 8.89 5.89 8.89

DS60 60A 100A-600V H, K 10.50 6.62 2.01 4.35 8.89 5.89 8.89

DS60 60A 100A-600V J 7.25 6.62 2.01 4.35 8.89 5.89 8.89

DS100 100A*** No fuse — 3.88 6.62 — 4.17 8.67 5.70 8.70

DS100 100A*** 100A-250V H, K, R 8.12 6.62 — 4.17 8.67 5.70 8.70

DS100 100A*** 100A-600V H, K, R 10.12 6.62 — 4.17 8.67 5.70 8.70

DS100 100A*** 100A-600V J 6.88 6.62 — 4.17 8.67 5.70 8.70

DS100 100A*** 60A-600V H, K, R 10.12 6.62 — 4.17 8.67 5.70 8.70

DS100 100A*** 60A-600V J 8.88 6.62 — 4.17 8.67 5.70 8.70

DS200 200A*** No fuse — 4.75 7.88 — — 8.12 — 8.12

DS200 200A*** 200A-250V H, K, R 10.88 7.88 — — 8.12 — 8.12

DS200 200A*** 200A-600V H, K, R 13.38 7.88 — — 8.12 — 8.12

DS200 200A*** 200A-600V J 9.50 7.88 — — 8.12 — 8.12

DS200 200A*** 100A-600V H, K, R 12.00 7.88 — — 8.12 — 8.12

DS200 200A*** 100A-600V J 8.75 7.88 — — 8.12 — 8.12

DS400 400A** No fuse — 10.75 10.88 — — — — —

DS400 400A** 400A-250V H, K, R 16.12 10.88 — — — — —

DS400 400A** 400A-600V H, K, R 19.12 10.88 — — — — —

DS400 400A** 400A-600V J 14.62 10.88 — — — — —

DS600 600A No fuse — 10.75 10.88 — — — — —

DS600 600A**** 600A-250V H, R 10.75 10.88 — — — — —

DS600 600A**** 600A-600V H, R 10.75 10.88 — — — — —

DS600 600A 600A-600V J 17.59 10.88 — — — — —

ALLEN-BRADLEY BULLETIN 1494V CIRCUIT BREAKERS

SPACE OCCUPIED

FG*

WHEN WHEN WHEN WHEN WHEN

D=8.00 D=10.00 D=12 OR 16 D=8.00 D=12.00

WB WB WB WB WB

WIRE BEND SPACE “WB” ABOVE DISCONNECT

M40 15A-150A

M50 70A-250A

M60 100A-400A

* Does not include space for optional auxiliary switch.

** The 400 amp disconnect switch and the 600 amp disconnect switch will only fit catalog number SDN12603812A

(see page F4). Wire bend space of 12.13" is provided above disconnect when installed.

*** Series B

**** ”F” and “G” do not include separately mounted fuse blocks.

EHD, FD, FDB

FDC, HFD, HMCP,

Circuit Breakers

HJD, HMCP

Circuit Breakers

HKD, HMCP

— 5.00 4.50 4.25 6.62 11.12 8.12 11.12

— 9.75 4.75 — — 10.62 — 10.62JD, JDB, JDC,

— 9.69 6.12 — — 10.50 — 10.50KD, KDB, KDC,

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

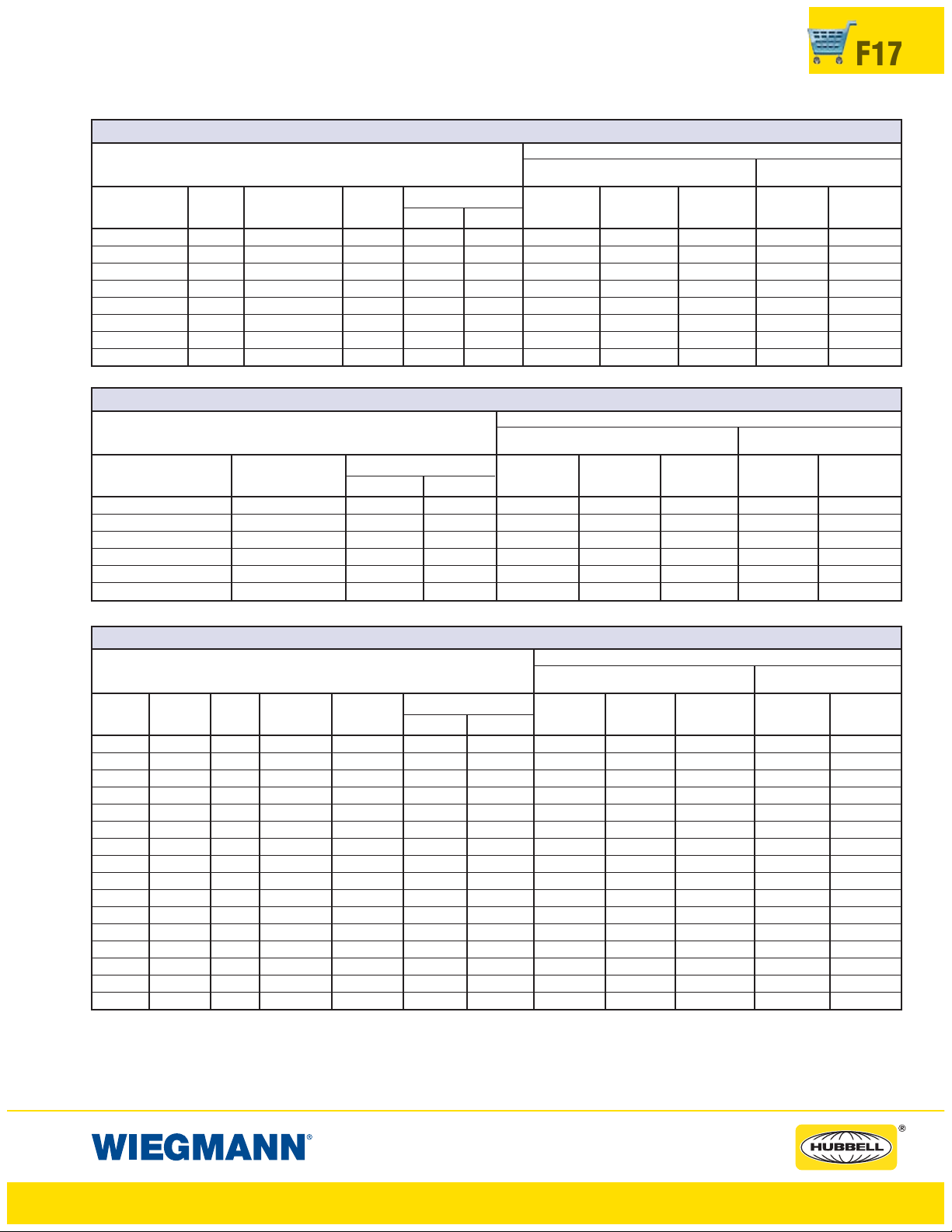

Page 17

ABN12, SDN12, SDN12PL, N412CD,

N412CSTD, N412CSSSTD, SN4 & SSN4X SERIES ENCLOSURES

DISCONNECT SPACE OCCUPIED & AVAILABLE WIRING SPACE INFORMATION

ABB CONTROLS DISCONNECT SWITCHES WITH FLANGE-MOUNTED OPERATORS

K2FHD-M

ABN12, SDN12, SDN12PL, N412CD, SN4 & SSN4X WALL-MOUNTS

N412CSTD & N412CSSSTD (PAGES F2-F9) (PAGES F10-F13)

TYPE AMP FUSE FUSE

NUMBER RATING CLIP CLASS

OETL-NF30-F 40A No fuse — 4.45 3.78 6.41 8.75 13.28 10.28 13.28

OETL-NF60-F 80A No fuse — 4.86 3.78 6.22 8.56 13.09 10.09 13.09

OETL-NF100-F 100A No fuse — 4.86 4.78 5.66 8.00 12.53 9.53 12.53

OETL-NF175-F 175A No fuse — 7.30 6.49 — 5.75 10.28 7.28 10.28

OETL-NF200-F 200A No fuse — 7.36 7.28 — 5.75 10.28 7.28 10.28

OESA-F30J6-F 30A 30A-600V J 4.28 6.58 4.73 7.07 11.61 8.61 11.61

OESA-F60J6-F 60A 60A-600V J 4.28 6.26 4.73 7.07 11.61 8.61 11.61

OESA-F100J6-F 100A 100A-600V J 6.54 7.65 4.30 6.64 11.17 8.17 11.17

ABB CONTROLS CIRCUIT BREAKERS WITH FLANGE-MOUNTED OPERATORS

MECHANISM AMP RATING

K2FHD-M 100A 6.92 3.94 3.39 5.73 10.26 7.26 10.26

K3FHD-M 150A-225A 5.98 4.23 — — 5.56 5.56 5.56

K4FHD-M 250A 7.44 4.23 — — 3.95 — 3.95

K5FHD-M 400A 9.71 5.62 — — — — —

K5FHD-M 600A/800A 8.28 11.26 — — — — —

K5FHD-M 800A 10.11 11.26 — — — — —

SPACE OCCUPIED

FG

SPACE OCCUPIED

FG

WHEN WHEN WHEN WHEN WHEN

D=8.00 D=10.00 D=12 OR 16 D=8.00 D=12.00

WB WB WB WB WB

ABN12, SDN12, SDN12PL, N412CD, SN4 & SSN4X WALL-MOUNTS

N412CSTD & N412CSSSTD (PAGES F2-F9) (PAGES F10-F13)

WHEN WHEN WHEN WHEN WHEN

D=8.00 D=10.00 D=12 OR 16 D=8.00 D=12.00

WB WB WB WB WB

WIRE BEND SPACE “WB” ABOVE DISCONNECT

WIRE BEND SPACE “WB” ABOVE DISCONNECT

F17

EATON CUTLER-HAMMER C361 CIRCUIT DISCONNECT SWITCHES

K2FHD-M

ABN12, SDN12, SDN12PL, N412CD, SN4 & SSN4X WALL-MOUNTS

N412CSTD & N412CSSSTD (PAGES F2-F9) (PAGES F10-F13)

SWITCH TYPE AMP FUSE FUSE

NUMBER NUMBER RATING CLIP CLASS

C361 NC 30A No fuse — 5.75 7.43 3.44 5.75 10.31 7.31 10.31

C361 SC21 30A 30A-250V H, K, R 8.38 7.43 3.44 5.75 10.31 7.31 10.31

C361 SC61 30A 60A-250V H, K, R 8.38 7.43 3.44 5.75 10.31 7.31 10.31

C361 SC61 30A 30A-600V H, J, K, R 8.38 7.43 3.44 5.75 10.31 7.31 10.31

C361 ND 60A No fuse — 5.75 7.43 3.44 5.75 10.31 7.31 10.31

C361 SD22 60A 60A-250V H, K, R 8.38 7.43 3.44 5.75 10.31 7.31 10.31

C361 SD22 60A 30A-600V J 8.38 7.43 3.44 5.75 10.31 7.31 10.31

C361 SD62 60A 60A-600V H, K, R 8.38 7.43 3.44 5.75 10.31 7.31 10.31

C361 SD62 60A 60A-600V J 8.38 7.43 3.44 5.75 10.31 7.31 10.31

C361 NE 100A No fuse — 5.56 8.95 3.00 5.38 9.91 7.47 9.91

C361 SE263 100A 100A-250V H, K, R 10.31 8.95 3.00 5.38 9.91 7.47 9.91

C361 SE263 100A 100A-600V H, K, R 10.31 8.95 3.00 5.38 9.91 7.47 9.91

C361 SE263 100A 100A-600V J 10.31 8.95 3.00 5.38 9.91 7.47 9.91

C361 NF* 200A No fuse — 13.06 10.00 — — 7.94 4.94 7.94

C361 SF264* 200A 200A-250V H, K, R 13.06 10.00 — — 7.94 4.94 7.94

C361 SF264* 200A 200A-600V H, J, K, R 13.06 10.00 — — 7.94 4.94 7.94

*200 amp switch should be installed in an enclosure with an "H" dimension of 30.00" (762mm) or more.

SPACE OCCUPIED

FG

WHEN WHEN WHEN WHEN WHEN

D=8.00 D=10.00 D=12 OR 16 D=8.00 D=12.00

WB WB WB WB WB

WIRE BEND SPACE “WB” ABOVE DISCONNECT

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 18

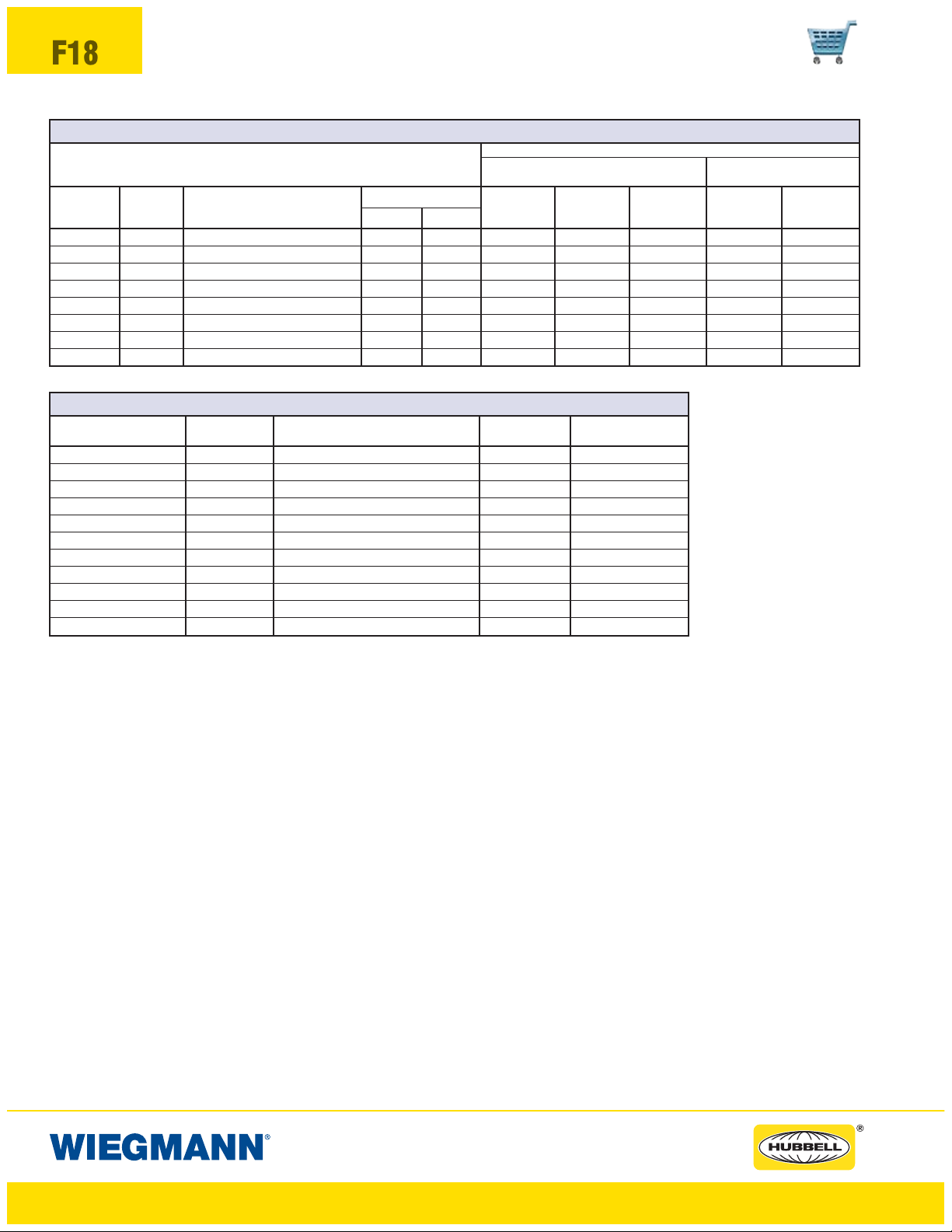

F18

ABN12, SDN12, SDN12PL, N412CD,

N412CSTD, N412CSSSTD, SN4 & SSN4X SERIES ENCLOSURES

DISCONNECT SPACE OCCUPIED & AVAILABLE WIRING SPACE INFORMATION

EATON CUTLER-HAMMER C371 CIRCUIT BREAKER OPERATORS FOR C-H CIRCUIT BREAKERS

ABN12, SDN12, SDN12PL, N412CD, SN4 & SSN4X WALL-MOUNTS

N412CSTD & N412CSSSTD (PAGES F2-F9) (PAGES F10-F13)

TYPE

NUMBER

C371E 225A F Frame: EHD, FDB, FD, HFD, FDC 6.00 5.50 4.44 6.81 11.44 8.44 11.44

C371E 150A F Frame: HMCP 6.00 5.50 4.44 6.81 11.44 8.44 11.44

C371F 250A J Frame: JDB, JD, HJD, JDC 8.94 8.00 — 6.75 11.25 — 11.25

C371F 250A J Frame: HMCP 10.94 8.00 — 6.75 11.25 — 11.25

C371F 400A K Frame: DK, KDB, KD, HKD 9.75 8.00 — — 10.75 — 10.75

C371F 400A K Frame: HMCP 9.75 8.00 — — 10.75 — 10.75

C371G 600A L Frame: LD, HLD, LDC 8.44 11.88 — — 9.18 — 9.18

C371G 600A L Frame: HMCP 8.44 11.88 — — 9.18 — 9.18

EATON CUTLER-HAMMER FLEX SHAFT™OPERATOR MECHANISMS FOR C-H CIRCUIT BREAKERS

COMPLETE OPERATOR AMP FRAME BREAKER BREAKER

MECHANISM RATING TYPE HEIGHT WIDTH

Catalog numbers for complete mechanisms include a flange-mounted handle, flexible shaft and circuit breaker mechanism.The last digit of the catalog number denotes the length of shaft (F1S03 = 3-foot shaft). The F, J, K frame Flex Shafts

are available in 3-foot to 10-foot lengths. The L, N, R frame Flex Shafts are available in 4-foot to 6-foot lengths.

Space Occupied by Disconnect

• The Flex Shaft

mechanism.

• Refer to National Electrical Code

• Choose the length of shaft based on placement of the circuit breaker in the enclosure ensuring a 4-inch min. bending

radius for the Flex Shaft

• Space occupied by circuit breaker is determined by overall height "X", width "Y", wire bend space "WB" and location "G"

as selected from right to left.

MAX

AMP

RATING WB WB WB WB WB

F1S03 225A F Frame: EHD, FDB, FD, HFD, FDC 6.00 4.12

F1S03 150A F Frame: HMCP 6.00 4.12

F2S03 250A J Frame: JDB, JD, HJD, JDC 10.00 4.12

F2S03 250A J Frame: HMCP 10.00 4.12

F3S03 400A K Frame: DK, KDB, KD, HKD 10.12 5.50

F3S03 400A K Frame: HMCP 12.45 5.50

F4S04 600A L Frame: LD, HLD, LDC 10.75 8.25

F4S04 600A L Frame: HMCP 12.50 8.25

F7S04 800A M Frame: MD, MDS 16.00 8.25

F5S04 1200A N Frame: ND, HND, NDC 16.00 8.25

F6S04 2500A R Frame: RD, CRD, RDC 16.00 15.50

™

system allows the circuit breaker to be positioned independent from the flange-mounted handle

™

.

FRAME TYPE

®

article 430-10(b) for wiring space "WB" required for line side conductors.

SPACE OCCUPIED

FG

WHEN WHEN WHEN WHEN WHEN

D=8.00 D=10.00 D=12 OR 16 D=8.00 D=12.00

WIRE BEND SPACE “WB” ABOVE DISCONNECT

™

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 19

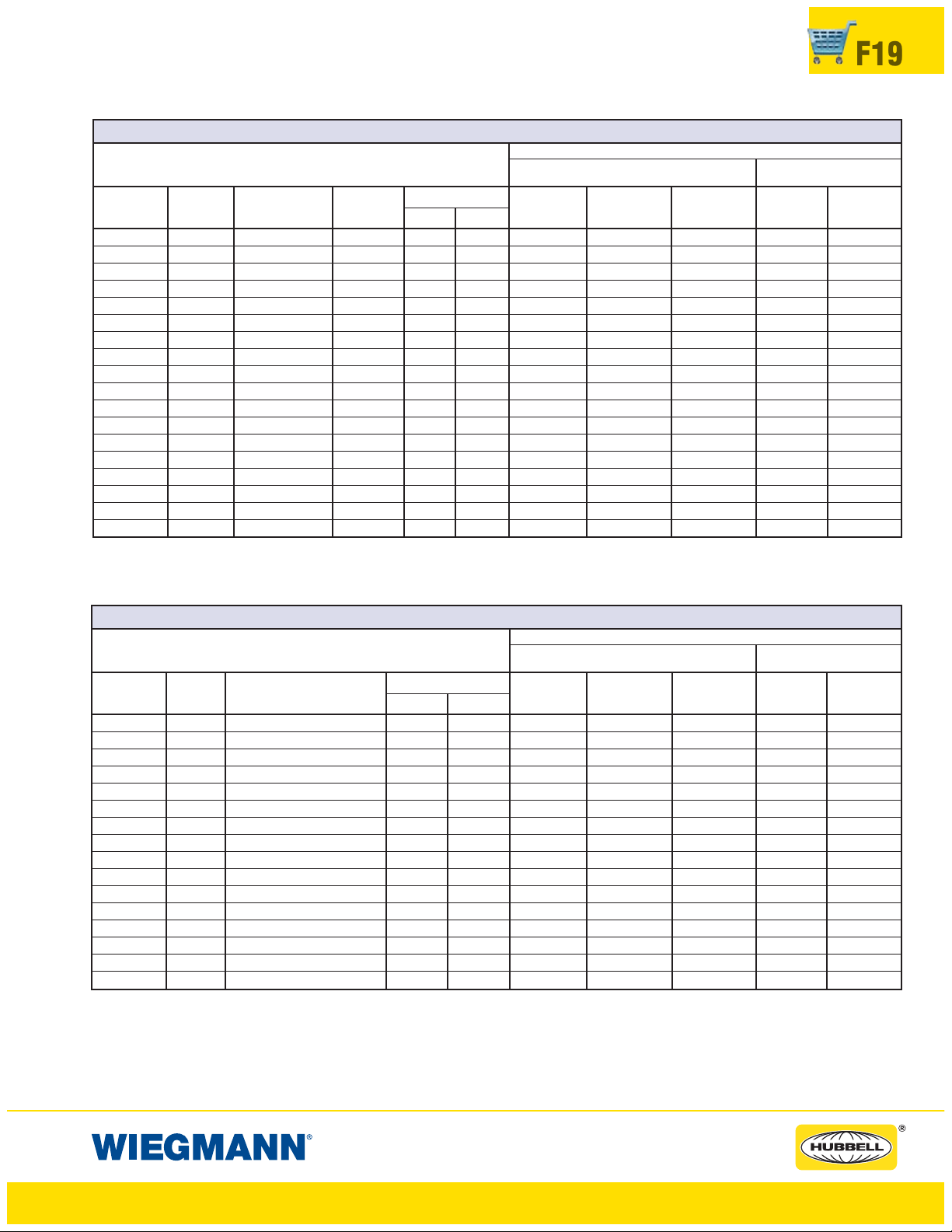

ABN12, SDN12, SDN12PL, N412CD,

N412CSTD, N412CSSSTD, SN4 & SSN4X SERIES ENCLOSURES

DISCONNECT SPACE OCCUPIED & AVAILABLE WIRING SPACE INFORMATION

GENERAL ELECTRIC TYPE STDA OPERATORS FOR DISCONNECTS

ABN12, SDN12, SDN12PL, N412CD, SN4 & SSN4X WALL-MOUNTS

N412CSTD, N412CSSSTD & SN4 (PAGES F2-F9) (PAGES F10-F13)

MECHANISM

TDOM1A 30A No fuse — 7.75** 5.25 6.18* 7.62 12.12 9.12 12.12

TDOM1A 30A 30A-250V H, R 7.75** 5.25 6.18* 7.62 12.12 9.12 12.12

TDOM1B 30A 30A-600V H, R 12.38** 5.25 6.18* 7.62 12.12 9.12 12.12

TDOM1B 30A 60A-250V H, R 12.38** 5.25 6.18* 7.62 12.12 9.12 12.12

TDOM1B 30A 60A-600V H, R 12.38** 5.25 6.18* 7.62 12.12 9.12 12.12

TDOM1A 60A No fuse — 7.75** 5.25 6.18* 7.62 12.12 9.12 12.12

TDOM1B 60A 60A-250V H, R 12.38** 5.25 6.18* 7.62 12.12 9.12 12.12

TDOM1B 60A 60A-600V H, R 12.38** 5.25 6.18* 7.62 12.12 9.12 12.12

TDOM1B 60A 100A-250V H, R 12.38** 5.25 6.18* 7.62 12.12 9.12 12.12

TDOM1B 60A 100A-600V H, R 12.38** 5.25 6.18* 7.62 12.12 9.12 12.12

TDOM1A 100A No fuse — 7.75** 5.25 6.18* 7.62 12.12 9.12 12.12

TDOM1B 100A 100A-250V H, R 12.38** 5.25 6.18* 7.62 12.12 9.12 12.12

TDOM1B 100A 100A-600V H, R 12.38** 5.25 6.18* 7.62 12.12 9.12 12.12

TDOM1B 100A 200A-250V H, R 12.38** 5.25 6.18* 7.62 12.12 9.12 12.12

TDOM1B 100A 200A-600V H, R 12.38** 5.25 6.18* 7.62 12.12 9.12 12.12

TDOM2 200A No fuse — 7.00 9.12 — — 9.50 6.50 9.50

TDOM2 200A 200A-250V H, R 15.38 9.12 — — 9.50 6.50 9.50

TDOM2 200A 200A-600V H, R 15.38 9.12 — — 9.50 6.50 9.50

* Disconnect moved down .88" to fit on panel.

**Dimension applies to 8.00" (203mm) deep enclosures and is .88" less in deeper enclosures.

AMP FUSE FUSE

RATING CLIP CLASS

SPACE OCCUPIED

FG

WHEN WHEN WHEN WHEN WHEN

D=8.00 D=10.00 D=12 OR 16 D=8.00 D=12.00

WB WB WB WB WB

WIRE BEND SPACE “WB” ABOVE DISCONNECT

F19

GENERAL ELECTRIC TYPE STDA OPERATORS FOR CIRCUIT BREAKERS

OPERATORS FOR CIRCUIT BREAKERS

MECHANISM

SDOM1A 150A TEB, TED, THED 7.75** 5.25 6.06* 7.50 12.06 9.06 12.06

SDOM1A 150A TEC 7.75** 5.25 6.06* 7.50 12.06 9.06 12.06

TDOM1B 150A TB1 12.38** 5.25 6.06* 7.50 12.06 9.06 12.06

TDOM1B 150A TEC, TECL 12.38** 5.25 6.06* 7.50 12.06 9.06 12.06

TDOM1C 150A TEL 7.75** 5.25 6.06* 7.50 12.06 9.06 12.06

TDOM1D 150A THLC1 7.75** 5.25 — 5.12 9.62 6.62 9.62

TDOM3 225A TFJ 10.38 5.75 — 6.06 10.62 7.62 10.62

TDOM3 225A TFK, THFK, TFL 10.38 5.75 — 6.06 10.62 7.62 10.62

TDOM4 400A TJJ, TJK4, THJK4, TJL4V 8.25 9.38 — 5.12 9.69 6.69 9.69

TDOM4 600A TJK6, THJK6, TJ4V, TJL4V 8.25 9.38 — 5.12 9.69 6.69 9.69

TDOM5 400A TB4, TJH6S 14.25 9.38 — 5.12 9.69 6.69 9.69

TDOM6 225A TLB2, THLC2 11.75 9.38 — — 9.12 6.12 9.12

TDOM6 400A TLB4, THLC4 11.75 9.38 — — 7.75 4.75 7.75

SDOM1A 150A SPECTRA SE150 7.75** 5.25 6.06* 7.50 12.06 9.06 12.06

SDOM3 250A SPECTR SF250 10.38 5.75 — 6.06 10.62 7.06 10.06

SDOM4 600A SPECTRA SG600 10.00 7.00 — — 7.93 — 7.93

* Disconnect moved down .88" to fit on panel.

**Dimension applies to 8.00" (203mm) deep enclosures and is .88" less in deeper enclosures.

AMP

RATING

FRAME TYPE

SPACE OCCUPIED

FG

ABN12, SDN12, SDN12PL, N412CD, SN4 & SSN4X WALL-MOUNTS

N412CSTD, N412CSSSTD & SN4 (PAGES F2-F9) (PAGES F10-F13)

WHEN WHEN WHEN WHEN WHEN

D=8.00 D=10.00 D=12 OR 16 D=8.00 D=12.00

WB WB WB WB WB

WIRE BEND SPACE “WB” ABOVE DISCONNECT

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 20

F20

ABN12, SDN12, SDN12PL, N412CD,

N412CSTD, N412CSSSTD, SN4 & SSN4X SERIES ENCLOSURES

DISCONNECT SPACE OCCUPIED & AVAILABLE WIRING SPACE INFORMATION

GENERAL ELECTRIC CIRCUIT BREAKERS WITH SPECTRA FLEX™CABLE OPERATORS

FRAME MAXIMUM CIRCUIT BREAKER CIRCUIT BREAKER

SIZE AMP RATING HEIGHT X WIDTH Y

E150 150A 6.31 4.12

SE150 150A 6.31 4.12

SF250 250A 10.12 4.12

SG600 600A 10.09 5.50

SK1200 1200A 15.50 8.25

FRAME BREAKER FLANGE-MOUNTING OPERATING

SIZE MECHANISM HANDLE** CABLE*

E150 SCOM1A SCH1 SC3L

SE150/SF250 SCOM1EF SCH1 SC3L

SG600 SCOM1G SCH1 SC3L

SK1200 SCOM1K SCH2K SC3H

* Operating cables are available in 3-foot to 10-foot lengths. (The number 3 in the catalog number denotes

3-foot cable.)

** Add “X” for NEMA 4 or 4X flange-mounted handle.

ABN12, SDN12, SDN12PL, N412CD, SN4 & SSN4X

N412CSTD, N412CSSSTD, SN4 & SSN4X WALL-MOUNTS

For enclosures that

accept these devices,

see pages F2-F9.

For enclosures that

accept these devices,

see pages F10-F13.

Space Occupied by Circuit Breaker

• The General Electric Spectra-Flex

the flange-mounted handle mechanism.

• Refer to National Electrical Code

• Choose the operating cable length based on placement of the circuit breaker in the enclosure ensuring a 3"

minimum bending radius for the cable.

• Space occupied by circuit breaker is determined by overall circuit breaker size ("X" height and "Y" width)

plus "WB" wire bend space and location "G" as selected from right to left.

I-T-E DISCONNECT SWITCHES FOR MAX-FLEX™OPERATORS

SWITCH

MCS603R 30A No fuse — 5.52 6.13

MCS603R 30A 30A-250V H, K, R 8.11 6.13

MCS603R 30A 30A-600V H, K, R 10.11 6.13

MCS603R 30A 30A-600V J 8.48 6.13

MCS606R 60A No fuse — 5.52 6.13

MCS606R 60A 60A-250V H, K, R 7.86 6.13

MCS606R 60A 60A-600V H, K, R 10.38 6.13

MCS606R 60A 60A-600V J 8.36 6.13

MCS610R 100A No fuse — 7.59 7.38

MCS610R 100A 100A-250V H, K, R 11.85 7.38

MCS610R 100A 100A-600V H, K, R 13.85 7.38

MCS610R 100A 100A-600V J 10.60 7.38

MCS620R 200A No fuse — 9.02 9.17

MCS620R 200A 200A-250V H, K, R 14.70 9.17

MCS620R 200A 200A-600V H, K, R 17.20 9.17

MCS620R 200A 200A-600V J 13.32 9.17

AMP FUSE FUSE DISCONNECT DISCONNECT

RATING CLIP CLASS HEIGHT X WIDTH Y

™

system allows the circuit breaker to be positioned independent from

®

article 430-10(b) for wiring space "WB" required for line side conductors.

ABN12, SDN12, SDN12PL, N412CD, SN4 & SSN4X

N412CSTD, N412CSSSTD, SN4 & SSN4X WALL-MOUNTS

For enclosures that

accept these devices,

see pages F2-F9.

For enclosures

that accept these

devices, see

pages F10-F13.

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 21

ABN12, SDN12, SDN12PL, N412CD,

N412CSTD, N412CSSSTD, SN4 & SSN4X SERIES ENCLOSURES

DISCONNECT SPACE OCCUPIED & AVAILABLE WIRING SPACE INFORMATION

SIEMENS ITE CIRCUIT BREAKERS FOR MAX-FLEX™OPERATORS

COMPLETE OPERATOR CIRCUIT BREAKER MAXIMUM CIRCUIT BREAKER CIRCUIT BREAKER

MECHANISM FRAME AMP RATING HEIGHT X WIDTH Y

FHOE036 ED 125A 6.34 3.00 ED2. ED4. ED6. HED4. HED6

FHOE036 CED 125A 9.58 3.00 CED6

FHOF036 FD 250A 9.50 4.50 FXD6-A, FD6-A, HFD6, FXD6-ETJ, HHFD6, HHFXD6

FHOJ036 CFD 250A 14.25 4.50 CFD6, CFD6-ETI

FHOJ036 JD 400A 11.00 7.50 JXD2, JXD6, JD6, HJD6, HHJD6, HHJXD6, JXD6-ETI

FHOJ036 CJD 400A 17.86 7.50 CJD6, CJD6-ETI

FHOJ036 LD 600A 11.00 7.50 LXD6, LD6, HLD6, HHLD6, HHLDX6, LXD6-ETI

FHOJ036 CLD 600A 17.86 7.50 CLD6, CLD6-ETI

FHOLM036 LMD 800A 16.00 9.00 LMD6, LMXD6, HLMD6, HLMXD6, LMXD6-ETI

FHON048* MD 80 0 A 24. 00 9.0 0 MD2, MXD6, HMD6, HMXD6, CMD6, MXD6-ETI, CMD6-ETI

FHON048* ND 1200A 24.00 9.00 ND6, NXD6, HND6, HNXD6, CND6

Mechanisms and circuit breakers listed above will fit any disconnect wall-mounts

on pages F10-F13, or SN4 wall-mounts on pages F2-F9 except as noted.

The last 3 digits of operator mechanism number indicates cable length in inches.

Also 48" cables are available for ED, FD, JD/LD operators, and 60" cables for

MD/ND, PD/RD operators.

For Type 4 applications order handle, cable and circuit breaker separately.

*This operator mechanism can only be installed in catalog number

SDN12603812A (see page F3) which has the appropriate flange cutout.

Space Occupied by Disconnect

• The Siemens ITE Max-Flex

tioned independent from the flange-mounted handle mechanism.

• Refer to National Electrical Code

required for line side conductors.

• Refer to Siemens ITE Max-Flex

nect location when 36-inch or 48-inch Max-Flex

• Space occupied by disconnect is determined by overall height “X”, width

“Y”, wire bend space “WB” and location “G” as selected from right to left.

™

CIRCUIT BREAKER TYPE

cable system allows the disconnect to be posi-

®

article 430-10(b) for wiring space “WB”

™

installation instructions for limits on discon-

™

cables.

F21

SCHNEIDER SQUARE D®CLASS 9422 DISCONNECT SWITCHES USED WITH CABLE MECHANISM 9422-CFT30 & 9422A-1 HANDLE MECHANISM

SWITCH

TCN-30C 30A No fuse — 5.90 6.20

TCF-30C 30A 30A-250V H, K, R 7.50 6.20

TCF-33C 30A 30A-600V H, K, R 10.15 6.20

TCF-33C 30A 60A-250V H, K, R 8.15 6.20

TCF-33C 30A 30A-600V J 7.50 6.20

TDN-60C 60A No fuse — 5.90 6.20

TDF-60C 60A 30A-600V H, K, R 10.15 6.20

TDF-60C 60A 60A-250V H, K, R 8.15 6.20

TDF-63C 60A 60A-600V H, K, R 10.65 6.20

TDF-63C 60A 60A-600V J 7.50 6.20

TEN-10C 100A No fuse — 5.90 6.20

TEF-10C 100A 100A-250V H, K, R 10.35 6.20

TEF-10C 100A 100A-600V H, K, R 10.35 6.20

TEF-10C 100A 100A-600V J 10.35 6.20

Use switches listed above with appropriate cable mechanism and 9422-A1 handle mechanism.

SCHNEIDER SQUARE D®CLASS 9422 CABLE MECHANISM FOR CIRCUIT BREAKERS

CABLE TYPE AMP FRAME CIRCUIT BREAKER CIRCUIT BREAKER ABN12, SDN12, SDN12PL, N412CD, SN4 & SSN4X

SWITCH RATING TYPE HEIGHT X WIDTH Y N412CSTD, N412CSSSTD, SN4 & SSN4X WAL L-M OUNTS

9422 CGJ30 75A GJL 4.75 3.50

9422 CGJ300 100A GJL 4.75 3.50

9422 CGJ30 100A FAL, FHL 6.00 4.50

9422 CGJ30 250A KAL, KHL 8.00 4.50

9422 CGJ30 400A LAL, LHL, Q4L 11.00 6.00

Use cable mechanism with appropriate circuit breaker and 9422-A1 handle mechanism. Cable operators are available in 3-foot, 5-foot, and 10-foot lengths.

Numbers shown (30) are for 3-foot cables.

Space Occupied by Disconnect Switch or Circuit Breaker

• Schneider Square D®cable mechanisms allows disconnect devices to be

positioned independent from the flange-mounted handle mechanism.

•RefertoNational Electrical Code

required for line side conductors.

AMP FUSE FUSE DISCONNECT DISCONNECT ABN12, SDN12, SDN12PL, N412CD, S N 4 & SS N 4 X

RATING CLIP CLASS HEIGHT X WIDTH Y N412CSTD, N412CSSSTD, SN4 & SSN4X WALL-MOUNTS

®

article 430-10(b) for wiring space "WB"

For enclosures that

accept these devices,

see pages F2-F9.

For enclosures that

accept these devices,

see pages F2-F9.

• Choose cable mechanism length based on placement of disconnect in

enclosure. See Schneider Square D®Instruction Bulletin for minimum bend

radius for cable.

• Space occupied by disconnect is determined by overall height “X”, width

“Y”, wire bend space “WB” and location “G” as selected from right to left.

For enclosures that

accept these devices,

see pages F10-F13.

For enclosures that

accept these devices,

see pages F10-F13.

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 22

F22

ABN12, SDN12, SDN12PL, N412CD,

N412CSTD, N412CSSSTD, SN4 & SSN4X SERIES ENCLOSURES

DISCONNECT SPACE OCCUPIED & AVAILABLE WIRING SPACE INFORMATION

SCHNEIDER SQUARE D®CLASS 9422 VARIABLE DEPTH DISCONNECTS

ABN12, SDN12, SDN12PL, N412CD, SN4 & SSN4X WALL-MOUNTS

N412CSTD, N412CSSSTD & SN4 (PAGES F2-F9) (PAGES F10-F13)

MECHANISM

TCN-30 30A No fuse — 3.80 6.84 3.69 6.03 10.56 7.56 10.56

TCF-30 30A 30A-250V H, K, R 5.53 6.84 3.69 6.03 10.56 7.56 10.56

TCF-33 30A 30A-600V H, K, R 8.15 6.84 3.69 6.03 10.56 7.56 10.56

TCF-33 30A 60A-250V H, K, R 6.15 6.84 3.69 6.03 10.56 7.56 10.56

TCF-33 30A 30A-600V J 5.53 6.84 3.69 6.03 10.56 7.56 10.56

TDN-60 60A No fuse — 3.80 6.84 3.69 6.03 10.56 7.56 10.56

TDF-60 60A 30A-600V H, K, R 8.15 6.84 3.69 6.03 10.56 7.56 10.56

TDF-60 60A 60A-250V H, K, R 6.15 6.84 3.69 6.03 10.56 7.56 10.56

TDF-63 60A 60A-600V H, K, R 8.65 6.84 3.69 6.03 10.56 7.56 10.56

TDF-63 60A 60A-600V J 5.53 6.84 3.69 6.03 10.56 7.56 10.56

TEN-10 100A No fuse — 3.80 6.84 — 5.91 10.44 7.44 10.44

TEF-10 100A 100A-250V H, K, R 8.25 6.84 — 5.91 10.44 7.44 10.44

TEF-10 100A 100A-600V H, K, R 10.25 6.84 — 5.91 10.44 7.44 10.44

TEF-10 100A 100A-600V J 7.05 6.84 — 5.91 10.44 7.44 10.44

TC-1 30A No fuse — 5.75 6.00 3.12 5.12 9.62 6.62 9.62

TC-2 30A 30A-250V H, K, R 5.75 6.00 3.12 5.12 9.62 6.62 9.62

TC-3 30A 30A-600V H, K, R 7.75 6.00 3.12 5.12 9.62 6.62 9.62

TC-3 30A 60A-250V H, K, R 5.88 6.00 3.12 5.12 9.62 6.62 9.62

TC-3 30A 30A-600V J 5.75 6.00 3.12 5.12 9.62 6.62 9.62

TD-1 60A No fuse — 6.38 6.62 3.62 6.00 10.50 7.50 10.50

TD-2 60A 30A-600V H, K, R 8.50 6.62 3.62 6.00 10.50 7.50 10.50

TD-2 60A 60A-250V H, K, R 6.50 6.62 3.62 6.00 10.50 7.50 10.50

TD-3 60A 60A-600V H, K, R 9.00 6.62 3.62 6.00 10.50 7.50 10.50

TD-3 60A 60A-600V J 6.38 6.62 3.62 6.00 10.50 7.50 10.50

TE-1 100A No fuse — 4.75 8.38 — 5.75 10.25 — 10.25

TE-2 100A 100A-250V H, K, R 7.50 8.38 — 5.75 10.25 — 10.25

TE-2 100A 100A-600V H, K, R 9.50 8.38 — 5.75 10.25 — 10.25

TE-2 100A 100A-600V J 6.25 8.38 — 5.75 10.25 — 10.25

TE-3 100A 200A-600V J 13.75 8.38 — 5.75 10.25 — 10.25

TF-1 200A No fuse — 5.50 11.62 — — 8.88 — 8.88

TF-2 200A 200A-250V H, K, R 11.50 11.62 — — 8.88 — 8.88

TF-2 200A 200A-600V H, K, R 14.00 11.62 — — 8.88 — 8.88

TF-2 200A 200A-600V J 10.12 11.62 — — 8.88 — 8.88

TF-3 200A 400A-600V J 14.50 11.62 — — 8.88 — 8.88

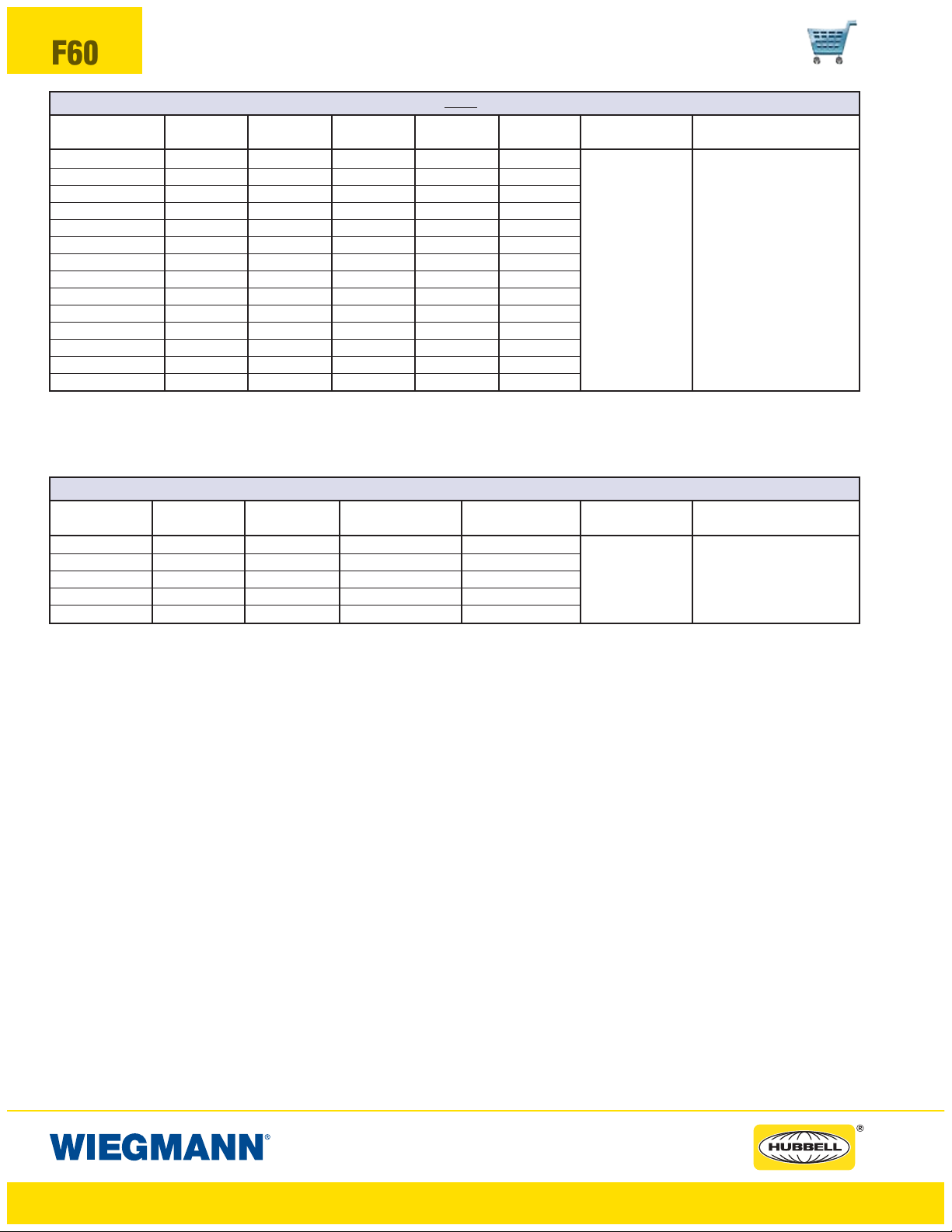

SCHNEIDER SQUARE D®CLASS 9422 VARIABLE DEPTH

RG-1 75A GJL Circuit breaker 3.53 3.74 3.59 5.93 10.47 7.47 10.47

RG-1 100A GJL Circuit breaker 3. 53 3.74 3.59 5.93 10.47 7.47 10.47

RN-1 100A FAL, FHL Circuit breaker 5. 12 5.25 3.75 6.12 10.62 7.62 10.62

RP-1 250A KAL, KHL Circuit breaker 7 .12 5.62 4.25* 6.88 11.38 8.38 11.38

RR-1 400A LAL,LHL,Q4L Circuit breaker 7.62 8.75 — — 7.00 — 7.00

*Not recommended except with #1 or smaller line conductors.

AMP FUSE FUSE

RATING CLIP CLASS

SPACE OCCUPIED

FG